1. Introduction

Lead-acid batteries remain the most common batteries found in off-grid PV-genset-battery hybrid power supply systems around the world today. While competing lithium battery technologies offer a number of performance advantages, they also have drawbacks. Compared to lead-acid, lithium technologies offer longer life, require virtually no maintenance, and are more energy dense. Lithium batteries are also higher in initial expense, require complex battery management systems (BMS) at the cell voltage level, are more limited in their allowable operating temperature range and have increased safety considerations [

1]. As a result, less complex lead-acid batteries continue to be implemented in remote solar-based power supply applications. However, lithium battery solutions are becoming increasingly more common due to their lower overall lifetime cost and stable field performance. A side-by-side comparison of lead vs. lithium for off grid power is found in [

2] where lead-based battery systems are found to be implemented more often based on their lower initial cost. However, the lithium-based battery systems are ultimately found to be lower in overall levelized cost of energy (LCOE) due to their longer life. Lead-acid batteries are also known to be problematic within off-grid solar-based power systems due to their dynamic and often-underwhelming (and usually un-monitored) effective storage capacity in the field. A summary of the main failure mechanisms of lead-acid batteries in service are detailed in [

3] where failure mechanisms related to undercharging are often reversible. Lead-acid batteries exhibit capacity loss when operated in a partial state of charge regime (PSoC) for an extended period of time. The simple remedy for reversible capacity loss is periodic full charging. The respective benefits of full charging through standard constant voltage (CV) and constant current (CC) charging methods are discussed in [

4]. Noting that while CC overcharging by 20–30% amp-hours is considered effective at providing a full charge, it is detrimental to overall battery life.

PV-genset-battery hybrid systems experiencing marginal energy available from the sun and without access to continuous long-duration charging (e.g., overnight grid-based charging) are particularly challenging operating conditions for lead-acid batteries. Unfortunately, this is often the case with PV-genset-battery hybrid systems operating during the Canadian winter season when the solar resource is inherently low and variables such as snow cover can temporarily reduce PV output to zero. These systems are therefore dependent on intermittent fuel-based genset (engine-generator) operation to compensate for reduced solar availability. However, gensets are invariably controlled to operate for a minimum amount of time and may not provide appropriate full charge reconciliation. Performing full battery charging with a genset using battery manufacturers guidelines for CV and CC based charging may require many hours of charging at low genset loading. This is undesirable from both a fuel consumption and machine wear perspective. Ultimately, the combination of battery manufacturer recommended CV and CC set-points, reduced solar resources in the winter and the impracticality of fully charging batteries with a genset creates challenges with respect to the effective battery management of PV-genset-battery hybrid systems; specifically with respect to correcting capacity loss resulting from prior periods of undercharging. Similar challenges with respect to PSoC battery operation are found within PV-genset-battery hybrid power systems for remote telecom tower applications [

5]. Interestingly PSoC conditions are tolerated with significantly less issue by lithium-based battery technologies as discussed in [

6]. In the absence of any improvements made to the management of lead-acid batteries, the fundamental resiliency of lithium-based batteries to partial cycling may be a defining characteristic in their future adoption within PV-based remote power applications. This communication illustrates, however, that the management of lead-acid batteries can be improved by implementing automatic adjustments to CV charging values based on feedback from an easy-to-implement coulomb counting device. This work presents a rarely documented example of non-ideal battery management within a field-based PV-genset-battery hybrid system. The example illustrates challenges with respect to PSoC operation and demonstrates the potential effectiveness of adjusting CV charging set points based on coulomb counting feedback in order to correct problematic reductions in battery capacity.

2. Background

The corresponding author has been involved with previous applied PV-genset-battery hybrid system research in the community for over 12 years [

7,

8] where there has been prior anecdotal experience concerning battery behaviour during winter season operation. The main symptom of which has been unusually frequent automatic genset operation which is indicative of a reduced battery capacity and ultimately reduced solar energy utilization. For this reason, newly deployed hybrid systems in the community feature detailed battery data logging capability in order to monitor and analyze long-term battery performance and to ensure optimal system economics and reliability. Detailed studies of lead-acid battery field behaviour in PV hybrid systems are rare; presumably due to the logistics and relatively long timelines involved. Many battery performance studies focus on simulation models (some very comprehensive) and/or limited laboratory testing, e.g., [

9,

10,

11], where it may not be pragmatic to accurately capture the practical dynamic aspects of lead-acid batteries operating under arbitrary and perhaps sub-optimal field conditions. Attempts have been made in [

12] to predict battery ageing of lithium-based batteries under complex non-laboratory test conditions by combining the knowledge of simpler elemental cycles. However, this work was done with respect to ageing of lithium cells and may not apply to the reversible capacity loss of lead-acid cells due to PSoC operation. Modelling and predicting the dynamic changes of lead-acid batteries under PSoC is complex and further complicated placing multiple non-identical cells in series. The increased challenges of modelling “packs” of battery cells are discussed in [

13] where the “Big Cell” method is the only method that can be applied without having voltage information for each individual cell—as is the case with most lead-acid battery applications. However, this method ignores inconsistent performance between cells, which, as this work will show, is both a significant reality and detrimental to overall performance. We argue that exposure to application data from operational field systems is important to contextualize challenges with respect to battery management. Furthermore, fully charging flooded lead-acid batteries on a regular basis does not necessarily require a complex understanding of battery behaviour. It does, however, require that a regular amount of overcharge is insured. A regular overcharge of 20% might be considered an extreme upper limit [

4], but in this work, we consider approximately 10% as a reasonable target with respect to overcharge-tolerant flooded lead-acid batteries.

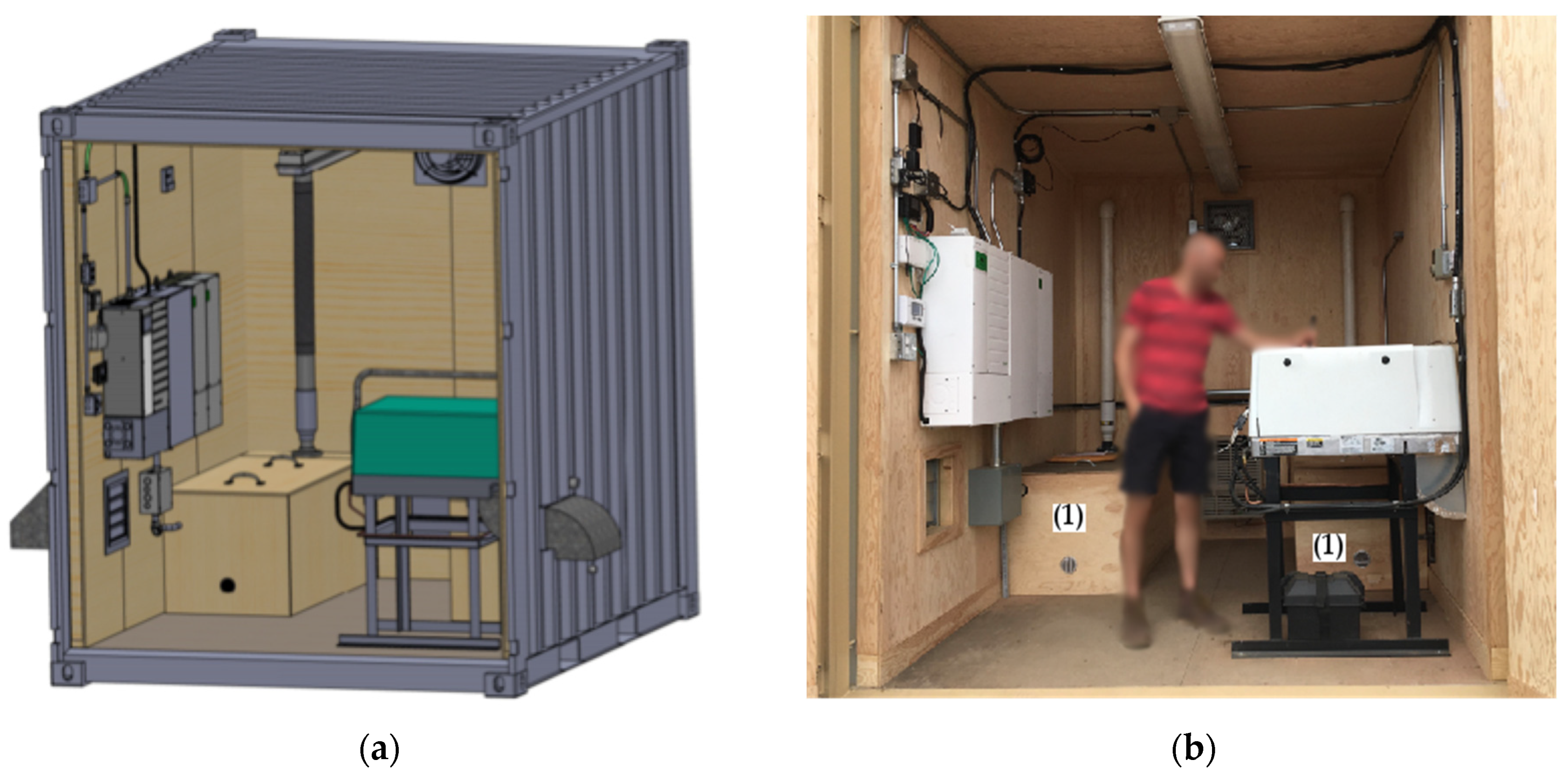

This work presents measured battery data from the inaugural winter-season of one-of-eight newly deployed off-grid residential PV-genset-battery hybrid power systems stated for long-term monitoring. The eight systems are part of an ongoing battery performance monitoring research initiative that aims to investigate battery behaviour over their entire lifetime in the field. The hybrid power systems are all located in the remote Nemiah Valley in British Columbia, Canada approximately 200 km west of the town of William’s Lake and 100 km from the nearest grid connection. Wide ranges of environmental conditions are experienced where the snowy winter climate drops to less than −30 °C and the dry summer climate often exceeds 30 °C. The eight PV-based power systems are implemented in a DC-coupled hybrid system architecture [

14] where the hybrid systems supply residences and their inhabitants with a continuous and reliable supply of AC electricity. Each PV hybrid power system is housed in an insulated 10’ ISO shipping container with provision for winter heating and fan-based summer cooling, as shown in

Figure 1. The power systems were dimensioned according to

Table 1 using HOMER techno-economic modelling software. The PV and battery components were sized to reduce genset operation to 250 hours per year based on previous experience in the community [

8].

The battery bank examined in this article suffered a significant loss in capacity due to a low state of charge (SOC) event at the beginning of its first winter season resulting from a combination of snow cover on the 45 degree inclined PV array and excessively low automatic genset start voltage. This was then followed by a month-long period of PSoC operation, not unlike what has been discussed in [

15,

16]. Eventually, the battery bank was examined on-site and considered terminally damaged by local technicians. However, due to the age of the battery, a decision was made under guidance from the corresponding author to try to slowly recover what appeared to be a chronically undercharged and sulphated battery. Higher CV charging set points were manually configured in the system’s controller by a remote interface in order to promote more-aggressive-than-normal overcharging in the hope of providing a gradual and restorative charge recovery of the battery. In March 2018, the battery was re-inspected and the data from the battery lifetime data logger was recovered and formed the basis for this communication. It is worth noting that the hybrid system should be tolerant of the temporary periods of snow cover provided the battery management system (BMS) is performing effectively. Furthermore, snow accumulation on the PV modules rarely persists for more than a few days and does not represent a significant loss of available energy. The example presented is also an extreme case that serves to highlight an underlying problem. The majority of the previously observed anecdotal examples of reduced battery capacity due to PSoC in the community were not as severe because the genset was programmed to start at a higher-than-default state of charge voltage, e.g., start below 46.5 V rather than start below 44.5 V.

The main contribution of this work is a rare and detailed insight into how lead-acid batteries managed by modern purpose-built power conversion equipment behave in the field. The intent is to document, with measured field data, challenges faced when managing battery banks that have been subject to challenging charging conditions. Future research work with respect to improving battery management is also proposed. The new closed-loop control method utilizes feedback from an amp-hour accumulator to optimally manage CV set points within lead-acid based PV-genset-battery hybrid power systems.

3. Methodology for Obtaining Battery Data

The PV hybrid system under study was commissioned in mid-2017 as part of a project to electrify eight residences in the community with stand-alone PV-genset-battery hybrid power systems. The hybrid systems were each equipped with supplemental battery data logging devices, as shown in

Figure 2, designed for archiving the entire life of each battery. Voltage, current (with zero offset), temperature, time-integrated current (amp-hours), and elapsed time are sampled and stored on a removable memory card at 30-second intervals. The analog-to-digital sampled voltage and current measurement range is 100 V and ±820 A full scale with 3.75 mV and 25 mA least significant bit step sizes respectively. Measured temperature range is −50 °C to +125 °C. The battery logger is unique in its ease of installation as it measures a temperature compensated voltage drop across a 60 cm portion of the negative battery lead to sense battery current. The logger can be installed without interrupting the battery current by inserting small sense screws into the cable insulation.

As mentioned, the installation of the supplemental battery data loggers is part of a forward-looking research initiative to assess the long-term battery management and the resulting life of newly installed lead-acid battery banks. The measured data is also to be used as multi-year baseline comparative data for the testing of a future replacement lithium solution that the authors are currently developing. However, due to the problems experienced over the first winter of operation, the data of the subject hybrid system was accessed sooner-than-expected in order to perform the investigative study documented herein.

The main theory of operation of the PV-genset-battery hybrid power system is straightforward. The solar charger attempts to charge the batteries on the DC bus whenever the sun is available via maximum power point tracking and programmable multi-stage CV regulation limits. If the battery is discharged below a voltage threshold by the DC/AC inverter (i.e., discharged too deeply by the load), a backup generator starts automatically and recharges the battery via the inverter/charger hardware. The inverter/charger also operates with programmable multi-stage CV and a single stage CC limits according to the battery manufacturer’s guidelines [

17]. All the newly deployed hybrid systems feature a communications interface gateway and are interconnected via a long-range wireless local area network (LAN) where the LAN is connected to the internet via satellite. Each hybrid system can be accessed, configured and updated from any internet connection.

The PV hybrid system in question is unique relative to the others in the community because it is connected to two residences and is designed with a double size PV array and twice the charge controller capacity. However, during the period in question, only one house was occupied and the hybrid system was operating with a substantially large PV array relative to the actual load. The fact that the system struggled to fully recharge the batteries with such a large PV array is indicative of a fundamental issue with respect to common multi-stage CV-CC battery charging techniques applied without consideration of coulomb counting feedback.

MATLAB was used to import, manipulate and display the information contained within the large data file containing approximately 500,000 samples. It should be noted that the high-resolution data logger collects over 1,000,000 samples per year and appropriate software tools are required.

4. Analysis of Measured Battery Data

4.1. Overall Battery Behaviour from 26 August 2017 to 7 March 2018

Analysis of the long-term high-resolution battery data allows for a detailed insight into battery bank management and control system operation as the PV-genset-battery hybrid systems operate and age in the field.

Figure 3 presents an overview of the measured field data of the system in question over its inaugural winter from August 2017 to March 2018. During November the 48 V 1000 Ah battery bank consisting of twenty-four 2 V lead-acid cells in series (24S1P) suffered a severe loss of effective storage capacity due to repeated undercharging and lack of regular full charge completion, i.e., a periodic 10% overcharge. In early December, after local technicians were alerted of deep discharge events which resulted in the loss of power to the associated residence, a manual intervention of the charging parameters was performed to recover the battery’s charging performance and storage capacity to an acceptable level. While the battery appears to have recovered over the four-month event as illustrated, any permanent life-shortening damage to the battery bank remains to be discovered. Interestingly, this one detailed and relatively extreme example supports anecdotal observations of hybrid system battery performance in the community over the last 12 years. Battery performance and effective capacity appear to suffer significantly during the winter season due to inadequate battery charge management resulting from a combination of lack of sun, premature solar charge regulation and intermittent and incomplete genset-based charging.

In

Figure 3, the topmost amp-hour plot is a time integration of the battery current and can accumulate higher than zero on charging but resets to zero upon subsequent discharge. Therefore, the time integration of positive amp-hours can be considered as overcharge. The middle plot of

Figure 3 shows battery voltage with the Y-axis scaled to display only significantly deep discharge conditions at voltages below 47 V. The battery enclosure temperature is also shown in

Figure 3 where the batteries are located in a closed wooden box, which is insulated on all five sides except for the top. Detailed information further explaining the events above are detailed in the following sections.

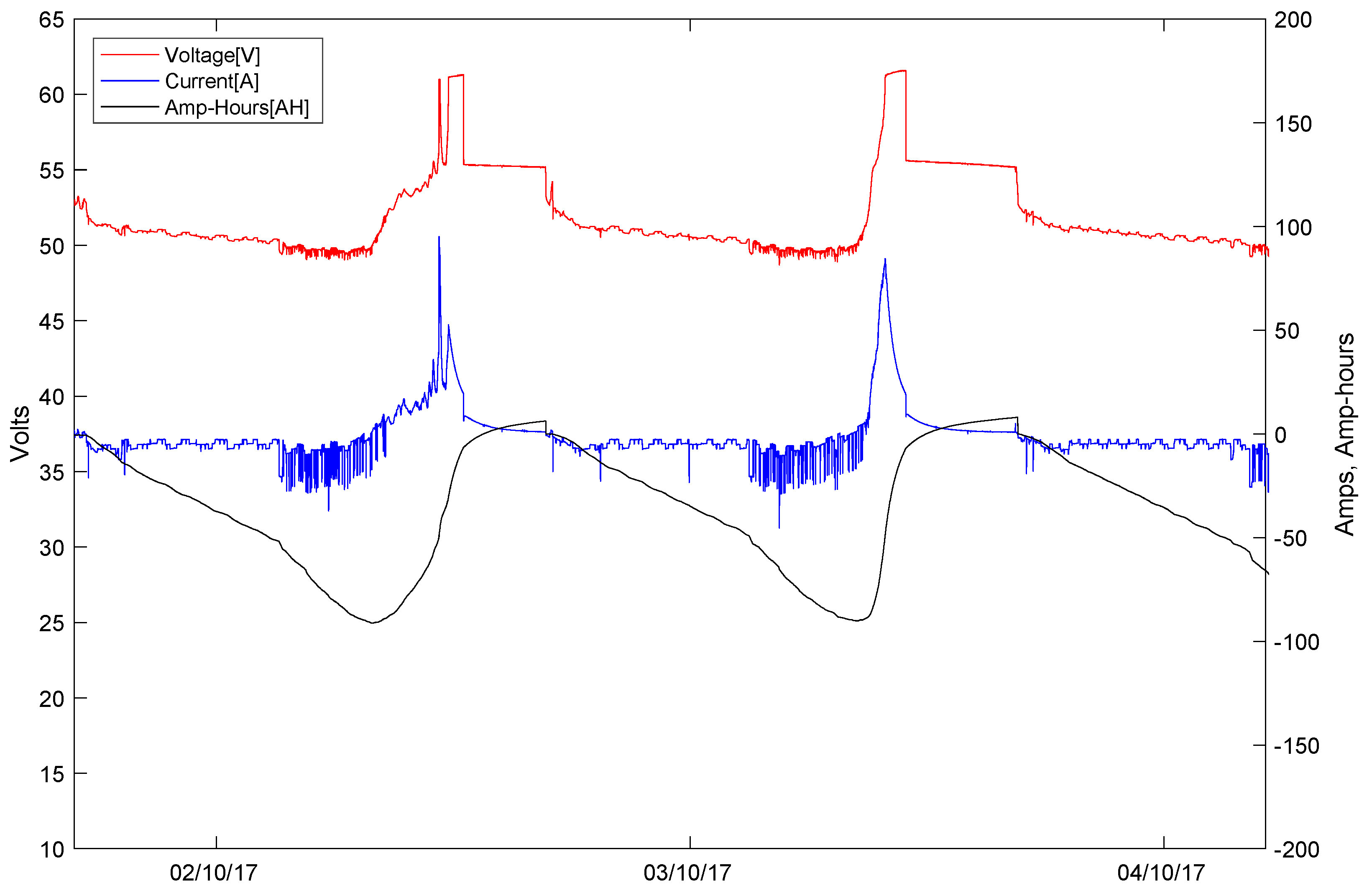

4.2. Normal Battery Operation from 26 August to 2 November 2017

During September and October of 2017, the amp-hour charge reconciliation is found to provide a normal and unremarkable 7% overcharge (see

Table 2). An example operation of the solar charging during this period can be observed in

Figure 4. An expected transition from the constant voltage (CV) “absorption” mode (i.e., on the threshold of battery gassing for maximum charge current) to a lower constant voltage (CV) “float” mode (i.e., minimize charging current) can be observed when the battery current falls to the solar charger’s default setting of 2% of the programmed battery capacity; in this case 2% of 1000 Ah or 20 A. This is a common method, based on instantaneous measurements, to determine when the battery is full and to prevent excessive overcharge by lowering the CV voltage.

Figure 4 also shows the absorption and float CV set points are elevated confirming operation of the automatic temperature compensation of the CV set points for the cooler 15 °C battery. This type of temperature compensation is standard practice for lead-acid battery charging. The solar charge controller was originally configured with 60 V and 54 V for absorption and float CV set points respectively based on 25 °C.

It is worth noting that in

Figure 4, the transition to float CV happens before any amount of overcharge is achieved. The battery is not fully recharged on transition to float as one might anticipate and full charge reconciliation depends on the available duration of the float CV window. This is an early sign of suboptimal battery management where the solar charge regulator should not stop charging (i.e., transition to float) before the battery is fully charged with ~10% overcharge. For example, as the days get shorter, there likely will not be enough sun hours available to fully charge the battery at the float CV.

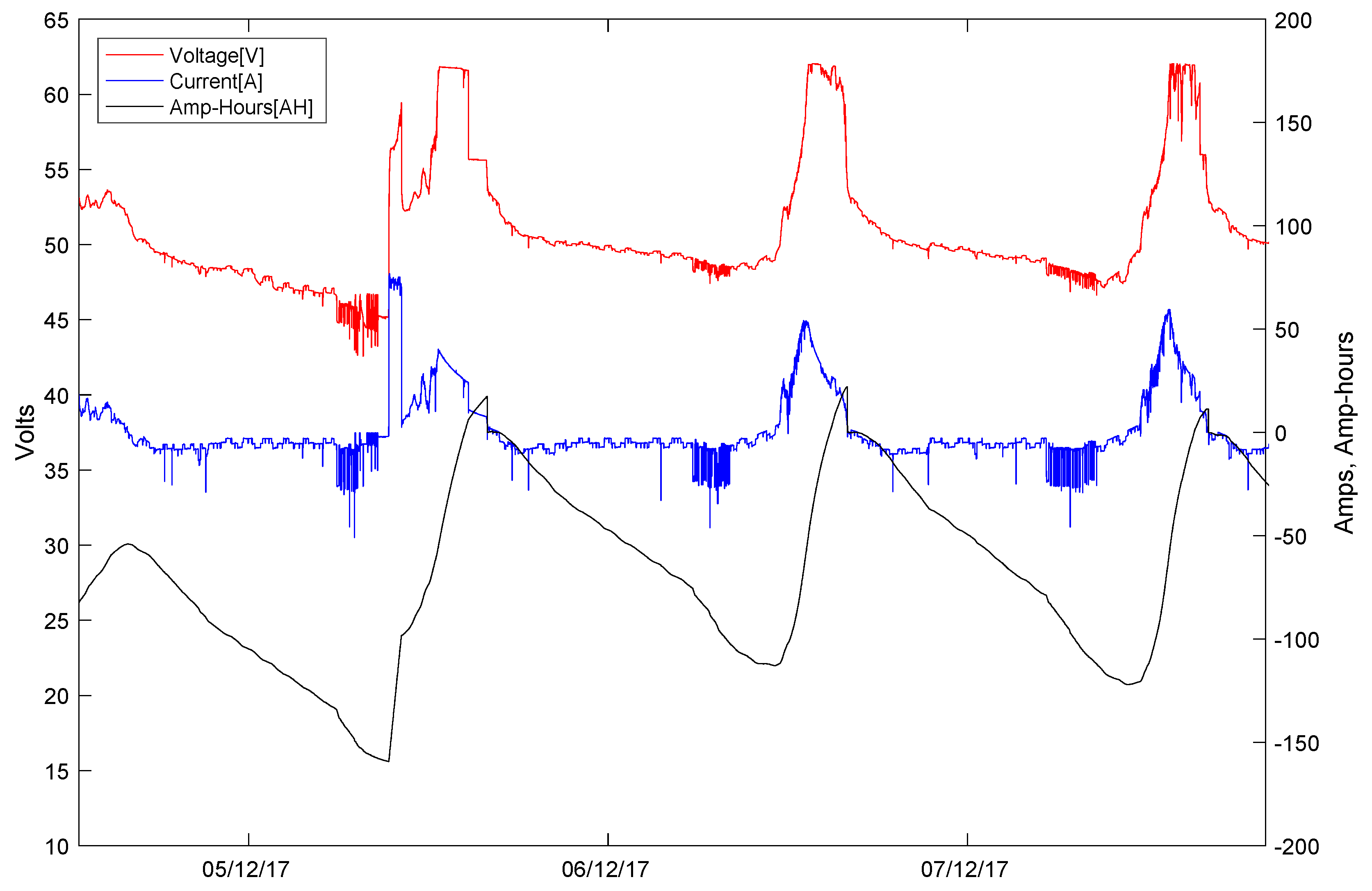

4.3. Battery Undercharging and PSoC Operation from 2 November to 7 December

After the initial deep discharge events in early November due to snow cover, the solar charger and automatic genset control system, i.e., the overall battery management system, as configured were unable to recharge the battery with an effective amount of regular full charge even though an abundance of solar charging energy was available. The accumulated result through to 7 December is a reduction in the effective capacity of the battery. In

Figure 5, the compromised battery bank accepted only 150 Ah from a completely discharged state before the battery management system considered it fully charged.

Throughout this period the system control’s default “genset quiet time” setting of 9 p.m. to 8 a.m. was enabled and blocked the automatic genset charging from starting in the early morning. An example of such behaviour is also shown in

Figure 5. Due to a lack of available automatic genset charging an early morning load repeatedly reduced the now high-impedance battery’s voltage to below the inverter cut-out threshold until the genset eventually started at 8 am. This would not happen with a normally functioning battery due to the battery’s large storage capacity and inherently low impedance. This abnormally low deep discharge event combined with the enabled “genset quiet time” alerted local technical experts to the problem. Since automatic genset start prevented before 8 a.m. the battery voltage dropped to below the AC inverter cut-out value of 42 V (an extremely low battery voltage) and intermittently shut down the AC power to the residence, which prompted the resident to call for assistance. It is worth noting that if “genset quiet time” mode was disabled the genset would have started automatically and the compromised battery would likely have gone unnoticed. This appears to be the case in other applications, allowing PV-genset-hybrid systems with compromised batteries to operate undetected and to increasingly rely on genset supplied energy.

Figure 5 also illustrates that when the genset eventually started at 8 a.m. it reached its stop trigger (stop on “absorption” CV voltage) after only charging the battery with less than 75 Ah. Thus, terminating genset-based charging while the 1000 Ah battery remained severely discharged. Shortly afterwards, solar charging begins and the solar charge regulator achieves its absorption CV setting while the battery continues to accept less than 50 A thus indicating very poor charge acceptance. The solar charge controller then transitions to its float CV setting after the default 180-minute absorption CV mode time limit expires.

Figure 5 thus illustrates a critical issue with the system’s battery management control. The charge management system considers the battery as full even though there is considerable charge energy available, the battery is far from fully charged and the battery is performing with a severely reduced storage capacity.

This process occurs repeatedly within the measured hybrid system battery data and defines an extended period of capacity-reducing PSoC operation between 2 November and 7 December without regular full-charge reconciliation. At the end of November 2017, the usable capacity of the expensive, eight-month-old 1000 Ah battery is approximately 150 Ah between empty and “full” as illustrated by

Figure 5. Also, during the month of November, the amp-hour counter eventually drifted up due to current consumed by secondary gassing reactions. The amp-hour value at this point does not indicate the state of charge of the battery due to the lack of prior overcharge and reset of the accumulator (see

Table 2).

In early December 2017, local technical experts investigated the issue of intermittent AC power. Two of the 24 battery cells were found to be at specific gravity levels of 1.10 and were significantly out of balance with the rest, which were near 1.25. It has been noticed in previous systems, albeit anecdotally, that after deep discharge events and subsequent partial state of charge operation a small number of cells drift to lower specific gravities than the rest, i.e., the appearance of so-called “bad” cells. It is in these situations that the inherent inconsistencies between batteries become evident and the “Big Cell” approximation method discussed previously is especially challenging. A battery bank can often be rebalanced or equalized with an appropriate amount of overcharge or amp-hour reconciliation. The procedure was described in [

17]. At the time of inspection, the severity of the reduction in effective battery capacity as now illustrated by the data in

Figure 5 was unknown. Rather than replace the two problematic cells, the decision was made to attempt to recover the relatively new battery with the following system control changes: 1) The float voltage of the solar charger was increased to the absorption voltage of 60 V thereby effectively eliminating float mode of operation and promoting increased overcharge and amp-hour reconciliation. 2) The automatic genset start trigger was significantly increased to 47.5 V to avoid further deep discharge of the unbalanced cells 3) genset “quiet time” feature was disabled and 4) the automatic genset stop trigger was changed from “stop on absorption voltage” to “stop on transition to float” thus allowing a more complete absorption charging period with each genset start event; albeit at the expense of lower genset loading and increased fuel consumption.

4.4. Battery Recovery from 7 December 2017 to 7 March 2018

An immediate battery recovery was not expected. The hypothesis was that over time, the twenty-four series cells would experience a more aggressive amp-hour reconciliation from the large PV array and gradually recover at the minor expense of increased water consumption. In the short term, several corrective charge events were also performed as facilitated by the equipment’s standard one-hour duration equalize feature. These events can be observed as the two ~100 amp-hour overcharges during the first week of December in

Figure 3. Unfortunately spending an hour (or multiple hours) at an elevated 64 V “equalize” CV voltage was not enough to adequately correct or recover the battery.

In retrospect, the battery may have been substantially recovered simply by performing a supervised 20-hour genset-based reconditioning charge at a constant current of 50 A and with no voltage limit to provide a total of 1000 Ah returned. However, at the time the extent of the capacity loss, or even if the battery would recover at all, was unknown. Also, constant current recovery charging with the genset would require relatively complex temporary control system setpoint overrides and also result in a long duration of battery heating and significant hydrogen and oxygen generation. In this case, the risk was thought to outweigh the benefit. Furthermore, it was fundamentally interesting and perhaps more useful to discover if the battery could be slowly recovered with less aggressive (and less risky) overcharging. The prior battery behaviour and subsequent success of this experiment form the basis of this communication.

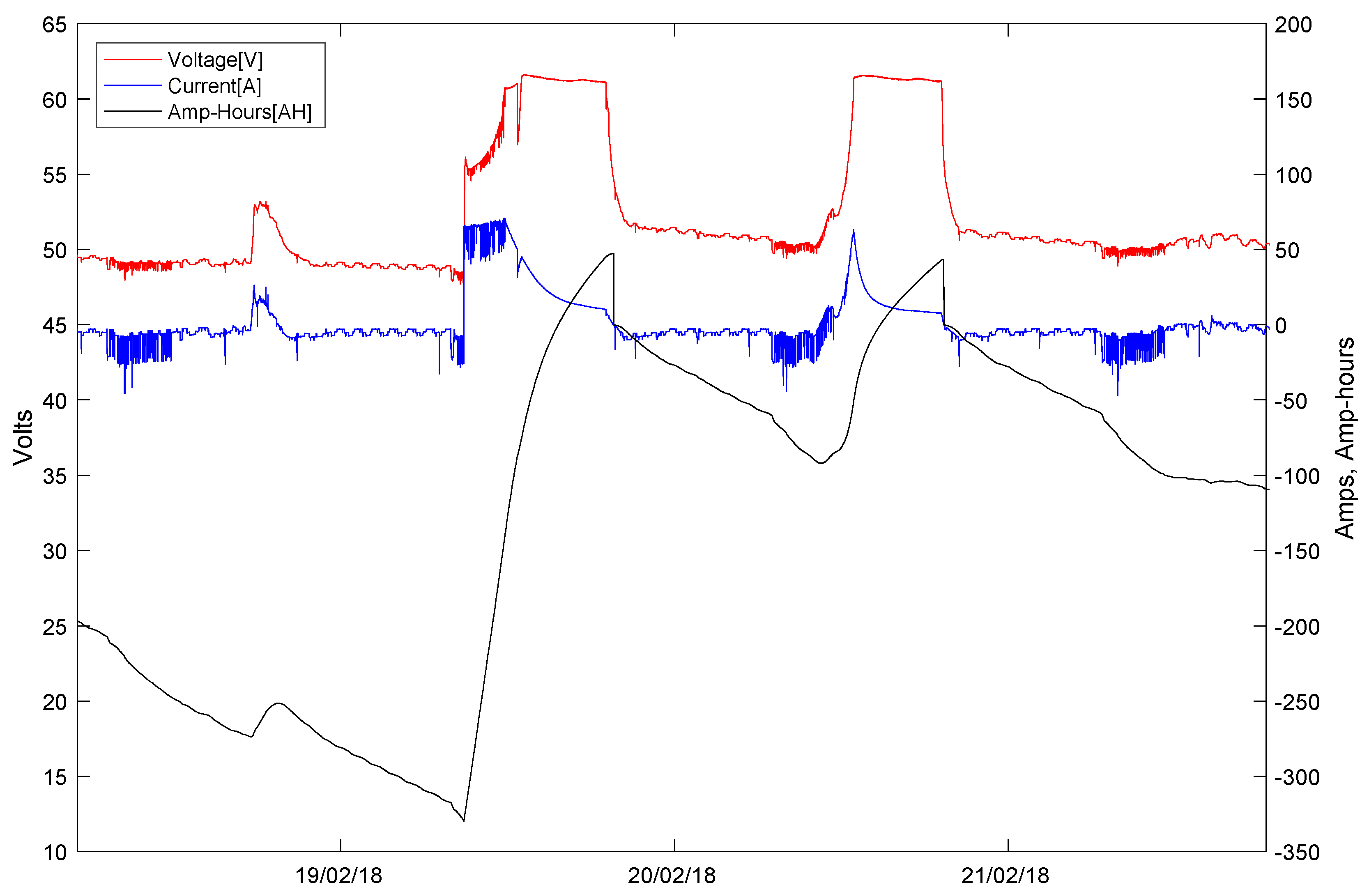

After the system set points were updated, there was another period of snow cover and reduced solar energy available at the end of December, as shown in

Figure 3. This time the automatic genset started reliably at the new 47.5 V threshold and charged completely through the absorption CV mode and down to the float transition current at which point the generator automatically stopped as shown in

Figure 6. However, during this period

Figure 6 also shows an obvious reduction in effective battery capacity for each charging cycle with the already reduced battery capacity reducing substantially more over the five cycles, i.e., less amp-hours available between the automatic genset start/stop triggers as set within the controller. This observed reduction in effective battery capacity due to incomplete genset-based cycle charging is a significant observation and is the basis for what has been previously seen anecdotally within other hybrid systems in the community.

PV-genset-battery hybrid systems operating in a genset charge cycling mode and where a full overcharge is not, or cannot be, performed regularly are challenged with maintaining effective battery capacity even if they endure a full absorption stage CV duration. In

Figure 6, the lack of 10% overcharge is clear where the amp-hour value barely returns to zero each cycle. The subsequent reduction in effective battery capacity is also apparent reducing by over 30% in just five cycles over five days. During this period of genset-based cycle charging, it would appear beneficial to manage the system in order to maintain appropriate charge return and to mitigate capacity loss by ensuring appropriate amp-hour replacement. It should be noted that only flooded lead-acid batteries, of various brands and sizes, have been used within the community to date.

Following the period of partial state of charge (PSoC) due to the snow cover and automatic genset cycling in late December, significant overcharge can be observed in the amp-hours plot of

Figure 3 as the sun returns and solar charger can spend more time slowly replenishing charge. In late February several low sun days again trigger the automatic genset to start. One of the genset start events is shown in

Figure 7 on the morning of February 19. The genset starts and shortly after solar charging takes over and directs the genset to shut down. The current remains above 10 A for over 12 h and illustrates an improved charge acceptance and the effect of operating in absorption CV charge mode for an extended time. The extra charging at absorption CV for a number of hours per day appears to have provided the overcharge critical for recovering the battery bank. The same automatic genset trigger points are used at the end of December as at the end of February, but the latter shows improved charge acceptance and shows a large improvement in effective storage capacity as noted in

Figure 3. In late February,

Figure 3 also shows a general increase in overcharge due to longer sun exposure and indicates sustained overcharge beyond 10%.

On 7 March, local technicians revisited the site to take a specific gravity (SG) measurement and to reinstate the float voltage from 60 V back to the original 54 V thereby reducing the overcharge due to longer days of sun. The battery bank recovered substantially improving from a SG range of 0.15; where 22 of the 24 cells were near 1.25 (full) and two at 1.10 (empty) in early December 2017, to all of the cells measuring above 1.30 (full) in March 2018. At this point, the precision battery data used in this article was also recovered from the data logger. The SG readings combined with post-event data analysis suggest substantial recovery of the battery capacity. However, a capacity measurement was not attempted due to the impracticality of such a test in the field.

To avoid future deep discharging and prevent premature genset starts, the system was adjusted to initiate genset charging below 46.5 V; 2 V above the default set point and 1 V below the 47.5 V that was used to recover the battery. While this will improve the situation for next year by reducing any deep discharge events and mitigate PSoC operation to some extent, it is not obvious that it will prevent notable wintertime capacity reduction. New battery data will be re-examined at the end of subsequent winters and compared to the prior years’ performance.

5. Discussion

The measured battery data details a sustained period of undercharging and subsequent capacity reduction of the battery. The battery management system as configured is unable to correct for the substantial reduction in effective battery capacity using standard CV and CC charging techniques. Manually configuring an extended “absorption” CV duration by adjusting the float voltage to the absorption voltage is shown to improve battery performance and recover the lost battery capacity. However, it is not suitable for permanent operation due to excessive overcharge once the battery is recovered.

Table 2 summarizes the measured overcharge in terms of amp-hour reconciliation for the main periods discussed in this work.

From 26 August to 2 November (before the first deep discharge event in November) the average overcharge was found to be 7% and the system is shown to operate stably on 100% solar power. However, the lack of full charge replenishment on the transition to float is notable. During the period of 2 November to 7 December, the battery system was subject to an extended duration of partial state of charge (PSoC) operation.

Figure 3 clearly shows a lack of regular full charge completion during this period. Regular operation at the absorption CV voltage results in some of the charging current contributing to secondary gassing reactions, which are not recoverable stored energy. As a result, the amp-hour integration slowly accumulates due to charge inefficiency and becomes increasingly unrelated to the available state-of-charge of the battery. In the previous period until 2 November, the amp-hour integration is regularly synchronized to a fully charged battery and provides a reasonable drift-free indicator of state-of-charge information. This also explains why on 7 December,

Figure 5 shows the amp-hour count to be positive, but the battery is still in a severely compromised and discharged state.

Table 2 shows the average amp-hour overcharge during this month was 1%. It might seem like the battery has been regularly charged, but the opposite is in fact true. In this circumstance, some insight with respect to interpreting the value of the amp-hour accumulator is important. The results of this study suggest that a 1% overcharge on average is not nearly enough to support reasonable lead-acid battery performance. However, if the CV voltage set points were to be actively controlled based on feedback from the amp-hour accumulator, a greater than 1% overcharge would be achieved. Furthermore, with an appropriate amount of overcharge, the amp-hour accumulator would remain synchronized with the fully charged battery and therefore provide direct insight with respect to available battery capacity.

During the recovery period of 7 December to 7 March, the resulting amount of average overcharge increased to 20%. This means a higher than normal contribution to the secondary gassing reaction was realized in order to allow the dischargeable primary reaction to recover. Both

Figure 3 and

Figure 7 show a substantial increase in the working capacity of the battery by March.

Over the total duration of 26 August to 7 March, the average amp-hour overcharge was what might be considered normal at 12%. Ideally, the sophisticated charging system comprised of sensors, power electronics and controllers might attempt to maintain a target long-term amp-hour reconciliation of approximately 10% in a “closed loop control mode” thereby increasing the robustness and performance of hybrid systems in the field. While the inherent details of insufficient charge reconciliation and battery management will likely go unnoticed by most users—as it may have in this example if the AC power had not been interrupted—anecdotal experience and the example data within suggest that inherent suboptimal charging and extended periods of PSoC may be occurring within many hybrid systems operating around the world. While it is common for battery charging CV set points to automatically adapt based on battery temperature, closed loop CV set point control designed to maintain a target percent overcharge is not thought to be found in solar-based hybrid power system technology today and provides an interesting direction for impactful future research.

It is unknown at this point what effects suboptimal charging will have on overall battery life in the field systems. What is known is that a reduction in battery capacity results in less utilization of the solar resource, increased dependence on the fuel burning genset and an overall negative shift in system economics and greenhouse gas (GHG) emissions. Batteries are also expensive and it stands to reason that a battery of a certain capacity should be managed according to recommended charging practices in order to maintain its rated capacity over time.

6. Future Work

Interesting future work is to recreate the PSoC period of 2 November to 7 December within an instrumented laboratory battery bank. This will provide an opportunity to further evaluate the effectiveness of advanced pack-based SOC state of charge estimation methods as described in [

13] including Kalman filter based estimators. However, the simple amp-hour integration method may prove to be adequate based on the inherent tolerance of and the requirement for lead-acid batteries to be overcharged and the ability of the amp-hour integrator to consistently reset at the full stage of charge. In this case, amp-hour (coulomb counting) drift is not the same concern it is with lithium-based batteries that are intolerant to overcharge.

An instrumented laboratory battery bank also permits controlled evaluation of the closed loop battery management method where CV set points are adjusted to regulate an appropriate amount of overcharge. However, work remains with respect to evaluating the sensitivity of battery management performance for adjustments in the CV regulation set point.

7. Conclusions

This paper has examined the performance of a lead-acid battery bank within a residential PV-genset-battery hybrid off-grid power system. Insufficient battery management and incomplete charging during the low-sun winter season have been observed over the last 12 years within other PV-genset-battery hybrid power systems in the community. To investigate characteristics of this battery behaviour, precision battery data loggers have been installed to collect multi-year high-resolution battery data from eight newly installed PV-genset-battery hybrid power systems in the community. Over the winter of 2017–2018, one of the monitored systems experienced an almost complete reduction in battery capacity due to an extended period of partial state of charge operation. High-resolution battery performance data for this particular system has been explored within this paper. The data shows that over four months, the effective battery capacity was severely depleted and then recovered via the manual intervention of system control set points.

Initially, the PV-genset-battery hybrid power system’s batteries performed without issue. However, after a deep discharge event due to snowfall, the control system is shown to be ineffective at maintaining battery capacity and the battery bank suffered a substantial loss in effective capacity. The power conversion and automatic charge control systems (i.e., the battery management system) are shown to be ineffective at maintaining battery capacity and overall battery health under the observed conditions. Manual intervention of battery charger set points is shown to slowly recover the battery bank over the subsequent three months; thus suggesting it is possible to maintain battery capacity if the battery management system is properly equipped. This paper illustrates that knowledge of the integrated amp-hour count is important for determining when adequate amounts of overcharge in the amp-hour charge reconciliation are achieved. An average overcharge rate of 1% overcharge is shown to be detrimental to flooded lead-acid battery performance. A temporary overcharge rate of near 20% is shown to recover a severely compromised battery over three months but would be detrimental for long-term operation. It would appear that maintaining an approximate 10% overcharge would ensure improved battery behaviour for both PV-genset-battery hybrid systems and elemental PV-battery only systems. This functionality is not obviously provided by the equipment available on the commercial market.

Using feedback from an amp-hour integrator to determine adaptive CV regulation set points in order to strategically increase or decrease the rate of the charging to achieve an overcharge target can be considered a closed loop charge control strategy. Closed-loop charge management of lead-acid batteries is not commonly implemented in the off-grid residential hybrid equipment industry today. This documented real-world example makes the case for its merit and supports further investigation into the concept.

Author Contributions

Conceptualization, A.S.; methodology, A.S. and J.T.; investigation, A.S.; writing—original draft preparation, A.S. and J.T.; writing—review and editing, A.S. and J.T.

Funding

This research received no external funding.

Acknowledgments

The authors would like to thank the community of Xeni Gwet’in and, in particular, George Colgate for their assistance in facilitating this work and supplying the data. The battery data studied was originally presented at the 3rd International Hybrid Power Systems Workshop in Tenerife Spain (2018).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Diouf, B.; Pode, R. Potential of lithium-ion batteries in renewable energy. Renew. Energy 2015, 76, 375–380. [Google Scholar] [CrossRef]

- Ayeng’o, S.P.; Schirmer, T.; Kairies, K.; Axelsen, H.; Sauer, D. Comparison of off-grid power supply systems using lead-acid and lithium-ion batteries. Sol. Energy 2018, 162, 140–152. [Google Scholar] [CrossRef]

- Rand, D.A.; Moseley, P.T. Lead-acid systems overview. In Valve Regulated Lead-Acid Batteries, 1st ed.; Moseley, P., Garche, C., Parker, C.D., Rand, D.A.J., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2004; pp. 1–14. ISBN 978-0-444-50746-4. [Google Scholar]

- Rand, D.A.; Moseley, P.T. Lead-acid systems overview. In Valve Regulated Lead-Acid Batteries, 1st ed.; Moseley, P., Garche, C., Parker, C.D., Rand, D.A.J., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2004; pp. 245–249. ISBN 978-0-444-50746-4. [Google Scholar]

- Bonduelle, G.; Coldrick, W.; Pope, M. Telecom hybrid power battery management in full and partial state of charge. In Proceedings of the 2011 IEEE 33rd International Telecommunications Energy Conference (INTELEC), Amsterdam, The Netherlands, 9–13 October 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Krieger, E.M.; Cannarella, J.; Arnold, C.B. A comparison of lead-acid and lithium-based battery behaviour and capacity fade in off-grid renewable charging applications. Energy 2013, 60, 492–500. [Google Scholar] [CrossRef]

- Swingler, A.; Edmunds, M. PV/Genset/Hybrid Power for the Remote Home: Cost Sensitivities and the Demonstration at Xeni Gwet’in. 2007. Available online: https://www.nrcan.gc.ca/sites/www.nrcan.gc.ca/files/canmetenergy/files/pubs/2007-148e.pdf (accessed on 18 November 2018).

- Swingler, A.; Colgate, G. 12 years of residential ‘off-grid’ hybrid power system operation and evolution in Nemiah Valley, Canada. In Proceedings of the 3rd International Hybrid Power System Workshop, Tenerife, Spain, 8–9 May 2018. [Google Scholar]

- Lujano-Rojas, J.M.; Dufo-López, R.; Atencio-Guerra, J.L.; Rodrigues, E.M.; Bernal-Agustín, J.L.; Catalão, J.P. Operating conditions of lead-acid batteries in the optimization of hybrid energy systems and microgrids. Appl. Energy 2016, 179, 590–600. [Google Scholar] [CrossRef]

- Halabi, L.; Mekhilef, S.; Olatomiwa, L.; Hazelton, J. Performance analysis of hybrid PV/diesel/battery system using HOMER: A case study Sabah, Malaysia. Energy Convers. Manag. 2017, 144, 322–339. [Google Scholar] [CrossRef]

- Zhou, W.; Lou, C.; Li, Z.; Lu, L.; Yang, H. Current status of research on optimum sizing of stand-alone hybrid solar–wind power generation systems. Appl. Energy 2010, 87, 380–389. [Google Scholar] [CrossRef]

- Barcellona, S.; Brenna, M.; Foiadelli, F.; Longo, M.; Piegari, L. Analysis of Ageing Effect on Li-Polymer Batteries. Sci. World J. 2015, 2015, 979321. [Google Scholar] [CrossRef] [PubMed]

- Xiong, R.; Cao, J.; Yu, Q.; He, H.; Sun, F. Critical Review on the Battery State of Charge Estimation Methods for Electric Vehicles. IEEE Access 2018, 6, 1832–1843. [Google Scholar] [CrossRef]

- Nejabatkhah, F.; Li, Y. Overview of Power Management Strategies of Hybrid AC/DC Microgrid. IEEE Trans. Power Electron. 2015, 30, 7072–7089. [Google Scholar] [CrossRef]

- Moseley, P.T.; Rand, D.A. Partial state-of-charge duty: A challenge but not a show-stopper for lead-acid batteries! ECS Trans. 2012, 41, 3–16. [Google Scholar] [CrossRef]

- Sanz-Gorrachategui, I.; Bernal, C.; Oyarbide, E.; Garayalde, E.; Aizpuru, I.; Canales, J.M.; Bono-Nuez, A. New battery model considering thermal transport and partial charge stationary effects in photovoltaic off-grid applications. J. Power Sources 2018, 378, 311–321. [Google Scholar] [CrossRef] [Green Version]

- Battery User Manual. Available online: http://rollsbattery.com/public/docs/user_manual/Rolls_Battery_Manual.pdf (accessed on 28 April 2019).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).