The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass

Abstract

1. Introduction

2. Materials and Methods

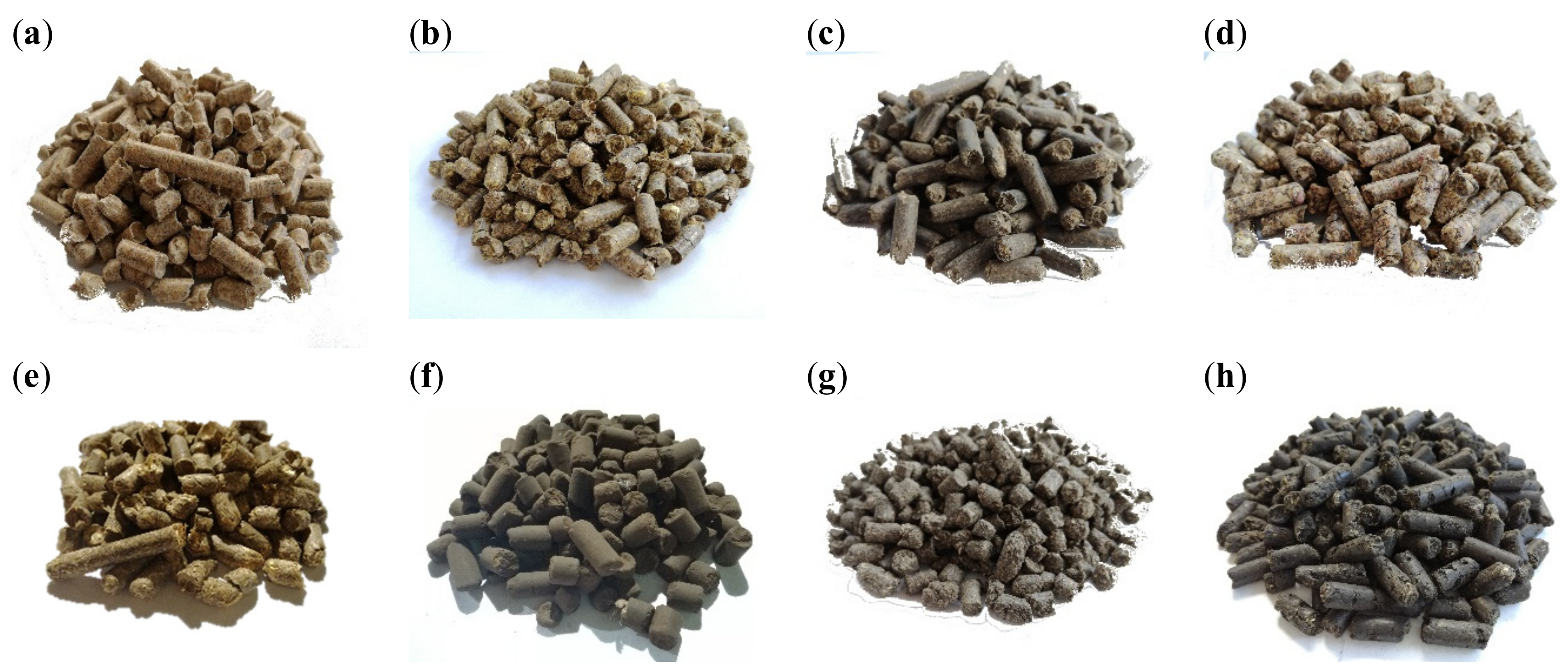

2.1. Materials Used in the Experiments

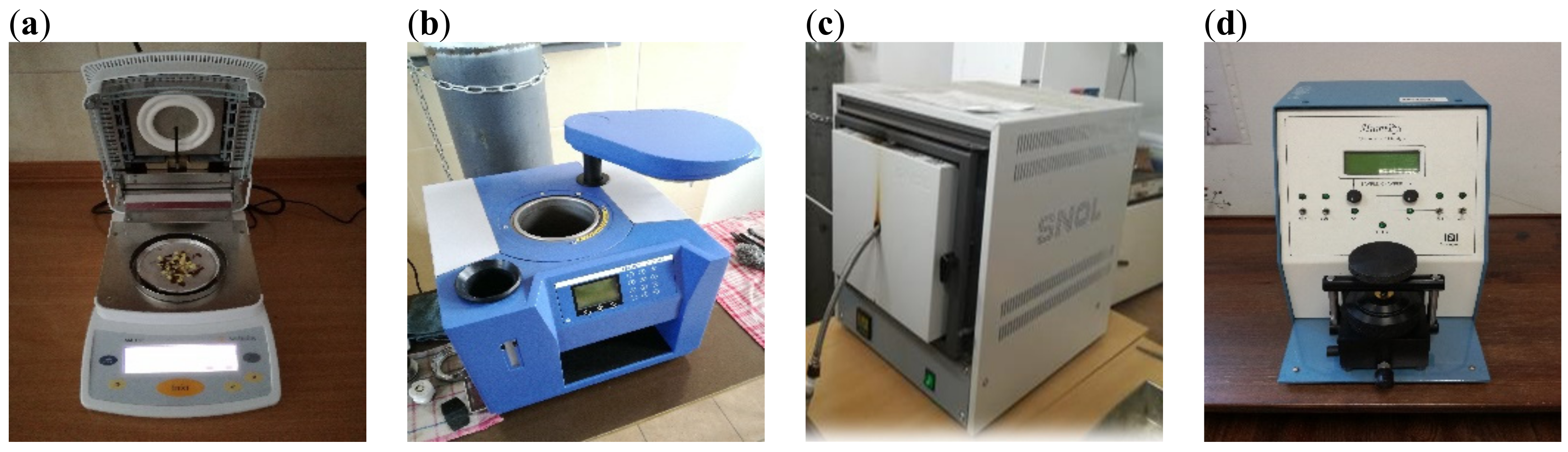

2.2. Technical and Chemical Analysis

2.3. Preparation of the Samples

- -

- Variant 1 (assumed as normal pellets): the reference sample was stored in the warehouse in the temperature of 20 °C at air humidity of 70% (the storage time was one month). The storage conditions (temperature and air humidity) inside the warehouse were controlled using a thermo hygrometer Kimo HD 50 (Kimo, Barcelona, Spain). All the pellets were packed in the 15 kg bags.

- -

- Variant 2 (assumed as frozen pellets): the pellets were stored in a laboratory freezer. The temperature inside the freezer was −28 °C. The storage time was 5 days. Hermetically packed 10 samples of each material were prepared for further tests. The mass of one sample was 500 g.

- -

- Variant 3 (assumed as defrosted pellets): after the storage of the pellets in the freezer, five samples of each investigated material were taken out and left for a period of 12 hours in the warehouse (in the temperature of 20 °C at air humidity of 70%) to enable the samples to have a natural defrosting process.

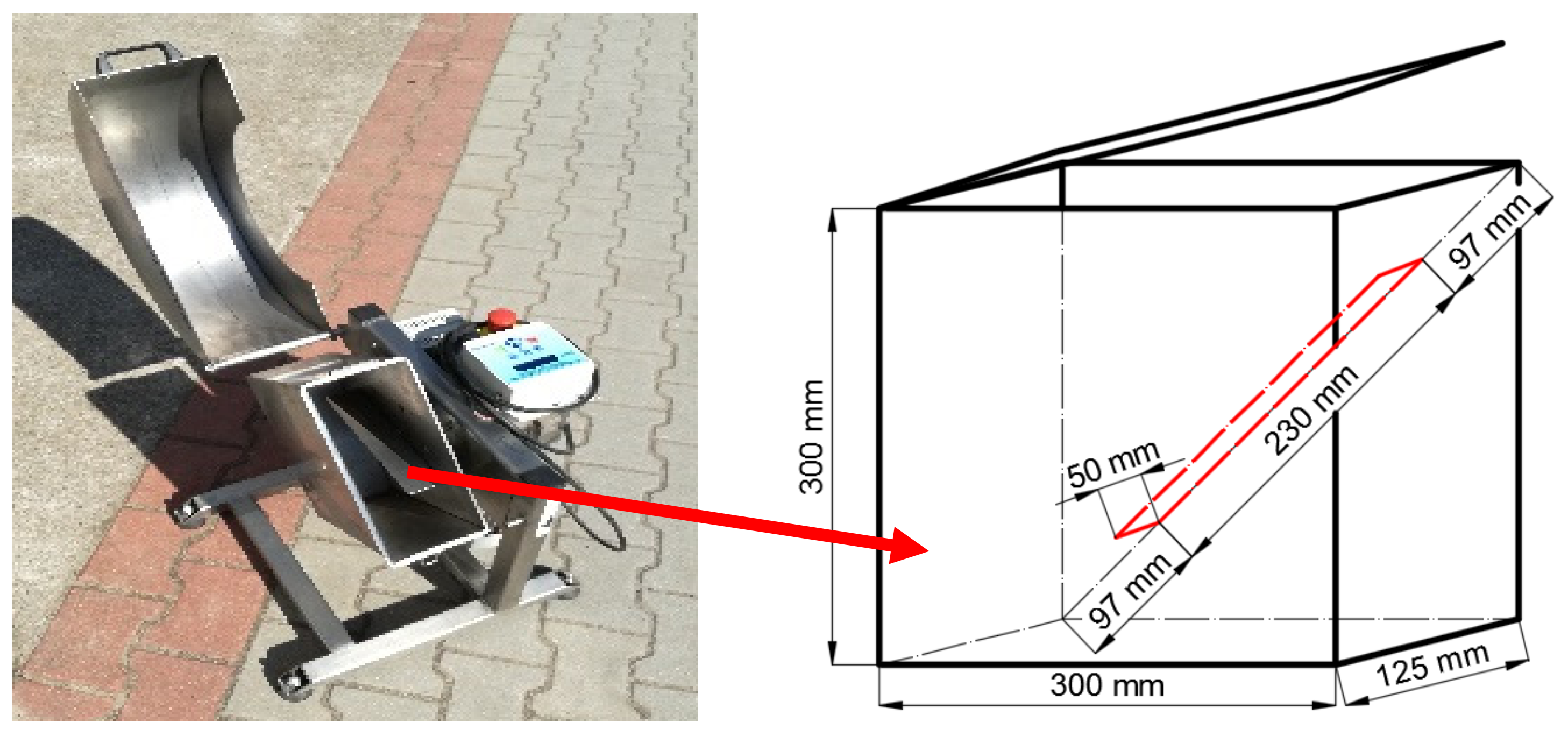

2.4. Mechanical Durability Test

3. Results and Discussion

3.1. Technical and Chemical Characteristics

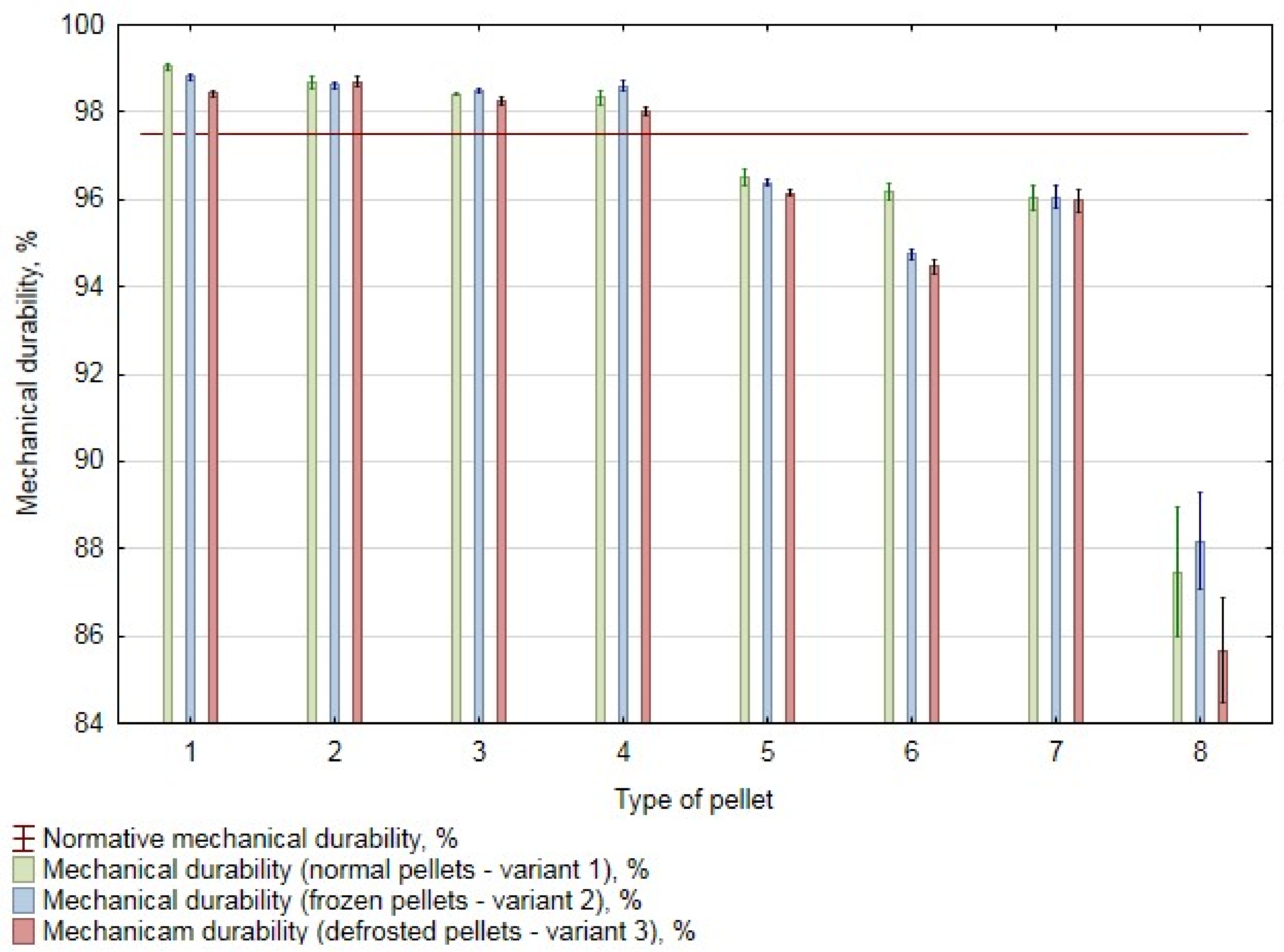

3.2. Mechanical Durability Index

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AC | ash content |

| EC | European Commission |

| EU | European Union |

| HHV | higher heating value |

| LHV | lower heating value |

| MC | moisture content |

| RES | renewable energy sources |

| VM | volatile matter content |

References

- EuroStat. Energy Consumption in Households. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Energy_consumption_in_households (accessed on 29 May 2019).

- European Commission. EUROPE 2020: A Strategy for Smart, Sustainable and Inclusive Growth; European Commission: Brussels, Belgium, 2010. [Google Scholar]

- World Bioenergy Association. WBA Global Bioenergy Statistics 2018; World Bioenergy Association: Stockholm, Sweden, 2018. [Google Scholar]

- Karakashev, D.; Zhang, Y. BioEnergy and BioChemicals Production from Biomass and Residual Resources. Energies 2018, 11, 2125. [Google Scholar] [CrossRef]

- PN-EN. CEN-EN 303-5. In Heating Boilers. Part 5: Heating Boilers for Solid Fuels, Manually and Automatically Stoked, Nominal Heat Output of Up to 500 kW—Terminology, Requirements, Testing and Marking; European Committee for Standardization: Brussels, Belgium, 2012.

- Nilsson, D.; Bernesson, S.; Hansson, P.A. Pellet production from agricultural raw materials—A systems study. Biomass Bioenergy 2011, 35, 679–689. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Thek, G.; Obernberger, I. Wood pellet production costs under Austrian and in comparison to Swedish framework conditions. Biomass Bioenergy 2004, 27, 671–693. [Google Scholar] [CrossRef]

- Sahoo, K.; Hawkins, G.L.; Yao, X.A.; Samples, K.; Mani, S. GIS-based biomass assessment and supply logistics system for a sustainable biorafinery: A case study with cotton stalks in the Southeastern US. Appl. Energy 2016, 182, 260–273. [Google Scholar] [CrossRef]

- Adapa, P.; Tabil, L.; Shoenau, G. Grinding performance and physical properties of non-treated and steam exploded barley, canola, oat and wheat straw. Biomass Bioenergy 2011, 35, 549–561. [Google Scholar] [CrossRef]

- Obidziński, S. Influence of selected structure parameters of pellet mill on the quality of the final product. Pol. J. Food Nutr. Sci. 2007, 57, 121–124. [Google Scholar]

- Tumuluru, J.S. Effect of process variables on the density and durability of the pellets made from high moisture corn stover. Biosyst. Eng. 2014, 119, 44–57. [Google Scholar] [CrossRef]

- Kraszkiewicz, A.; Kachel-Jakubowska, M.; Szpryngiel, M.; Niedziółka, I. Analiza wybranych cech jakościowych peletów wytworzonych z surowców roślinnych. Inżynieria Rolnicza 2013, 2, 167–173. [Google Scholar]

- Novaes, E.; Kirst, M.; Chiang, V.; Winter-Sederoff, H.; Sederoff, R. Lignin and biomass: A negative Correlations for wood formation and lignin content in trees. Plant Physiol. 2010, 154, 555–561. [Google Scholar] [CrossRef]

- Lehmann, B.; Schroder, H.W.; Wollenberg, R.; Repke, J.U. Effect of miscanthus addition and different grinding processes on the quality of wood pellets. Biomass Bioenergy 2012, 44, 150–159. [Google Scholar] [CrossRef]

- Rynkiewicz, M.; Dobek, T.K. Wybrane właściwości fizyczne i mechaniczne pelletów w zależności od składu i temperatury ich przechowywania. Inżynieria Rolnicza 2013, 3, 321–330. [Google Scholar]

- Niedziółka, I.; Szpryngiel, M. Ocena cech jakościowych peletów wytworzonych z biomasy roślinnej. Inżynieria Rolnicza 2012, 2, 267–276. [Google Scholar]

- Graham, S.; Eastwick, C.; Snape, C.; Quick, W. Mechanical degradation of biomass wood pellets during long term stockpile storage. Fuel Process. Technol. 2017, 160, 143–151. [Google Scholar] [CrossRef]

- Kulig, R. Wpływ procesu kondycjonowania wybranych surowców strączkowych na właściwości fizyczne granulatu. Inżynieria Rolnicza 2009, 1, 147–155. [Google Scholar]

- Sahoo, K.; Bilek, E.M.; Mani, S. Techno-economic and environmental assessments of storing woodchips and pellets for bioenergy applications. Renew. Sustain. Energy Rev. 2018, 98, 27–39. [Google Scholar] [CrossRef]

- Noll, M.; Jirjis, R. Microbial communities in large-scale wood piles and their effects on wood quality and the environment. Appl. Microbiol. Biotechnol. 2012, 95, 551–563. [Google Scholar] [CrossRef]

- Jirjis, R.; Theander, O. The effect of seasonal storage on the chemical composition of forest residue chips. Scand. J. For. Res. 1990, 5, 437–438. [Google Scholar] [CrossRef]

- Nielsen, N.P.K.; Gardner, D.L.; Poulsen, T.; Felby, C. Importance of temperature, moisture content, and species for the conversion process of wood residues into fuel pellets. Wood Fiber Sci. 2009, 41, 414–425. [Google Scholar]

- Arshadi, M.; Gref, R.; Geladi, P.; Dahlqvist, S.A.; Lestander, T.A. The influence of raw material characteristics on the industrial pelletizing process and pellet quality. Fuel Process. Technol. 2008, 89, 1442–1447. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef]

- Sultana, A.; Kumar, A. Development of energy and emission parameters for densiefied form of lignocellulosic biomass. Energy 2011, 36, 2716–2732. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding performance and physical properties of wheat and barley straws, corn stover and switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- Ahn, B.J.; Chang, H.; Lee, S.M.; Choi, D.H.; Cho, S.T.; Han, G.; Yang, I. Effect of binders on the durability of wood pellets fabricated from Larix kaemferi C. and Liriodendron tulipifera L. sawdust. Renew. Energy 2014, 62, 18–23. [Google Scholar] [CrossRef]

- Carroll, J.P.; Finnan, J. Physical and chemical properties of pellets from energy crops and cereal straws. Biosyst. Eng. 2012, 112, 151–159. [Google Scholar] [CrossRef]

- Adapa, P.; Tabil, L.; Shoenau, G.; Opoku, A. Pelleting characteristic of selected biomass with and without steam explosion pretreatment. Int. J. Agric. Biol. Eng. 2010, 3, 62–79. [Google Scholar]

- Kirsten, C.; Lenz, V.; Schroder, H.W.; Repke, J.U. Hay pellets—The influence of particle size reduction on their physical-mechanical quality and energy demand during production. Fuel Process. Technol. 2016, 148, 163–174. [Google Scholar] [CrossRef]

- Theerarattananoon, K.; Xu, F.; Wilson, J.; Ballard, R.; McKinney, L.; Staggenborg, S.; Vadlani, P.; Pei, Z.J.; Wang, D. Physical properties of pellets made from sorghum stalk, corn stover, wheat straw and big bluestem. Ind. Crops Prod. 2011, 33, 325–332. [Google Scholar] [CrossRef]

- Lee, S.; Ahn, B.J.; Choi, D.H.; Han, G.S.; Jeong, H.S.; Ahn, S.M.; Yang, I. Effect on densification variables on the durability of wood pellets fabricated with Larix kaempferi C. and Liriodendron tulipifera L. sawdust. Biomass Bioenergy 2013, 48, 1–9. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass palletization—A review. Bioresources 2012, 7, 4451–4490. [Google Scholar]

- Hansen, M.T.; Rosentoft-Jein, A.; Wach, E.; Bastian, M. Poradnik użytkowania pelet drzewnych; Bałtycka Agencja Poszanowania Energii S.A.: Gdańsk, Poland, 2009.

- PN-EN. ISO 18134-2:2017-03E. In Solid Biofuels. Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method; European Committee for Standardization: Brussels, Belgium, 2017.

- PN-EN. ISO 18125:2017-07. In Solid Biofuels-Determination of Calorific Value; European Committee for Standardization: Brussels, Belgium, 2017.

- Porowski, R. Analiza metod określania ciepła spalania i wartości opałowej paliw. Zeszyty Naukowe SGSP 2016, 59, 45–70. [Google Scholar]

- PN. ISO 1171:2010. In Solid Mineral Fuels. Determination of Ash; European Committee for Standardization: Brussels, Belgium, 2010.

- PN-EN. ISO 18123:2016-01. In Solid Fuels. Determination of Volatile Content by Gravimetric Method; European Committee for Standardization: Brussels, Belgium, 2016.

- PN-EN 1936:2010. In Metody badań kamienia naturalnego. Oznaczanie gęstości i gęstości objętościowej oraz całkowitej i otwartej porowatości; European Committee for Standardization: Brussels, Belgium, 2010.

- PN-EN 1237:2000. In Fertilizers—Determination of Bulk Density (Tapped); European Committee for Standardization: Brussels, Belgium, 2000.

- PN-EN. ISO 17831-1:2016-02. In Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 1: Pellets; European Committee for Standardization: Brussels, Belgium, 2016.

- Damirichi, H.; Najafi, G.; Alizadehnia, S.; Mamat, R.; Azwadi, N.; Sidik, C.; Azmi, W.H.; Noor, M.M. Micro Cimbined Heat and Power to provide heat and electrical power using biomass and Gamma-type Striling engine. Appl. Therm. Eng. 2016, 103, 1460–1469. [Google Scholar] [CrossRef]

- Bai, Z.; Liu, Q.; Lei, J.; Hong, H.; Jin, H. New-solar biomass power generation system integrated a two-stage gasifier. Appl. Energy 2017, 194, 310–319. [Google Scholar] [CrossRef]

- Gehring, M.; Wohler, M.; Pelz, S.; Steinbrink, J.; Thorwarth, H. Kaolin as additive in wood pellet combustion with several mixtures of spruce and short-rotation-coppice willow and it influence on emissions and ashes. Fuel 2019, 235, 610–616. [Google Scholar] [CrossRef]

- Lim, C.H.; Lam, H.L. Biomass supply chain optimisation via novel Biomass Element Life Cycle Analysis (BELCA). Appl. Energy 2016, 161, 733–745. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Pelleting of Pine and Switchgrass Blends: Effect of Process Variables and Blend Ratio on the Pellet Quality and Energy Consumption. Energies 2019, 12, 1198. [Google Scholar] [CrossRef]

- Ellis, N.; Masnadi, M.S.; Roberts, D.G.; Kochanek, M.A.; Ilyushechkin, A.Y. Mineral matter interactions during co-pyrolysis of coal and biomass and their impact in intrinsic char co-gasification reactivity. Chem. Eng. J. 2015, 279, 402–408. [Google Scholar] [CrossRef]

- Matali, S.; Rahman, N.A.; Idris, S.S.; Yaacob, N.; Alias, A.B. Lignocellulosic Biomass solid Fuel Properties Anhancement via Torrefaction. Procedia Eng. 2016, 148, 671–678. [Google Scholar] [CrossRef]

- Stasiak, M.; Molenda, M.; Bańda, M.; Wiącek, J.; Parafiuk, P.; Gondek, E. Mechanical and combustion properties of sawdust—Straw pellets blended in different proportions. Fuel Process. Technol. 2017, 156, 366–375. [Google Scholar] [CrossRef]

- Welker, C.M.; Balasubramanian, V.K.; Petti, C.; Rai, K.M.; DeBolt, S.; Mendu, V. Enginnering Plant Biomass Lignin Content and composition for Biofuels and Bioproducts. Energies 2015, 8, 7654–7676. [Google Scholar] [CrossRef]

- Šavija, B. Smart Crack Control in Concrete through Use of Phase Change Materials (PCMs): A Review. Materials 2018, 11, 654. [Google Scholar]

| Type of Pellet | Proximate Analysis | Ultimate Analysis | Additional Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| MC * | HHV * | LHV * | AC * | VM * | C | H | N | Relative Density | Bulk Density | Porosity | |

| % | kJ∙kg−1 | kJ∙kg−1 | % | % | % | kg∙m−3 | kg∙m−3 | % | |||

| Pine sawdust pellet | 3.01 5.07 ** | 19523 | 17887 | 0.66 | 77.84 | 47 | 6.7 | 0.11 | 1385.2 | 432.4 | 68.78 |

| Wheat straw pellet | 10.33 11.69 ** | 17574 | 15992 | 7.27 | 72.83 | 40 | 6.1 | 0.69 | 1429.3 | 358.3 | 74.93 |

| Digestate pellet | 16.45 16.99 ** | 19051 | 17224 | 7.10 | 67.28 | 40 | 6.5 | 1.5 | 1463.4 | 488.0 | 66.65 |

| Corn settlements pellet | 7.82 8.91 ** | 18797 | 17181 | 1.27 | 74.91 | 42 | 6.4 | 0.5 | 1431.3 | 651.5 | 54.49 |

| Agricultural residues pellet | 10.97 12.41 ** | 18129 | 16511 | 8.27 | 71.05 | 39 | 6.2 | 1.3 | 1461.8 | 467.5 | 68.02 |

| Post-hydrolytic wood pellet | 20.08 20.26 ** | 21532 | 19914 | 8.99 | 56.17 | 46 | 5.7 | 0.3 | 1665.5 | 822.1 | 50.64 |

| Sunflower husk pellet | 13.77 13.80 ** | 19946 | 18246 | 2.99 | 71.83 | 44 | 6.4 | 0.8 | 1409.4 | 533.4 | 62.15 |

| Fine coal (45%) and straw (55%) pellet | 8.89 9.18 ** | 23269 | 21880 | 9.43 | 44.15 | 54 | 5.3 | 2.1 | 1653.1 | 737.9 | 55.36 |

| Mechanical Durability and Its Variations * | |||

|---|---|---|---|

| Type of pellet | Variant 1 (normal pellets) | Variant 2 (frozen pellets) | Variant 3 (defrosted pellets) |

| % | Δ% | Δ% | |

| Digestate | 99.0 | −0.2 | −0.6 |

| Pine sawdust | 98.7 | −0.1 | 0.0 |

| Wheat straw | 98.4 | +0.1 | −0.2 |

| Post-hydrolytic wood | 98.3 | +0.3 | −0.3 |

| Agricultural residues | 96.5 | −0.1 | −0.3 |

| Fine coal (45%) and straw (55%) | 96.2 | −1.5 | −1.7 |

| Corn settlements | 96.0 | 0.0 | 0.0 |

| Sunflower husk | 87.4 | +0.8 | −1.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dyjakon, A.; Noszczyk, T. The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass. Energies 2019, 12, 2627. https://doi.org/10.3390/en12132627

Dyjakon A, Noszczyk T. The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass. Energies. 2019; 12(13):2627. https://doi.org/10.3390/en12132627

Chicago/Turabian StyleDyjakon, Arkadiusz, and Tomasz Noszczyk. 2019. "The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass" Energies 12, no. 13: 2627. https://doi.org/10.3390/en12132627

APA StyleDyjakon, A., & Noszczyk, T. (2019). The Influence of Freezing Temperature Storage on the Mechanical Durability of Commercial Pellets from Biomass. Energies, 12(13), 2627. https://doi.org/10.3390/en12132627