The Influence of Changing Hydropower Potential on Performance Parameters of Pumps in Turbine Mode

Abstract

:1. Introduction

2. Materials and Methods

Parameters of Hydrodynamic Pumps in Turbine Operation

3. Conversion Relationships of Hydraulic Machine Parameters

4. Experimental Verification of Model Calculations of Turbine Operation

5. Results

6. Discussion

7. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| A | measured value |

| b | impeller width in the meridional section, m |

| BEP | best efficiency point |

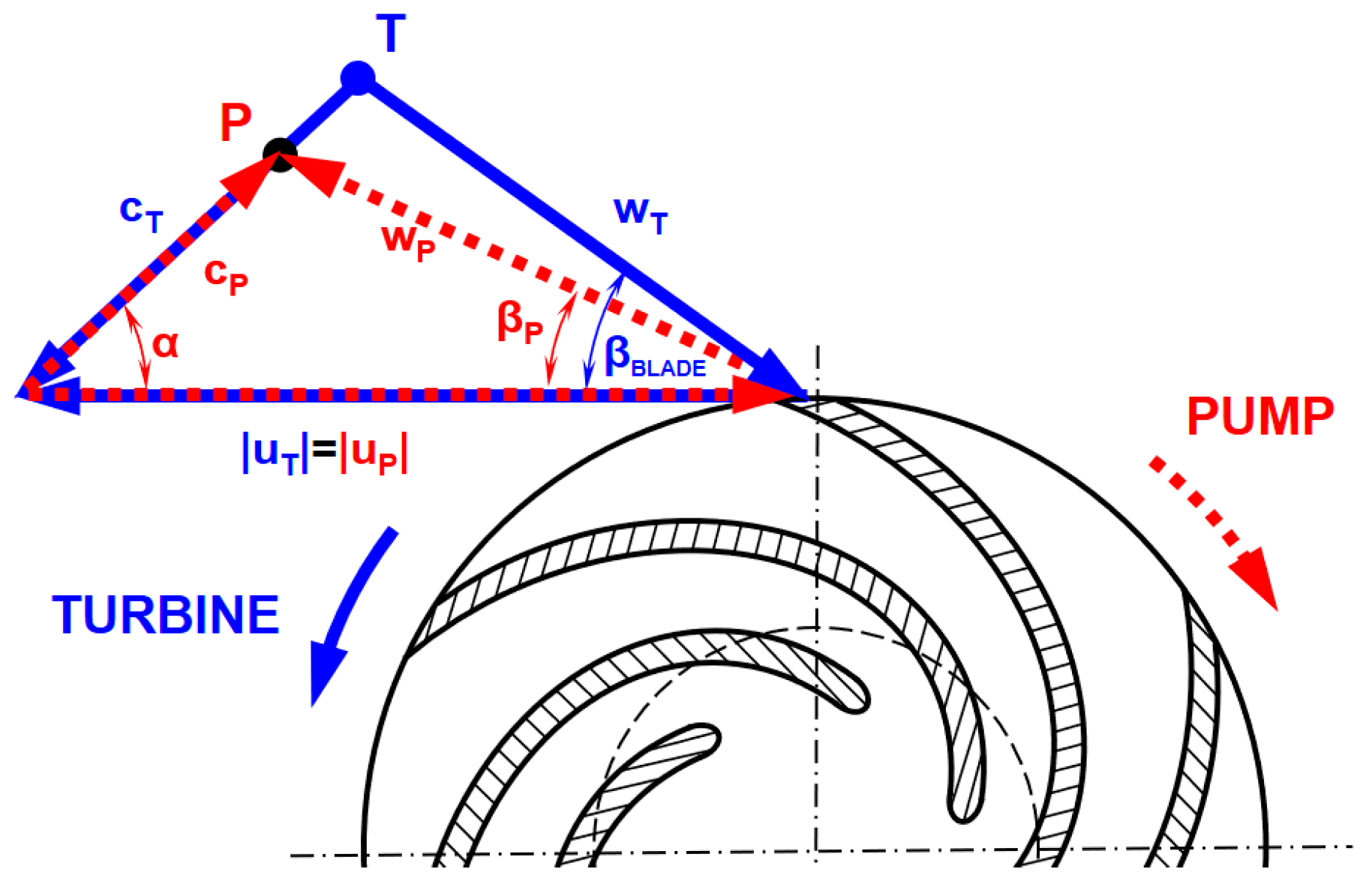

| c | absolute velocity of water, m·s−1 |

| D | impeller diameter, m |

| FC | frequency inverter |

| FP | feed pump |

| H | total head, m |

| M | torque, N.m |

| N | rotational speed, rpm |

| Ns | specific speed, rpm |

| P | power output, W |

| p | pressure, Pa |

| PAT | pump as turbine |

| Q | flow rate, l·s−1 |

| S | cross section, m2 |

| u | circumferential velocity of impeller, m·s−1 |

| w | relative velocity of water, m·s−1 |

| WDN | water distribution network |

| Y | specific energy, J·kg−1 |

Subscripts and superscripts

| m | meridional component |

| P | pump |

| T | turbine |

| u | circumferential component |

| * | parameter after the change |

| 1 | inlet |

| 2 | outlet |

Greek symbols

| α | angle between circumferential and absolute velocity, ° |

| β | angle between relative and circumferential velocity, ° |

| η | total efficiency, % |

| ρ | fluid density, kg·m−3 |

References

- Giosio, D.R.; Henderson, A.D.; Walker, J.M.; Brandner, P.A.; Sargison, J.E.; Gautam, P. Design and performance evaluation of a pump-as-turbine micro-hydro test facility with incorporated inlet flow control. Renew. Energy 2015, 78, 1–6. [Google Scholar] [CrossRef]

- Williams, A.A. Pumps as turbines for low cost micro hydro power. Renew. Energy 1996, 9, 1227–1234. [Google Scholar] [CrossRef]

- Pugliese, F.; De Paola, F.; Fontana, N.; Giugni, M.; Marini, G. Experimental characterization of two pumps as turbines for hydropower generation. Renew. Energy 2016, 99, 180–187. [Google Scholar] [CrossRef]

- Jain, S.V.; Patel, R.N. Investigations on pump running in turbine mode: A review of the state-of-the-art. Renew. Sustain. Energy Rev. 2014, 30, 841–868. [Google Scholar] [CrossRef]

- Carravetta, A.; del Giudice, G.; Fecarotta, O.; Ramos, H.M. PAT design strategy for energy recovery in water distribution networks by electrical regulation. Energies 2013, 6, 411–424. [Google Scholar] [CrossRef]

- Fontana, N.; Giugni, M.; Portolano, D. Losses reduction and energy production in water-distribution networks. J. Water Res. Plan. 2012, 138, 237–244. [Google Scholar] [CrossRef]

- Førsund, F.R. Pumped-storage hydroelectricity. In Hydropower Economics; International Series in Operations Research & Management Science: Springer, Boston, MA, USA, 2015; Volume 127. [Google Scholar]

- Barbarelli, S.; Amelio, M.; Florio, G. Experimental activity at test rig validating correlations to select pumps running as turbines in microhydro plants. Energy Convers. Manag. 2017, 149, 781–797. [Google Scholar] [CrossRef]

- Polák, M. Experimental evaluation of hydraulic design modifications of radial centrifugal pumps. Agron. Res. 2017, 15, 1189–1197. [Google Scholar]

- Singh, P. Optimization of the Internal Hydraulics and of System Design for Pumps as Turbines with Field Implementation and Evaluation. Ph.D. Thesis, University of Karlsruhe, Karlsruhe, Germany, 2005. [Google Scholar]

- Singh, P.; Nestmann, F. Internal hydraulic analysis of impeller rounding in centrifugal pumps as turbines. Exp. Therm. Fluid Sci. 2011, 35, 121–134. [Google Scholar] [CrossRef]

- Derakhshan, S.; Mohmmadi, B.; Nourbakhsh, A. Efficiency improvement of centrifugal reverse pumps. J. Fluids Eng. 2009, 131, 021103. [Google Scholar] [CrossRef]

- Jain Sanjay, V.; Swarnkar Abhishek Motwani Karan, H.; Patel Rajesh, N. Effects of impeller diameter and rotational speed on performance of pump running in turbine mode. Energy Convers. Manag. 2015, 89, 808–824. [Google Scholar] [CrossRef]

- Venturini, M.; Alvisi, S.; Simani, S.; Manservigi, L. Energy production by means of pumps as turbines in water distribution networks. Energies 2017, 10, 1666. [Google Scholar] [CrossRef]

- Capurso, T.; Stefanizzi, M.; Torresi, M.; Pascazio, G.; Caramia, G.; Camporeale, S.; Fortunato, B.; Bergamini, L. How to improve the performance prediction of a pump as turbine by considering the slip phenomenon. Proceedings 2018, 2, 683. [Google Scholar] [CrossRef]

- Bláha, J.; Melichar, J.; Mosler, P. Contribution to the use of hydrodynamic pumps as turbines. Energetika 2012, 5, 1–5. (In Czech) [Google Scholar]

- Polák, M. Determination of conversion relations for the use of small hydrodynamic pumps in reverse turbine operation. Agron. Res. 2018, 16, 1200–1208. [Google Scholar]

- Stepanoff, A.J. Centrifugal and Axial Flow Pumps, Design and Applications; John Willy and Sons, Inc.: New York, NY, USA, 1957; 462p. [Google Scholar]

- Childs, S.M. Convert pumps to turbines and recover HP. Hydro Carbon Process. Petrol. Refin. 1962, 41, 173–174. [Google Scholar]

- Hancock, J.W. Centrifugal pump or water turbine. Pipe Line News 1963, 6, 25–27. [Google Scholar]

- Grover, K.M. Conversion of Pumps to Turbines; GSA Inter Corp.: Katonah, NY, USA, 1980; pp. 125–138. [Google Scholar]

- Lewinsky-Keslitz, H.P. Pumpen als Turbinen fur Kleinkraftwerke. Wasserwirtschaft 1987, 77, 531–537. [Google Scholar]

- Sharma, K. Small Hydroelectric Project-Use of Centrifugal Pumps as Turbines; Technical Report; Kirloskar Electric Co.: Bangalore, India, 1985; pp. 14–26. [Google Scholar]

- Schmiedl, E. Serien-Kreiselpumpen im Turbinenbetrieb; Pumpentagung: Karlsruhe, Germany, 1988. [Google Scholar]

- Alatorre-Frenk, C. Cost Minimization in Micro Hydro Systems Using Pumps-As-Turbines. Ph.D. Thesis, University of Warwick, Warwick, UK, 1994. [Google Scholar]

- Gülich, J.F. Centrifugal Pumps, 3rd ed.; Springer: Berlin, Germany, 2008; 1116p, ISBN 978-3-642-40113-8. [Google Scholar]

- Stefanizzi, M.; Torresi, M.; Fortunato, B.; Camporeale, S.M. Experimental investigation and performance prediction modeling of a single stage centrifugal pump operating as turbine. Energy Procedia 2017, 126, 589–596. [Google Scholar] [CrossRef]

- Kramer, M.; Terheiden, K.; Wieprecht, S. Pumps as turbines for efficient energy recovery in water supply networks. Renew. Energy 2018, 122, 17–25. [Google Scholar] [CrossRef] [Green Version]

- Frosina, E.; Buono, D.; Senatore, A. A performance prediction method for pumps as turbines (PAT) using a computational fluid dynamics (CFD) modeling approach. Energies 2017, 10, 103. [Google Scholar] [CrossRef]

- Melichar, J.; Bláha, J. Problems of Contemporary Pumping Technology, Selected Parts; ČVUT: Prague, Czech Republic, 2007; p. 265. (In Czech) [Google Scholar]

- Melichar, J.; Vojtek, J.; Bláha, J. Small Hydro Turbines, Construction and Operation; ČVUT: Prague, Czech Republic, 1998; p. 296. (In Czech) [Google Scholar]

- European Committee for Standardization. Rotodynamic Pumps—Hydraulic Performance Acceptance Tests—Grades 1, 2 and 3; ČSN EN ISO 9906; European Committee for Standardization: Brussels, Belgium, 2013. (In Czech) [Google Scholar]

| Author, Source | Head Ratio HT/HP | Flow Rate Ratio QT/QP | Note |

|---|---|---|---|

| Stepanoff, [18] | Accurate for Ns = 40÷60 | ||

| Childs, [19] | - | ||

| Hancock, [20] | - | ||

| Grover, [21] | Applied for Ns = 10÷50 | ||

| Hergt, [22] | - | ||

| Sharma, [23] | Accurate for Ns = 40÷60 | ||

| Schmiedl, [24] | - | ||

| Alatorre-Frenk, [25] | - | ||

| Güllich, [26] | Volute casing Nq = 25÷220 |

| Hydropower Potential (Mode) | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Total efficiency: ηT [%] | 44 ± 1.9 | 53 ± 1.6 | 57 ± 0.6 | 61 ± 0.7 | 62 ± 0.7 | 63 ± 0.7 |

| Shaft speed: NT [min−1] | 950 | 1350 | 1650 | 1950 | 2200 | 2450 |

| Flow rate: QP [l.s−1] | 4.1 ± 0.16 | 5.7 ± 0.12 | 6.6 ± 0.07 | 7.5 ± 0.05 | 8.5 ± 0.07 | 9.3 ± 0.08 |

| Total head: HT [m] | 6.0 ± 0.25 | 10.5 ± 0.31 | 16.0 ± 0.17 | 20.7 ± 0.23 | 25.0 ± 0.30 | 30.2 ± 0.31 |

| Power output: PT [W] | 107 ± 0.9 | 306 ± 0.8 | 588 ± 1.0 | 926 ± 1.5 | 1282 ± 2.3 | 1737 ± 4.0 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Polák, M. The Influence of Changing Hydropower Potential on Performance Parameters of Pumps in Turbine Mode. Energies 2019, 12, 2103. https://doi.org/10.3390/en12112103

Polák M. The Influence of Changing Hydropower Potential on Performance Parameters of Pumps in Turbine Mode. Energies. 2019; 12(11):2103. https://doi.org/10.3390/en12112103

Chicago/Turabian StylePolák, Martin. 2019. "The Influence of Changing Hydropower Potential on Performance Parameters of Pumps in Turbine Mode" Energies 12, no. 11: 2103. https://doi.org/10.3390/en12112103

APA StylePolák, M. (2019). The Influence of Changing Hydropower Potential on Performance Parameters of Pumps in Turbine Mode. Energies, 12(11), 2103. https://doi.org/10.3390/en12112103