Development of Hardware-in-the-Loop-Simulation Testbed for Pitch Control System Performance Test

Abstract

1. Introduction

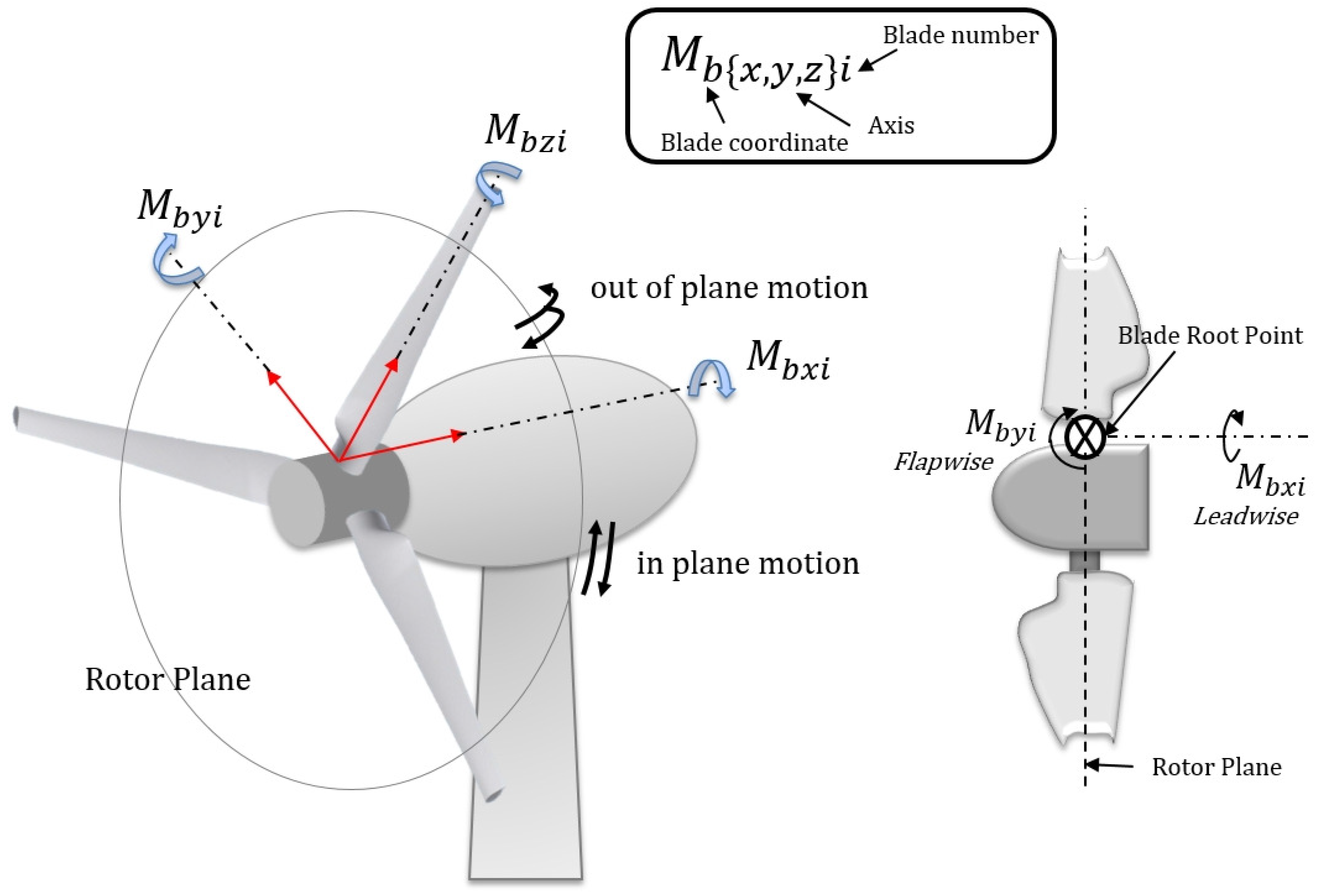

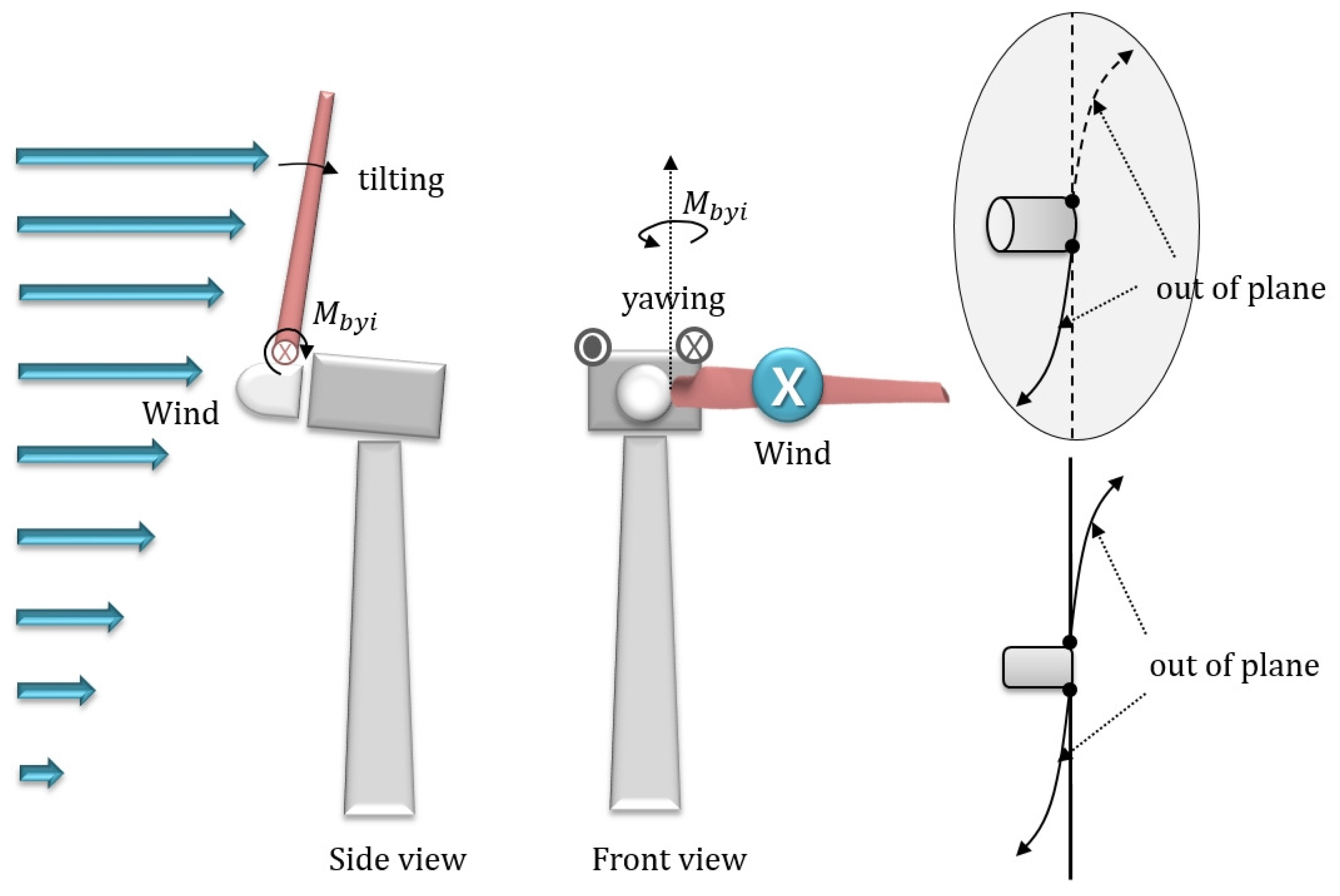

2. Design of the Pitch System

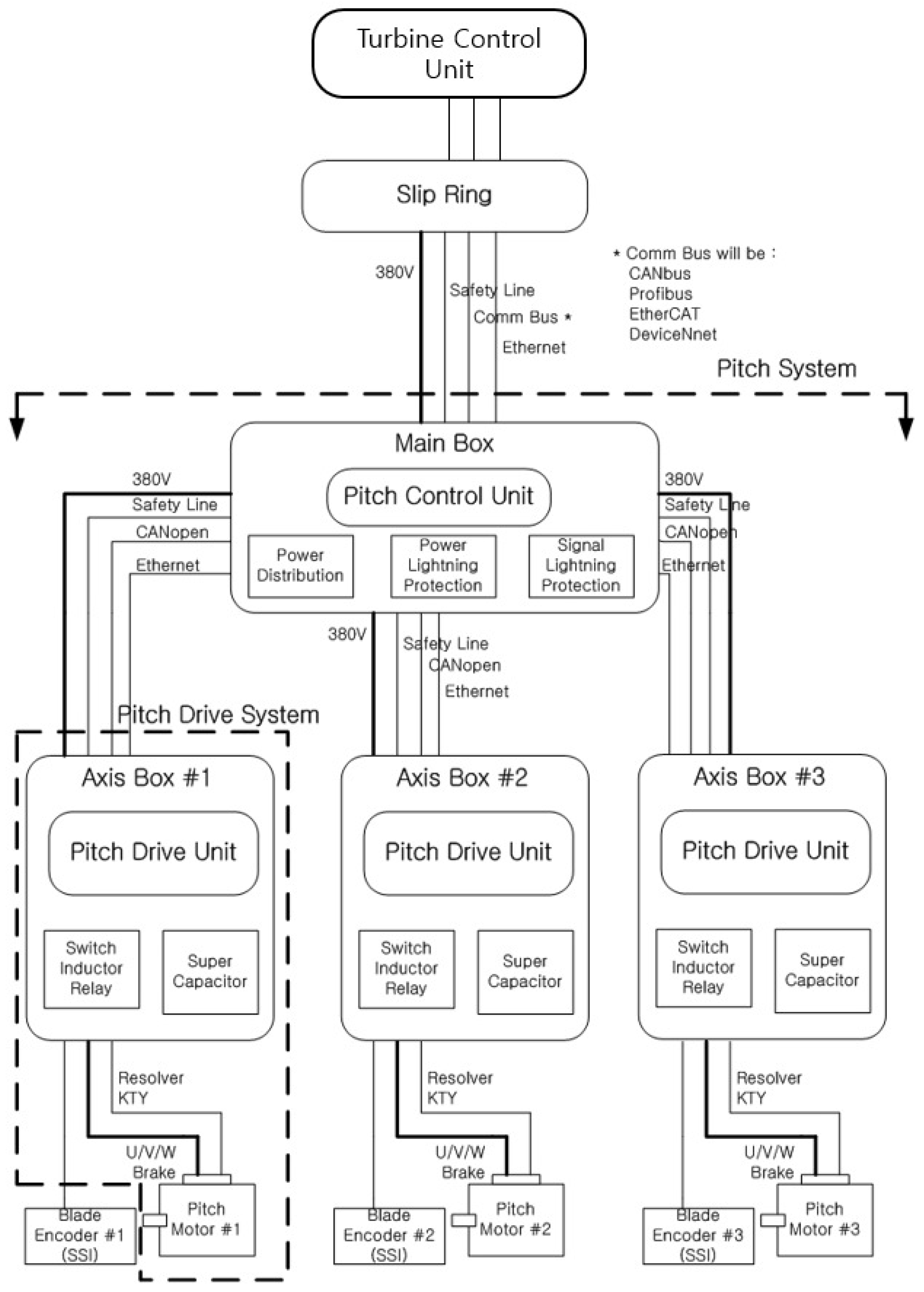

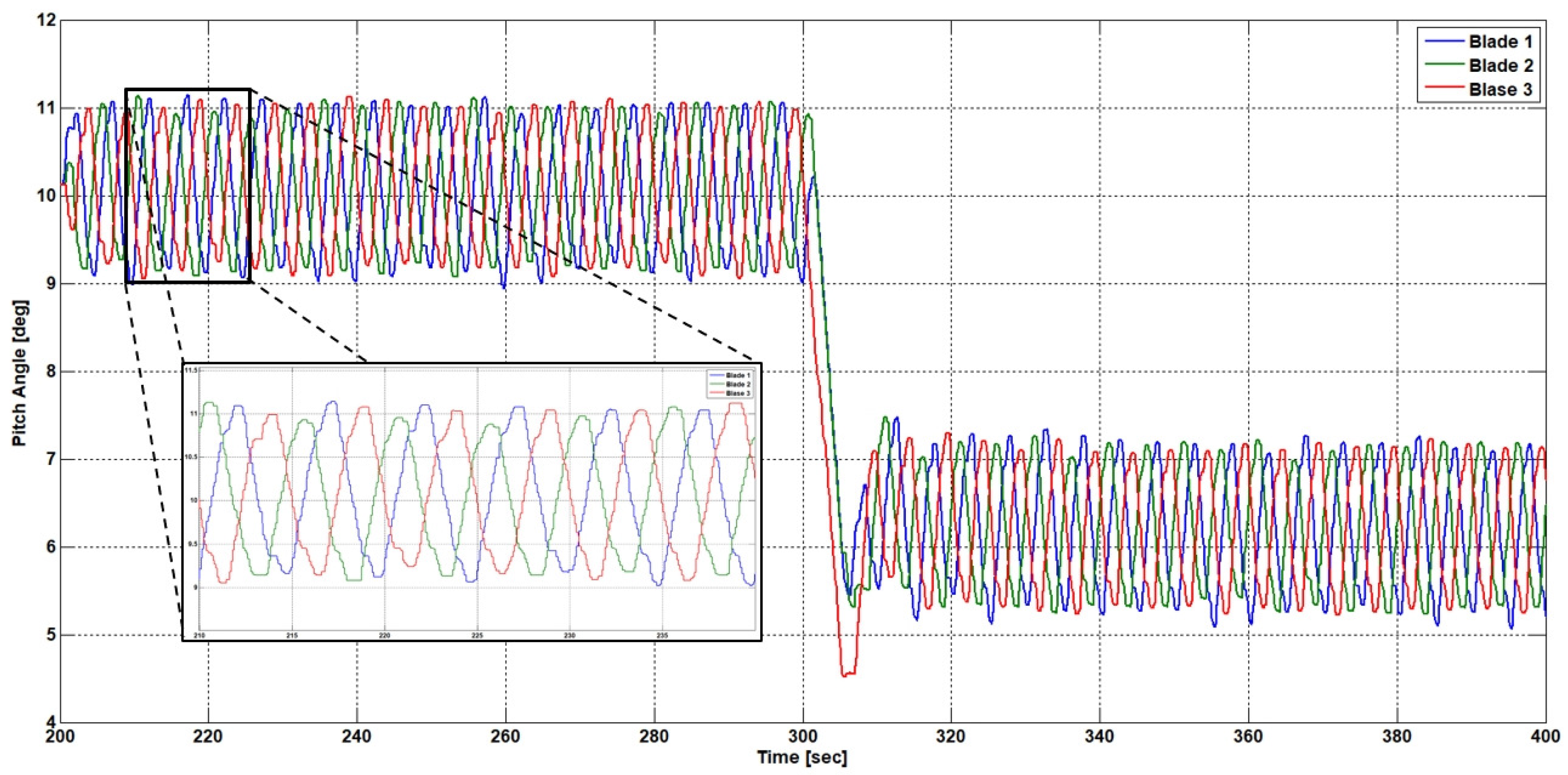

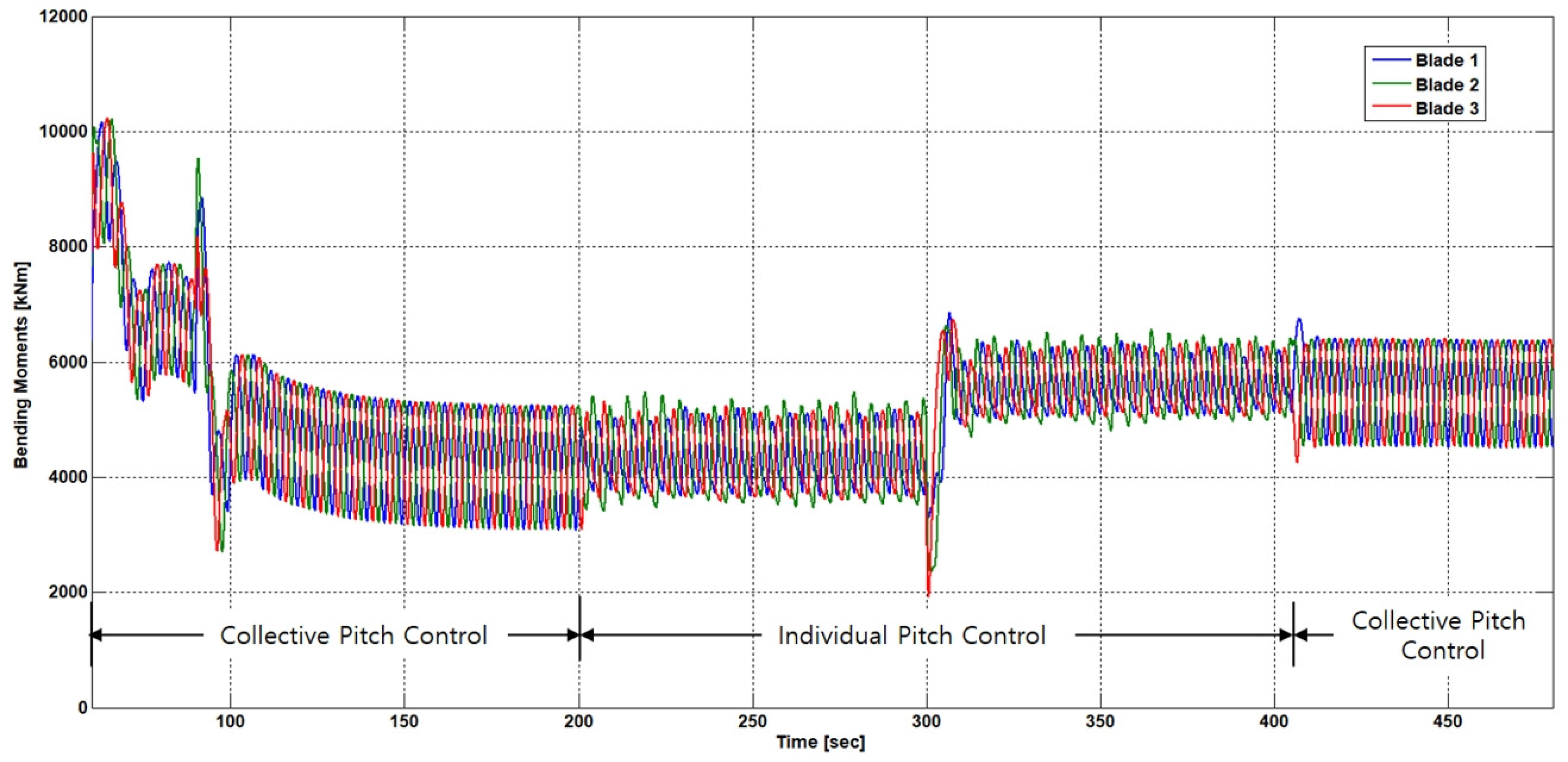

2.1. Configuration of the Pitch System

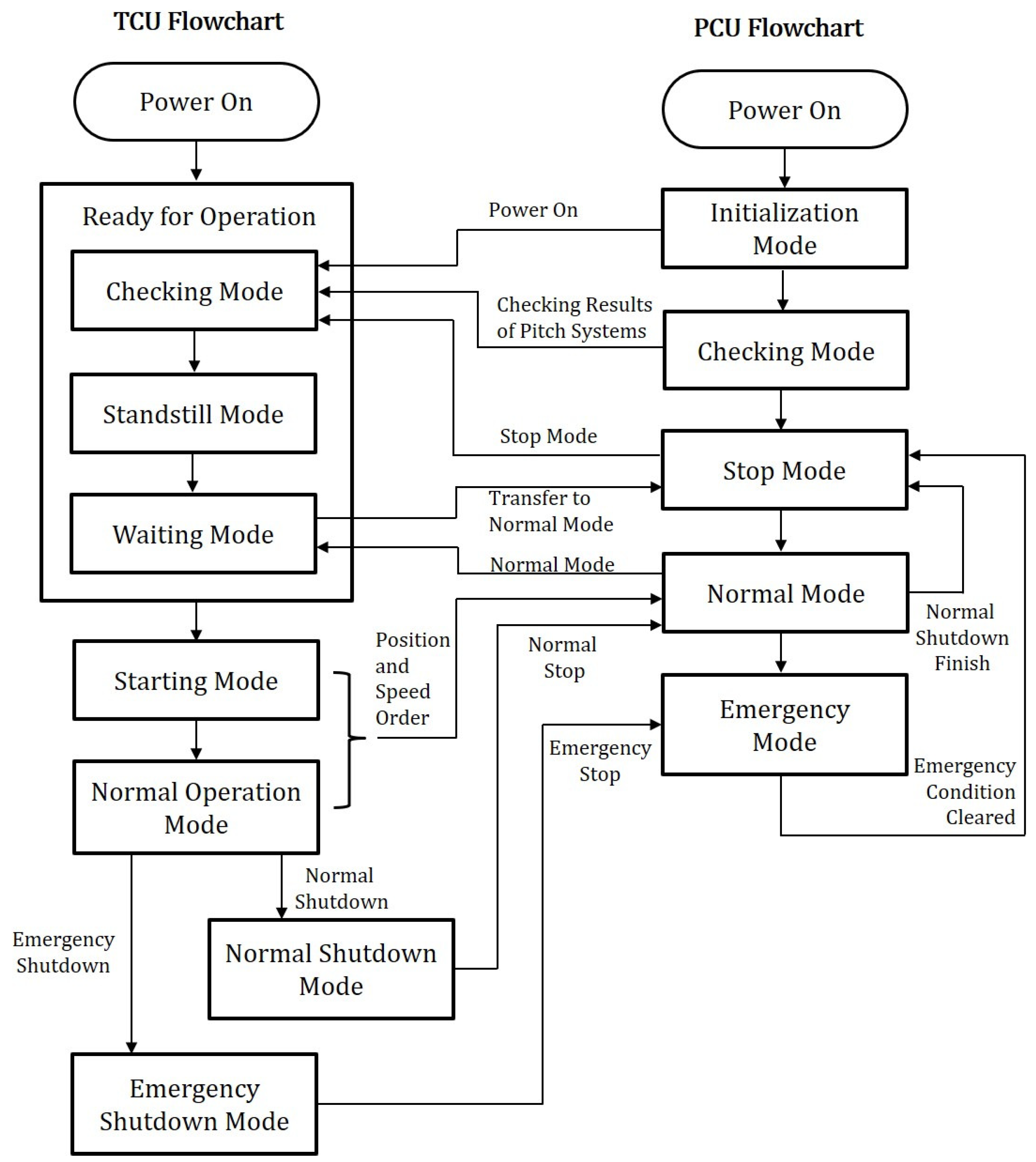

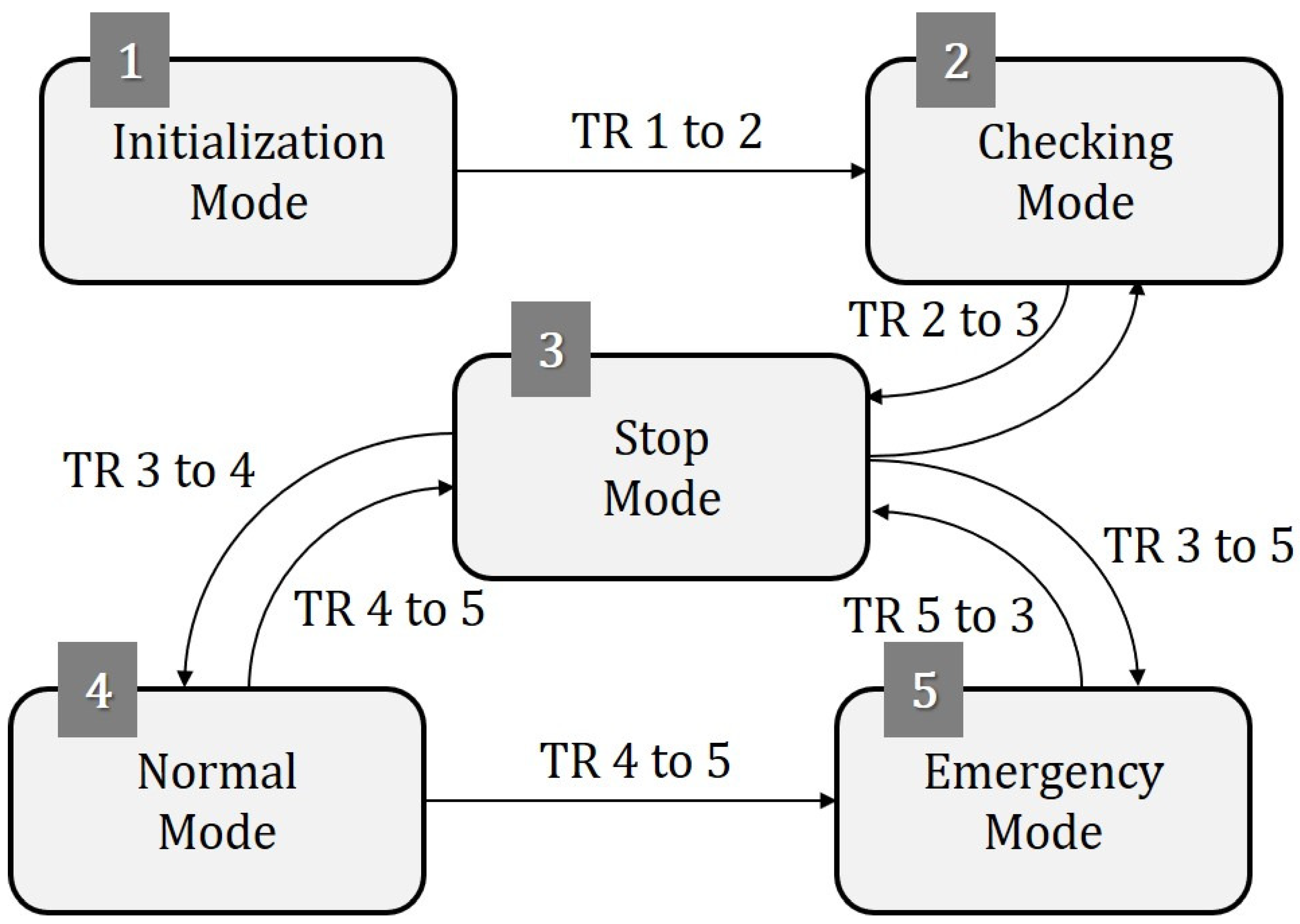

2.2. Pitch Control Unit

2.2.1. Overview

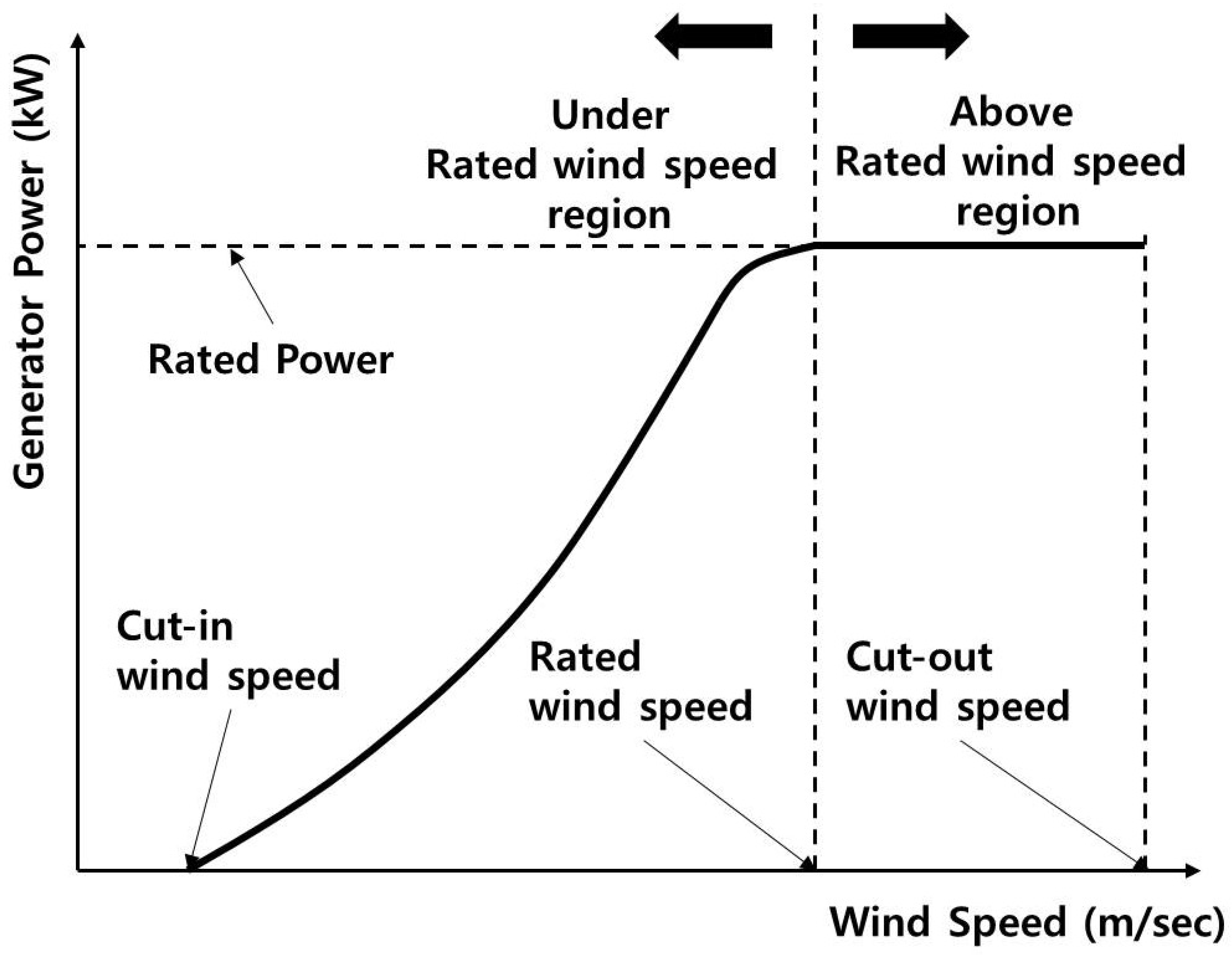

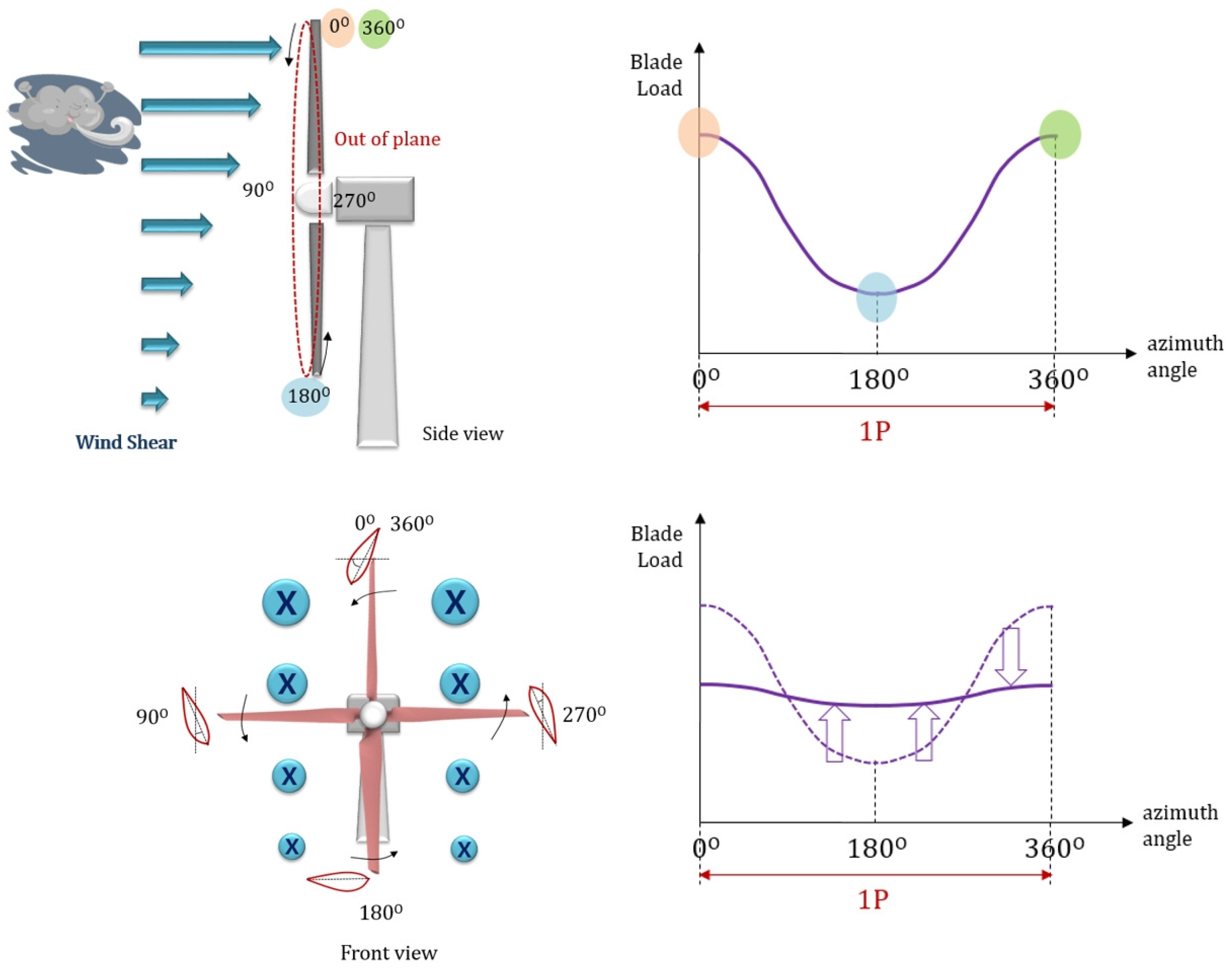

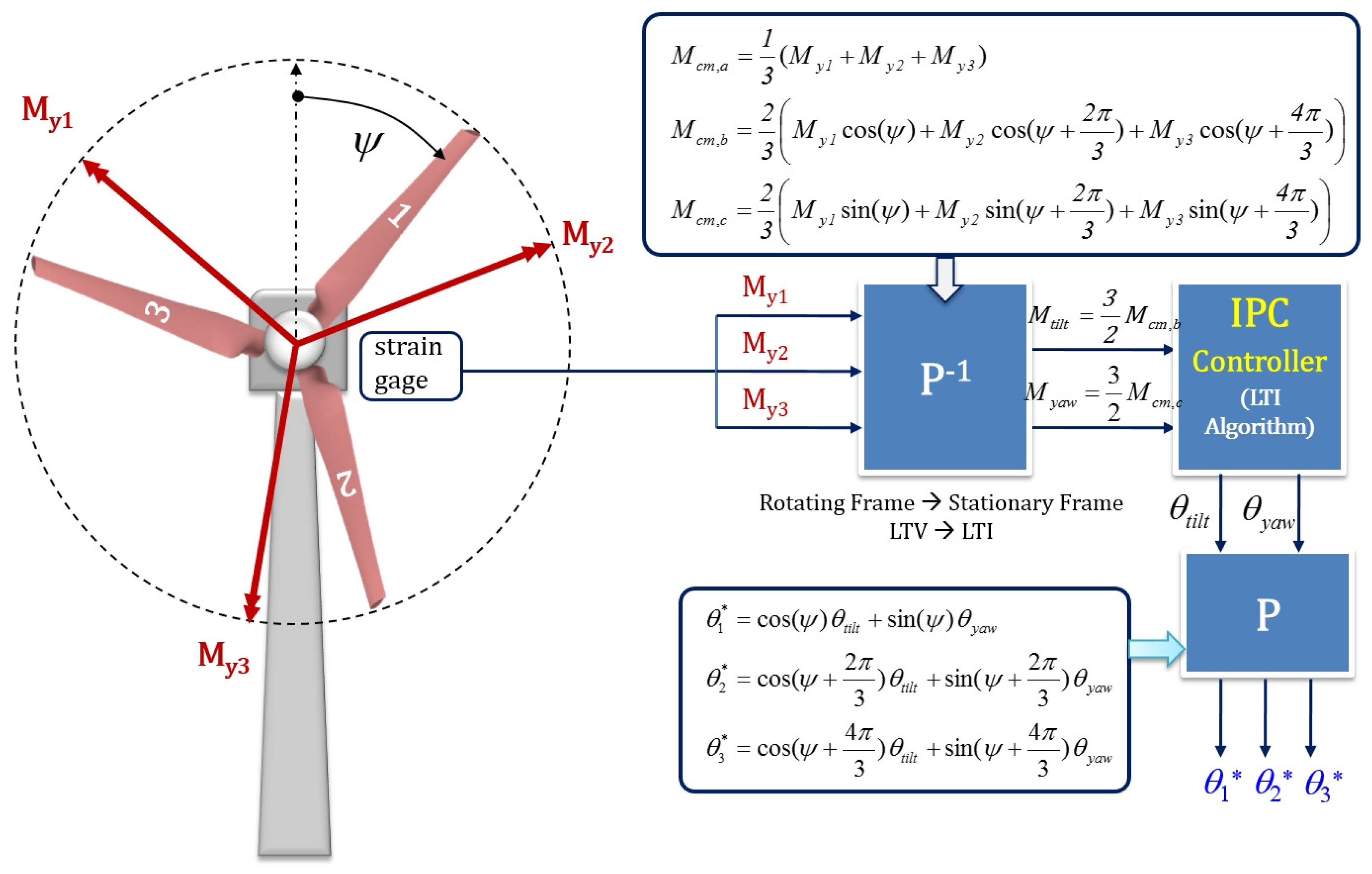

2.2.2. Control Algorithm

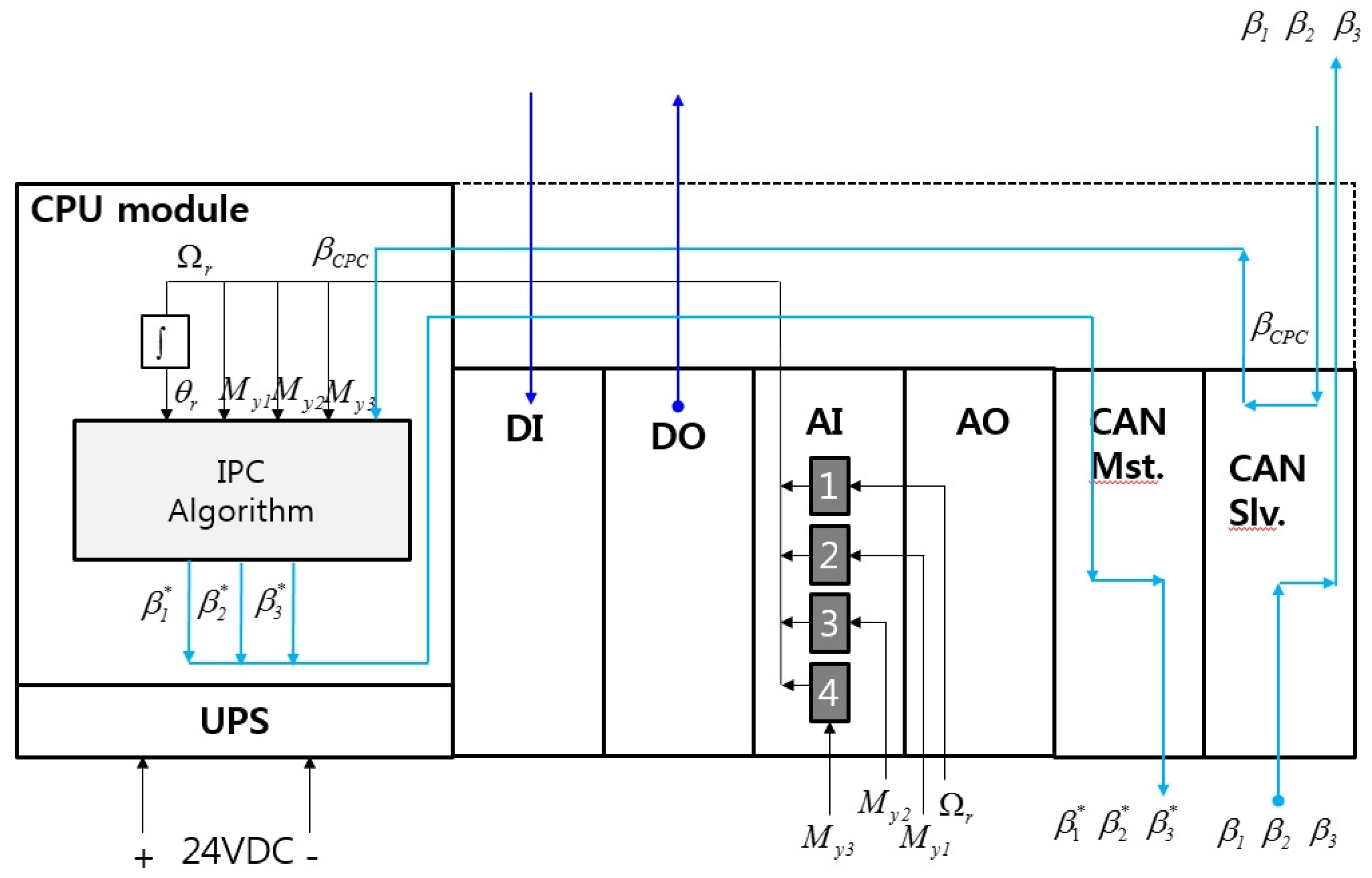

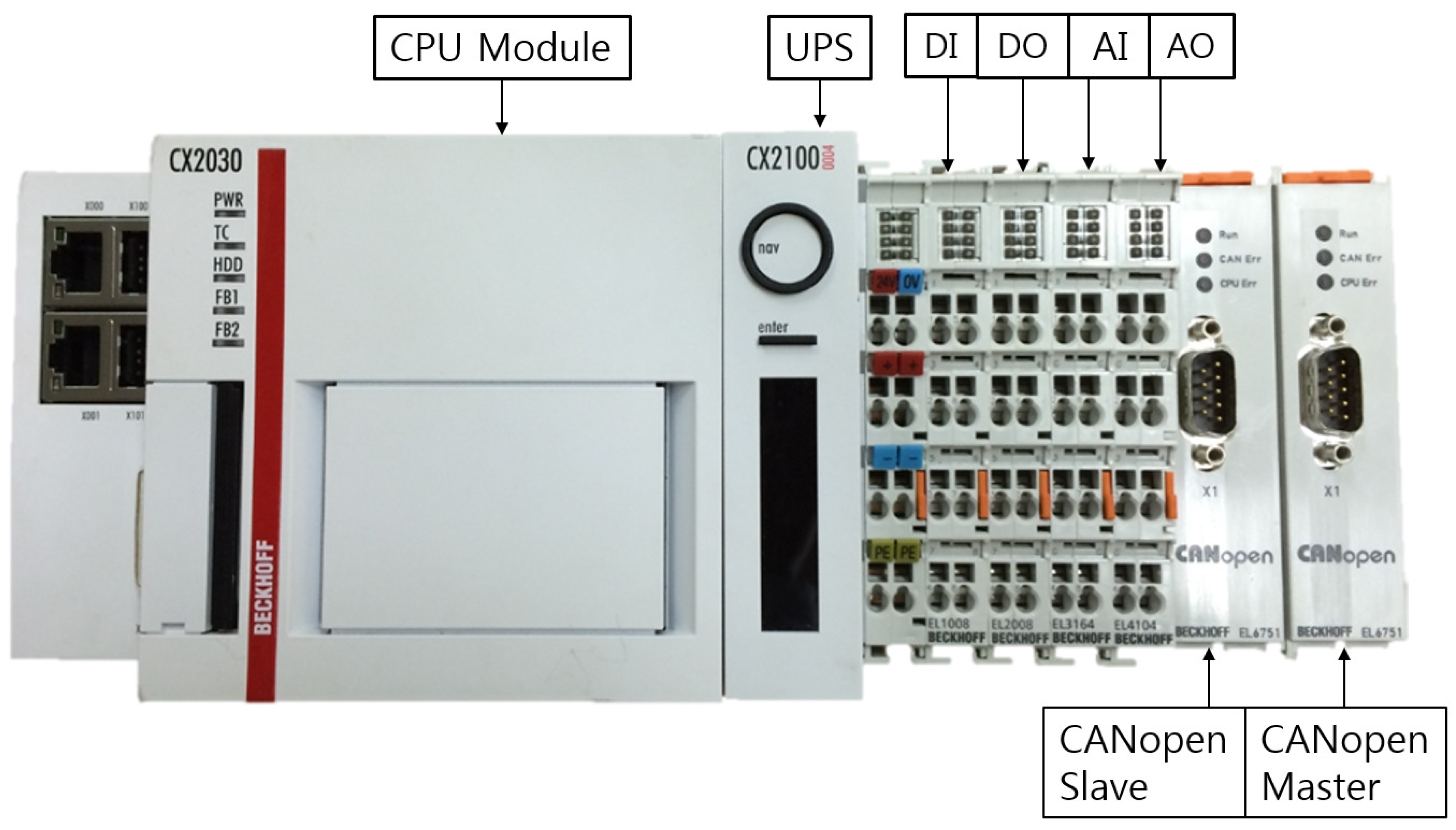

2.2.3. Hardware Design

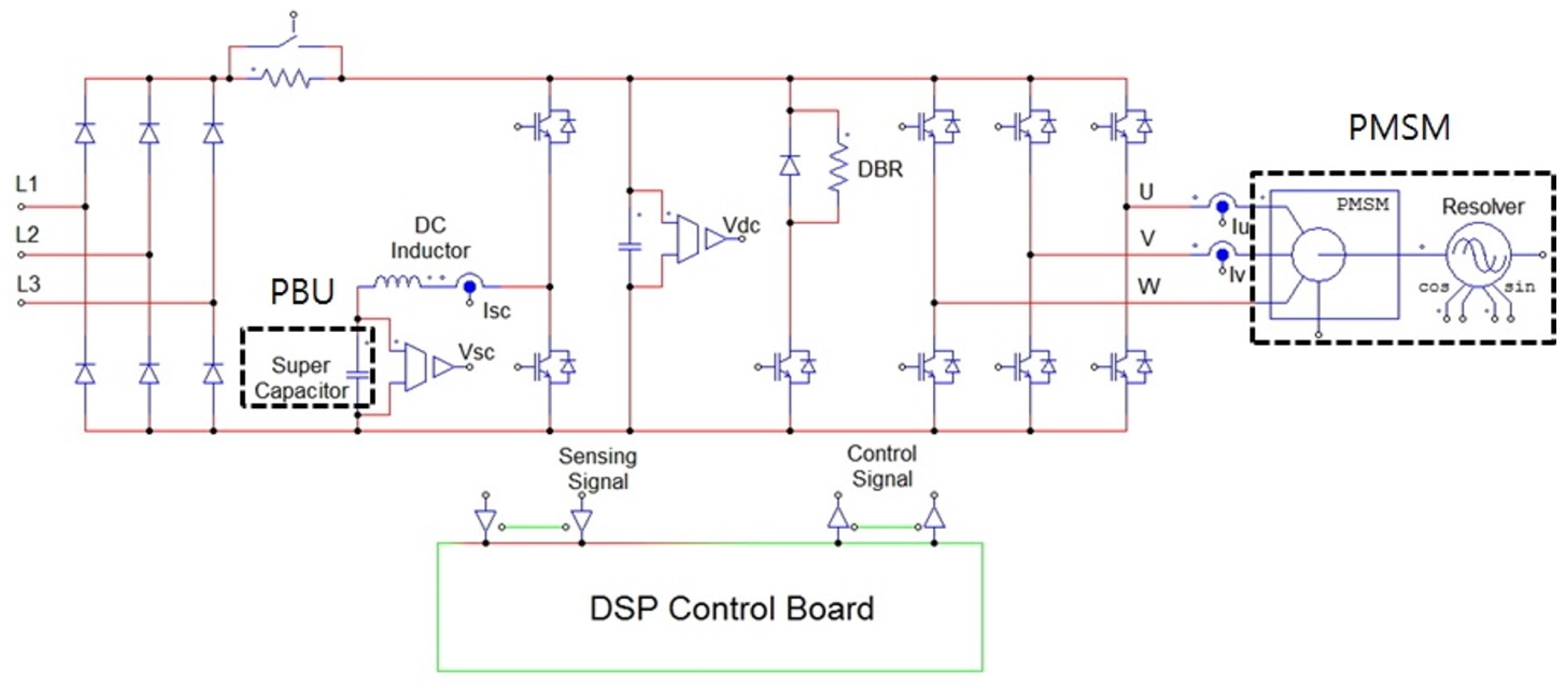

2.3. Pitch Drive System

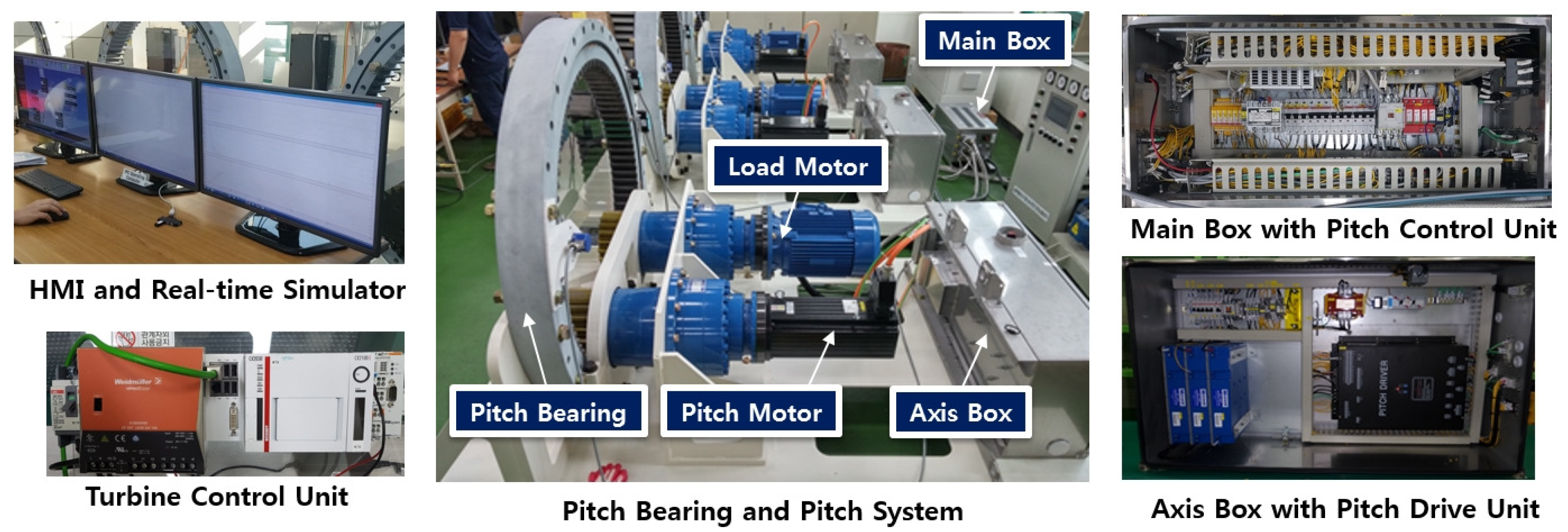

3. The Construction of Testbed

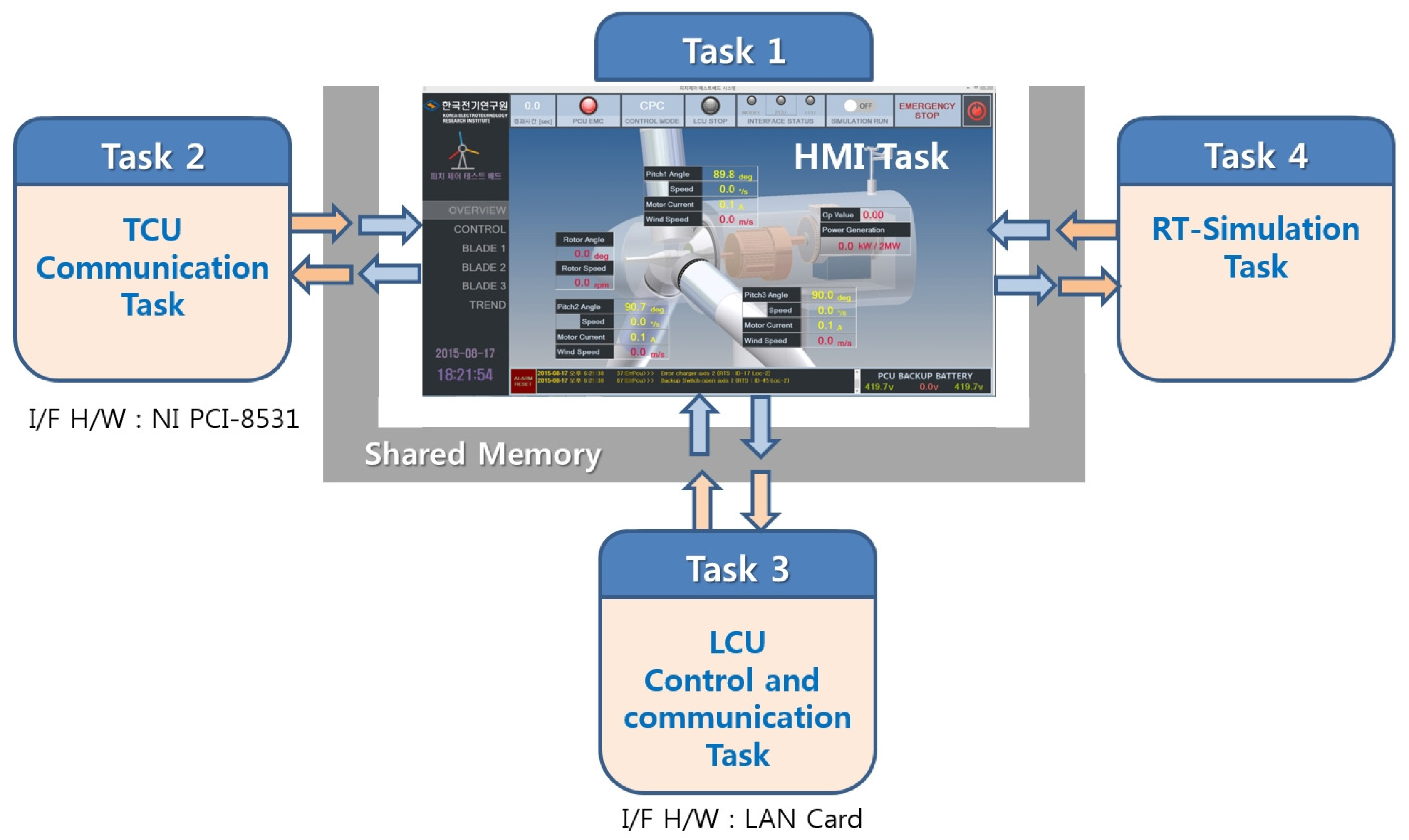

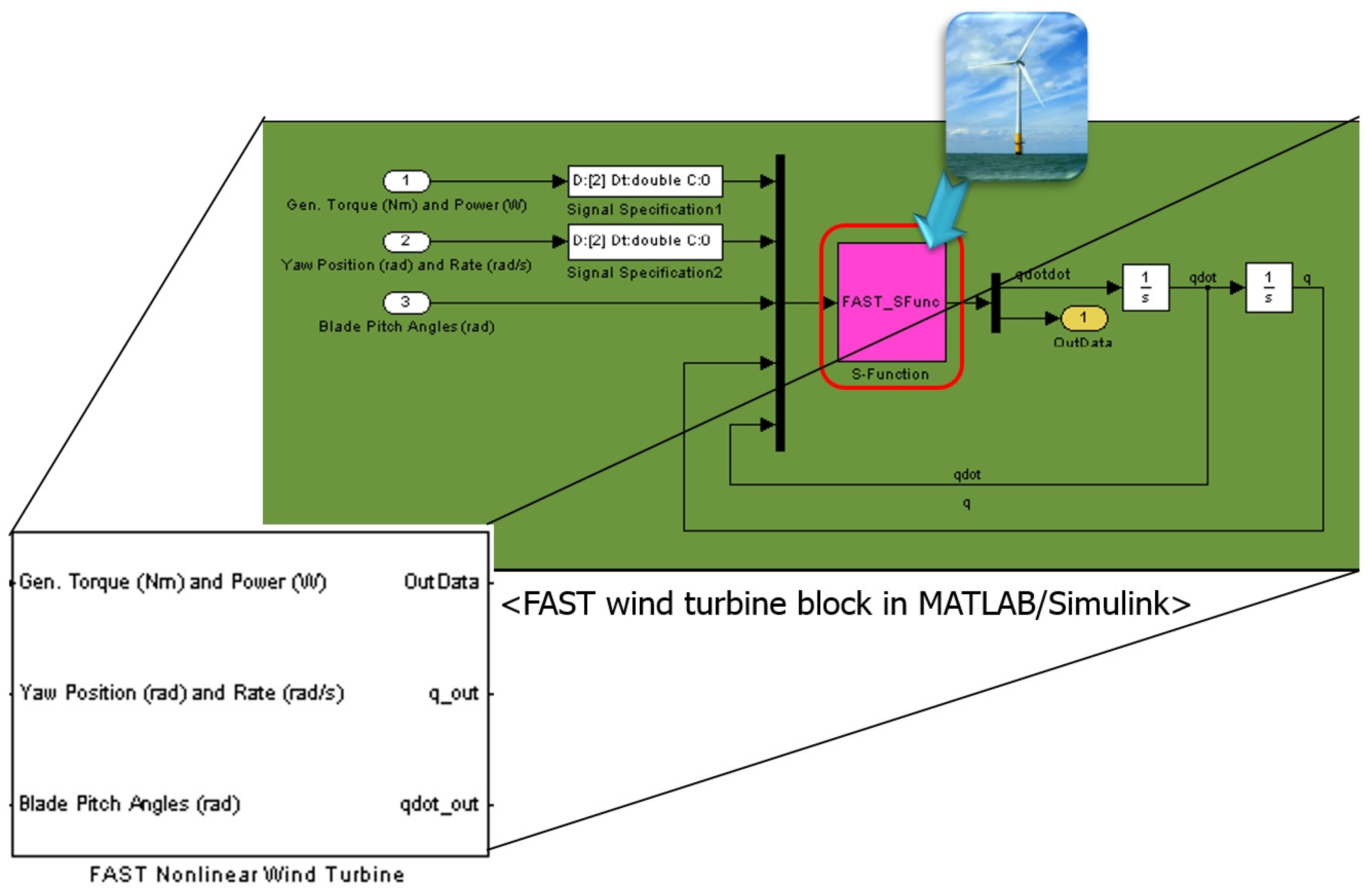

3.1. Host Computer

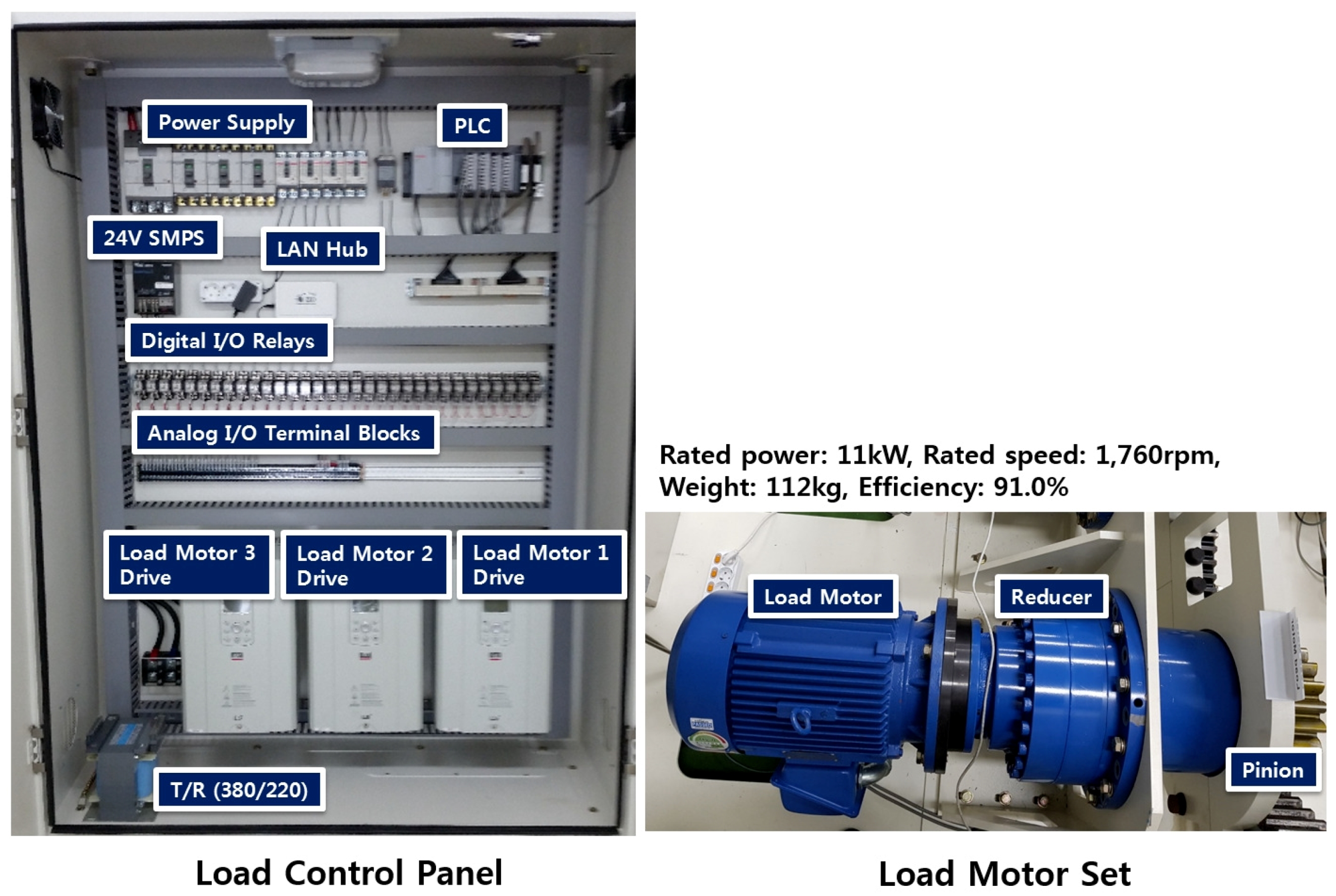

3.2. Wind Load Simulation System

3.3. Pitch Bearing

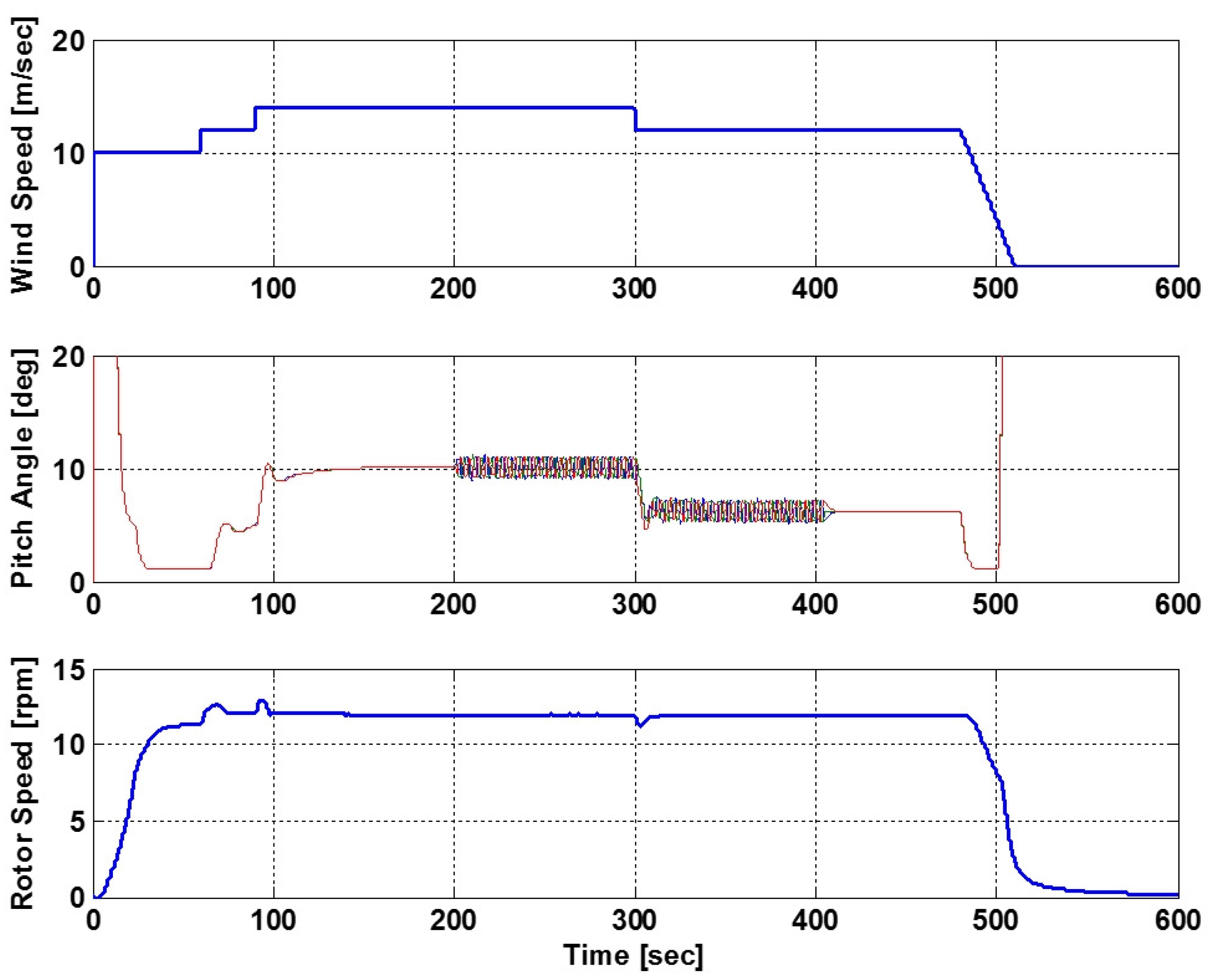

4. Test Results

5. Conclusions

Author Contributions

Acknowledgments

References

- Bianchi, F.; de Battista, H.; Mantz, R. Wind Turbine Control Systems: Principles, Modelling and Gain Scheduling Design; Advances in Industrial Control; Springer: London, UK, 2007. [Google Scholar]

- Senjyu, T.; Sakamoto, R.; Urasaki, N.; Funabashi, T.; Fujita, H.; Sekine, H. Output power leveling of wind turbine Generator for all operating regions by pitch angle control. IEEE Trans. Energy Convers. 2006, 21, 467–475. [Google Scholar] [CrossRef]

- Cheon, J.; Kwon, S.; Choi, Y. Design of a pitch controller using disturbance accommodating control for wind turbines under stochastic environments. In Proceedings of the 2014 IEEE 23rd International Symposium on Industrial Electronics, Istanbul, Turkey, 1–4 June 2014; pp. 2572–2577. [Google Scholar]

- Jing, Y.; Sun, H.; Zhang, L.; Zhang, T. Variable speed control of wind turbines based on the quasi-continuous high-order sliding mode method. Energies 2017, 10, 1626. [Google Scholar] [CrossRef]

- Park, S.; Nam, Y. Two LQRI based Blade Pitch Controls for Wind Turbines. Energies 2012, 5, 1998–2016. [Google Scholar] [CrossRef]

- He, K.; Qi, L.; Zheng, L.; Chen, Y. Combined Pitch and Trailing Edge Flap Control for Load Mitigation of Wind Turbines. Energies 2018, 11, 2519. [Google Scholar] [CrossRef]

- Corcuera, A.D.D.; Pujana-Arrese, A.; Ezquerra, J.M.; Segurola, E.; Landaluze, J. H∞ Based Control for Load Mitigation in Wind Turbines. Energies 2012, 5, 938–967. [Google Scholar] [CrossRef]

- Selvam, K. Individual Pitch Control for Large Scale Wind Turbines-Multivariable Control Approach; Rept. ECN-E-07-053; Energy Research Centre of the Netherlands: Petten, The Netherlands, 2007. [Google Scholar]

- Kim, G.H.; Kim, J.Y.; Jeon, J.H.; Kim, S.K.; Kim, E.S.; Lee, J.H.; Park, M.; Yu, I.K. Hardware-in-the-loop Simulation Method for a Wind Farm Controller Using Real Time Digital Simulator. J. Electr. Eng. Technol. 2014, 5. [Google Scholar] [CrossRef]

- Caselitz, P.; Geyler, M.; Giebhardt, J.; Panahandeh, B. Hardware-in-the-Loop development and testing of new pitch control algorithms. In Proceedings of the European Wind Energy Conference & Exhibition, Athens, Greece, 27 February–2 March 2006; pp. 19–28. [Google Scholar]

- Jonkman, J.M.; Buhl, M.L., Jr. FAST User’S Guide; Technical Report No. NREL/EL-500-38230; National Renewable Energy Laboratory: Golden, CO, USA, 2005. [Google Scholar]

- Perng, J.W.; Chen, G.Y.; Hsieh, S.C. Optimal PID controller design based on PSO-RBFNN for wind turbine systems. Energies 2014, 7, 191–209. [Google Scholar] [CrossRef]

- Nam, Y. Control System Design. In Wind Turbines; Al-Bahadly, I.H., Ed.; IntechOpen: London, UK, 2011. [Google Scholar]

- Arnaltes, S.; Rodriguez-Amenedo, J.; Montilla-DJesus, M. Control of Variable Speed Wind Turbines with Doubly Fed Asynchronous Generators for Stand-Alone Applications. Energies 2018, 11, 26. [Google Scholar] [CrossRef]

- IEC Technical Specification 61400-13. Wind Turbine Generator Systems–Part 13: Measurement of Mechanical Loads, 1st ed.; International Electrotechnical Commission: Geneva, Switzerland, 2011. [Google Scholar]

- Markou, H.; Buhl, T.; Marrant, B.; Van Engelen, T. Morphological Study of Aeroelastic Control Concepts for Wind Turbines; STABCON Task-7 Report EU-Contract ENK5-CT-2002-00627; Energy Research Centre of the Netherlands: Petten, The Netherlands, 2002. [Google Scholar]

- Wright, A.D. Modern Control Design for Flexible Wind Turbines; Technical Report No. NREL/TP-500-35816; National Renewable Energy Laboratory: Golden, CO, USA, 2004. [Google Scholar]

- Van Engelen, T.; Van der Hooft, E. Individual Pitch Control Inventory; Technical Report No. ECN-C-03-138; Technical University of Delft: Delft, The Netherlands, 2005. [Google Scholar]

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW Reference Wind Turbine for Offshore System Development; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2009. [Google Scholar]

- Vidal, Y.; Acho, L.; Luo, N.; Tutiven, C. Hardware in the Loop Wind Turbine Simulator for Control System Testing; Springer: Cham, Switzerland, 2014; pp. 449–466. [Google Scholar]

- Wang, C.S.; Chiang, M.H. A novel dynamic co-simulation analysis for overall closed loop operation control of a large wind turbine. Energies 2016, 9, 637. [Google Scholar] [CrossRef]

- Wang, C.S.; Chiang, M.H. A novel pitch control system of a large wind turbine using two-degree-of-freedom motion control with feedback linearization control. Energies 2016, 9, 791. [Google Scholar] [CrossRef]

- Imran, R.; Hussain, D.; Chowdhry, B. Parameterized Disturbance Observer Based Controller to Reduce Cyclic Loads of Wind Turbine. Energies 2018, 11, 1296. [Google Scholar] [CrossRef]

- Wright, A.D.; Fingersh, L. Advanced Control Design for Wind Turbines; Part I: Control Design, Implementation, and Initial Tests; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2008. [Google Scholar]

| Item | Model | Specification | Remarks |

|---|---|---|---|

| CPU Module | CX2030 | Intel Core i7 2610UE GHz, dual core | |

| Power Supply Module | CX2100-0004 | 24VDC UPS | |

| CANopen Master Module | EL6751 | CANopen kBaudrate | For Communication with PDU (the lower controller) |

| CANopen Slave Module | EL6751-0100 | CANopen kBaudrate | For Communication with TCU (the upper controller) |

| Digital Input Module | EL1008 | 8 CH, EN61131-2, type 1/3 | For Communication with TCU (the upper controller) |

| Digital Output Module | EL2008 | 8 CH, : μs, : μs | |

| Analog Input Module | EL3164 | 4 CH, V, ADC: μs | For receiving sensor signals |

| Analog Output Module | EL4104 | 4 CH, V, DAC: μs |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheon, J.; Kim, J.; Lee, J.; Lee, K.; Choi, Y. Development of Hardware-in-the-Loop-Simulation Testbed for Pitch Control System Performance Test. Energies 2019, 12, 2031. https://doi.org/10.3390/en12102031

Cheon J, Kim J, Lee J, Lee K, Choi Y. Development of Hardware-in-the-Loop-Simulation Testbed for Pitch Control System Performance Test. Energies. 2019; 12(10):2031. https://doi.org/10.3390/en12102031

Chicago/Turabian StyleCheon, Jongmin, Jinwook Kim, Joohoon Lee, Kichang Lee, and Youngkiu Choi. 2019. "Development of Hardware-in-the-Loop-Simulation Testbed for Pitch Control System Performance Test" Energies 12, no. 10: 2031. https://doi.org/10.3390/en12102031

APA StyleCheon, J., Kim, J., Lee, J., Lee, K., & Choi, Y. (2019). Development of Hardware-in-the-Loop-Simulation Testbed for Pitch Control System Performance Test. Energies, 12(10), 2031. https://doi.org/10.3390/en12102031