CFD Computation of the H-Darrieus Wind Turbine—The Impact of the Rotating Shaft on the Rotor Performance

Abstract

1. Introduction

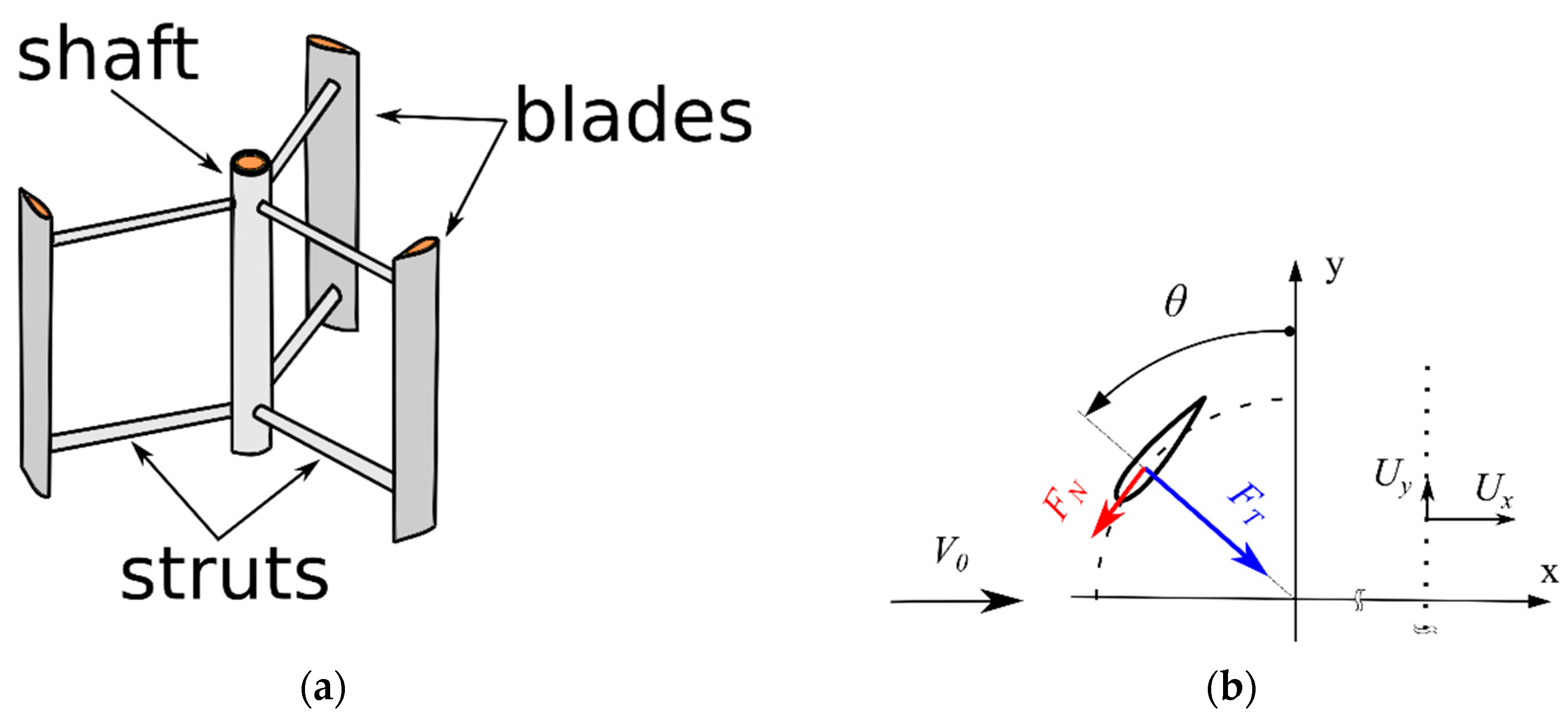

2. Characteristics of the VAWT

2.1. Vertical Axis Wind Turbine Concept and Aerodynamic Characteristics

2.2. Method

3. Wind Turbine and Computational Model

3.1. Experimental Test Case

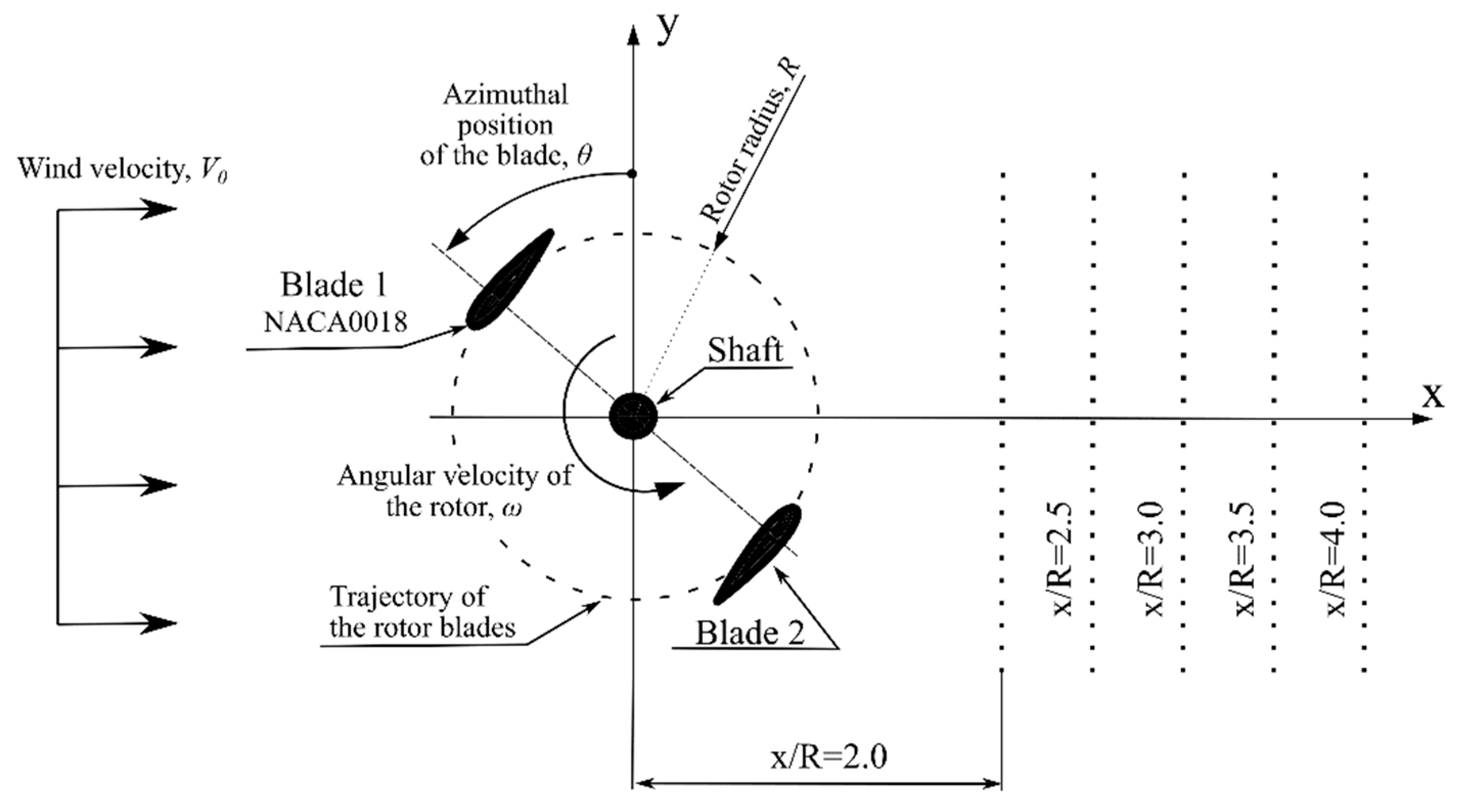

3.2. Wind Turbine Overview

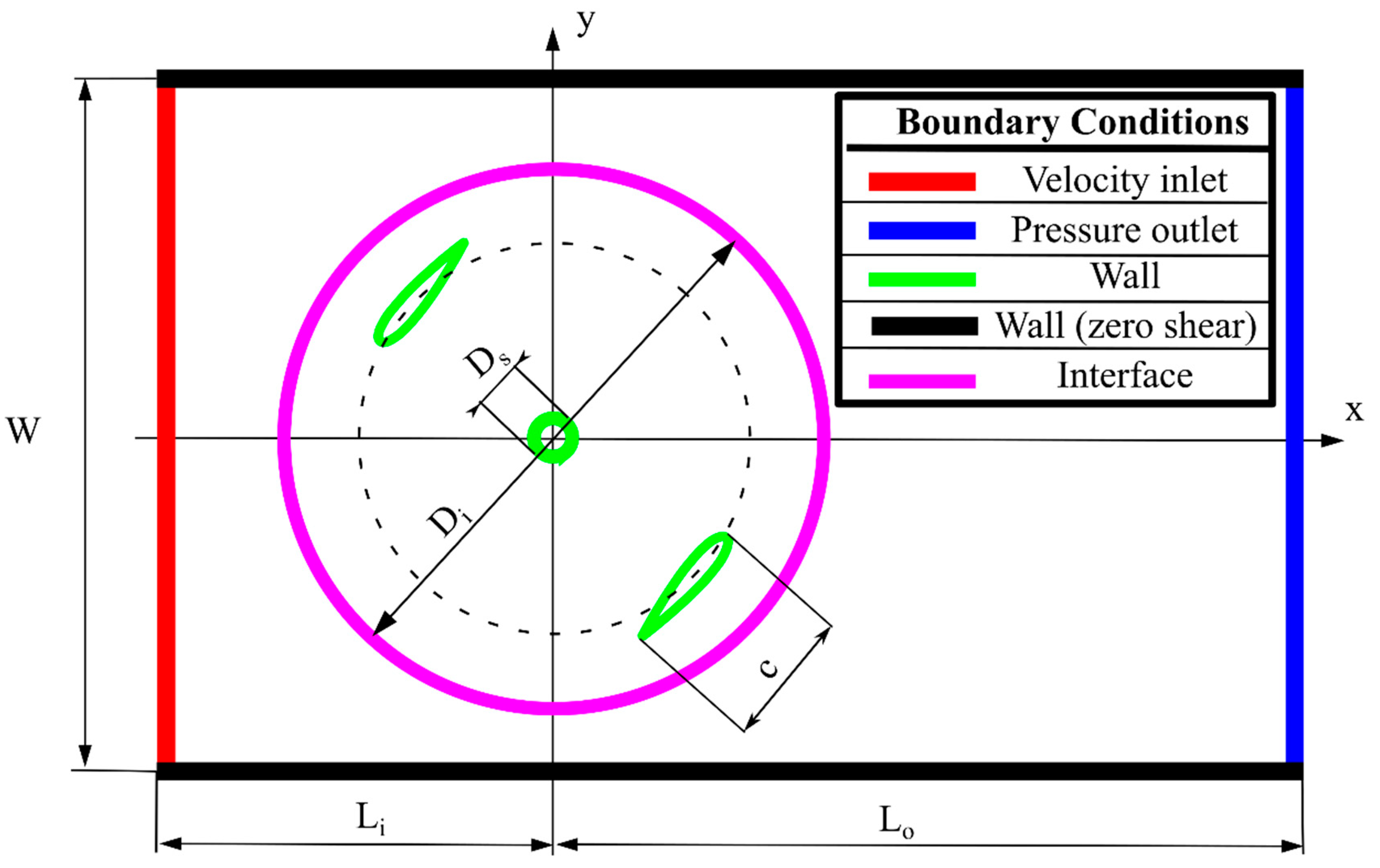

3.3. Computational Domain and Boundary Conditions

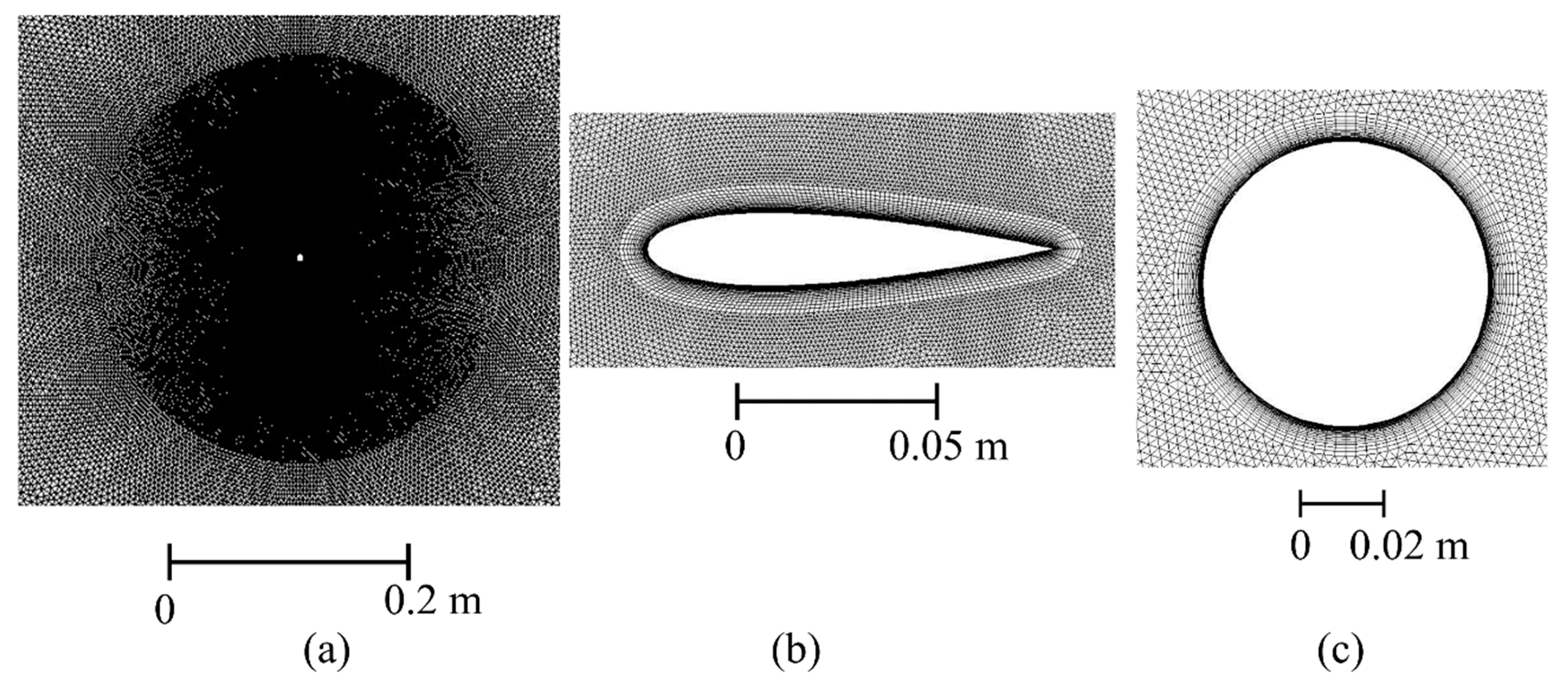

3.4. Mesh

4. Results

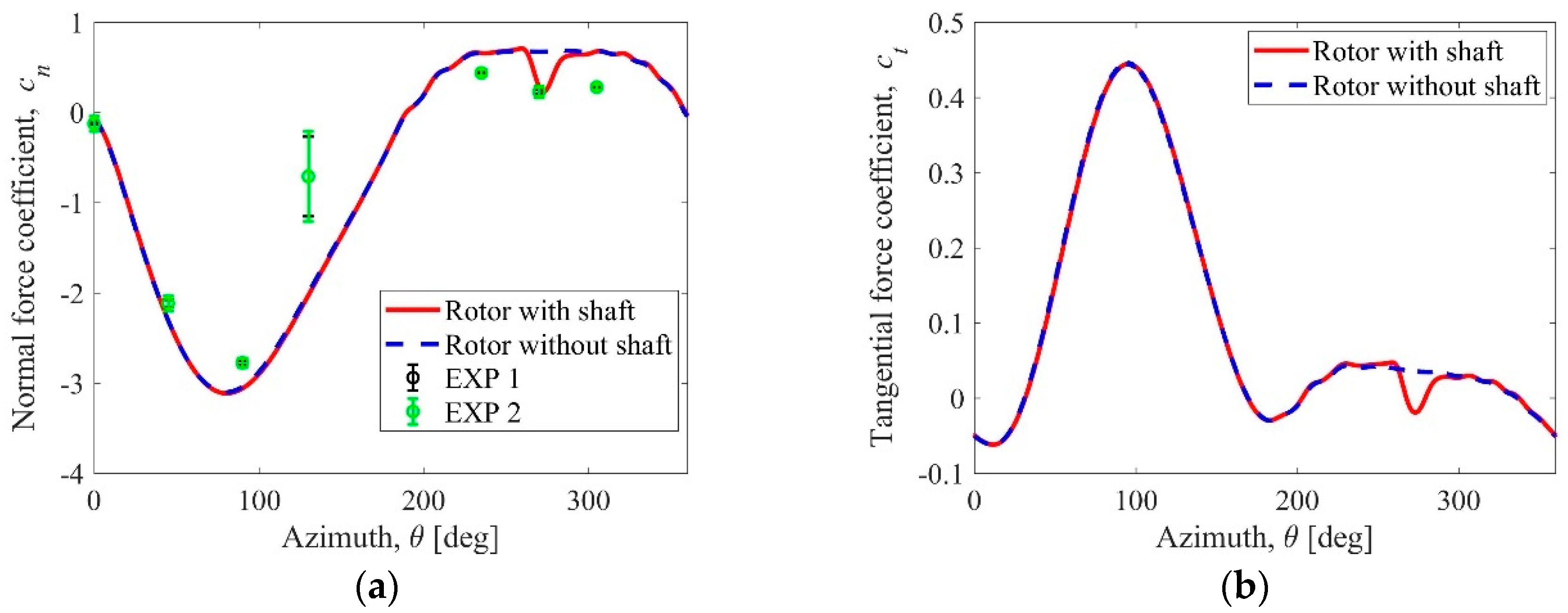

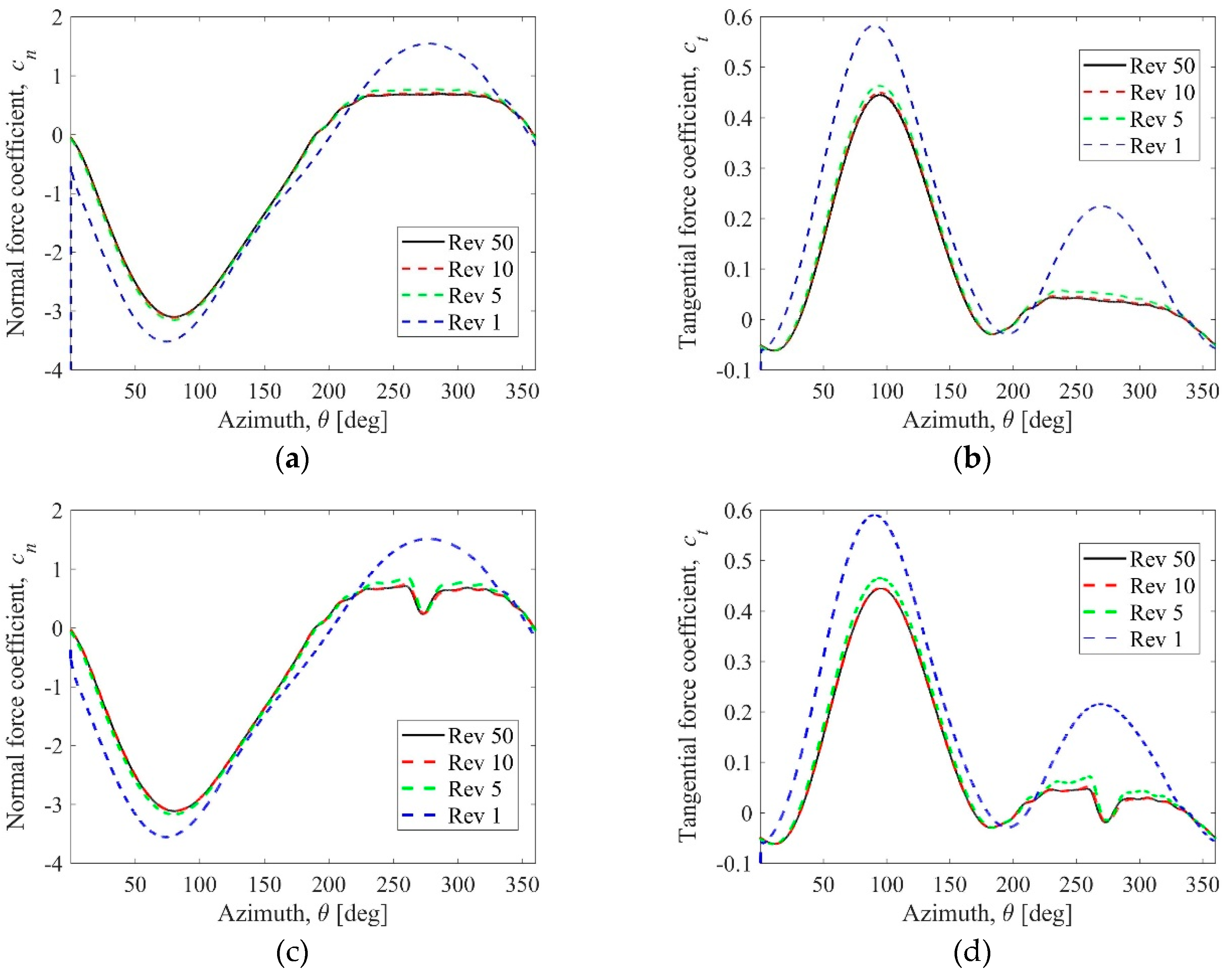

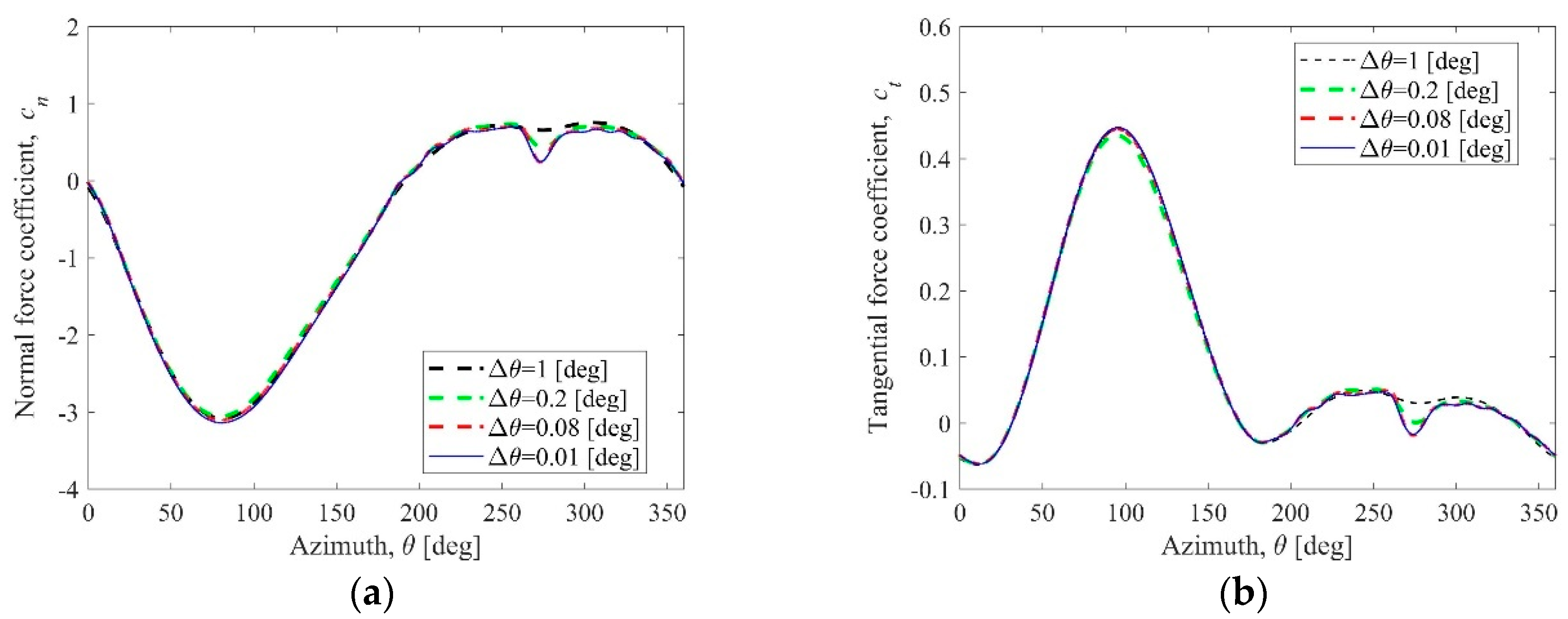

4.1. Aerodynamic Blade Loads

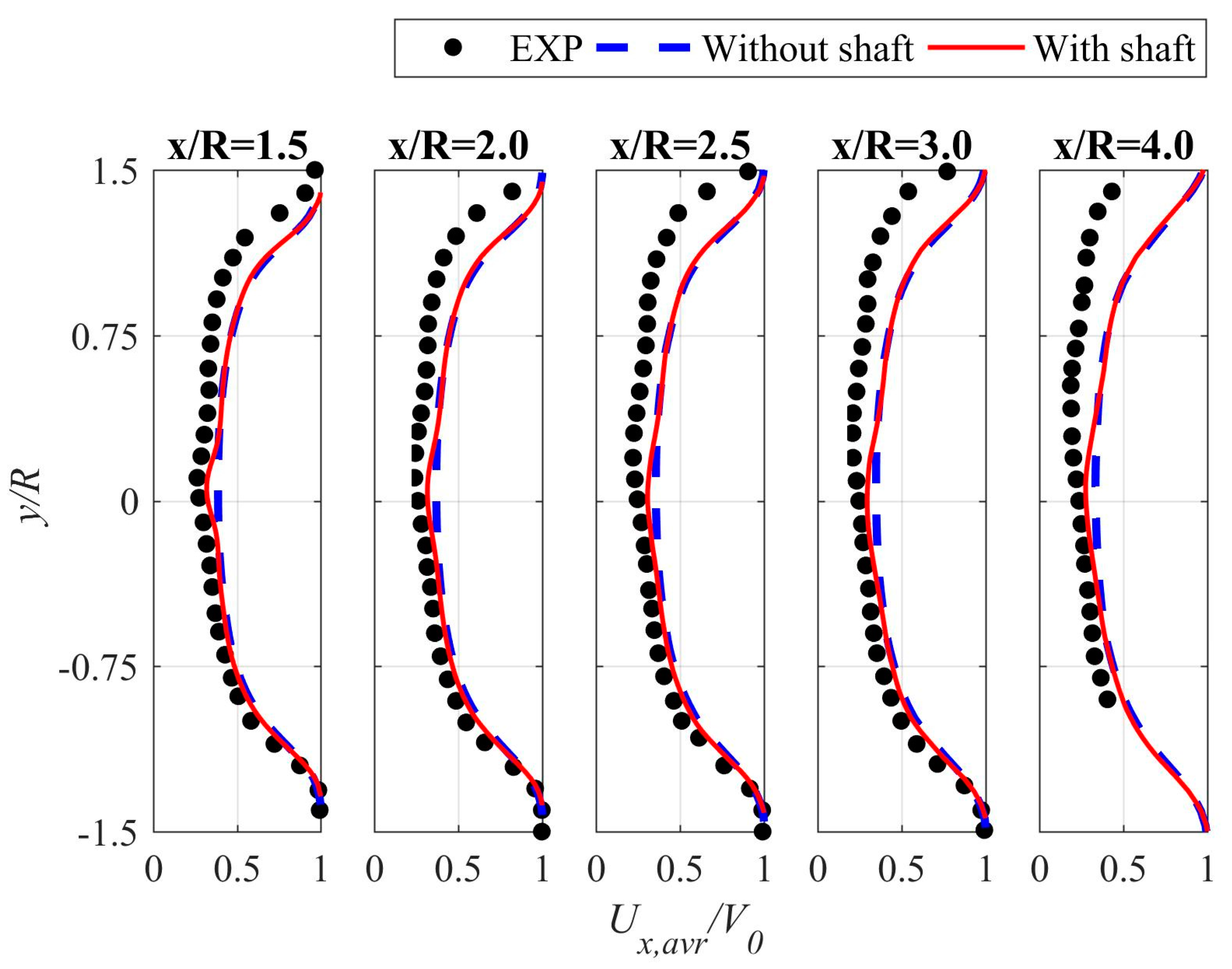

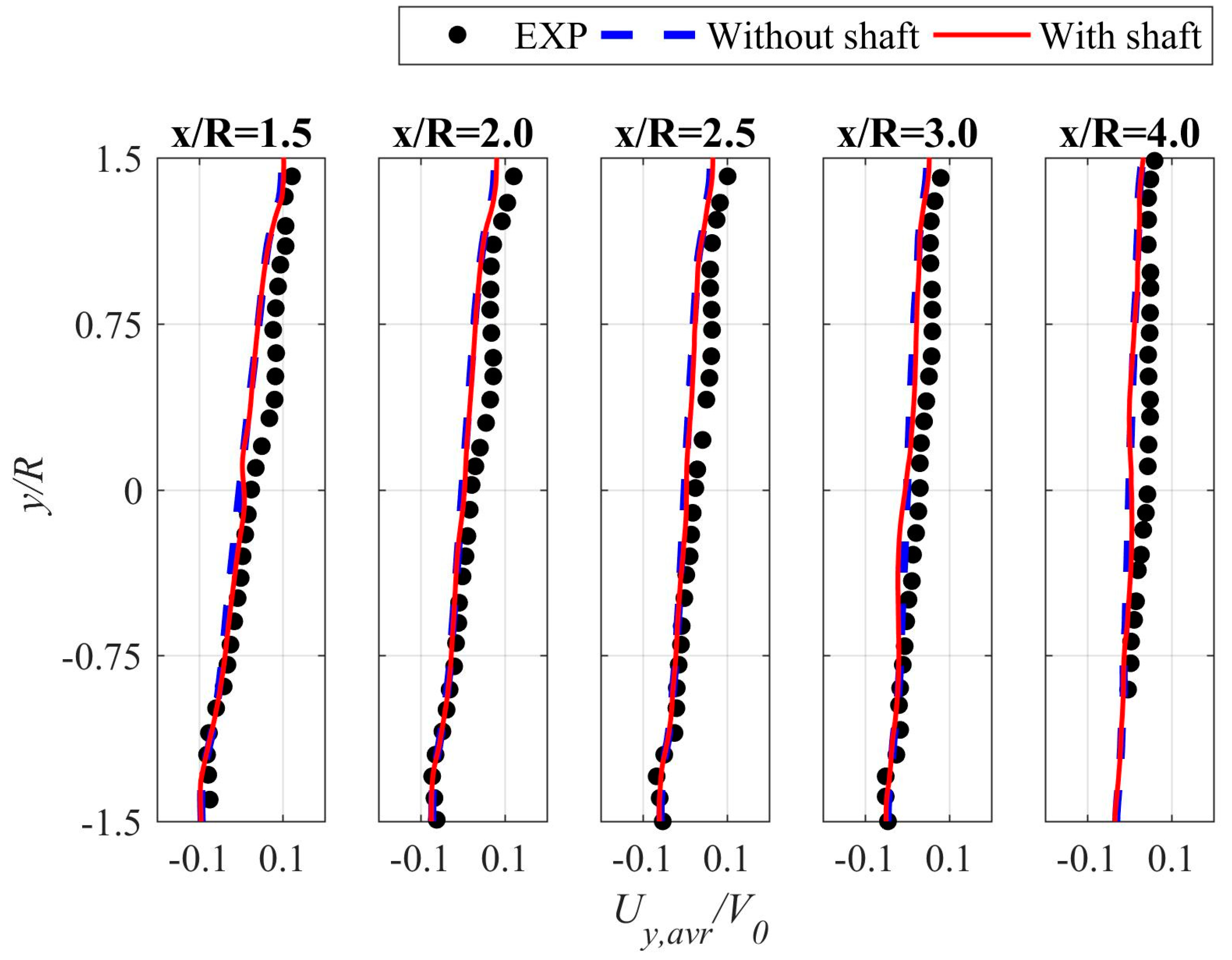

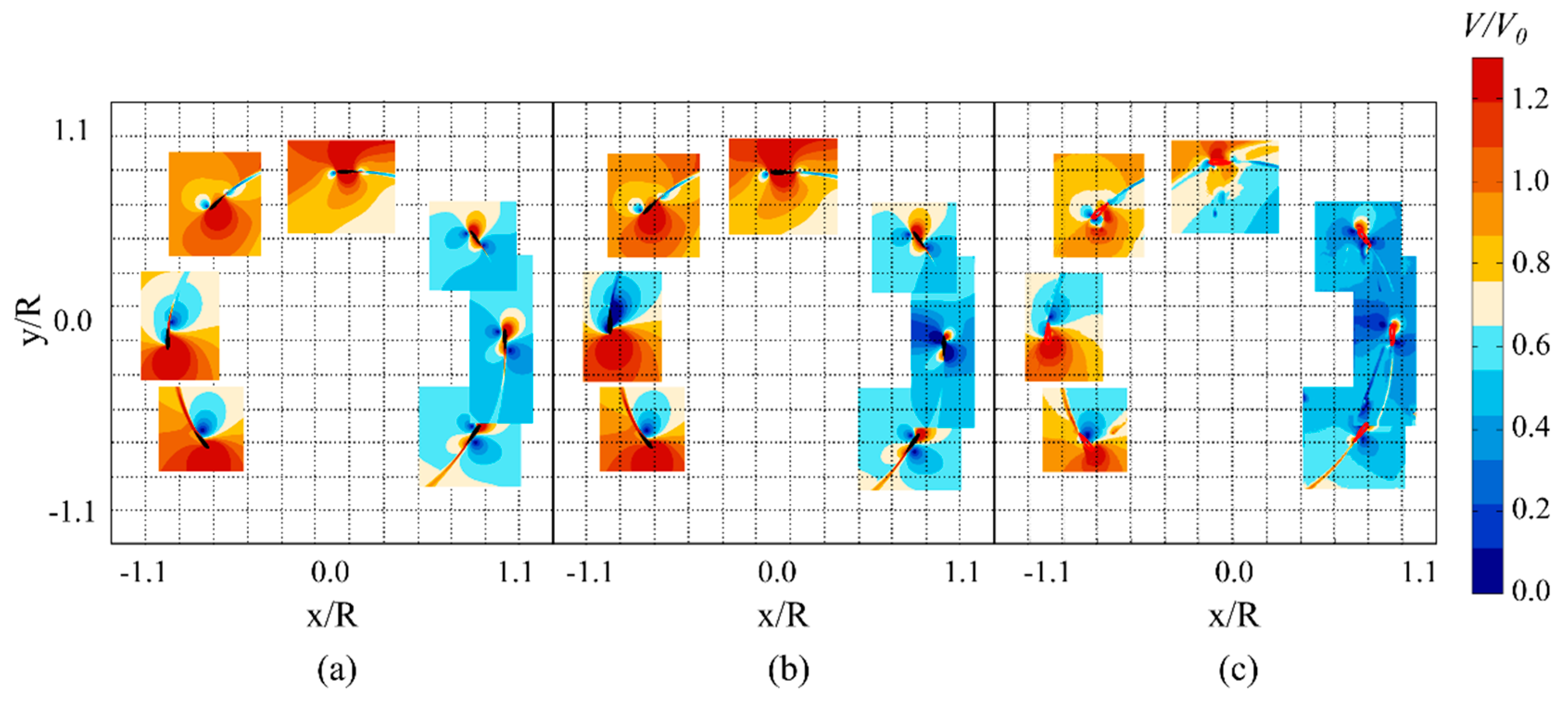

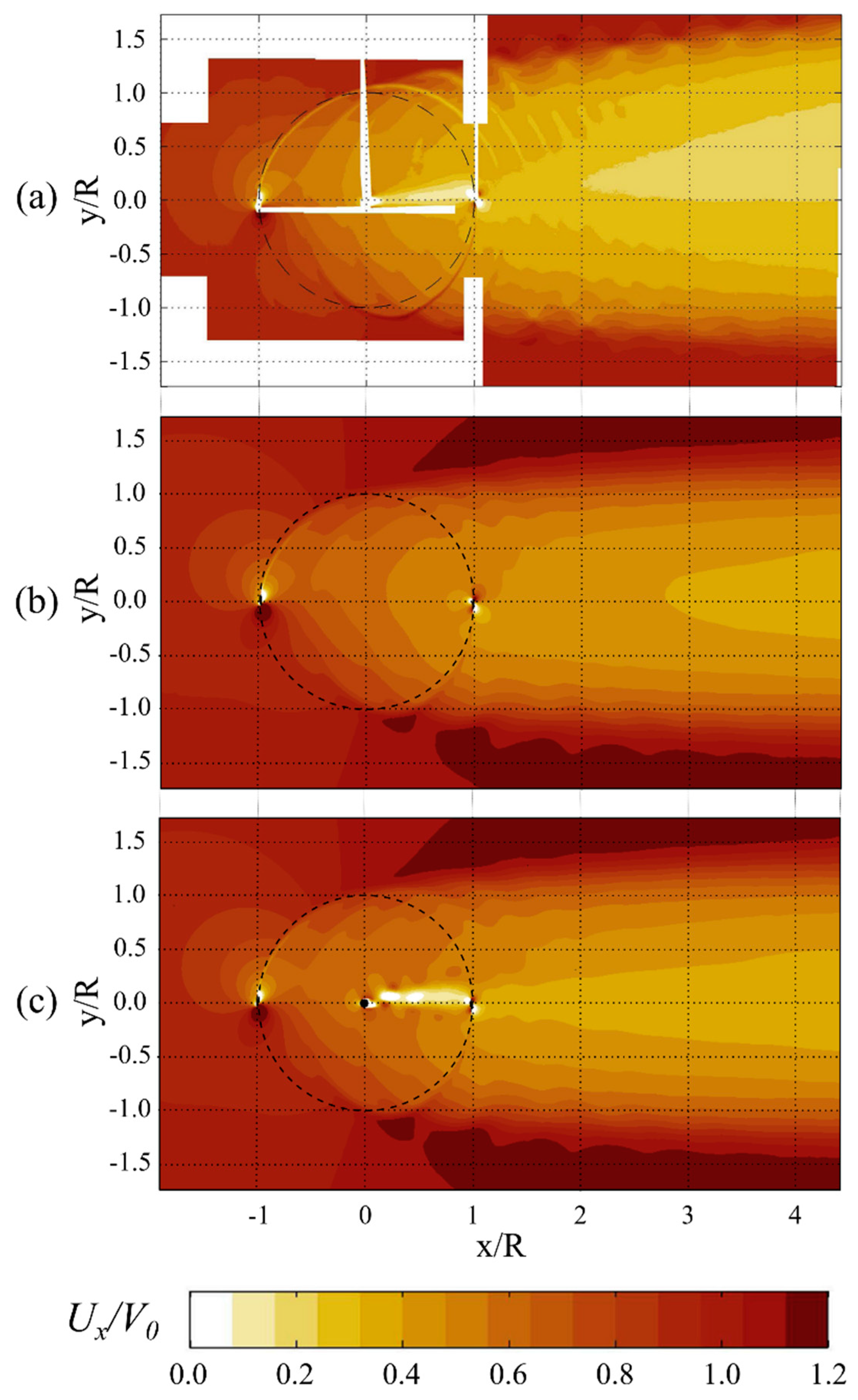

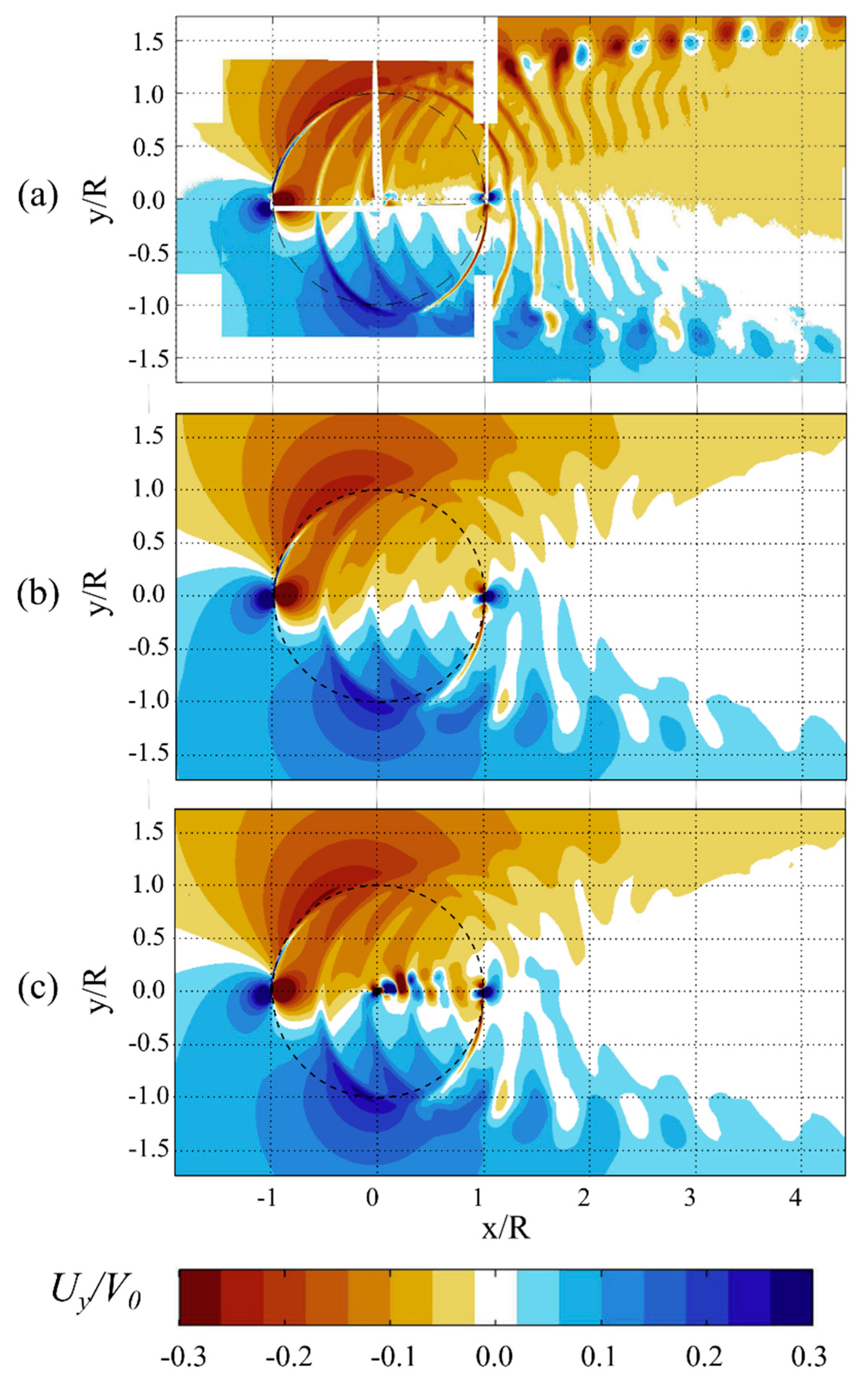

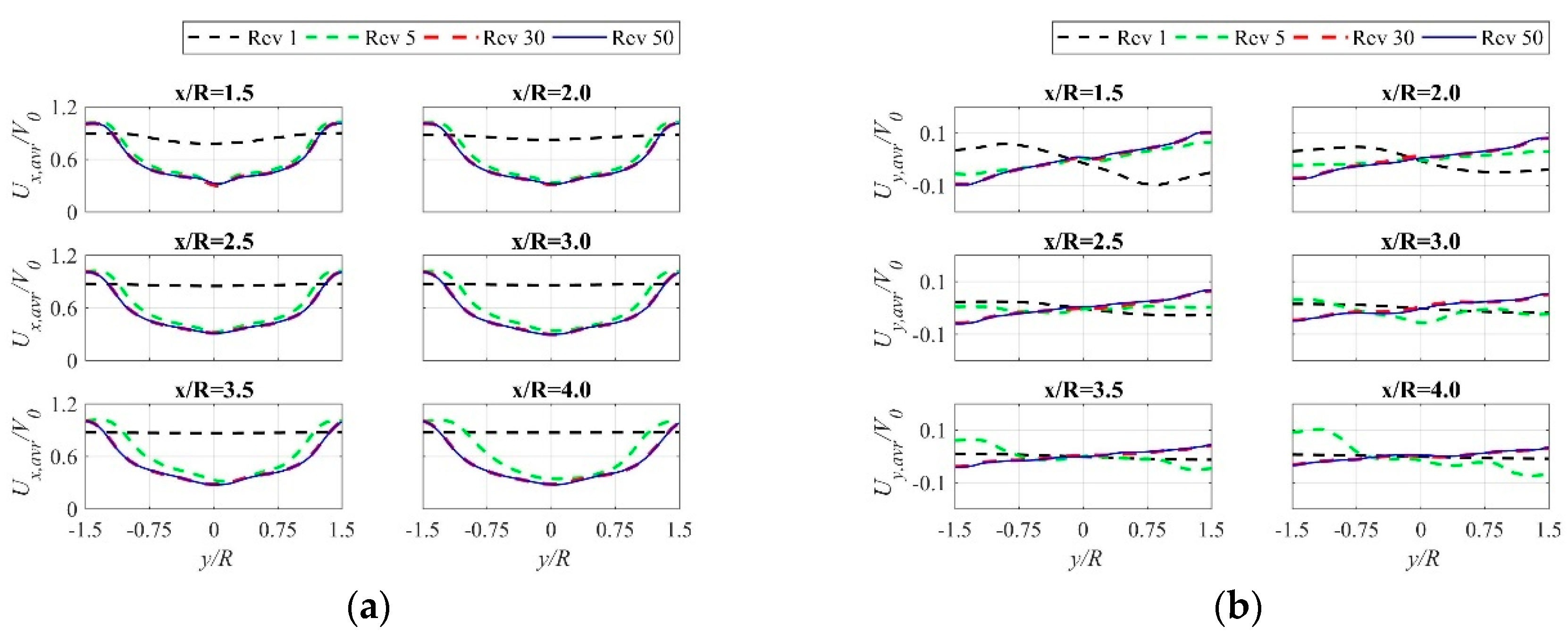

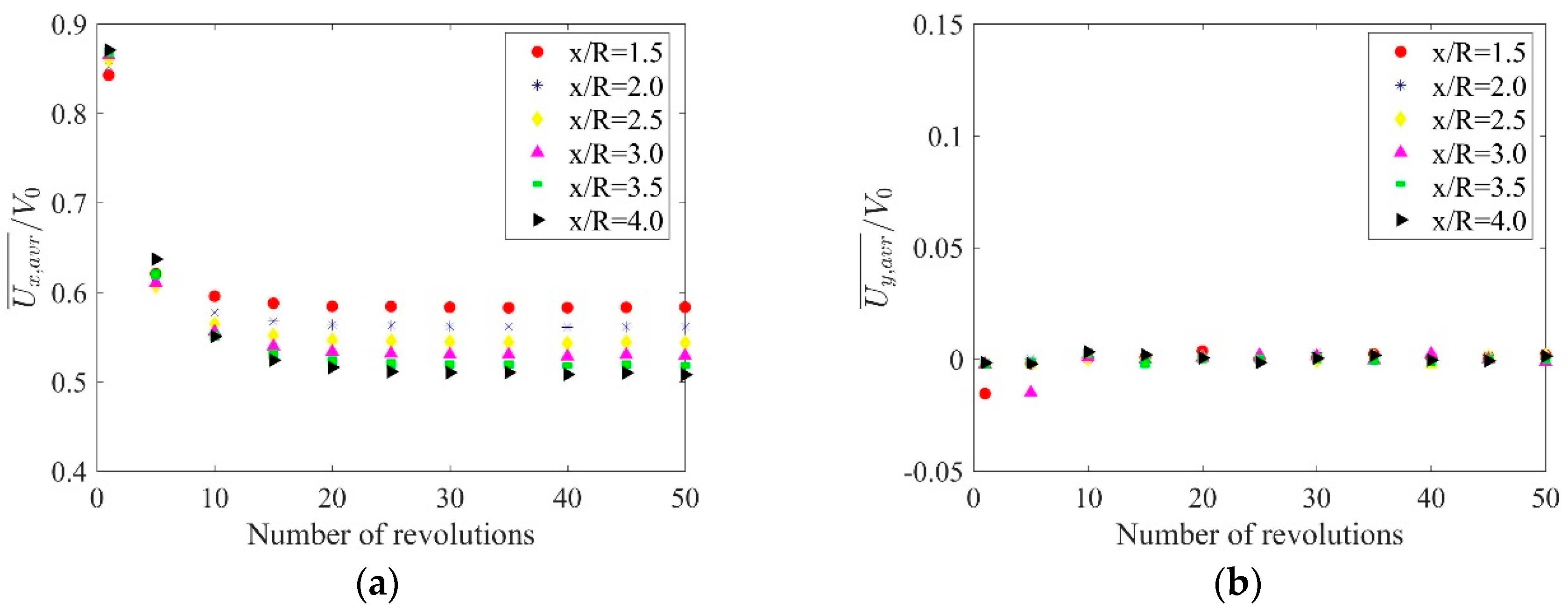

4.2. Aerodynamic Wake Characteristics

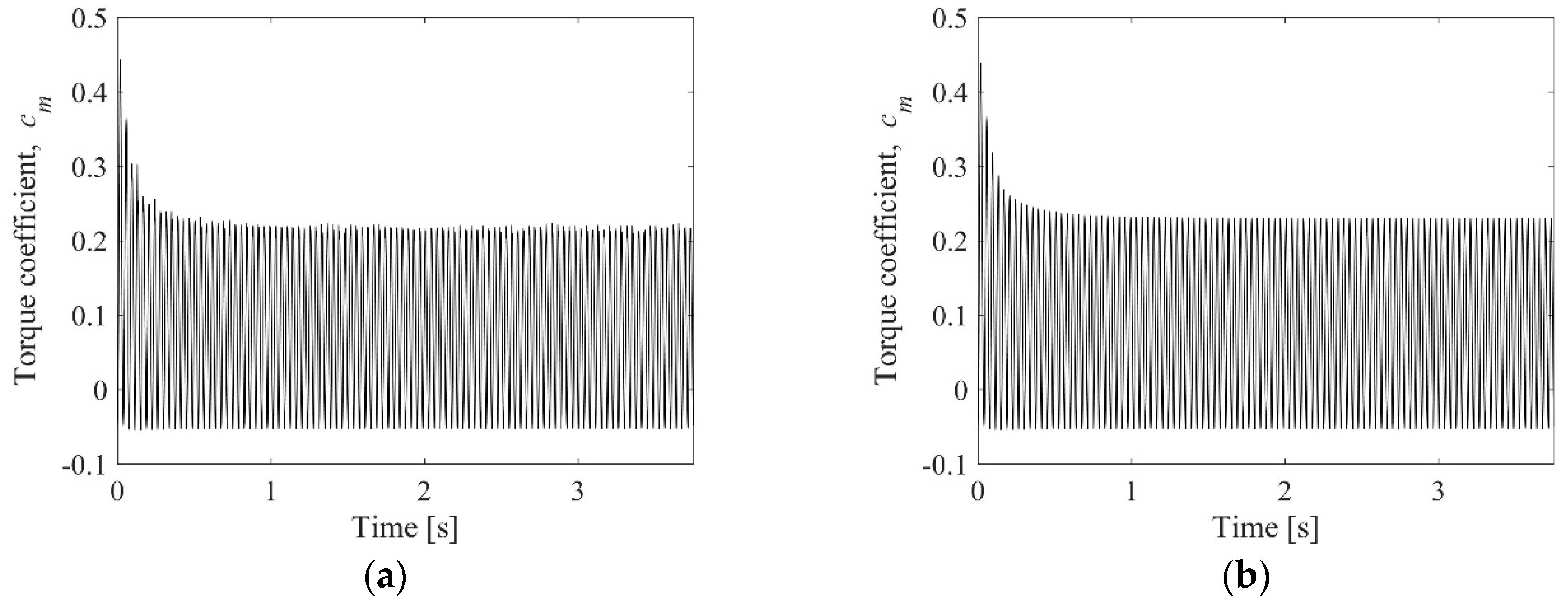

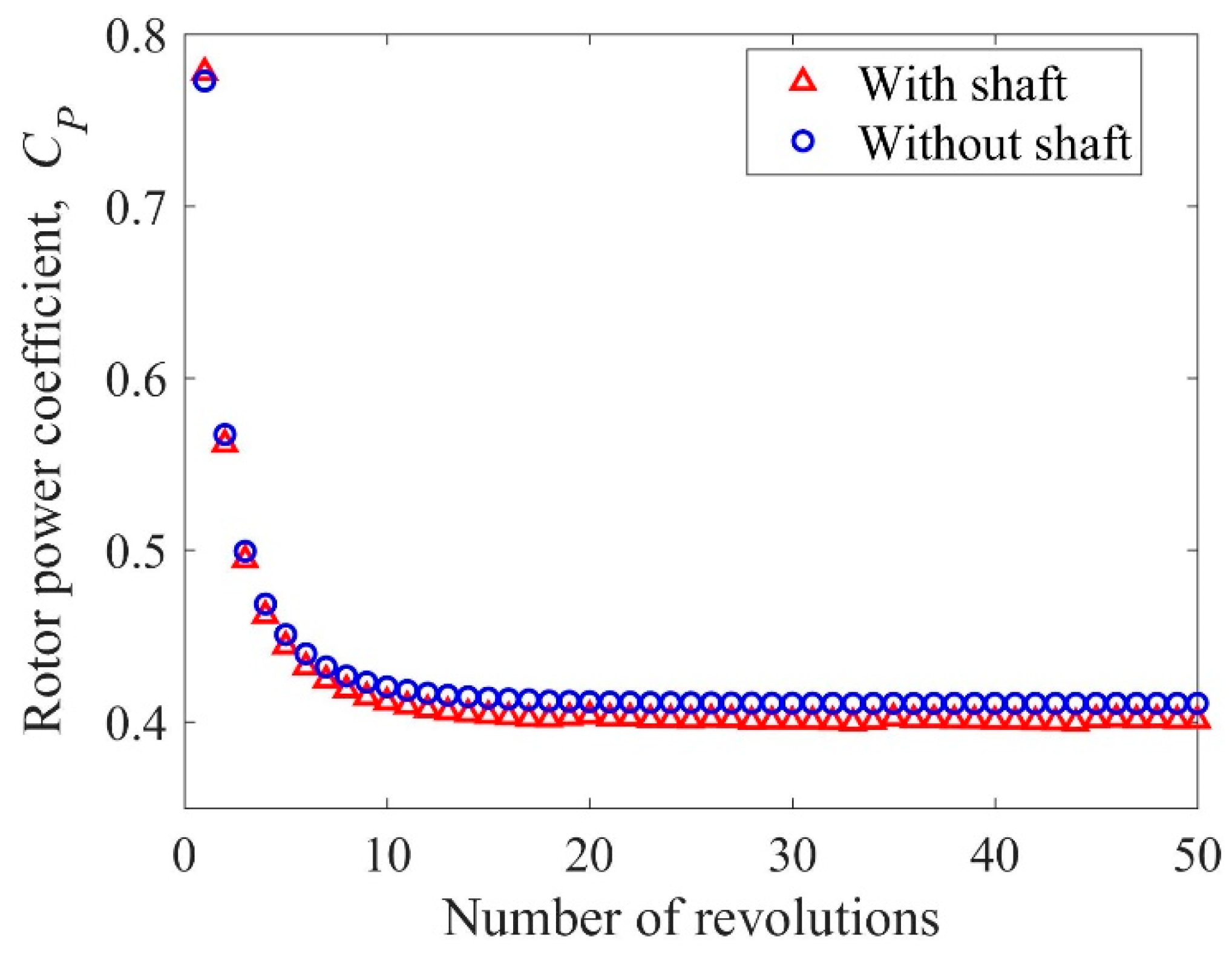

4.3. Revolution Convergence Analysis

4.4. Impact of Time Step Size

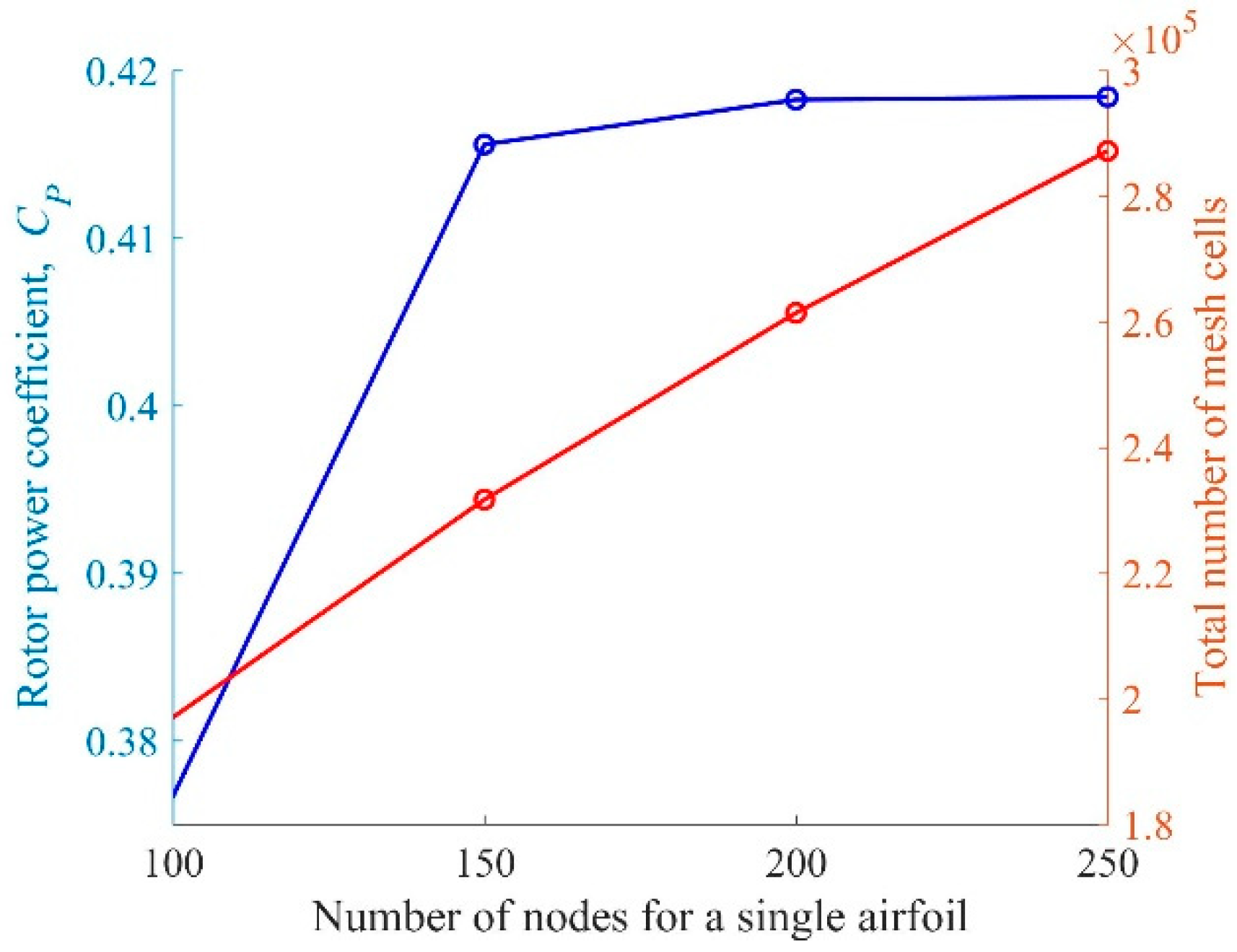

4.5. Mesh Convergence Study

5. Conclusions

- The SST k-ω turbulence model provides the results of the normal aerodynamic force component that appears to be satisfactory by comparing it with experimental results. However, slightly overestimated results of this force component may be due to 3D effects, which are not included in this work.

- The reason why the calculated velocity profiles (the velocity component parallel to the wind direction) downstream behind the rotor are not asymmetrical as in the case of the experimental studies it is not entirely clear. One possible reason is the simplification of the numerical model.

- The results of the second velocity component profiles agree much better with experimental research.

- The flow field around the wind turbine rotor is highly three-dimensional. The occurrence of flow separation is very likely in such conditions that are not favorable for URANS approach. Nevertheless, for the two-equation k-ω SST turbulence model and the URANS model, that were used here, the instantaneous velocity fields are consistent with the PIV studies.

- The influence of the rotating shaft is visible mainly in the central part of the velocity profiles and rapidly decreases with the distance downstream from the axis of rotation.

- The drop in the mean velocity for each Ux velocity profile is linear for six distances x/R downstream behind the rotor from 1.5 to 4.0. The average value of the velocity component parallel to the wind direction decreased by 13% for the given x/R range.

- The rotor in a non-shaft configuration achieves a power coefficient of 2.468% compared to a rotor equipped with a shaft.

- The frequency of the aerodynamic force acting on the shaft is 113.6% higher compared to the frequency of aerodynamic force of the rotor blade.

- Ten full rotor revolutions are sufficient to obtain repeatable results of the torque coefficient and almost constant values of the averaged rotor power coefficients. However, in order to obtain appropriate velocity profiles at the distance of 4R downstream behind the rotor, 15 full rotor revolutions are required for simulation.

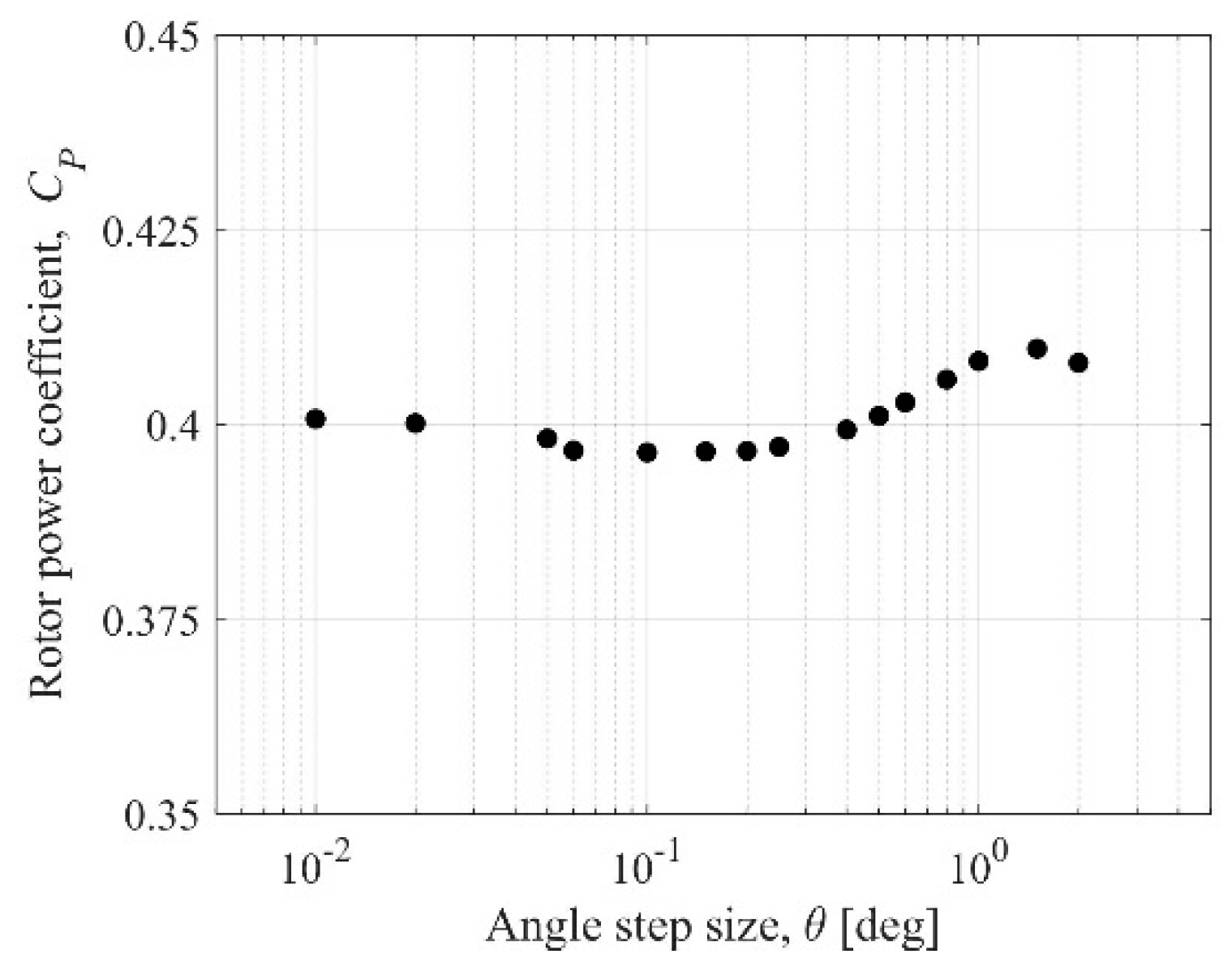

- The selection of the appropriate time step size has the greatest impact on the estimation of the aerodynamic blade loads of the blade moving in the rotor shaft. If the time step size is too large, the shaft influence is invisible. Below the time step size corresponding to the angle step size of 0.05 degrees, the rotor power coefficient begins to be constant.

Funding

Conflicts of Interest

References

- Santoni, C.; Carrasquillo, K.; Arenas-Navarro, I.; Leonardi, S. Effect of tower and nacelle on the flow past a wind turbine. Wind Energy 2017, 20, 1927–1939. [Google Scholar] [CrossRef]

- Hansen, M.O.L.; Madsen, H.A. Review paper on wind turbine aerodynamics. J. Fluids Eng. 2011, 133, 114001. [Google Scholar] [CrossRef]

- Cai, X.; Gu, R.; Pan, P.; Zhu, J. Unsteady aerodynamic simulation of a full-scale horizontal axis wind turbine using CFD methodology. Energy Convers. Manag. 2016, 112, 146–156. [Google Scholar] [CrossRef]

- Paraschivoiu, I. Wind Turbine Design—With Emphasis on Darrieus Concept; Polytechnic International Press: Montreal, QC, Canada, 2002. [Google Scholar]

- Paraschivoiu, I.; Delclaux, F. Double multiple streamtube model with recent improvements. J. Energy. 1983, 7, 250–255. [Google Scholar] [CrossRef]

- Paraschivoiu, I.; Delclaux, F.; Fraunie, P.; Beguier, C. Aerodynamic Analysis of the Darrieus Rotor Including Secondary Effects. J. Energy 1983, 7, 416–422. [Google Scholar] [CrossRef]

- Beri, H.; Yao, Y. Double multiple streamtube model and numerical analysis of vertical axis wind turbine. Energy Power Eng. 2011, 3, 262–270. [Google Scholar] [CrossRef]

- Lazauskas, L. Three pitch control systems for vertical axis wind turbines compared. Wind Eng. 1992, 16, 269–282. [Google Scholar]

- Klimas, P.C. Proceedings of the Vertical Axis Wind Turbine (VAWT) Design Technology Seminar for Industry; Technical Report SAND80-0984; Sandia National Laboratories: Albuquerque, NM, USA, 1948.

- Wang, Z.; Wang, Y.; Zhuang, M. Improvement of the aerodynamic performance of vertical axis wind turbines with leading-edge serrations and helical blades using CFD and Taguchi method. Energy Convers. Manag. 2018, 177, 107–121. [Google Scholar] [CrossRef]

- Lam, H.; Peng, H. Study of wake characteristics of a vertical axis wind turbine by two- and three-dimensional computational fluid dynamics simulations. Renew. Energy 2016, 90, 386–398. [Google Scholar] [CrossRef]

- Li, C.; Zhu, S.; Xu, Y.L.; Xiao, Y. 2.5 D large eddy simulation of vertical axis wind turbine inconsideration of high angle of attack flow. Renew. Energy 2013, 51, 317. [Google Scholar] [CrossRef]

- Castelli, M.R.; Benini, E. Effect of blade inclination angle on a Darrieus wind turbine. J. Turbomach. 2012, 134, 031016. [Google Scholar] [CrossRef]

- Lanzafame, R.; Mauro, S.; Messina, M. 2D CFD modeling of H-darrieus wind turbines using a transition Turbulence Model. Energy Procedia 2014, 45, 131–140. [Google Scholar] [CrossRef]

- Shamsoddin, S.; Porté-Agel, F. Large eddy simulation of vertical axis wind turbine wakes. Energies 2014, 7, 890–912. [Google Scholar] [CrossRef]

- Rezaeiha, A.; Montazeri, H.; Blocken, B. Towards accurate CFD simulations of vertical axis wind turbines at different tip speed ratios and solidities: Guidelines for azimuthal increment, domain size and convergence. Energy Convers. Manag. 2018, 156, 301–316. [Google Scholar] [CrossRef]

- Bangga, G.; Lutz, T.; Jost, E.; Krämer, E. CFD studies on rotational augmentation at the inboard sections of a 10MW wind turbine rotor. J. Renew. Sustain. Energy 2017, 9, 023304. [Google Scholar] [CrossRef]

- Bangga, G.; Hutomo, G.; Wiranegara, R.; Sasongko, H. Numerical study on a single bladed vertical axis wind turbine under dynamic stall. J. Mech. Sci. Technol. 2017, 31, 261–267. [Google Scholar] [CrossRef]

- Alaimo, A.; Esposito, A.; Messineo, A.; Orlando, D.; Tumino, D. 3D CFD Analysis of a Vertical Axis Wind Turbine. Energies 2015, 8, 3013–3033. [Google Scholar] [CrossRef]

- Rogowski, K. Numerical studies on two turbulence models and a laminar model for aerodynamics of a vertical-axis wind turbine. J. Mech. Sci. Technol. 2018, 32, 2079–2088. [Google Scholar] [CrossRef]

- Rogowski, K.; Hansen, M.O.L.; Lichota, P. 2-D CFD Computations of the Two-Bladed Darrieus-Type Wind Turbine. J. Appl. Fluid. Mech. 2018, 11, 835–845. [Google Scholar] [CrossRef]

- Wekesa, D.W.; Wang, C.; Wei, Y.; Kamau, J.N.; Danao, L.A. A numerical analysis of unsteady inflow wind for site specific vertical axis wind turbine: A case study for Marsabit and Garissa in Kenya. Renew. Energy 2015, 76, 648–661. [Google Scholar] [CrossRef]

- Rezaeiha, A.; Montazeri, H.; Blocken, B. On the accuracy of turbulence models for CFD simulations of verticalaxis wind turbines. Energy 2019, 180, 838–857. [Google Scholar] [CrossRef]

- Rezaeiha, A.; Kalkman, I.; Montazeri, H.; Blocken, B. Effect of the shaft on the aerodynamic performance of urban vertical axis wind turbines. Energy Convers. Manag. 2017, 149, 616–630. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, K.; Zhong, J.; Zhang, L.; Jiang, T.; Li, S.; Zhang, Z. Numerical Investigations of the Effects of the Rotating Shaft and Optimization of Urban Vertical Axis Wind Turbines. Energies 2018, 11, 1870. [Google Scholar] [CrossRef]

- Tescione, G.; Ragni, D.; He, C.; Simão Ferreira, C.J.; van Bussel, G.J.W. Near wake flow analysis of a vertical axis wind turbine by stereoscopic particle image velocimetery. Renew. Energy 2014, 70, 47–61. [Google Scholar] [CrossRef]

- Castelein, D.; Ragni, D.; Tescione, G.; Simão Ferreira, C.J.; Gaunaa, M. Proceedings of the 33rd Wind Energy Symposium; AIAA 2015-0723; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 1963. [Google Scholar]

- Menter, F.R. Two-Equation Eddy-Viscosity Turbulence Models for Engineering Applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Barth, T.; Jespersen, D. The design and application of upwind schemes on unstructured meshes. In Proceedings of the 27th Aerospace Sciences Meeting, Reno, NV, USA, 9–12 January 1989; Paper 89-0366. AIAA: Reston, VA, USA, 1963. [Google Scholar] [CrossRef]

- FLUENT Manual—ANSYS Release Version 17.1, Theory Guide; ANSYS, Inc.: Cannonsburg, PA, USA, 1970.

- Strickland, J.H.; Webster, B.T.; Nguyen, N. A Vortex Model of the Darrieus Turbine: An Analytical and Experimental Study. J. Fluids Eng. 1979, 101, 500–505. [Google Scholar] [CrossRef]

- Laneville, A.; Vittecoq, P. Dynamic Stall: The Case of the Vertical Axis Wind Turbine. J. Sol. Energy Eng. 1986, 108, 141–145. [Google Scholar] [CrossRef]

- Rogowski, K.; Hansen, M.O.L.; Maroński, R.; Lichota, P. Scale Adaptive Simulation Model for the Darrieus Wind Turbine. J. Phys. Conf. Ser. 2016, 753, 022050. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Number of blades, N | 2 |

| Rotor diameter, D=2R | 1 m |

| Chord length, c | 0.06 m |

| Solidity, Nc/R | 0.24 |

| Blade airfoil | NACA0018 |

| Rotor shaft diameter, DS | 0.04 m |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rogowski, K. CFD Computation of the H-Darrieus Wind Turbine—The Impact of the Rotating Shaft on the Rotor Performance. Energies 2019, 12, 2506. https://doi.org/10.3390/en12132506

Rogowski K. CFD Computation of the H-Darrieus Wind Turbine—The Impact of the Rotating Shaft on the Rotor Performance. Energies. 2019; 12(13):2506. https://doi.org/10.3390/en12132506

Chicago/Turabian StyleRogowski, Krzysztof. 2019. "CFD Computation of the H-Darrieus Wind Turbine—The Impact of the Rotating Shaft on the Rotor Performance" Energies 12, no. 13: 2506. https://doi.org/10.3390/en12132506

APA StyleRogowski, K. (2019). CFD Computation of the H-Darrieus Wind Turbine—The Impact of the Rotating Shaft on the Rotor Performance. Energies, 12(13), 2506. https://doi.org/10.3390/en12132506