1. Introduction

At present, most common mobile robots are wheeled or tracked, which are more suitable for flat surface. However, these robots still have some difficulties and limitations to pass through tough terrain. Compared with wheeled or tracked robots, legged robots can perform better in tough terrain. After years of development, there has been huge improvements in stability and mobility of the legged robot. However, in the view of energy, the performances of the legged robots are far less than wheeled or tracked robots. Many researchers have turned their attentions to the energy efficiency and energy consumption of legged robots.

Boston Dynamics developed the first generation of the Bigdog robot in 2004 and made a great improvement in the 2008 version [

1]. Bigdog has about 50 sensors, including inertial, joint and power system sensors. Joint sensors were integrated on the hydraulic cylinders to measure motions and forces of the actuators. The virtual model was used to control the joint torques of the robot. Semini et al. from IIT (Italian Institute of Technology) built their hydraulic actuated quadruped robot HyQ in 2010 [

2]. HyQ used

as its joint actuator. Different from the Bigdog, the joint sensors of the HyQ were not integrated. It used the relative encoder

and absolute encoder

to measure the joint positions. The force acting on the cylinder rod was measured by

force sensor, the force range is 0–5 kN and its accuracy is ±0.5% of the full scale. With this prototype, Boaventura [

3] started to study active compliance and realize the force control of the HyQ.

Quadruped robots are widely used in the fields in transporting on rough terrains. The Bigdog and LS3 [

4] were used to carry loads in jungle and hill environments. Keisuke et al. [

5] designed a quadruped walking robot TITAN-IX, which was used in mine detection and removal. Other quadruped robots were designed with visual system or even an robot arm like HyQ2Max [

6], Spot [

7] and SpotMini [

8]. These robots could identify the environment and realize the functions like climbing stairs or opening doors, which could be used in reconnaissance and rescue missions.

When modelling the quadruped robots, nonlinearity must be taken into consideration. Konstantinos et al. [

9] designed an active compliance controller for quadruped robots. Stribeck velocity was added to the modelling of the ground force. For hydraulic actuated quadruped robots, nonlinearity often exists in the modelling of the hydraulic friction. Focchi et al. [

10] used a Stribeck friction model to obtain the hydraulic frictions for a hydraulically actuated robot leg.

Compared to other kinds of robots or human beings, the energy analyses of legged robots are different. Researchers started to pay attention to the energy problems on legged robots. Gregorio et al. [

11] built an one-legged robot named ARL Monopod; comparisons showed that the Monopod with its 125 W average power was more energy efficient than previously built robots. Li et al. [

12] studied the legged robots’ dynamics and optimal control during the flight phase and constructed an optimal path. Wang et al. [

13] used an energy-efficient support vector machine to study the energy consumption of the biped walking robots. Bhounsule et al. [

14] proposed the concept of the leg ratio and studied the cost of transport with different leg ratio and gait parameters. Roy et al. [

15] established the energy model of an electrical six-legged robot and studied the energy consumption during crab walking. Bodrov et al. [

16] extended the loss analysis to the actuator motors and proposed a novel strategy to control a hexpod robot. However, the dynamics and energy models of the quadruped robots are different from other kinds of legged robots, which makes them unsuitable for quadruped applications.

Quadruped robots are more stable than monopod or biped robots, and have simple structure compared with the hexpod or robots with more than six legs [

17]. Silva et al. [

18] studied the best set of gait and locomotion variables during walking of the quadruped locomotion systems. Ikeda et al. [

19] analysed the energy flow of a quadruped robot with a flexible trunk joint. Seok et al. [

20,

21] built an electric actuated quadruped robot Cheetah and established the energy flow of it. Based on the energy flow, several design principles were proposed and implementations of the principles were done to reduce the energy consumption of the robot. The COT (Cost of Transport) of the Cheetah robot is eliminated to 0.51, which is on the same level as other biological runners of similar mass. Kim et al. [

22] built a hydraulic actuated quadruped robot with redundancy. In order to decrease the hydraulic flow consumption, a foot rotation angle generation algorithm was proposed, and the energy consumption of the robot was reduced at the same time. Mastalli et al. [

23] and Neunert et al. [

24] studied the trajectory optimization problem for rough terrain locomotion and contacts conditions. Du et al. [

25] formulated two indexes to quantitatively describe the performances of quadruped robots and studied a gait pattern based on the Bezier curve. Wang et al. [

26] established the energy model of a quadruped robot and studied the energy consumptions under different gait parameters. The friction rate was not considered and the foot force was simply regarded as half of the total weight. Sanz-Merodio [

27] studied the energy efficiency of the hexapod robot SILO6 under different leg configurations. Montes [

28] studied the energy consumption and energy efficiency of a hexapod robot. The SCARA configuration legs were used, which could bear high payloads with low energy expenditure, and the slope of the power consumption was low to 0.1606 W/kg. However, the above-mentioned works only studied the energy consumption of electric robots or lacked of a complete energy model for hydraulic actuated robots. To optimize the motion of the robot from the energy perspective, a compact energy model needed to be established to study the energy consumptions of hydraulic actuated quadruped robots.

This work focuses on the motions of the quadruped robot in sagittal plane. The main purpose of this work is to design a energy efficient foot trajectory for the hydraulic driven quadruped robot SCalf. Firstly, the kinematics and dynamics models of the robot leg are built. Then, the foot forces are obtained by using the minimization of norm of foot force method. The energy model of the robot is established by combining the mechanical power and heat rate. Then, an energy efficient foot trajectory based on Fourier series is proposed, and the coefficients of the foot trajectory are obtained through the Pattern Search method. The energy consumption of the proposed trajectory is compared with a reference foot trajectory which is based on the cubic spline interpolation. Computer simulations and physical experiments will be conducted to verify the proposed energy efficient trajectory.

2. Robot Modeling

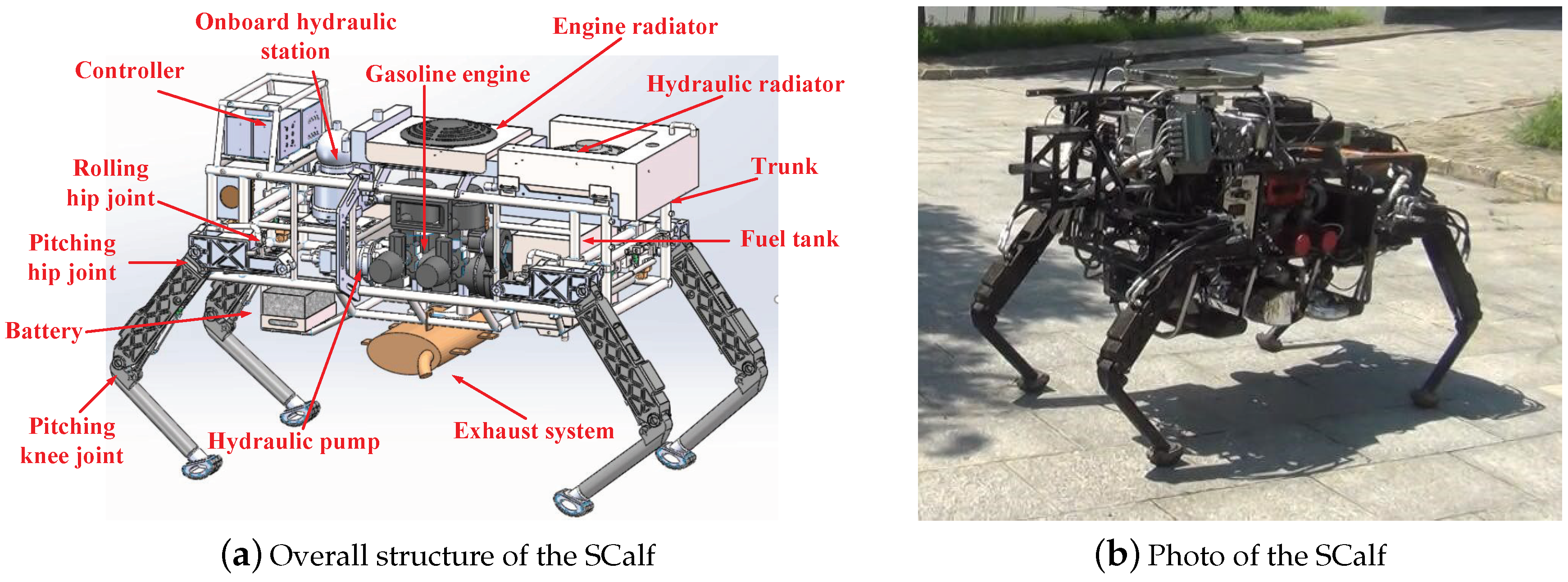

The SCalf robot was built by the Center for Robotics of Shandong University in 2017, and some improvements were made in 2018. The SCalf is a hydraulic driven quadruped robot, which consists of a trunk and four legs as shown in

Figure 1. The robot is powered by hydraulic system driven by a gasoline engine. A variable displacement piston pump is connected to the gasoline engine to provide hydraulic flow for the whole robot system. The legs configuration of the robot use backward/forward configuration to improve the gradeability and load capacity [

29]. The control system, hydraulic system and battery are placed inside the trunk. Each leg of the robot has three degree of freedoms (DOFs), which are defined as pitching knee joint, pitching hip joint and rolling hip joint. The joints of the robot are all actuated by hydraulic cylinders. With the 3DOF structure, the endpoint of the foot can move in a three-dimensional workspace with the hip joint as its origin, and the robot can realize omnidirectional movement in space. To make the robot easy to control, the trunk of the SCalf is built using a symmetric structure. The SCalf is used to transport loads on rough terrains and has a load capacity of 200 kg. The robot can be controlled by a remoter or follow with a navigator by using the visual system.

The hydraulic cylinder and sensors used on the SCalf are shown in

Figure 2. The stroke of the hydraulic cylinder is 98 mm. The selection of the position sensor depends on the piston stroke of the actuator. The

series position sensor of

is chosen, the span and accuracy of the position sensor are 100 mm and 0.1 mm, respectively. The force sensor is the

series from

. The output voltage of the force sensor is −5 mV to 5 mV, and the range of the force sensor is 0 to 14,000 N.

2.1. General Method

With the development of legged robots, the studies of energy consumption are getting further. Most motions of the legged robots are realized by the motions of leg joints with specific trajectories. This work explains the method to design an energy efficient foot trajectory for legged robots. In order to find the energy efficient trajectory, the following research routine can be used in

Figure 3.

The main contents of the study can be divided into following parts.

1. Robotic modelling. The first thing is to establish the model of the robot including the kinematic and dynamics model. Kinematic model is used to obtain the relationship between the foot endpoints and joint positions, while dynamics model can acquire the joint torques . When the robot is in the stance phase, joint torques will be increased and the foot force algorithm is used to calculate the joint torques.

2. Establishment of the energy model. In order to obtain the energy consumption of the robot, the energy model has to be established. From the introduction section, many researchers only considered the mechanical power in their work. However, in a real robot system, heat rate can be really big and can’t be neglected. The frictional characteristic and modelling of different actuators varies greatly and need to be analyzed according to the actuator type.

3.

Design of the energy efficient trajectory. To minimize the energy consumption, the energy efficient trajectory will be designed and the parameters of the trajectory need to be optimized. Here, the energy consumption is used as the objective function as shown in Equation (

1). The energy consumption

E is written as the integral of the joint power and represented by the joint position

, where

P and

H are the mechanical power and heat rate of the joint respectively. The constraints of the objective function are defined by the mechanical limitations of the joint positions. With the objective function, optimization algorithms can be used to decide the parameters of the energy efficient trajectory:

In order to study the energy consumption of legged robots, the SCalf robot is used as an example in this work. To simplify the calculation of the energy consumption, the following preconditions are made:

(a) The robot moves forward in a straight path on flat surface. The robot uses trot gait to move with the duty cycle as 50%. As the robot doesn’t have lateral movement, only the pitching knee and pitching hip joints are taken into consideration. When looking from front of the robot, the legs are perpendicular to the ground, as the joint positions of the rolling hip joints are set as zero.

(b) When walking on a flat surface, the variation of the trunk height is small, and the height of robot trunk can be regarded as constant. Therefore, the acceleration along the z-axis is considered as zero.

(c) The center of mass (COM) of the trunk body is assumed to be at the geometric center of the body.

(d) The right-front (RF) leg and left-hind (LH) leg are in the stance phase.

2.2. Kinematics of the SCalf Robot

The four legs of the robot have the same mechanical parameters and structure. Here, the RF leg of the robot is used to establish corresponding models, the model of the RF leg is shown in

Figure 4. According to the precondition (a), the robot only moves in the sagittal plane, the kinematics are discussed in planar view in in

Figure 4b.

In

Figure 4, the RF leg can be divided into the hip, thigh and shank parts. The origin of the coordinate frame {

} is fixed at the rolling hip joint.

x-direction is pointing horizontally to the front of the robot.

z-direction is vertical to the ground and points upwards.

y-direction is confirmed by the right-hand rule.

and

are the mechanical parameters of the hip joint, where

= 45 mm and

= 57 mm.

and

are the length and mass of the thigh part, and

and

are the length and mass of the shank part.

and

are the joint positions of the pitching hip and pitching knee joints.

and

are the joint torques of the two joints. The COMs of the thigh and shank part are defined by

,

,

and

. When these parts rotate around their own joint shafts, the moments of inertia are

and

respectively. The values of the above structure parameters are shown in

Table 1.

The location of the foot endpoint in {

} can be expressed as follows. The legs are perpendicular to the ground (precondition a), the foot endpoint position in

y axis equals

:

By solving Equation (

2), the joint positions can be obtained as

where

For the LH leg, the joint positions are obtained as the following equation:

The Jacobian matrix of the single leg model can also be calculated by Equation (

2):

According to the foot trajectory and Equation (

3), the joint positions can be obtained. The angular velocities

and angular accelerations

of the joints can be calculated through the differential of the joint positions

and angular velocities

respectively, where

.

2.3. Dynamics of the SCalf Robot

The dynamics equation of the robot is used to calculate the joint torque vector

. Here, the Lagrangian method is used to acquire the dynamics model of the single leg. The Lagrangian method can establish the dynamic model in the view of energy. It can avoid complex calculations of the interaction forces between the joints, and can describe the relationship between the external forces and motions in a generalized coordinate [

30].

The dynamic model of the single leg with

n-DOF can be written as follows:

where

In the above equations,

L is the Lagrangian function,

is the joint position vector,

is the joint angular velocity vector, and

is the generalized force vector in the generalized coordinate [

31].

and

are the kinetic and potential energy of the single leg system, respectively.

The generalized force vector is defined in Equation (

9), where

is the ground reaction force vector,

is the transposed matrix of the single leg Jacobian matrix, and

is the joint torque vector

During the swing phase, there are no contacts between foot and ground, therefore the ground reaction force equals 0. During the stance phase, the ground reaction force vector becomes undetermined. A foot force distribution method will be introduced in the next section.

According to Equations (

7)–(

9), the dynamic equation can be written as Equation (

10):

In Equation (

10),

is the Coriolis and centrifugal forces matrix,

is the inertia matrix, and

is the gravitational loading vector.

For the movement in the sagittal plane, only 2 DOFs need to be considered, hence

n = 2. According to the parameters in

Figure 4, the kinetic energy

and potential energy

can be calculated. In the following equations,

,

, and

.

The kinetic energy of the single leg system, thigh and shank parts are shown as follows:

where

and

are the COM velocities of each parts, which are calculated as follows:

The potential energy of the single leg system, thigh and shank parts can be obtained by the following equations:

In Equation (

10),

is a 2 × 2 matrix and written as follows:

where

The matrix

is shown in Equation (

23):

where

The gravitational loading vector

is shown in the following equation.

g is the gravity acceleration:

3. The Foot Force Distribution

When analysing the foot force distribution, the slippages between the foot endpoint and ground are neglected [

32]. In addition, compared with the trunk mass, the masses of the swing legs are very small. Therefore, the inertia of the swing legs can be negligible. For the motions in the sagittal plane, the ground force of each leg can be simplified into a two component force, one normal and one tangential to the surface (along the

x-axis and

z-axis). The static force diagram of the robot in the sagittal plane is shown in

Figure 5.

For the foot force distribution problem, the method with the minimization of norm of foot force is used. For a heavy robot like the SCalf, the contact forces between feet and ground can cause many negative effects, which may damage the mechanical structure and make the robot hard to control [

33]. The minimization of norm of foot force method can minimum the norm solution of the foot force and reduce the compact between ground and robot [

34].

A coordinate frame

is established at the geometric center of the body, the coordinates of the support foot endpoints in

are

and

, respectively (the positions in the

y-axis are 0). In

Figure 5, the ground reaction force

, where

and

are the ground reaction forces of the RF and LH legs, respectively, and the subscripts

x and

z represent for the normal and tangential component of the ground reaction force. The vector

contains the forces and moment acting on the robot’s COM in the sagittal plane. In addition, the inertial effects of the legs are neglected. Under these conditions, the forces and moment balance equations can be written as follows:

Equations (

29)–(

31) can be written in a matrix form as follows:

where

is shown here:

The values of , and are given for the straight motion on the flat surface, , and , where M is the trunk mass, and g is the gravitational acceleration. a is the acceleration of the trunk and can be obtained by the foot trajectory during the stance phase.

In the Equation (

32), there are four unknowns but only three equations, which is indeterminate. Here, we use the least squared method. It uses the closest solution under Euclidean distance as the approximate solution. The result can be written in matrix form as follows:

In Equation (

34), the matrix

is the pseudoinverse matrix of

. As the third component of

(

) is zero, the parameters in the last column of

can be neglected. The value of

is shown as follows:

where

The joint torques

produced by the feet forces can be written as follows:

where

In Equation (

46),

and

are the Jacobian of the front and hind legs, respectively.

4. The Energy Model of the SCalf

In this work, the joint energy consumptions are obtained by the integral of the joint powers. For different foot trajectories, the gait parameters including the step height, step length and gait cycle are set as the same. Therefore, the robot can move the same distance in one gait cycle with different foot trajectories. In Equation (

47), the energy consumption of a cycle is calculated, where

P is the joint power,

T is the gait cycle, and

E is the joint energy consumption of a cycle:

The mechanical power and heat rate are both included in the calculation of the joint power:

In Equation (

48), the two terms on the right of the equal mark are the mechanical power and heat rate caused by the cylinder frictions, where both the shortening/lengthening processes are included.

is the joint angular velocity,

is the joint torque provided,

and

are the velocity and friction of the cylinder respectively, where

is the differential of the corresponding cylinder length.

The frictions of hydraulic cylinders are highly nonlinear. In the most general case, the nonlinear friction force on the piston depends not only on the actuator velocity

but also on the pressure difference

across the piston, and possibly on the piston position

and temperature

t [

35]:

A more practical model of the friction was proposed by Stribeck [

36]. The model divides friction forces into static friction, Coulomb friction and viscous friction. The viscous friction is proportional to the velocity and contributes to stability and damping in hydraulic systems. The Coulomb friction is a constant force only depends on the sign of the piston velocity. The static friction acts mainly at zero velocity. It decays exponentially to zero as soon as the piston starts to move [

3]. An empirical friction function is shown here:

where

is the static friction coefficient (N),

B is the viscous friction coefficient (Ns/m),

is the static decay friction coefficient (m/s), and

is the Coulomb friction coefficient (N).

For the asymmetry cylinder used on the SCalf robot, the frictions during extension and shortening are different. To calculate the friction properly, Equation (

50) should be extended to the following equation [

37]:

Using the measured result made by Polzer et al. [

38], the parameters in Equation (

51) can be obtained as follows. When

0,

B = 220 Ns/m,

= 50 N,

= 30 N and

= 0.015 m/s. When

0,

B = 180 Ns/m,

= 50 N,

= 20 N and

= 0.007 m/s.

According to the joint positions and the mechanical structure of the single leg, the lengths of hydraulic cylinders and joint positions are mapped as follows, where

and

are the cylinder lengths,

and

are the joint positions. The structure parameters in the following equation are illustrated in

Figure 6 and listed in

Table 2:

The cylinder velocities can be obtained by the differential of the cylinder lengths:

6. Simulations and Experiments

In this section, some simulations and experiments are conducted to verify the joint energy consumptions of the proposed foot trajectory.

According to the theoretical analyses in this work, the PS method is used in MATLAB (R2016a, Mathwork Co., Natick, MA, USA) to obtain trajectory parameters of different legs. The proposed trajectory is verified in simulation and experiments. The results of the energy efficient trajectory are compared with the reference trajectory. The flow chart of this work is illustrated in

Figure 7.

6.1. MATLAB Simulation

In this section, the foot trajectory parameters need to be obtained through the PS method. Here, we set the gait cycle T as 0.5 s. The terrain clearance in the middle of the swing phase () H is set as 0.08 m. To verify the proposed trajectory, the step length S is set as 0.25 m. Therefore, the speed of the robot can be obtained as 1.0 m/s. The duty cycles of the RF and LH foot trajectories are both 50%. The time duration of the stance phase and swing phase are both 0.25 s. The trunk of the robot can be regarded as a cuboid. The distances between the COM of the robot and rolling hip joint in x- and z-directions are 0.68 m and 0.15 m, respectively, which are used to confirm the position of the foot endpoints in the trunk coordinate frame .

The parameters of the PS method are chosen as follows, acceleration coefficient , shrinkage coefficient . The initial point and initial step are defined as (0,0) and (0.5,0.5) respectively. In order to improve the speed of the algorithm, the precision is chosen as 0.1.

The optimization processes of RF leg by using the PS method are shown in

Figure 8. The variations of constants

,

and the values of the objective function

during swing phases (different trajectories have same energy consumptions in stance phase) are illustrated. The optimal parameters of the RF leg are

= −33.76,

= 15.30, and the iteration number is 108.

The trajectory parameters of the LH leg can also be calculated and shown in

Table 5.

According to

Table 5 and results in

Appendix A, the foot trajectory equations of the joints during the swing phase can be obtained in Equations (

63)–(

66).

The pitching hip joint of the RF leg,

The pitching knee joint of the RF leg,

The pitching hip joint of the LH leg,

The pitching knee joint of the LH leg,

For the MATLAB simulation, the joint torques can be acquired according to the analyses of the foot force distribution. In this section, only the curves of the RF leg are illustrated. However, the energy consumption of the RF and LH legs are both obtained. The sample frequency of the MATLAB is 200 Hz. The joint positions and torques are illustrated in

Figure 9 and

Figure 10. The curves of the leg powers and foot trajectories can be obtained in

Figure 11 and

Figure 12.

The mean energy consumptions of 10 cycles in MATLAB are shown in

Table 6. For the RF leg, the energy consumption during swing phase and whole cycle are decrease by 26.26% and 8.56%. For the LH leg, the decrements are 22.98% and 7.46% respectively. The other two legs have same structure and mechanical parameters as the RF and LH legs, hence the energy consumptions are same. The total consumption is decreased by 8.02% and the average total leg power in one cycle is reduced from 671.52 W to 617.68 W.

6.2. Experiments on the SCalf Robot

The SCalf robot adopts the centralized control system, and all of the motion plannings and servo controls are completed by the cRIO-9039 controller from the National Instruments corporation (Austin, TX, USA). The controller can record the sensor data with a frequency of 80 Hz. The displacement and force sensors mounted on the cylinders can be used to measure the cylinder lengths and joint forces, respectively. In order to obtained the data of the joint positions and torques, transitions need to be made. Here, we still use the RF leg as an example.

For joint calculations, the parameters in Equations (

67) and (

68) are illustrated in

Figure 6. The joint positions can be acquired by the cylinder lengths:

The torques are equal to the forces multiplied by their force arms, where

i = 1, 2:

The foot force distribution algorithm is verified in the prototype experiment. The curve of real foot force is compared with the simulation as in

Figure 13. During the stance phase, the foot force is increased dramatically and fluctuates around half of the trunk weight (980N).

The reference and proposed trajectories are tested on the SCalf. With the data of sensors, the joint positions and torques can be calculated by the above two equations and are shown in

Figure 14 and

Figure 15. The curve of the leg powers and foot trajectories can also be acquired in

Figure 16 and

Figure 17. The mean energy consumptions of five gait cycles in experiments are shown in

Table 7.

Based on

Table 7, the energy consumptions of the RF leg during the swing phase and whole cycle have dropped by 8.82% and 7.82%. For the LH leg, the decrements become 12.80% and 7.27%, respectively. The decrement of the total energy is 7.55%. The average total power in one cycle is decreased from 559.96 W to 517.68 W.

The energy efficient trajectory curve is plotted in

Figure 18.

Figure 18a shows the discrete snapshots of the foot, and, when putting these snapshots together, the full trajectory is obtained in

Figure 18b.

6.3. Discussion

In the precondition (b) of Section II, the height of the robot trunk is regarded as constant and the acceleration along the

z-axis is considered as zero. Actual changes of the trunk height above the ground is hard to measure by existed sensors. Therefore, the data in Webots are used. Webots is a robot simulator that provides a complete development environment to model, program and simulate robots [

41]. A GPS is mounted on the robot trunk to record the trunk height in Webots. In

Figure 19, the height and acceleration of the trunk COM along the

z-axis are illustrated. Based on the results, the biggest fluctuation of the height and acceleration are 0.004 m and

m/s

, respectively, and the precondition (b) is proved to be valid.

Figure 20 shows the comparison of the joint positions of MATLAB (given values) and physical experiment by using the energy efficient trajectory. In order to see the variations clearly, the joint position curves are plotted separately. It is shown that the physical prototype can track the given trajectory effectively. In addition, the joint positions in MATLAB and experiments are within the ranges in

Table 4.

By comparing

Figure 10 and

Figure 15, we can find that the change trends of different torque data are similar. During the stance phase, the legs need to support the weight of the trunk. Therefore, the joint torques in stance phase are much higher than in the swing phase, especially for the pitching knee joints.

The energy consumption results of different foot trajectories in simulations and experiments are illustrated in

Table 6 and

Table 7. By using the energy efficient foot trajectory, the total joint energy consumptions in simulations and experiments are dropped by 8.02% and 7.55%. The advantages of the proposed trajectory are mainly reflected in the swing phase. During the swing phase, the decrements become to 28.02% and 10.81%. The data in

Table 6 and

Table 7 are close, which means the models proposed in this work can be proved by the experiment results. However, there are still some differences between the results of the simulation and experiment, especially for the data during the stance phase, which are caused by different foot force distributions.

7. Conclusions

In this work, an energy efficient foot trajectory based on the Fourier series for a hydraulic actuated quadruped robot was proposed. First, the kinematics model, dynamics model and foot force distribution of the robot were analysed. Then, a detailed joint energy model of the hydraulic actuated quadruped robot including mechanical power and heat rate was derived. According to the energy model, a energy efficient trajectory is obtained based on the Fourier series, and the coefficients of the proposed trajectory are obtained by using the Pattern Search method. The energy consumptions of the proposed trajectory were compared with a reference trajectory which is based on the cubic spline interpolation.

An obvious decline of the energy consumption can be seen with the energy efficient trajectory. The total joint energy consumptions in simulation and experiment are dropped by 8.02% and 7.55%. The average power of the physical prototype is decreased from 559.96 W to 517.68 W. In addition, the terrain clearance in the middle of the swing phase makes the proposed trajectory have a certain obstacle crossing ability. Through the results of computer simulation and physical experiment, the effectiveness of the energy efficient trajectory for the hydraulic actuated quadruped robots can be proved.