Experimental Study of a Moored Floating Oscillating Water Column Wave-Energy Converter and of a Moored Cubic Box

Abstract

:1. Introduction

2. Experimental Setup

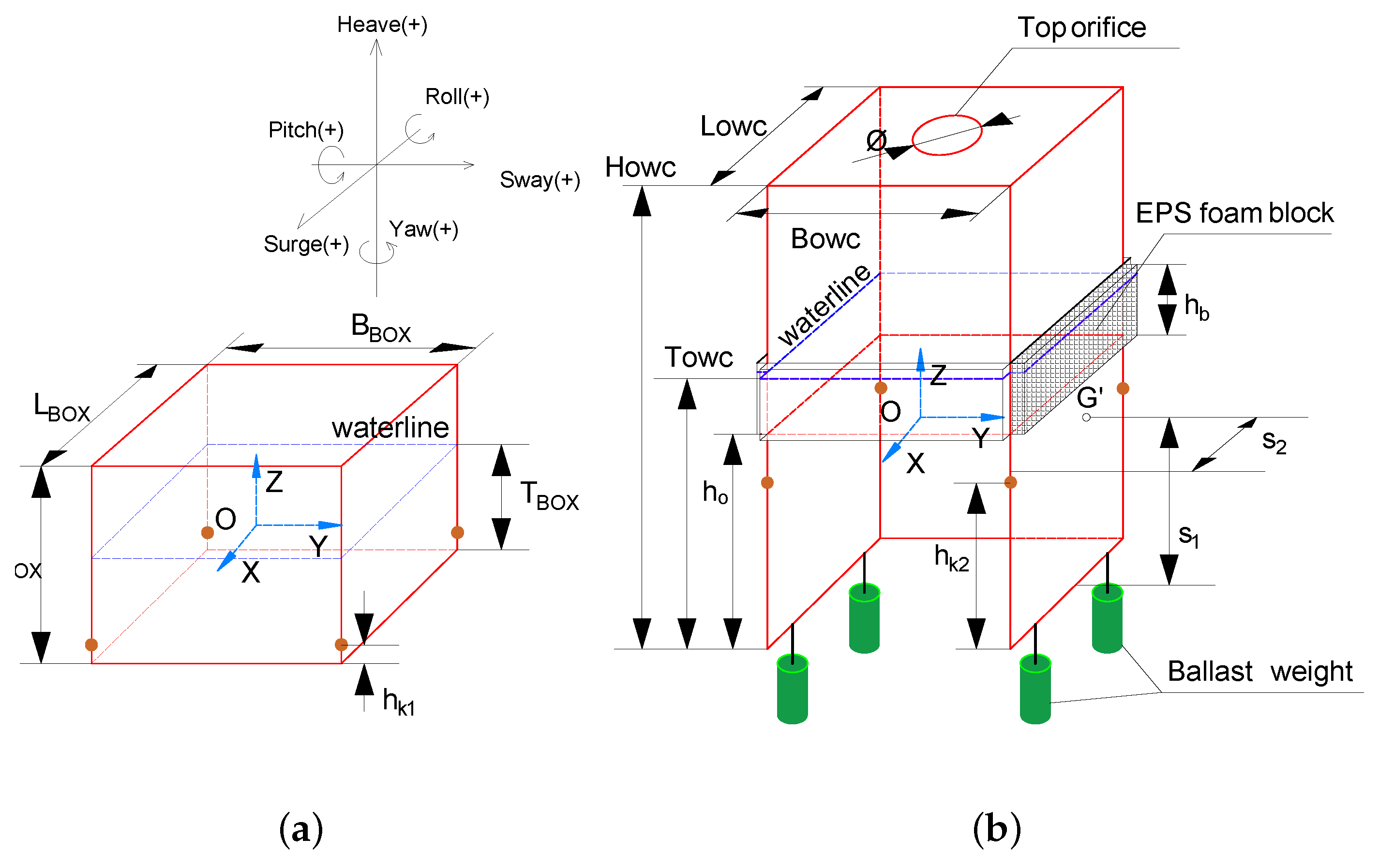

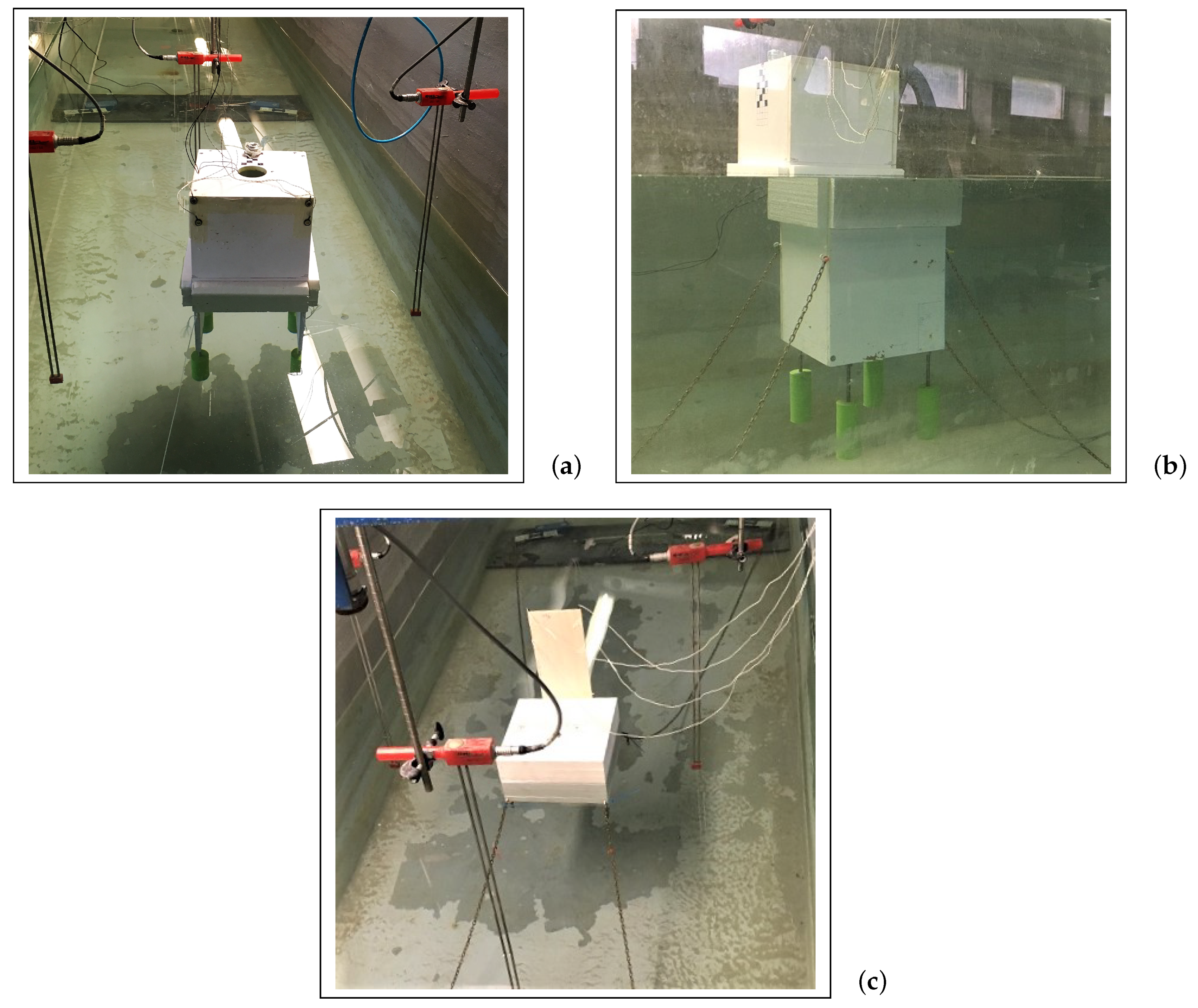

2.1. Description of the Models

2.2. Wave Flume Setup and Instrumentation

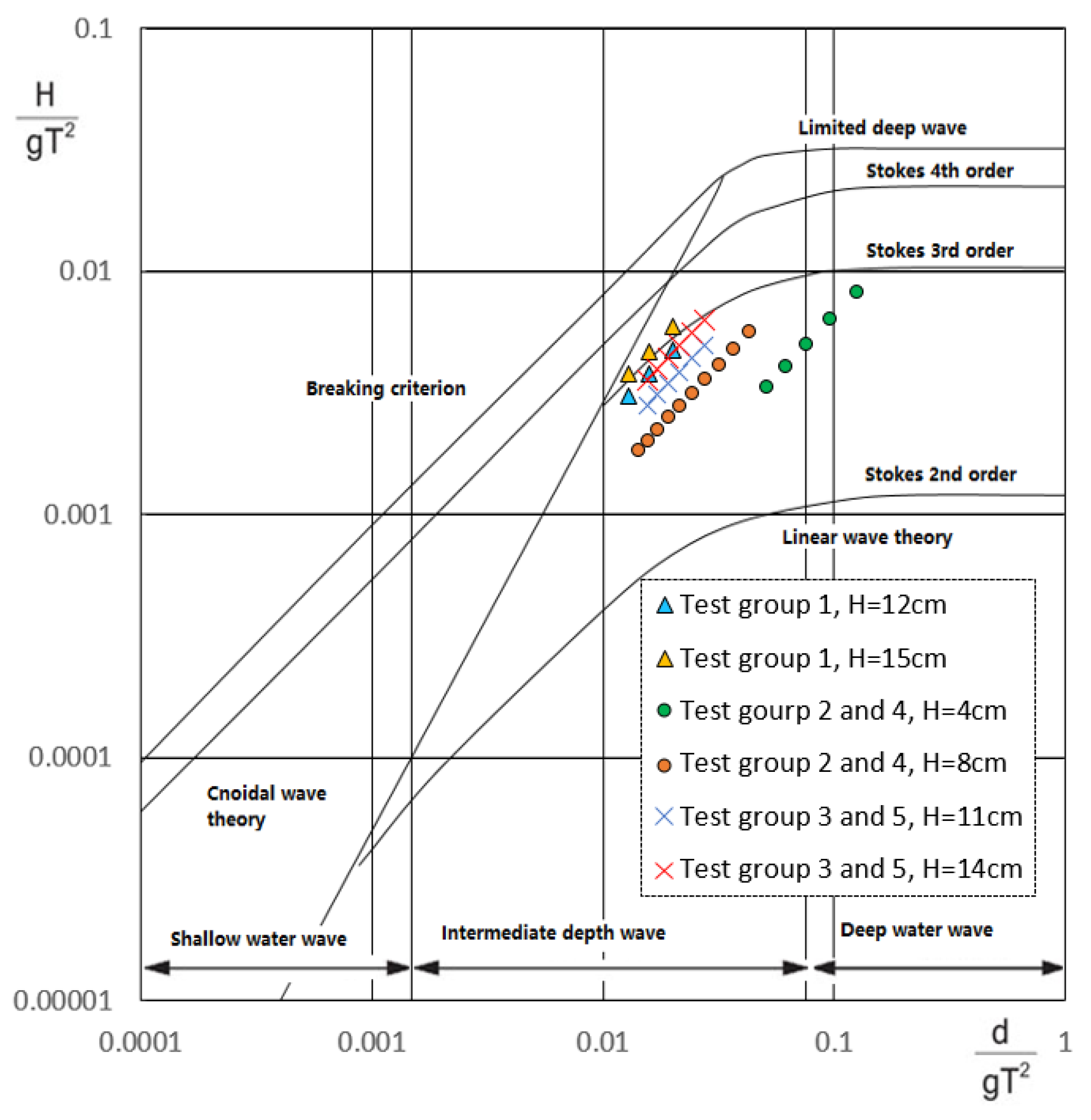

2.3. Experimental Program

2.4. Uncertainty Sources

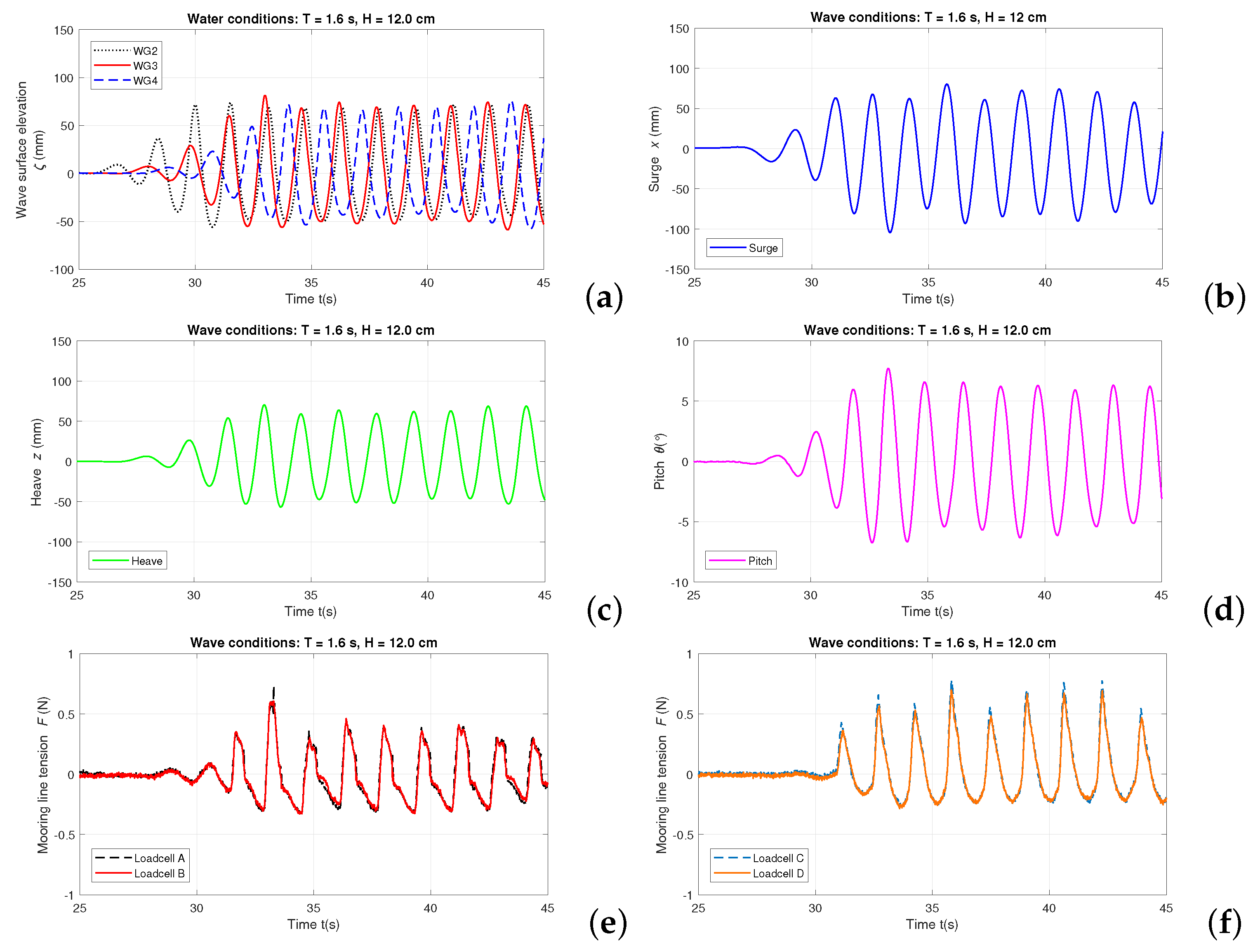

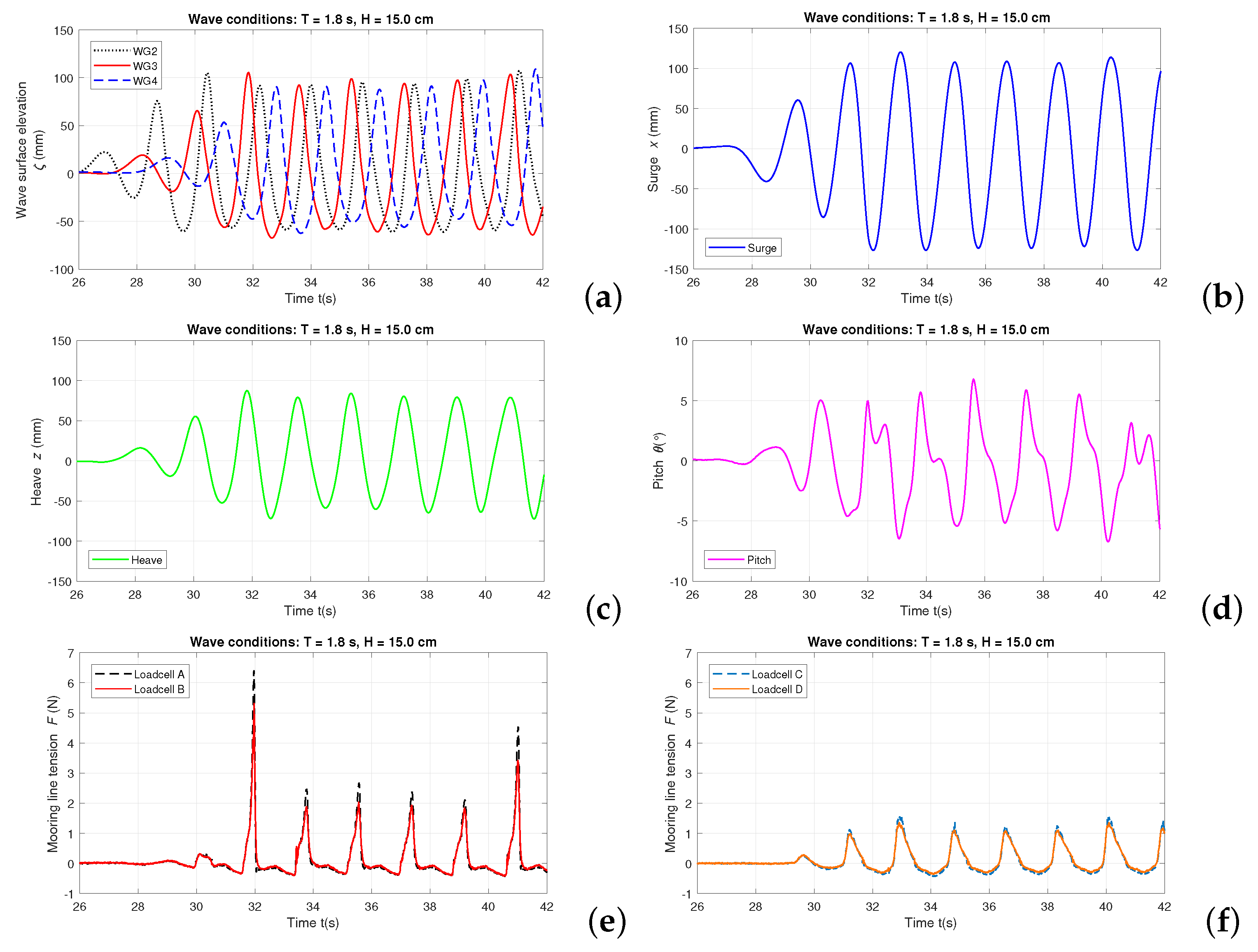

3. BOX model Experimental Results

4. OWC WEC Model Experimental Results

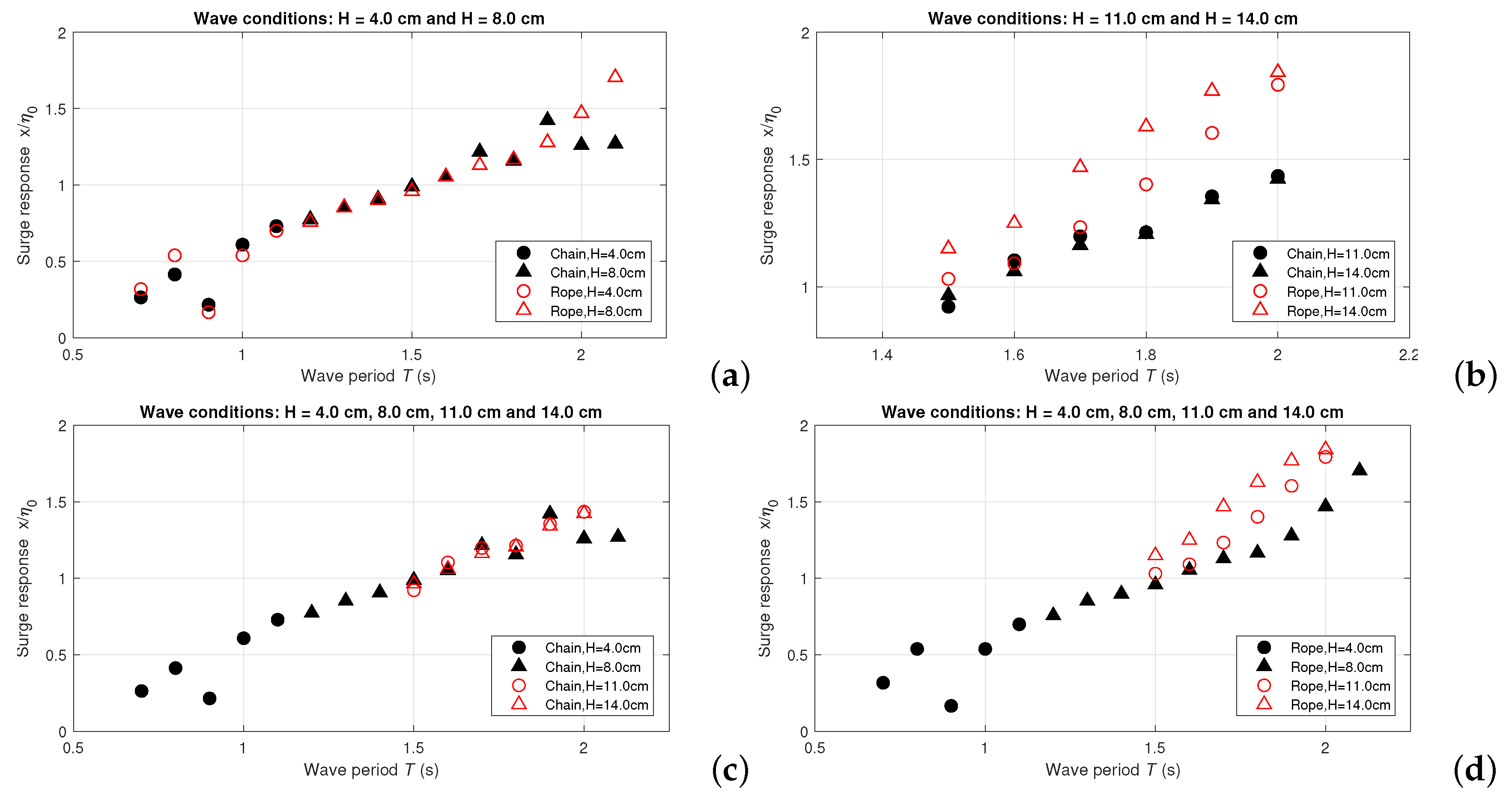

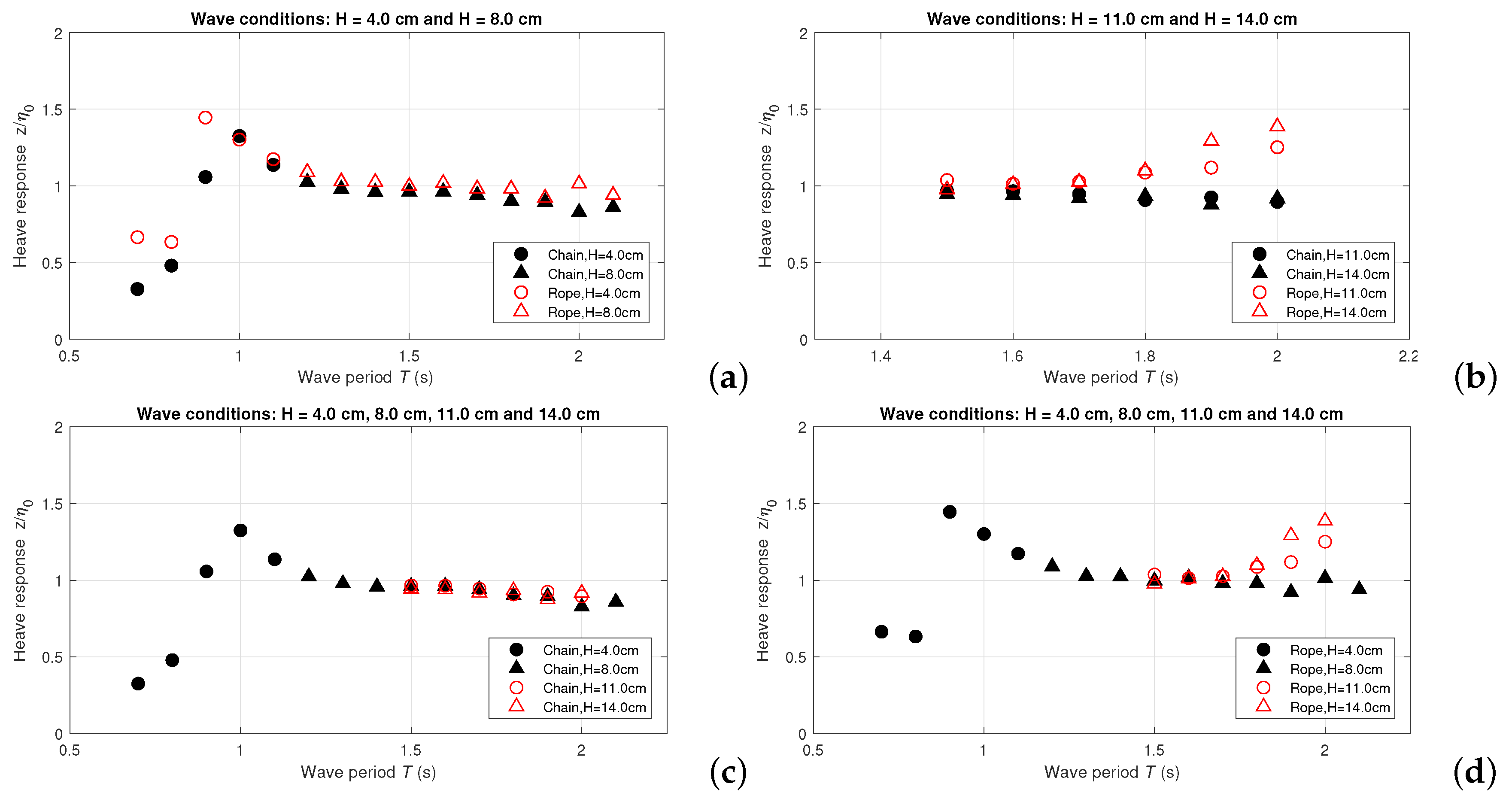

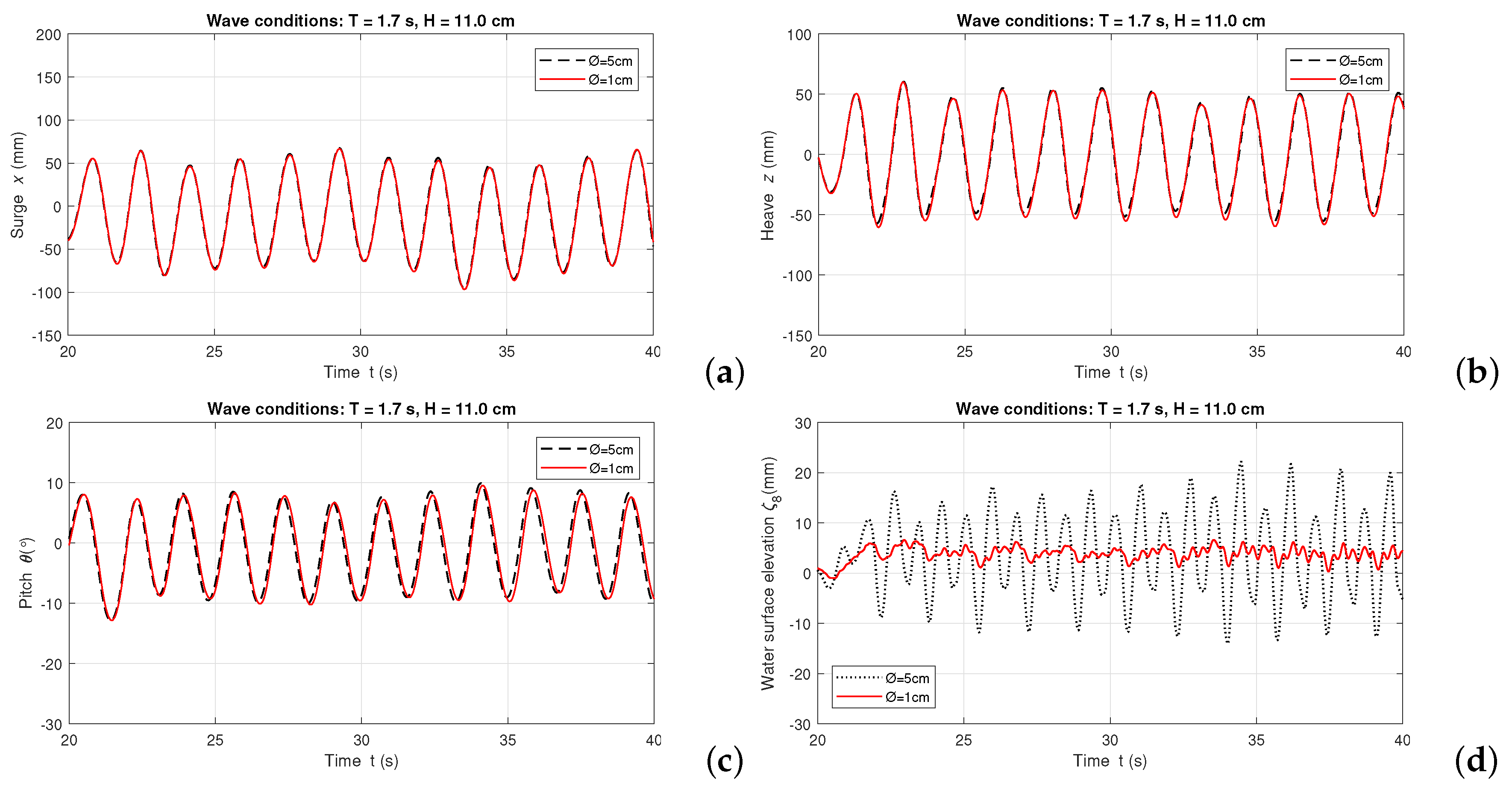

4.1. OWC WEC Motion Response

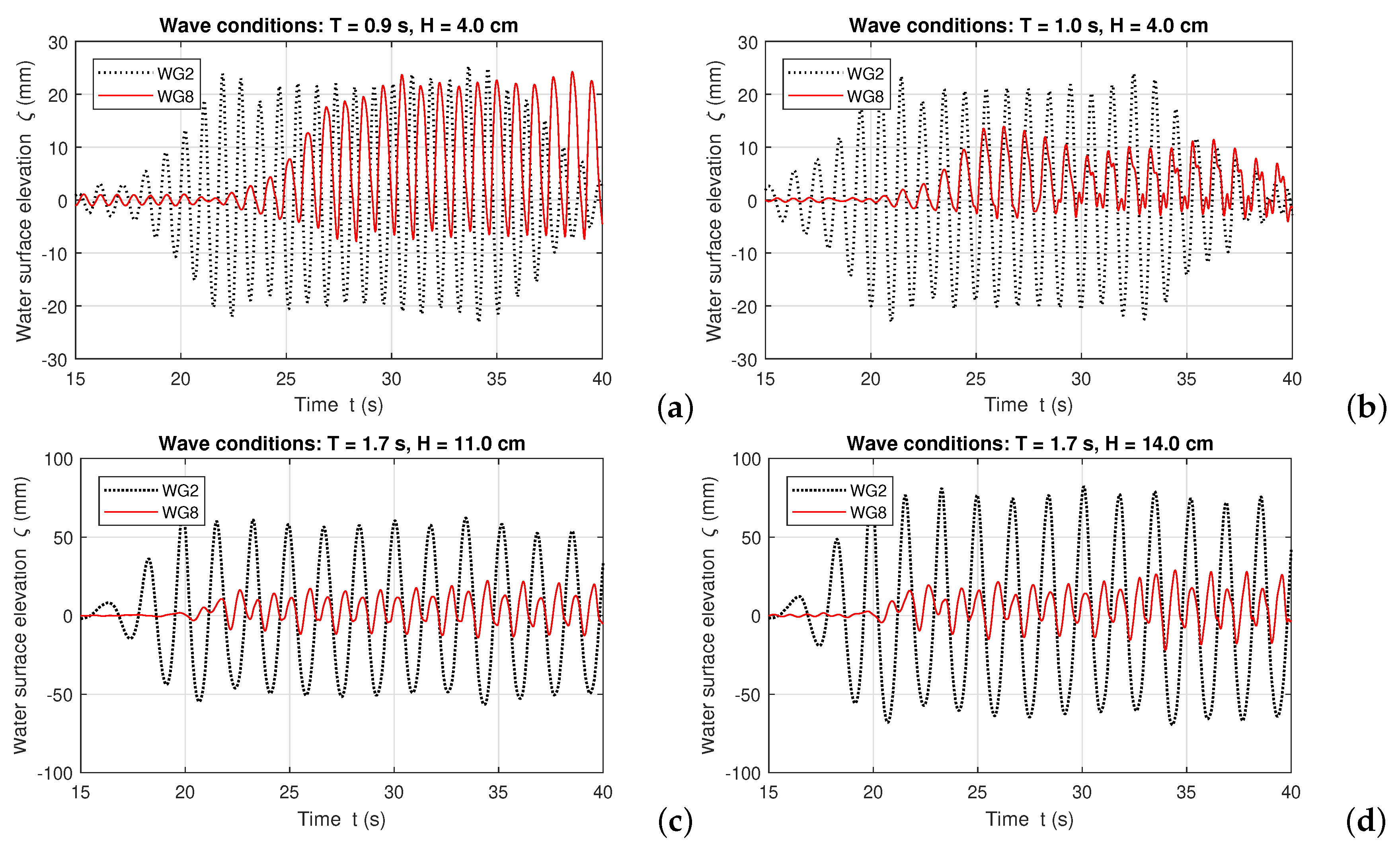

4.2. Water Surface Elevation Variation Inside the OWC WEC Vhamber

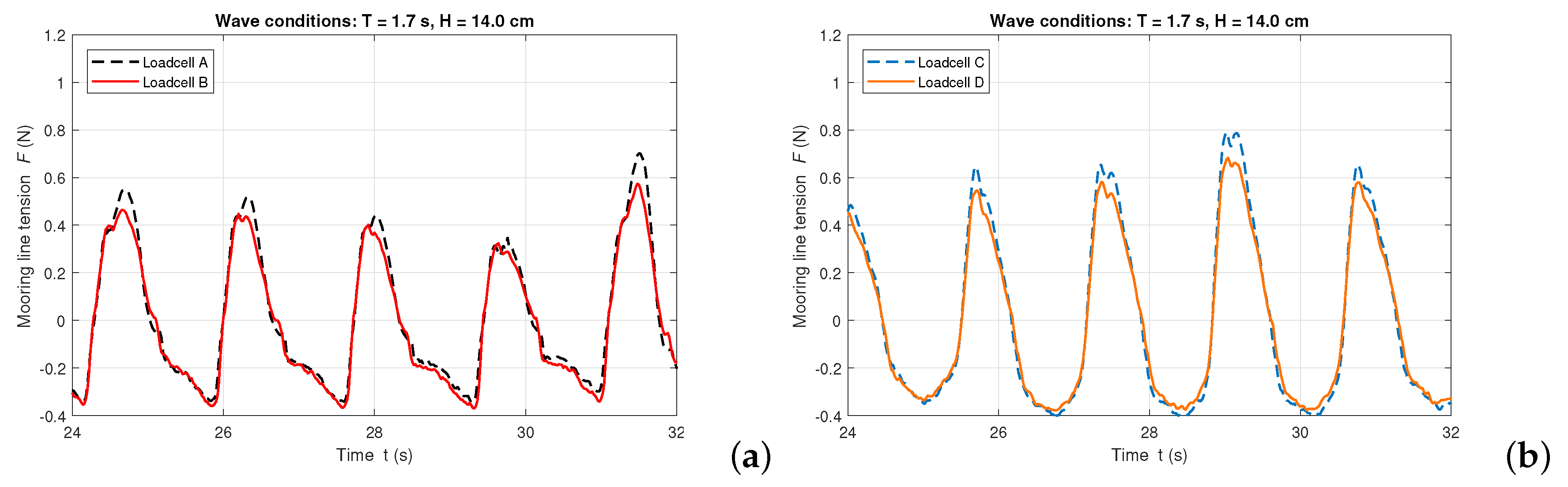

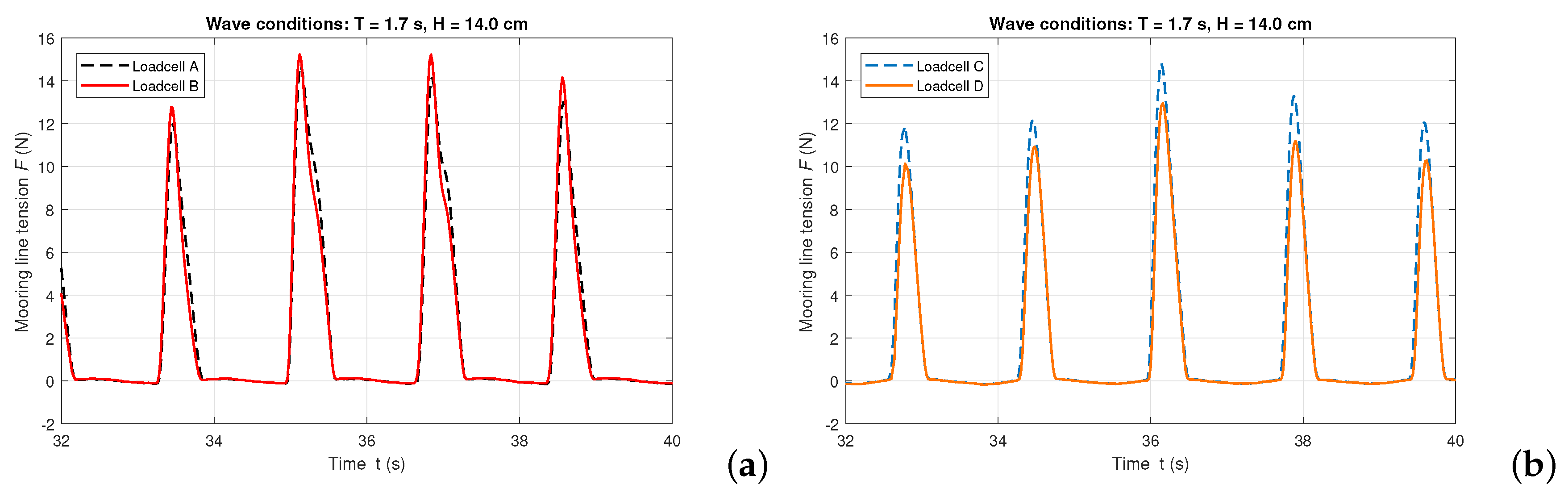

4.3. Mooring-Line Tensions

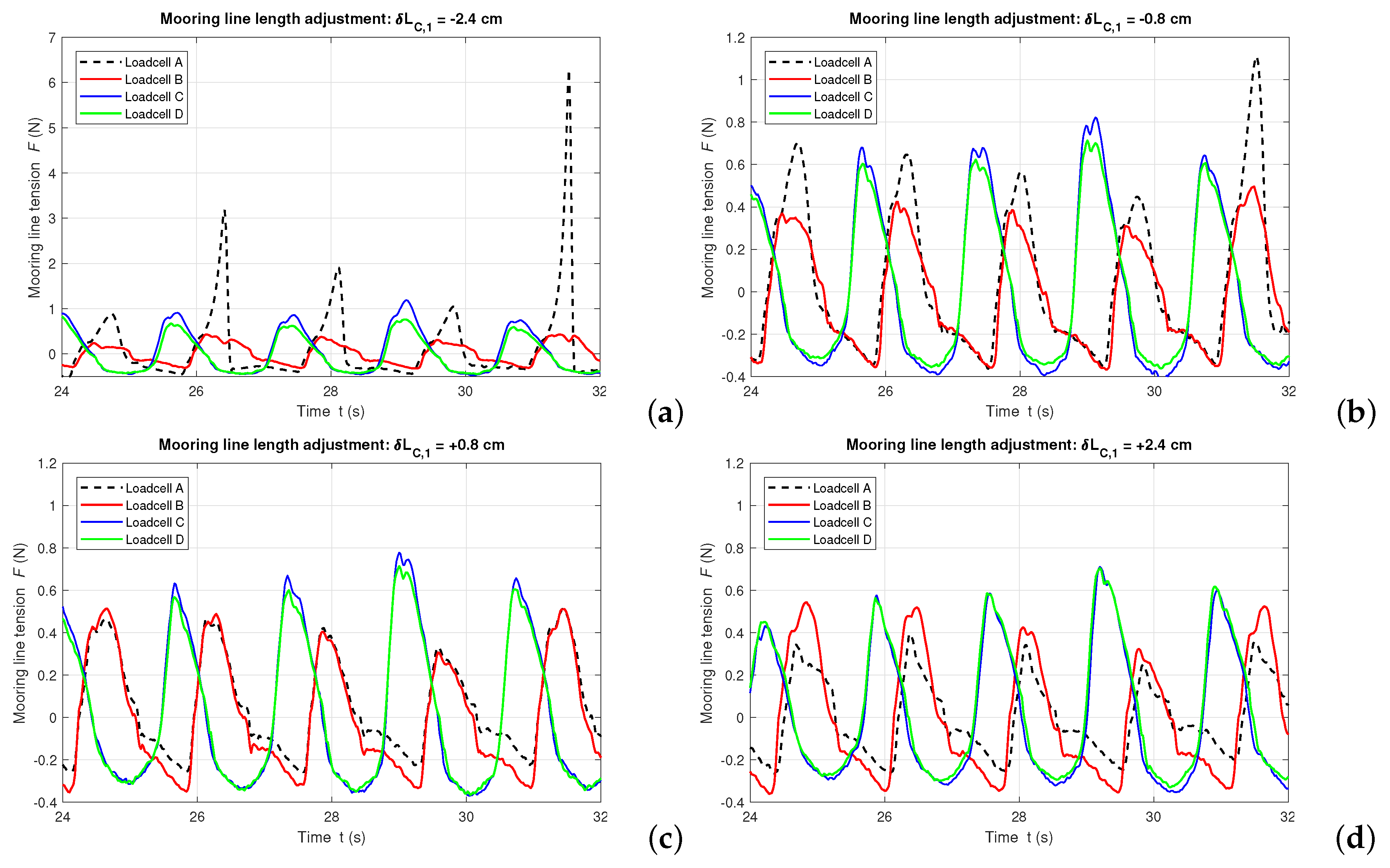

4.4. Effect of Unequal Mooring-Line Lengths

4.5. Effect of the Orifice Diameter at the Top of the OWC WEC Chamber

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| BBDB | Backward Bend Duck Buoy |

| BOX | cubic floating box model |

| CFD | Computational Fluid Dynamics |

| DOF | Degree of Freedom |

| EMEC | The European Marine Energy Center |

| EPS | Expanded Polystyrene |

| ITTC | The International Towing Tank Conference |

| OWC | Oscillating Water Column |

| PTO | power-take-off |

| SPH | Smoothed Particle Hydrodynamics |

| WEC | Wave-Energy Converter |

| WG | wave gauge |

References

- Falcão, A.F.O. Wave energy utilization: A review of the technologies. Renew. Sustain. Energy Rev. 2010, 14, 899–918. [Google Scholar] [CrossRef]

- Falcão, A.F.O.; Henriques, J.C.C. Oscillating-water-column wave energy converters and air turbines: A review. Renew. Energy 2016, 85, 1391–1424. [Google Scholar] [CrossRef]

- Masuda, Y.; Yamazaki, T.; Outa, Y.; McCormick, M.E. Study of back bent duct buoy. Proc. OCEANS’87 1987, 19, 384–389. [Google Scholar]

- McCormick, M.E. Analysis of a wave energy conversion buoy. J. Hydronaut. 1974, 8, 77–82. [Google Scholar] [CrossRef]

- Fonseca, N.; Pessoa, J. Numerical modelling of a wave energy converter based on U-shaped interior oscillating water column. Appl. Ocean Res. 2013, 40, 60–73. [Google Scholar] [CrossRef]

- WAMIT Inc. WAMIT User Manual; Version 6.4; WAMIT Inc.: Chestnut Hill, MA, USA, 2019. [Google Scholar]

- Sheng, W.; Lewis, A.; Alcorn, R. Numerical studies of a floating cylindrical OWC WEC. In Proceedings of the ASME 2012 31st International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012. [Google Scholar]

- Sheng, W.; Lewis, A.; Alcorn, R. Numerical studies on hydrodynamics of a floating oscillating water column. In Proceedings of the ASME 2011 30th International Conference on Ocean, Offshore and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011. [Google Scholar]

- Bailey, H.; Robertson, B.R.D.; Buckham, B.J. Wave-to-wire simulation of a floating oscillating water column wave energy converter. Ocean Eng. 2016, 125, 248–260. [Google Scholar] [CrossRef]

- Gomes, R.P.F.; Henriques, J.C.C.; Gato, L.M.C.; Falcão, A.F.O. Wave power extraction of a heaving floating oscillating water column in a wave channel. Renew. Energy 2016, 99, 1262–1275. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, Z.; Peng, G.; Xiao, Y.; Zhai, L.; Liu, X.; Zhang, Q. Numerical simulation of a heave-only floating OWC (oscillating water column) device. Energy 2014, 76, 799–806. [Google Scholar] [CrossRef]

- ANSYS. Ansys Manual, Release12.1. Available online: http://www.afs.enea.it/project/neptunius/docs/fluent/ (accessed on 14 May 2019).

- Elhanafi, A.; Macfarlane, G.; Fleming, A.; Leong, Z. Experimental and numerical investigations on the hydrodynamic performance of a floating-moored oscillating water column wave energy converter. Appl. Energy 2017, 205, 369–390. [Google Scholar] [CrossRef]

- CD-Adapco. User Guide STAR-CCM+, Version 10.02. Available online: https://mdx.plm.automation.siemens.com/star-ccm-plus (accessed on 14 May 2019).

- Elhanafi, A.; Macfarlane, G.; Fleming, A.; Leong, Z. Experimental and numerical investigations on the intact and damage survivability of a floating-moored oscillating water column device. Appl. Ocean Res. 2017, 68, 276–292. [Google Scholar] [CrossRef]

- Crespo, A.J.C.; Altomare, C.; Domínguez, J.M.; González-Cao, J.; Gómez-Gesteira, M. Towards simulating floating offshore oscillating water column converters with smoothed particle hydrodynamics. Coast. Eng. 2017, 126, 11–26. [Google Scholar] [CrossRef]

- Crespo, A.J.C.; Matthew, H.; Domínguez, J.M.; Altomare, C.; Wu, M.; Verbrugghe, T.; Stratigaki, V.; Troch, P.; Gómez-Gesteira, M. Floating moored oscillating water column with meshless SPH method. In Proceedings of the ASME 2018 37th International Conference on Ocean, Offshore and Arctic Engineering, Madrid, Spain, 17–22 June 2018. [Google Scholar]

- Correia da Fonseca, F.X.; Gomes, R.P.F.; Henriques, J.C.C.; Gato, L.M.C.; Falcão, A.F.O. Model testing of an oscillating water column spar-buoy wave energy converter isolated and in array: Motion and mooring forces. Energy 2016, 112, 1207–1218. [Google Scholar] [CrossRef]

- He, F.; Leng, J.; Zhao, X. An experimental investigation into the wave power extraction of a floating box-type breakwater with dual pneumatic chambers. Appl. Ocean Res. 2017, 67, 21–30. [Google Scholar] [CrossRef]

- Rapaka, E.V.; Natarajan, R.; Neelamani, S. Experimental investigation on the dynamic response of a moored wave energy device under regular sea waves. Ocean Eng. 2004, 31, 725–743. [Google Scholar] [CrossRef]

- Gomes, R.P.F.; Henriques, J.C.C.; Gato, L.M.C.; Falcão, A.F.O. Wave channel tests of a slack-moored floating oscillating water column in regular waves. In Proceedings of the 11th European Wave and Tidal Energy Conference, Nantes, France, 6–11 September 2015. [Google Scholar]

- EMEC. Tank testing of wave energy conversion systems. In Marine Renewable Energy Guides; The European Marine Energy Center Ltd.: London, UK, 2009. [Google Scholar]

- Crema, I.; Simonetti, L.; Cappietti, H.; Oumeraci, H. Laboratory experiments on oscillating water column wave energy converters integrated in a very large floating structure. In Proceedings of the 11th European Wave and Tidal Energy Conference, Nantes, France, 6–11 September 2015. [Google Scholar]

- LABIMA. Available online: https://www.labima.unifi.it/ (accessed on 13 May 2019).

- Thorimbert, Y.; Latt, J.; Cappietti, L.; Chopard, B. Virtual wave flume and oscillating water column modeled by lattice Boltzmann method and comparison with experimental data. Int. J. Mar. Energy 2016, 14, 41–51. [Google Scholar] [CrossRef]

- Simonetti, I.; Cappietti, L.; Elsafti, H.; Oumeraci, H. 3D numerical modelling oscillating water column wave energy conversion devices: Current knowledge and OpenFOAM® implementation. In Proceedings of the 1st International Conference on Renewable Energies Offshore, Lisbon, Portugal, 24–26 Novermber 2014; pp. 497–504. [Google Scholar]

- Simonetti, I.; Cappietti, L.; Elsafti, H.; Oumeraci, H. Optimization of the geometry and the turbine induced damping for fixed detached and asymmetric OWC devices: A numerical study. Energy 2017, 139, 1197–1209. [Google Scholar] [CrossRef]

- Ren, B.; He, M.; Dong, P.; Wen, H. Nonlinear simulations of wave-induced motions of a freely floating body using WCSPH method. Appl. Ocean Res. 2015, 50, 1–12. [Google Scholar] [CrossRef]

- Hadžić, I.; Hennig, J.; Perić, C.; Xing-Kaeding, Y. Computation of flow-induced motion of floating bodies. Appl. Math. Model. 2005, 29, 1196–1210. [Google Scholar] [CrossRef]

- Ctech. Available online: http://www.ctechmetrology.com/ (accessed on 13 May 2019).

- Troch, P. Experimentele Studie en Numerieke Modellering van Golfinteractie Met Stortsteengolfbrekers—Appendix E (in Dutch). Ph.D. Thesis, Ghent University, Ghent, Belgium, 2000. [Google Scholar]

- Le Méhauté, B. An Introduction to Hydrodynamics and Water Waves; Springer: Berlin, Germany, 1976. [Google Scholar]

- ITTC. Seakeeping Experiments, Recommended Procedures and Guidelines; International Towing Tank Conference. Available online: https://ittc.info/ (accessed on 14 May 2019).

| Symbol | Description | Unit | Value |

|---|---|---|---|

| B | Width of BOX model | cm | 20.0 |

| L | Length of BOX model | cm | 20.0 |

| H | Height of BOX model | cm | 13.2 |

| T | Draft of BOX model | cm | 7.9 |

| M | Mass of BOX model | g | 3148.0 |

| h | Mooring-line fairlead height | cm | 0.5 |

| I | Moment of inertia around X axis | g· | 1.5 × 10 |

| I | Moment of inertia around Y axis | g· | 1.5 × 10 |

| I | Moment of inertia around Z axis | g· | 2.1 × 10 |

| Symbol | Description | Unit | Value |

|---|---|---|---|

| B | Width of OWC model | cm | 20.0 |

| L | Length of OWC model | cm | 20.0 |

| H | Height of OWC model | cm | 44.0 |

| T | Draft of OWC model | cm | 26.0 |

| M | Mass of OWC model | g | 2593.0 |

| I | Moment of inertia around X axis | g· | 7.2 × 10 |

| I | Moment of inertia around Y axis | g· | 9.4 × 10 |

| I | Moment of inertia around Z axis | g· | 5.6 × 10 |

| h | Front opening height | cm | 19.0 |

| h | Mooring-line fairlead height | cm | 15.0 |

| h | EPS foam block height | cm | 8.0 |

| s | Vertical height of center of gravity | cm | 15.2 |

| s | Distance from center of gravity to front surface | cm | 9.9 |

| ∅ | Orifice diameter | cm | 5.0 |

| Material | Symbol | Description | Units | Parameter |

|---|---|---|---|---|

| Iron chain | L | Total length of chain mooring line | cm | 145.5 |

| k | Chain elasticity | N/mm | 19.0 | |

| l | Length per chain segment | cm | 0.8 | |

| w | Chain weight per centimeter | g/cm | 0.6 | |

| v | Chain volume per centimeter | /cm | 0.1 | |

| Nylon rope | L | Total length of rope mooring line | cm | 144.0 |

| k | Rope elasticity | N/mm | 1.1 |

| Test Group | Model | Range of Regular Wave Period, T (s) | Range of Regular Wave Height, H (cm) | Water Depth, d (cm) | Mooring Line Material | Note |

|---|---|---|---|---|---|---|

| 1 | BOX | 1.6–2.0 | 12.0–15.0 | 50.0 | Chain | Benchmark test |

| 2 | OWC | 0.7– 2.1 | 4.0–8.0 | 60.0 | Chain | Small wave amplitude |

| 3 | OWC | 1.5– 2.0 | 11.0–14.0 | 60.0 | Chain | Large wave amplitude |

| 4 | OWC | 0.7–2.1 | 4.0–8.0 | 60.0 | Rope | Small wave amplitude |

| 5 | OWC | 1.5–2.0 | 11.0–14.0 | 60.0 | Rope | Large wave amplitude |

| 6 | OWC | 1.7 | 14.0 | 60.0 | Chain | Unbalanced mooring |

| 7 | OWC | 1.5–2.0 | 11.0 | 60.0 | Chain | ∅ = 1.0 cm |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, M.; Stratigaki, V.; Troch, P.; Altomare, C.; Verbrugghe, T.; Crespo, A.; Cappietti, L.; Hall, M.; Gómez-Gesteira, M. Experimental Study of a Moored Floating Oscillating Water Column Wave-Energy Converter and of a Moored Cubic Box. Energies 2019, 12, 1834. https://doi.org/10.3390/en12101834

Wu M, Stratigaki V, Troch P, Altomare C, Verbrugghe T, Crespo A, Cappietti L, Hall M, Gómez-Gesteira M. Experimental Study of a Moored Floating Oscillating Water Column Wave-Energy Converter and of a Moored Cubic Box. Energies. 2019; 12(10):1834. https://doi.org/10.3390/en12101834

Chicago/Turabian StyleWu, Minghao, Vasiliki Stratigaki, Peter Troch, Corrado Altomare, Tim Verbrugghe, Alejandro Crespo, Lorenzo Cappietti, Matthew Hall, and Moncho Gómez-Gesteira. 2019. "Experimental Study of a Moored Floating Oscillating Water Column Wave-Energy Converter and of a Moored Cubic Box" Energies 12, no. 10: 1834. https://doi.org/10.3390/en12101834

APA StyleWu, M., Stratigaki, V., Troch, P., Altomare, C., Verbrugghe, T., Crespo, A., Cappietti, L., Hall, M., & Gómez-Gesteira, M. (2019). Experimental Study of a Moored Floating Oscillating Water Column Wave-Energy Converter and of a Moored Cubic Box. Energies, 12(10), 1834. https://doi.org/10.3390/en12101834