A Review of Gerotor Technology in Hydraulic Machines

Abstract

:1. Introduction

1.1. The Aim of this Article

- Provide a complete literature review of the last decade, while paying more attention articles published in the last five years by journals in the English language;

- Identify the state-of-the-art in gerotor pumps and orbital-motors;

- Grasp the current mainstream of this technology;

- Be a guide and a directory of gerotor technology for inexperienced engineers working with hydraulic machines;

- Promote this fascinating research field to young researchers and PhD students;

- Disseminate the works of the researchers and investigators employing gerotor technology around the world;

- Provide a scenario for future international collaboration and projects by bringing together the researchers working in the field;

- Collect recommendations that combine academia and industry expertise to make better use of these extensive studies;

- Be a catalogue of guidelines;

- Focus the attention of readers on this technology.

1.2. What the Article is Not

- A systematic review or a meta-analysis report. The article intends to follow the PRISMA checklist and its flow diagram within reasonable bounds;

- It is not a bibliometric analysis;

- It is not a survey, or review, of patents, a collection of commercial catalogues or a summary of technical reports;

- It is not a study of PhD or Masters theses;

- It is not an in-depth reading and a totally-in-detail study of all the references included in it.

1.3. The Limitations of this Article

- Being a document than comprises published, open and available articles, as well as papers and texts from the own authors’ collection, archived over the past years;

- Citing and quoting, when required, definitions, keywords, nomenclature and sentences of the researchers;

- Keeping the trochoidal-envelope denomination as the researchers originally named them. We are not able to standardize the published nomenclature in this article, and we do not want to increase the misunderstanding either;

- Not differentiating between articles. Out of context, figures and specific results tend to lose significance. Then, this article undertakes a thorough and objective the search of the figures to be selected and referenced from relevant articles to gain in readability. Nevertheless, we recommend going to the sources referenced. Moreover, we believe we are not eligible to distinguish between published works, since all of them are presumed to come from great effort, resources and time. This report expects not to be subject of bias.

1.4. The Structure of this Article

2. Analysis of this Literature Review

2.1. The Gear Set

2.2. The Background of this Analysis

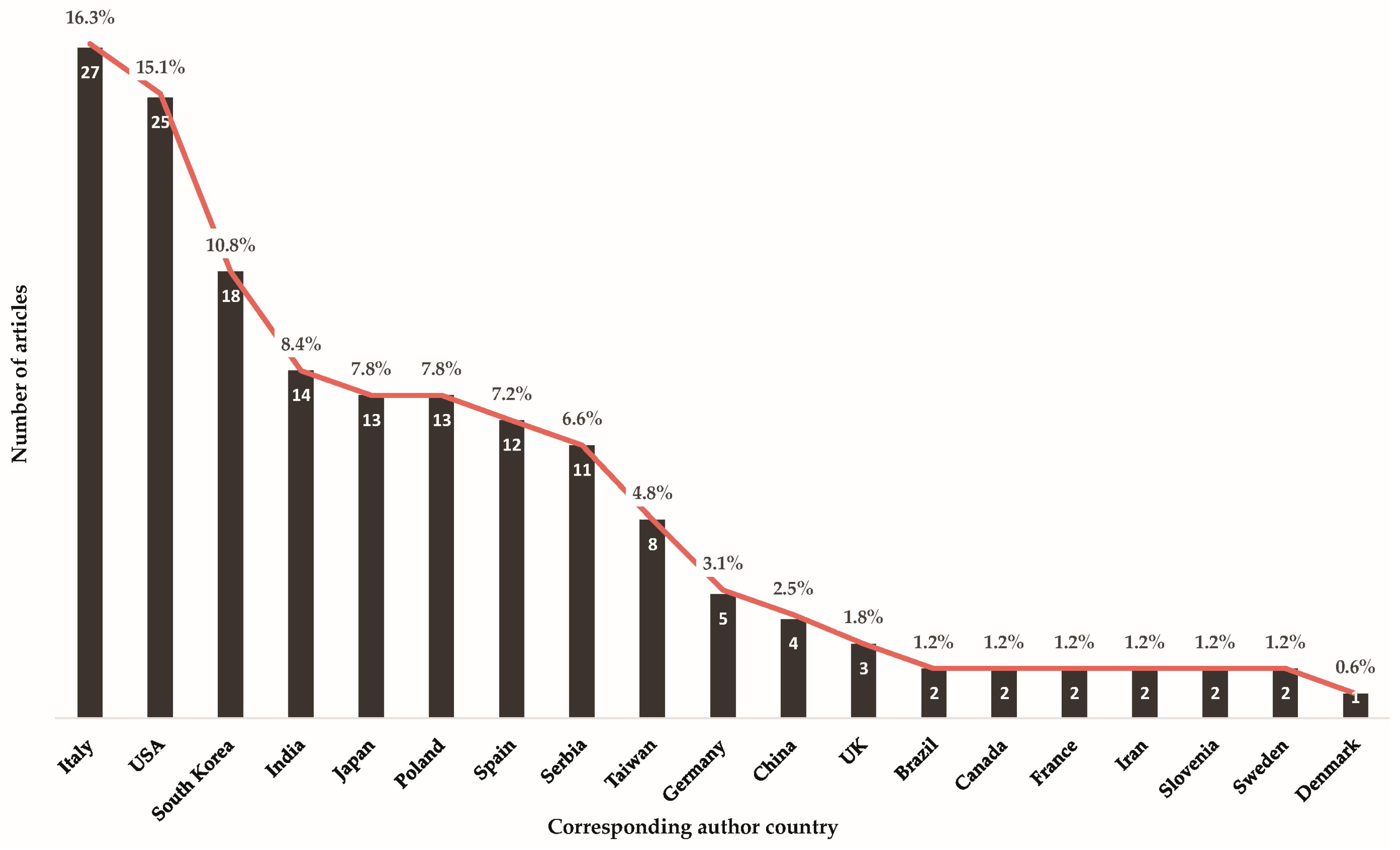

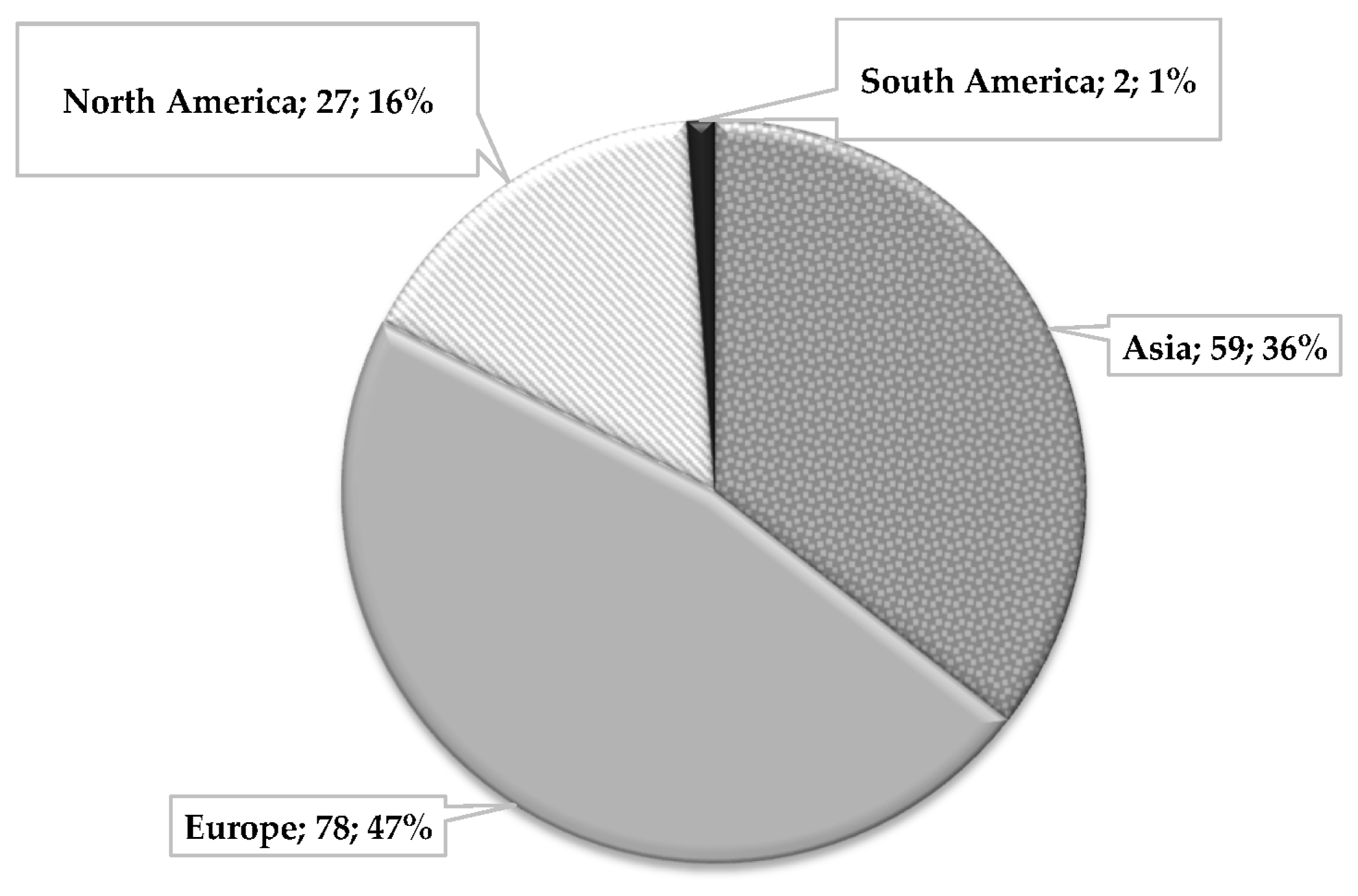

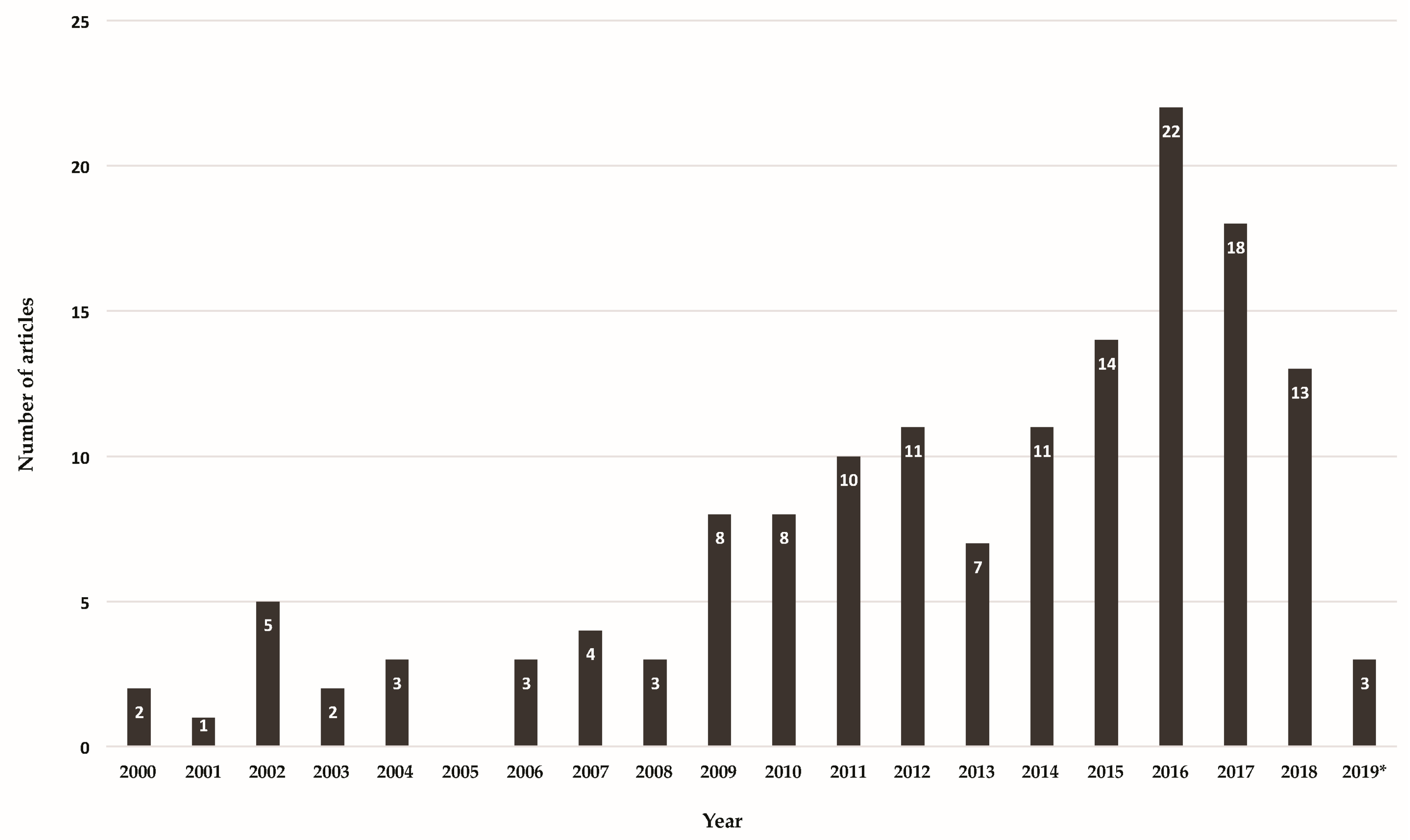

2.2.1. Distribution of Articles

- Last five years, 2014–2018: 78 items—54%;

- Last decade, 2009–2018: 122 items—84%;

- Current 21st century, 2000–2018: 145 items—100%.

2.2.2. Keywords

3. Historical Background

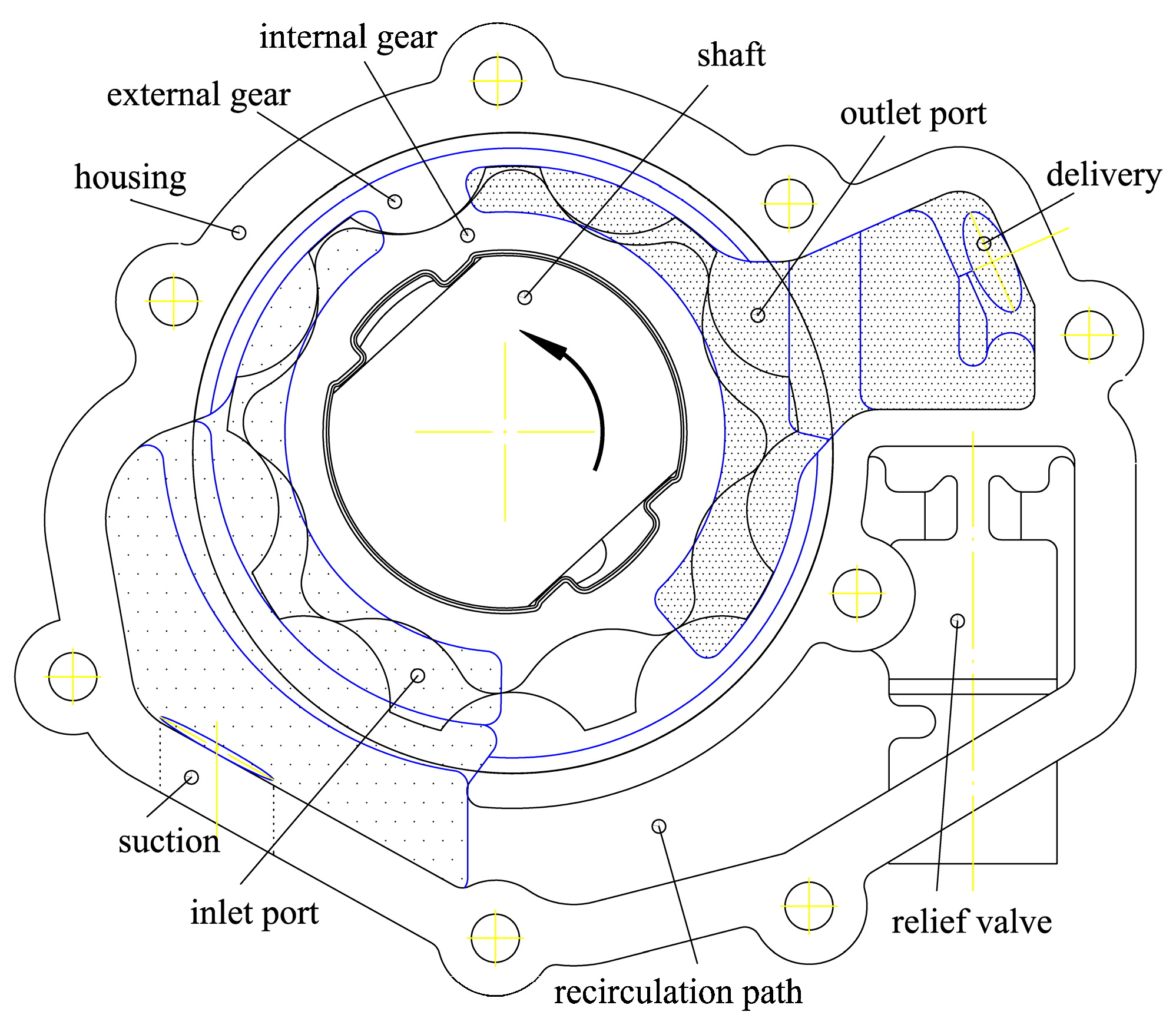

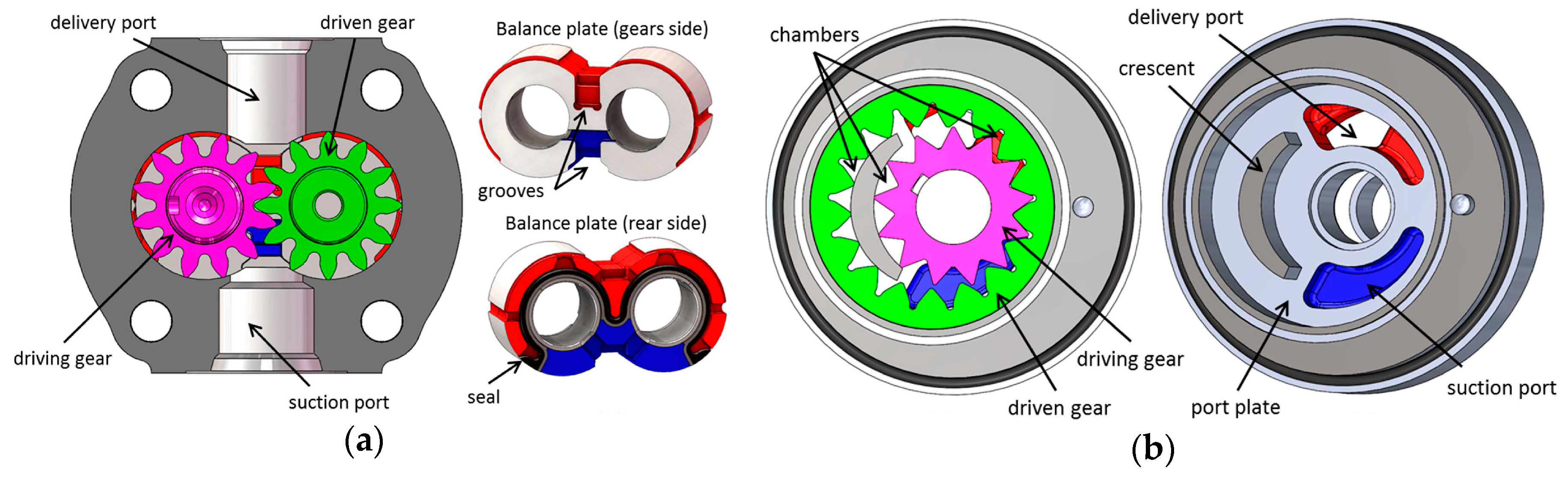

4. Current Approaches to Gerotor Pumps

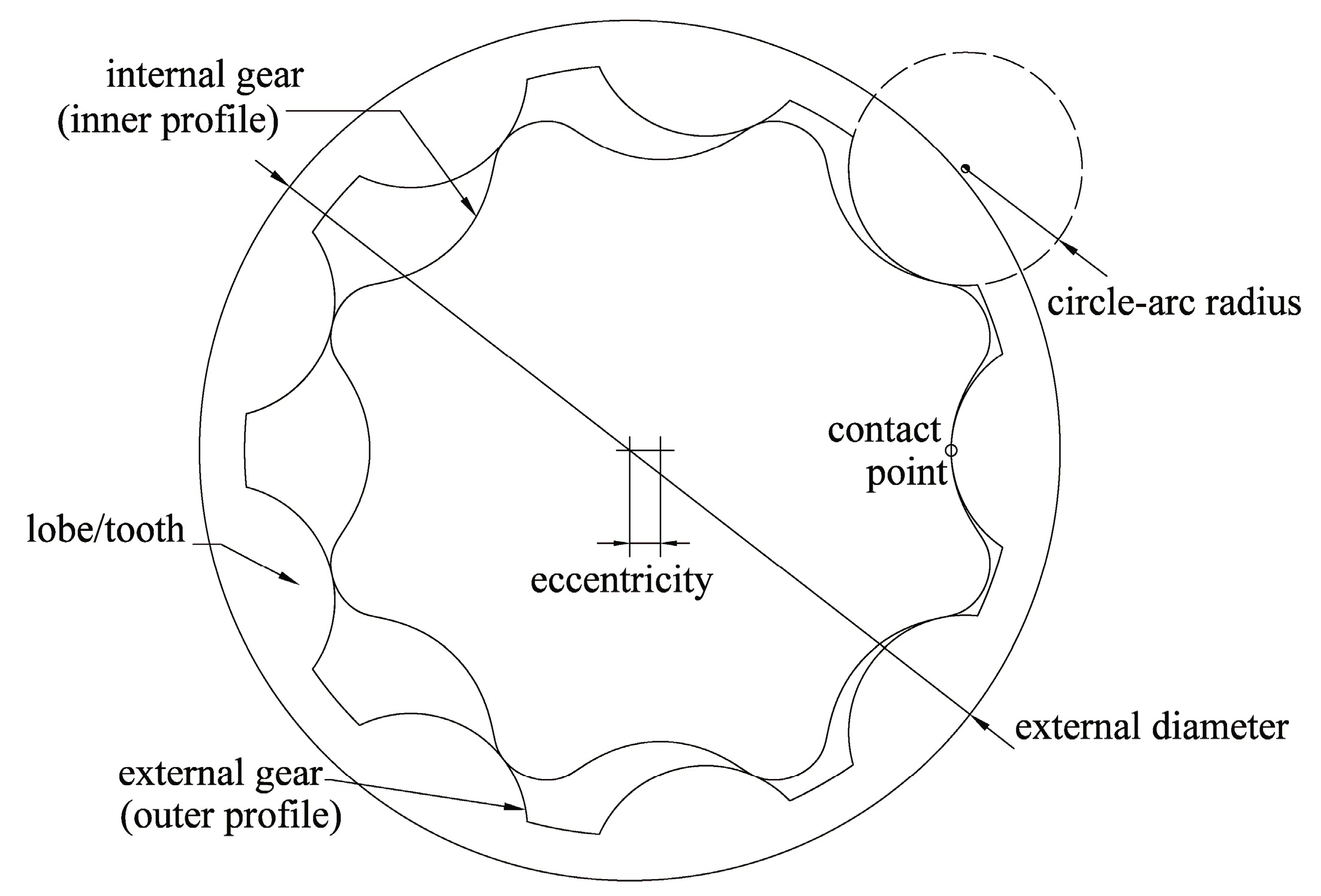

4.1. Geometric Approach

- Conventional profiles: Circular-tooth profiles (conventional-toothed gerotor);

- Unconventional profiles: Circular, polycircular and geometrical non-circular-tooth disposition (elliptic, involute, asymmetric) profiles (unconventional-toothed gerotor);

- High Efficiency Profiles: Tailored-tooth profiles (tailored-toothed gerotor).

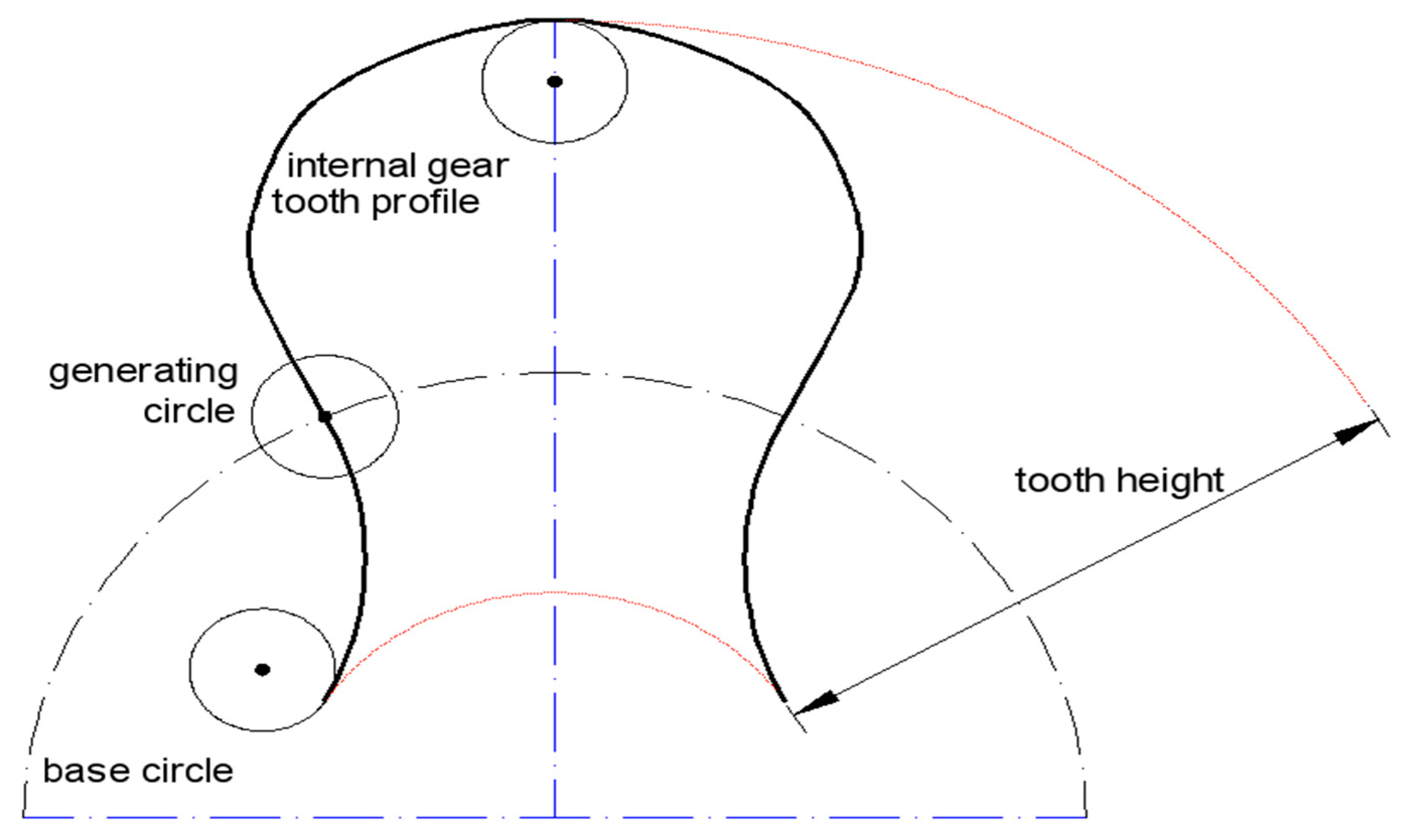

4.1.1. Conventional Profiles

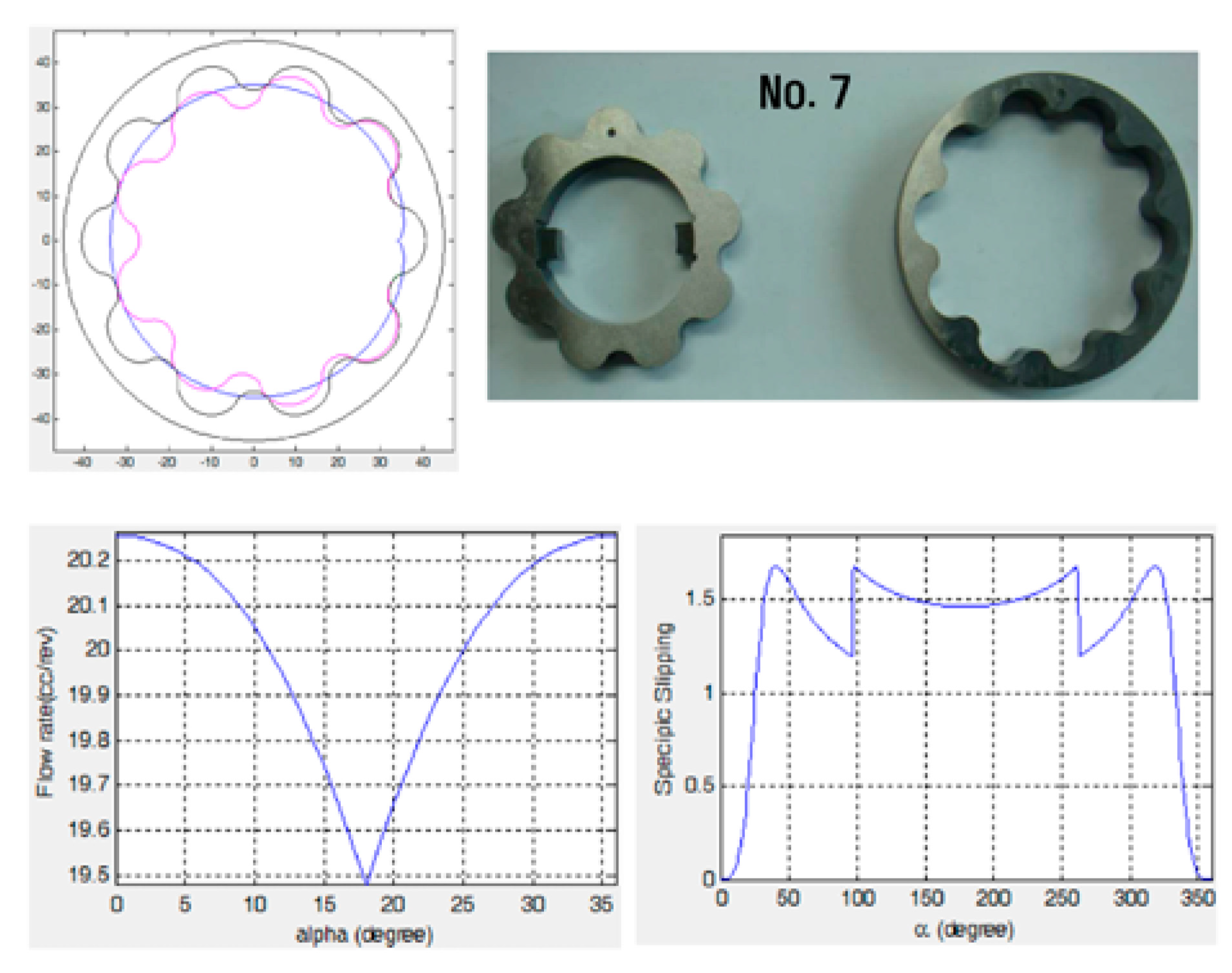

4.1.2. Unconventional Profiles

4.1.3. High Efficiency Profiles

4.1.4. Geometric Approach: Selected Contributions

- The work of Bonandrini, Mimmi and Rottenbacher [25] is selected as the starting point for a novel engineer in conventional profiles based on the accurate description, the synthetic equations and the geometry defined by the choice of four non-dimensional parameters. A natural step forward is the work of Hsieh [31] where the influence of geometric configuration in conjunction with the performance characteristics (kinematic, sealing and stress) leads to the flow rate and the volumetric efficiency evaluation.

4.2. Performance Approach

4.2.1. Energy, Flow, Friction and Stress Index Evaluation

4.2.2. Manufacturing, Clearances and Porting

4.2.3. Materials

4.2.4. Optimization Techniques

4.2.5. Software Techniques

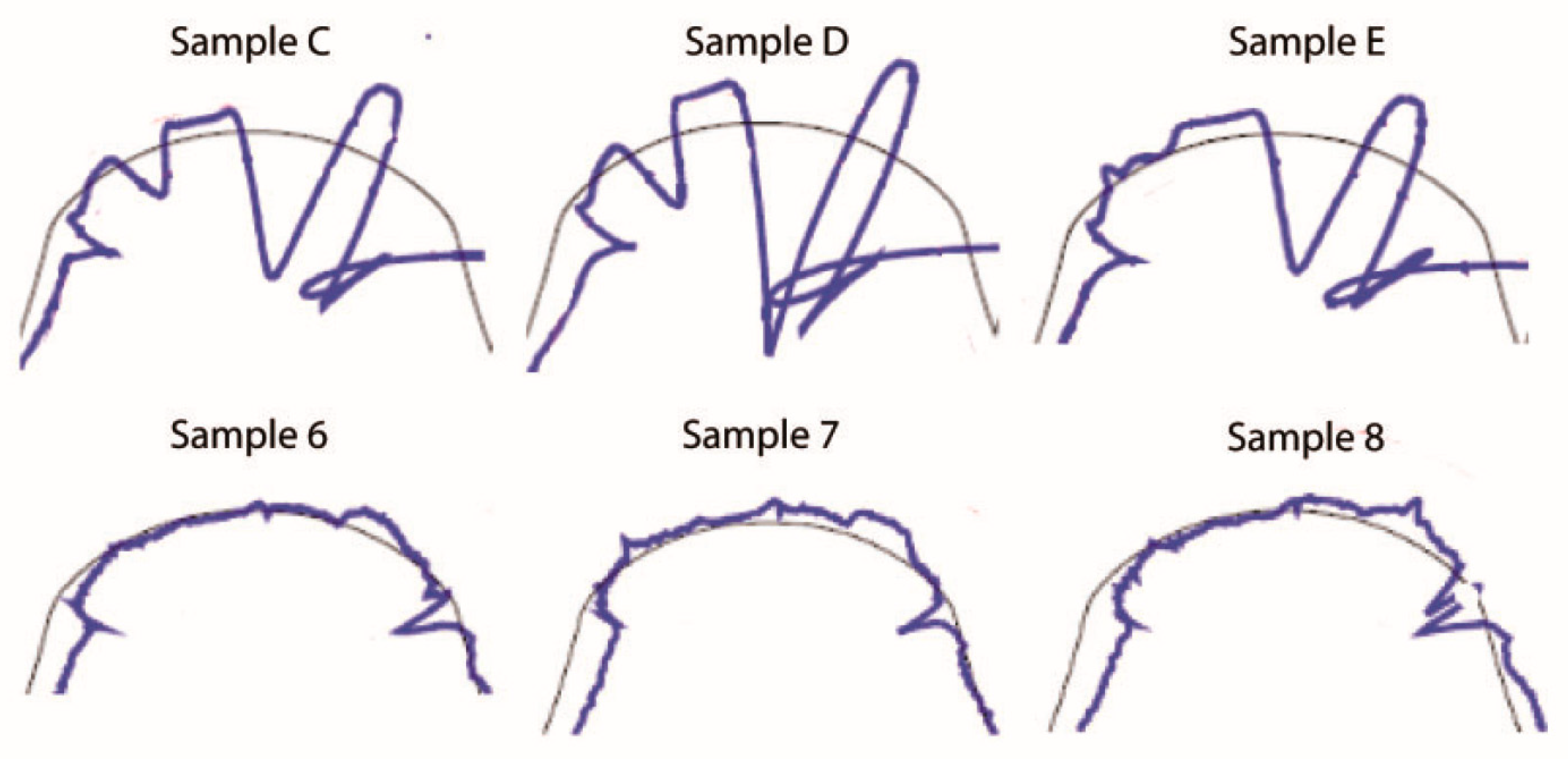

4.2.6. Visualization Techniques

4.2.7. Variable Flow Development

4.2.8. Performance Approach: Selected Contributions

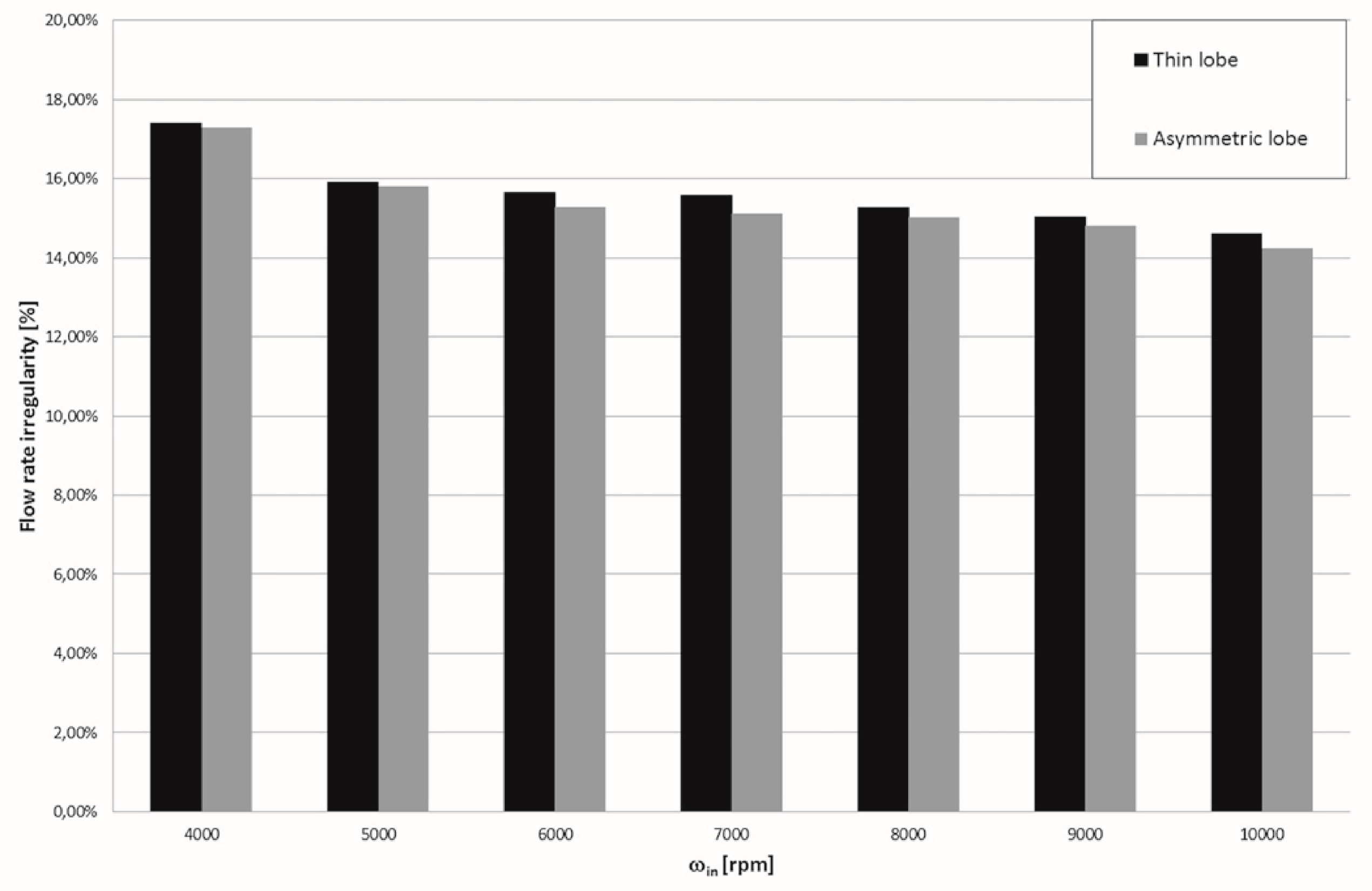

- Jacazio and De Martin presented a comparison of the performance indexes of circular, elliptic and asymmetric tooth profiles. Reference [56] is a significant summary of profile characterization;

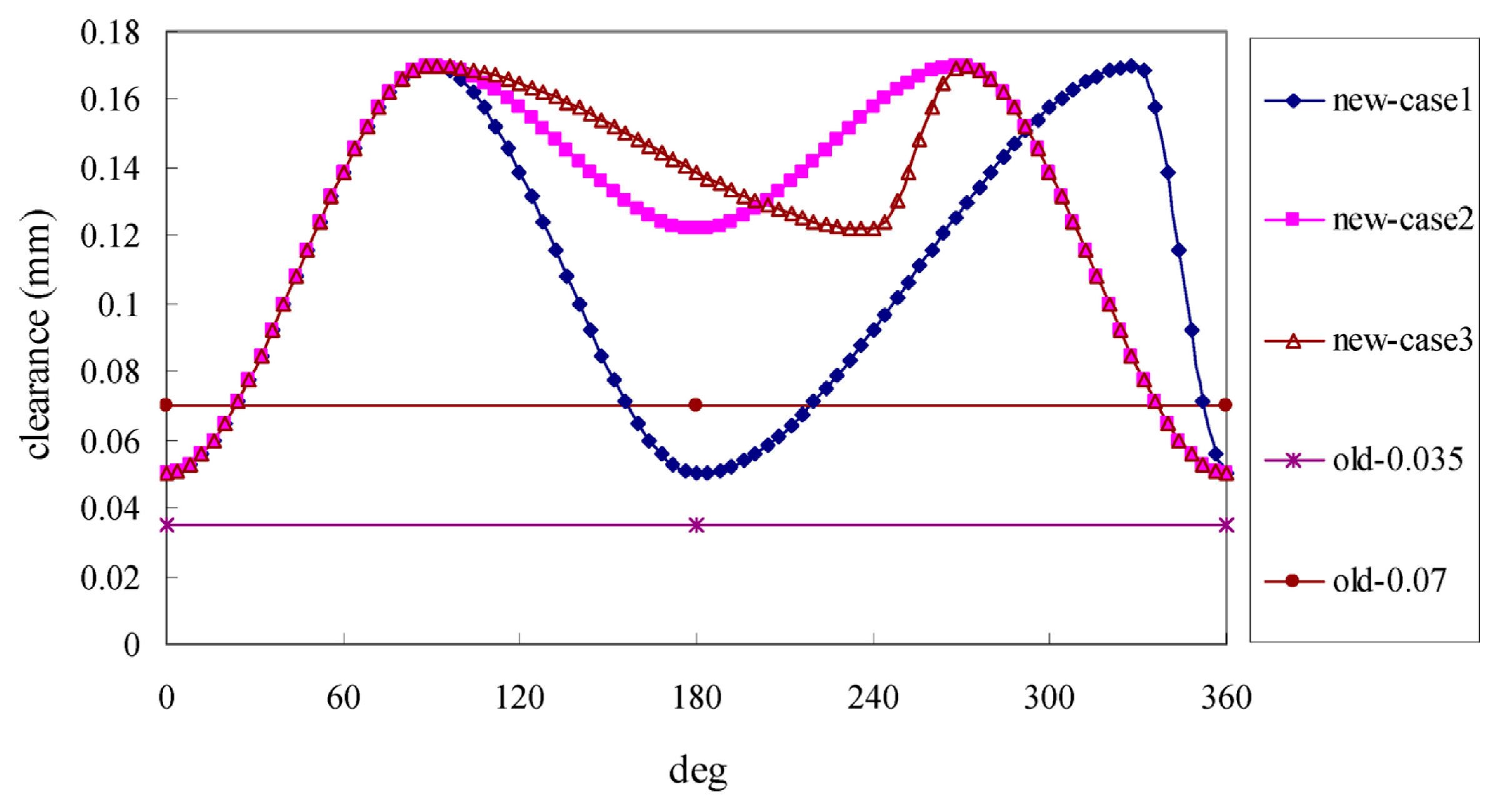

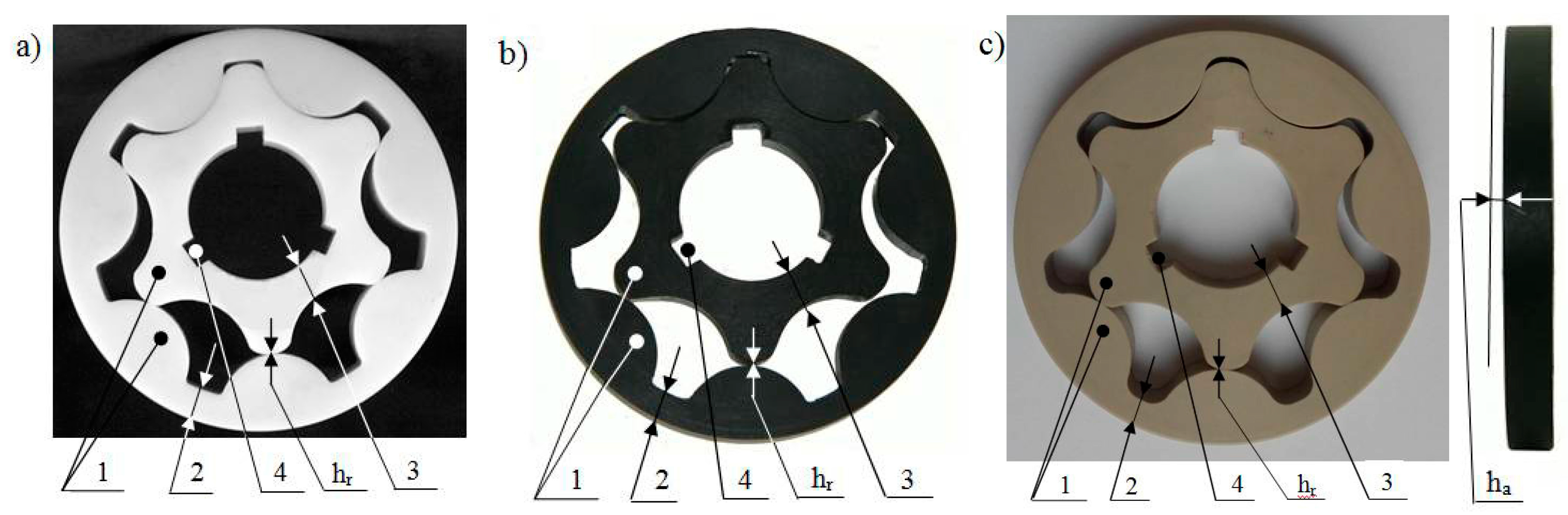

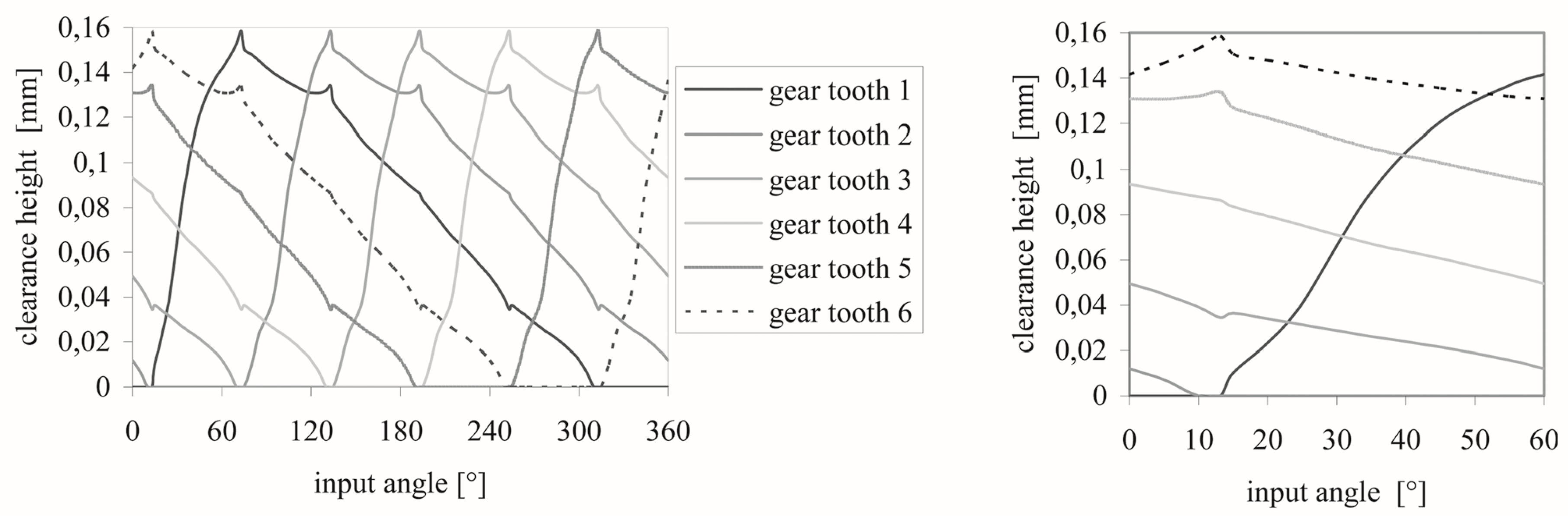

- The knowledge of the influence of the clearance design and porting in the leakage rates is mandatory in gerotor pumps, and the work of Hsieh [64] is a key contribution. If the manufacturing of a new-born gerotor pump is the objective, the work of Gamez-Montero et al. [72] will guide the designer by following a catalogue of best practice rules;

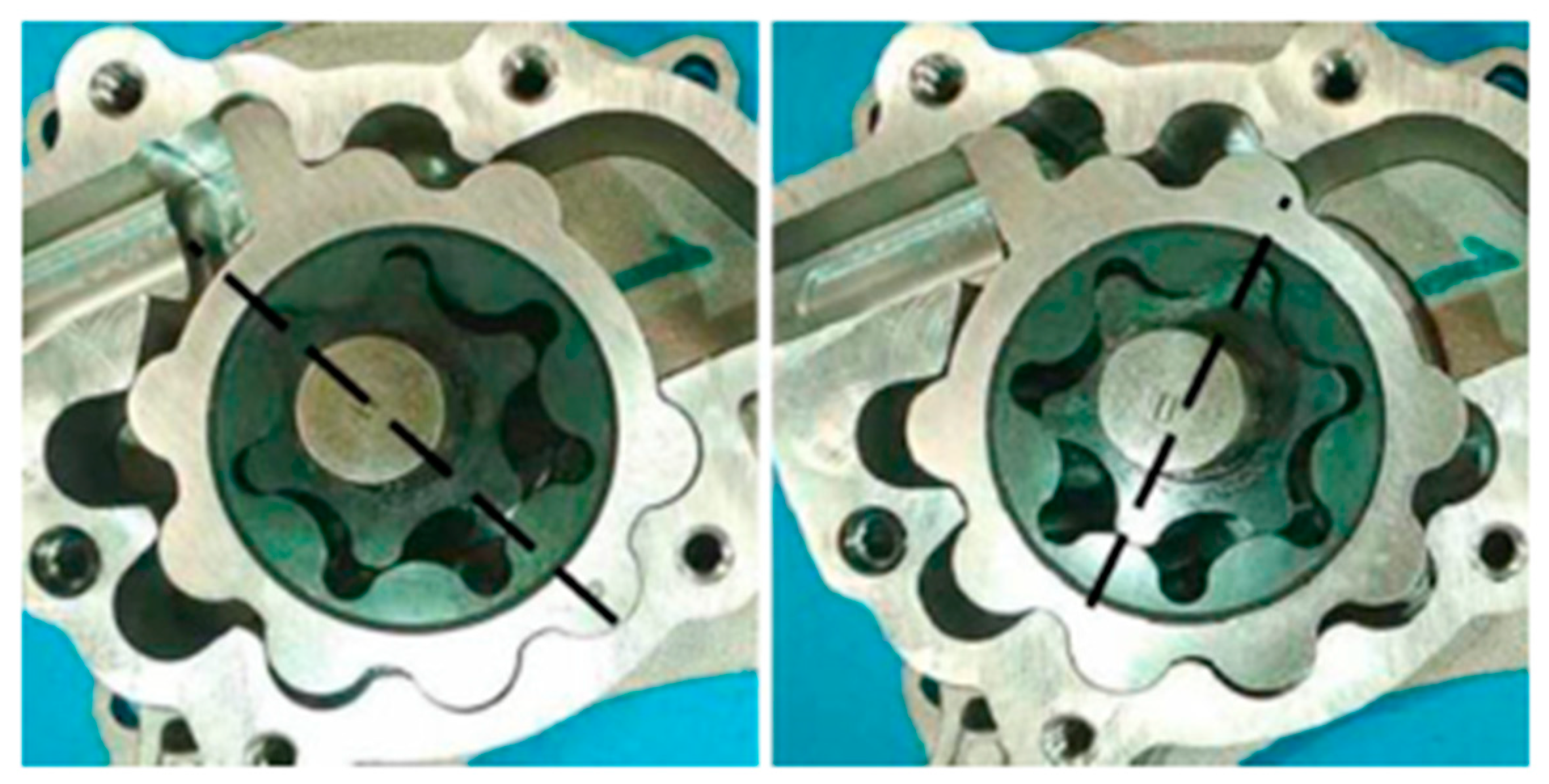

- Without a doubt, the works of Stryczek and the colleagues are fundamental in the learning of fluid power elements with non-metallic materials, and it is recommended to start with Stryczek et al. [80];

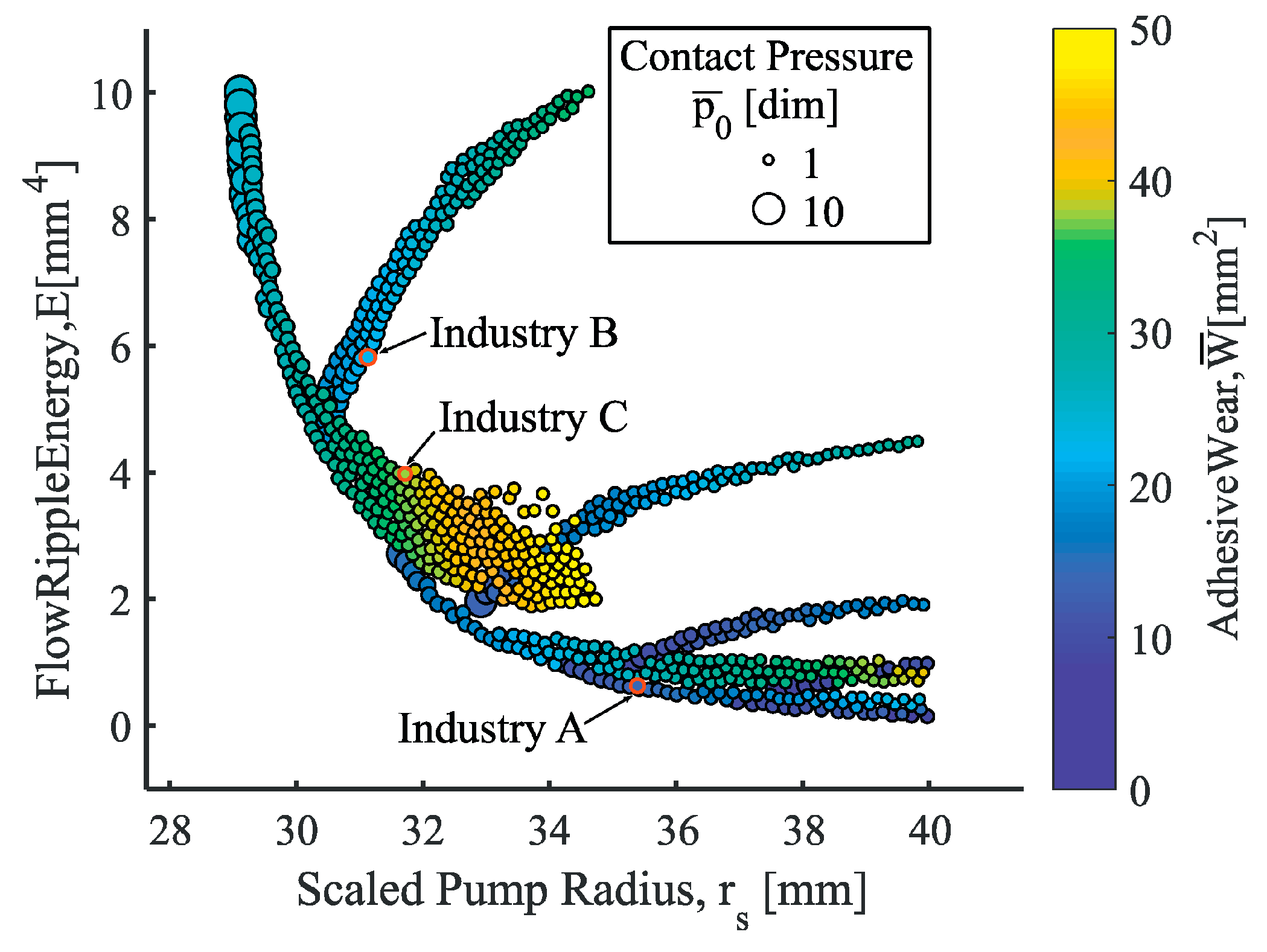

- Regarding optimization techniques, Robinson and Vacca [86] presented the most comprehensive work with circular-toothed gerotor, being the scatter matrix of feasible designs an extraordinary contribution;

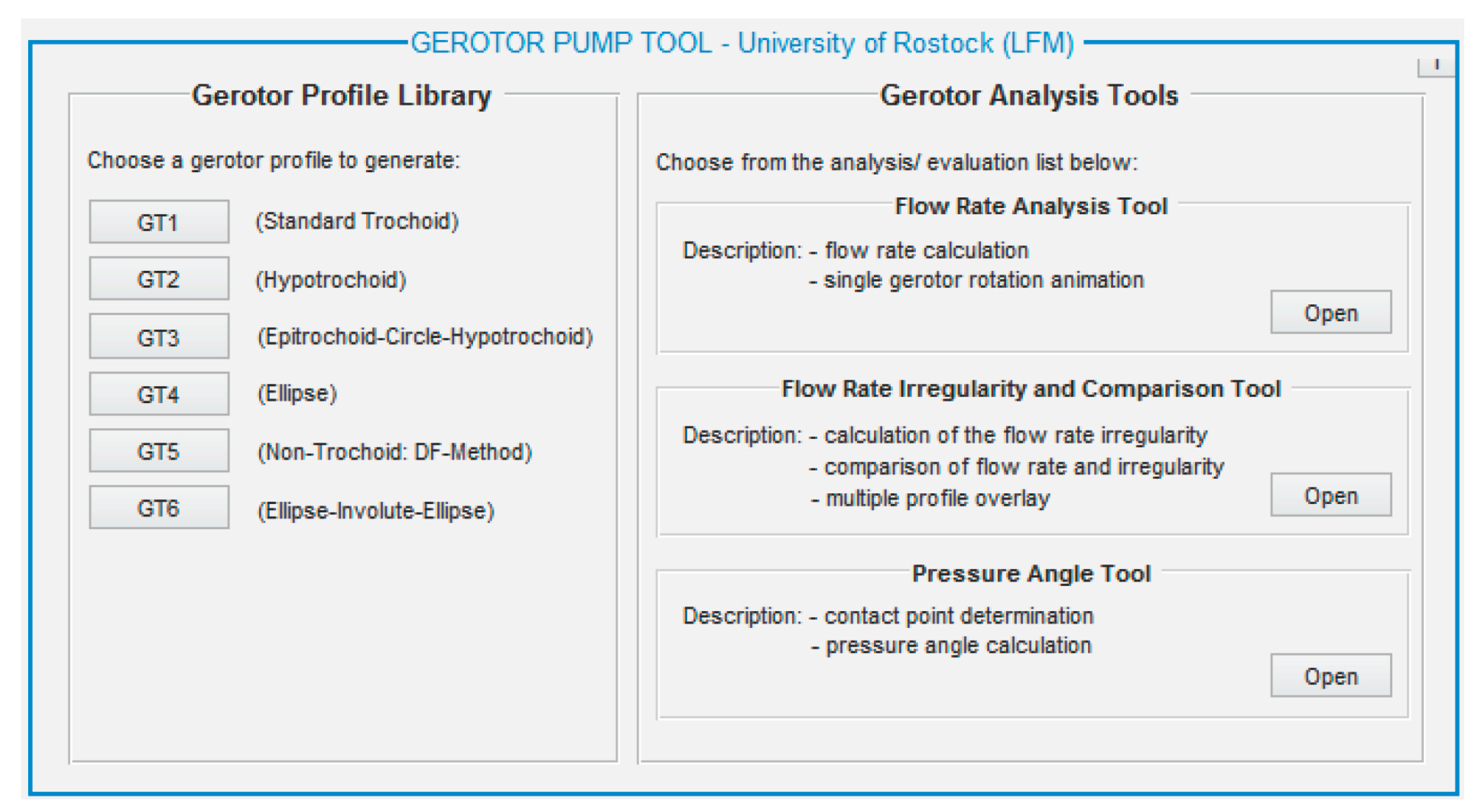

- The software techniques contribute to the design of a gerotor pump with different strategies, and it is difficult and inadvisable to highlight a specific one. The researcher has to approach each of them based on its characteristics (open access, platform, features, user-friendliness, etc.);

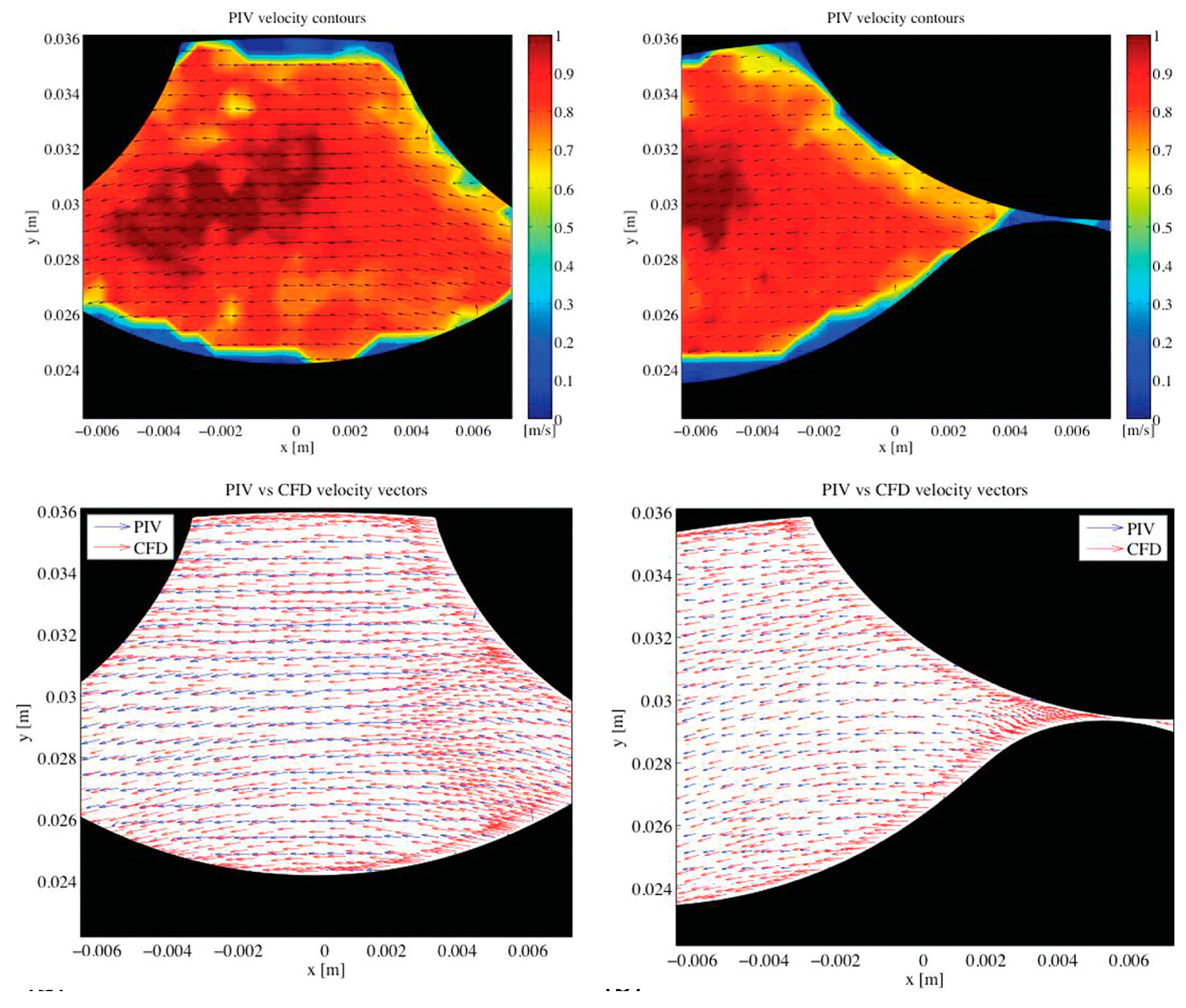

- If the attention of the research is the visualization of the cavitation phenomenon, the selected work is Antoniak and Stryczek [103]. If the attention of the research is focused on the measurement of the instantaneous flow of a gerotor pump without altering its behavior, the experimental study in Garcia-Vilchez et al. [100] is worth to be read;

4.3. Modelling and Numerical Simulation

4.3.1. Analytical Methods

4.3.2. Integrated Methods

4.3.3. CAD Methods

4.3.4. Fluid-dynamic Methods

4.3.5. Modelling and Numerical Simulation: Selected Contributions

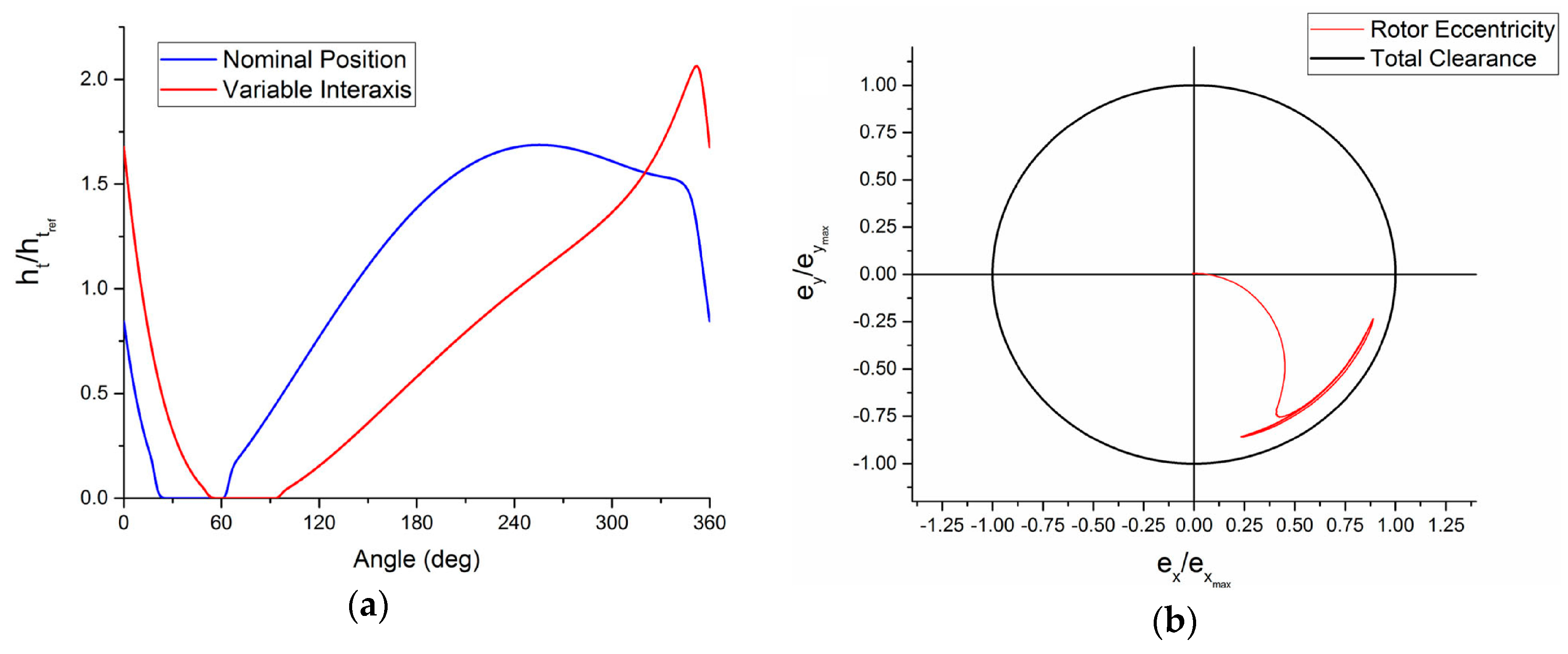

- Since integrated methods are widely used, the works presented are complex. Nevertheless, the selected contributions to the integrated approaches are Altare and Rundo [116] (the most comprehensive integrated method regarding the analysis of three commercial tools) and Pellegri et al. [118] (the best integrated method regarding the comparison with experimental work). If a modelling of the cavitation phenomenon is pursued, the works of Buono et al. [122] and Shah et al. [124] have to be studied. Finally, the work of Pellegri and Vacca [121] is the successful contribution of considering the actual position of contact points between gears, as a function of the real geometric tolerances. The experimental validation with a prototype gerotor pump probably makes this work the best contribution to the field in the last five years;

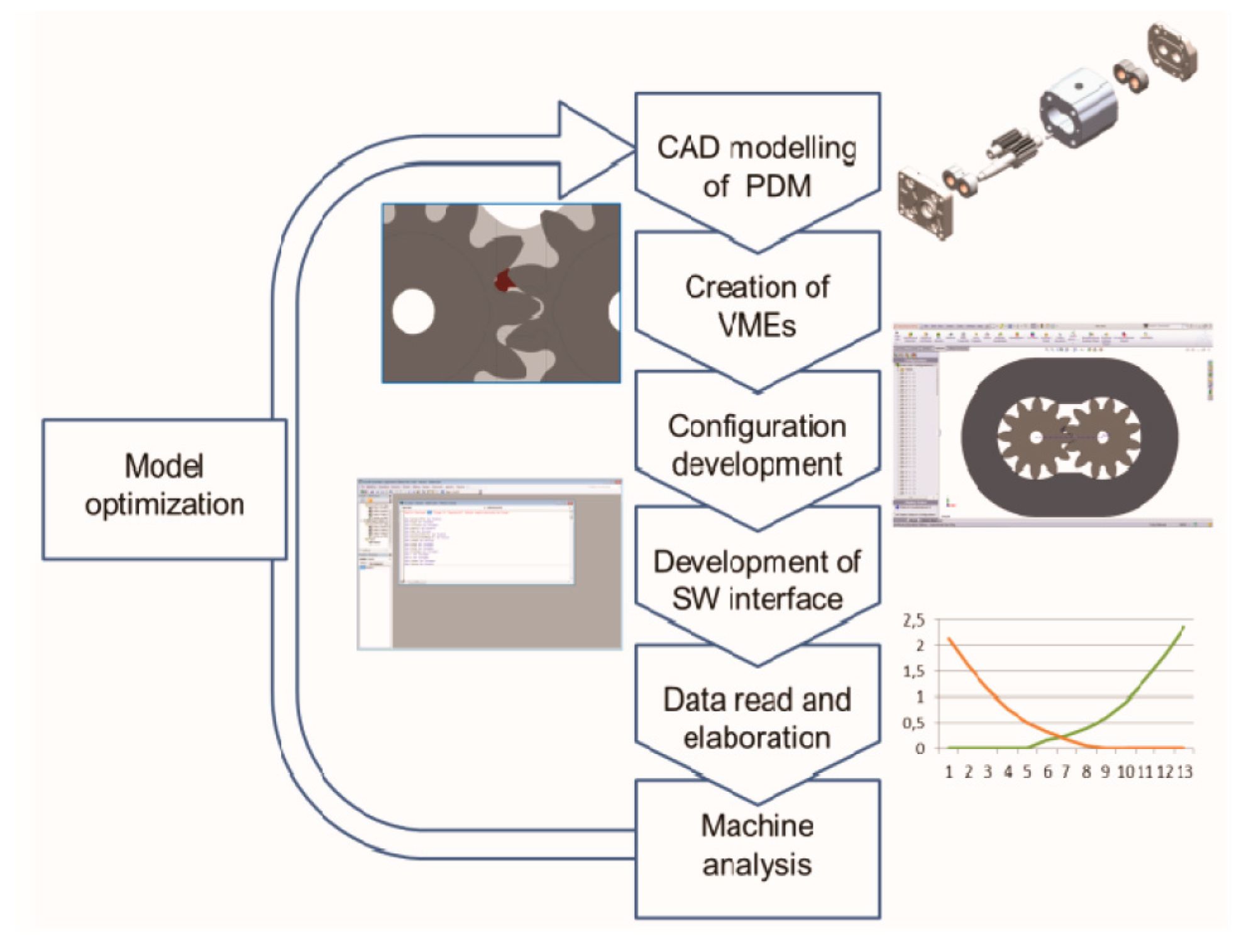

- Up to date, the work of Gherardini et al. [131] uses innovative CAD-based methods, since the geometrical data of three types of positive displacement machines, including gerotor pump, are automatically extrapolated to fluid dynamic analyses;

- With regard to the numerical simulation by using a commercial CFD software, the paper of Altare and Rundo [140] is the most comprehensive work, because it presents the compendium of main geometric characteristics influencing the volumetric performance of a gerotor pump. By using an open source CFD tool, the work of Castilla et al. [141] is the cutting-edge work by numerically simulating contact points between rotors in conjunction with an innovative deforming mesh strategy in gerotor pumps.

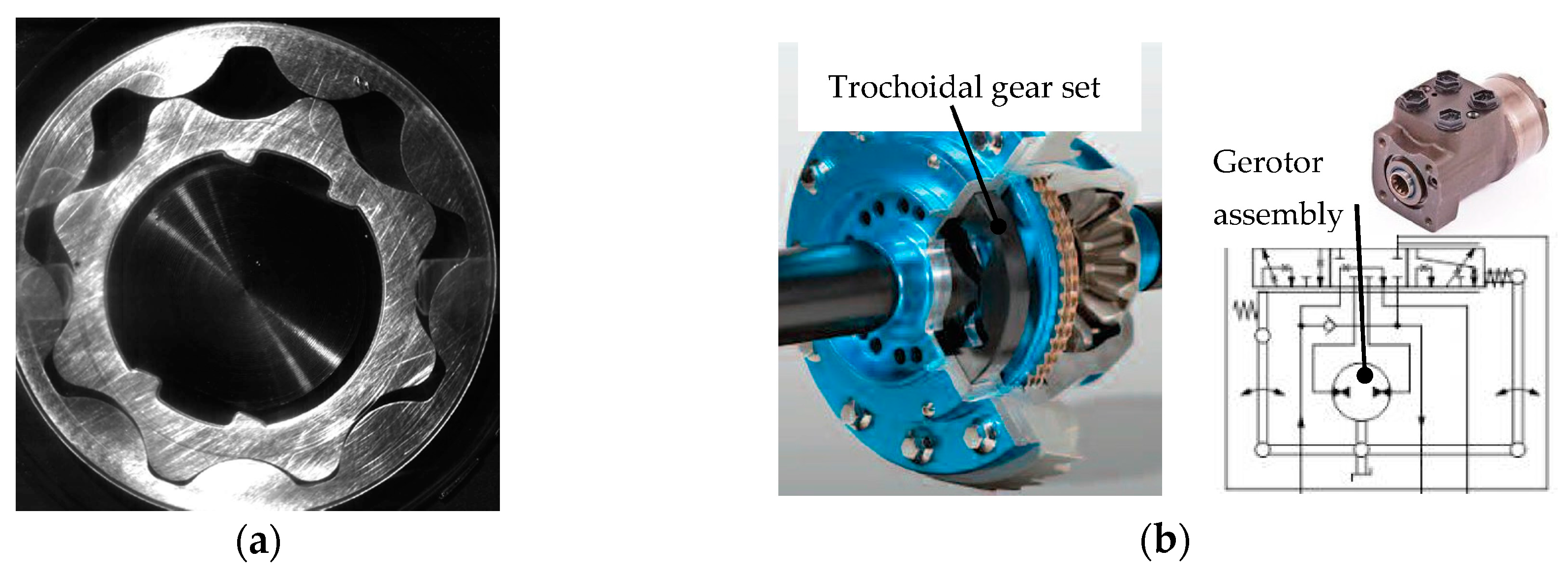

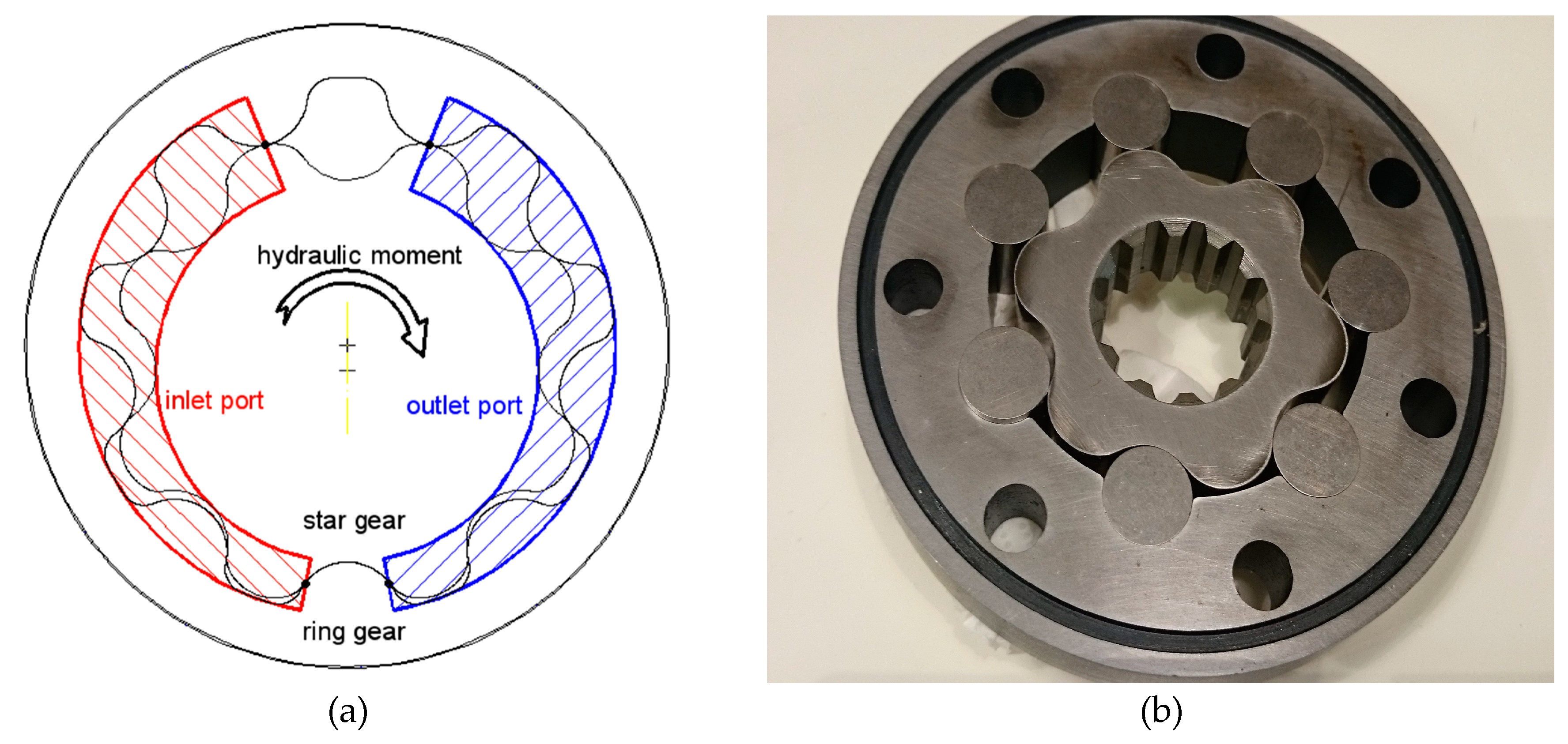

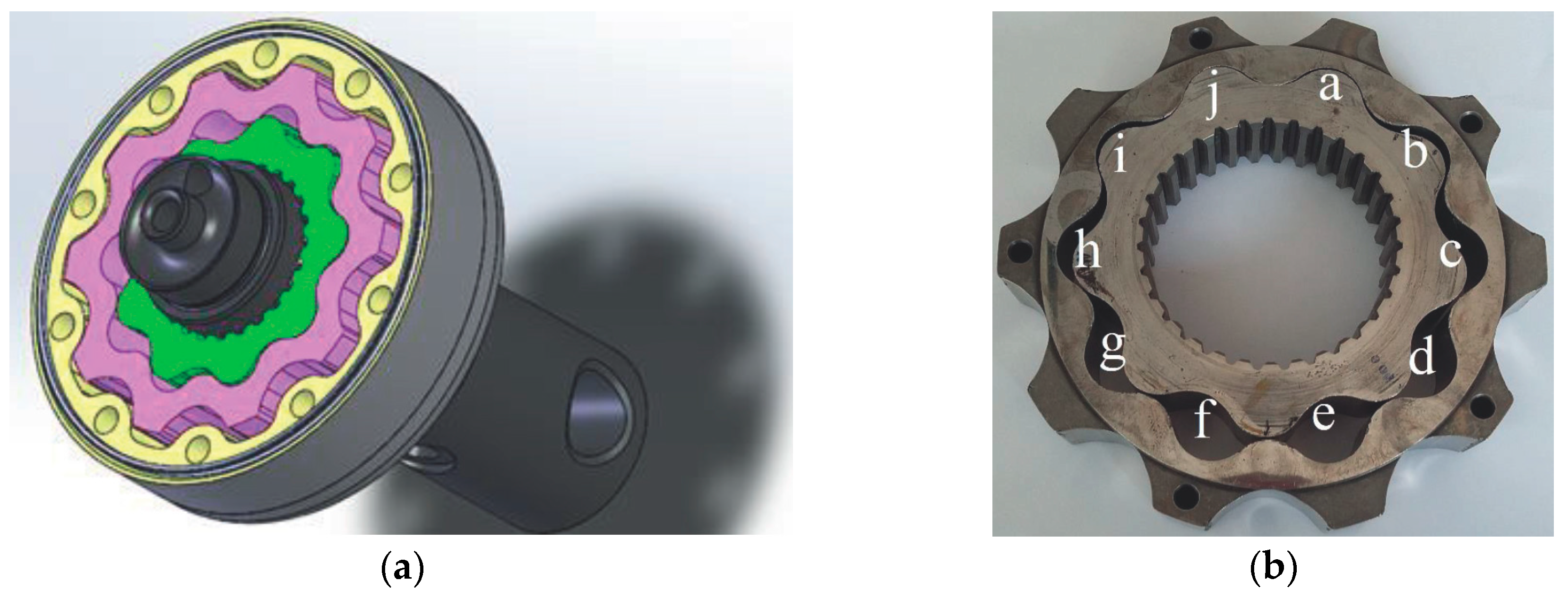

5. Hydraulic Orbital Motors

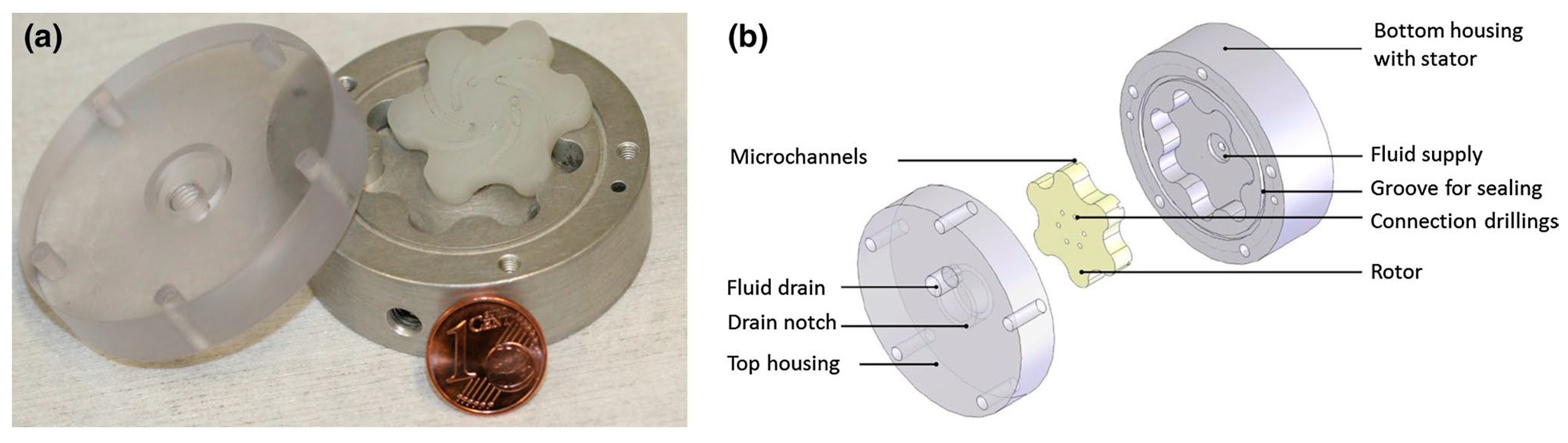

6. New Scales and Concepts in Gerotor Technology

7. Discussion

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Decade | Year | Contribution | Ref. |

|---|---|---|---|

| 1960–1969 | |||

| 1968 | Historical Background | Ansdale and Lockley [5] | |

| 1970–1979 | |||

| 1974 | Historical Background | Colbourne [6] | |

| 1976 | Historical Background | Colbourne [7] | |

| Robinson and Lyon [8] | |||

| 1980–1989 | |||

| 1988 | Historical Background | Maiti and Sinha [12] | |

| 1990–1999 | |||

| 1990 | Historical Background | Maiti and Sinha [13] | |

| 1992 | Historical Background | Beard et al. [9] | |

| 1993 | Historical Background | Maiti [14] | |

| 1994 | Historical Background | Shung and Pennock [10] | |

| 1996 | Historical Background | Stryczek [11] | |

| Dasgupta et al. [15] | |||

| 1999 | Historical Background | Fabiani et al. [17] | |

| New Scales and Concepts | Harada et al. [156] | ||

| 2000–2009 | |||

| 2000 | Historical Background | Mimmi and Pennacchi [16] | |

| Manufacturing, Clearances and Porting | Mancò et al. [61] | ||

| 2001 | Historical Background | Vecchiato et al. [19] | |

| 2002 | Historical Background | Mancò et al. [18] | |

| Demenego et al. [20]. | |||

| Ivantysyn and Ivantysynova [24] | |||

| New Scales and Concepts | Harada et al. [157] | ||

| Mancò et al. [158] | |||

| 2003 | Historical Background | Paffoni [21] | |

| New Scales and Concepts | Huber and Aktaa [160] | ||

| 2004 | Historical Background | Paffoni et al. [22] | |

| Litvin [23] | |||

| Variable Flow Development | Mancò et al. [106] | ||

| 2006 | Manufacturing, Clearances and Porting | Kim et al. [62] | |

| Visualization Techniques | Itoh et al. [97] | ||

| New Scales and Concepts | Maruo and Inoue [162] | ||

| 2007 | Conventional Profiles | Hwang and Hsieh [28] | |

| Hsieh and Hwang [29] | |||

| Manufacturing, Clearances and Porting | Chen et al. [67] | ||

| Software Techniques | Chang et al. [89] | ||

| 2008 | High Efficiency Profiles | Sasaki et al. [41] | |

| Energy, Flow, Friction and Stress Indexes Evaluation | Kwon et al. [50] | ||

| Variable Flow Development | Toyoda et al. [105] | ||

| 2009 | Conventional Profiles | Bonandrini et al. [25] | |

| Hsieh [31] | |||

| 2009 | Unconventional Profiles | Tong et al. [34] | |

| Yan et al. [35] | |||

| Software Techniques | Gamez-Montero et al. [91] | ||

| Gamez-Montero et al. [92] | |||

| Fluid-dynamic Methods | Elayaraja et al. [132] | ||

| Hydraulic Orbital Motors | Michael et al. [150] | ||

| 2010–2014* | |||

| 2010 | Conventional Profiles | Known et al. [30] | |

| Bonandrini et al. [26] | |||

| Energy, Flow, Friction and Stress Indexes Evaluation | Rundo [44] | ||

| Ivanović et al. [51] | |||

| Manufacturing, Clearances and Porting | Hsieh [63] | ||

| Materials | Biernacki and Stryczek [73] | ||

| Visualization Techniques | Antoniak [98] | ||

| Fluid-dynamic Methods | Suresh Kumar and Manonmani [133] | ||

| 2011 | Unconventional Profiles | Yang et al. [36] | |

| Jung et al. [37] | |||

| Energy, Flow, Friction and Stress Indexes Evaluation | Meira et al. [45] | ||

| Inaguma [46] | |||

| Karamooz Ravari [55] | |||

| Optimization Techniques | Kwon et al. [82] | ||

| Software Techniques | Schweiger et al. [94] | ||

| CAD Methods | Kim et al. [127] | ||

| Fluid-dynamic Methods | Ruvalcaba and Hu [134] | ||

| Hydraulic Orbital Motors | Garcia [144] | ||

| 2012 | Conventional Profiles | Bonandrini et al. [27] | |

| Hsieh [32] | |||

| Unconventional Profiles | Choi et al. [38] | ||

| High Efficiency Profiles | Yoshida et al. [42] | ||

| Energy, Flow, Friction and Stress Indexes Evaluation | Inaguma [47] | ||

| Optimization Techniques | Karamooz Ravari et al. [83] | ||

| Software Techniques | Gamez-Montero et al. [93] | ||

| Analytical Methods | Ivanović et al. [110] | ||

| CAD Methods | Carconi et al. [128] | ||

| Fluid-dynamic Methods | Gamez-Montero et al. [135] | ||

| Hydraulic Orbital Motors | Ding et al. [145] | ||

| 2013 | Energy, Flow, Friction and Stress Indexes Evaluation | Inaguma [48] | |

| Manufacturing, Clearances and Porting | Jamadar et al. [65] | ||

| Analytical Methods | Ivanović et al. [111] | ||

| Ivanović et al. [112] | |||

| Fluid-dynamic Methods | Frosina et al. [136] | ||

| Hydraulic Orbital Motors | Nag and Maiti [146] | ||

| New Scales and Concepts | O’Sea et al. [165] | ||

| 2014 | Conventional Profiles | Liu et al. [33] | |

| Materials | Biernacki [74] | ||

| Stryczek et al. [75] | |||

| Stryczek et al. [77] | |||

| Krawczyk and Stryczek [78] | |||

| CAD Methods | Jeong et al. [126] | ||

| Prakash and Manjula [129] | |||

| Fluid-dynamic Methods | Frosina et al. [137] | ||

| New Scales and Concepts | Leester-Schädel et al. [161] | ||

| Malvasi et al. [163] | |||

| Heisel and Mishev [164] | |||

| 2015–2019* | |||

| 2015 | Unconventional Profiles | Bae and Kim [39] | |

| Manufacturing, Clearances and Porting | Hsieh [64] | ||

| Materials | Biernacki [76] | ||

| Software Techniques | Klopsch et al. [95] | ||

| Visualization Techniques | Stryczek et al. [99] | ||

| Garcia-Vilchez et al. [100] | |||

| Variable Flow Development | Avery and Johnston [109] | ||

| Integrated Methods | Frosina et al. [114] | ||

| Hussain et al. [115] | |||

| CAD Methods | Moetakef and Zouani [130] | ||

| Fluid-dynamic Methods | Hsieh [138] | ||

| Sang et al. [139] | |||

| Hydraulic Orbital Motors | Maiti et al. [147] | ||

| Furustig et al. [149] | |||

| 2016 | Unconventional Profiles | Hao et al. [40] | |

| High Efficiency Profiles | Arinaga et al. [43] | ||

| Energy, Flow, Friction and Stress Indexes Evaluation | Kamal et al. [49] | ||

| Ivanović [52] | |||

| Ivanović et al. [53] | |||

| Ivanović et al. [54] | |||

| Jacazio et al. [56] | |||

| Kwak et al. [57] | |||

| O’Shea [59] | |||

| Manufacturing, Clearances and Porting | Harrison et al. [66] | ||

| Kwak et al. [70] | |||

| Materials | Krawczyk and Stryczek [79] | ||

| Software Techniques | Bae et al. [90] | ||

| Visualization Techniques | Sahoo et al. [102] | ||

| Integrated Methods | Pellegri et al. [118] | ||

| Pellegri et al. [119] | |||

| Buono et al. [122] | |||

| CAD Methods | Gherardini et al. [131] | ||

| Fluid-dynamic Methods | Altare and Rundo [140] | ||

| Gamez-Montero et al. [142] | |||

| Hydraulic Orbital Motors | Bigliardi et al. [148] | ||

| Furustig et al. [151] | |||

| 2017 | Energy, Flow, Friction and Stress Indexes Evaluation | Siano et al. [60] | |

| Manufacturing, Clearances and Porting | Kwak et al. [71] | ||

| Materials | Stryczek et al. [80] | ||

| Mancini et at. [81] | |||

| Optimization Techniques | Ivanović et al. [84] | ||

| Ivanović et al. [85] | |||

| Software Techniques | Zhang et al. [96] | ||

| Visualization Techniques | Raush et al. [101] | ||

| Variable Flow Development | Yamamoto et al. [107] | ||

| Integrated Methods | Altare and Rundo [116] | ||

| Fangwei et al. [117] | |||

| Pellegri and Vacca [120] | |||

| Pellegri and Vacca [121] | |||

| Buono et al. [123] | |||

| Shah et al. [124] | |||

| Fluid-dynamic Methods | Castilla et al. [141] | ||

| New Scales and Concepts | Gamez-Montero et al. [159] | ||

| Gamez-Montero et al. [166] | |||

| 2018 | Energy, Flow, Friction and Stress Indexes Evaluation | Lee et al. [58] | |

| Manufacturing, Clearances and Porting | Ham et al. [68] | ||

| Sung et al. [69] | |||

| Gamez-Montero et al. [72] | |||

| Optimization Techniques | Robinson and Vacca [86] | ||

| Visualization Techniques | Antoniak and Stryczek [103] | ||

| Antoniak et al. [104] | |||

| Variable Flow Development | Nishida et al. [108] | ||

| Analytical Methods | Ivanović et al. [113] | ||

| Fluid-dynamic Methods | Gamez-Montero et al. [143] | ||

| Hydraulic Orbital Motors | Bates et al. [152] | ||

| Strmčnik and Majdič [153,154] | |||

| Zardin et al. [155] | |||

| 2019 | Optimization Techniques | Robinson and Vacca [87] | |

| De Martin et al. [88] | |||

| Integrated Methods | Singh et al. [125] |

| Approach | Contribution | Year | Ref. |

|---|---|---|---|

| Historical | |||

| Historical Background | 1968 | Ansdale and Lockley [5] | |

| 1974 | Colbourne [6] | ||

| 1976 | Colbourne [7] | ||

| Robinson and Lyon [8] | |||

| 1988 | Maiti and Sinha [12] | ||

| 1990 | Maiti and Sinha [13] | ||

| 1992 | Beard et al. [9] | ||

| 1993 | Maiti [14] | ||

| 1994 | Shung and Pennock [10] | ||

| 1996 | Stryczek [11] | ||

| Dasgupta et al. [15] | |||

| 1999 | Fabiani et al. [17] | ||

| 2000 | Mimmi and Pennacchi [16] | ||

| 2001 | Vecchiato et al. [19] | ||

| 2002 | Mancò et al. [18] | ||

| Demenego et al. [20]. | |||

| Ivantysyn and Ivantysynova [24] | |||

| 2003 | Paffoni [21] | ||

| 2004 | Paffoni et al. [22] | ||

| Litvin [23] | |||

| Geometric | |||

| Conventional Profiles | 2007 | Hwang and Hsieh [28] | |

| Hsieh and Hwang [29] | |||

| 2009 | Bonandrini et al. [25] | ||

| Hsieh [31] | |||

| 2010 | Known et al. [30] | ||

| Bonandrini et al. [26] | |||

| 2012 | Bonandrini et al. [27] | ||

| Hsieh [32] | |||

| 2015 | Liu et al. [33] | ||

| Unconventional Profiles | 2009 | Tong et al. [34] | |

| Yan et al. [35] | |||

| 2011 | Yang et al. [36] | ||

| Jung et al. [37] | |||

| 2012 | Choi et al. [38] | ||

| 2015 | Bae and Kim [39] | ||

| 2016 | Hao et al. [40] | ||

| High Efficiency Profiles | 2008 | Sasaki et al. [41] | |

| 2012 | Yoshida et al. [42] | ||

| 2016 | Arinaga et al. [43] | ||

| Performance | |||

| Energy, Flow, Friction and Stress Indexes Evaluation | 2008 | Kwon et al. [50] | |

| 2010 | Rundo [44] | ||

| Ivanović et al. [51] | |||

| 2011 | Meira et al. [45] | ||

| Inaguma [46] | |||

| Karamooz Ravari [55] | |||

| 2012 | Inaguma [47] | ||

| 2013 | Inaguma [48] | ||

| 2016 | Kamal et al. [49] | ||

| Ivanović [52] | |||

| Ivanović et al. [53] | |||

| Ivanović et al. [54] | |||

| Jacazio et al. [56] | |||

| Kwak et al. [57] | |||

| O’Shea [59] | |||

| 2017 | Siano et al. [60] | ||

| 2018 | Lee et al. [58] | ||

| Manufacturing, Clearances and Porting | 2000 | Mancò et al. [61] | |

| 2006 | Kim et al. [62] | ||

| 2007 | Chen et al. [67] | ||

| 2010 | Hsieh [63] | ||

| 2013 | Jamadar et al. [65] | ||

| 2015 | Hsieh [64] | ||

| 2016 | Harrison et al. [66] | ||

| Kwak et al. [70] | |||

| 2017 | Kwak et al. [71] | ||

| 2018 | Ham et al. [68] | ||

| Sung et al. [69] | |||

| Gamez-Montero et al. [72] | |||

| Materials | 2010 | Biernacki and Stryczek [73] | |

| 2014 | Biernacki [74] | ||

| Stryczek et al. [75] | |||

| Stryczek et al. [77] | |||

| Krawczyk and Stryczek [78] | |||

| 2015 | Biernacki [76] | ||

| 2016 | Krawczyk and Stryczek [79] | ||

| 2017 | Stryczek et al. [80] | ||

| Mancini et at. [81] | |||

| Optimization Techniques | 2011 | Kwon et al. [82] | |

| 2012 | Karamooz Ravari et al. [83] | ||

| 2017 | Ivanović et al. [84,85] | ||

| 2018 | Robinson and Vacca [86] | ||

| 2019 | Robinson and Vacca [87] | ||

| De Martin et al. [88] | |||

| Software Techniques | 2007 | Chang et al. [89] | |

| 2009 | Gamez-Montero et al. [91] | ||

| Gamez-Montero et al. [92] | |||

| 2011 | Schweiger et al. [94] | ||

| 2012 | Gamez-Montero et al. [93] | ||

| 2015 | Klopsch et al. [95] | ||

| 2016 | Bae et al. [90] | ||

| 2017 | Zhang et al. [96] | ||

| Visualization Techniques | 2006 | Itoh et al. [97] | |

| 2010 | Antoniak [98] | ||

| 2015 | Stryczek et al. [99] | ||

| Garcia-Vilchez et al. [100] | |||

| 2017 | Raush et al. [101] | ||

| 2016 | Sahoo et al. [102] | ||

| 2018 | Antoniak and Stryczek [103] | ||

| Antoniak et al. [104] | |||

| Variable Flow Development | 2004 | Mancò et al. [106] | |

| 2008 | Toyoda et al. [105] | ||

| 2015 | Avery and Johnston [109] | ||

| 2017 | Yamamoto et al. [107] | ||

| 2018 | Nishida et al. [108] | ||

| Modelling and Numerical Simulation | |||

| Analytical Methods | 2012 | Ivanović et al. [110] | |

| 2013 | Ivanović et al. [111,112] | ||

| 2018 | Ivanović et al. [113] | ||

| Integrated Methods | 2015 | Frosina et al. [114] | |

| Hussain et al. [115] | |||

| 2016 | Pellegri et al. [118,119] | ||

| Buono et al. [122] | |||

| 2017 | Altare and Rundo [116] | ||

| Fangwei et al. [117] | |||

| Pellegri and Vacca [120,121] | |||

| Buono et al. [123] | |||

| Shah et al. [124] | |||

| 2019 | Singh et al. [125] | ||

| CAD Methods | 2011 | Kim et al. [127] | |

| 2012 | Carconi et al. [128] | ||

| 2014 | Jeong et al. [126] | ||

| Prakash and Manjula [129] | |||

| 2015 | Moetakef and Zouani [130] | ||

| 2016 | Gherardini et al. [131] | ||

| Fluid-dynamic Methods | 2009 | Elayaraja et al. [132] | |

| 2010 | Suresh Kumar and Manonmani [133] | ||

| 2011 | Ruvalcaba and Hu [134] | ||

| 2012 | Gamez-Montero et al. [135] | ||

| 2013 | Frosina et al. [136] | ||

| 2014 | Frosina et al. [137] | ||

| 2015 | Hsieh [138] | ||

| Sang et al. [139] | |||

| 2016 | Altare and Rundo [140] | ||

| Gamez-Montero et al. [142] | |||

| 2017 | Castilla et al. [141] | ||

| 2018 | Gamez-Montero et al. [143] | ||

| Hydraulic Orbital Motors | Hydraulic Orbital Motors | 2009 | Michael et al. [150] |

| 2011 | Garcia [144] | ||

| 2012 | Ding et al. [145] | ||

| 2013 | Nag and Maiti [146] | ||

| 2015 | Maiti et al. [147] | ||

| Furustig et al. [149] | |||

| 2016 | Bigliardi et al. [148] | ||

| Furustig et al. [151] | |||

| 2018 | Bates et al. [152] | ||

| 2018 | Strmčnik and Majdič [153,154] | ||

| Zardin et al. [155] | |||

| New Scales and Concepts | New Scales and Concepts | 1999 | Harada et al. [156] |

| 2002 | Harada et al. [157] | ||

| Mancò et al. [158] | |||

| 2003 | Huber and Aktaa [160] | ||

| 2006 | Maruo and Inoue [162] | ||

| 2013 | O’Sea et al. [165] | ||

| 2014 | Leester-Schädel et al. [161] | ||

| 2014 | Malvasi et al. [163] | ||

| Heisel and Mishev [164] | |||

| 2017 | Gamez-Montero et al. [159] | ||

| Gamez-Montero et al. [166] |

References

- Rundo, M.; Nervegna, N. Lubrication Pumps for Internal Combustion Engines: A Review. Int. J. Fluid Power 2015, 16, 59–74. [Google Scholar] [CrossRef]

- Rundo, M. Models for flow rate simulation in gear pumps: A review. Energies 2017, 10, 1261. [Google Scholar] [CrossRef]

- Miladinović, S.; Ivanović, L.; Blagojević, M.; Stojanović, B. The development of magnetic gears for transportation applications. Mobil. Veh. Mech. 2017, 43, 41–55. [Google Scholar] [CrossRef]

- Vacca, A. Energy efficiency and controllability of fluid power systems. Energies 2018, 11, 1169. [Google Scholar] [CrossRef]

- Ansdale, R.F.; Lockley, D.J. The Wankel RC Engine Design and Performance; London Iliffe Books: London, UK, 1968. [Google Scholar]

- Colbourne, J.R. The geometry of trochoid envelopes and their application in rotary pumps. Mech. Mach. Theory 1974, 9, 421–435. [Google Scholar] [CrossRef]

- Colbourne, J.R. Reduction of contact stress in internal gear pumps. J. Eng. Ind. 1976, 98, 1296–1300. [Google Scholar] [CrossRef]

- Robinson, F.J.; Lyon, J.R. An analysis of epitrochoidal profiles with constant difference modification suitable for rotary expanders and pumps. J. Manuf. Sci. Eng. Trans. ASME 1976, 98, 161–165. [Google Scholar] [CrossRef]

- Beard, J.E.; Yannitell, D.W.; Pennock, G.R. The effects of the generating pin size and placement on the curvature and displacement of epitrochoidal gerotors. Mech. Mach. Theory 1992, 27, 373–389. [Google Scholar] [CrossRef]

- Shung, J.B.; Pennock, G.R. Geometry for trochoidal-type machines with conjugate envelopes. Mech. Mach. Sci. 1994, 29, 25–42. [Google Scholar] [CrossRef]

- Stryczek, J. Hydraulic machines with cycloidal gearing. Archiwum Budowy Maszyn 1996, 43, 29–71. [Google Scholar]

- Maiti, R.; Sinha, G.L. Kinematics of active contact in modified epitrochoid generated rotary piston machines. Mech. Mach. Theory 1988, 23, 39–45. [Google Scholar] [CrossRef]

- Maiti, R.; Sinha, G.L. Limits on modification of epitrochoid used in rotary piston machines and the effects of modification on geometric volume displacement and ripple. Ingenieur-Archiv 1990, 60, 183–194. [Google Scholar] [CrossRef]

- Maiti, R. Torque characteristics of epitrochoid generated orbital rotary piston type hydraulic motors. Mech. Mach. Theory 1993, 28, 225–231. [Google Scholar] [CrossRef]

- Dasgupta, K.; Mukherjee, A.; Maiti, R. Theoretical and experimental studies of the steady state performance of an orbital rotor low-speed high-torque hydraulic motor. Proc. Inst. Mech. Eng. A 1996, 210, 423–429. [Google Scholar] [CrossRef]

- Mimmi, G.C.; Pennacchi, P.E. Non-undercutting conditions in internal gears. Mech. Mach. Theory 2000, 35, 477–490. [Google Scholar] [CrossRef]

- Fabiani, M.; Mancò, S.; Nervegna, N.; Rundo, M. Modelling and simulation of gerotor gearing in lubricating oil pumps. SAE Trans. J. Engines 1999, 108, 989–1003. [Google Scholar]

- Mancò, S.; Nervegna, N.; Rundo, M. A contribution to the design of hydraulic lube pumps. Int. J. Fluid Power 2002, 3, 21–32. [Google Scholar] [CrossRef]

- Vecchiato, D.; Demenego, A.; Argyris, J.; Litvin, F.L. Geometry of a cycloidal pump. Comput. Methods Appl. Mech. Eng. 2001, 190, 2309–2330. [Google Scholar] [CrossRef]

- Demenego, A.; Vecchiato, D.; Litvin, F.L.; Nervegna, N.; Mancó, S. Design and simulation of meshing of a cycloidal pump. Mech. Mach. Theory 2002, 37, 311–332. [Google Scholar] [CrossRef]

- Paffoni, B. Pressure and film thickness in a trochoidal hydrostatic gear pump. Proc. Inst. Mech. Eng. G 2003, 217, 179–187. [Google Scholar] [CrossRef]

- Paffoni, B.; Progri, R.; Gras, R. Teeth clearance effects upon pressure and film thickness in a trochoidal hydrostatic gear pump. Proc. Inst. Mech. Eng. G 2004, 218, 247–256. [Google Scholar] [CrossRef]

- Litvin, F.L.; Fuentes, A. Gear Geometry and Applied Theory, 2nd ed.; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar]

- Ivantysyn, J.; Ivantysynova, M. Hydrostatic Pumps and Motors, Principles, Designs, Performance, Modelling, Analysis, Control and Testing; Akademia Books International: New Delhi, India, 2002. [Google Scholar]

- Bonandrini, G.; Mimmi, G.; Rottenbacher, C. Theoretical analysis of internal epitrochoidal and hypotrochoidal machines. Proc. Inst. Mech. Eng. C 2009, 223, 1469–1480. [Google Scholar] [CrossRef]

- Bonandrini, G.; Mimmi, G.; Rottenbacher, C. Theoretical Analysis of an Original Rotary Machine. J. Mech. Des. 2010, 132, 024501. [Google Scholar] [CrossRef]

- Bonandrini, G.; Mimmi, G.; Rottenbacher, C. Design and simulation of meshing of a particular internal rotary pump. Mech. Mach. Theory 2012, 49, 104–116. [Google Scholar] [CrossRef]

- Hwang, Y.-W.; Hsieh, C.-F. Geometric design using hypotrochoid and nonundercutting conditions for an internal cycloidal gear. J. Mech. Des. 2007, 129, 413–420. [Google Scholar] [CrossRef]

- Hsieh, C.-F.; Hwang, Y.-W. Geometric design for a gerotor pump with high area efficiency. J. Mech. Des. 2007, 129, 1269–1277. [Google Scholar] [CrossRef]

- Kwon, S.-M.; Kang, H.S.; Shin, J.-H. Rotor profile design in a hypogerotor pump. J. Mech. Sci. Technol. 2010, 23, 3459–3470. [Google Scholar] [CrossRef]

- Hsieh, C.-F. Influence of gerotor performance in varied geometrical design parameters. J. Mech. Des. 2009, 131, 121008. [Google Scholar] [CrossRef]

- Hsieh, C.F. Fluid and dynamics analyses of a gerotor pump using various span angle designs. J. Mech. Des. 2012, 134, 121003. [Google Scholar] [CrossRef]

- Liu, H.; Lee, J.-C.; Yoon, A.; Kim, S.-T. Profile design and numerical calculation of instantaneous flow rate of a gerotor pump. J. Appl. Math. Phys. 2015, 3, 92–97. [Google Scholar] [CrossRef]

- Tong, S.-H.; Yan, J.; Yang, D.C.H. Design of deviation-function based gerotors. Mech. Mach. Theory 2009, 44, 1595–1606. [Google Scholar] [CrossRef]

- Yan, J.; Yang, D.C.H.; Tong, S.H. A new gerotor design method with switch angle assignability. J. Mech. Des. 2009, 131, 239–246. [Google Scholar] [CrossRef]

- Yang, D.C.H.; Yan, J.; Tong, S.-H. Flowrate formulation and displacement analyses for deviation function-based gerotor pumps. Proc. Inst. Mech. Eng. C 2011, 225, 480–487. [Google Scholar] [CrossRef]

- Jung, S.-Y.; Bae, J.-H.; Kim, M.-S.; Kim, C. Development of a new gerotor for oil pumps with multiple profiles. Int. J. Precis. Eng. Manuf. 2011, 12, 835–841. [Google Scholar] [CrossRef]

- Choi, T.H.; Kim, M.S.; Lee, G.S.; Jung, S.Y.; Bae, J.H.; Kim, C. Design of rotor for internal gear pump using cycloid and circular-arc curves. J. Mech. Des. 2012, 134, 011005. [Google Scholar] [CrossRef]

- Bae, J.-H.; Kim, C. Design of rotor profile of internal gear pump for improving fuel efficiency. Int. J. Precis. Eng. Manuf. 2015, 16, 113–120. [Google Scholar] [CrossRef]

- Hao, C.; Wenming, Y.; Guangming, L. Design of gerotor oil pump with new rotor profile for improving performance. Proc. Inst. Mech. Eng. C 2016, 230, 592–601. [Google Scholar] [CrossRef]

- Sasaki, H.; Inui, N.; Shimada, Y.; Ogata, D. Development of High Efficiency P/M Internal Gear Pump Rotor (Megafloid Rotor). SEI Tech. Rev. 2008, 66, 124–128. [Google Scholar]

- Yoshida, K.; Uozumi, M.; Shimada, Y.; Kosuge, T. Development of Continuously Variable Discharge Oil Pump. SEI Tech. Rev. 2012, 74, 43–47. [Google Scholar]

- Arinaga, S.; Yoshida, K.; Takada, S.; Noda, M.; Inoue, K. The latest trends in oil pump rotors for automobiles. SEI Tech. Rev. 2016, 82, 59–65. [Google Scholar]

- Rundo, M. Energy Consumption in ICE Lubricating Gear Pumps; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Meira, J.; Filho, A.; Melo, W.; Ribeiro, E. Strategies for Energy Savings with Use of Constant and Variable Oil Pump Systems; SAE Technical Papers 2011-36-0150; SAE International: Warrendale, PA, USA, 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Inaguma, Y. Friction torque characteristics of an internal gear pump. Proc. Inst. Mech. Eng. C 2011, 225, 1523–1534. [Google Scholar] [CrossRef]

- Inaguma, Y. Oil temperature influence on friction torque characteristics in hydraulic pumps. Proc. Inst. Mech. Eng. C 2012, 226, 2267–2280. [Google Scholar] [CrossRef]

- Inaguma, Y. A practical approach for analysis of leakage flow characteristics in hydraulic pumps. Proc. Inst. Mech. Eng. C 2013, 227, 980–991. [Google Scholar] [CrossRef]

- Kamal, A.; Kaundabalaraman, K.; Rathi, H.; Muley, A. Design Analysis & Parametric Optimization of Gerotor Oil Pump for Improving Volumetric Efficiency; SAE Technical Papers 2016-28-0113; SAE International: Warrendale, PA, USA, 2016; pp. 1–10. [Google Scholar] [CrossRef]

- Kwon, S.-M.; Kim, C.-H.; Shin, J.-H. Analytical wear model of a gerotor pump without hydrodynamic effect. J. Adv. Mech. Des. Syst. Manuf. 2008, 2, 230–237. [Google Scholar] [CrossRef]

- Ivanović, L.; Devedžić, G.; Mirić, N.; Ćuković, S. Analysis of forces and moments in gerotor pumps. Proc. Inst. Mech. Eng. C 2010, 224, 2257–2269. [Google Scholar] [CrossRef]

- Ivanović, L. Reduction of the maximum contact stresses by changing geometric parameters of the trochoidal gearing teeth profile. Meccanica 2016, 51, 2243–2257. [Google Scholar] [CrossRef]

- Ivanović, L.; Rakić, B.; Stojanović, B.; Matejić, M. Comparative analysis of analytical and numerical calculations of contact stresses at rotational elements of gerotor pumps. Appl. Eng. Lett. 2016, 1, 1–7. [Google Scholar]

- Ivanović, L.; Mackić, T.; Stojanović, B. Analysis of the instantaneous friction coefficient of the trochoidal gear pair. J. Balk. Tribol. Assoc. 2016, 22, 281–293. [Google Scholar]

- Karamooz Ravari, M.R. Elliptical lobe shape gerotor pump design to minimize wear. Front. Mech. Eng. 2011, 6, 429–434. [Google Scholar] [CrossRef]

- Jacazio, G.; De Martin, A. Influence of rotor profile geometry on the performance of an original low-pressure gerotor pump. Mech. Mach. Theory 2016, 100, 296–312. [Google Scholar] [CrossRef]

- Kwak, H.-S.; Li, S.-H.; Kim, C. Optimal design of the gerotor (2-ellipses) for reducing maximum contact stress. J. Mech. Sci. Technol. 2016, 30, 5595–5603. [Google Scholar] [CrossRef]

- Lee, M.-C.; Kwak, H.-S.; Seong, H.-S.; Kim, C. A Study on Theoretical Flowrate of Gerotor Pump Using Chamber Areas. Int. J. Precis. Eng. Manuf. 2018, 19, 1385–1392. [Google Scholar] [CrossRef]

- O’Shea, C. Hydraulic Flow Ripple Cancellation Using the Primary Flow Source. In Proceedings of the BATH/ASME 2016 Symposium on Fluid Power and Motion Control, American Society of Mechanical Engineers, Bath, UK, 7–9 September 2016. [Google Scholar] [CrossRef]

- Siano, D.; Frosina, E.; Senatore, A. Diagnostic Process by Using Vibrational Sensors for Monitoring Cavitation Phenomena in a Getoror Pump Used for Automotive Applications. Energy Procedia 2017, 126, 1115–1122. [Google Scholar] [CrossRef]

- Mancò, S.; Nervegna, N.; Rundo, M. Effects of Timing and Odd/Even Number of Teeth on Noise Generation of Gerotor Lubricating Pumps for IC Engines; SAE Technical Papers 2000-01-2630; SAE International: Warrendale, PA, USA, 2000; pp. 109–118. [Google Scholar] [CrossRef]

- Kim, S.-Y.; Nam, Y.-J.; Park, M.-K. Design of port plate in gerotor pump for reduction of pressure pulsation. J. Mech. Sci. Technol. 2006, 20, 1626–1637. [Google Scholar] [CrossRef]

- Hsieh, C.-F. Non-undercutting region and property evaluation of epitrochoidal gerotor geometry. Proc. Inst. Mech. Eng. C 2010, 224, 473–481. [Google Scholar] [CrossRef]

- Hsieh, C.F. Flow characteristics of gerotor pumps with novel variable clearance designs. J. Fluid. Eng. 2015, 137, 041107. [Google Scholar] [CrossRef]

- Jamadar, M.; Jose, A.; Ramdasi, S.S.; Marathe, N.V. Development of In-House Competency to Build Compact Gerotor Oil Pump for High Speed Diesel Engine Application; SAE Technical Papers 2013-01-2738; SAE International: Warrendale, PA, USA, 2013; pp. 1–13. [Google Scholar] [CrossRef]

- Harrison, J.; Aihara, R.; Eisele, F. Modeling Gerotor Oil Pumps in 1D to Predict Performance with Known Operating Clearances. SAE Int. J. Engines 2016, 9, 1839–1846. [Google Scholar] [CrossRef]

- Chen, T.-T.; Wang, J.-P.; Huang, G.-M.; Hsu, M.-H.; Chen, C.-L.; Hong, B.-W.; Wey, J.-M. High-precision technology with negative punch clearance for the manufacturing of a cycloid pump. Int. J. Adv. Manuf. Technol. 2007, 95, 1179–1183. [Google Scholar] [CrossRef]

- Ham, J.; Kim, S.; Oh, J.; Cho, H. Theoretical investigation of the effect of a relief groove on the performance of a gerotor oil pump. J. Mech. Sci. Technol. 2018, 32, 3687–3698. [Google Scholar] [CrossRef]

- Sung, H.-J.; Min, H.-K.; Nam, Y.-J.; Park, M.-K. Design and experimental verification of a port plate in a gerotor pump to reduce pressure pulsation. J. Mech. Sci. Technol. 2018, 32, 671–678. [Google Scholar] [CrossRef]

- Kwak, H.-S.; Li, S.-H.; Kim, C. Performance improvement of an oil pump: Design of port assembled with gerotor (2-ellipses-combined lobe). Int. J. Precis. Eng. Manuf. 2016, 17, 1017–1024. [Google Scholar] [CrossRef]

- Kwak, H.; Kim, C. Design of port shape for reducing irregularity of oil pump. J. Mech. Sci. Technol. 2017, 31, 5839–5848. [Google Scholar] [CrossRef]

- Gamez-Montero, P.J.; Castilla, R.; Codina, E. Methodology based on best practice rules to design a new-born trochoidal-gear pump. Proc. Inst. Mech. Eng. C 2018, 232, 1057–1068. [Google Scholar] [CrossRef]

- Biernacki, K.; Stryczek, J. Analysis of stress and deformation in plastic gears used in gerotor pumps. J. Strain Anal. Eng. Des. 2010, 45, 465–479. [Google Scholar] [CrossRef]

- Biernacki, K. Selection of the optimum tooth profile for plastic cycloidal gears. Proc. Inst. Mech. Eng. C 2014, 228, 3395–3404. [Google Scholar] [CrossRef]

- Stryczek, J.; Bednarczyk, S.; Biernacki, K. Strength analysis of the polyoxymethylene cycloidal gears of the gerotor pump. Arch. Civ. Mech. Eng. 2014, 14, 647–660. [Google Scholar] [CrossRef]

- Biernacki, K. Analysis of the material and design modifications influence on strength of the cycloidal gear system. Int. J. Adv. Manuf. Technol. 2015, 16, 537–546. [Google Scholar] [CrossRef]

- Stryczek, J.; Bednarczyk, S.; Biernacki, K. Gerotor pump with POM gears: Design, production technology, research. Arch. Civ. Mech. Eng. 2014, 14, 391–397. [Google Scholar] [CrossRef]

- Krawczyk, J.; Stryczek, J. Construction and experimental research on plastic cycloidal gears used in gerotor pumps. In Proceedings of the 8th FPNI Ph.D Symposium on Fluid Power, Lappeenranta, Finland, 11–13 June 2014. [Google Scholar] [CrossRef]

- Krawczyk, J.; Stryczek, J. Designing of the gerotor pump body made of plastics. In Proceedings of the 9th FPNI Ph.D Symposium on Fluid Power, Florianópolis, SC, Brazil, 26–28 October 2016. [Google Scholar] [CrossRef]

- Stryczek, J.; Banaś, M.; Krawczyk, J.; Marciniak, L.; Stryczek, P. The fluid power elements and systems made of plastics. Procedia Eng. 2017, 176, 600–609. [Google Scholar] [CrossRef]

- Mancini, S.D.; Santos Neto, A.D.O.; Cioffi, M.O.H.; Bianchi, E.C. Replacement of metallic parts for polymer composite materials in motorcycle oil pumps. J. Reinf. Plast. Compos. 2017, 36, 149–160. [Google Scholar] [CrossRef]

- Kwon, S.-M.; Kim, C.-H.; Shin, J.-H. Optimal rotor wear design in hypotrochoidal gear pump using genetic algorithm. J. Cent. South Univ. Technol. 2011, 18, 718–725. [Google Scholar] [CrossRef]

- Karamooz Ravari, M.R.; Forouzan, M.R.; Moosavi, H. Flow irregularity and wear optimization in epitrochoidal gerotor pumps. Meccanica 2012, 47, 917–928. [Google Scholar] [CrossRef]

- Ivanović, L.T.; Veličković, S.N.; Stojanović, B.Ž.; Kandeva, M.; Jakimovska, K. The selection of optimal parameters of gerotor pump by application of factorial experimental design. FME Trans. 2017, 45, 159–164. [Google Scholar] [CrossRef] [Green Version]

- Ivanović, L.; Stojanović, B.; Blagojević, J.; Bogdanović, G.; Marinković, A. Analysis of the flow rate and the volumetric efficiency of the trochoidal pump by application of Taguchi method. Tehnicki Vjesnik 2017, 24, 265–270. [Google Scholar] [CrossRef] [Green Version]

- Robison, A.; Vacca, A. Multi-objective optimization of circular-toothed gerotors for kinematics and wear by genetic algorithm. Mech. Mach. Theory 2018, 128, 150–168. [Google Scholar] [CrossRef]

- Robinson, A.; Vacca, A. Multi-Objective Optimization of Gerotor Port Design by Genetic Algorithm with Considerations on Kinematic vs. Actual Flow Ripple; SAE Technical Papers 2019-01-0827; SAE International: Warrendale, PA, USA, 2019; in press. [Google Scholar]

- De Martin, A.; Jacazio, G.; Sorli, M. Optimization of gerotor pumps with asymmetric profiles through evolutionary strategy algorithm. Machines 2019, 7, 17. [Google Scholar] [CrossRef]

- Chang, Y.J.; Kim, J.H.; Jeon, C.H.; Kim, C.; Jung, S.Y. Development of an integrated system for the automated design of a gerotor oil pump. J. Mech. Des. 2007, 129, 1099–1105. [Google Scholar] [CrossRef]

- Bae, J.; Kwak, H.; San, S.; Kim, C. Design and CFD analysis of gerotor with multiple profiles (ellipse–involute–ellipse type and 3-ellipses type) using rotation and translation algorithm. Proc. Inst. Mech. Eng. C 2016, 230, 804–823. [Google Scholar] [CrossRef]

- Gamez-Montero, P.J.; Castilla, R.; Mujal, R.; Khamashta, M.; Codina, E. GEROLAB package system: Innovative tool to design a trochoidal-gear pump. J. Mech. Des. 2009, 131, 074502. [Google Scholar] [CrossRef]

- GeroLAB Package System. Available online: http://www.gerolab.es (accessed on 22 February 2019).

- Gamez-Montero, P.J.; Garcia-Vilchez, M.; Raush, G.; Freire, J.; Codina, E. Teeth Clearance and Relief Grooves Effects in a Trochoidal-Gear Pump Using New Modules of GeroLAB. J. Mech. Des. 2012, 134, 054502. [Google Scholar] [CrossRef]

- Schweiger, W.; Schoefmann, W.; Vacca, A. Gerotor Pumps for Automotive Drivetrain Applications: A Multi Domain Simulation Approach. SAE Int. J. Passeng. Cars 2011, 4, 1358–1376. [Google Scholar] [CrossRef]

- Klopsch, V.; Germann, T.; Seitz, H. Numerical simulation of low-pulsation gerotor pumps for use in the pharmaceutical industry and in biomedicine. Curr. Direct. Biomed. Eng. 2015, 1, 433–436. [Google Scholar] [CrossRef] [Green Version]

- Zhang, E.; Chen, M.; Deng, B. Parametric Design on Internal Gear of Cycloid Gear Pump with NX10.0. IOP Conf. Ser. Mater. Sci. Eng. 2017, 250, 1–5. [Google Scholar] [CrossRef]

- Itoh, Y.; Murai, Y.; Ueno, Y.; Oiwa, H.; Miyagi, N.; Yamamoto, F. Visualization of Internal Flow in an Inscribed Trochoid Gear Pump. Trans. Vis. Soc. Jpn. 2006, 26, 27–32. [Google Scholar] [CrossRef] [Green Version]

- Antoniak, P. Application of the PIV method to optimization of the internal channels of gerotor pumps. In Proceedings of the 7th International Fluid Power Conference, Aachen, Germany, 22–24 March 2010. [Google Scholar]

- Stryczek, J.; Antoniak, P.; Jakhno, O.; Kostyuk, D.; Kryuchkov, A.; Belov, G.; Rodionov, L. Visualisation research of the flow processes in the outlet chamber–outlet bridge–inlet chamber zone of the gear pumps. Arch. Civ. Mech. Eng. 2015, 15, 95–108. [Google Scholar] [CrossRef]

- Garcia-Vilchez, M.; Gamez-Montero, P.J.; Codina, E.; Castilla, R.; Raush, G.; Freire, J.; Rio, C. Computational fluid dynamics and particle image velocimetry assisted design tools for a new generation of trochoidal gear pumps. Adv. Mech. Eng. 2015, 7. [Google Scholar] [CrossRef] [Green Version]

- Raush, G.; Gamez-Montero, P.J.; Castilla, R.; Codina, E. Experimental study on the impulsion port of a trochoidal wheeled pump. Flow Meas. Instrum. 2017, 55, 13–22. [Google Scholar] [CrossRef]

- Sahoo, V.; Mukherjee, U.; Das, M.K.; Maiti, R.; Antoniak, P.; Stryczek, J.; Rodionov, L. Visualization of leakage flow through active contacts in toothed external gear pumps—CFD and photo imaging techniques. J. Flow Vis. Image Process. 2016, 23, 345–376. [Google Scholar] [CrossRef]

- Antoniak, P.; Stryczek, J. Visualization study of the flow processes and phenomena in the external gear pump. Arch. Civ. Mech. Eng. 2018, 18, 1103–1115. [Google Scholar] [CrossRef]

- Antoniak, P.; Stryczek, J.; Banas, M.; Lyhovskyi, O.; Gryshko, I.; Zilinskyi, A.; Kovalov, V. Visualization research on the influence of an ultrasonic degassing system on the operation of a hydraulic gear pump. MATEC Web Conf. 2018, 211, 03005. [Google Scholar] [CrossRef]

- Toyoda, F.; Kobayashi, Y.; Miura, Y.; Koga, Y. Development of Variable Discharge Oil Pump; SAE Technical Papers 2008-04-14; SAE International: Warrendale, PA, USA, 2008; pp. 1–6. [Google Scholar] [CrossRef]

- Mancò, S.; Nervegna, N.; Rundo, M.; Armenio, G. Displacement vs. Flow Control in IC Engines Lubricating Pumps; SAE Technical Papers 2004-01-1602; SAE International: Warrendale, PA, USA, 2004; pp. 1–9. [Google Scholar] [CrossRef]

- Yamamoto, M.; Hosogi, T.; Watanabe, T.; Nishida, Y. Development of Engine Lubrication System with New Internal Gear Fully Variable Discharge Oil Pump. SAE Int. J. Fuels Lubr. 2017, 10, 1–9. [Google Scholar] [CrossRef]

- Nishida, Y.; Toyoda, F.; Terashima, H.; Ono, H.; Nunami, K. Development of Continuously Variable Discharge Oil Pump; SAE Technical Papers 2018-01-0932; SAE International: Warrendale, PA, USA, 2018; pp. 1–7. [Google Scholar] [CrossRef]

- Avery, N.; Johnston, N. Variable Displacement Gear and Gerotor Pumps. In Proceedings of the ASME/BATH 2015 Symposium on Fluid Power and Motion Control, Chicago, IL, USA, 12–14 October 2015. [Google Scholar] [CrossRef]

- Ivanović, L.; Devedžić, G.; Ćuković, S.; Mirić, N. Modeling of the Meshing of Trochoidal Profiles with Clearances. J. Mech. Des. 2012, 134, 041003. [Google Scholar] [CrossRef]

- Ivanović, L.; Josifović, D.; Ilić, A. Modelling of trochoidal gearing at the gerotor pump. Mech. Mach. Sci. 2013, 13, 553–562. [Google Scholar] [CrossRef]

- Ivanović, L.; Josifović, D.; Ilić, A.; Stojanović, B. Analytical model of the pressure variation in the gerotor pump chambers. Tech. Technol. Educ. Manag. 2013, 8, 323–331. [Google Scholar]

- Ivanović, L.; Ilić, A.; Miloradović, D.; Josifović, D. Modelling and simulation of the load in the epicyclic rotary pump with trochoidal gear profiles. IOP Conf. Ser. Mater. Sci. Eng. 2018, 393, 1–9. [Google Scholar] [CrossRef]

- Frosina, E.; Senatore, A.; Buono, D.; Santato, L. Analysis and simulation of an oil lubrication pump for internal combustion engines. J. Fluids Eng. 2015, 137, 051102. [Google Scholar] [CrossRef]

- Hussain, T.; Sivaramakrishna, M.; Suresh Kumar, S.P. In-House Development of Gerotor Pump for Lubrication System of a Gas Turbine Engine. In Proceedings of the ASME 2015 Gas Turbine India Conference, Hyderabad, India, 2–3 December 2015. [Google Scholar] [CrossRef]

- Altare, G.; Rundo, M. Computational Fluid Dynamics Analysis of Gerotor Lubricating Pumps at High Speed: Geometric Features Influencing the Filling Capability. J. Fluid Eng. 2017, 138, 111101. [Google Scholar] [CrossRef]

- Fangwei, X.; Rui, X.; Gang, S.; Cuntang, W. Flow characteristics of accelerating pump in hydraulic-type wind power generation system under different wind speeds. Int. J. Adv. Manuf. Technol. 2017, 92, 189–196. [Google Scholar] [CrossRef]

- Pellegri, M.; Vacca, M.; Frosina, E.; Buono, D.; Senatore, A. Numerical analysis and experimental validation of Gerotor pumps: A comparison between a lumped parameter and a computational fluid dynamics-based approach. Proc. Inst. Mech. Eng. C 2016, 231, 4413–4430. [Google Scholar] [CrossRef] [Green Version]

- Pellegri, M.; Vacca, A.; Devendran, R.; Dautry, E.; Ginsberg, B. A Lumped Parameter Approach for GEROTOR Pumps: Model Formulation and Experimental Validation. In Proceedings of the 10th International Fluid Power Conference, Dresden, Germany, 8–10 March 2016. [Google Scholar]

- Pellegri, M.; Vacca, A. A simulation approach for the evaluation of power losses in the axial gap of gerotor units. In Proceedings of the 10th JFPS International Symposium on Fluid Power, Fukuoka, Japan, 24–27 October 2017. [Google Scholar]

- Pellegri, M.; Vacca, A. Numerical simulation of Gerotor pumps considering rotor micro-motions. Meccanica 2017, 52, 1851–1870. [Google Scholar] [CrossRef]

- Buono, D.; Schiano di Cola, F.D.; Senatore, A.; Frosina, E.; Buccilli, G.; Harrison, J. Modelling approach on a Gerotor pump working in cavitation conditions. Energy Procedia 2016, 101, 701–709. [Google Scholar] [CrossRef]

- Buono, D.; Siano, D.; Frosina, E.; Senatore, A. Gerotor pump cavitation monitoring and fault diagnosis using vibration analysis through the employment of auto-regressive-moving-average technique. Simul. Model. Pract. Theory 2017, 71, 61–82. [Google Scholar] [CrossRef]

- Shah, Y.G.; Vacca, A.; Dabiri, S.; Frosina, E. A fast lumped parameter approach for the prediction of both aeration and cavitation in Gerotor pumps. Meccanica 2017, 53, 175–191. [Google Scholar] [CrossRef] [Green Version]

- Singh, R.; Salutagi, S.S.; Piotr, P.; Madhavan, J. Study of Effect of Air Content in Lubrication Oil on Gerotor Pump Performance Using CFD Simulations; SAE Technical Papers 2019-26-0300; SAE International: Warrendale, PA, USA, 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Jeong, S.W.; Chung, W.J.; Kim, M.S.; Kim, M.S. Application of SolidWorks® & AMESim®—Based Updated Simulation Technique to Back-flow Analysis of Trochoid Hydraulic Pump for Lubrication. In Proceedings of the 2014 World Congress in Computer Science, Computer Engineering and Applied Computing, Las Vegas, NV, USA, 21–24 July 2014. [Google Scholar]

- Kim, M.S.; Chung, W.J.; Jung, C.D.; Park, S.S.; Ahn, H.C.; Kim, H.C. On new methodology of AMESim® & CATIA® V5—Based cavitation simulation for flow rate control of trochoid hydraulic pump. In Proceedings of the 2011 International Conference on Mechatronics and Automation, Beijing, China, 7–10 August 2011. [Google Scholar] [CrossRef]

- Carconi, G.; D’Arcano, C.; Nervegna, N.; Rundo, M. Geometric Features of Gerotor Pumps: Analytic vs. CAD Methods. In Proceedings of the Bath/ASME Symposium on Fluid Power and Motion Control, Bath, UK, 12–14 September 2012. [Google Scholar]

- Prakash, H.R.; Manjula, S. Design and Analysis of Gerotors of Main Gear Box Lubricating Oil Pump. Int. J. Eng. Tech. Res. 2014, 2, 79–81. [Google Scholar]

- Moetakef, M.; Zouani, A. CAE Simulation of Engine Tonal Noise Generated by Gerotor Oil Pumps; SAE Technical Papers 2015-01-2245; SAE International: Warrendale, PA, USA, 2015; pp. 1–4. [Google Scholar] [CrossRef]

- Gherardini, F.; Zardin, B.; Leali, F. A parametric CAD-based method for modelling and simulation of positive displacement machines. J. Mech. Sci. Technol. 2016, 30, 3253–3263. [Google Scholar] [CrossRef]

- Elayaraja, R.; Lingeswaramurthy, P.; Govindarajan, S. Performance of Gerotor Oil Pump for an Automotive Engine—Prediction Using CFD Analysis and Experimental Validation; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Suresh Kumar, M.; Manonmani, K. Computational fluid dynamics integrated development of gerotor pump inlet components for engine lubrication. Proc. Inst. Mech. Eng. D 2010, 224, 1555–1567. [Google Scholar] [CrossRef]

- Ruvalcaba, M.A.; Hu, X. Gerotor fuel pump performance and leakage study. In Proceedings of the ASME 2011 International Mechanical Engineering Congress & Exposition, Denver, CO, USA, 11–17 November 2011. [Google Scholar] [CrossRef]

- Gamez-Montero, P.J.; Castilla, R.; del Campo, D.; Ertürk, N.; Raush, G.; Codina, E. Influence of the interteeth clearances on the flow ripple in a gerotor pump for engine lubrication. Proc. Inst. Mech. Eng. D 2012, 226, 930–942. [Google Scholar] [CrossRef]

- Frosina, E.; Senatore, A.; Buono, D.; Monterosso, F.; Olivetti, M.; Arnone, L.; Santato, L. A Tridimensional CFD Analysis of the Lubrication Circuit of a Non-Road Application Diesel Engine; SAE Technical Paper 2013-24-0130; SAE International: Warrendale, PA, USA, 2013; pp. 1–14. [Google Scholar] [CrossRef]

- Frosina, E.; Senatore, A.; Buono, D.; Unicini Manganelli, M.; Olivetti, M. A tridimensional CFD analysis of the oil pump of an high performance motorbike engine. Energy Procedia 2014, 45, 938–948. [Google Scholar] [CrossRef]

- Hsieh, C.-F. Flow characteristics of multistage roots pumps by CFD investigation. Mech. Ind. 2015, 16, 1–11. [Google Scholar] [CrossRef]

- Sang, X.; Zhou, X.; Liu, X. Numerical simulation of an inner engaging gerotor based on the optimization of inlet and outlet cavities. In Proceedings of the 5th International Conference on Advanced Design and Manufacturing Engineering, Shenzhen, China, 19–20 September 2015. [Google Scholar]

- Altare, G.; Rundo, M. Advances in simulation of gerotor pumps: An integrated approach. Proc. Inst. Mech. Eng. D 2016, 231, 1221–1236. [Google Scholar] [CrossRef]

- Castilla, R.; Gamez-Montero, P.J.; Raush, G.; Codina, E. Method for Fluid Flow Simulation of a Gerotor Pump using OpenFOAM. J. Fluid. Eng. 2017, 139. [Google Scholar] [CrossRef]

- Gamez-Montero, P.J.; Castilla, R.; Buza, A.; Khamashta, M.; Codina, E. Numerical study in a mini trochoidal-gear pump with multi-meshing contact points. In Proceedings of the ASME/BATH 2016 Symposium on Fluid Power and Motion Control, FPMC 2016, Bath, UK, 7–9 September 2016. [Google Scholar] [CrossRef]

- Gamez-Montero, P.J.; Castilla, R.; Raush, G.; Codina, E. Fluid Dynamic Effects of Interteeth and Sideway Clearances on a Mini Gerotor Pump using Dynamic Meshing Decomposition. In Proceedings of the 11th International Fluid Power Conference, Aachen, Germany, 19–21 March 2018. [Google Scholar] [CrossRef]

- Garcia, J.M. Surface Effects on Start-Up Friction and Their Application to Compact Gerotor Motor Design. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 3 September 2011. [Google Scholar]

- Ding, H.; Lu, X.J.; Jiang, B. A CFD model for orbital gerotor motor. IOP Conf. Ser. Earth Environ. Sci. 2012, 15, 062006. [Google Scholar] [CrossRef]

- Nag, A.; Maiti, R. Unification of epitrochoid origin profile design approaches for external lobed star member used in hydrostatic and gear units. Proc. Inst. Mech. Eng. C 2013, 227, 299–310. [Google Scholar] [CrossRef]

- Maiti, R.; Das, M.K.; Sahoo, V.; Avula, K.C.; Anukaran, A.; Tolambia, V.P.; Nag, A. Leakage Past Active Contacts in Involute and Cycloidal Gear Hydrostatic Units. In Proceedings of the 14th Scandinavian International Conference on Fluid Power, Tampere, Finland, 20–22 May 2015. [Google Scholar]

- Bigliardi, E.; Francia, M.; Milani, M.; Montorsi, L.; Paltrinieri, F.; Stefani, M. A combined methodology for studying the axial balancing mechanism of orbit annular hydraulic machines. IFAC-PapersOnLine 2016, 28, 427–432. [Google Scholar] [CrossRef]

- Furustig, J.; Larsson, R.; Almqvist, A.; Bates, C.A.; Ennemark, P. A wear model for EHL contacts in gerotor type hydraulic motors. Proc. Inst. Mech. Eng. C 2015, 229, 254–264. [Google Scholar] [CrossRef]

- Michael, P.; Burgess, K.; Kimball, A.; Wanke, T. Hydraulic Fluid Efficiency Studies in Low-Speed High-Torque Motors; SAE Technical Papers 2009-01-2848; SAE International: Warrendale, PA, USA, 2009; pp. 1–7. [Google Scholar] [CrossRef]

- Furustig, J.; Almqvist, A.; Pelcastre, L.; Bates, C.A.; Ennemark, P.; Larsson, R. A strategy for wear analysis using numerical and experimental tools, applied to orbital type hydraulic motors. Proc. Inst. Mech. Eng. C 2016, 230, 2086–2097. [Google Scholar] [CrossRef]

- Bates, C.A.; Broe-Richter, H.W.; Bendlin, C.R.; Ennemark, P. The effect of an amorphous hydrogenated carbon-coated gear-wheel on a hydraulic orbital motor’s efficiency over time. Proc. Inst. Mech. Eng. J 2018, 1–14. [Google Scholar] [CrossRef]

- Strmčnik, E.; Majdič, F. The pressure and efficiency characteristic of hydraulic gerotor motor with the floating outer ring. Tehnicki Vjesnik 2018, 25, 609–615. [Google Scholar] [CrossRef]

- Strmčnik, E.; Majdič, F. The improvement of the total efficiency of the gerotor orbital hydraulic motor. In Proceedings of the 11th International Fluid Power Conference, Aachen, Germany, 19–21 March 2018. [Google Scholar] [CrossRef]

- Zardin, B.; Borghi, M.; Gherardini, F.; Zanasi, N. Modelling and simulation of a hydrostatic steering system for agricultural tractors. Energies 2018, 11, 230. [Google Scholar] [CrossRef]

- Harada, T.; Sasaki, Y.; Kouno, A. Development of High Power Micropump. IEICE Tech. Rep. 1999, 122, 7–12. [Google Scholar]

- Harada, T.; Yoshimura, Y.; Kouno, A. High-output micro-trochoid pump fabricated by a surface treatment technique. IEEJ Trans. Sens. Micromach. 2002, 122, 73–77. [Google Scholar] [CrossRef] [Green Version]

- Mancò, S.; Nervegna, N.; Rundo, M.; Margaria, M. Miniature gerotor pump prototype for automotive applications. In Proceedings of the 3rd IFK International Fluid Power Conference, Aachen, Germany, 5–6 March 2002; pp. 153–167. [Google Scholar]

- Gamez-Montero, P.J.; Antoniak, P.; Castilla, R.; Freire, J.; Krawczyk, K.; Stryczek, S.; Codina, E. Magnet-Sleeve-Sealed Mini Trochoidal-Gear Pump Prototype with Polymer Composite Gear. Energies 2017, 10, 1458. [Google Scholar] [CrossRef]

- Huber, N.; Aktaa, J. Dynamic finite element analysis of a micro lobe pump. Microsyst. Technol. 2003, 9, 465–469. [Google Scholar] [CrossRef]

- Leester-Schädel, N.; Thies, J.W.; Schubert, T.; Büttgenbach, S.; Dietzel, A. Rotational micro actuator for microsurgery. Microsyst. Technol. 2014, 20, 879–888. [Google Scholar] [CrossRef]

- Maruo, S.; Inoue, H. Optically driven micropump produced by three-dimensional two-photon microfabrication. Appl. Phys. Lett. 2006, 89, 1–3. [Google Scholar] [CrossRef]

- Malvasi, A.; Squarcini, R.; Armenio, G.; Brömmel, A. Design process of an electric powered oil pump. Autotechreview 2014, 3, 36–39. [Google Scholar] [CrossRef]

- Heisel, U.; Mishev, A. Development of a new gerotor pump with innovative gerotor design and investigation of its hydraulic characteristics through CFD Analysis. In Proceedings of the 9th International Fluid Power Conference, Aachen, Germany, 24–26 March 2014. [Google Scholar]

- O’Shea, C.; Xia, Y.; Lowry, S. Analysis and optimization of an electrohydraulic power pack for use in a fully-active vehicle suspension through the use of computational fluid dynamics. In Proceedings of the ASME/BATH 2013 Symposium on Fluid Power and Motion Control, FPMC 2013, Sarasota, FL, USA, 6–9 October 2013. [Google Scholar] [CrossRef]

- Gamez-Montero, P.J.; Castilla, R.; Codina, E.; Freire, J.; Morató, J.; Sanchez-Casas, E.; Flotats, I. GeroMAG: In-House Prototype of an Innovative Sealed, Compact and Non-Shaft-Driven Gerotor Pump with Magnetically-Driving Outer Rotor. Energies 2017, 10, 435. [Google Scholar] [CrossRef]

| Keywords (1 to 10) | Times | Keywords (11 to 20) | Times | Keywords (21 to 30) | Times |

|---|---|---|---|---|---|

| pump | 83 | power | 13 | teeth | 10 |

| gerotor | 60 | pressure | 13 | profile | 9 |

| gear | 37 | cycloidal | 12 | analysis | 9 |

| flow | 28 | clearance | 12 | internal | 8 |

| trochoidal | 19 | port | 11 | wear | 7 |

| hydraulic | 17 | oil | 10 | system | 7 |

| design | 17 | motor | 10 | rotary | 6 |

| CFD | 17 | simulation | 10 | lubrication | 6 |

| contact | 15 | efficiency | 10 | leakage | 6 |

| stress | 14 | method | 10 | modelling | 6 |

| Manufacturing | Part | Tolerance |

|---|---|---|

| Radial clearance | Inner to outer profile | 25–80 × 10−6 m |

| External gear to housing | 25–80 × 10−6 m | |

| Side clearance | Internal gear | 2–4 × 10−6 m |

| External gear | 2–4 × 10−6 m | |

| Flatness | Housing | 25 × 10−6 m |

| Cover | 25 × 10−6 m | |

| Internal gear | 1 × 10−6 m | |

| External gear | 1 × 10−6 m | |

| Surface finishing | Housing | 60 × 10−6 m |

| Cover | 15–20 × 10−6 m | |

| Internal gear | 15–20 × 10−6 m | |

| External gear | 15–20 × 10−6 m |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gamez-Montero, P.J.; Codina, E.; Castilla, R. A Review of Gerotor Technology in Hydraulic Machines. Energies 2019, 12, 2423. https://doi.org/10.3390/en12122423

Gamez-Montero PJ, Codina E, Castilla R. A Review of Gerotor Technology in Hydraulic Machines. Energies. 2019; 12(12):2423. https://doi.org/10.3390/en12122423

Chicago/Turabian StyleGamez-Montero, Pedro Javier, Esteve Codina, and Robert Castilla. 2019. "A Review of Gerotor Technology in Hydraulic Machines" Energies 12, no. 12: 2423. https://doi.org/10.3390/en12122423

APA StyleGamez-Montero, P. J., Codina, E., & Castilla, R. (2019). A Review of Gerotor Technology in Hydraulic Machines. Energies, 12(12), 2423. https://doi.org/10.3390/en12122423