Evaluation of a Scale-Resolving Methodology for the Multidimensional Simulation of GDI Sprays

Abstract

1. Introduction

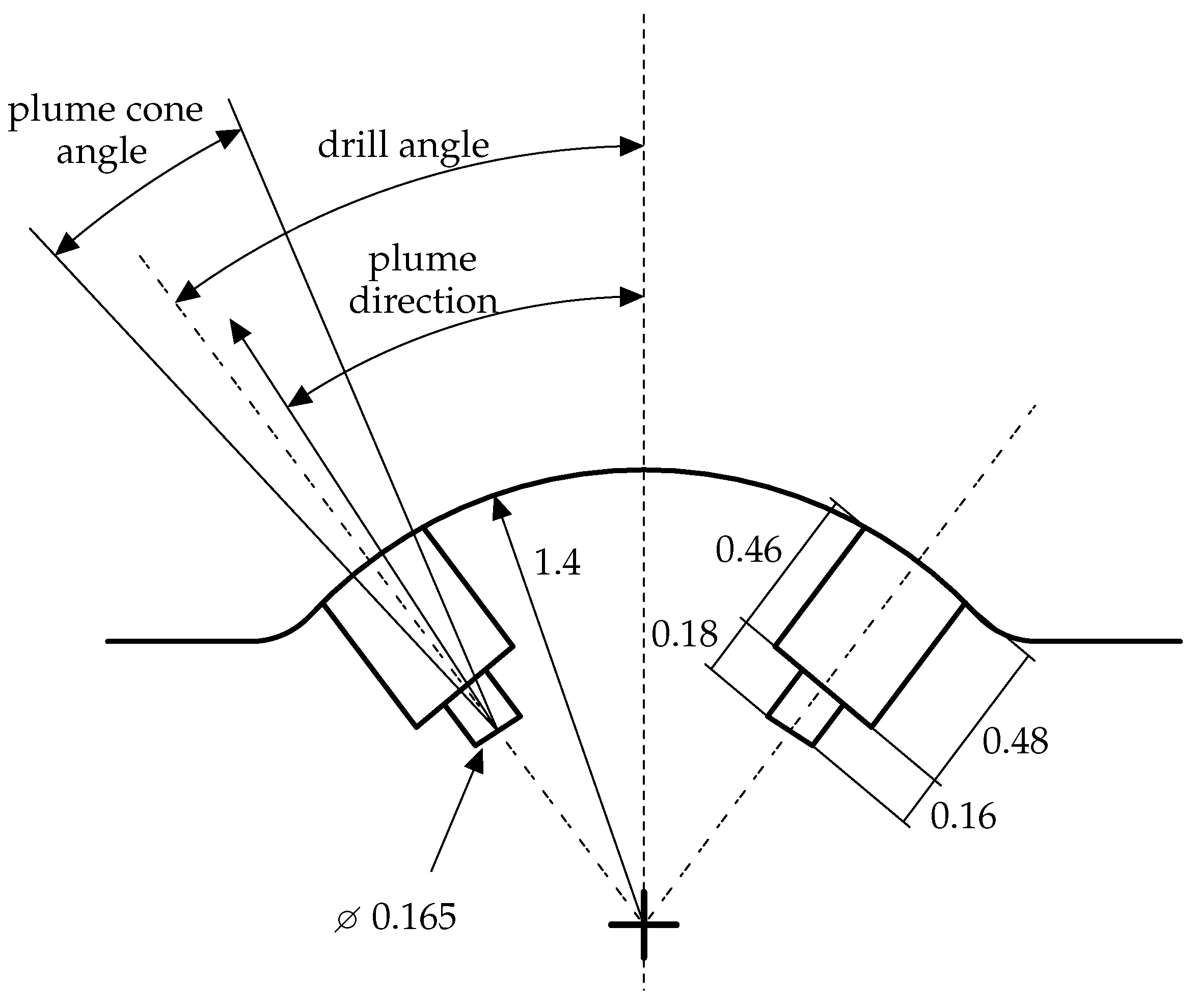

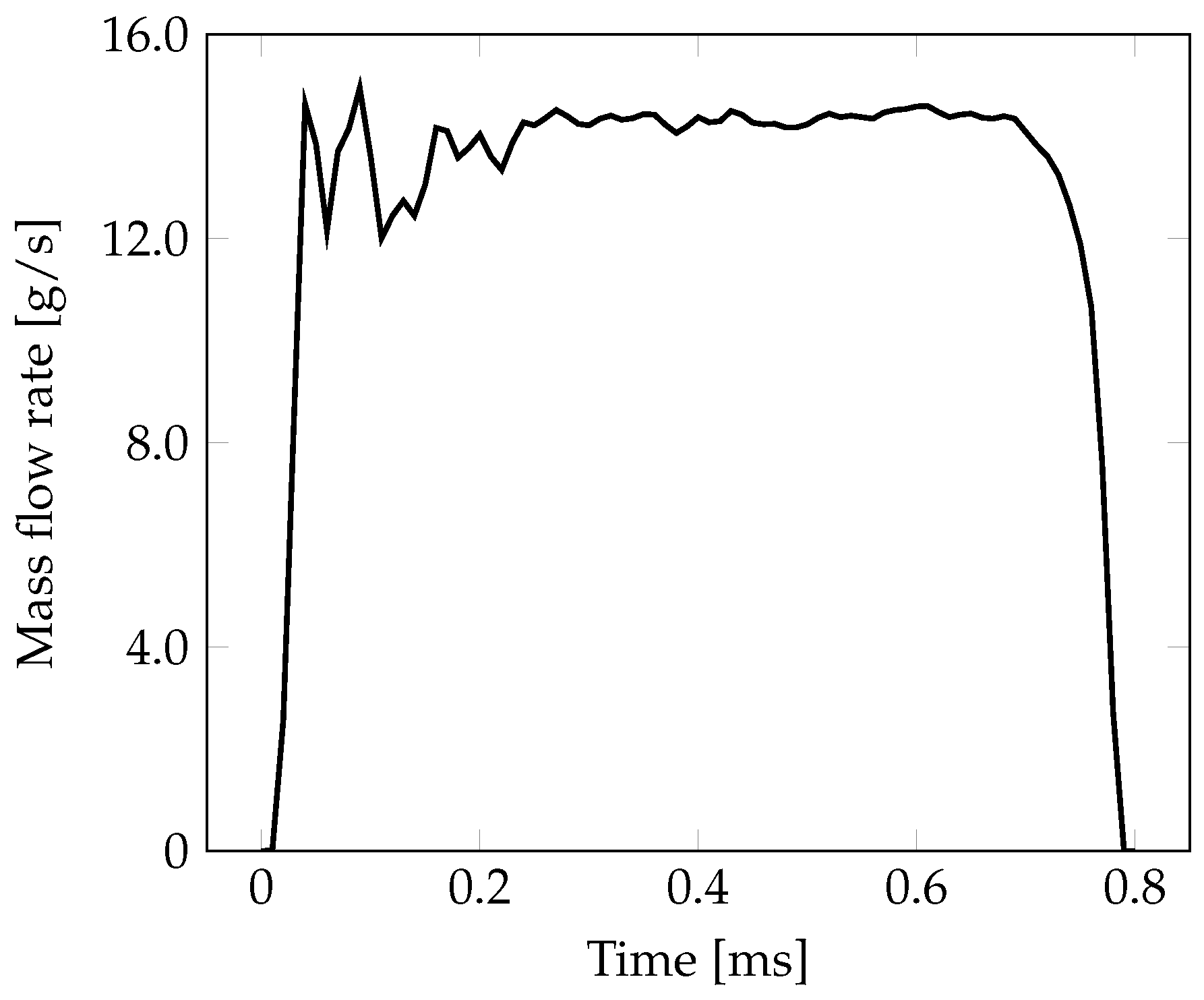

2. Standard ECN “Spray G” Operating Conditions

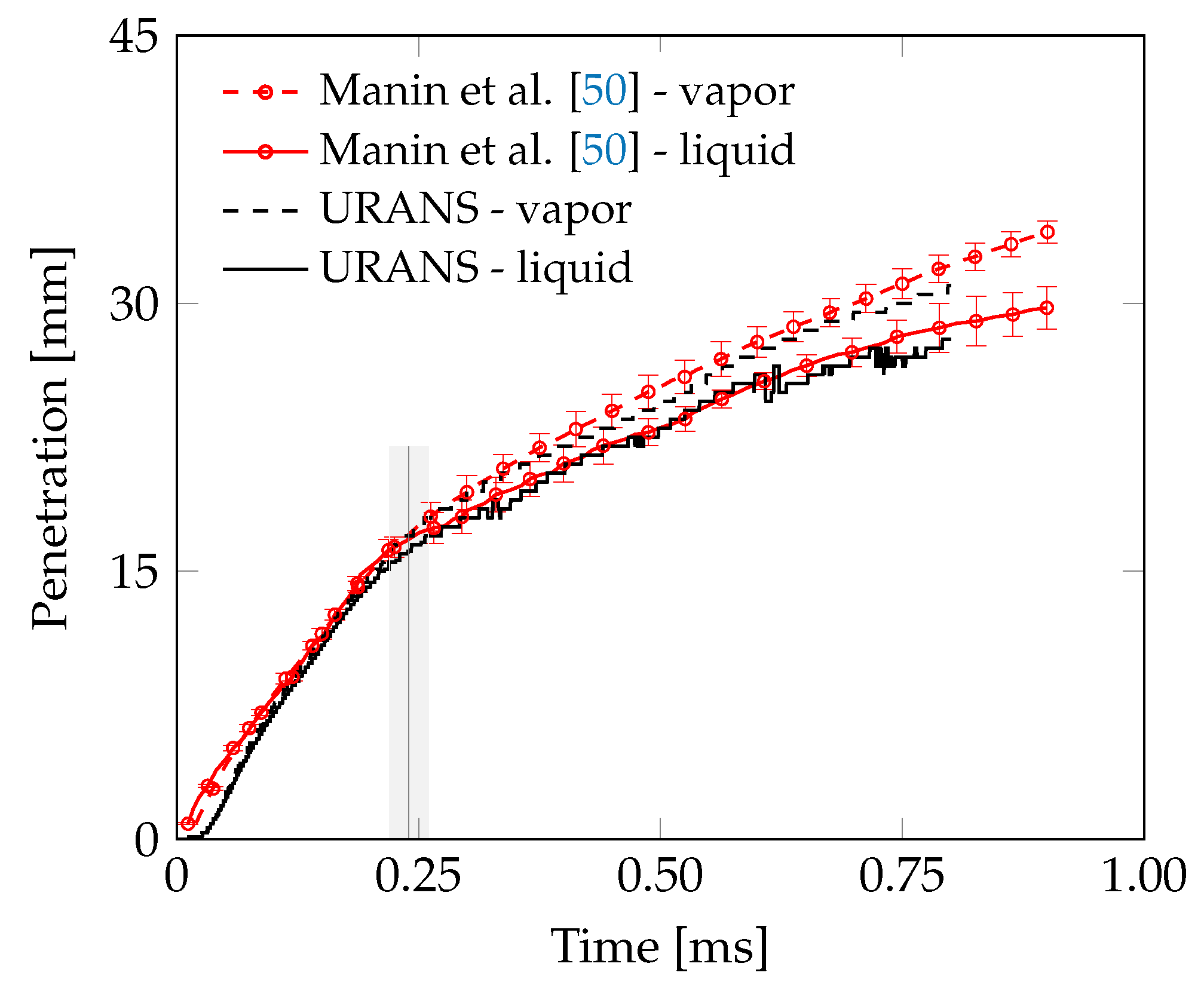

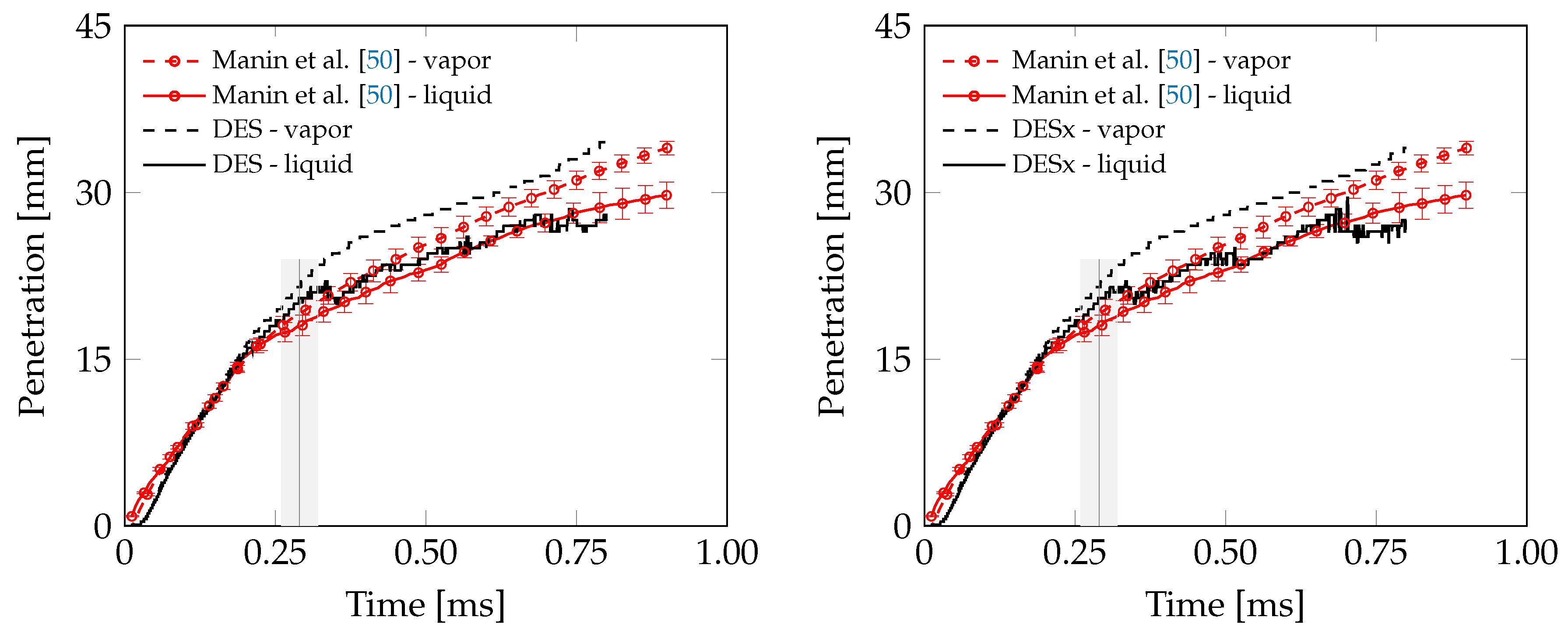

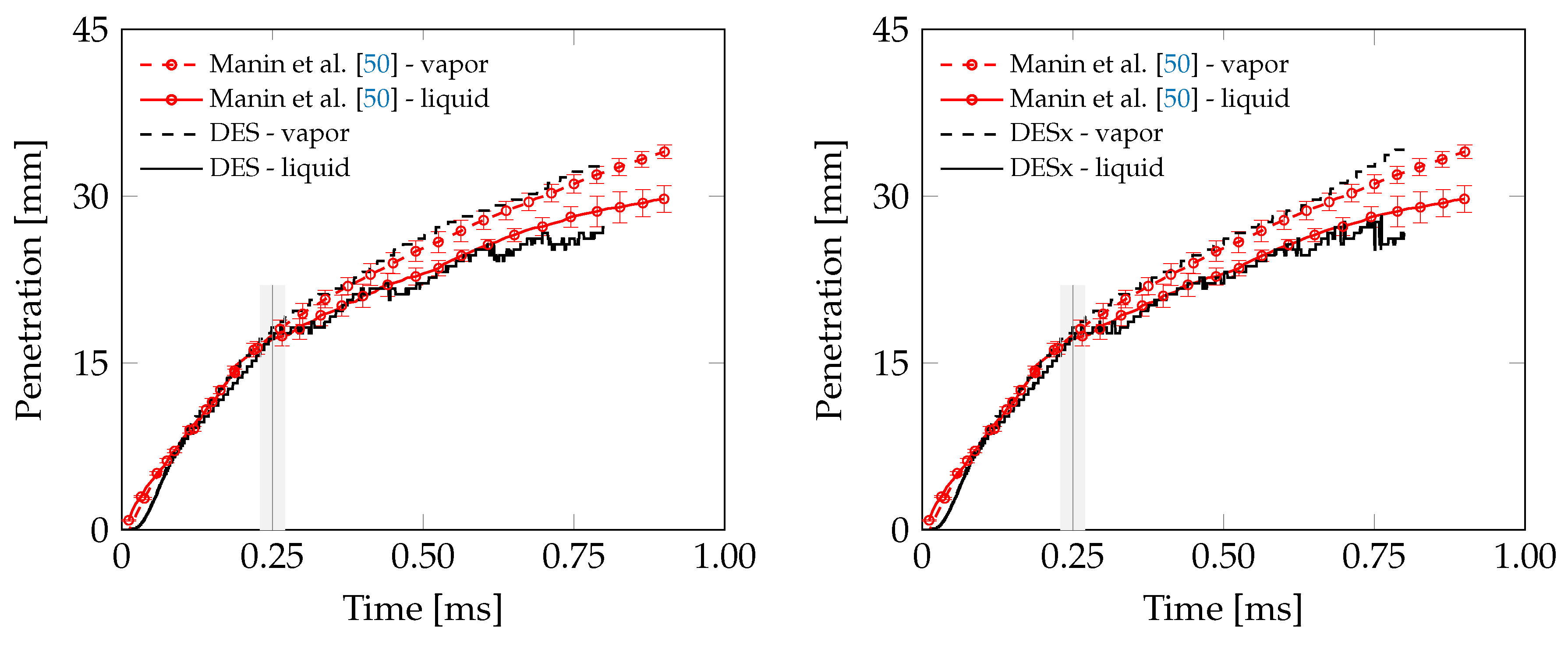

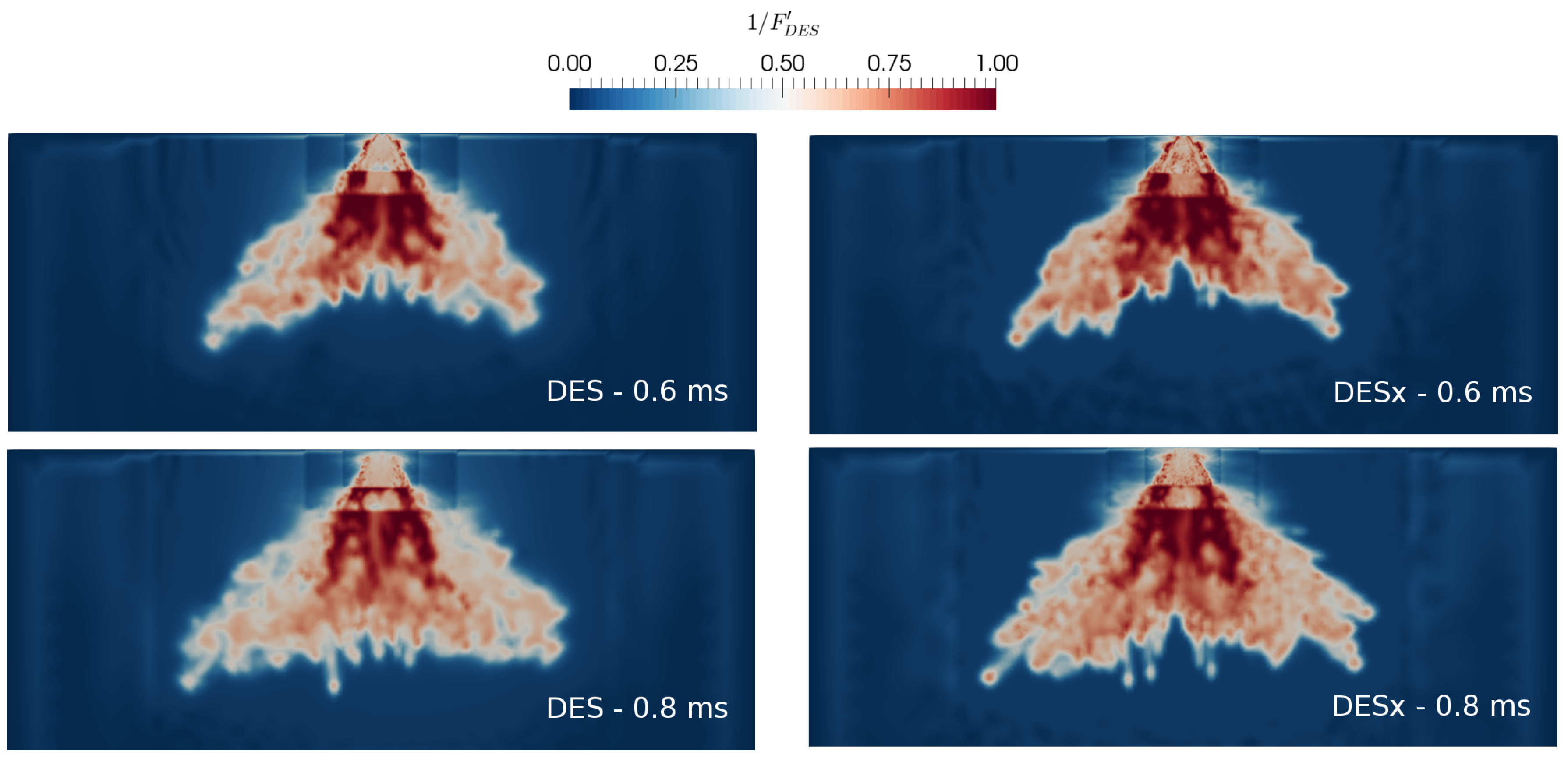

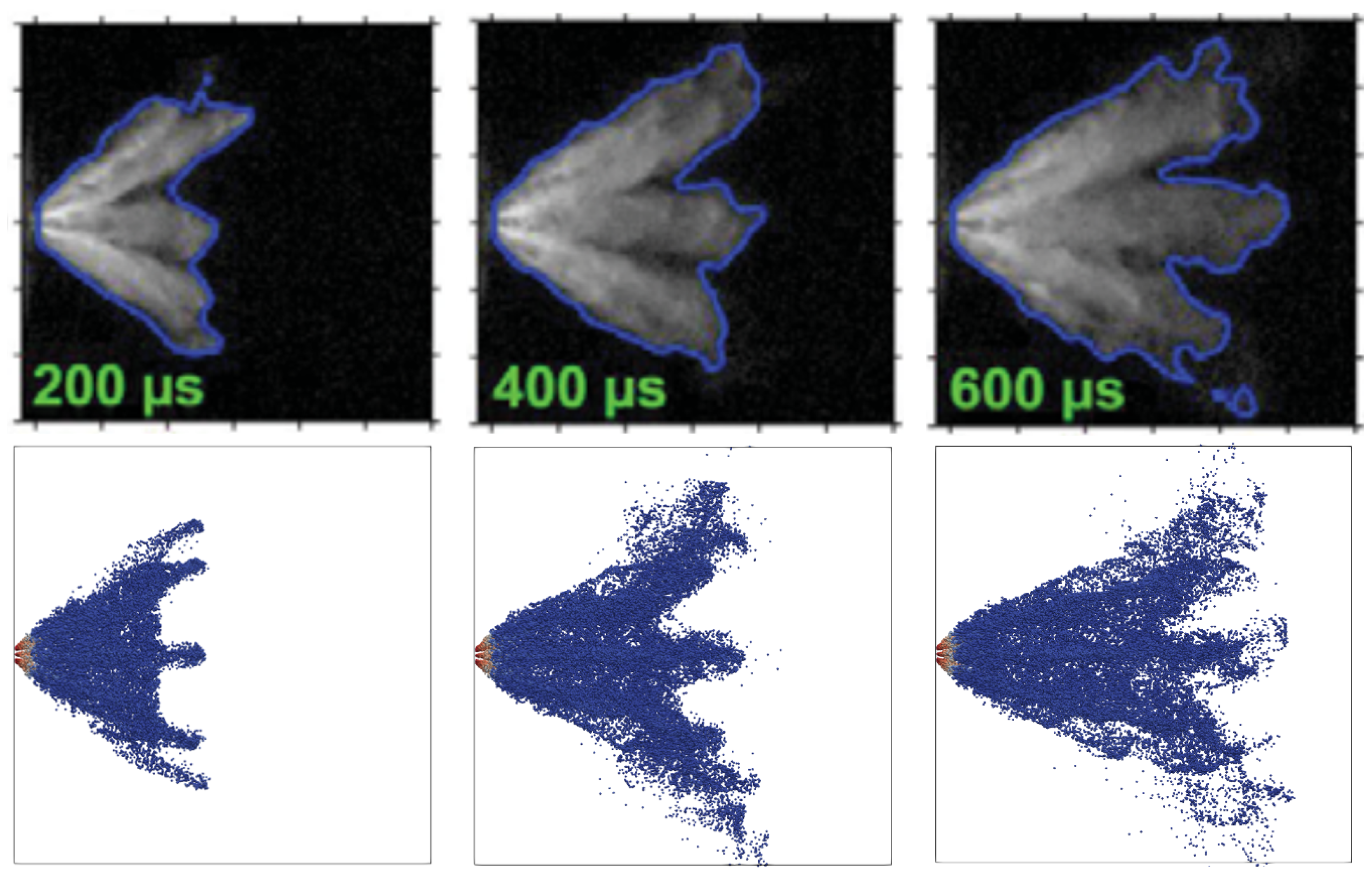

3. Materials and Methods

3.1. Spray Models

3.2. Turbulence Modeling

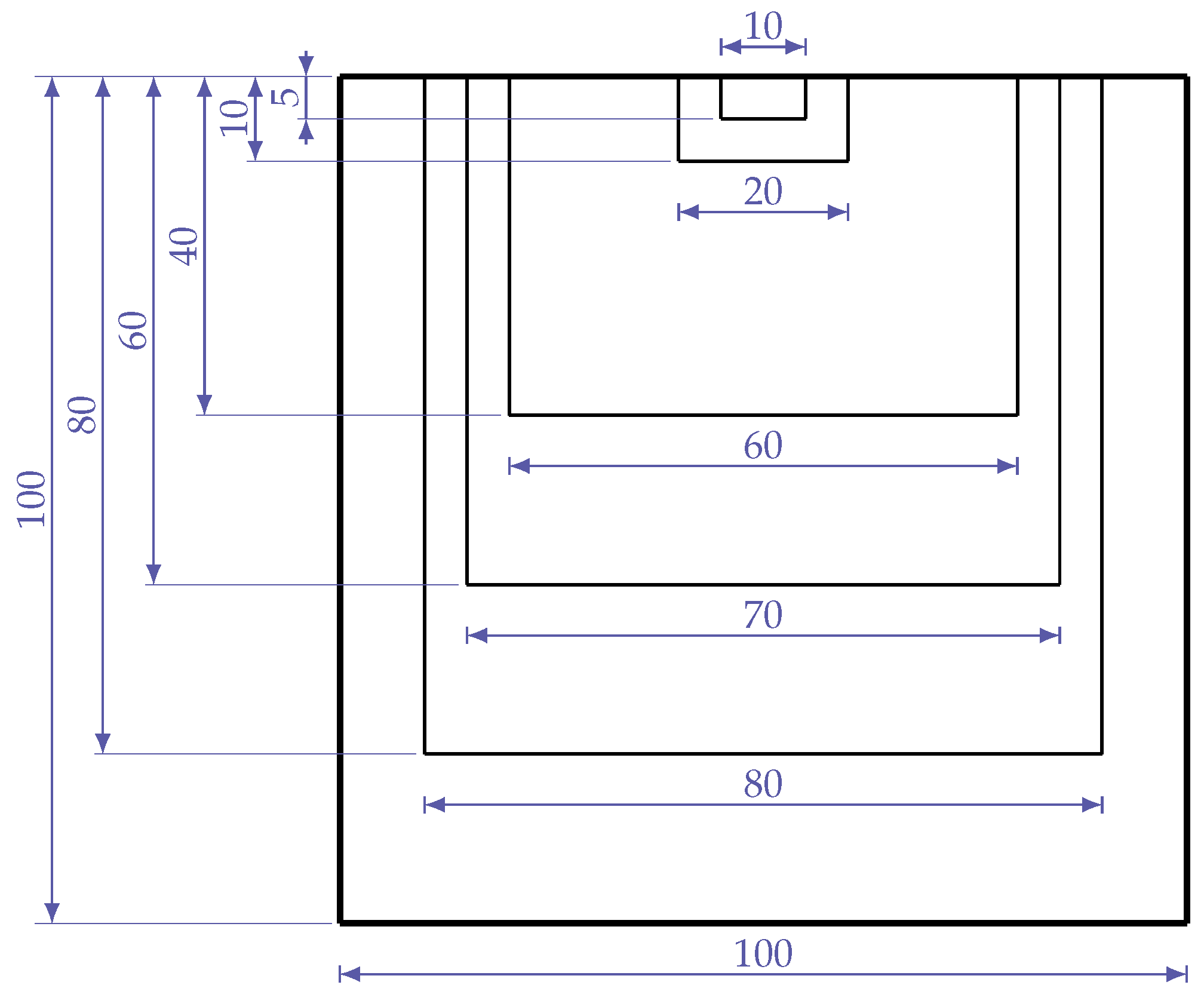

3.3. Numerical Setup

4. Results and Discussion

5. Conclusions

Author Contributions

Conflicts of Interest

Abbreviations

| RDE | Real Driving Emissions |

| WLTP | World Harmonised Light Vehicle Test Procedure |

| GDI | Gasoline Direct Injection |

| CFD | Computational Fluid Dynamics |

| EL | Eulerian–Lagrangian |

| LP | Lagrangian Particles |

| URANS | Unsteady Reynolds-Averaged Navier–Stokes |

| LES | Large Eddy Simulation |

| ECN | Engine Combustion Network |

| SNL | Sandia National Laboratories |

| KHRT | Kelvin–Helmholtz–Rayleigh–Taylor |

| DES | Detached Eddy Simulation |

| X-LES / DESx | Extra Large Eddy Simulation |

| PISO | Pressure Implicit with Splitting Operators |

| ASOI | After the Start Of Injection |

References

- Emissions in the Automotive Sector. Available online: https://ec.europa.eu/growth/sectors/automotive/environment-protection/emissions_en (accessed on 15 July 2019).

- Chakraborty, N.; Mastorakos, E.; Cant, R. Effects of turbulence on spark ignition in inhomogeneous mixtures: A direct numerical simulation (DNS) study. Combust. Sci. Technol. 2007, 179, 293–317. [Google Scholar] [CrossRef]

- Vermorel, O.; Richard, S.; Colin, O.; Angelberger, C.; Benkenida, A.; Veynante, D. Towards the understanding of cyclic variability in a spark ignited engine using multi-cycle LES. Combust. Flame 2009, 156, 1525–1541. [Google Scholar] [CrossRef]

- Shao, J.; Rutland, C. Modeling investigation of different methods to suppress engine knock on a small spark ignition engine. J. Eng. Gas Turbines Power 2015, 137, 061506. [Google Scholar] [CrossRef]

- Pontoppidan, M.; Ausiello, F.; Bella, G.; De Maio, A. Study of the Impact of Variations in the Diesel-Nozzle Geometry Parameters on the Layout of Multiple Injection Strategy; SAE Technical Paper 2002-01-0217; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

- Rutland, C.J. Large-Eddy Simulations for internal combustion engines—A review. Int. J. Eng. Res. 2011, 12, 421–451. [Google Scholar] [CrossRef]

- Bharadwaj, N.; Rutland, C.J.; Chang, S. Large Eddy Simulation modelling of spray-induced turbulence effects. Int. J. Eng. Res. 2009, 10, 97–119. [Google Scholar] [CrossRef]

- Vuorinen, V.; Hillamo, H.; Kaario, O.; Nuutinen, M.; Larmi, M.; Fuchs, L. Effect of Droplet Size and Atomization on Spray Formation: A Priori Study Using Large-Eddy Simulation. Flow Turbul. Combust. 2011, 86, 533–561. [Google Scholar] [CrossRef]

- Wehrfritz, A.; Vuorinen, V.; Kaario, O.; Larmi, M. Large Eddy Simulation of High-Velocity Fuel Srays: Studying Mesh Resolution and Breakup Model Effects for Spray A. At. Sprays 2013, 23, 419–442. [Google Scholar] [CrossRef]

- Jangi, M.; Solsjo, R.; Johansson, B.; Bai, X.S. On large eddy simulation of diesel spray for internal combustion engines. Int. J. Heat Fluid Flow 2015, 53, 68–80. [Google Scholar] [CrossRef]

- Tsang, C.W.; Kuo, C.W.; Trujillo, M.; Rutland, C. Evaluation and validation of large-eddy simulation sub-grid spray dispersion models using high-fidelity volume-of-fluid simulation data and engine combustion network experimental data. Int. J. Eng. Res. 2018. [Google Scholar] [CrossRef]

- Hasse, C.; Sohm, V.; Durst, B. Detached Eddy Simulation of cyclic large scale fluctuations in a simplified engine setup. Int. J. Heat Fluid Flow 2009, 30, 32–43. [Google Scholar] [CrossRef]

- Hasse, C.; Sohm, V.; Durst, B. Numerical investigation of cyclic variations in gasoline engines using a hybrid URANS/LES modeling approach. Comput. Fluids 2010, 39, 25–48. [Google Scholar] [CrossRef]

- Hasse, C. Scale-resolving simulations in engine combustion process design based on a systematic approach for model development. Int. J. Eng. Res. 2016, 17, 44–62. [Google Scholar] [CrossRef]

- Buhl, S.; Hartmann, F.; Hasse, C. Identification of Large-Scale Structure Fluctuations in IC Engines using POD-Based Conditional Averaging. Oil & Gas Sci. Technol.-Rev. IFP 2016, 71. [Google Scholar] [CrossRef]

- Buhl, S.; Dietzsch, F.; Buhl, C.; Hasse, C. Comparative study of turbulence models for scale-resolving simulations of internal combustion engine flows. Comput. Fluids 2017, 156, 66–80. [Google Scholar] [CrossRef]

- Buhl, S.; Hain, D.; Hartmann, F.; Hasse, C. A comparative study of intake and exhaust port modeling strategies for scale-resolving engine simulations. Int. J. Eng. Res. 2018, 19, 282–292. [Google Scholar] [CrossRef]

- Piscaglia, F.; Montorfano, A.; Onorati, A. A Scale Adaptive Filtering Technique for Turbulence Modeling of Unsteady Flows in IC Engines. SAE Int. J. Engines 2015, 8, 426–436. [Google Scholar] [CrossRef]

- Wu, Y.; Montorfano, A.; Piscaglia, F.; Onorati, A. A Study of the Organized in-Cylinder Motion by a Dynamic Adaptive Scale-Resolving Turbulence Model. Flow Turbul. Combust. 2018, 100, 797–827. [Google Scholar] [CrossRef]

- Krastev, V.K.; Bella, G.; Campitelli, G. Some Developments in DES Modeling for Engine Flow Simulation; SAE Technical Paper 2015-24-2414; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Krastev, V.K.; Bella, G. A Zonal Turbulence Modeling Approach for ICE Flow Simulation. SAE Int. J. Engines 2016, 9, 1425–1436. [Google Scholar] [CrossRef]

- Krastev, V.K.; Silvestri, L.; Falcucci, G.; Bella, G. A Zonal-LES Study of Steady and Reciprocating Engine-Like Flows Using a Modified Two-Equation DES Turbulence Model; SAE Technical Paper 2017-24-0030; SAE International: Warrendale, PA, USA, 2017. [Google Scholar]

- Krastev, V.K.; Silvestri, L.; Falcucci, G. A Modified Version of the RNG k-ε Turbulence Model for the Scale-Resolving Simulation of Internal Combustion Engines. Energies 2017, 10, 2116. [Google Scholar] [CrossRef]

- Krastev, V.K.; Silvestri, L.; Bella, G. Effects of Turbulence Modeling and Grid Quality on the Zonal URANS/LES Simulation of Static and Reciprocating Engine-Like Geometries. SAE Int. J. Engines 2018, 11, 669–686. [Google Scholar] [CrossRef]

- Krastev, V.K.; Di Ilio, G.; Falcucci, G.; Bella, G. Notes on the hybrid URANS/LES turbulence modeling for Internal Combustion Engines simulation. Energy Procedia 2018, 148, 1098–1104. [Google Scholar] [CrossRef]

- Krastev, V.K.; d’Adamo, A.; Berni, F.; Fontanesi, S. Validation of a zonal hybrid URANS/LES turbulence modeling method for multi-cycle engine flow simulation. Int. J. Eng. Res. 2019. [Google Scholar] [CrossRef]

- Kaario, O.T.; Vuorinen, V.; Zhu, L.; Larmi, M.; Liu, R. Mixing and evaporation analysis of a high-pressure SCR system using a hybrid LES-RANS approach. Energy 2017, 120, 827–841. [Google Scholar] [CrossRef]

- Di Ilio, G.; Krastev, V.K.; Piscaglia, F.; Bella, G. Hybrid URANS/LES Turbulence Modeling for Spray Simulation: A Computational Study; SAE Technical Paper 2019-01-0270; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Di Ilio, G.; Krastev, V.K.; Bella, G. Effects of the LES-Mode SGS Viscosity Formulation on the Hybrid URANS/LES Modeling of Turbulent Fuel Sprays; SAE Technical Paper 2019-24-0127; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Engine Combustion Network. Available online: https://ecn.sandia.gov/ (accessed on 15 July 2019).

- ECN Workshop. Available online: https://ecn.sandia.gov/ecn-workshop/ (accessed on 15 July 2019).

- Paredi, D.; Lucchini, T.; D’Errico, G.; Onorati, A.; Montanaro, A.; Allocca, L.; Ianniello, R. Combined Experimental and Numerical Investigation of the ECN Spray G Under Different Engine-Like Conditions; SAE Technical Paper 2018-01-0281; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Payri, R.; Gimeno, J.; Marti-Aldaravi, P.; Vaquerizo, D. Momentum Flux Measurements on an ECN GDI Injector; SAE Technical Paper 2015-01-1893; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Spalding, D. The combustion of liquid fuels. Symp. (Int.) Combust. 1953, 4, 847–864. [Google Scholar] [CrossRef]

- Beale, J.; Reitz, R. Modeling spray atomization with the Kelvin-Helmhotz/Rayleigh-Taylor hybrid model. At. Sprays 1999, 9, 623–650. [Google Scholar] [CrossRef]

- Reitz, R. Modeling Atomization Processes in High-pressure Vaporizing Sprays. At. Spray Technol. 1987, 3, 309–337. [Google Scholar]

- Patterson, M.; Reitz, R. Modeling the Effects of Fuel Spray Characteristics on Diesel Engine Combustion and Emission; SAE Technical Paper 980131; SAE International: Warrendale, PA, USA, 1998. [Google Scholar]

- Xin, J.; Ricart, L.; Reitz, R. Computer Modeling of Diesel Spray Atomization and Combustion. Combust. Sci. Technol. 1998, 137, 171–176. [Google Scholar] [CrossRef]

- Spalart, P.R.; Jou, W.H.; Strelets, M.; Allmaras, S.R. Comments on the feasibility of LES for wings, and on a hybrid RANS/LES approach. In Advances in DNS/LES; Liu, C., Liu, Z., Eds.; Greyden Press: Columbus, OH, USA, 1997; pp. 137–147. [Google Scholar]

- Travin, A.; Shur, M.L.; Strelets, M.; Spalart, P.R. Physical and numerical upgrades in the Detached-Eddy Simulation of complex turbulent flows. In Advances in LES of Complex Flows, Fluid Mechanics and Its Applications; Friedrich, R., Rodi, W., Eds.; Springer: Dordrecht, The Nederland, 2002; Volume 65, pp. 239–254. [Google Scholar]

- Spalart, P.R. Detached-Eddy Simulation. Annu. Rev. Fluid Mech. 2009, 41, 181–202. [Google Scholar] [CrossRef]

- Kalitzin, G.; Gould, A.R.B.; Benton, J.J. Application of Two-Equation Turbulence Models in Aircraft Design; AIAA Paper 96-0327; SAE International: Warrendale, PA, USA, 1996. [Google Scholar]

- Bella, G.; Krastev, V.K. On the RANS Modeling of Turbulent Airflow Over a Simplified Car Model. In Proceedings of the ASME-JSME-KSME 2011 Joint Fluids Engineering Conference: Volume 1, Symposia—Parts A, B, C, and D, Hamamatsu, Japan1, 24–29 July 2011; pp. 871–883. [Google Scholar] [CrossRef]

- Krastev, V.K.; Bella, G. On the Steady and Unsteady Turbulence Modeling in Ground Vehicle Aerodynamic Design and Optimization; SAE Technical Paper 2011-24-0163; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Durbin, P.A. On the k-ε stagnation point anomaly. Int. J. Heat Fluid Flow 1996, 17, 89–90. [Google Scholar] [CrossRef]

- Durbin, P.A. Limiters and wall treatments in applied turbulence modeling. Fluid Dyn. Res. 2009, 41, 012203. [Google Scholar] [CrossRef]

- Kok, J.; Dol, H.; Oskam, H.; Van Der Ven, H. Extra-Large Eddy Simulation of massively separated flows. In Proceedings of the 42nd AIAA Aerospace Sciences Meeting and Exhibit, AIAA Paper 04-0264. Reno, NV, USA, 5–8 January 2004. [Google Scholar]

- Yan, J.; Mockett, C.; Thiele, F. Investigation of Alternative Length Scale Substitutions in Detached-Eddy Simulation. Flow Turbul. Combust. 2005, 74, 85–102. [Google Scholar] [CrossRef]

- CFD Direct. Available online: https://cfd.direct/openfoam/user-guide/ (accessed on 15 July 2019).

- Manin, J.; Jung, Y.; Skeen, S.; Pickett, L.; Parrish, S.; Markle, L. Experimental Characterization of DI Gasoline Injection Processes; SAE Technical Paper 2015-01-1894; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

| Fuel Type | iso-Octane () |

|---|---|

| Ambient composition (by volume) | 0% |

| 6.52% | |

| 3.77% | |

| 89.71% | |

| Ambient gas temperature | 573 K |

| Ambient gas pressure | 600 kPa |

| Ambient gas density | 3.5 kg/m |

| Injection duration | 0.78 ms |

| Injection mass | 10.4 mg |

| Injection pressure | 20 MPa |

| Injection temperature | 363 K |

| Nozzle | 8-hole |

| Injector hole diameter | 165 m |

| 0.61 | 2 | 1 | 0.1 | 1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Ilio, G.; Krastev, V.K.; Falcucci, G. Evaluation of a Scale-Resolving Methodology for the Multidimensional Simulation of GDI Sprays. Energies 2019, 12, 2699. https://doi.org/10.3390/en12142699

Di Ilio G, Krastev VK, Falcucci G. Evaluation of a Scale-Resolving Methodology for the Multidimensional Simulation of GDI Sprays. Energies. 2019; 12(14):2699. https://doi.org/10.3390/en12142699

Chicago/Turabian StyleDi Ilio, Giovanni, Vesselin K. Krastev, and Giacomo Falcucci. 2019. "Evaluation of a Scale-Resolving Methodology for the Multidimensional Simulation of GDI Sprays" Energies 12, no. 14: 2699. https://doi.org/10.3390/en12142699

APA StyleDi Ilio, G., Krastev, V. K., & Falcucci, G. (2019). Evaluation of a Scale-Resolving Methodology for the Multidimensional Simulation of GDI Sprays. Energies, 12(14), 2699. https://doi.org/10.3390/en12142699