Analysis of Pouch Performance to Ensure Impact Safety of Lithium-Ion Battery

Abstract

:1. Introduction

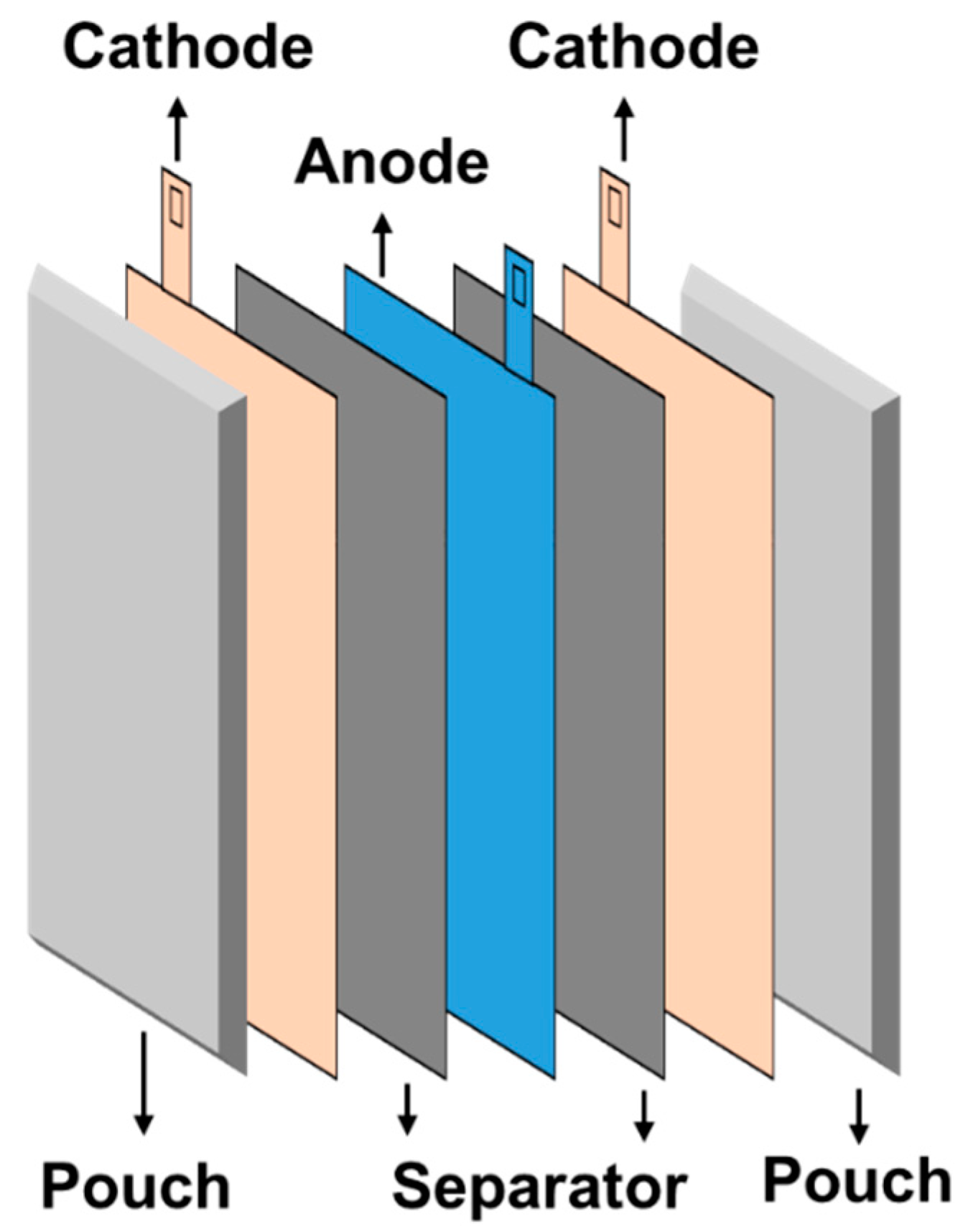

2. Pouch Type Lithium Ion Battery

2.1. Pouch-Type Battery Configuration

2.2. Pouch Material Characteristics

3. Pouch Performance Analysis

3.1. Tensile Strength and Elongation Measurement

3.1.1. Tensile Strength Properties

3.1.2. Elongation Properties

3.1.3. Measured Data by Pouch Material

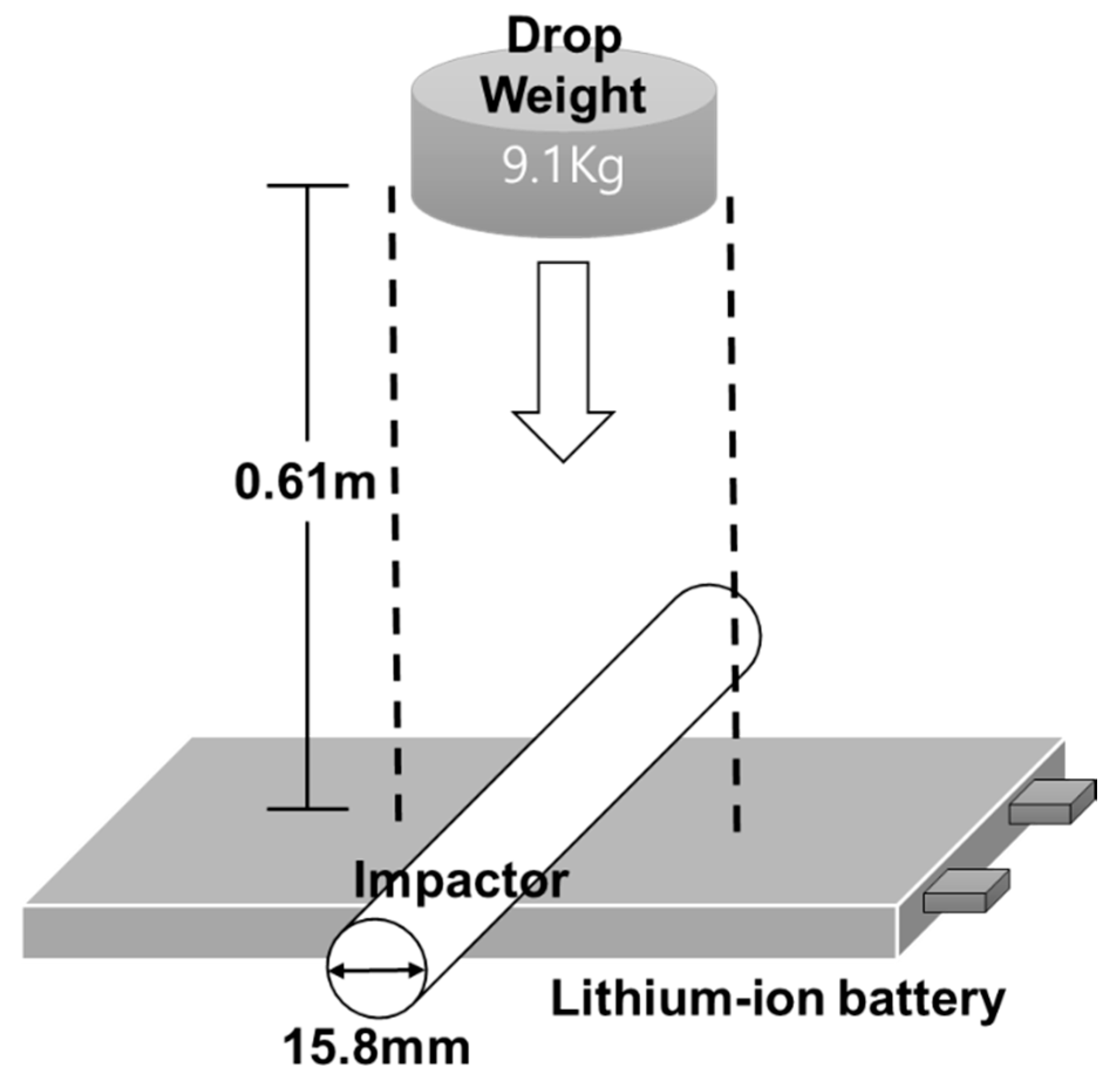

3.2. Impact Evaluation

Impulse and Impulsive Force

3.3. Impact Evaluation and Analysis Results

4. Battery Performance Test According to Pouch Type

4.1. Experimental Method

4.2. Experiment Result

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Larsson, F.; Andersson, P.; Mellander, B.E. Lithium-ion battery aspects on fires in electrified vehicles on the basis of experimental abuse tests. Batteries 2016, 2, 9. [Google Scholar] [CrossRef]

- Choi, J.W.; Aurbach, D. Promise and reality of post-lithium-ion batteries with high energy densities. Nat. Rev. Mater. 2016, 1, 16013. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L.; Sun, F.; Wang, Z. An Overview on Thermal Safety Issues of Lithium-ion Batteries for Electric Vehicle Application. IEEE Access 2018, 6, 23848–23863. [Google Scholar] [CrossRef]

- Balakrishnan, P.G.; Ramesh, R.; Kumar, T.P. Safety mechanisms in lithium-ion batteries. J. Power Sources 2006, 155, 401–414. [Google Scholar] [CrossRef]

- Wen, J.W.; Yu, Y.; Chen, C.H. A review on lithium-ion batteries safety issues: Existing problems and possible solutions. Mater. Express 2012, 2, 197–212. [Google Scholar] [CrossRef]

- Lee, Y.M.; Lee, C.H. Separators for Li-ion Secondary Batteries. Membr. J. 2004, 14, 263–274. [Google Scholar]

- Wang, Z.; Sang, L.; Liu, Z.; Chen, Q. The modification of Lithium ion battery separator by SiOx coatings. In Proceedings of the IEEE International Conference on Plasma Science, Edinburgh, UK, 8–13 July 2012. [Google Scholar]

- Lee, Y.K. The Effect of Active Material, Conductive Additives, and Binder in a Cathode Composite Electrode on Battery Performance. Energies 2019, 12, 658. [Google Scholar] [CrossRef]

- Liu, K.; Pei, A.; Lee, H.R.; Kong, B.; Liu, N.; Lin, D.; Liu, Y.; Liu, C.; Hsu, P.-C.; Bao, Y.Z.; et al. Lithium metal anodes with an adaptive “solid liquid” interfacial protective layer. J. Am. Chem. Soc. 2017, 139, 4815–4820. [Google Scholar] [CrossRef] [PubMed]

- Li, N.-W.; Yin, Y.-X.; Yang, C.-P.; Guo, Y.-G. An artificial solid electrolyte interphase layer for stable lithium metal anodes. Adv. Mater. 2016, 28, 1853–1858. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S. Improved Cyclability of Liquid Electrolyte Lithium/Sulfur Batteries by Optimizing Electrolyte/Sulfur Ratio. Energies 2012, 5, 5190–5197. [Google Scholar] [CrossRef]

- Zhang, S.S. A review on electrolyte additives for lithium-ion batteries. J. Power Sources 2006, 162, 1379–1394. [Google Scholar] [CrossRef]

- Aurbach, D.; Gamolsky, K.; Markovsky, B.; Gofer, Y.; Schmidt, M.; Heider, U. On the use of vinylene carbonate (VC) as an additive to electrolyte solutions for Li-ion batteries. Electrochim. Acta 2002, 47, 1423–1439. [Google Scholar] [CrossRef]

- Hess, S.; Wohlfahrt-Mehrens, M.; Wachtler, M. Flammability of Li-ion battery electrolytes: Flash point and self-extinguishing time measurements. J. Electrochem. Soc. 2015, 162, A3084–A3097. [Google Scholar] [CrossRef]

- Dudney, N.J. Addition of a thin-film inorganic solid electrolyte (Lipon) as a protective film in lithium batteries with a liquid electrolyte. J. Power Sources 2000, 89, 176–179. [Google Scholar] [CrossRef]

- Doughty, D.H.; Roth, E.P. A general discussion of Li ion battery safety. Electrochem. Soc. Interface 2012, 21, 37–44. [Google Scholar] [CrossRef]

- Underwriters Laboratories. UL Standard for Safety for Lithium Batteries, 4th ed.; (UL 1642); Underwriters Laboratories Inc.: Northbrook, IL, USA; p. 2007.

- Reddy, T.B. Linden’s Handbook of Batteries, 4th ed.; McGraw-Hill companies Inc.: New York, NY, USA, 2010. [Google Scholar]

- Daniel, C.; Besenhard, J.O. Handbook of Battery Materials, 2nd ed.; Wiley-VCH Verlag, GmbH & Co. KGaA: Weinheim, Germany, 2011. [Google Scholar]

- International Organization for Standardization. Metallic Materials-Tensile Testing at Ambient Temperature (ISO 6892); International Organization for Standardization: Geneva, Switzerland, 1998. [Google Scholar]

- Gisberg, J. Engineering Dynamics; Cambridge University Press: New York, NY, USA, 2007. [Google Scholar]

- Wang, Q.; Ping, P.; Zhao, X.; Chu, G.; Sun, J.; Chen, C. Thermal runaway caused fire and explosion of lithium ion battery. J. Power Sources 2012, 208, 210–224. [Google Scholar] [CrossRef]

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. A critical review of thermal issues in lithium-ion batteries. J. Electrochem. Soc. 2011, 158, R1–R25. [Google Scholar] [CrossRef]

- Ashok, L.; Nirav, S.; Cameron, D. Building a safer, denser lithium-ion battery. IEEE Spectr. 2018, 55, 34–39. [Google Scholar]

| Item | Unit | Direction | Oriented Nylon | Aluminum | Adhesive | PP | ||

|---|---|---|---|---|---|---|---|---|

| 8021 | 8079 | |||||||

| Density | g/cm2 | - | 1.15 | 2.73 | 2.72 | 0.9 | 0.9 | |

| Melting point | °C | - | 220 | 650 | 660 | 160 | 140 | |

| Tensile | Tensile strength | MPa (N/mm2) | MD | 250 | 95 | 75 | - | - |

| TD | 280 | |||||||

| Tensile stretch Rates | % | MD | 130 | 17 | 10 | - | - | |

| TD | 110 | |||||||

| Sample Width (4 mm) | Tensile Strength (MD) | Elongation (MD) | Tensile Strength (TD) | Elongation (TD) | |||

|---|---|---|---|---|---|---|---|

| Thickness () | Pouch | N | N/mm2 | % | N | N/mm2 | % |

| 68 | A | 17.8 | 64.5 | 32.9 | 21.0 | 76.4 | 67.5 |

| 75 | B | 23.8 | 86.7 | 84.1 | 18.6 | 67.8 | 31.9 |

| B/A | 134% | 134% | 256% | 89% | 89% | 47% | |

| Item | Cathode | Anode |

|---|---|---|

| Initial charge capacity | 153 mAh/g | 386 mAh/g |

| Initial discharge capacity | 146 mAh/g | 361 mAh/g |

| efficiency | 96.2% | 93.76% |

| Current density | 3.48 ± 0.2 mA/cm2 | |

| Loading level | 24.1 ± 0.5 mg/cm2 | 10.2 ± 0.5 mg/cm2 |

| Electrode density | 3.45 g/cc | 1.62 g/cc |

| NP/Ratio | 1.13 | |

| Classification | Item | Contents | |

|---|---|---|---|

| Cathode | Cathode electrode | Cathode material | LiCO2, 95 wt% |

| Conductive material | Super P, 2 wt% | ||

| Binder | PVDF, 3 wt% | ||

| Solid Content | 74.35% | ||

| Loading quantity | 47.01 mg/cm2 (A side: 23.52 mg/cm2; B side: 23.49 mg/cm2) | ||

| Electrode density (after roll pressing) | 3.45 g/cc | ||

| Electrode thickness | 147 ± 3 | ||

| Cathode foil (Aluminum-foil) | Thickness | 15 | |

| Weight | 4.10 mg/cm2 | ||

| Anode | Anode electrode | Anode material | Natural graphite (DAG-E1), 97.6 wt% |

| Binder | SBR (Zeon-BM400B), 1.4 wt% | ||

| Carboxymethyl Cellulose (CMC) | Daitchi SBH-12, 1.0 wt% | ||

| Solid Content | 53.3% | ||

| Loading quantity | 19.61 mg/cm2 (A side: 9.85 mg/cm2; B side: 9.76 mg/cm2) | ||

| Electrode density (after roll pressing) | 1.62 g/cc | ||

| Electrode thickness | 131 ± 3 | ||

| Anode foil (Copper-foil) | Thickness | 8 | |

| Weight | 7.64 mg/cm2 | ||

| Electrolyte | Lithium salt | LiPF6, 1 Mole | |

| Solvent | EC:EMC:DMC = 3:4:3 | ||

| additive | VC, 3 wt% | ||

| Amount of input | 2.50 ± 0.04 g | ||

| Pre-charging | Capacity | 130 mA | |

| Type | Tensile Strength (MD) (N/mm2) | Elongation (MD) (%) | Tensile Strength (TD) (N/mm2) | Elongation (TD) (%) | Impact Failure Rate (%) | |

|---|---|---|---|---|---|---|

| C | 111 | 63.74 | 30.48 | 76.02 | 41.98 | 20 |

| D | 86 | 60.72 | 38.23 | 58.38 | 36.20 | 40 |

| E | 111 | 71.21 | 44.97 | 76.77 | 75.46 | 0 |

| Type | Pouch Components | |||||

|---|---|---|---|---|---|---|

| CPP() | Total() | |||||

| C | 20 | 3 | 40 | 3 | 45 | 111 |

| D | 15 | 3 | 35 | 3 | 30 | 86 |

| E | 25 | 3 | 40 | 3 | 40 | 111 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoo, S.; Hong, C.; Chong, K.T.; Seul, N. Analysis of Pouch Performance to Ensure Impact Safety of Lithium-Ion Battery. Energies 2019, 12, 2865. https://doi.org/10.3390/en12152865

Yoo S, Hong C, Chong KT, Seul N. Analysis of Pouch Performance to Ensure Impact Safety of Lithium-Ion Battery. Energies. 2019; 12(15):2865. https://doi.org/10.3390/en12152865

Chicago/Turabian StyleYoo, Sunggoo, Chonggi Hong, Kil To Chong, and Namo Seul. 2019. "Analysis of Pouch Performance to Ensure Impact Safety of Lithium-Ion Battery" Energies 12, no. 15: 2865. https://doi.org/10.3390/en12152865

APA StyleYoo, S., Hong, C., Chong, K. T., & Seul, N. (2019). Analysis of Pouch Performance to Ensure Impact Safety of Lithium-Ion Battery. Energies, 12(15), 2865. https://doi.org/10.3390/en12152865