Study on a New Gasoline Particulate Filter Structure Based on the Nested Cylinder and Diversion Channel Plug

Abstract

1. Introduction

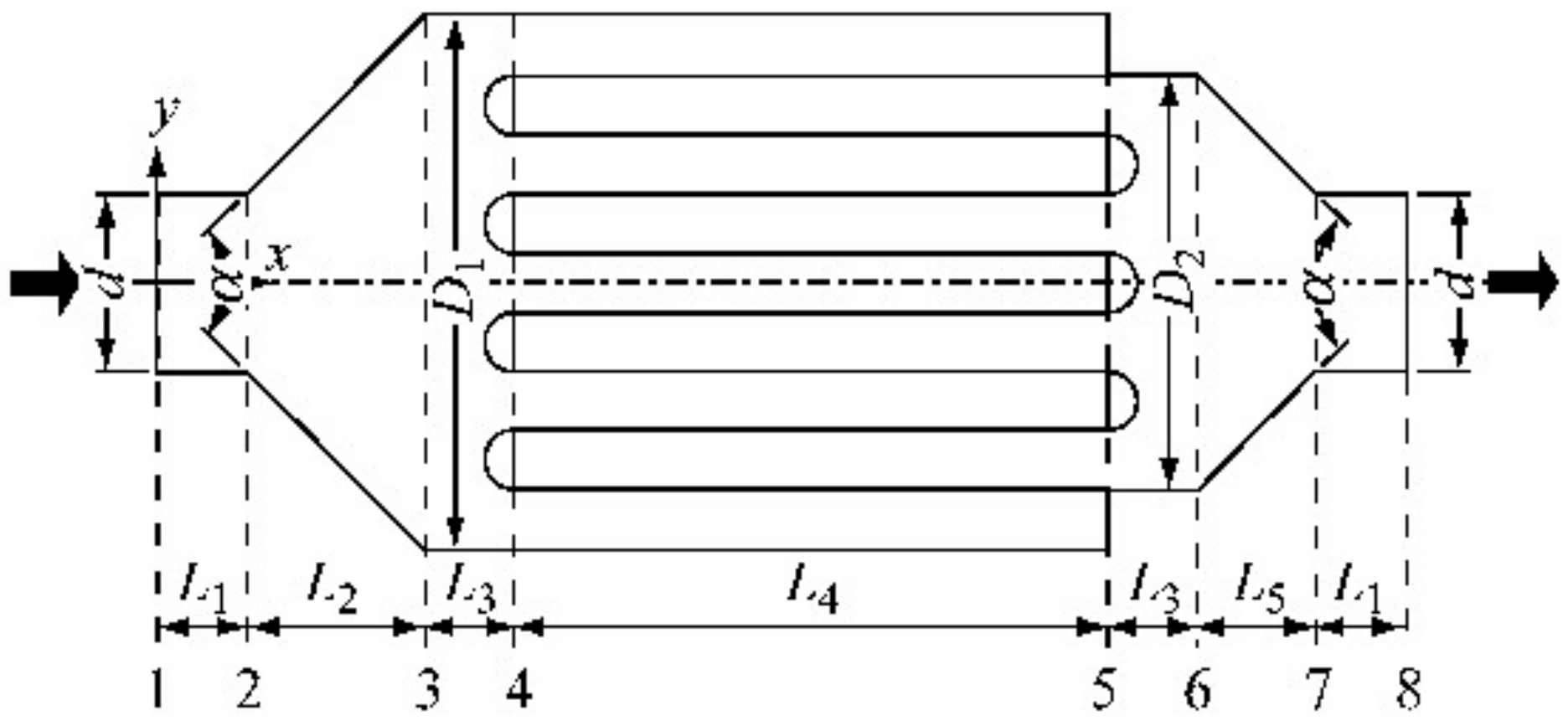

2. Structural Design of the NC-DCP GPF

2.1. Design of the Filter Element and Overall Structure

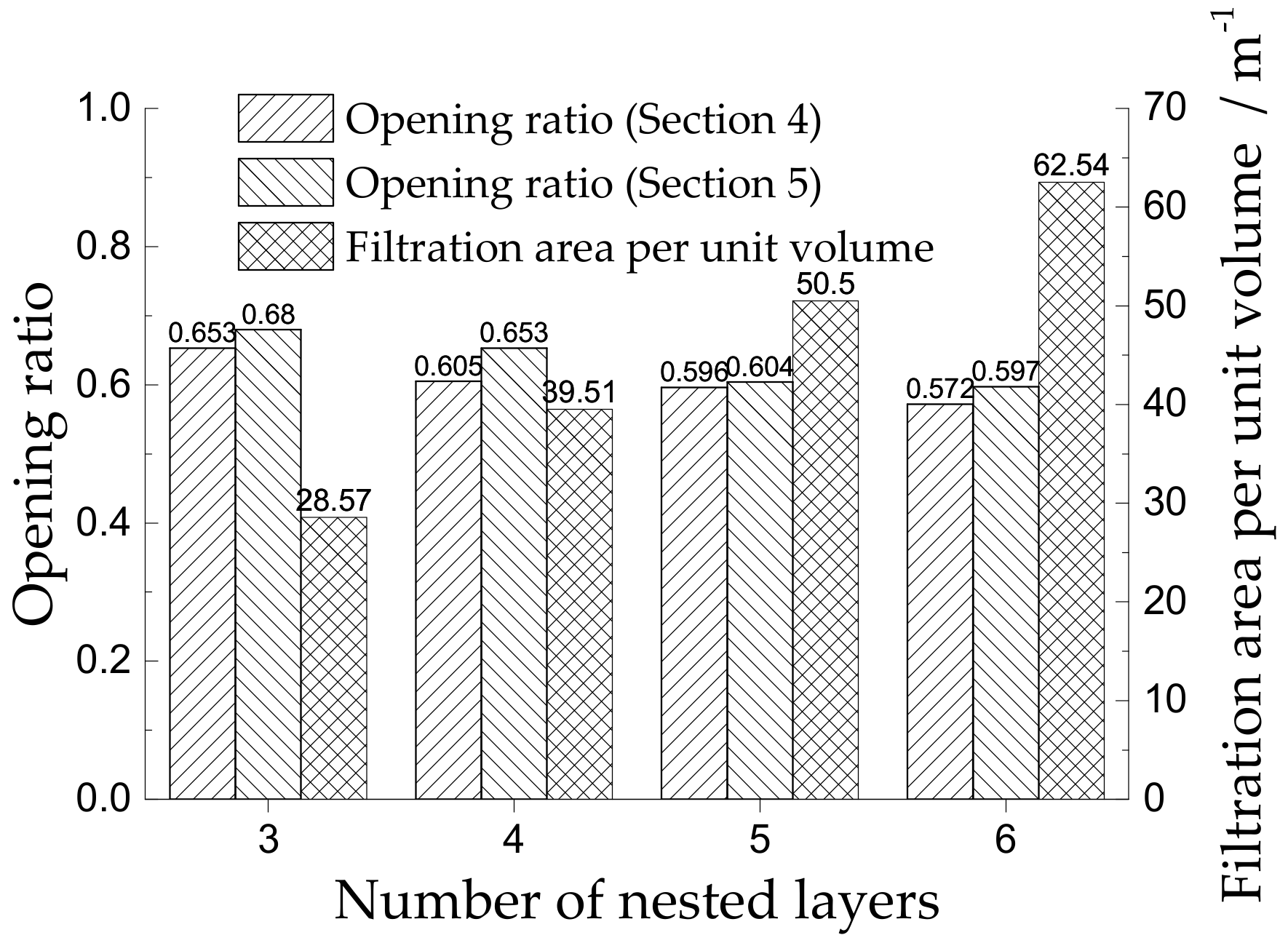

2.2. Analysis of the Structural Parameters of the NC-DCP GPF

3. Model Formulation

3.1. Governing Equations of the Flow

3.2. Turbulence Model

3.3. Porous Jump Model

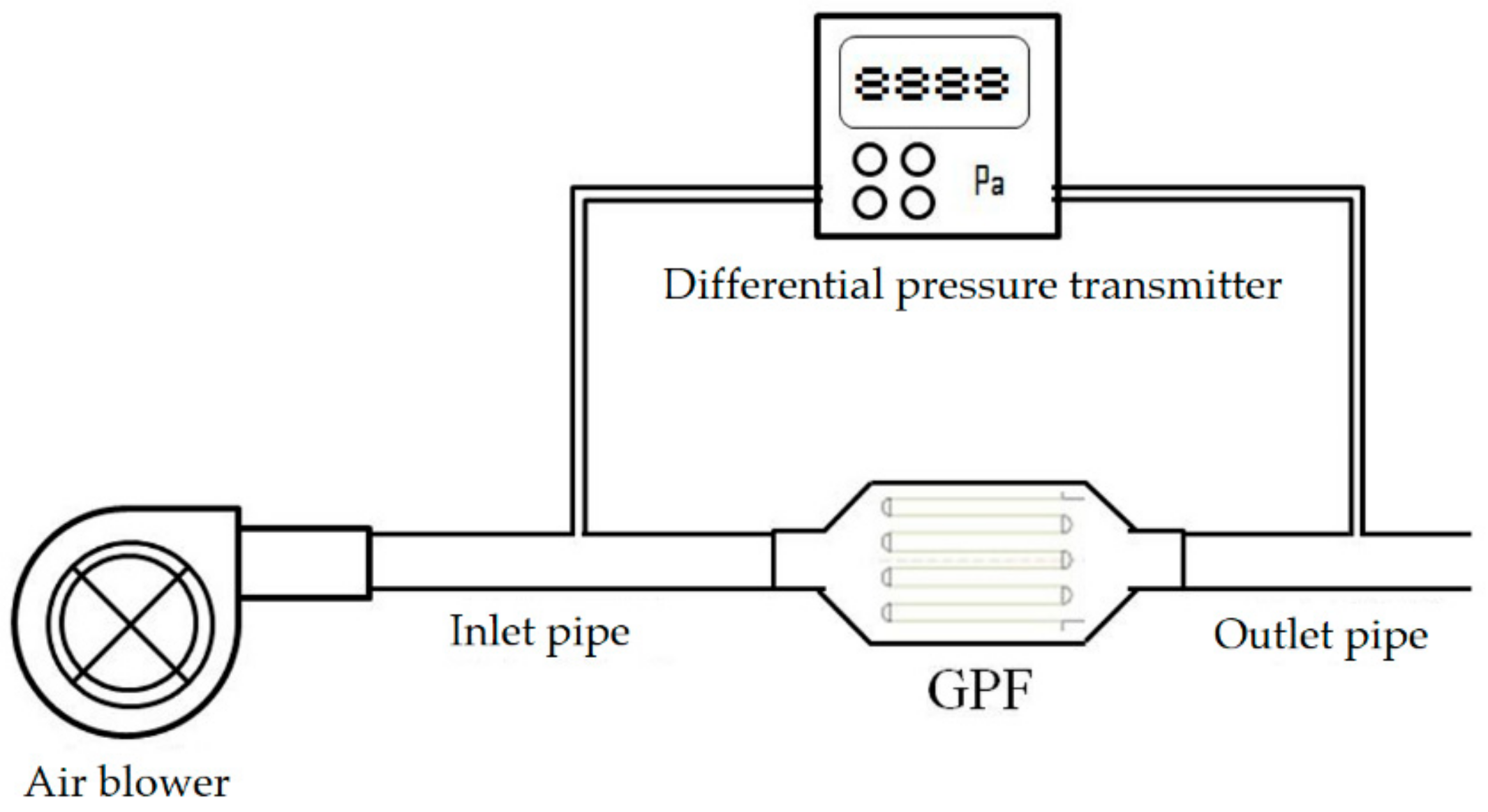

3.4. Model Volidation

4. Simulation Results and Discussion

4.1. The Effect of the Number of Nested Layers on the Pressure Drop

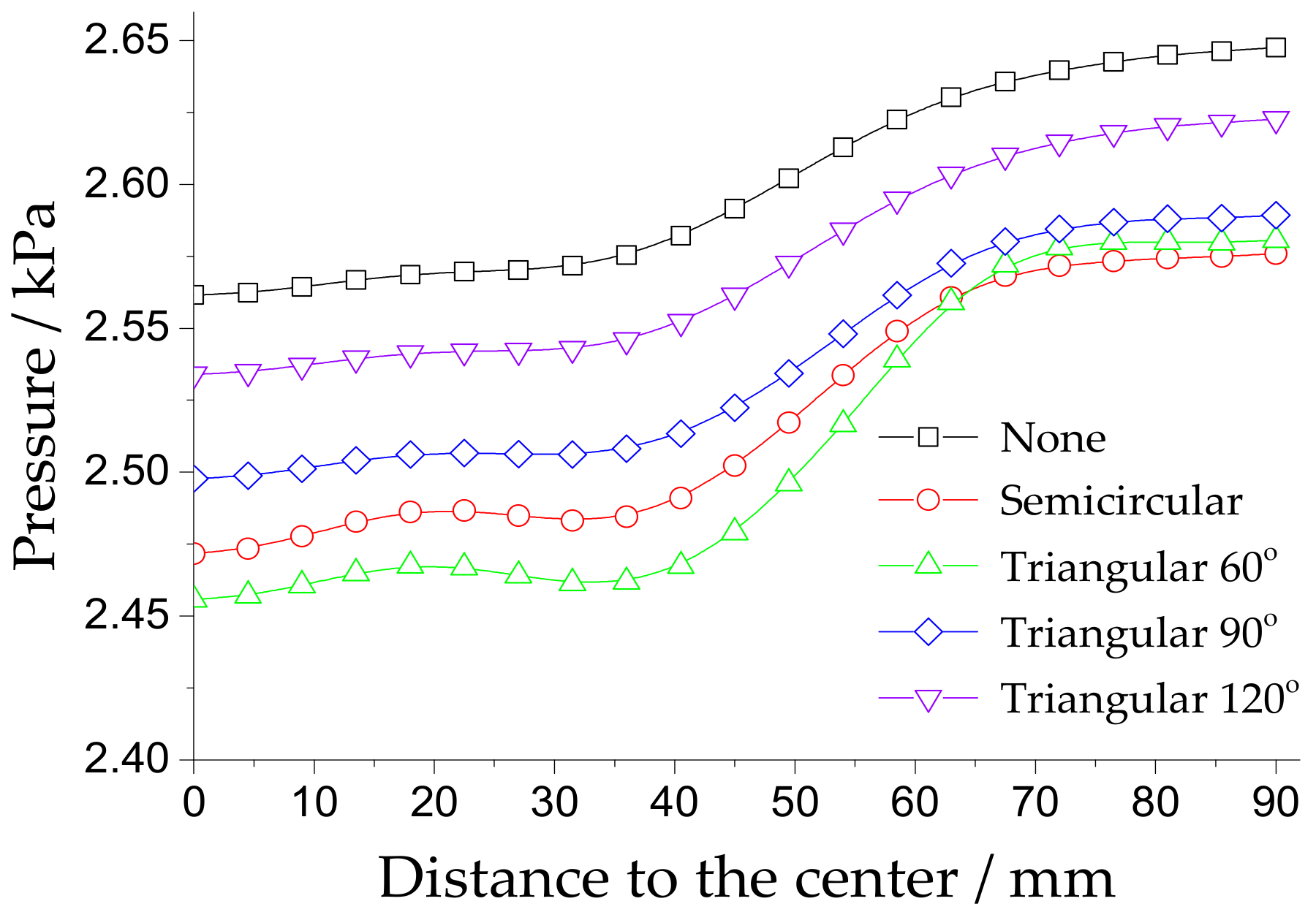

4.2. Optimization of the Diversion Plug and Its Influence

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Davis, S.C.; Williams, S.E.; Boundy, R.G.; Moore, S.M. Vehicle Technologies Market Report; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2016.

- Zhao, F.; Harrington, D.L.; Lai, M.-C.D. Automotive Gasoline Direct-Injection Engines; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

- Bandel, W.; Fraidl, G.K.; Kapus, P.E.; Sikinger, H.; Cowland, C.N. The turbocharged GDI engine: Boosted synergies for high fuel economy plus ultra-low emission. SAE Tech. Pap. 2006, 1, 1266. [Google Scholar]

- Woldring, D.; Landenfeld, T.; Christie, M.J. DI boost: Application of a high performance gasoline direct injection concept. SAE Tech. Pap. 2007, 1, 1410. [Google Scholar]

- Davis, R.S.; Mandrusiak, G.D.; Landenfeld, T.; Davis, R.S.; Mandrusiak, G.D.; Landenfeld, T.; Davis, R.S.; Mandrusiak, G.D.; Landenfeld, T.; Davis, R.S. Development of the combustion system for general motors’ 3.6L DOHC 4V V6 engine with direct injection. SAE Int. J. Engines 2008, 1, 85–100. [Google Scholar] [CrossRef]

- Johnson, T.; Joshi, A. Review of vehicle engine efficiency and emissions. SAE Int. J. Engines 2018, 11, 1307–1330. [Google Scholar] [CrossRef]

- Spicher, U.; Reissing, J.; Kech, J.M.; Gindele, J. Gasoline direct injection (GDI) engines—Development potentialities. SAE Tech. Pap. 1999, 1, 2938. [Google Scholar]

- Aakko, P.; Nylund, N.-O. Particle emissions at moderate and cold temperatures using different fuels. SAE Tech. Pap. 2003, 1, 3285. [Google Scholar]

- Wu, G.; Kuznetsov, A.V.; Jasper, W.J. Distribution characteristics of exhaust gases and soot particles in a wall-flow ceramics filter. J. Aerosol Sci. 2011, 42, 447–461. [Google Scholar] [CrossRef]

- Mohr, M.; Forss, A.-M.; Steffen, D. Particulate emissions of gasoline vehicles and influence of the sampling procedure. SAE Tech. Pap. 2000, 1, 1137. [Google Scholar]

- Graskow, B.R.; Kittelson, D.B.; Ahmadi, M.R.; Morris, J.E. Exhaust particulate emissions from a direct injection spark ignition engine. SAE Trans. 1999, 108, 602–609. [Google Scholar]

- Raza, M.; Chen, L.F.; Leach, F.; Ding, S.T. A review of particulate umber (PN) emissions from gasoline direct injection (GDI) engines and their control techniques. Energies 2018, 11, 1417. [Google Scholar] [CrossRef]

- Platt, S.M.; El Haddad, I.; Pieber, S.M.; Zardini, A.A.; Suarez-Bertoa, R.; Clairotte, M.; Daellenbach, K.R.; Huang, R.J.; Slowik, J.G.; Hellebust, S.; et al. Gasoline cars produce more carbonaceous particulate matter than modern filter-equipped diesel cars. Sci. Rep. 2017, 7, 4926. [Google Scholar] [CrossRef]

- Tandon, P.; Heibel, A.K.; Whitmore, J.; Kekre, N.; Chithapragada, K. Measurement and prediction of filtration efficiency evolution of soot loaded diesel particulate filters. Chem. Eng. Sci. 2010, 65, 4751–4760. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Pham, M.; Zhao, D.; Deng, Y.; Le, D.; Zuo, W.; Zhu, H.; Liu, T.; Peng, Q.; Zhang, Z. Effect of different technologies on combustion and emissions of the diesel engine fueled with biodiesel: A review. Renew. Sustain. Energy Rev. 2017, 80, 620–647. [Google Scholar]

- Chan, T.W.; Lax, D.; Gunter, G.C.; Hendren, J.; Kubsh, J.; Brezny, R. Assessment of the fuel composition impact on black carbon mass, particle number size distributions, solid particle number, organic materials, and regulated gaseous emissions from a light-duty gasoline direct injection truck and passenger car. Energy Fuels 2017, 31, 10452–10466. [Google Scholar] [CrossRef]

- Merkel, G.A.; Cutler, W.A.; Warren, C.J. Thermal durability of wall-flow ceramic diesel particulate filters. SAE Trans. 2001, 110, 168–182. [Google Scholar]

- Boger, T.; Rose, D.; Nicolin, P.; Gunasekaran, N.; Glasson, T. Oxidation of soot (Printex® U) in particulate filters operated on gasoline engines. Emiss. Control Sci. Technol. 2015, 1, 49–63. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Calmidi, V.V.; Mahajan, R.L. Thermophysical properties of high porosity metal foams. Int. J. Heat Mass Transf. 2002, 45, 1017–1031. [Google Scholar] [CrossRef]

- Incera Garrido, G.; Patcas, F.C.; Lang, S.; Kraushaar-Czarnetzki, B. Mass transfer and pressure drop in ceramic foams: A description for different pore sizes and porosities. Chem. Eng. Sci. 2008, 63, 5202–5217. [Google Scholar] [CrossRef]

- Myung, C.L.; Kim, J.; Jang, W.; Jin, D.; Park, S.; Lee, J. Nanoparticle filtration characteristics of advanced metal foam media for a spark ignition direct injection engine in steady engine operating conditions and vehicle test modes. Energies 2015, 8, 1865–1881. [Google Scholar] [CrossRef]

- Sosnick, B. Process for Making Foam Like Mass of Metal. U.S. Patent 2,434,775, 20 January 1948.

- Kamath, P.M.; Balaji, C.; Venkateshan, S.P. Convection heat transfer from aluminium and copper foams in a vertical channel—An experimental study. Int. J. Therm. Sci. 2013, 64, 1–10. [Google Scholar] [CrossRef]

- Masoudi, M.; Konstandopoulos, A.G.; Nikitidis, M.S.; Skaperdas, E.; Zarvalis, D.; Kladopoulou, E.; Altiparmakis, C. Validation of a model and development of a simulator for predicting the pressure drop of diesel particulate filters. SAE Trans. 2001, 110, 650–656. [Google Scholar]

- Konstandopoulos, A.G.; Skaperdas, E.; Masoudi, M. Inertial contributions to the pressure drop of diesel particulate filters. SAE Tech. Pap. 2001. [Google Scholar] [CrossRef]

- Haralampous, O.A.; Kandylas, I.P.; Koltsakis, G.C.; Samaras, Z.C.; Haralampous, O.A. Diesel particulate filter pressure drop Part 1: Modelling and experimental validation. Int. J. Engine Res. 2004, 5, 149–162. [Google Scholar] [CrossRef]

- Masoudi, M. Pressure drop of segmented diesel particulate filters. SAE Trans. 2005, 114, 503–511. [Google Scholar]

- Bermúdez, V.; Serrano, J.; Piqueras, P.; Sanchis, E. On the impact of particulate matter distribution on pressure drop of wall-flow particulate filters. Appl. Sci. 2017, 7, 234. [Google Scholar] [CrossRef]

- Torregrosa, A.J.; Serrano, J.R.; Arnau, F.J.; Piqueras, P. A fluid dynamic model for unsteady compressible flow in wall-flow diesel particulate filters. Energy 2011, 36, 671–684. [Google Scholar] [CrossRef]

- Ma, L.; Paraschivoiu, M.; Yao, J.; Blackman, L. Improving flow uniformity in a diesel particulate filter system. SAE Tech. Pap. 2001. [Google Scholar] [CrossRef]

- Howitt, J.S.; Sekella, T.C. Flow effects in monolithic honeycomb automotive catalytic converters. SAE Trans. 1974, 83, 1067–1075. [Google Scholar]

- Bella, G.; Rocco, V.; Maggiore, M. A study of inlet flow distortion effects on automotive catalytic converters. J. Eng. Gas Turbines Power 1991, 113, 419. [Google Scholar] [CrossRef]

- Qiu, Y.; Li, X.; Mu, M.; Li, X. Structure design and parameter optimization of new GPF based on FLUENT. Comput. Aided Eng. 2017, 26, 19–24. [Google Scholar]

- Persoons, T. Experimental Flow Dynamics in Automotive Exhaust Systems with Close-Coupled Catalyst. Ph.D. Thesis, Catholic University of Leuven, Leuven, Belgium, 2006. [Google Scholar]

- Mu, M.; Li, X.; Aslam, J.; Qiu, Y.; Yang, H.; Kou, G.; Wang, Y. A study of shape optimization method on connection cones for diesel particulate filter (DPF). In Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition, Phoenix, AR, USA, 11–17 November 2016; p. V012T16A001. [Google Scholar]

- Mu, M.; Sjöblom, J.; Ström, H.; Li, X. Analysis of the flow field from connection cones to monolith reactors. Energies 2019, 12, 455. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, S.L.; Johnson, J.H. Modeling and numerical simulation of diesel particulate trap performance during loading and regeneration. SAE Trans. 2002, 111, 471–483. [Google Scholar]

- Shuai, S.; Wang, J.; Zhuang, R. Application of CFD to the optimal design of automotive catalytic converyers. Automot. Eng. 2000, 22, 129–133. [Google Scholar]

- Chandesris, M.; Jamet, D. Derivation of jump conditions for the turbulence model at a fluid/porous interface. Int. J. Heat Fluid Flow 2009, 30, 306–318. [Google Scholar] [CrossRef]

- Weltens, H.; Bressler, H.; Terres, F.; Neumaier, H.; Rammoser, D. Optimisation of catalytic converter gas flow distribution by CFD prediction. SAE Tech. Pap. 1993. [Google Scholar] [CrossRef]

| σk | σε | C1ε | C2ε | Cμ |

|---|---|---|---|---|

| 1.0 | 1.3 | 1.44 | 1.92 | 0.09 |

| Thickness, mm | Mean Pore Diameter, mm | Porosity | Permeability, m2 | Factor of Porous Jump C2, m−1 |

|---|---|---|---|---|

| 2 | 0.34 | 0.75 | 1 × 10−11 | 14,000 |

| Type | Speed, r/min | Air Volume, m2/min | Power, W |

|---|---|---|---|

| Q1B-XP-2.5 | 0–16,000 | 3.5 | 1200 |

| Inlet Velocity, m/s | Pressure Drop, Pa | |

|---|---|---|

| Positive | Negative | |

| 2 | 196.5 | 201.6 |

| 4 | 382.2 | 392.2 |

| 6 | 579.0 | 591.8 |

| 8 | 778.5 | 790.0 |

| 10 | 989.0 | 995.5 |

| 12 | 1210 | 1221 |

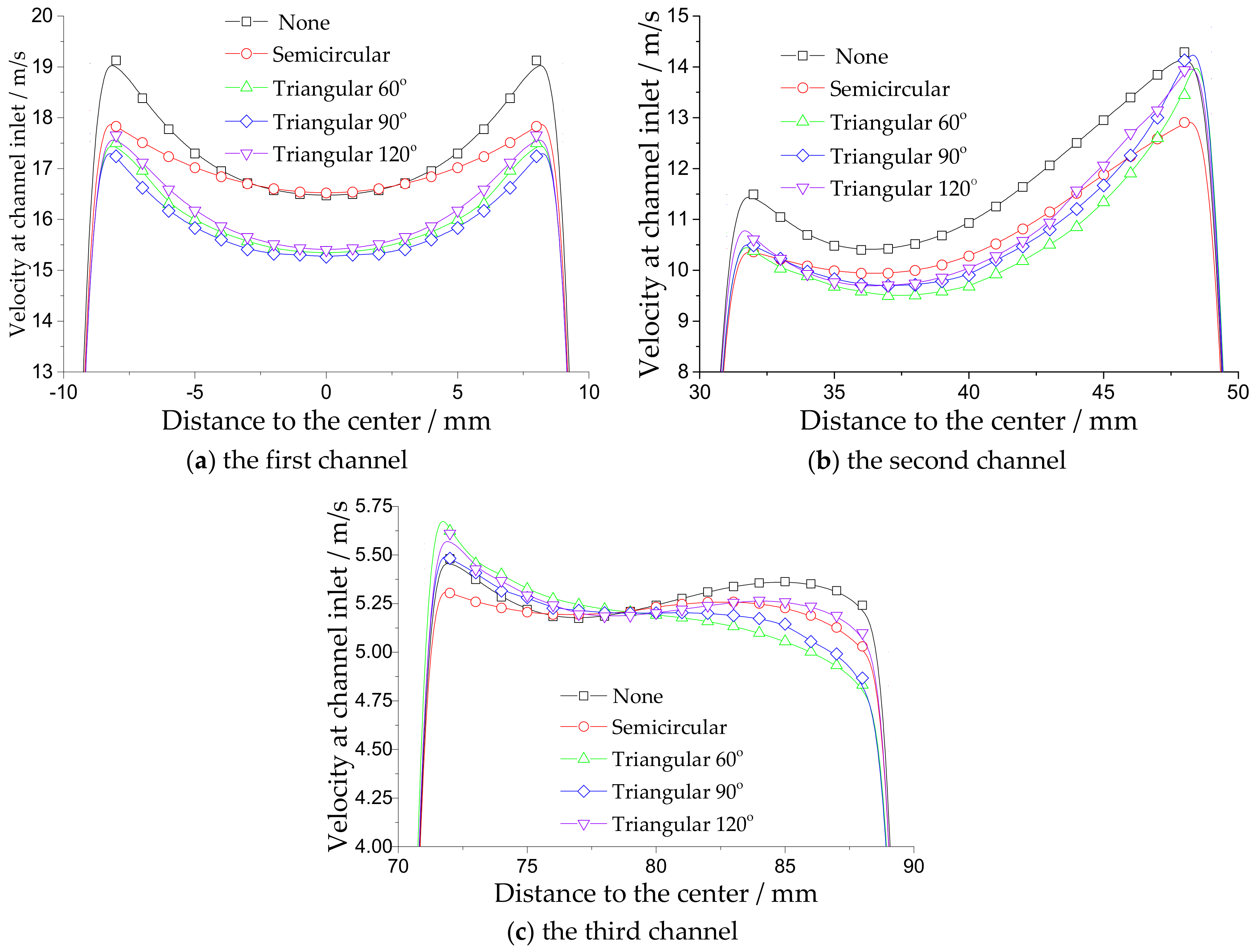

| Cross-Sectional Shape of Diversion Plug in the NC-DCP GPF Element | Flow Uniformity Index | ||

|---|---|---|---|

| First Channel | Second Channel | Third Channel | |

| none | 0.9082 | 0.9119 | 0.9282 |

| semicircular | 0.9669 | 0.9688 | 0.9501 |

| triangular (apex angle = 60°) | 0.9576 | 0.9657 | 0.9550 |

| triangular (apex angle = 90°) | 0.9464 | 0.9617 | 0.9443 |

| triangular (apex angle = 120°) | 0.9317 | 0.9497 | 0.9374 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, M.; Li, X.; Qiu, Y.; Shi, Y. Study on a New Gasoline Particulate Filter Structure Based on the Nested Cylinder and Diversion Channel Plug. Energies 2019, 12, 2045. https://doi.org/10.3390/en12112045

Mu M, Li X, Qiu Y, Shi Y. Study on a New Gasoline Particulate Filter Structure Based on the Nested Cylinder and Diversion Channel Plug. Energies. 2019; 12(11):2045. https://doi.org/10.3390/en12112045

Chicago/Turabian StyleMu, Mingfei, Xinghu Li, Yong Qiu, and Yang Shi. 2019. "Study on a New Gasoline Particulate Filter Structure Based on the Nested Cylinder and Diversion Channel Plug" Energies 12, no. 11: 2045. https://doi.org/10.3390/en12112045

APA StyleMu, M., Li, X., Qiu, Y., & Shi, Y. (2019). Study on a New Gasoline Particulate Filter Structure Based on the Nested Cylinder and Diversion Channel Plug. Energies, 12(11), 2045. https://doi.org/10.3390/en12112045