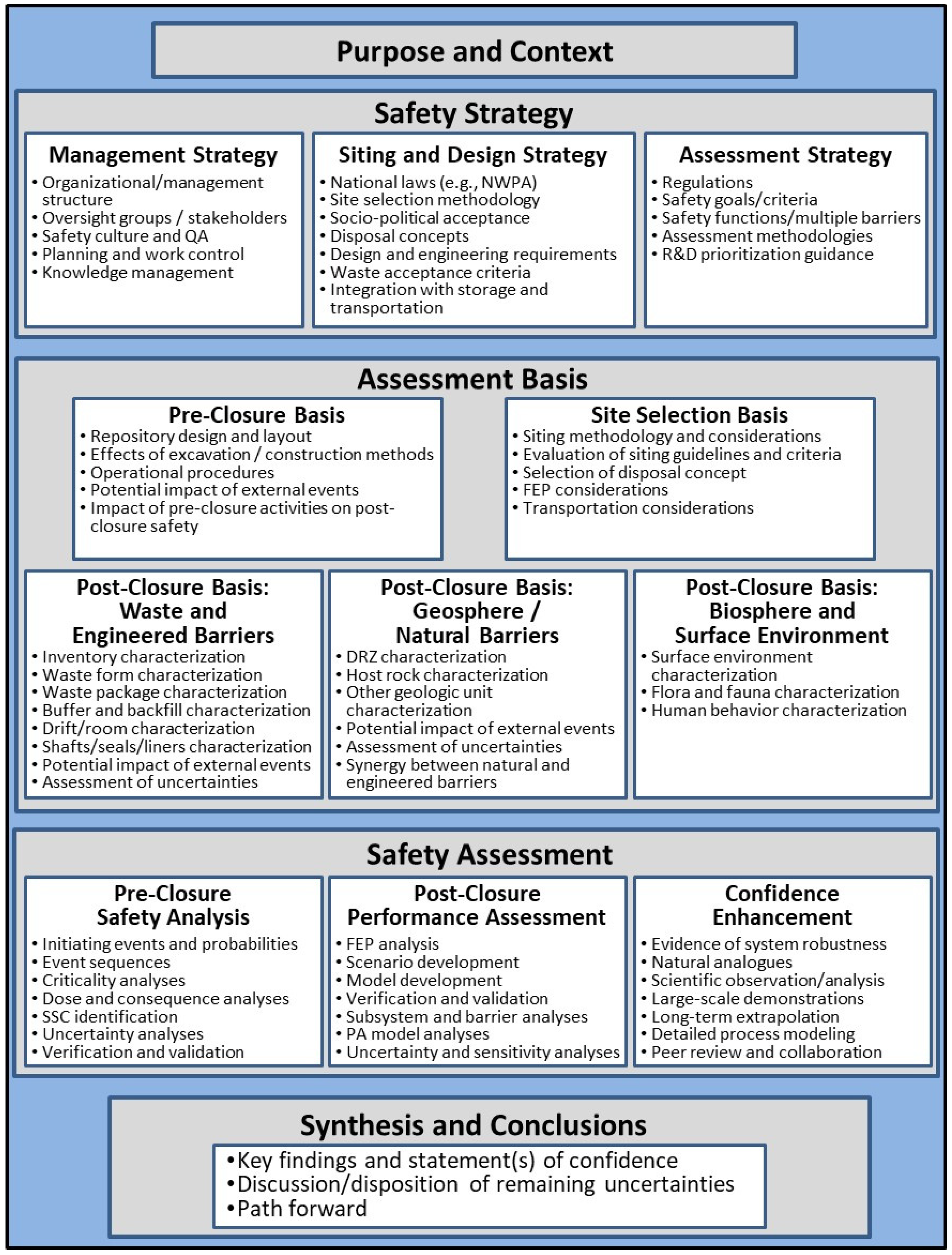

Deep Borehole Disposal Safety Case

Abstract

:1. Introduction

- Relevant portions of the existing general standards (10 CFR 60 and 40 CFR 191),

- Anticipated updates consistent with the risk-informed approach in 10 CFR 63 and 40 CFR 197, and

- Generic standards that incorporate dose or risk metrics recognized internationally to be important to establishing repository safety.

2. Deep Borehole Disposal Assessment Basis

- DBD site design and layout (surface facilities, borehole, and engineered barriers)

- Borehole drilling and construction requirements

- DBD site operations (surface facility operations, waste package surface handling, waste package downhole emplacement, borehole sealing and plugging, and facility closure)

- Potential impacts of off-normal events (dropping a waste package, retrieval of a waste package stuck in upper portion of borehole, pre-closure breach of a waste package) and/or external/disruptive events (flooding and extreme weather, seismicity, sabotage) on pre-closure safety

- Potential impacts of pre-closure activities and components on post-closure safety (e.g., waste package stuck in borehole and abandoned, hydrogen (H2) gas generation from metal corrosion, efficacy of borehole seals and plugs)

- Inventory characteristics and quantities (Cs, Sr, and other constituents)

- Waste form characteristics (degradation and solubility)

- Waste package characteristics (carbon steel corrosion)

- Characteristics of the EZ (buffer/backfill/annulus brine evolution, cement plug degradation, perforated steel liner corrosion)

- Characteristics of the borehole seals (degradation of bentonite seals, cement plugs, and sand/crushed rock ballast)

- Crystalline basement host rock characteristics (permeability, porosity, diffusion coefficient, thermal properties, pore fluid chemistry, solubility, sorption)

- DRZ characteristics (extent and properties)

- Overburden characteristics (sedimentary sequence and properties)

- Biosphere characteristics (for this preliminary, generic iteration of the safety case, the biosphere is not yet conceptualized and is not part of the PA model)

- Potential impacts of external events (climate change, glaciation/erosion, seismicity, igneous activity, human intrusion)

3. Deep Borehole Disposal Safety Assessment

- Adequacy of site characterization

- Achievability of deep drilling

- Safety of site operations

- Great depth of disposal

- Isolation and long residence time of deep groundwater

- Density stratification of brine at depth

- Low permeability of crystalline host rock

- High-likelihood of slow diffusion-dominated radionuclide transport

- Geochemically-reducing conditions at depth

- Low permeability and high sorption capacity of seal materials

- Multi-barrier design

- Evidence for isolation and long residence time of deep groundwater

- Hydrologic modeling of density stratification of brine at depth

- Review of borehole sealing materials and technologies

4. Evidence for Isolation and Long Residence Time of Deep Groundwater

- Sampling and Evaluation While Drilling: Drilling fluid (mud) logging, coring and core analysis, borehole geophysical logging, single-packer hydraulic testing and sampling, and hydraulic fracturing (mini-frac) test.

- Open Hole Testing and Sampling: Flowing fluid electrical conductivity (FFEC) logging, multi-packer hydraulic testing and sampling, hydraulic fracturing stress measurement tests, and injection/withdrawal (push-pull) tracer tests.

4.1. Chemical Composition and Salinity

- Shallow zone (0–500 m depth), where groundwater regularly interacts with surface water and has a low total dissolved solids (TDS) (<30 g/L). Fluids are dilute to brackish with major element compositions dominated by sodium (Na+), calcium (Ca2+) and bicarbonate (HCO3−).

- Intermediate zone (500–1500 m depth), where the transition to higher TDS occurs. Fluids are more saline and evolve toward Na and Ca sulfate (SO42−) and chloride (Cl−) compositions.

- Deep zone (>1500 m depth), where fluids have TDS from >50 g/L to a maximum of about 350 g/L. Deep fluids are typically saline brines of NaCl or CaCl2 composition (with Ca/Na ratio increasing with depth), although magnesium (Mg2+) and/or bromide (Br−) may be a minor presence (Frape 2015). Densities of deep brine can range from 2.5% greater than pure water (similar to seawater, ρ = 1.025 g/cm3) to more than 30% greater than pure water (ρ = 1.300 g/cm3) [23,24,25].

4.2. Environmental Tracers

- Major Anions: Br−, F−, I−, SO42−, NO3− + NO2‒

- Major Cations: Na+, Ca2+, K+, Mg2+, Fe2+, Fe3+

- Trace Elements: Al, Sb, As, Ba, Be, Cd, Cr, Co, Pb, Li, Mn, Hg, Mo, Ni, Se, Sr, Ag, Sn, U

- Trace Elements (to compare with concentrations in rock samples/isotopic ratios): Li, Sr, Th, U

- Noble Gases: He, Ne, Ar, and Xe

- Cosmogenic/Anthropogenic Isotopes: 3H, 21Ne, 36Cl, 85Kr, and 129I

- Fission Products Isotopes: 36Cl and 129I

- Radiogenic/Nucleogenic Noble Gas Tracers: 3He, 4He, 39Ar, 81Kr, and 129Xe

- Isotopic Ratios: 234U/238U, 87Sr/86Sr, 6Li/7Li

- Stable Isotopes: δ18O (oxygen) and δ2H (deuterium)

- Water Quality Parameters: pH, Eh, temperature, viscosity, salinity, TDS, density/specific gravity.

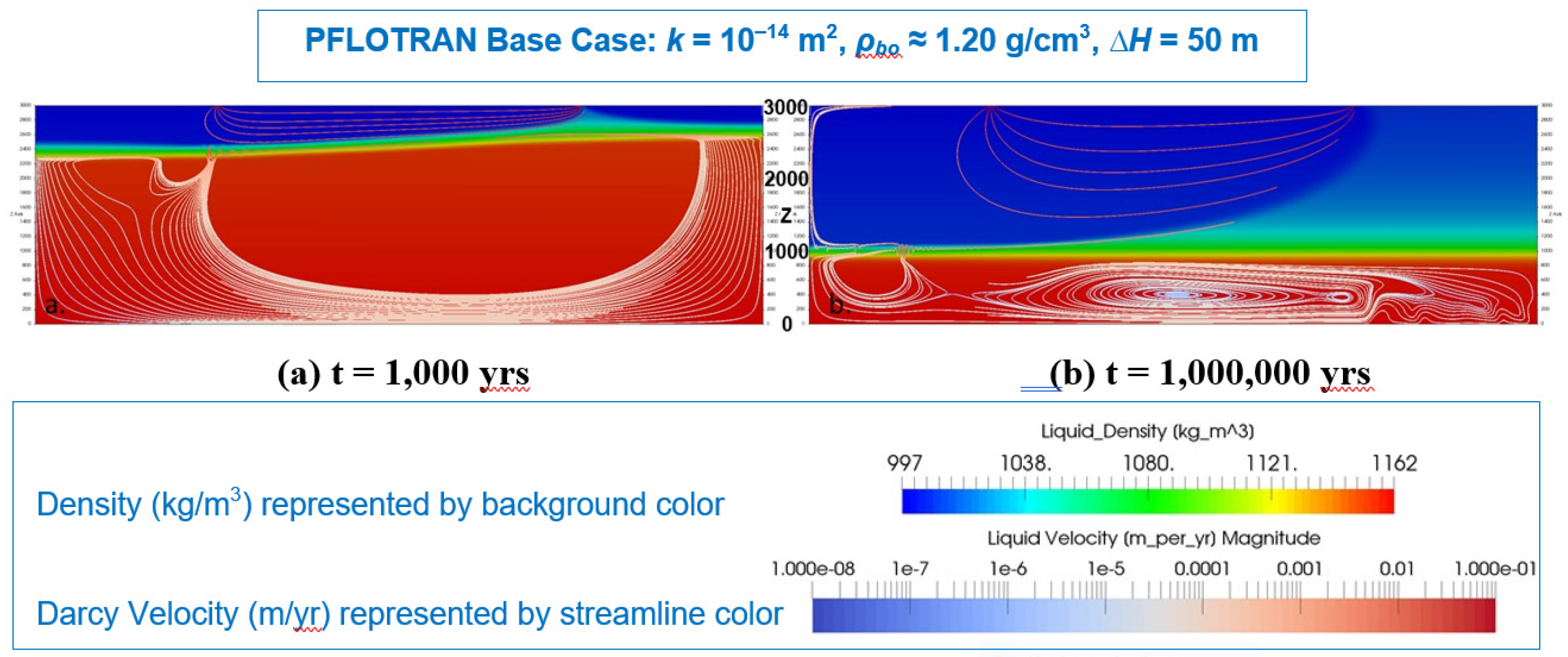

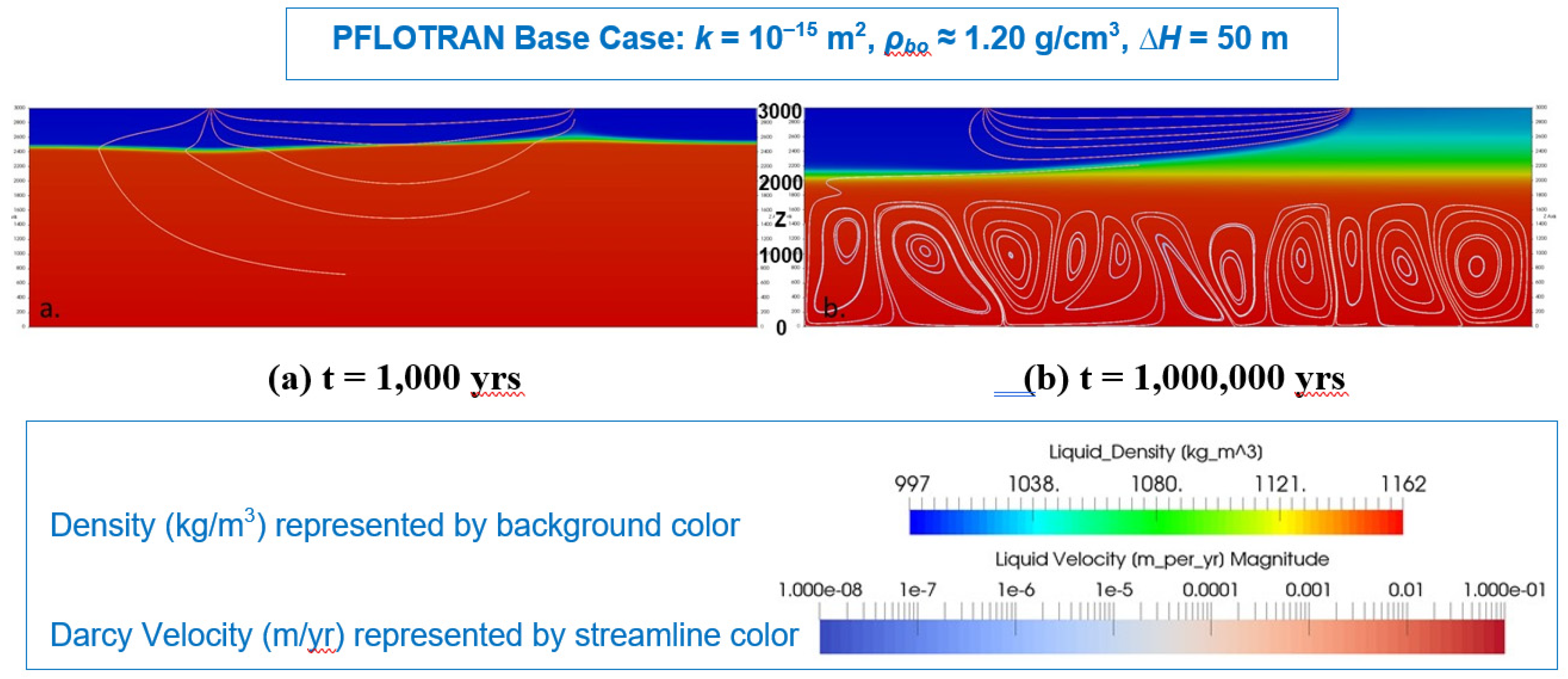

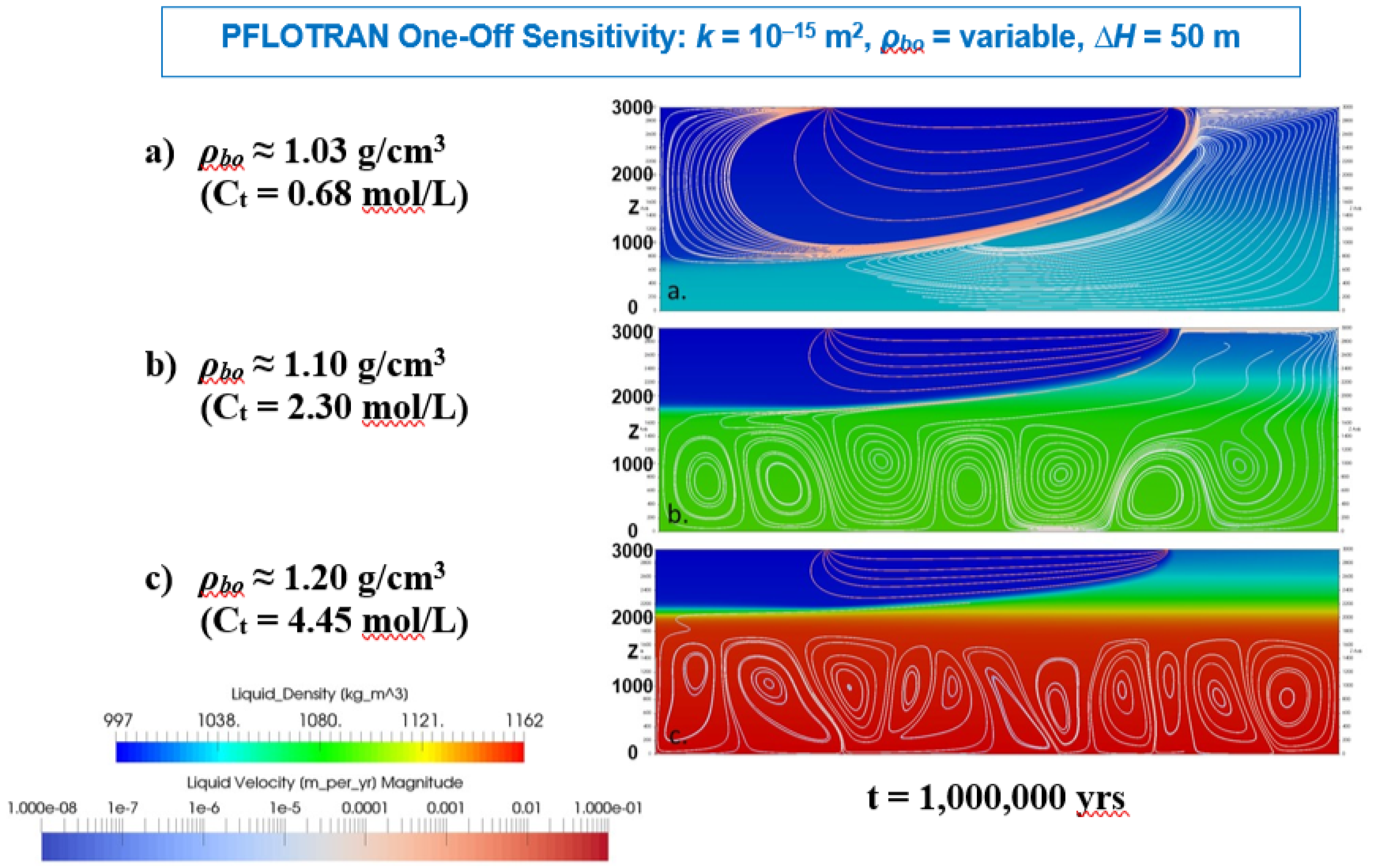

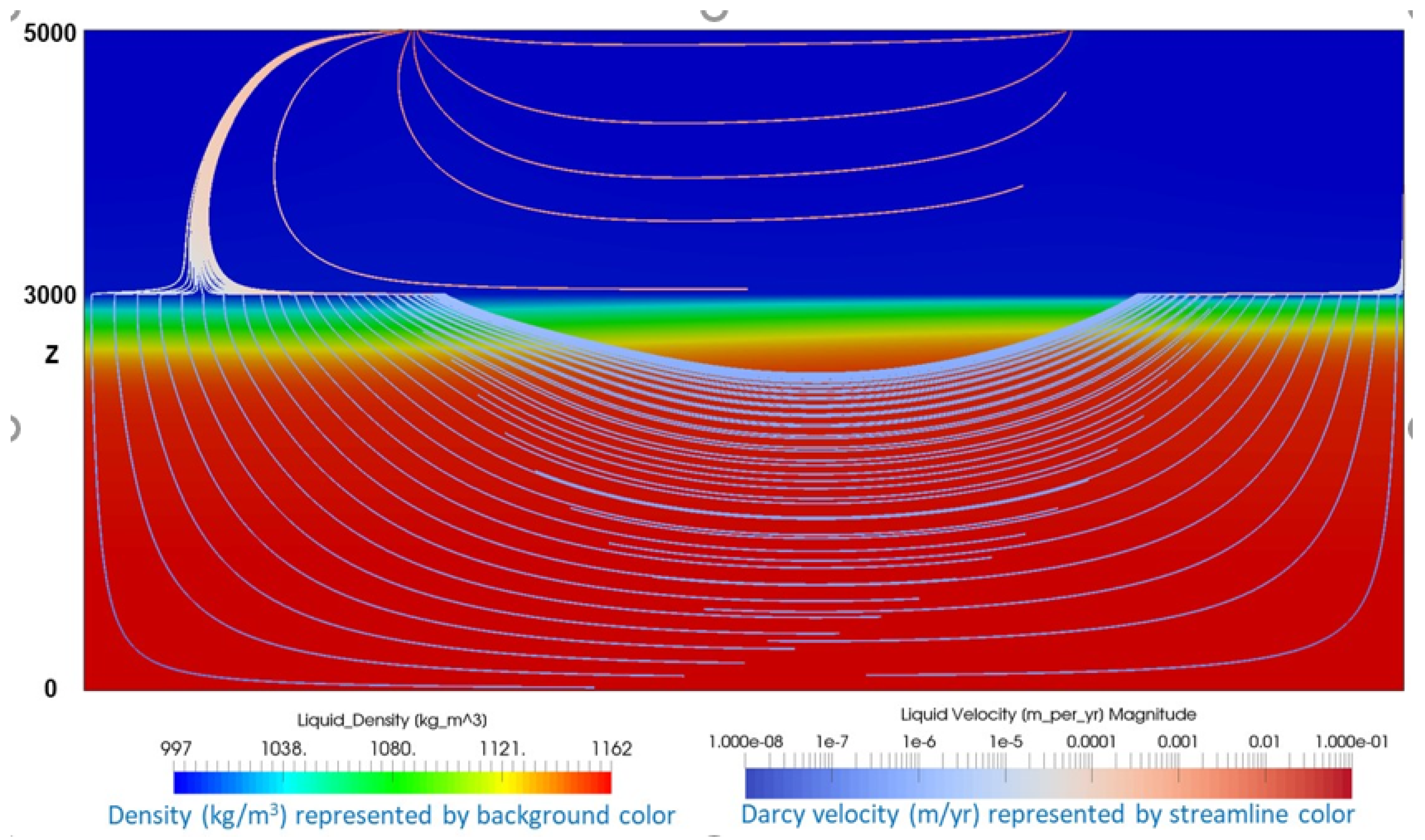

5. Hydrologic Modeling of Density Stratification of Brine

5.1. Numerical Implementation

5.1.1. Regional-Scale Simulations

- homogeneous rock properties: k = 10−14 m2 (intrinsic permeability), ϕ = 0.01 (porosity)

- initial salinity at depth: Ct = 4.45 mol/L, to approximate brine density ρbo ≈ 1.20 g/cm3

- hydraulic head difference: ∆H = 50 m, corresponding to a hydraulic head gradient of 0.01

- initial salinity at depth: Ct = 0.029, 0.68, and 2.3 mol/L at depth, corresponding to ρbo ≈ 1.00, 1.03, and 1.10 g/cm3, respectively

- hydraulic head difference: ∆H = 25, 100, and 500 m, corresponding to hydraulic head gradients of 0.005, 0.02, and 0.10, respectively

5.1.2. DBD-Scale Simulation

- the domain is extended to a depth of 5000 m

- the upper 2000 m (undifferentiated sediments) have k = 10−15 m2, ϕ = 0.20, and initial Ct = 0.029 mol/L (ρo ≈ 1.00 g/cm3)

- the lower 3000 m (crystalline basement) have k = 10−18 m2, ϕ = 0.005, and initial Ct = 4.45 mol/L (ρbo ≈ 1.20 g/cm3)

5.2. Model Results

5.2.1. Regional-Scale Model Domain

5.2.2. DBD-Scale Model Domain

6. Borehole Sealing

6.1. Performance Targets

6.2. Materials

6.2.1. Cements

6.2.2. Bentonite and Other Clay-Based Systems

6.2.3. Geopolymers

6.2.4. Silicone Rubber

6.2.5. Asphalt

6.2.6. Crushed Rock

6.2.7. Sandaband®

6.2.8. Ceramic Seals

6.2.9. Rock Welding

6.2.10. DRZ Minimization

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Freeze, G.; Leigh, C.D.; Sevougian, S.D.; Gross, M. A Safety Framework for Disposal of Heat-Generating Waste in Salt: Annotated Outline. FCRD-USED-2012-000431, SAND2012-10797P; Sandia National Laboratories: Albuquerque, NM, USA, 2012. [Google Scholar]

- NEA (Nuclear Energy Agency). Methods for Safety Assessment of Geological Disposal Facilities for Radioactive Waste: Outcomes of the NEA MeSA Initiative. NEA No. 6923; Organisation for Economic Co-operation and Development, Nuclear Energy Agency: Paris, France, 2012. [Google Scholar]

- NEA (Nuclear Energy Agency). Confidence in the Long-term Safety of Deep Geological Repositories: Its Development and Communication; Organisation for Economic Co-operation and Development, Nuclear Energy Agency: Paris, France, 1999. [Google Scholar]

- NEA. Communicating Confidence in the Safety of Deep Geologic Disposal: Approaches and Arguments; OECD/NEA: Paris, France, 2002. [Google Scholar]

- NEA (Nuclear Energy Agency). Post-Closure Safety Case for Geological Repositories, Nature and Purpose. NEA Report No. 3679; Organisation for Economic Co-operation and Development, Nuclear Energy Agency: Paris, France, 2004. [Google Scholar]

- Freeze, G.; Voegele, M.; Vaughn, P.; Prouty, J.; Nutt, W.; Hardin, E.; Sevougian, S. Generic Deep Geologic Disposal Safety Case, SAND2013-0974P, REV 1; Sandia National Laboratories: Albuquerque, NM, USA, 2013. [Google Scholar]

- Arnold, B.W.; Brady, P.; Altman, S.; Vaughn, P.; Nielson, D.; Lee, J.; Gibb, F.; Mariner, P.; Travis, K.; Halsey, W. Deep Borehole Disposal Research: Demonstration Site Selection Guidelines, Borehole Seals Design, and RD&D Needs; SAND2013-9490P, Report for the US Department of Energy; Sandia National Laboratories: Albuquerque, NM, USA, 2013. [Google Scholar]

- Freeze, G.; Stein, E.; Price, L.; MacKinnon, R.; Tillman, J. Deep Borehole Disposal Safety Analysis. FCRD-UFD-2016-000075 Rev. 0, SAND2016-10949R; Sandia National Laboratories: Albuquerque, NM, USA, 2016. [Google Scholar]

- Freeze, G.; Stein, E.; Brady, P.V.; Lopez, C.; Sassani, D.; Travis, K.; Gibb, F. Deep Borehole Disposal Safety Case. SAND2019-1915; Sandia National Laboratories: Albuquerque, NM, USA, 2019. [Google Scholar]

- NEA (Nuclear Energy Agency). The Nature and Purpose of the Post-Closure Safety Cases for Geological Repositories, NEA/RWM/R(2013)1; Organisation for Economic Co-operation and Development, Nuclear Energy Agency: Paris, France, 2013. [Google Scholar]

- IAEA (International Atomic Energy Agency). The Safety Case and Safety Assessment for the Disposal of Radioactive Waste, Specific Safety Guide. IAEA Safety Standards Series No. SSG-23; IAEA: Vienna, Austria, 2012. [Google Scholar]

- Chapman, N.A. Who Might Be Interested in a Deep Borehole Disposal Facility for Their Radioactive Waste? Energies 2019, 12, 1542. [Google Scholar] [CrossRef]

- EPA (U.S. Environmental Protection Agency). EPA’s Environmental Radiation Protection Standards for SNF, H., and TRU Waste: Applicability of 40 CFR Part 191 to Deep Boreholes. Presented at the U.S. Nuclear Waste Technical Review Board International Technical Workshop on Deep Borehole Disposal of Radioactive Waste, Washington, DC, USA, 20–21 October 2015. [Google Scholar]

- Freeze, G.; Stein, E.; Brady, P.V. Post-closure Performance Assessment for Deep Borehole Disposal of Cs/Sr Capsules. Energies 2019, 12, 1980. [Google Scholar] [CrossRef]

- Hardin, E.L.; Clark, A.; Su, J.; Peretz, F. Preclosure Risk Assessment for Deep Borehole Disposal. Energies 2019. In Review. [Google Scholar]

- Hardin, E.L.; Clark, A.; Su, J.; Peretz, F. Preclosure Risk Assessment for Deep Borehole Disposal. SAND2019-1827; Sandia National Laboratories: Albuquerque, NM, USA, 2019. [Google Scholar]

- Kuhlman, K.L.; Brady, P.V.; MacKinnon, R.J.; Heath, J.E.; Herrick, C.G.; Jensen, R.P.; Gardner, W.P.; Sevougian, S.D.; Bryan, C.R.; Jang, J.-H. Deep Borehole Field Test Laboratory and Borehole Testing Strategy; Sandia National Lab.(SNL-NM): Albuquerque, NM, USA, 2016. [Google Scholar]

- Kuhlman, K.L.; Hardin, E.; Rigali, M.J. Deep Borehole Laboratory and Borehole Testing Strategy: Generic Drilling and Testing Plan; Sandia National Lab.(SNL-NM): Albuquerque, NM, USA, 2019. [Google Scholar]

- Frape, S.; Fritz, P.; McNutt, R. Water-rock interaction and chemistry of groundwaters from the Canadian Shield. Geochim. Et Cosmochim. Acta 1984, 48, 1617–1627. [Google Scholar] [CrossRef]

- Juhlin, C.; Wallroth, T.; Smellie, J.; Leijon, B.; Eliasson, T.; Ljunggren, C.; Beswick, J. The Very Deep Hole Concept-Geoscientific Appraisal of Conditions at Great Depth; Swedish Nuclear Fuel and Waste Management Co.: Stockholm, Sweden, 1998. [Google Scholar]

- Kietäväinen, R.; Ahonen, L.; Kukkonen, I.T.; Niedermann, S.; Wiersberg, T. Noble gas residence times of saline waters within crystalline bedrock, Outokumpu Deep Drill Hole, Finland. Geochim. Et Cosmochim. Acta 2014, 145, 159–174. [Google Scholar] [CrossRef] [Green Version]

- Gascoyne, M. Hydrogeochemistry, groundwater ages and sources of salts in a granitic batholith on the Canadian Shield, southeastern Manitoba. Appl. Geochem. 2004, 19, 519–560. [Google Scholar] [CrossRef]

- DeMaio, W.; Bates, E. Salinity and Density in Deep Boreholes. MIT Undergrad. Res. J. 2013, 26, 42–48. [Google Scholar]

- Park, Y.-J.; Sudicky, E.; Sykes, J. Effects of shield brine on the safe disposal of waste in deep geologic environments. Adv. Water Resour. 2009, 32, 1352–1358. [Google Scholar] [CrossRef]

- Phillips, S.; Igbene, A.; Fair, J.; Ozbek, H.; Tavana, M. A Technical Databook for Geothermal Energy Utilization; Lawrence Berkeley Laboratory, University of California: Berkeley, CA, USA, 1981. [Google Scholar]

- Holland, G.; Lollar, B.S.; Li, L.; Lacrampe-Couloume, G.; Slater, G.; Ballentine, C. Deep fracture fluids isolated in the crust since the Precambrian era. Nature 2013, 497, 357. [Google Scholar] [CrossRef] [PubMed]

- Bethke, C.M.; Johnson, T.M. Groundwater age and groundwater age dating. Annu. Rev. Earth Planet. Sci. 2008, 36, 121–152. [Google Scholar] [CrossRef]

- Aggarwal, P.K.; Froehlich, K.F.; Gat, J.R. Isotopes in the Water Cycle; Springer: Dordrecht, The Netherlands, 2005. [Google Scholar]

- IAEA (International Atomic Energy Agency). Isotope Methods for Dating Old Groundwater. STI/PUB/1587; IAEA: Vienna, Austria, 2013. [Google Scholar]

- Lippmann-Pipke, J.; Lollar, B.S.; Niedermann, S.; Stroncik, N.A.; Naumann, R.; van Heerden, E.; Onstott, T.C. Neon identifies two billion year old fluid component in Kaapvaal Craton. Chem. Geol. 2011, 283, 287–296. [Google Scholar] [CrossRef]

- Bottomley, D.J.; Gregoire, D.C.; Raven, K.G. Saline ground waters and brines in the Canadian Shield: Geochemical and isotopic evidence for a residual evaporite brine component. Geochim. Et Cosmochim. Acta 1994, 58, 1483–1498. [Google Scholar] [CrossRef]

- Lichtner, P.; Hammond, G. Quick Reference Guide: PFLOTRAN 2.0 (LA-CC-09-047) Multiphase-Multicomponent-Multiscale Massively Parallel Reactive Transport Code; DRAFT LA-UR-06-7048; Los Alamos National Laboratory: Los Alamos, NM, USA, 8 December 2012. [Google Scholar]

- Freeze, R.A.; Cherry, J.A. Groundwater; Prentice-Hall: Englewood Cliffs, NJ, USA, 1979. [Google Scholar]

- Chapman, N.; Gibb, F. A truly final waste management solution: Is very deep borehole disposal a realistic option for high-level waste or fissile materials. Radwaste Solut. 2003, 10, 26. [Google Scholar]

- Beswick, A.J.; Gibb, F.G.; Travis, K.P. Deep borehole disposal of nuclear waste: Engineering challenges. Proc. Inst. Civ. Eng. Energy 2014, 167, 47–66. [Google Scholar] [CrossRef]

- Collier, N.C.; Travis, K.P.; Gibb, F.G.; Milestone, N.B. Cementitious grouts for disposal of nuclear wasteforms in deep boreholes. In Proceedings of the American Nuclear Society International High-level Radioactive Waste Management, Charleston, SC, USA, 12–16 April 2015. [Google Scholar]

- Woodward-Clyde Consultants. Very Deep Hole Systems Engineering Studies; ONWI: Columbus, OH, USA, 1983. [Google Scholar]

- Arnold, B.W.; Brady, P.V.; Bauer, S.J.; Herrick, C.; Pye, S.; Finger, J. Reference Design and Operations for Deep Borehole Disposal of High-Level Radioactive Waste; SAND2011-6749; Sandia National Laboratories: Albuquerque, NM, USA, 2011. [Google Scholar]

- Arnold, B.W.; Brady, P.V.; Tillman, J. Deep Borehole Disposal of Nuclear Waste; Sandia National Laboratories: Albuquerque, NM, USA, 2013. [Google Scholar]

- Gibb, F.G.F.; Taylor, K.J.; Bukarov, B.E. The ‘granite encapsulation’ route to the safe disposal of Pu and other actinides. J. Nucl. Mater. 2008, 374, 364–369. [Google Scholar] [CrossRef]

- Gibb, F.G.; Travis, K.P. Sealing deep borehole disposals of radioactive waste by “rock welding”. In Proceedings of the 15th International High Level Radioactive Waste Management Conference, Charleston, SC, USA, 12–16 April 2015; pp. 12–16. [Google Scholar]

- Lowry, B.; Coates, K.; Wohletz, K.; Dunn, S.; Patera, E.; Duguid, A.; Arnold, B.; Zyvoloski, G.; Groven, L.; Kuramyssova, K. Ceramic Borehole Seals for Nuclear Waste Disposal Applications. In Proceedings of the AGU Fall Meeting Abstracts, San Francisco, CA, USA, 14–16 December 2015. [Google Scholar]

- Gibb, F.G.F.; Travis, K.P.; McTaggart, N.A.; Burley, D. Modelling temperature distribution around very deep borehole disposals of HLW. Nucl. Technol. 2006, 163, 62–73. [Google Scholar] [CrossRef]

- Travis, K.P.; Gibb, F.G.F.; Burley, D. Determining salinity recharge time for deep borehole disposal. In Proceedings of the Waste Management 2017 Conference, Phoenix, AZ, USA, 5–9 March 2017. [Google Scholar]

- Pusch, R.; Ramqvist, G.; Kasbohm, J.; Knutsson, S.; Mohammed, M.H. The concept of highly radioactive waste (HLW) in very deep boreholes in a new perspective. J. Earth Sci. Geotech. Eng. 2012, 2, 1–24. [Google Scholar]

| Tracer | Half-Life (yrs) | Groundwater Timescale (yrs) | Dominant Source | Other Source(s) |

|---|---|---|---|---|

| δ2H/δ18O | n/a | 0.1–3 | Stable isotopes | |

| 3H/3He | n/a | 0.5–40 | Anthropogenic/Stable | |

| 85Kr | 10.72 | 1–40 | Anthropogenic (nuc. industry) | |

| CFCs, SF6 | n/a | 1–40 | Anthropogenic (manufacturing) | |

| 3H (tritium) | 12.3 | 1–50 | Anthropogenic (bomb tests) | Cosmogenic Anthropogenic (nuc. industry) |

| 32Si | ~150 | 50–1000 | Cosmogenic | |

| 39Ar | 269 | 50–1000 | Cosmogenic | |

| 14C | 5730 | 1000–40,000 | Cosmogenic | Anthropogenic (bomb tests) Anthropogenic (nuc. industry) |

| 4He | Stable | 100–1,000,000 | Nucleogenic | |

| 81Kr | 210,000 | 50,000–1,000,000 | Cosmogenic | |

| 36Cl | 301,000 | 50,000–1,000,000 | Cosmogenic | Anthropogenic (bomb tests) |

| 234U/238U | 245,500/4,468,000,000 | 10,000–1,000,000 | Nucleogenic | |

| 129I | 15,700,000 | 3,000,000–80,000,000 | Anthropogenic (nuc. industry) | Anthropogenic (bomb tests) Cosmogenic |

| 87Sr/86Sr | Stable | Radiogenic |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Freeze, G.A.; Stein, E.; Brady, P.V.; Lopez, C.; Sassani, D.; Travis, K.; Gibb, F.; Beswick, J. Deep Borehole Disposal Safety Case. Energies 2019, 12, 2141. https://doi.org/10.3390/en12112141

Freeze GA, Stein E, Brady PV, Lopez C, Sassani D, Travis K, Gibb F, Beswick J. Deep Borehole Disposal Safety Case. Energies. 2019; 12(11):2141. https://doi.org/10.3390/en12112141

Chicago/Turabian StyleFreeze, Geoff A., Emily Stein, Patrick V. Brady, Carlos Lopez, David Sassani, Karl Travis, Fergus Gibb, and John Beswick. 2019. "Deep Borehole Disposal Safety Case" Energies 12, no. 11: 2141. https://doi.org/10.3390/en12112141

APA StyleFreeze, G. A., Stein, E., Brady, P. V., Lopez, C., Sassani, D., Travis, K., Gibb, F., & Beswick, J. (2019). Deep Borehole Disposal Safety Case. Energies, 12(11), 2141. https://doi.org/10.3390/en12112141