1. Introduction

Oilseed rape (OSR,

Brassica napus L.) belongs to the Brassicaceae family, is a globally important oilseed crop that probably originated in the Mediterranean region, and is widely grown in temperate agricultural regions [

1,

2,

3]. OSR ranks third amongst the global key sources of vegetable oil after soy and palm. It is widely used for industrial purposes (mainly for biodiesel production) [

1,

4,

5]. Recently, its worldwide production reached approximately 70 million tons from approximately 34 million hectares, 22 million tons of which was produced from approximately 6.5 million ha in the European Union [

6]. OSR has become a major commercial crop in Europe, where it is also considered to be important in crop rotation [

7,

8]. In Europe, winter OSR is more widely grown than spring OSR because winter OSR is 1.5–2 times more productive than spring OSR [

9,

10].

Unusually for major agricultural field crops, OSR tends to shed its seed as soon as the fruits become fully ripe, reflecting the primitive need for seed dissemination [

11,

12]. The botanical name of Brassicaceae fruits is siliques or agronomically, pods, which enclose the seeds during their development [

13,

14]. Siliques consist of two valves (i.e., the carpels or fruit walls) that form two locules separated by the replum. The site where the valve margin connects to the replum is called the dehiscence zone, a layer where cell separation occurs so that the silique could open [

15]. The process of pod dehiscence, also known as pod shattering, which is accompanied in OSR by the degradation of the cell wall of the siliques.

One of the causes of cell wall degradation is the weakening of the valve attachment leading to pod shattering [

16]. Pod shattering is caused by a build-up of tension in the pod due to lignification of cells surrounding the dehiscence zone in the final stage of pod development. OSR pod shattering can be reduced by lowering the tension occurring in the pod wall or by widening the dehiscence zone [

17]. The process of dehiscence usually starts at the proximal end of the siliques [

14]. In addition, physical pressure build up, as the silique dries, creates mechanical stresses that contribute to the pod shattering [

11].

Pod shattering leads to major seed (and hence yield) total losses of 15–70%, depending on the conditions. Pod shattering is also the main source of OSR soil seedbanks and volunteers in the subsequent crop [

18,

19]. Loss of seeds in OSR variates a lot and depends on the varieties and genotype [

20,

21,

22]. Winter

Brassica napus cultivars are more resistant to pod shattering than spring cultivars [

23]. OSR loss of seeds is generally split into two periods: shattering prior to and at the time of harvesting. Preharvest OSR seed loss can reach up to 2.5% under favorable weather conditions [

24], which may increase due to unfavorable weather conditions, such as strong winds [

25], hail [

26], and frequent changes in temperature and moisture [

11]. Kosteckas et al. [

27] reported that under adverse weather conditions, the loss of seed due to pod shattering could be >400 kg ha

−1 or >12%. Preharvest seed losses are caused not only by pod shattering but also due to pod drop [

28] and more synchronous maturation of the pods on the plant [

29]. Gan et al. [

30] observed that higher OSR plant populations and reduced branching of individual plants induce greater synchronicity in the maturation of OSR pods. Preharvest seed loss of OSR can be lowered by decreasing the maturation time [

31]. Fully mature pods of OSR are very prone to splitting, resulting in pod shattering and seed loss [

32].

Seed loss at harvesting of winter OSR usually is from 2 to 5% (under ideal conditions), and from 11 to 25% or higher (under adverse conditions) [

24,

33,

34]. Yield losses of 20–25% have been reported in cases of delay in harvesting beyond the optimal time [

26,

34]. The two main methods of harvesting OSR are swathing (or windrowing) and direct harvest (direct combining). Nunes et al. [

21] have corroborated their hypothesis that swathing reduces pod shattering when pods are harvested at the ideal time. During the direct harvest method, pod shattering occurs due to the application of external forces, such as contact with the combine harvester reel [

35]. Use of appropriate harvest management strategies can minimize the impact of unfavorable weather conditions and the yield loss of OSR due to pod shattering [

30]. OSR seed loss can be reduced using well-equipped (with extended cutter bar table and vertical double-knife active dividers) and adjusted combine harvester reels [

35,

36]. In addition, an inappropriate working speed of the combine harvester can be associated with seed loss at harvest [

33]. Furthermore, use of plant growth regulators can decrease OSR seed losses at harvest [

37].

Trials on the application of commercial pod sealants to OSR crops have generated variable results, particularly under field conditions [

21,

23,

27,

36,

38,

39]. Currently, the most promising method of controlling pod shattering in OSR is the application of a recently developed acrylic- and trisiloxane-based pod sealant, these substances work by physically preventing valve separation by gluing them together and altering the pod moisture regime. The sealant allows moisture to leave the pod but prevents from getting into it, thus decreasing pod expansion and contraction resulting from watering and drying cycles [

38]. Previous studies have suggested that this acrylic- and trisiloxane-based pod sealant (PS4) is environmentally friendly, does not penetrate seeds in the treated pods, and does not reduce oil content [

38]. However, no study has evaluated the influence of different weather conditions on OSR pods treated with this sealant in terms of their pod strength or moisture content and subsequent losses prior to and during harvesting. Moreover, the published studies have not evaluated the effectiveness of this sealant in terms of environment and economic benefit nor have they compared its effects with those of commercial sealants of different compositions.

In order to rate the sustainability of OSR production, all possible environmental factors that have an impact over the entire lifespan must be considered. This can be achieved by employing a Life Cycle Assessment (LCA). LCA is among the best and common methods for the evaluation environmental impacts of agricultural technologies and products [

40]. This method also gives a possibility to identify opportunities for environmental improvement. LCA methodology can be used to evaluate the environmental load of OSR cultivation and products during their life cycle “from inception to the death” [

41].

It is possible to conclude from the LCA analysis that was performed that the carbon footprint is affected by the OSR yield per hectare: the yield of the plot with the lowest environmental impact was the highest and, and on the contrary, the yield of the plot with the highest impact was the lowest [

42]. In research of Forleo et al. [

42] related to the Greenhouse gas (GHG) emissions of OSR cultivation, the carbon footprint was 768 kg CO

2 eq Mg

−1 (or one ton), i.e., lower than emerged in some other studies. The authors stated that this could happen due to the differences between data, approaches, and the employed agricultural practices. While, in the study of Saarinen et al. [

43], the determined carbon footprint of rapeseed cultivation was 1480 kg CO

2 eq Mg

−1. Naujokienė et al. [

44] in a Lithuanian study found that the carbon footprint for winter oilseed rape (WOSR) cultivation depends on soil biopreparation and varies in range from 682.00 to 1136.89 kg CO

2 eq Mg

−1. It can be concluded from the LCA results that the global warming potential (GWP) for OSR production in Italian regions amounts to 1106 kg CO

2 eq Mg

−1 in Sardinia [

45] and to 1300 kg CO

2 eq Mg

−1 of seed generated in the Campania [

46]. Bieńkowski et al. [

47] determined that the carbon footprint of OSR crops in Poland showed that on average it was 794.2 kg CO

2 eq Mg

−1 of seed. Mousavi-Avval et al. [

40] employed an LCA of OSR production and showed that the GWP was 1181.6 kg CO

2 eq Mg

−1 of seed, of which 845 kg CO

2 eq was related to the emissions from farms. In addition, the acidification and eutrophication potentials were found to be 23.3 kg SO

2 eq Mg

−1 and 18 kg PO

4 eq Mg

−1, respectively. These authors have confirmed that fertilizers and their emissions from fields contribute more than 90% of GWP in OSR cultivation.

From the perspective of the environment and in relation to the GWP, the study of Forleo et al. [

42] highlighted that rapeseed crop (carbon footprint 768 CO

2 eq Mg

−1) is more sustainable than sunflower (895 CO

2 eq Mg

−1) crop cultivation. Rapeseed farms could generate higher yields and be way less environmentally damaging than the farms of sunflowers in Italy. Similar conclusions, that rapeseed profile is way better than that of sunflower, were made also in Chilean conditions [

48] due to the following factors: there were less mineral fertilizers per unit of seeds produced, the application of less toxic herbicides, and use of no-tillage systems (which reduces both diesel consumption and equipment use in the field).

Research of Khanali et al. [

49] shows values of impact categories per one ton of packaged OSR edible oil, from the farm to the end of the packaging stage. The authors reported that 3085.70 kg CO

2 eq are emitted to the atmosphere per production of one ton of packaged OSR edible oil. Emissions from the farm stage are much more than others and consist 78% (direct 1587.6 kg CO

2 eq and indirect 848.0 kg CO

2 eq) [

49]. The total GWP (kg CO

2 eq) is a crucial factor, in which variations can also be addressed for other GHG changes and dependencies [

44].

LCA based evaluation of OSR shows that the difference in the carbon footprint of the farms is predominantly a result of the following factors: the different values of seed yield of OSR; the different levels of fuel consumption; and the differing amounts of nitrogen fertilizers used [

42]. Previous experiments [

50] confirmed the research results of Forleo et al. [

42]. Both the choice of fertilizer type [

51] and fertilization management [

52] have significant implications in the environmental impacts. There is a large amount of published LCA studies of OSR cultivation, especially about feedstock for biofuels production. Many researchers used LCA to study environmental impacts in production of OSR [

40,

44,

49,

52,

53]. A wide range of calculators have been developed to assess the GHG emissions of agricultural products [

54]. Therefore, there is still a need to evaluate the environmental sustainability of OSR pod sealants.

The main objectives of this study were (i) to investigate the effects of this novel pod sealant (PS4) on seed and pod valve moisture during harvesting and on pod strength and shattering and (ii) to evaluate the environmental and commercial benefits (if any) of using different pod sealants.

The hypothesis states that the developed acrylic- and trisiloxane-based pod sealant reduces rapeseed losses and the adverse environmental impacts prior and during winter OSR harvesting.

4. Conclusions

Natural seed losses before harvest in the control plots (in the absence of sealants) were approximately 1.5% under good weather conditions of 2014, 3% under wetter conditions of 2015, and 8% under very wet and windy conditions of 2016. When pods were sprayed with our developed experimental sealant PS4, which combines an acrylic sealant with a surfactant trisiloxane, 2 weeks prior to harvest, natural losses in the control plots could be reduced by 20–70%.

Regardless of different weather conditions in 2014, 2015, and 2016, pods sprayed with PS4 on the day of harvesting showed approximately 14% lower seed moisture and approximately 34% lower pod valve moisture than those receiving other treatments.

The force necessary to open OSR valves depended on sealant composition and weather conditions in July. The required force decreased when precipitation occurred during the indicated period. The force necessary for opening the OSR pods during harvesting was 10–20% higher in pods sprayed with PS4 than in those sprayed with other sealants.

By spraying OSR with PS4, seed losses at harvest due to the impact of combine harvester reel tines could be reduced by up to three-fold from those in control plots. The economic viability of using a sealant on OSR varied according to year and, to some extent, weather conditions. Using the most-effective sealant PS4 for processing of pods, additional net income of €30–€150 ha−1 could be achieved. Comparing the economic viability of PS4 use to that of commercial sealants with different active ingredients, the differences in net additional income ranged from 3.5 to 9.5 times in 2014, from 1.7 to 2.7 times in 2015, and from 1.4 to 2.7 times in 2016.

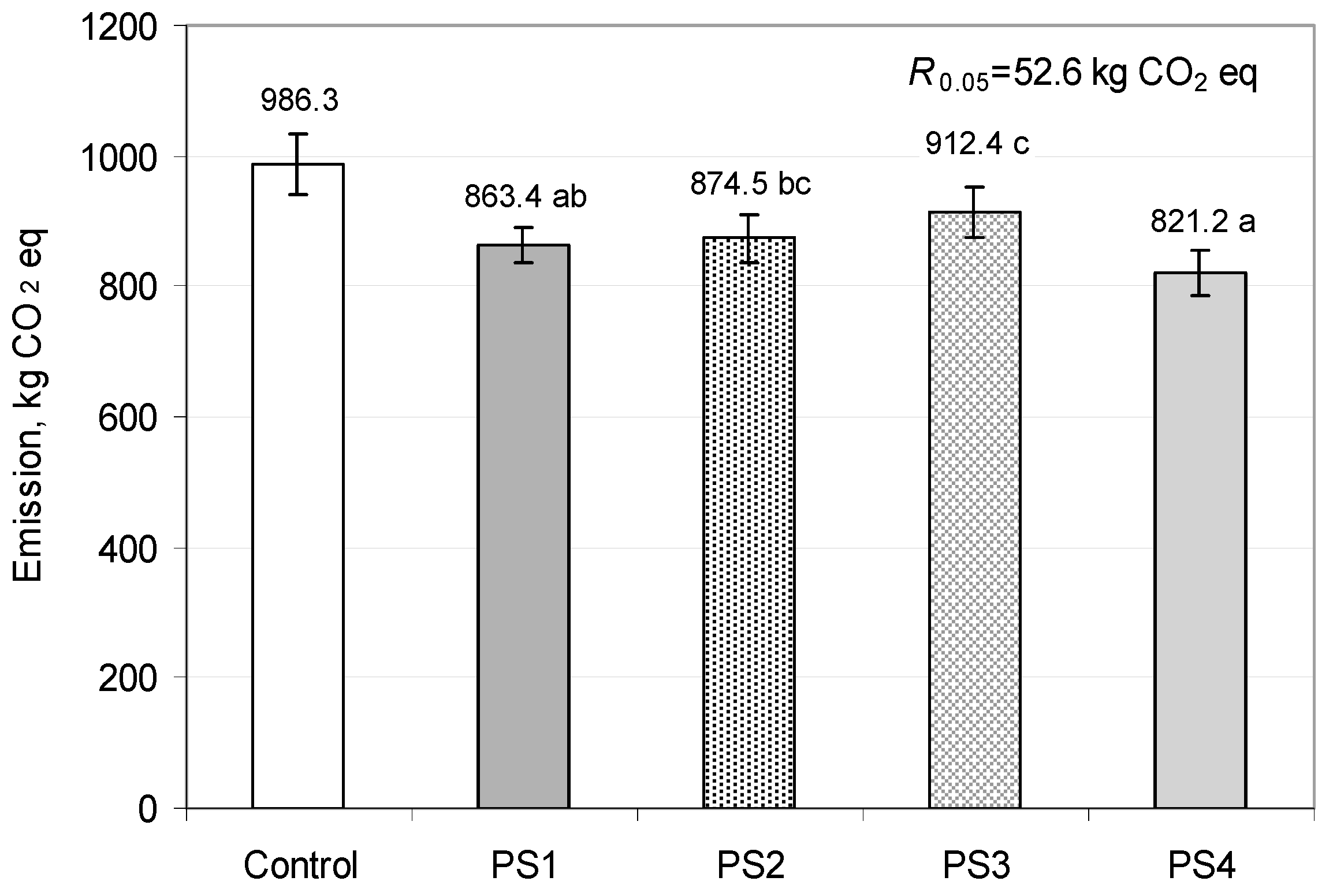

The life cycle assessment showed that during 2014–2016 WOSR cultivation, the largest effect on global warming emission (kg CO2 eq) reduction was experimental sealant PS4, i.e., approximately 17% compared to the control.