Performance Analysis of a Flexi-Fuel Turbine-Combined Free-Piston Engine Generator

Abstract

1. Introduction

1.1. Free-Piston Engine (FPE) Powered Gas Turbines

1.2. Hydraulic Free-Piston Engine

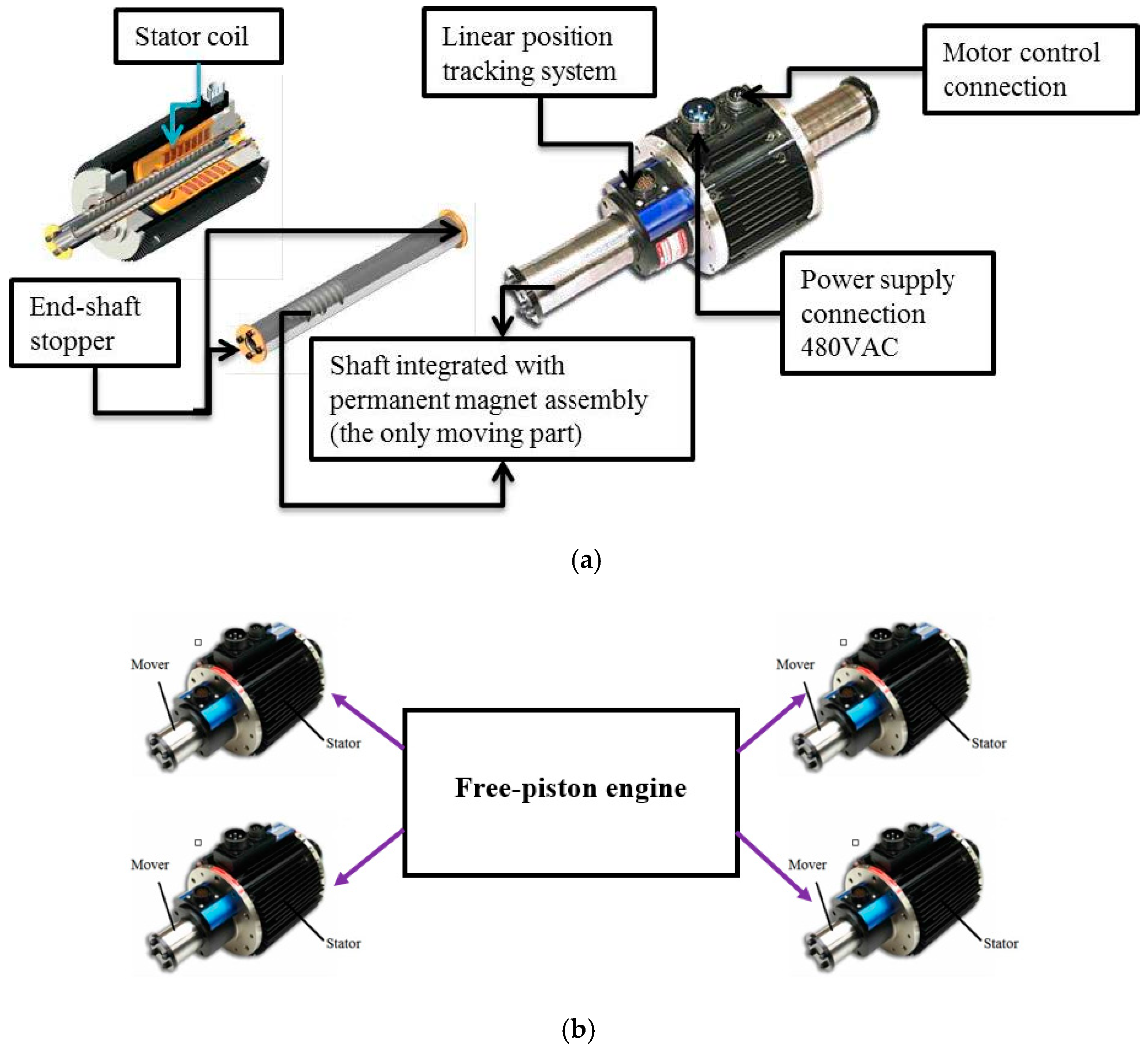

1.3. Free-Piston Engine Generator

1.4. Aims and Objectives

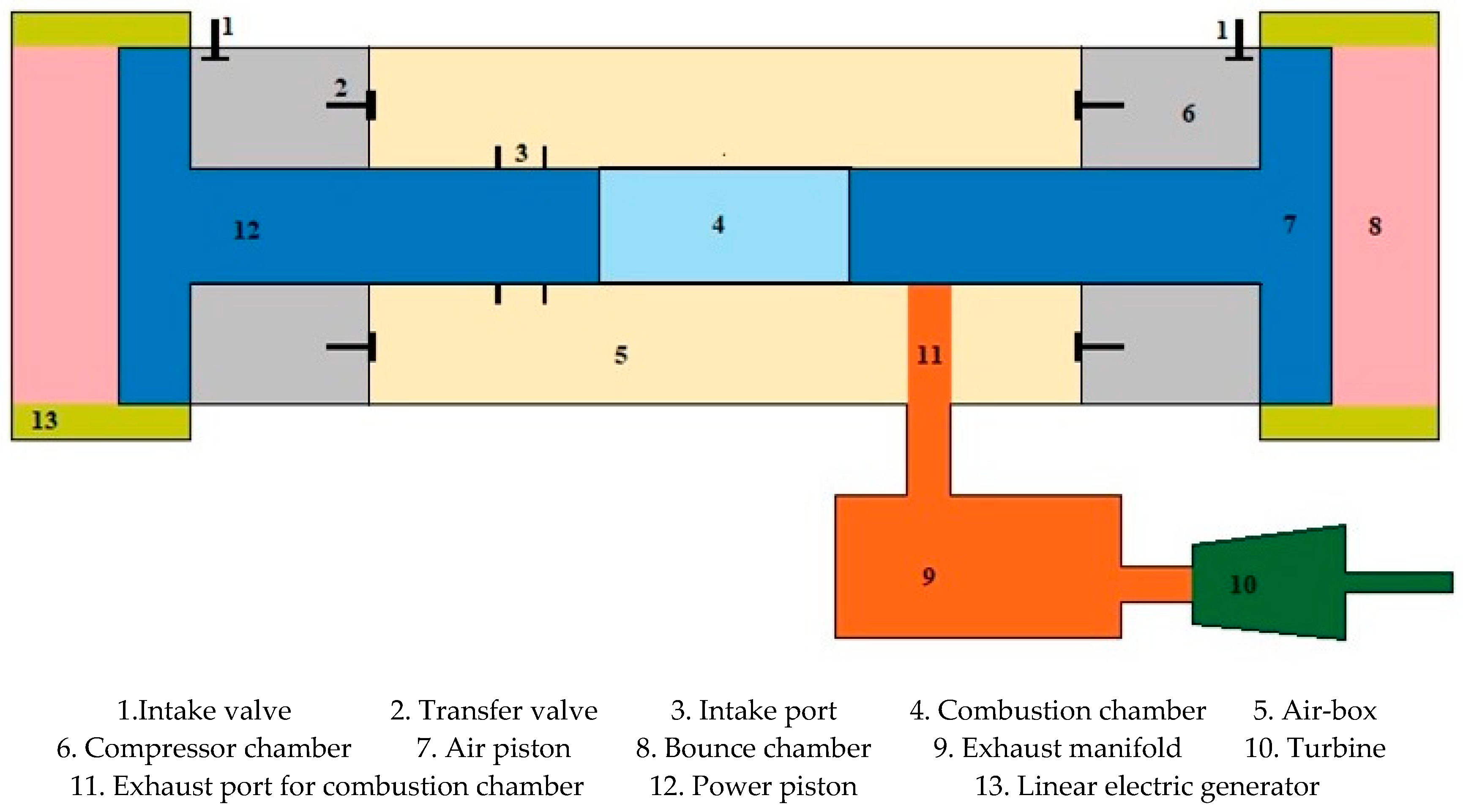

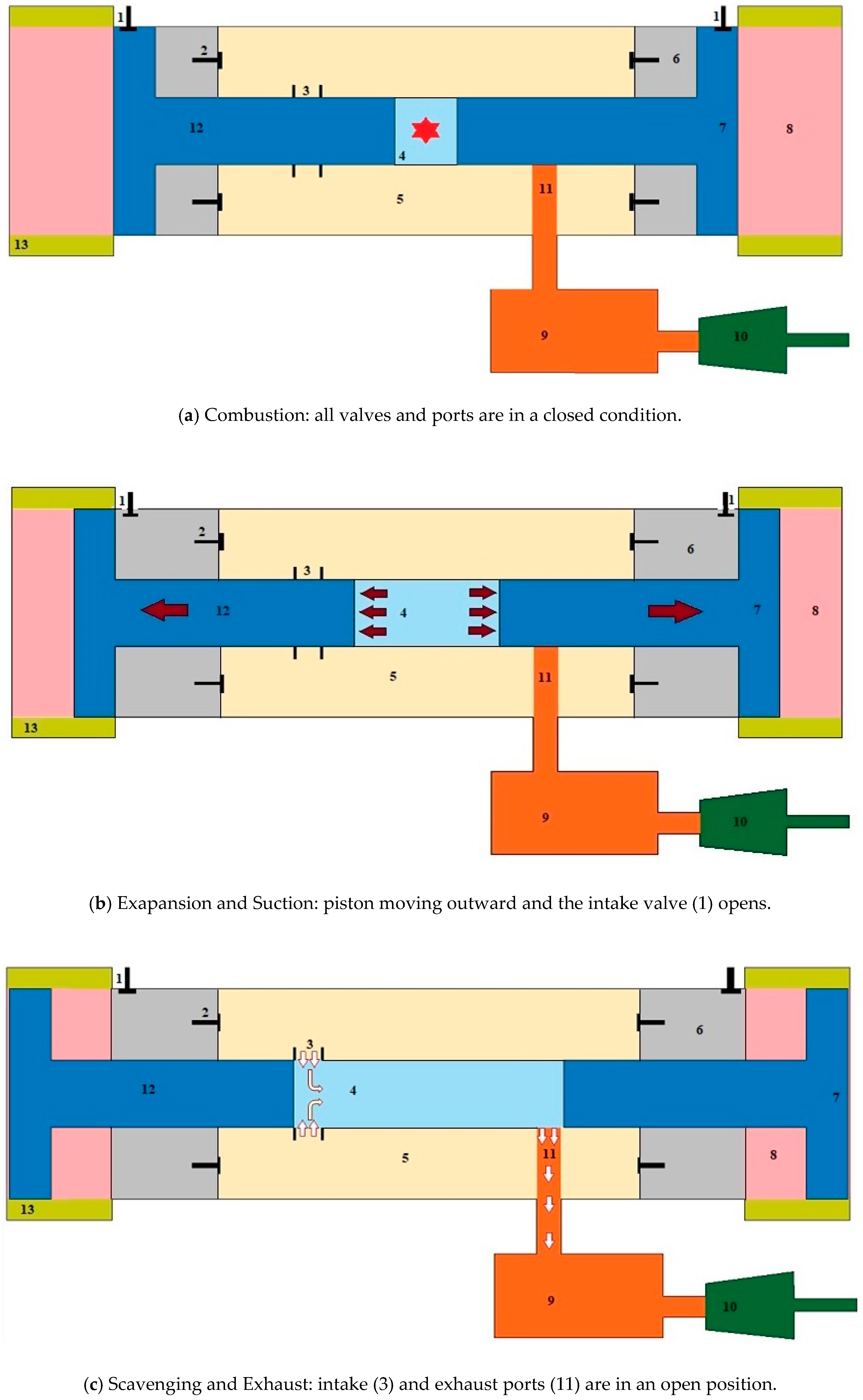

2. System Configuration

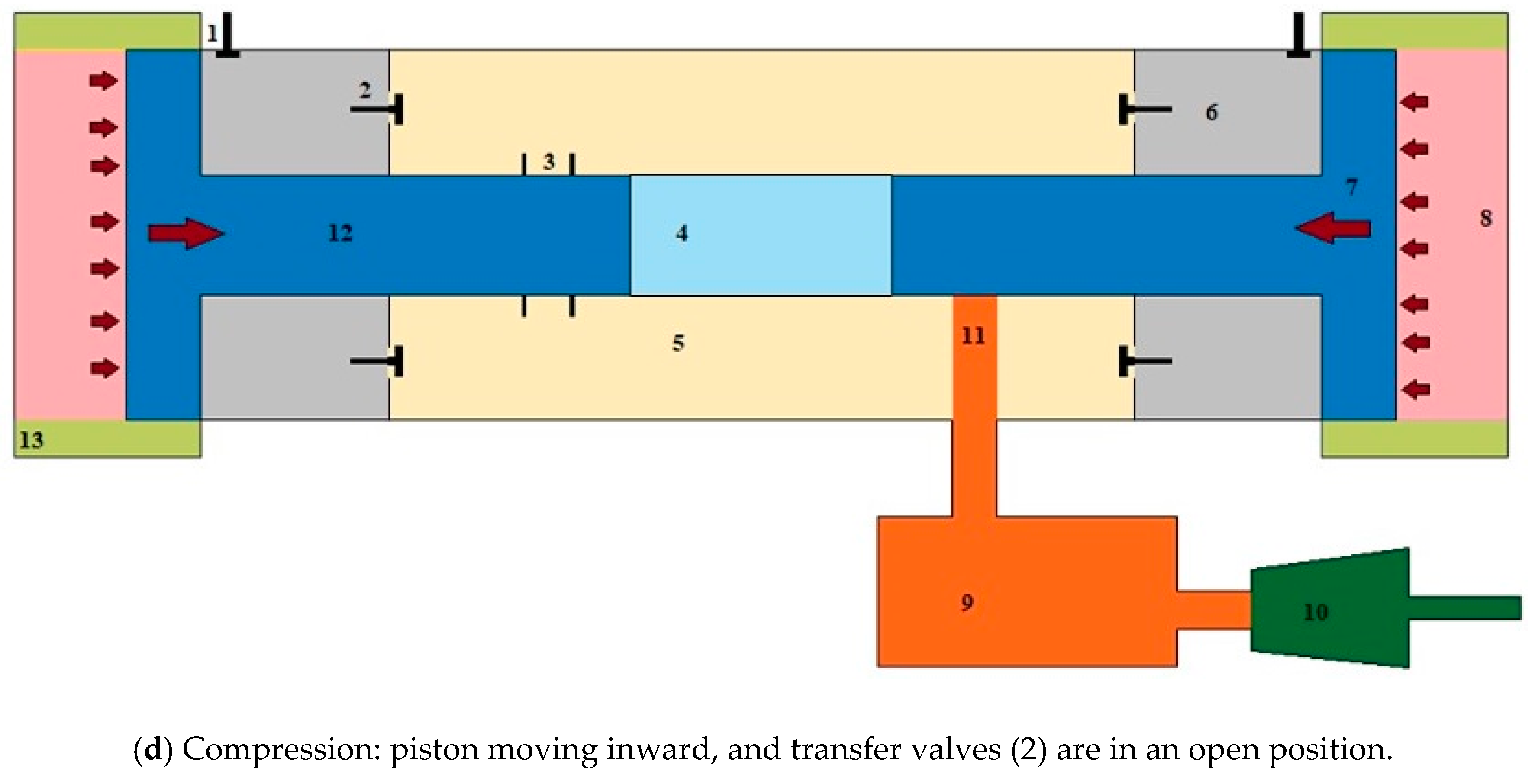

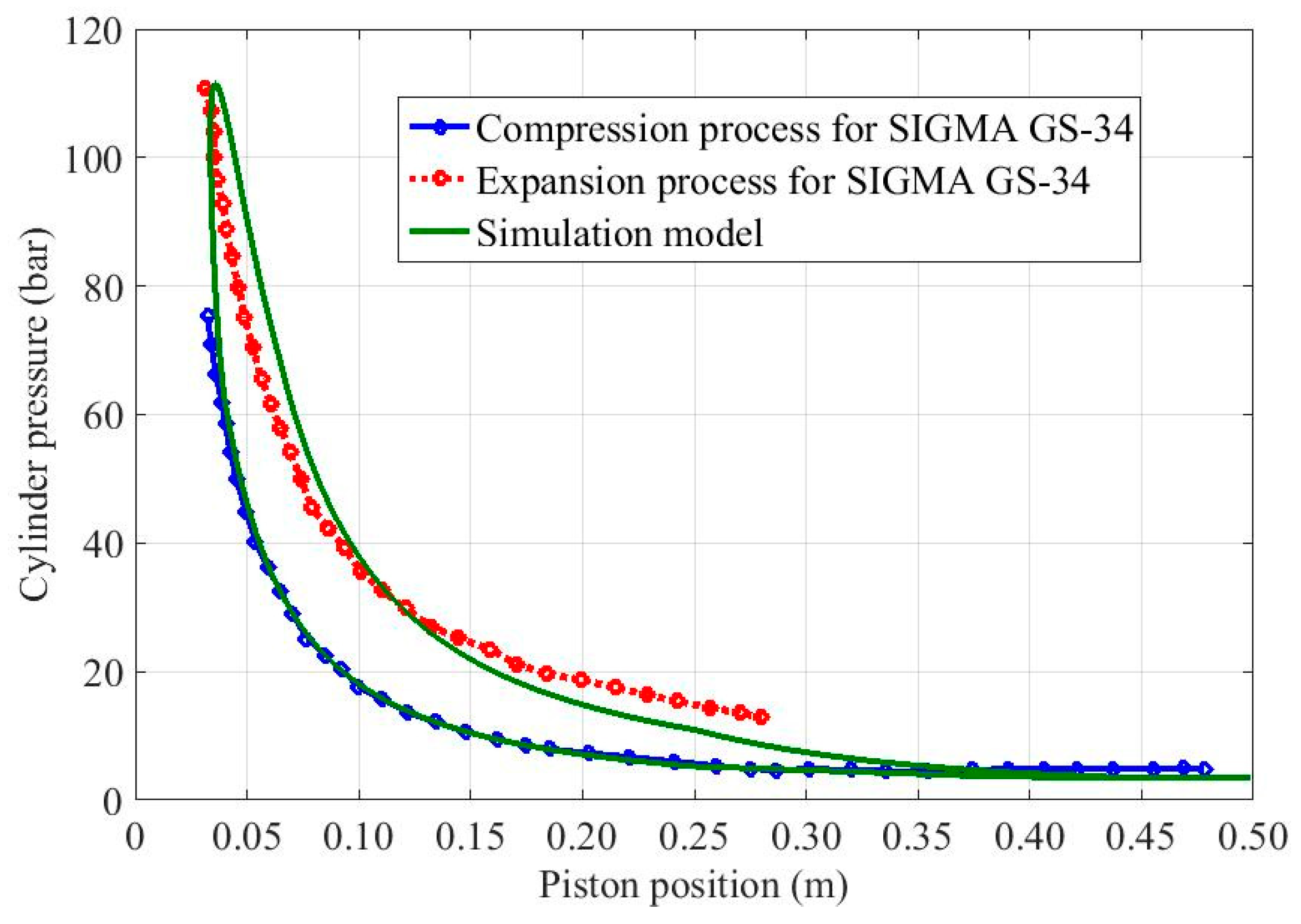

3. Simulation Model and Validation

3.1. Mathematical Modelling

- During the gas exchange process, when the intake or exhaust port is open, the in-cylinder pressure is equal to the charge air exhaust back pressure.

- In-cylinder gas kinetic and potential energy is neglected.

- In-cylinder gas is considered to be a homogeneous medium, uniform in both temperature & composition.

3.2. Validation Results

4. System Performance Prediction

4.1. Introduction

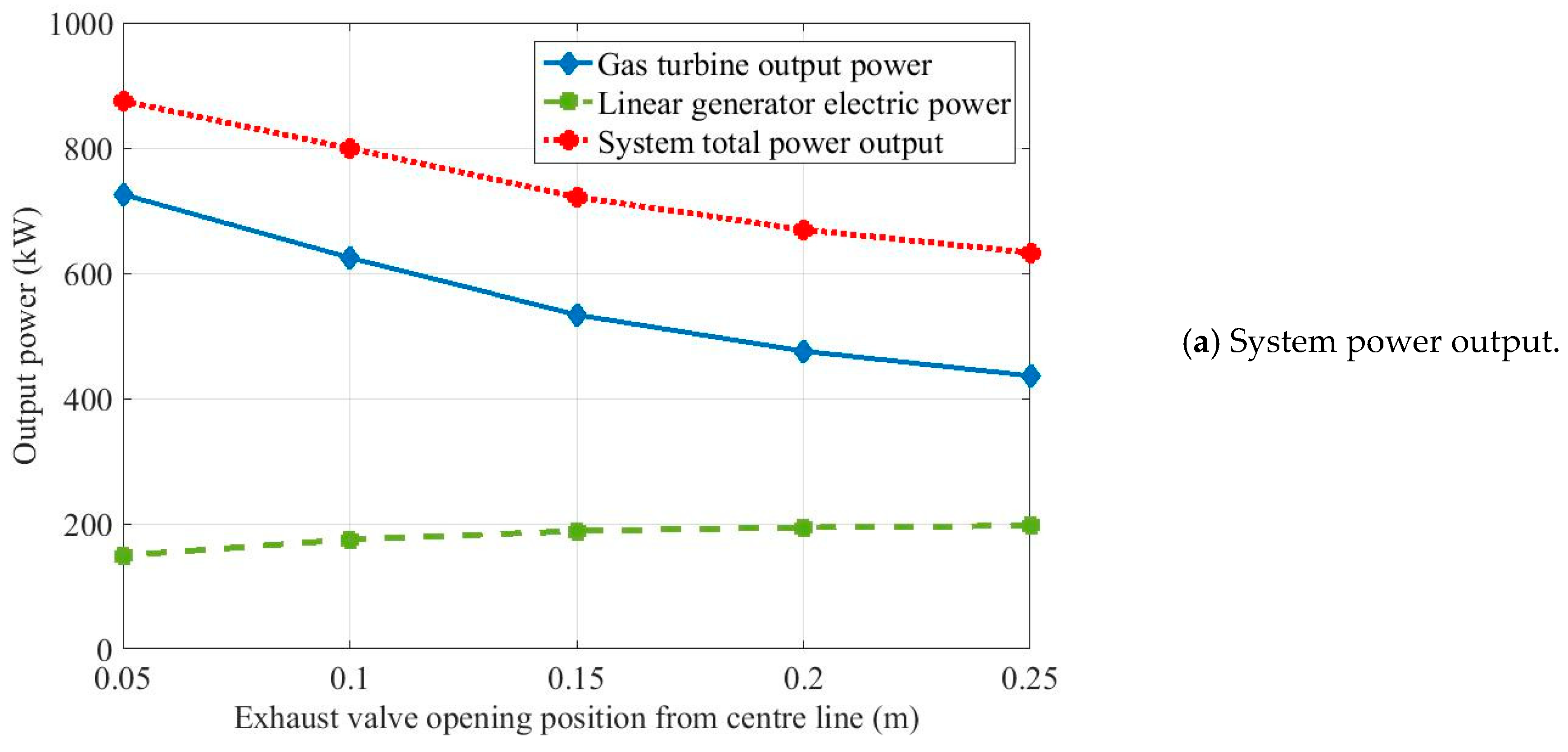

4.2. Power Output

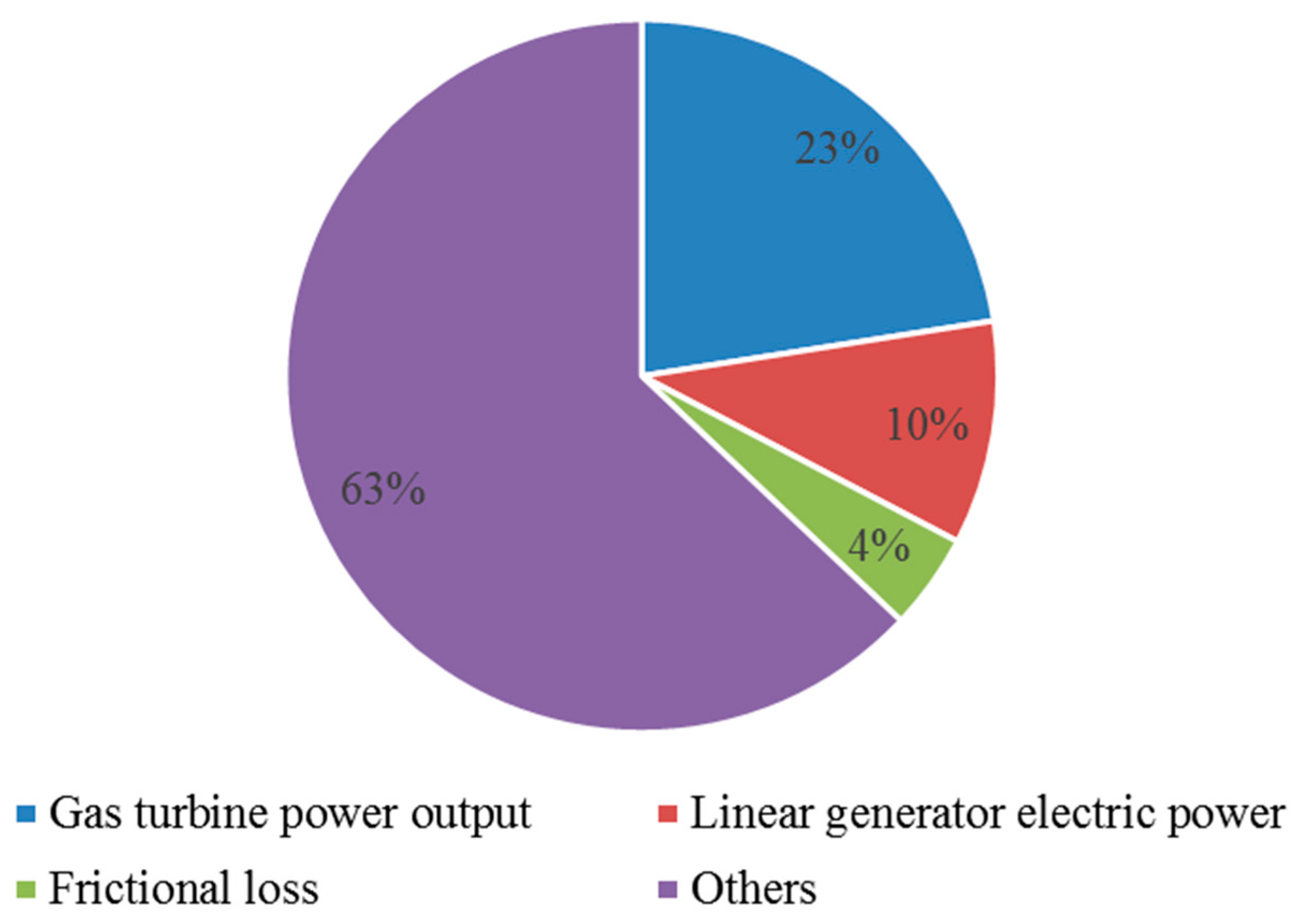

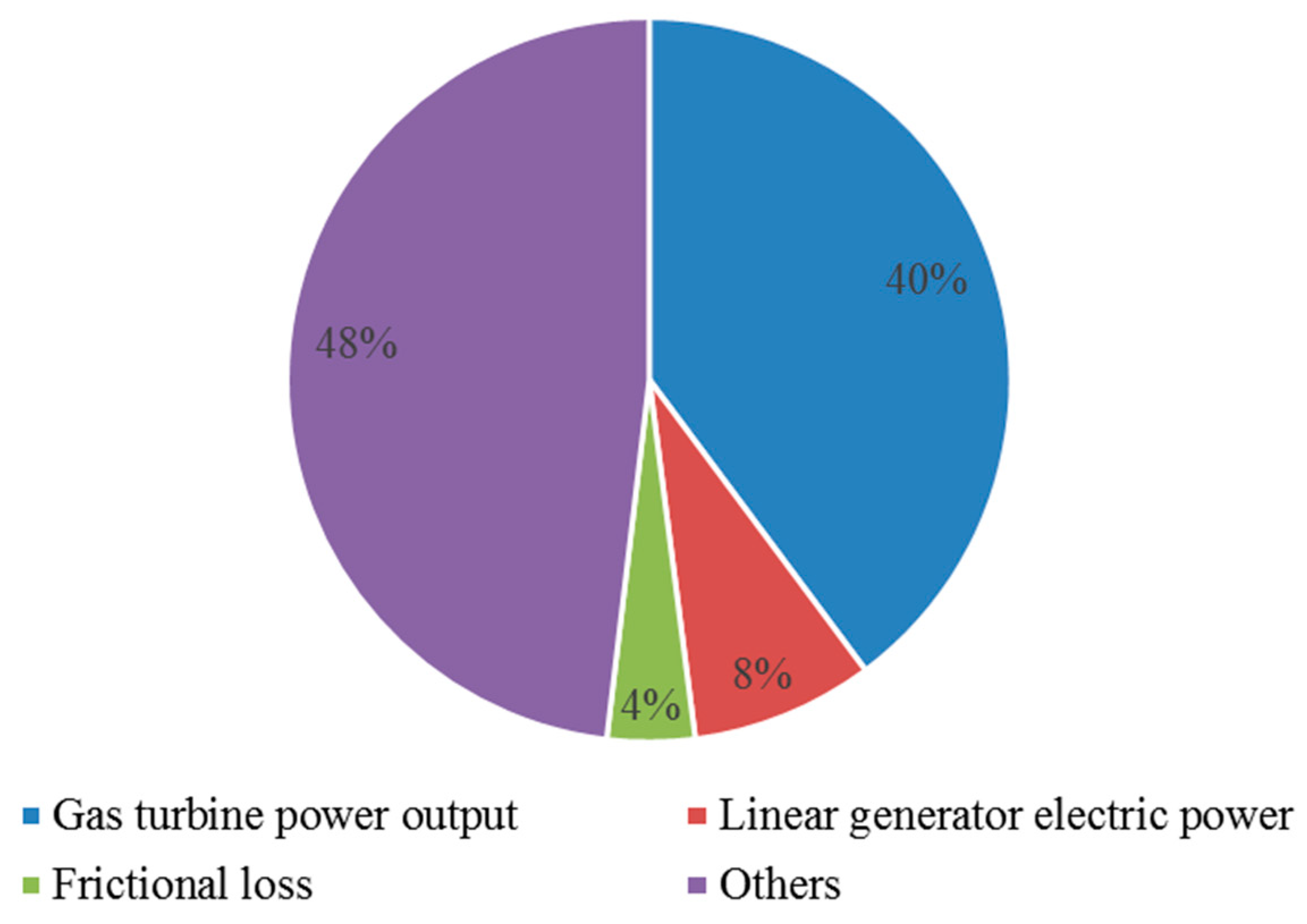

4.3. Energy Distribution

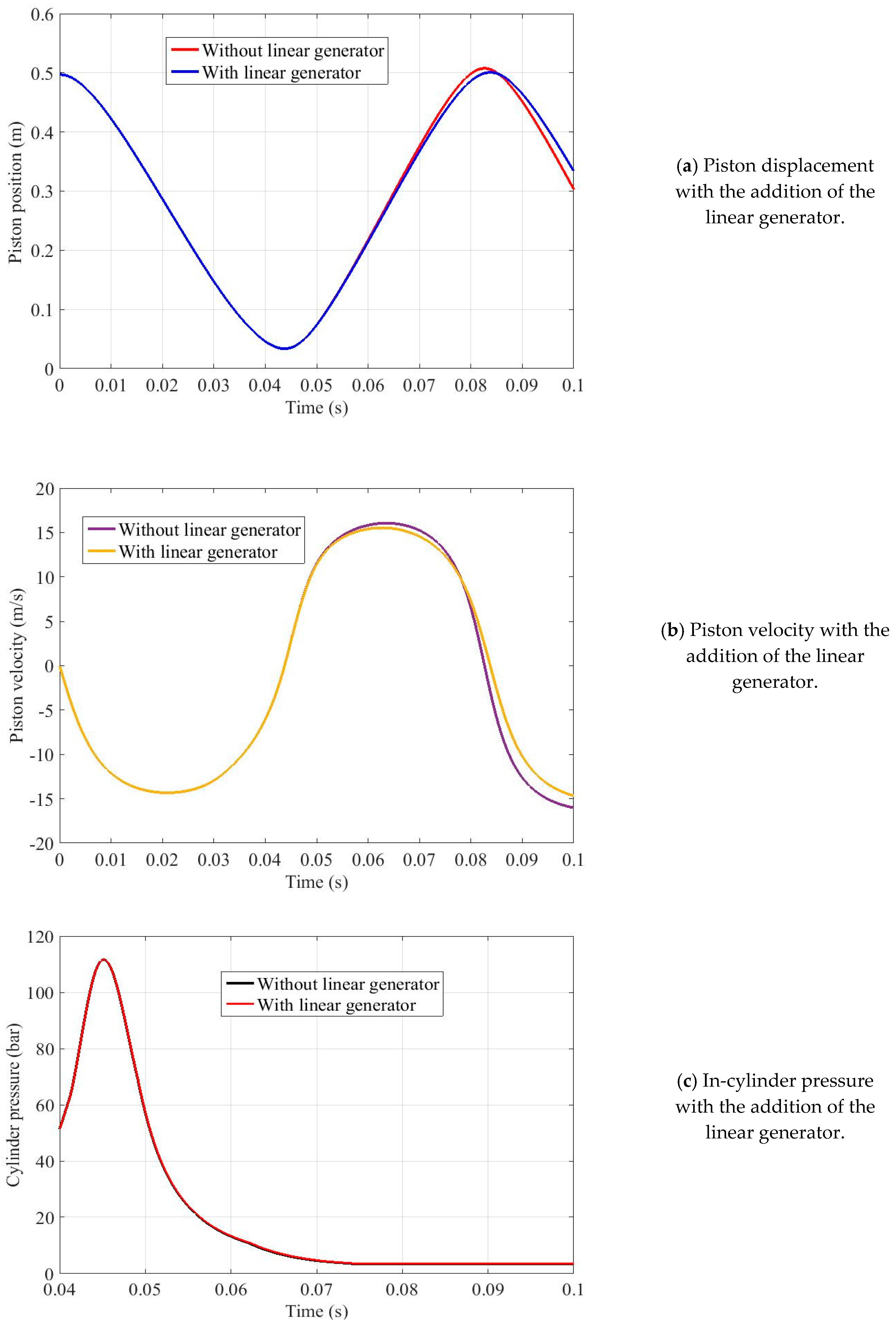

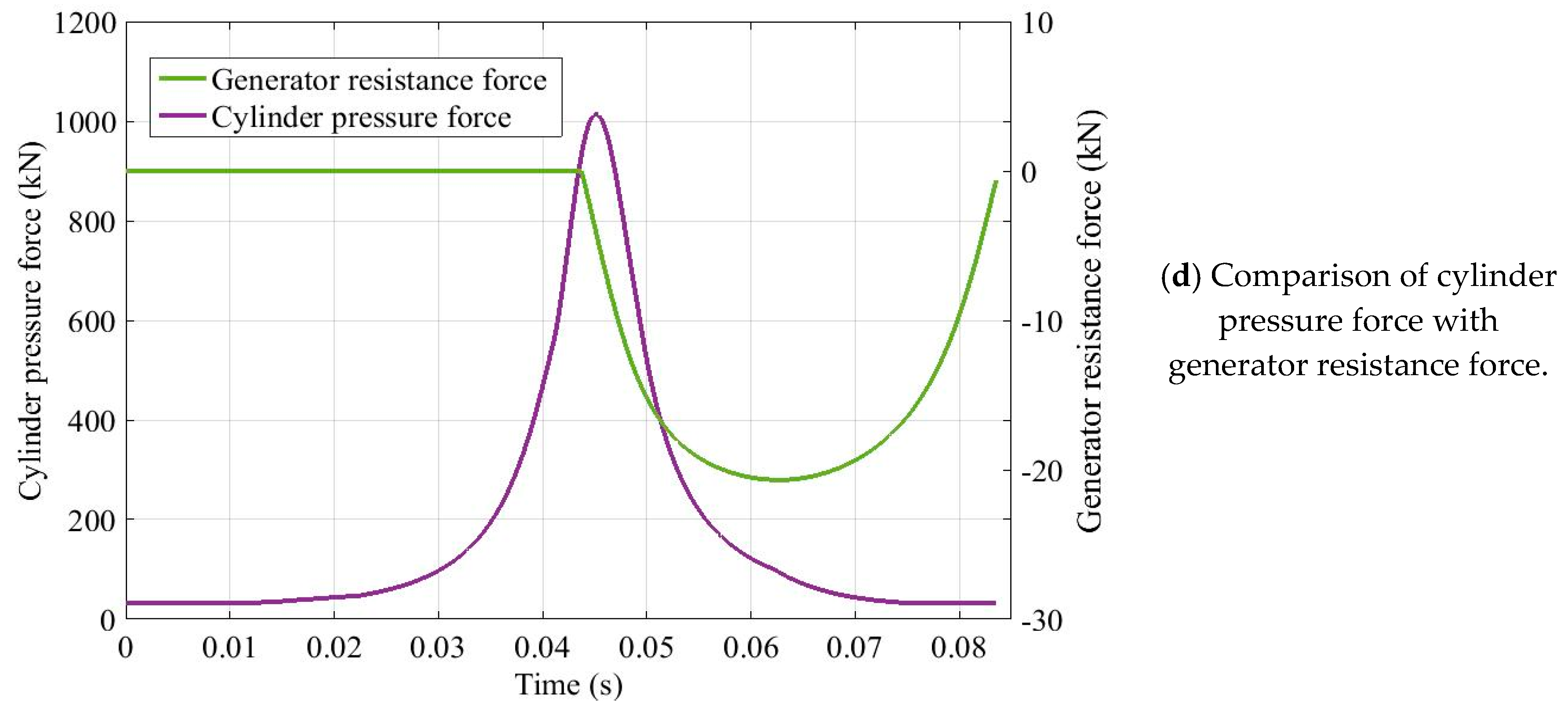

4.4. Piston Dynamics

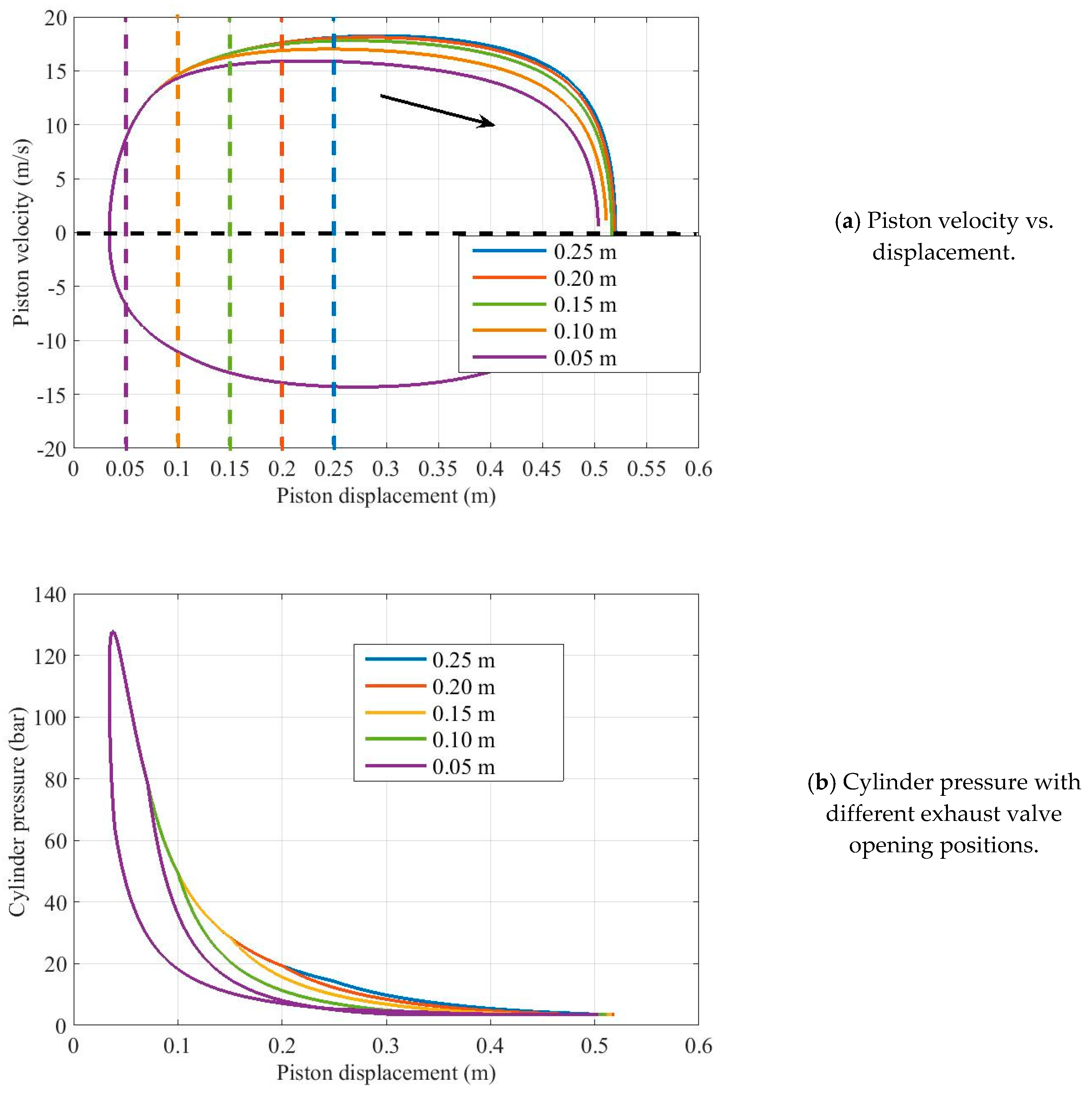

4.5. Engine Thermodynamics

5. Parametric Analysis

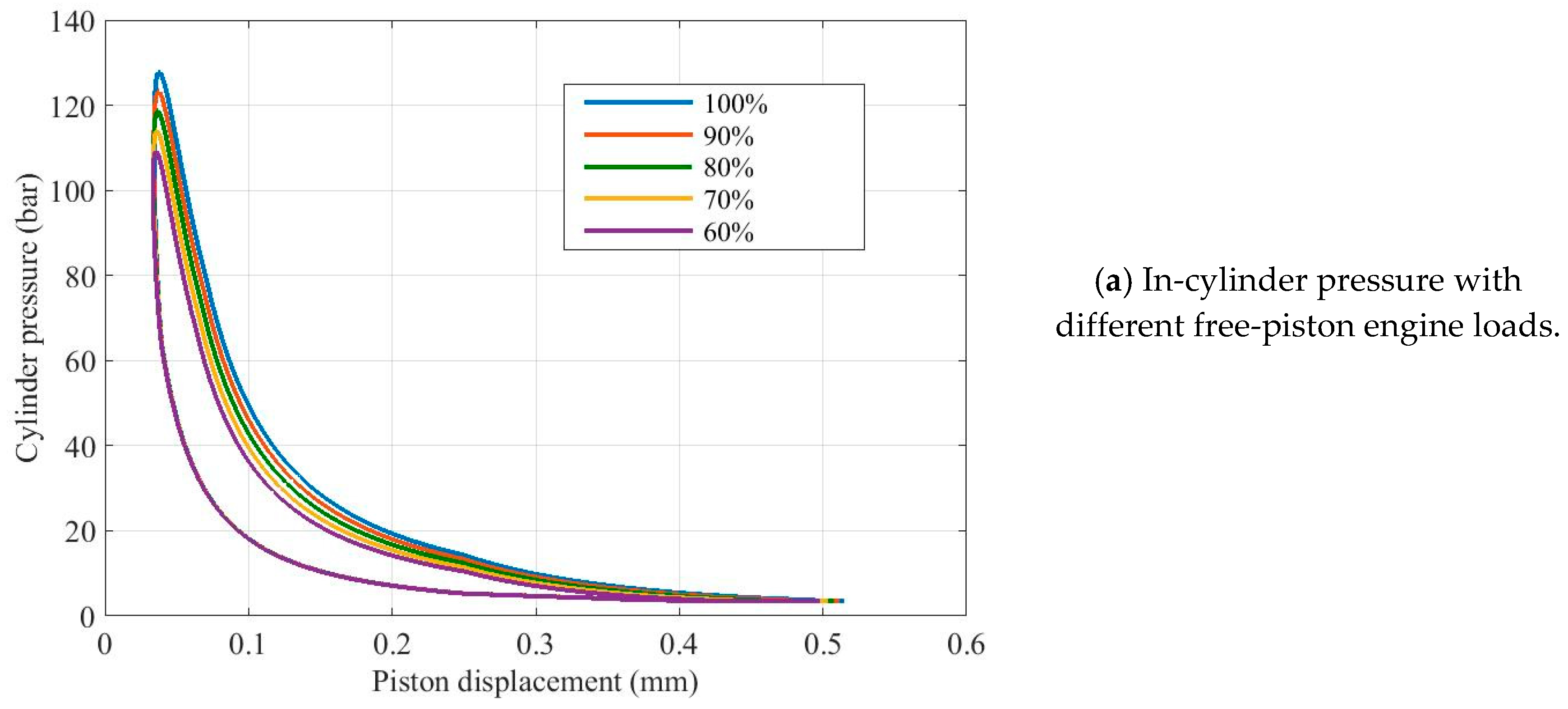

5.1. Different Engine Load

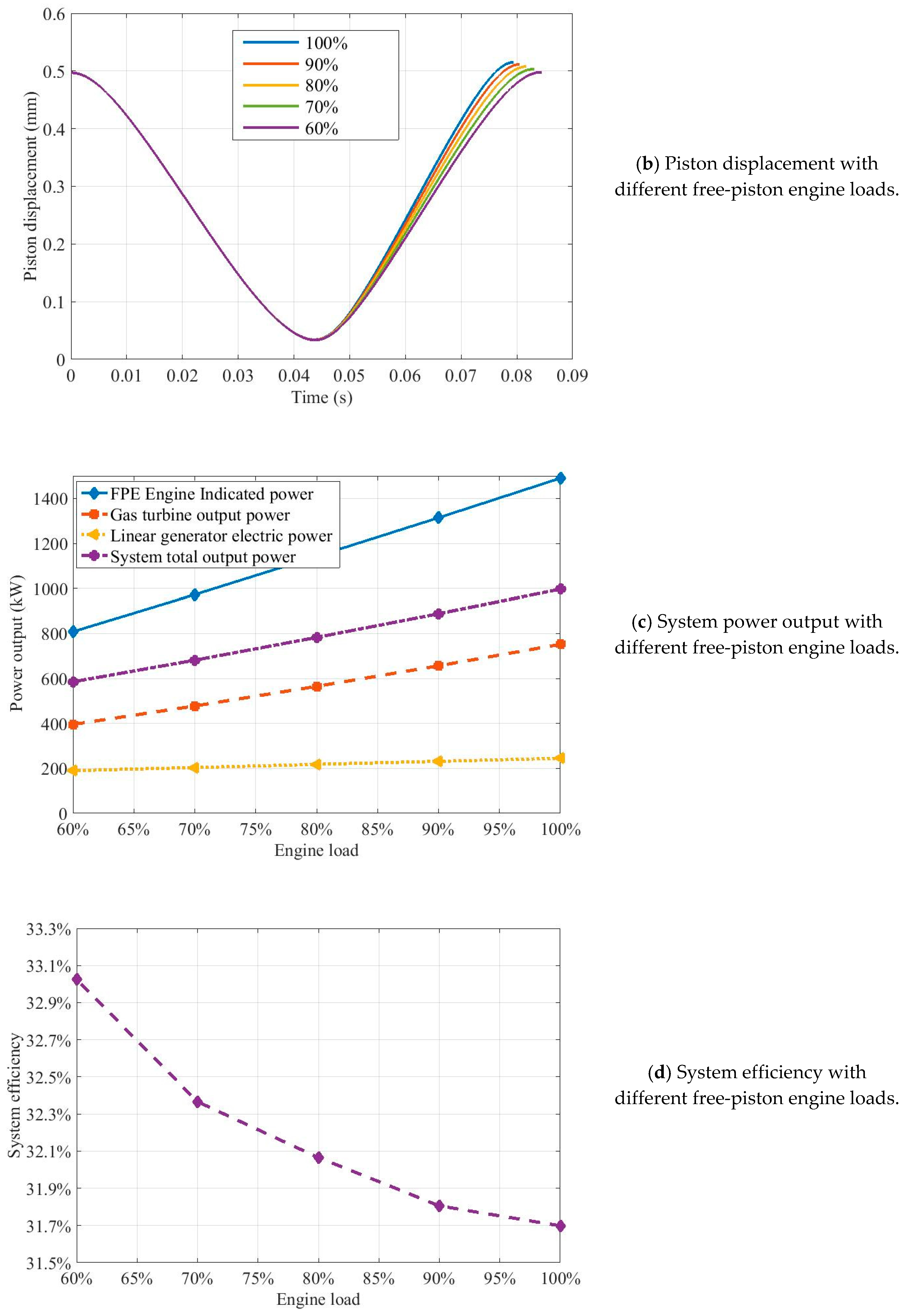

5.2. Effect of the Number of Linear Generators Connected with the Free-Piston Engine

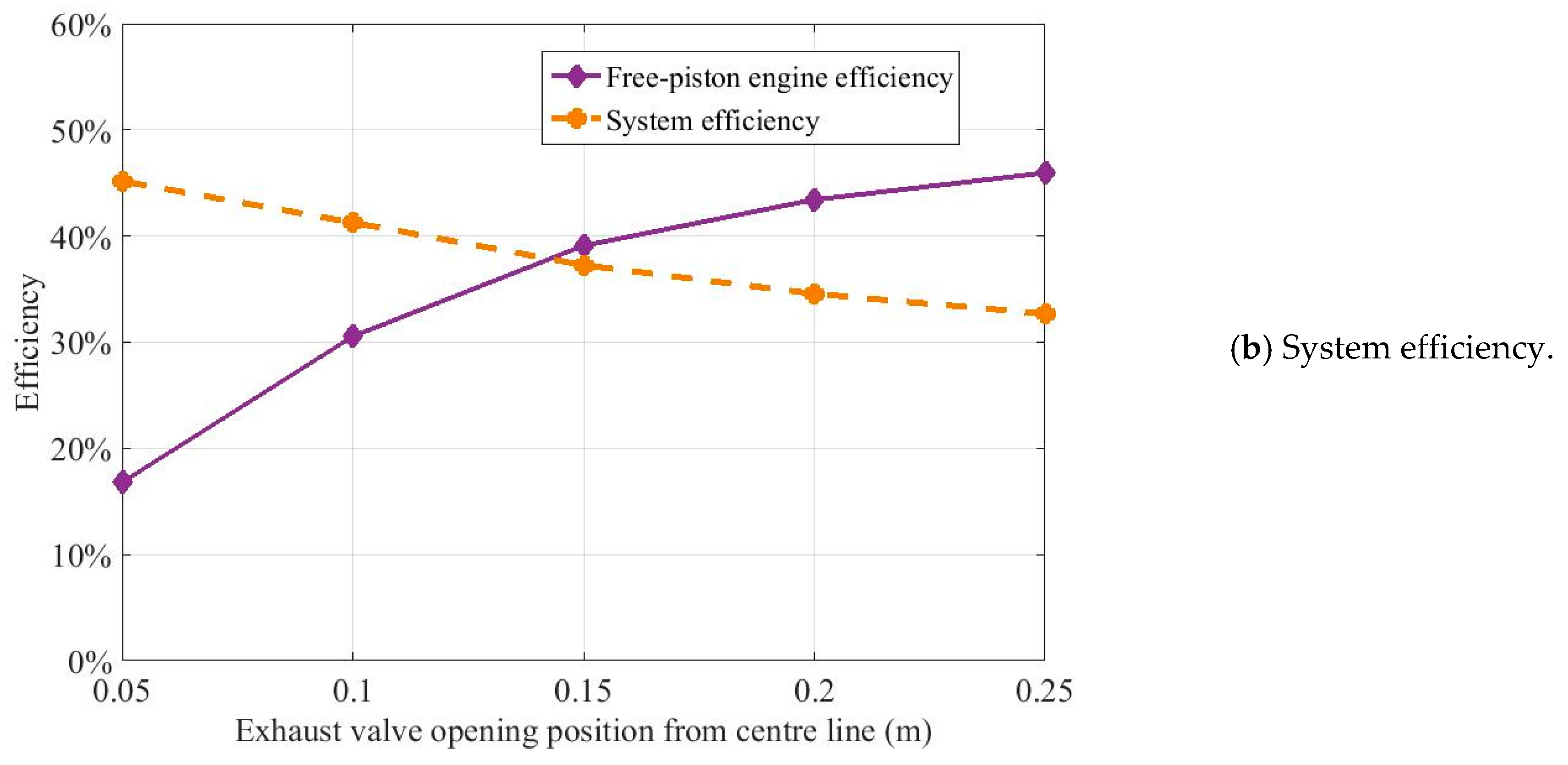

5.3. Different Valve Timings

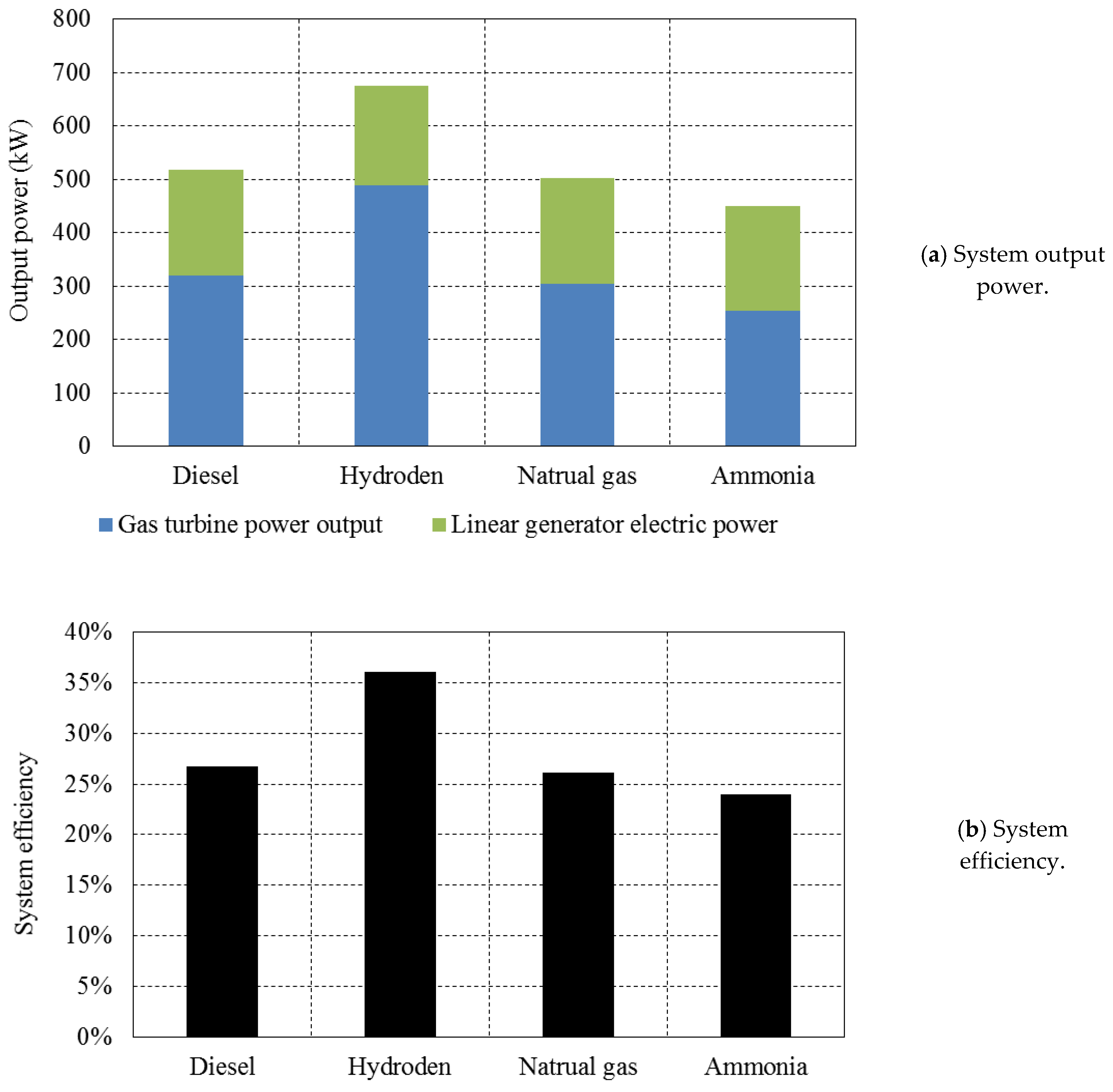

5.4. Potential for Fuel Flexibility for a TCFPEG

6. Conclusions

- The analysis confirmed that the peak cylinder pressure varied in positive correlation with the engine load without notable effect on the engine compression ratio.

- With a higher load, the engine operated at higher frequency, and its indicated power changing rate was developed. The system attained more efficiency, whereas the inlet temperature of the turbine was lowered at partial engine load.

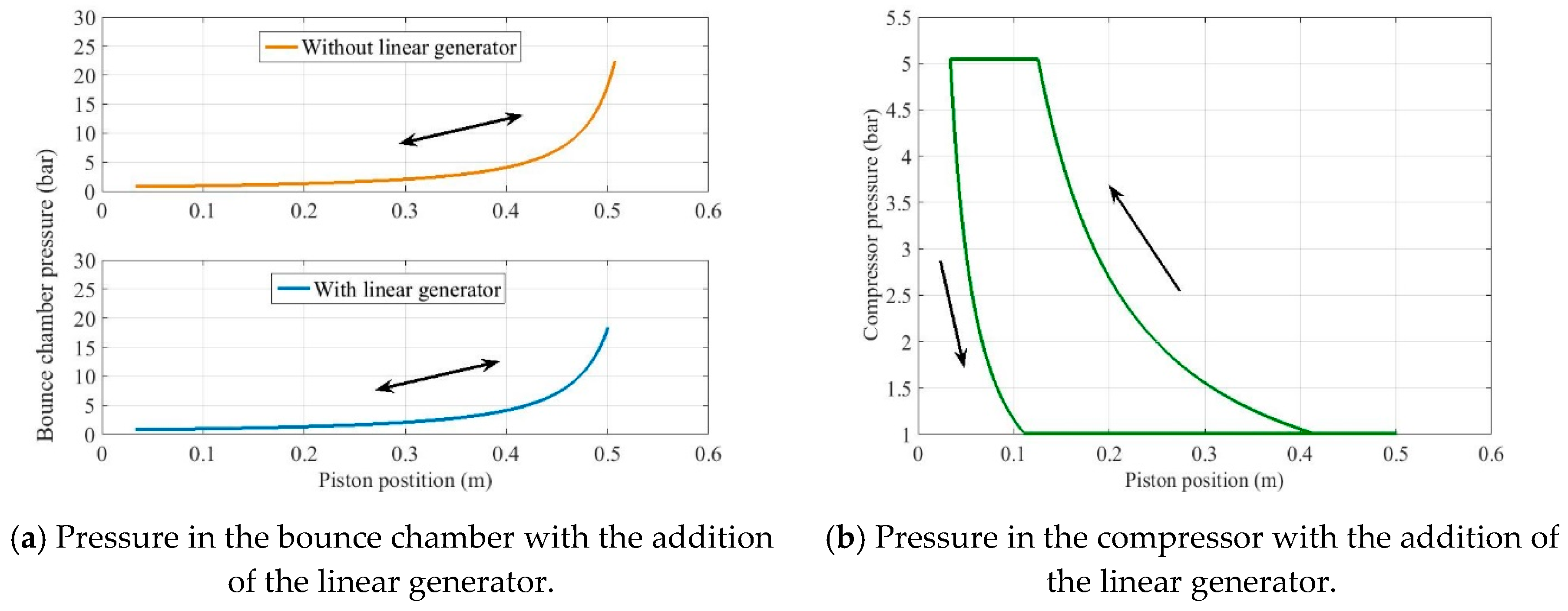

- It was found that the bottom dead centre (BDC), the peak piston velocity, and the engine operation frequency were all reduced when linear electric generators were connected to the system. Very minimal difference in the in-cylinder pressure and the compressor pressure were observed, while the peak pressure in the bounce chamber was reduced.

- The system’s total output and efficiency were increased when it operated at 65% of engine’s total load with 4 linear electric generators. Meanwhile, the turbine power output was reduced due to a drop in operating pressure.

- The system achieved 25% of efficiency when it operated without a linear electric generator. This could be improved to nearly 50% by optimising the engine load and the number of linear generators adopted in the TCFPEG system.

- It was found that the system gives more power output and efficiency with the use of hydrogen fuel compared to other fuels. With the hydrogen fuel, the system efficiency could reach up to 36%, and it was around 24% for ammonia as a fuel.

Author Contributions

Funding

Conflicts of Interest

Abbreviations:

| BDC | Bottom dead centre |

| FPE | Free-piston engine |

| FPEG | Free-piston engine generator |

| EGR | Exhaust gas recirculation |

| HCCI | Homogeneous charge compression ignition |

| HFPE | Hydraulic free-piston engine |

| kW | Kilowatt |

| NOx | Oxides of nitrogen |

| PPM | Pulse pause modulation |

| PR | Pressure ratio |

| SIGMA GS | Société Industrielle Générale de Mécanique Appliquée (General Industrial Company of Applied Mechanics) generator system |

| TCFPEG | Turbine-combined free-piston engine generator |

| TDC | Top dead centre |

References

- Jia, B.; Tian, G.; Feng, H.; Zuo, Z.; Roskilly, A.P. An experimental investigation into the starting process of free-piston engine generator. Appl. Energy 2015, 157, 798–804. [Google Scholar] [CrossRef]

- Feng, H.; Guo, C.; Yuan, C.; Guo, Y.; Zuo, Z.; Roskilly, A.P.; Jia, B. Research on combustion process of a free piston diesel linear generator. Appl. Energy 2016, 161, 395–403. [Google Scholar] [CrossRef]

- Mikalsen, R.; Roskilly, A.P. A computational study of free-piston diesel engine combustion. Appl. Energy 2009, 86, 1136–1143. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, F.; Huang, Y.; Zhao, C. Determination of TDC in a hydraulic free-piston engine by a novel approach. Appl. Therm. Eng. 2014, 70, 524–530. [Google Scholar] [CrossRef]

- Lim, O.; Hung, N.B.; Oh, S.; Kim, G.; Song, H.; Iida, N. A study of operating parameters on the linear spark ignition engine. Appl. Energy 2015, 160, 746–760. [Google Scholar] [CrossRef]

- Li, K.; Zhang, C.; Sun, Z. Precise piston trajectory control for a free piston engine. Control Eng. Pract. 2015, 34, 30–38. [Google Scholar] [CrossRef]

- Jia, B.; Smallbone, A.; Mikalsen, R.; Feng, H.; Zuo, Z.; Roskilly, A.P. Disturbance analysis of a free-piston engine generator using a validated fast-response numerical model. Appl. Energy 2017, 185, 440–451. [Google Scholar] [CrossRef]

- Lee, C.-P. Turbine-Compound Free-Piston Linear Alternator Engine. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2014. [Google Scholar]

- Underwood, A.F. The GMR 4-4 “HYPREX” Engine A Concept of the Free-Piston Engine for Automotive Use; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1957. [Google Scholar]

- Tikkanen, S.; Lammila, M.; Herranen, M.; Vilenius, M. First Cycles of the Dual Hydraulic Free Piston Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Zhang, S.; Zhao, C.; Zhao, Z. Stability analysis of hydraulic free piston engine. Appl. Energy 2015, 157, 805–813. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, F.; Huang, Y.; Zhao, C.; Guo, F. An experimental study of the hydraulic free piston engine. Appl. Energy 2012, 99, 226–233. [Google Scholar] [CrossRef]

- Woo, Y.; Lee, Y.J. Free piston engine generator: Technology review and an experimental evaluation with hydrogen fuel. Int. J. Automot. Technol. 2014, 15, 229–235. [Google Scholar] [CrossRef]

- Jia, B.; Zuo, Z.; Feng, H.; Tian, G.; Smallbone, A.; Roskilly, A.P. Effect of closed-loop controlled resonance based mechanism to start free piston engine generator: Simulation and test results. Appl. Energy 2016, 164, 532–539. [Google Scholar] [CrossRef]

- Miao, Y.; Zuo, Z.; Feng, H.; Guo, C.; Song, Y.; Jia, B.; Guo, Y. Research on the Combustion Characteristics of a Free-Piston Gasoline Engine Linear Generator during the Stable Generating Process. Energies 2016, 9, 655. [Google Scholar] [CrossRef]

- Max, E. FPEC, Free piston energy converter. In Proceedings of the 21st Electric Vehicle Symposium & Exhibition, EVS, Monte Carlo, Monaco, 2–6 April 2005. [Google Scholar]

- Kock, F.; Haag, J.; Friedrich, H.E. The Free Piston Linear Generator-Development of an Innovative, Compact, Highly Efficient Range-Extender Module; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Haag, J.; Ferrari, C.; Starcke, J.H.; Stöhr, M.; Riedel, U. Numerical and Experimental Investigation of In-Cylinder Flow in A Loop-Scavenged Two-Stroke Free Piston Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Haag, J.; Kock, F.; Chiodi, M.; Mack, O.; Bargende, M.; Naumann, C.; Slavinskaya, N.; Heron, A.; Riedel, U.; Ferrari, C. Development Approach for the Investigation of Homogeneous Charge Compression Ignition in a Free-Piston Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Kosaka, H.; Akita, T.; Moriya, K.; Goto, S.; Hotta, Y.; Umeno, T.; Nakakita, K. Development of Free Piston Engine Linear Generator System Part 1-Investigation of Fundamental Characteristics; SAE Technical Paper 0148-7191; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Goto, S.; Moriya, K.; Kosaka, H.; Akita, T.; Hotta, Y.; Umeno, T.; Nakakita, K. Development of Free Piston Engine Linear Generator System Part 2-Investigation of Control System for Generator; SAE Technical Paper 0148-7191; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Jia, B.; Zuo, Z.; Feng, H.; Tian, G.; Roskilly, A.P. Development Approach of A Spark-Ignited Free-Piston Engine Generator; SAE Technical Paper 0148-7191; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Jia, B.; Zuo, Z.; Feng, H.; Tian, G.; Roskilly, A.P. Investigation of the starting process of free-piston engine generator by mechanical resonance. Energy Procedia 2014, 61, 572–577. [Google Scholar] [CrossRef]

- Li, Y.-X.; Zuo, Z.-X.; Feng, H.-H.; Jia, B.-R. Parameters matching requirements for diesel free piston linear alternator start-up. Adv. Mech. Eng. 2015, 7, 1–8. [Google Scholar] [CrossRef]

- Jia, B.; Zuo, Z.; Tian, G.; Feng, H.; Roskilly, A.P. Development and validation of a free-piston engine generator numerical model. Energy Convers. Manag. 2015, 91, 333–341. [Google Scholar] [CrossRef]

- Jia, B.; Smallbone, A.; Feng, H.; Tian, G.; Zuo, Z.; Roskilly, A.P. A fast response free-piston engine generator numerical model for control applications. Appl. Energy 2016, 162, 321–329. [Google Scholar] [CrossRef]

- Jia, B.; Smallbone, A.; Zuo, Z.; Feng, H.; Roskilly, A.P. Design and simulation of a two-or four-stroke free-piston engine generator for range extender applications. Energy Convers. Manag. 2016, 111, 289–298. [Google Scholar] [CrossRef]

- Mikalsen, R.; Roskilly, A.P. The design and simulation of a two-stroke free-piston compression ignition engine for electrical power generation. Appl. Therm. Eng. 2008, 28, 589–600. [Google Scholar] [CrossRef]

- Barnes, A.F. Simulation of Full and Part-Load Performance of A Free-Piston Gas Generator by Electronic Analog Methods. Master’s Thesis, US Naval Postgraduate School, Monterey, CA, USA, 1960. [Google Scholar]

- Ngwaka, U.; Jia, B.; Lawrence, C.; Wu, D.; Smallbone, A.; Roskilly, A.P. The characteristics of a Linear Joule Engine Generator operating on a dry friction principle. Appl. Energy 2019, 237, 49–59. [Google Scholar] [CrossRef]

- Hanipah, M.R. Development of A Spark Ignition Free-Piston Engine Generator. Ph.D. Thesis, Newcastle University, Newcastle, UK, 2015. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamentals; Mcgraw-Hill: New York, NY, USA, 1988; Volume 930. [Google Scholar]

| Parameter [Unit] | Value | |

|---|---|---|

| Combustion engine | Cylinder bore [m] | 0.340 |

| Engine stroke [m] | 0.965 | |

| Piston mass [kg] | 500 | |

| Bounce chamber | Bore [m] | 0.895 |

| Stroke (per piston) [m] | 0.445 | |

| Compressor chamber | Effective bore [m] | 0.823 |

| Stroke (per piston) [m] | 0.445 | |

| Linear Generator | With | Without |

|---|---|---|

| Free-piston engine indicated efficiency (%) | 45.9 | 46.30 |

| Bottom dead centre (m) | 0.5007 | 0.05075 |

| Top dead centre (m) | 0.03374 | 0.03374 |

| Engine indicated power (kW) | 891.9 | 908.6 |

| Gas turbine generator output (kW) | 422.7 | 441.9 |

| Linear generator electric power output (kW) | 197.2 | 0 |

| Overall system efficiency (%) | 32 | 22.50 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, B.; Smallbone, A.; Mikalsen, R.; Shivaprasad, K.V.; Roy, S.; Roskilly, A.P. Performance Analysis of a Flexi-Fuel Turbine-Combined Free-Piston Engine Generator. Energies 2019, 12, 2657. https://doi.org/10.3390/en12142657

Jia B, Smallbone A, Mikalsen R, Shivaprasad KV, Roy S, Roskilly AP. Performance Analysis of a Flexi-Fuel Turbine-Combined Free-Piston Engine Generator. Energies. 2019; 12(14):2657. https://doi.org/10.3390/en12142657

Chicago/Turabian StyleJia, Boru, Andrew Smallbone, Rikard Mikalsen, K.V. Shivaprasad, Sumit Roy, and Anthony Paul Roskilly. 2019. "Performance Analysis of a Flexi-Fuel Turbine-Combined Free-Piston Engine Generator" Energies 12, no. 14: 2657. https://doi.org/10.3390/en12142657

APA StyleJia, B., Smallbone, A., Mikalsen, R., Shivaprasad, K. V., Roy, S., & Roskilly, A. P. (2019). Performance Analysis of a Flexi-Fuel Turbine-Combined Free-Piston Engine Generator. Energies, 12(14), 2657. https://doi.org/10.3390/en12142657