New Perspective on Performances and Limits of Solar Fresh Air Cooling in Different Climatic Conditions

Abstract

1. Introduction

2. Materials and Methods

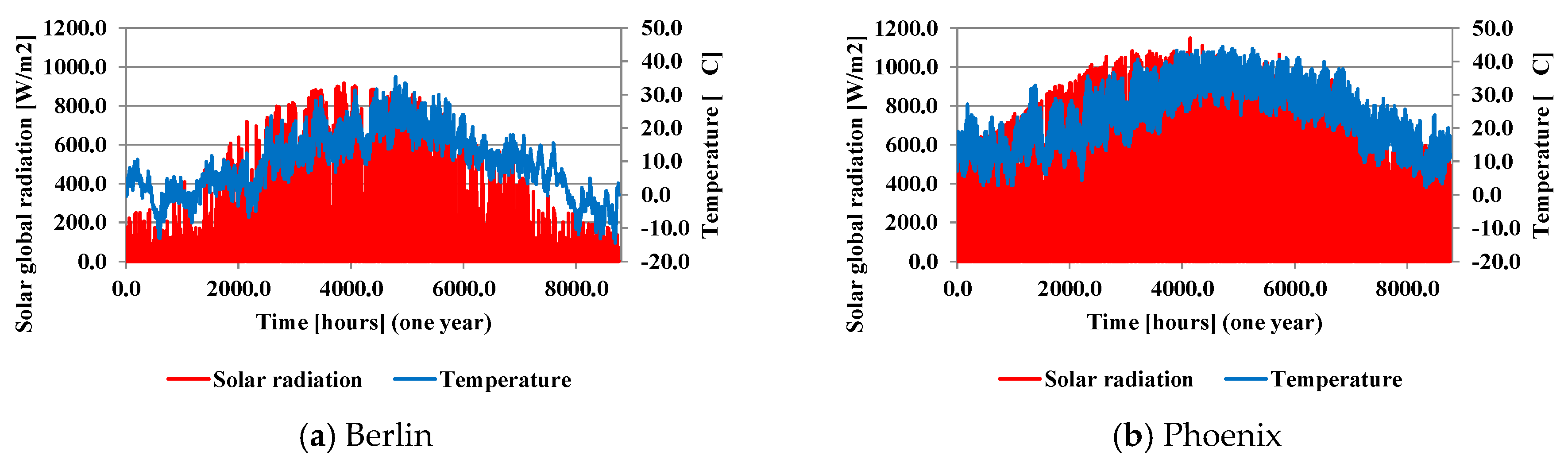

2.1. Characteristics of the Building and Climatic Conditions

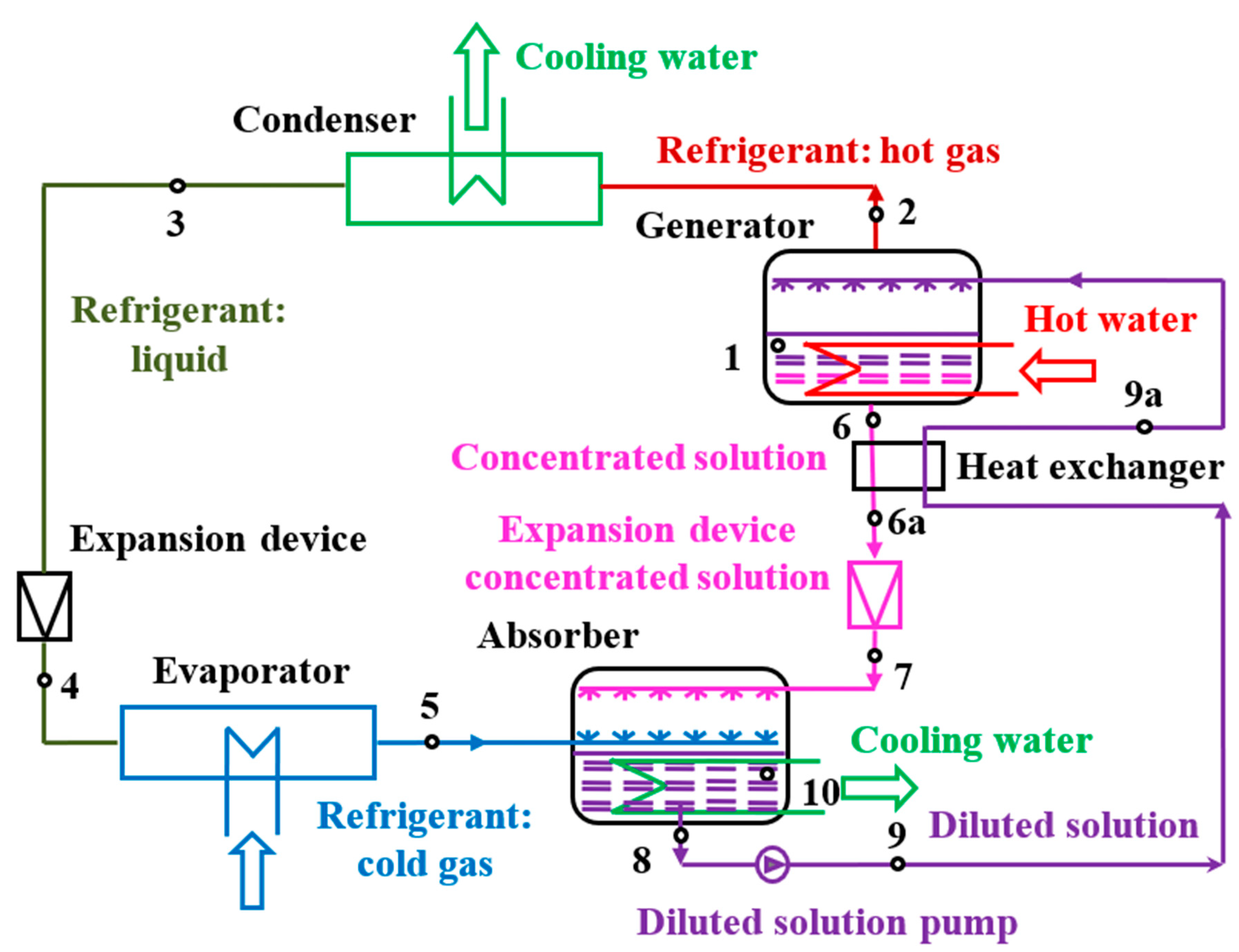

2.2. Characteristics of the Solar Cooling System

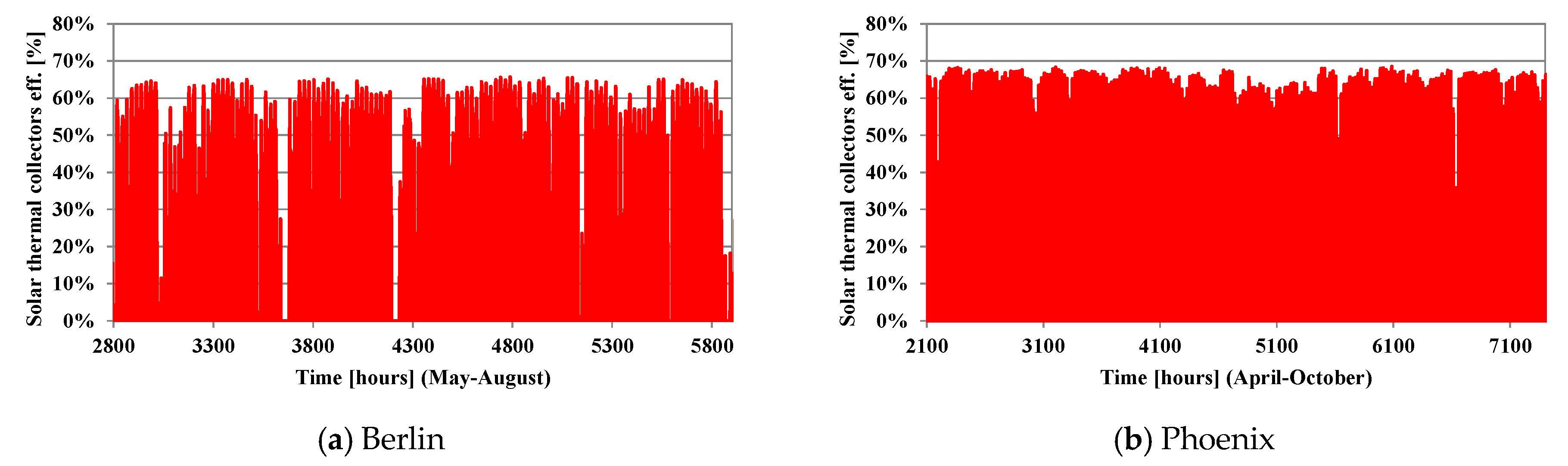

2.3. Characteristics of the Solar Thermal Collectors

3. Results and Discussion

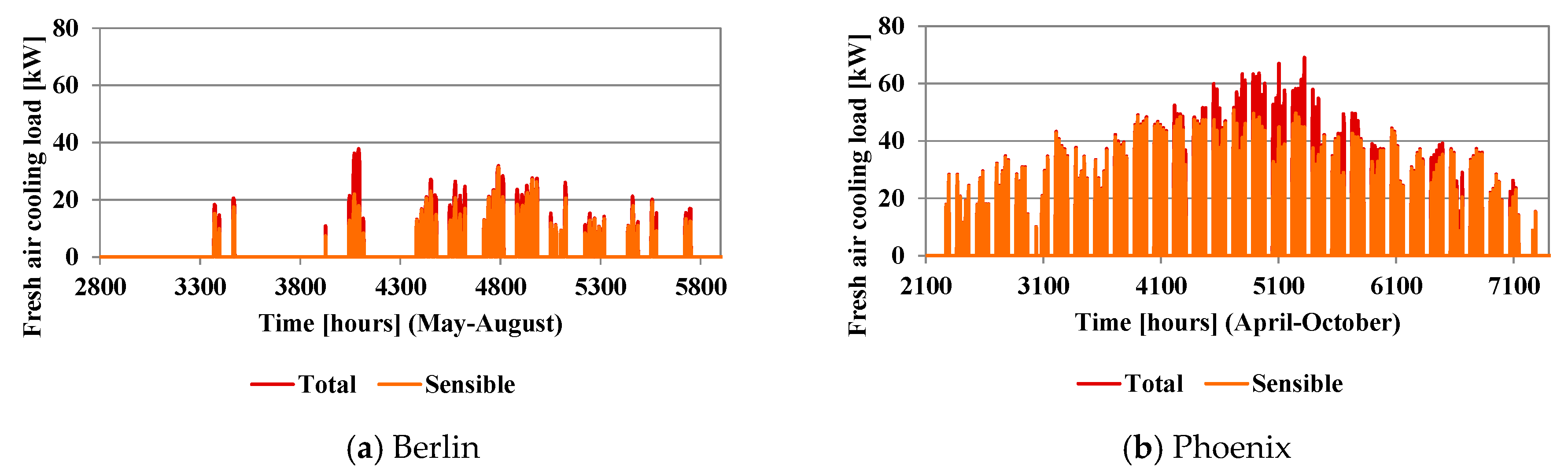

3.1. Cooling Load

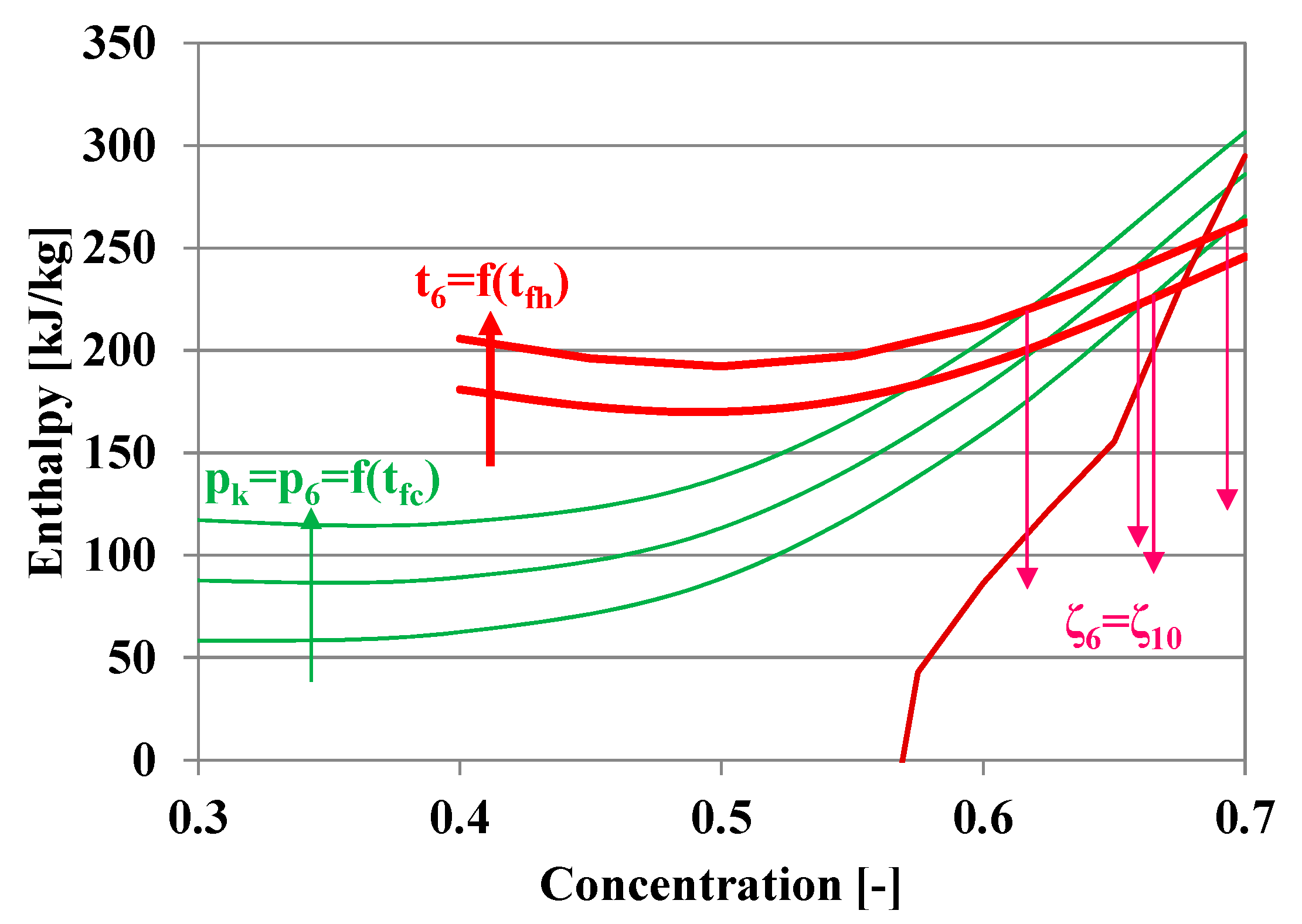

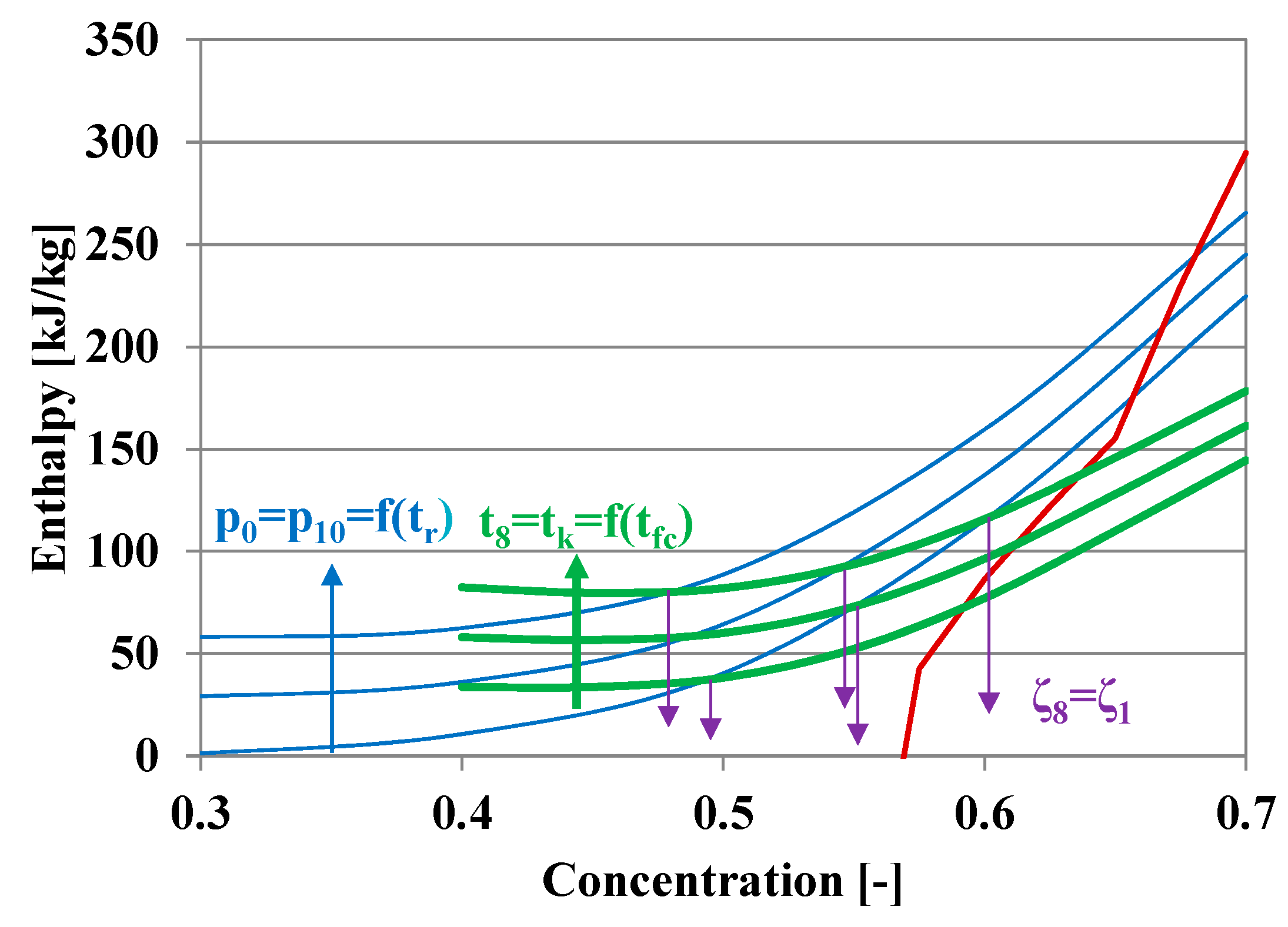

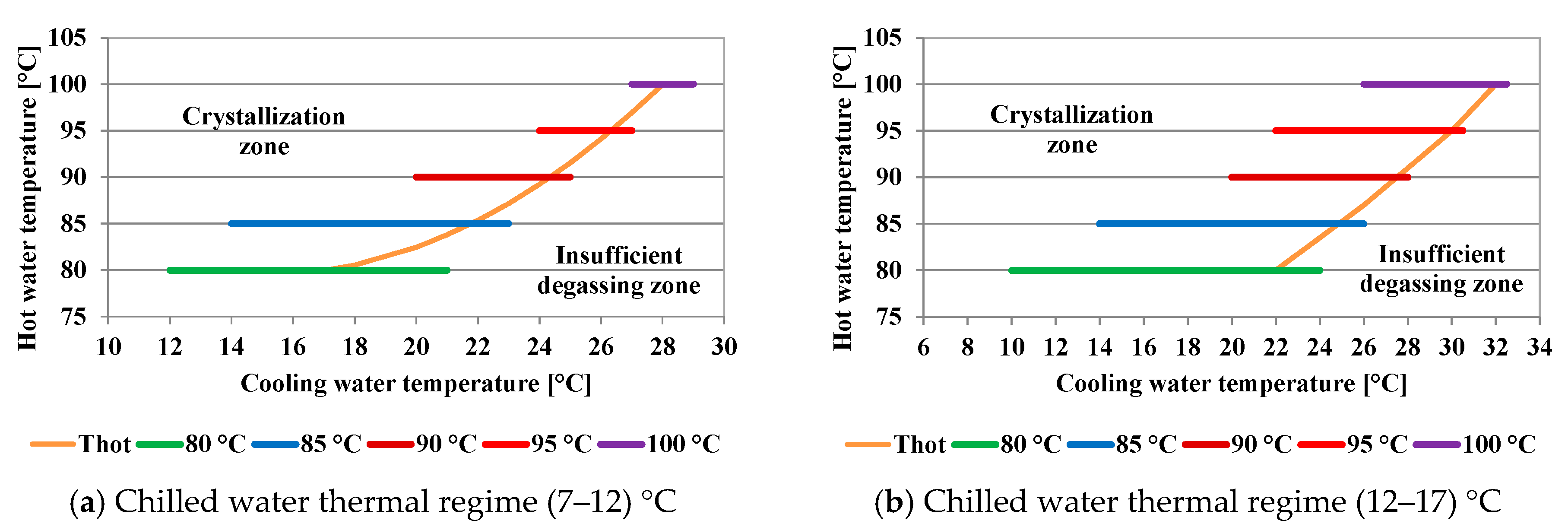

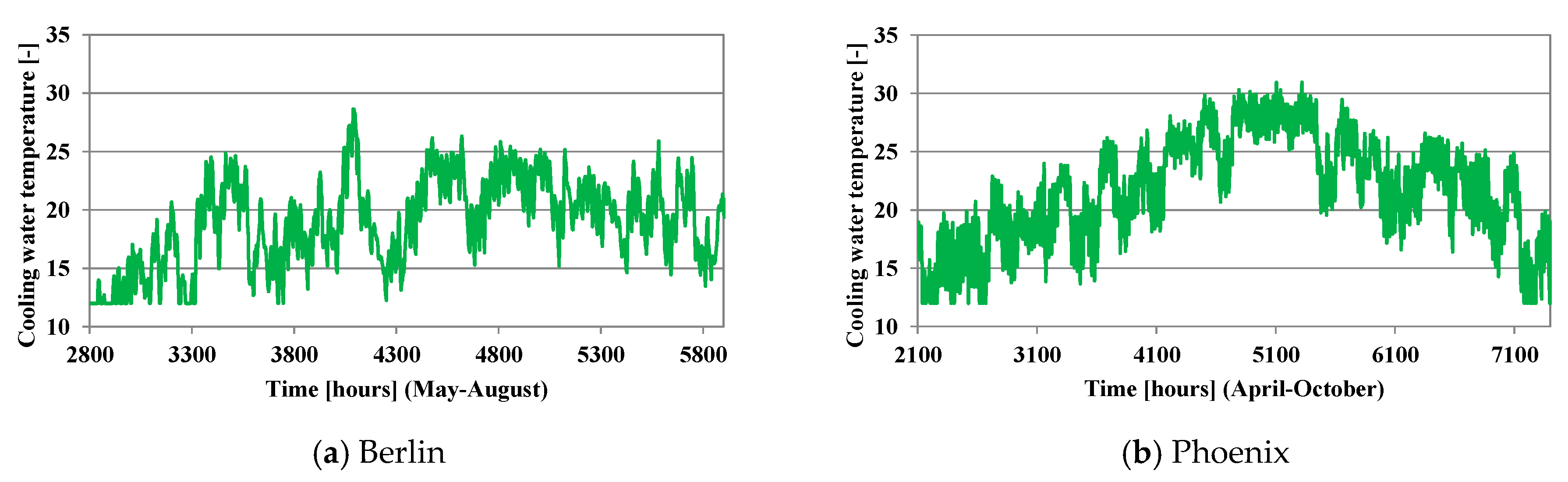

3.2. Operating Limits

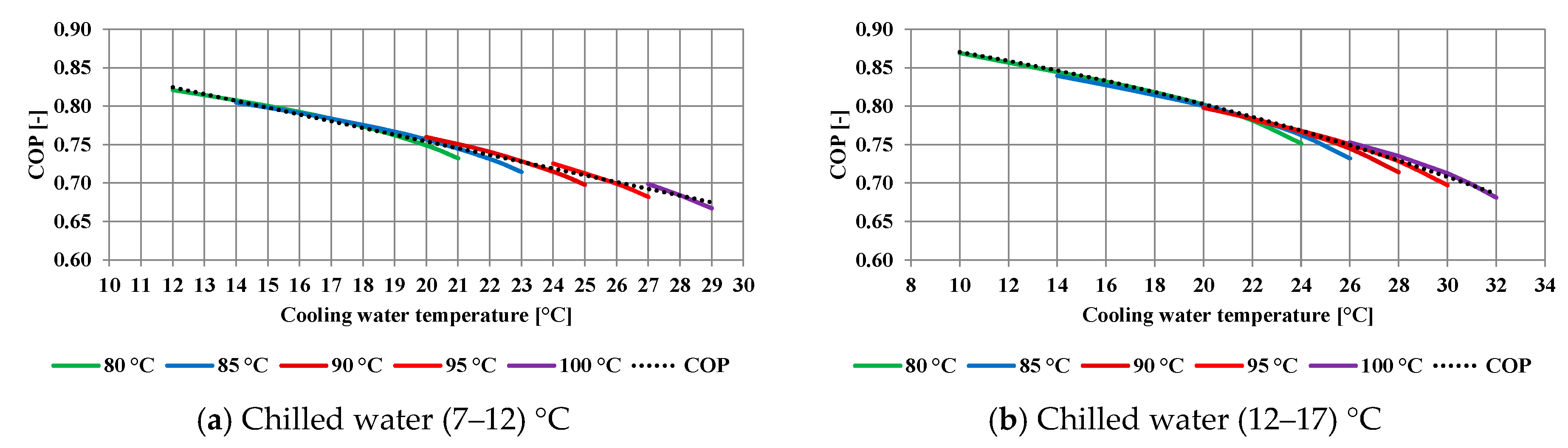

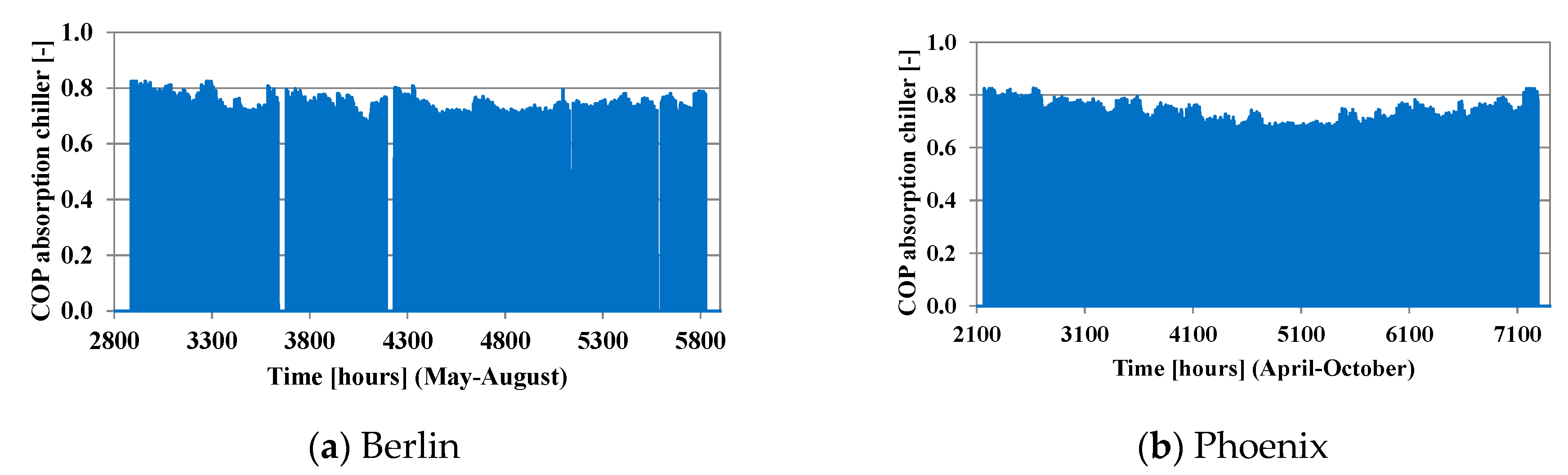

3.3. COP of the Solar Absorption Chiller and of the Electric Chiller

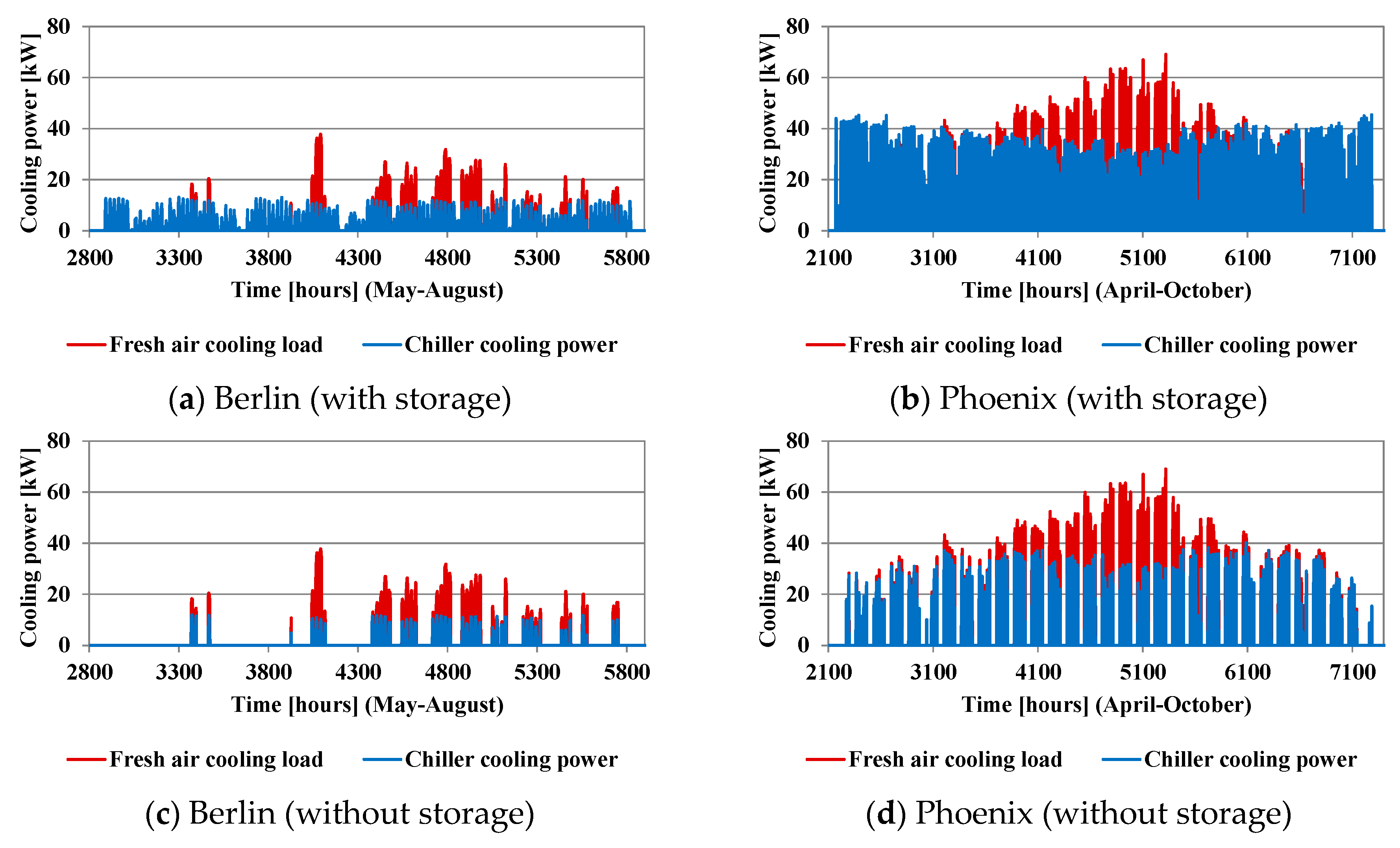

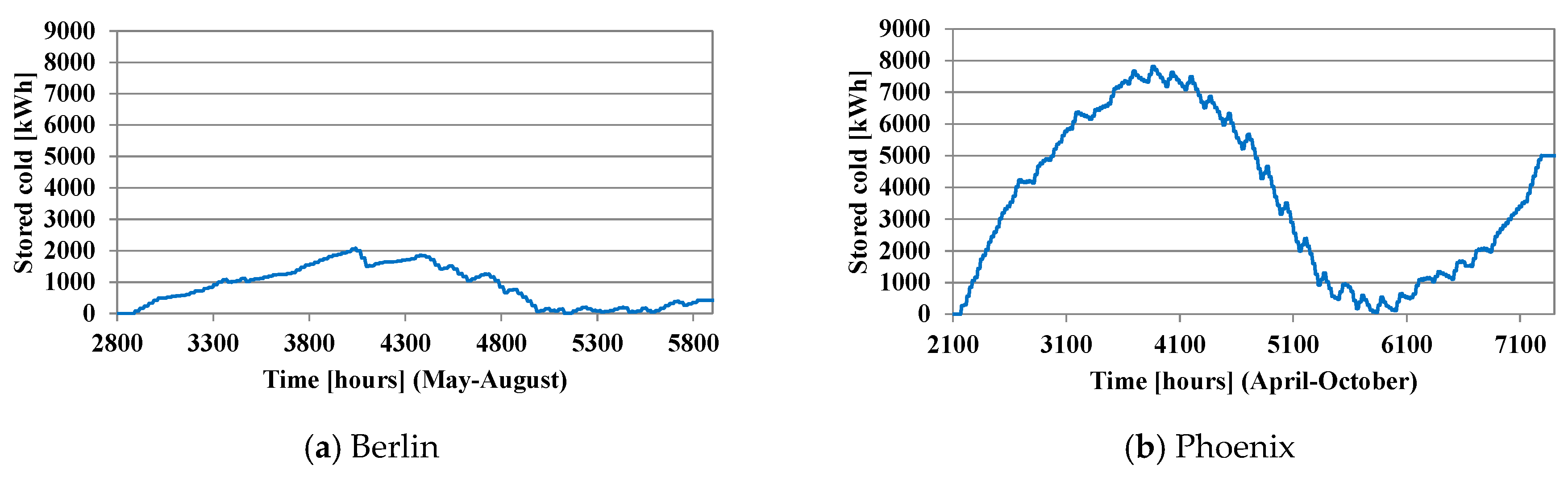

3.4. Effect of Chilled Water Storage

- -

- The number of ETCS varied from 12 in Paris up to 44 in Phoenix and the corresponding total aperture area varied from 22.4 m2 in Paris to 82.0 m2 in Phoenix;

- -

- The total seasonal cooling load represents the total required cooling energy. This parameter was calculated hourly as the product between the cooling load (thermal power) and the period of time when cold was required. The sum of the hourly required cooling energy represents the total seasonal cooling load and varied between 2.09 MWh in Monaco up to 41.90 MWh in Phoenix.

- -

- The cooling power of the absorption chiller with cooling storage varied from 10.75 kW in Paris up to 45.29 kW in Phoenix;

- -

- The cooling power of the absorption chiller without cooling storage varied from 10.40 kW in Paris up to 40.06 kW in Phoenix;

- -

- The cooling storage proved to be capable of covering the cooling load without the electric chiller and the corresponding electrical energy consumption;

- -

- The maximum required electric power of the electric chiller, without storage varied between 6.73 kW in Cairo up to 18.04 kW in Phoenix;

- -

- The seasonal solar fraction with storage was higher than 100%, meaning that with storage more cold could be produced than required for the fresh air cooling, the extra cold production being, possibly, used to cover other types of cooling loads inside the building (through envelope, from occupants, from lighting, etc.);

- -

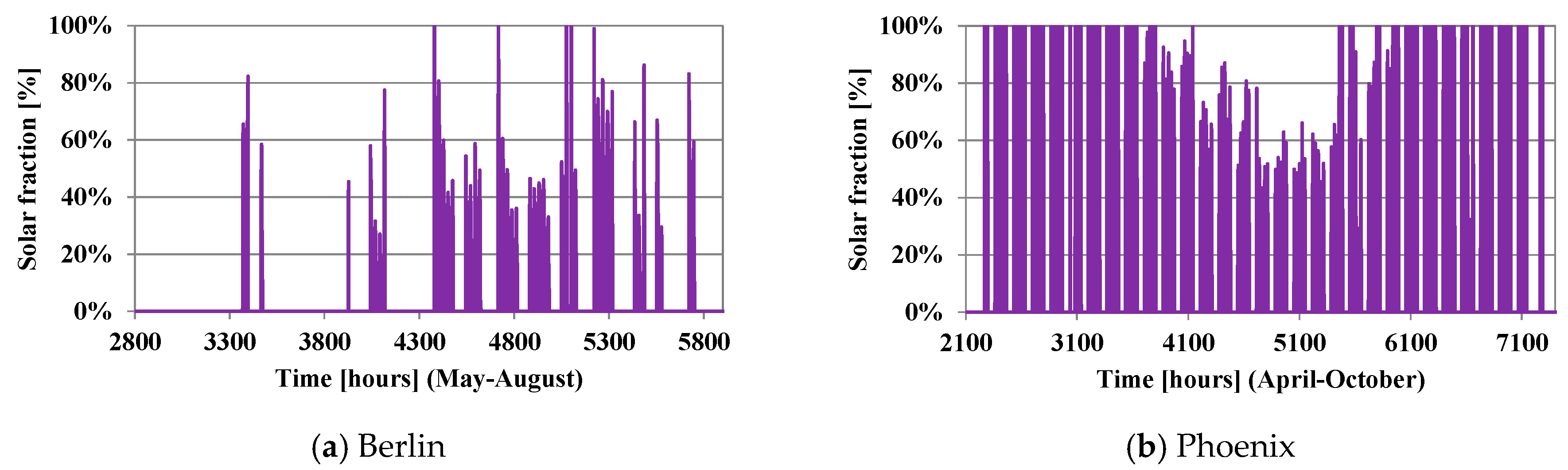

- The seasonal solar fraction without storage varied between 29.5% in Paris up to 62.0% in Phoenix;

- -

- The total amount of electrical energy required without storage was situated in the range of 382.3 kW (Monaco) up to 4192.3 kW (Phoenix);

- -

- The seasonal energy efficiency ratio (SEER) represents the ratio between the seasonal provided cold and the total required seasonal electrical energy. Two types of SEER were defined—(a) the electrical seasonal energy efficiency ratio (SEERel) calculated considering only the electrical provided cold; and (b) the global seasonal energy efficiency ratio (SEERgl) considering the whole amount of provided cold (solar + electric). SEERel was between 3.5 in Monaco and 6.0 in Cairo. SEERgl was between 5.5 in Paris or Monaco and 14.1 in Cairo.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Directive/31/EU, Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings in 2010. Available online: https://www.google.com.tw/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&cad=rja&uact=8&ved=2ahUKEwi3mvHtsMriAhUVPnAKHYpUDAAQFjAAegQIBhAC&url=https%3A%2F%2Feur-lex.europa.eu%2FLexUriServ%2FLexUriServ.do%3Furi%3DOJ%3AL%3A2010%3A153%3A0013%3A0035%3AEN%3APDF&usg=AOvVaw0pOZGXaqo5VZyusosxfeop (accessed on 7 April 2019).

- Wei, Y.; Zhang, X.; Shi, Y.; Xia, L.; Pan, S.; Wu, J.; Han, M. A review of data-driven approaches for prediction and classification of building energy consumption. Renew. Sustain. Energy Rev. 2018, 82, 1027–1047. [Google Scholar] [CrossRef]

- Roaf, S.; Brotas, L.; Nicol, F. Counting the costs of comfort. Build. Res. Inf. 2015, 43, 269–273. [Google Scholar] [CrossRef]

- Mammoli, A.; Vorobieff, P.; Barsun, H.; Burnett, R.; Fisher, D. Energetic, economic and environmental performance of a solar-thermal-assisted HVAC system. Energy Build. 2010, 42, 1524–1535. [Google Scholar] [CrossRef]

- Wang, J.; Yan, R.; Wang, Z.; Zhang, X.; Shi, G. Thermal Performance Analysis of an Absorption Cooling System Based on Parabolic Trough Solar Collectors. Energies 2018, 11, 2679. [Google Scholar] [CrossRef]

- Ma, Y.; Saha, S.C.; Miller, W.; Guan, L. Comparison of Different Solar-Assisted Air Conditioning Systems for Australian Office Buildings. Energies 2017, 10, 1463. [Google Scholar] [CrossRef]

- Chan, J.J.; Best, R.; Cerezo, J.; Barrera, M.A.; Lezama, F.R. Experimental Study of a Bubble Mode Absorption with an Inner Vapor Distributor in a Plate Heat Exchanger-Type Absorber with NH3-LiNO3. Energies 2018, 11, 2137. [Google Scholar] [CrossRef]

- Cerezo, J.; Romero, R.J.; Ibarra, J.; Rodríguez, A. Dynamic Simulation of an Absorption Cooling System with Different Working Mixtures. Energies 2018, 12, 259. [Google Scholar] [CrossRef]

- Sarbu, I.; Sebarchievici, C. Review of solar refrigeration and cooling systems. Energy Build. 2013, 67, 286–297. [Google Scholar] [CrossRef]

- Manu, S.; Chandrashekar, T.K. A simulation study on performance evaluation of single-stage LiBr-H2O vapor absorption heat pump for chip cooling. Int. J. Sustain. Built Environ. 2016, 5, 370–386. [Google Scholar] [CrossRef]

- Patel, H.A.; Patel, L.N.; Jani, D.; Christian, A. Energetic analysis of single stage lithium bromide water absorption refrigeration system. Procedia Technol. 2016, 23, 488–495. [Google Scholar] [CrossRef]

- Farnós, J.; Papakokkinos, G.; Castro, J.; Morales, S.; Oliva, A. Dynamic Modelling of an Air-Cooled LiBr-H2O Absorption Chiller Based on Heat and Mass Transfer Empirical Correlations. Available online: https://www.google.com.tw/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&ved=2ahUKEwirvLucscriAhUN-2EKHRJ7B8EQFjAAegQIBhAC&url=https%3A%2F%2Fhpc2017.org%2Fwp-content%2Fuploads%2F2017%2F06%2Fo454.pdf&usg=AOvVaw1CSUoj6w0EocuFqv91wyTW (accessed on 7 April 2019).

- Stanciu, C.; Stanciu, D.; Gheorghian, A.T.; Tanase, E.B.; Dobre, C.; Spiroiu, M. Maximum Exergetic Efficiency Operation of a Solar Powered H2O-LiBr Absorption Cooling System. Entropy 2017, 19, 676. [Google Scholar] [CrossRef]

- Lizarte, R.; Izquierdo, M.; Marcosc, J.D.; Palacios, E. Experimental comparson of two solar-driven air-cooled LiBr/H2O absorption chillers: Indirect versus direct air-cooled system. Energy Build. 2013, 62, 323–334. [Google Scholar] [CrossRef]

- Chen, J.F.; Dai, Y.J.; Wang, R.Z. Experimental and analytical study on an air-cooled single effect LiBr-H2O absorption chiller driven by evacuated glass tube solar collector for cooling application in residential buildings. Sol. Energy 2017, 151, 110–118. [Google Scholar] [CrossRef]

- Salehi, S.; Yari, M.; Mahmoudi, S.M.S.; Farshi, L.G. Investigation of crystallization risk in different types of absorption LiBr/H2O heat transformers. Ther. Sci. Eng. Prog. 2019, 10, 48–58. [Google Scholar] [CrossRef]

- Porumb, R.; Porumb, B.; Balan, M.C. Numerical investigation on solar absorption chiller with LiBr-H2O operating conditions and performances. Energy Procedia 2017, 112, 108–117. [Google Scholar] [CrossRef]

- Pop, O.G.; Fechete Tutunaru, L.; Bode, F.; Abrudan, A.C.; Balan, M.C. Energy efficiency of PCM integrated in fresh air cooling systems in different climatic conditions. Appl. Energy 2018, 212, 976–996. [Google Scholar] [CrossRef]

- Todoran, T.P.; Balan, M.C. Long term behavior of a geothermal heat pump with oversized horizontal collector. Energy Build. 2016, 133, 799–809. [Google Scholar] [CrossRef]

- Porumb, B.; Balan, M.C.; Porumb, R. Potential of indirect evaporative cooling to reduce the energy consumption in fresh air conditioning applications. Energy Procedia 2016, 85, 433–441. [Google Scholar] [CrossRef]

- Badescu, V.; Laaser, N.; Crutescu, R. Warm season cooling requirements for passive buildings in Southeastern Europe (Romania). Energy 2010, 35, 3284–3300. [Google Scholar] [CrossRef]

- Badescu, V.; Laaser, N.; Crutescu, R.; Crutescu, M.; Dobrovicescu, A.; Tsatsaronis, G. Modeling, validation and time-dependent simulation of the first large passive building in Romania. Renew. Energy 2011, 36, 142–157. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; Wiley&Sons: Singapore, 1980. [Google Scholar]

- Quaschning, V. Understanding Renewable Energy Systems; Earthscan: London, UK, 2007. [Google Scholar]

- Unguresan, P.V.; Porumb, R.A.; Petreus, D.; Pocola, A.G.; Pop, O.G.; Balan, M.C. Orientation of Facades for Active Solar Energy Applications in Different Climatic Conditions. J. Energy Eng. 2017, 143, 04017059. [Google Scholar] [CrossRef]

- Prieto, A.; Knaack, U.; Auer, T.; Klein, T. Feasibility Study of Self-Sufficient Solar Cooling Façade Applications in Different Warm Regions. Energies 2018, 11, 1475. [Google Scholar] [CrossRef]

- Unguresan, P.; Petreus, D.; Pocola, A.; Balan, M. Potential of solar ORC and PV systems to provide electricity under Romanian climatic conditions. Energy Procedia 2016, 85, 584–593. [Google Scholar] [CrossRef]

- Porumb, R.; Porumb, B.; Balan, M. Baseline evaluation of potential to use solar radiation in air conditioning applications. Energy Procedia 2016, 85, 442–451. [Google Scholar] [CrossRef][Green Version]

- Syed, A.; Izquierdo, M.; Rodriguez, P.; Maidment, G.; Missenden, J. A novel experimental investigation of a solar cooling system in Madrid. Int J. Refrig. 2005, 28, 859–871. [Google Scholar] [CrossRef]

- Stanford, H.W., III. HVAC Water Chillers and Cooling Towers. Fundamentals, Application, and Operation; Marcel Dekker: New York, NY, USA, 2003. [Google Scholar]

- Chen, J.F.; Dai, Y.J.; Wang, H.B.; Wang, R.Z. Experimental investigation on a novel air-cooled single effect LiBr-H2O absorption chiller with adiabatic flash evaporator and adiabatic absorber for residential application. Sol. Energy 2018, 159, 579–587. [Google Scholar] [CrossRef]

| Location | Country | Latitude (°) | Longitude (°) | Altitude (m) | Time Zone (hours) | Climate Classification | Climate Description |

|---|---|---|---|---|---|---|---|

| Berlin | DEU | 52.517 N | 13.389 E | 44 | 1 | Dfb | Warm humid continental climate |

| Paris | FRA | 48.857 N | 2.351 E | 30 | 1 | Cfb | Oceanic climate |

| Monaco | FRA | 43.731 N | 7.420 E | 2 | 1 | Csa | Hot-summer Mediterranean climate |

| Rome | ITA | 41.893 N | 12.483 E | 42 | 1 | Csa | Hot-summer Mediterranean climate |

| Seville | ESP | 37.094 N | 2.358 E | 499 | 1 | Csa | Hot-summer Mediterranean climate |

| Cairo | EGY | 30.049 N | 31.244 E | 41 | 2 | BWh | Hot desert climate |

| Phoenix | USA | 33.450 N | 111.983 W | 337 | −7 | BWh | Hot desert climate |

| Las Vegas | USA | 30.083 N | 115.15 W | 648 | −8 | BWk | Tropical and subtropical desert climate |

| TMY Based Criteria | Min | Max |

|---|---|---|

| Total yearly global solar radiation on horizontal plane | Berlin | Cairo |

| Maximum dry bulb temperature | Monaco | Las Vegas, Phoenix |

| Maximum wet bulb temperature | Berlin | Phoenix |

| Location | Total Yearly Global Solar Radiation on Horizontal Plane (kWh/m2/year) | Maximum Dry Bulb Temperature (°C) | Maximum Wet Bulb Temperature (°C) |

|---|---|---|---|

| Berlin | 1077 | 35.4 | 23.6 |

| Paris | 1153 | 32.5 | 23.8 |

| Monaco | 1595 | 28.1 | 25.2 |

| Rome | 1669 | 32.1 | 24.8 |

| Seville | 1851 | 40.4 | 25.2 |

| Cairo | 2209 | 39.7 | 24.7 |

| Phoenix | 2094 | 44.4 | 26.0 |

| Las Vegas | 2032 | 44.4 | 24.4 |

| Location | Beginning Month | Ending Month | Max. Sensible Cooling Load (kW) | Max. Total Cooling Load (kW) |

|---|---|---|---|---|

| Berlin | May | August | 31.30 | 37.84 |

| Paris | June | September | 24.68 | 44.00 |

| Monaco | August | August | 14.62 | 33.04 |

| Rome | June | September | 23.89 | 42.29 |

| Seville | April | September | 42.23 | 55.71 |

| Cairo | April | October | 46.31 | 46.64 |

| Phoenix | April | October | 50.75 | 69.09 |

| Las Vegas | April | October | 50.75 | 55.87 |

| Chilled Water Thermal Regime | Correlation Coefficients | Availability Range (Cooling Water Thermal Regime) | ||

|---|---|---|---|---|

| a | b | c | ||

| (7–12) °C | 0.1233 | 3.7314 | 107.76 | (17–28) °C |

| (12–17) °C | 0.0424 | 0.3116 | 66.18 | (10–32) °C |

| Chilled Water Thermal Regime | Correlation Coefficients | Availability Range (Cooling Water Thermal Regime) | ||

|---|---|---|---|---|

| a | b | c | ||

| (7–12) °C | 0.0 | −0.0088 | 0.93 | (17–28) °C |

| (12–17) °C | −0.000135 | −0.0027 | 0.9107 | (10–32) °C |

| Location | Berlin | Paris | Monaco | Rome | Seville | Cairo | Phoenix | Las Vegas |

|---|---|---|---|---|---|---|---|---|

| No. of ETSC (pcs) | 14 | 12 | 18 | 28 | 30 | 29 | 44 | 32 |

| Total aperture surface (m2) | 26.1 | 22.4 | 33.6 | 52.2 | 55.9 | 54.1 | 82.0 | 59.6 |

| Max. cooling load (kW) | 37.84 | 44.00 | 33.04 | 42.29 | 55.71 | 46.64 | 69.09 | 55.87 |

| No. of operating hours at (12–17) °C chilled water (h) | 0 | 0 | 121 | 25 | 32 | 0 | 157 | 4 |

| Max. absorption cooling power (with storage) (kW) | 13.15 | 10.75 | 14.70 | 23.89 | 26.86 | 30.26 | 45.29 | 33.48 |

| Max. absorption cooling power (without storage) (kW) | 11.99 | 10.40 | 14.41 | 22.36 | 26.46 | 29.62 | 40.06 | 30.86 |

| Electrical power (with storage) (kW) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Max. electrical power (without storage) (kW) | 9.10 | 11.58 | 9.56 | 10.14 | 12.72 | 6.73 | 18.04 | 13.67 |

| Total cooling load (seasonal) (MWh) | 6.14 | 2.56 | 2.09 | 12.74 | 24.18 | 31.79 | 41.90 | 31.07 |

| Seasonal solar fraction (with storage) (%) | 106.8% | 176.9% | 114.4% | 121.0% | 102.9% | 109.9% | 111.9% | 115.8% |

| Seasonal solar fraction (without storage) (%) | 35.7% | 29.5% | 35.3% | 57.2% | 52.4% | 57.4% | 62.0% | 53.9% |

| Seasonal electric fraction (without storage) (%) | 64.3% | 70.5% | 64.7% | 42.8% | 47.6% | 42.6% | 38.0% | 46.1% |

| Total electrical energy (with storage) (kWh) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Total electrical energy (without storage) (kWh) | 955.7 | 465.0 | 382.3 | 1455.0 | 1048.2 | 2261.6 | 4192.3 | 3431.8 |

| Seasonal energy efficiency ratio (electric) (SEERel) (-) | 4.1 | 3.9 | 3.5 | 3.7 | 3.8 | 6.0 | 3.8 | 4.2 |

| Seasonal energy efficiency ratio (global) (SEERgl) (-) | 6.4 | 5.5 | 5.5 | 8.8 | 8.8 | 14.1 | 10.0 | 9.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abrudan, A.C.; Pop, O.G.; Serban, A.; Balan, M.C. New Perspective on Performances and Limits of Solar Fresh Air Cooling in Different Climatic Conditions. Energies 2019, 12, 2113. https://doi.org/10.3390/en12112113

Abrudan AC, Pop OG, Serban A, Balan MC. New Perspective on Performances and Limits of Solar Fresh Air Cooling in Different Climatic Conditions. Energies. 2019; 12(11):2113. https://doi.org/10.3390/en12112113

Chicago/Turabian StyleAbrudan, Ancuta C., Octavian G. Pop, Alexandru Serban, and Mugur C. Balan. 2019. "New Perspective on Performances and Limits of Solar Fresh Air Cooling in Different Climatic Conditions" Energies 12, no. 11: 2113. https://doi.org/10.3390/en12112113

APA StyleAbrudan, A. C., Pop, O. G., Serban, A., & Balan, M. C. (2019). New Perspective on Performances and Limits of Solar Fresh Air Cooling in Different Climatic Conditions. Energies, 12(11), 2113. https://doi.org/10.3390/en12112113