The Acoustic Properties of Sandy and Clayey Hydrate-Bearing Sediments

Abstract

1. Introduction

2. Experiment Design

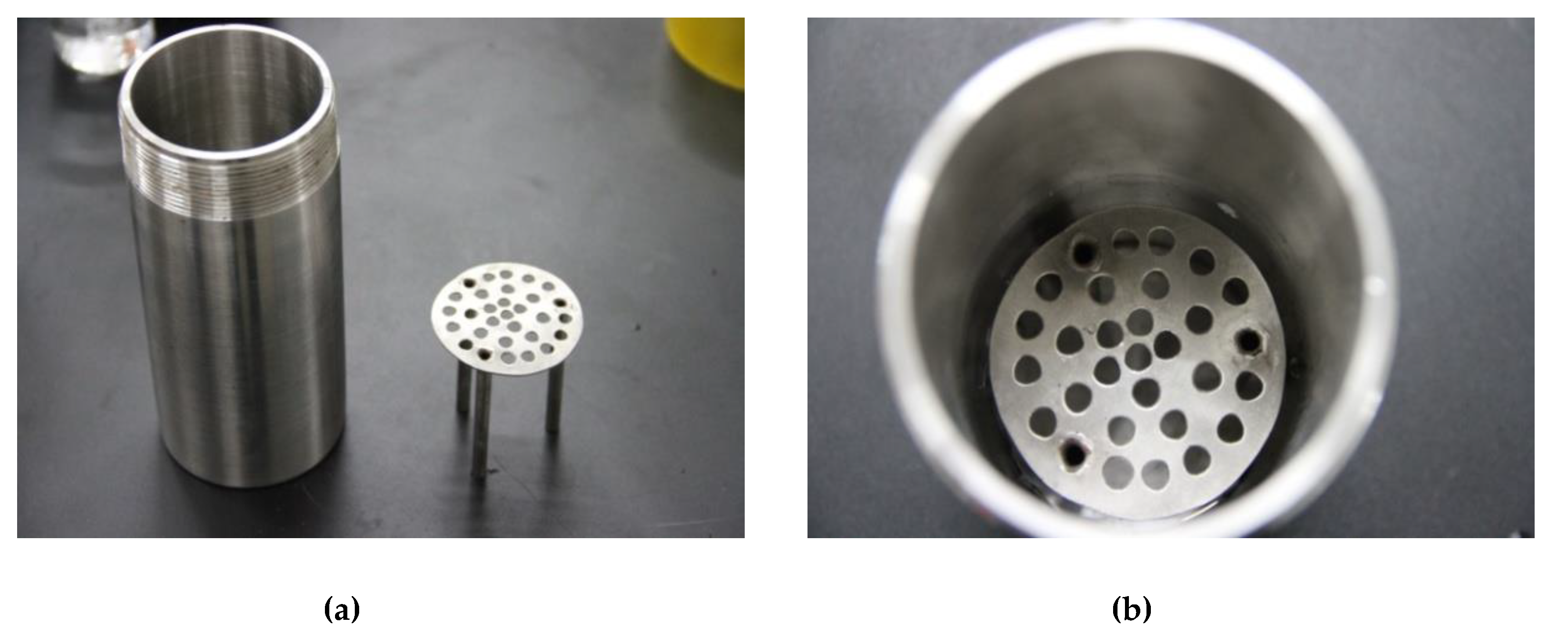

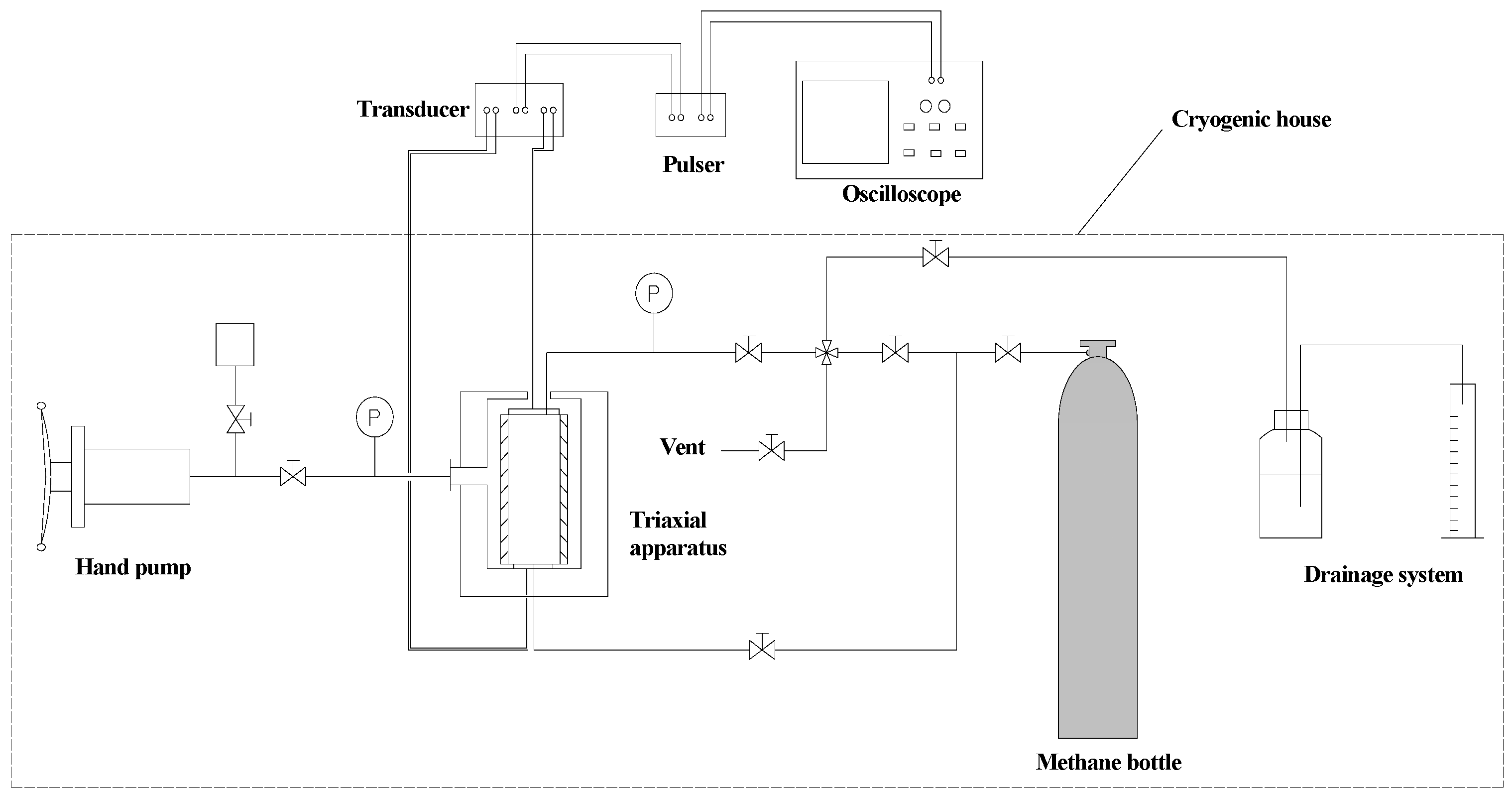

2.1. Apparatus

2.2. Materials

2.3. Experimental Procedure

3. Calculation Equations

4. Results and Discussion

4.1. Acoustic Signal

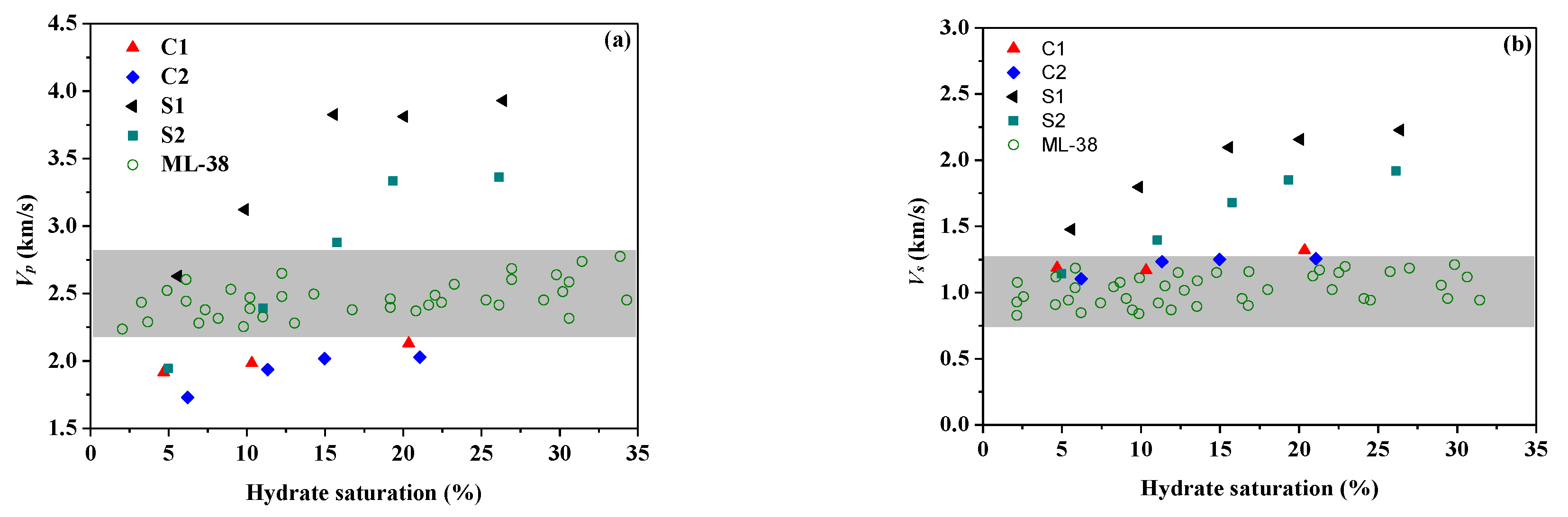

4.2. Effect of Pore Occupants

4.3. Effects of Host Sediments

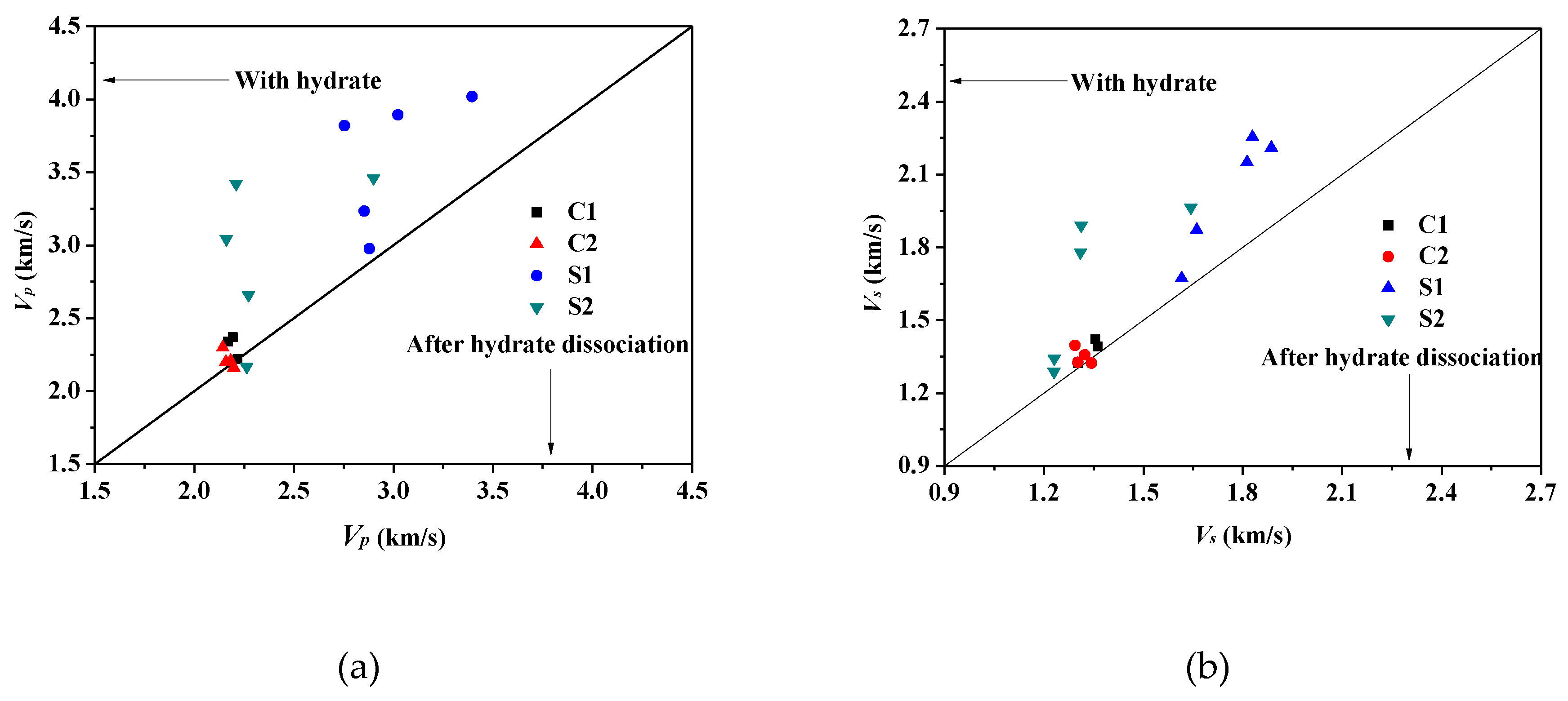

4.4. Effects of Hydrate Dissociation

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sloan, E.D.; Koh, C.A. Clathrate Hydrates of Natural Gases; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Chong, Z.R.; Yang, S.H.B.; Babu, P.; Linga, P.; Li, X.S. Review of natural gas hydrates as an energy resource: Prospects and challenges. Appl. Energy 2016, 162, 1633–1652. [Google Scholar] [CrossRef]

- Li, X.S.; Xu, C.G.; Zhang, Y.; Ruan, X.K.; Li, G.; Wang, Y. Investigation into gas production from natural gas hydrate: A review. Appl. Energy 2016, 172, 286–322. [Google Scholar] [CrossRef]

- Makogon, Y.F. Natural gas hydrates—A promising source of energy. J. Nat. Gas Sci. Eng. 2010, 2, 49–59. [Google Scholar] [CrossRef]

- Boswell, R.; Collett, T.S. Current perspectives on gas hydrate resources. Energy Environ. Sci. 2011, 4, 1206–1215. [Google Scholar] [CrossRef]

- Song, Y.; Zhu, Y.; Liu, W.; Zhao, J.; Li, Y.; Chen, Y.; Shen, Z.; Lu, Y.; Ji, C. Experimental research on the mechanical properties of methane hydrate-bearing sediments during hydrate dissociation. Mar. Pet. Geol. 2014, 51, 70–78. [Google Scholar] [CrossRef]

- Priest, J.A.; Best, A.I.; Clayton, C.R.I. A laboratory investigation into the seismic velocities of methane gas hydrate-bearing sand. J. Geophys. Res. Solid Earth 2005, 110, B04102. [Google Scholar] [CrossRef]

- Li, F.G.; Sun, C.Y.; Zhang, Q.; Liu, X.X.; Guo, X.Q.; Chen, G.J. Laboratory measurements of the effects of methane/tetrahydrofuran concentration and grain size on the P-Wave velocity of hydrate-bearing sand. Energy Fuels 2011, 25, 2076–2082. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, F.G.; Sun, C.Y.; Li, Q.P.; Wu, X.Y.; Liu, B.; Chen, G.J. Compressional wave velocity measurements through sandy sediments containing methane hydrate. Am. Mineral. 2011, 96, 1425–1432. [Google Scholar] [CrossRef]

- Winters, W.J.; Waite, W.F.; Mason, D.H.; Gilbert, L.Y.; Pecher, I.A. Methane gas hydrate effect on sediment acoustic and strength properties. J. Petrol. Sci. Eng. 2007, 56, 127–135. [Google Scholar] [CrossRef]

- Waite, W.F.; Winters, W.J.; Mason, D.H. Methane hydrate formation in partially water-saturated Ottawa sand. Am. Mineral. 2004, 89, 1202–1207. [Google Scholar] [CrossRef]

- Hu, G.W.; Ye, Y.G.; Zhang, J.; Liu, C.L.; Diao, S.B.; Wang, J.S. Acoustic properties of gas hydrate–bearing consolidated sediments and experimental testing of elastic velocity models. J. Geophys. Res. Solid Earth 2010, 115, B02102. [Google Scholar] [CrossRef]

- Hu, G.W.; Ye, Y.G.; Zhang, J.; Liu, C.L.; Li, Q. Acoustic response of gas hydrate formation in sediments from South China Sea. Mar. Pet. Geol. 2014, 52, 1–8. [Google Scholar] [CrossRef]

- Konno, Y.; Jin, Y.; Yoneda, J.; Kida, M.; Egawa, K.; Ito, T.; Suzuki, K.; Nagao, J. Effect of methane hydrate morphology on compressional wave velocity of sandy sediments: Analysis of pressure cores obtained in the Eastern Nankai Trough. Mar. Pet. Geol. 2015, 66, 425–433. [Google Scholar] [CrossRef]

- Winters, W.J.; Pecher, I.A.; Waite, W.F.; Mason, D.H. Physical properties and rock physics models of sediment containing natural and laboratory-formed methane gas hydrate. Am. Mineral. 2004, 89, 1221–1227. [Google Scholar] [CrossRef]

- Ren, S.R.; Liu, Y.J.; Liu, Y.X.; Zhang, W.D. Acoustic velocity and electrical resistance of hydrate bearing sediments. J. Petrol. Sci. Eng. 2010, 70, 52–56. [Google Scholar] [CrossRef]

- Yamamoto, K. Overview and introduction: Pressure core-sampling and analyses in the 2012–2013 MH21 offshore test of gas production from methane hydrates in the eastern Nankai Trough. Mar. Pet. Geol. 2015, 66, 296–309. [Google Scholar] [CrossRef]

- Ashi, J.; Tokuyama, H.; Taira, A. Distribution of methane hydrate BSRs and it simplication for the prism growth in the Nankai Trough. Mar. Geol. 2006, 187, 177–191. [Google Scholar] [CrossRef]

- Riedel, M.; Collett, T.S.; Malone, M.J. Stages of gas hydrate evolution on the Northern Cascadia Margin. Sci. Drill. 2006, 3, 18–24. [Google Scholar] [CrossRef]

- Boswell, R.; Collett, T.S.; Frye, M.; Shedd, W.; McConnell, D.R.; Shelander, D. Subsurface gas hydrates in the northern Gulf of Mexico. Mar. Pet. Geol. 2012, 34, 4–30. [Google Scholar] [CrossRef]

- Liu, C.; Ye, Y.; Meng, Q.; He, X.; Li, C.; Zhang, G.; Liang, J.; Lu, J.; Lu, Z.; Zhu, Y. Characterization of natural gas hydrate recovered from both marine and terrestrial regions in China: Laboratory studies. In Proceedings of the 8th International Conference on Gas Hydrates, Beijing, China, 28 July–1 August 2014. [Google Scholar]

- Pohlman, J.W.; Canuel, E.A.; Chapman, N.R.; Spence, G.D.; Whiticar, M.J.; Coffin, R.B. The origin of thermogenic gas hydrates on the northern Cascadia Margin as inferred from isotopic 13C/12C and D/H) and molecular composition of hydrate and vent gas. Org. Geochem. 2005, 36, 703–716. [Google Scholar] [CrossRef]

- Waite, W.F.; Santamarina, J.C.; Cortes, D.D.; Dugan, B.; Espinoza, D.N.; Germaine, J.; Jang, J.; Jung, J.W.; Kneafsey, T.J.; Shin, H.; et al. Physical properties of hydrate-bearing sediments. Rev. Geophys. 2009, 47, 465–484. [Google Scholar] [CrossRef]

- Liu, B.; Pan, H.; Wang, X.; Li, F.; Sun, C.; Chen, G. Evaluation of different CH4-CO2 replacement processes in hydrate-bearing sediments by measuring P-wave velocity. Energies 2013, 6, 6242–6254. [Google Scholar] [CrossRef]

- Kneafsey, T.J.; Tomutsa, L.; Moridis, G.J.; Seol, Y.; Freifeld, B.M.; Taylor, C.E.; Gupta, A. Methane hydrate formation and dissociation in a partially saturated core-scale sand sample. J. Petrol. Sci. Eng. 2007, 56, 108–126. [Google Scholar] [CrossRef]

- Luo, Y.; Peng, J.; Li, P.; He, J.; Li, L. Influence of heterogeneous hydrate distribution on the compressional wave velocity of hydrate-bearing sediment specimens. J. Nat. Gas Sci. Eng. 2015, 22, 90–97. [Google Scholar] [CrossRef]

- Wang, X.H.; Sun, Y.F.; Wang, Y.F.; Li, N.; Sun, C.Y.; Chen, G.J.; Liu, B.; Yang, L.Y. Gas production from hydrates by CH4-CO2/H2 replacement. Appl. Energy 2017, 188, 305–314. [Google Scholar] [CrossRef]

- Stern, L.A.; Circone, S.; Kirby, S.H. Anomalous preservation of pure methane hydrate at 1 atm. Phys. Chem. Phys.Chem. 2001, 105, 1756–1762. [Google Scholar] [CrossRef]

- Stern, L.A.; Circone, S.; Kirby, S.H.; Durham, W.B. Temperature, pressure, and compositional effects on anomalous or self preservation of gas hydrates. Can. J. Phys. 2003, 81, 271–283. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, C.; Yang, M.; Liu, W.; Xu, K.; Liu, Y.; Song, Y. Existence of a memory effect between hydrates with different structures (I, II, and H). J. Nat. Gas Sci. Eng. 2015, 26, 330–335. [Google Scholar] [CrossRef]

- Sowa, B.; Maeda, N. Statistical study of the memory effect in model natural gas hydrate systems. J. Phys. Chem. A 2015, 119, 10784–10790. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Li, X.S.; Li, G.; Feng, J.C.; Wang, Y. Depressurization induced gas production from hydrate deposits with low gas saturation in a pilot-scale hydrate simulator. Appl. Energy 2014, 129, 274–286. [Google Scholar] [CrossRef]

- Duchkov, A.D.; Golikov, N.A.; Duchkov, A.A.; Manakov, A.Y.; Per-myakov, M.E.; Drobchik, A.N. Equipment for the studies of the acoustic properties of hydrate-containing samples in laboratory conditions. Seism. Instrum. 2016, 52, 70–78. [Google Scholar] [CrossRef]

- Wang, X.H.; Sun, J.S.; Jiang, L.Y.; Sun, Y.F.; Sun, C.Y.; Chen, G.J. Occurrence characteristics of gas hydrates formed from seepage gas in sandy deposits. J. Petrol. Sci. Eng. 2016, 147, 451–458. [Google Scholar] [CrossRef]

- Dai, J.; Xu, H.; Snyder, F.; Dutta, N. Detection and estimation of gas hydrates using rock physics and seismic inversion: Examples from the northern deepwater Gulf of Mexico. Lead. Edge 2004, 23, 60–66. [Google Scholar] [CrossRef]

- Li, D.L.; Wu, Q.; Wang, Z.; Lu, J.; Liang, D.; Li, X. Tri-axial shear tests on hydrate-bearing sediments during hydrate dissociation with depressurization. Energies 2018, 11, 1819. [Google Scholar] [CrossRef]

- Terry, D.A.; Knapp, C.C.; Knapp, J.H. Effective-medium models and rock physics analysis for marine gas hydrates in Northern Gulf of Mexico. In Proceedings of the Seventh International Conference on Gas Hydrates, Edinburgh, UK, 17–21 July 2011. [Google Scholar]

- Wang, F.; Zhao, B.; Li, G. Prevention of potential hazards associated with marine gas hydrate exploitation: A review. Energies 2018, 11, 2384. [Google Scholar] [CrossRef]

- Liu, Z.; Wei, H.; Peng, L.; Wei, C.F.; Ning, F.L. An easy and efficient way to evaluate mechanical properties of gas hydrate-bearing sediments: The direct shear test. J. Petrol. Sci. Eng. 2016, 149, 56–64. [Google Scholar] [CrossRef]

- Kwon, T.; Cho, G. Submarine slope failure primed and triggered by bottom water warming in oceanic hydrate-bearing deposits. Energies 2012, 5, 2849–2873. [Google Scholar] [CrossRef]

- Yamamoto, K.; Suzuki, K.; Nagano, Y.; Nakatsuka, Y. Approach to study mechanical stability of wellbore and formation for the offshore production test from methane hydrate deposits. In Proceedings of the 8th International Conference on Gas Hydrates, Beijing, China, 28 July–1 August 2014. [Google Scholar]

- Dallimore, S.R.; Wright, J.F.; Nixon, F.M.; Kurihara, M.; Yamamoto, K.; Fujii, T.; Fujii, K.; Numasawa, M.; Yasuda, M.; Imasato, Y. Geologic and porous media factors affecting the 2007 production response characteristics of the JOGMEC/NRCan/Aurora Mallik gas hydrate production research well. In Proceedings of the 6th International Conference on Gas Hydrates, Vancouver, BC, Canada, 6–10 July 2008. [Google Scholar]

| Cores | Density (g/cm3) | Porosity (%) | Length (mm) | Diameter (mm) |

|---|---|---|---|---|

| C1 | 1.97 | 29.74 | 54.77 | 37.28 |

| C2 | 2.03 | 27.93 | 54.67 | 36.83 |

| S1 | 1.72 | 38.74 | 52.30 | 37.16 |

| S2 | 1.89 | 34.45 | 47.65 | 36.27 |

| Cores | Sh (%) | Density (g/cm3) | Vp (km/s) | Vs (km/s) | Vp/Vs | Elastic Modulus (GPa) | Bulk Modulus (GPa) | Shear Modulus (GPa) | Poisson’s Rato |

|---|---|---|---|---|---|---|---|---|---|

| C1 | 4.69 | 2.018 | 1.92 | 1.19 | 1.61 | 6.77 | 3.61 | 2.85 | 0.19 |

| 10.32 | 2.005 | 1.98 | 1.17 | 1.70 | 6.75 | 4.25 | 2.73 | 0.23 | |

| 20.35 | 2.060 | 2.13 | 1.32 | 1.61 | 8.53 | 4.55 | 3.59 | 0.19 | |

| C2 | 6.21 | 2.060 | 1.73 | 1.10 | 1.57 | 5.81 | 2.81 | 2.51 | 0.16 |

| 11.32 | 2.070 | 1.94 | 1.23 | 1.57 | 7.29 | 3.56 | 3.15 | 0.16 | |

| 14.96 | 2.074 | 2.02 | 1.25 | 1.61 | 7.71 | 4.10 | 3.25 | 0.19 | |

| 21.06 | 2.077 | 2.03 | 1.26 | 1.61 | 7.80 | 4.16 | 3.28 | 0.19 | |

| S1 | 5.60 | 1.787 | 2.63 | 1.48 | 1.78 | 9.90 | 7.15 | 3.90 | 0.27 |

| 9.88 | 1.794 | 3.12 | 1.80 | 1.74 | 14.50 | 9.75 | 5.79 | 0.25 | |

| 15.58 | 1.824 | 3.83 | 2.10 | 1.82 | 20.62 | 16.01 | 8.02 | 0.29 | |

| 20.06 | 1.834 | 3.81 | 2.16 | 1.77 | 21.56 | 15.29 | 8.52 | 0.26 | |

| 26.40 | 1.855 | 3.93 | 2.23 | 1.76 | 23.25 | 16.39 | 9.20 | 0.26 | |

| S2 | 4.98 | 1.934 | 1.94 | 1.14 | 1.70 | 6.23 | 3.95 | 2.52 | 0.24 |

| 11.04 | 1.917 | 2.39 | 1.40 | 1.71 | 9.28 | 5.97 | 3.74 | 0.24 | |

| 15.77 | 1.913 | 2.88 | 1.68 | 1.71 | 13.41 | 8.64 | 5.40 | 0.24 | |

| 19.35 | 1.947 | 3.33 | 1.85 | 1.80 | 17.03 | 12.73 | 6.67 | 0.28 | |

| 26.13 | 1.955 | 3.36 | 1.92 | 1.75 | 18.12 | 12.49 | 7.20 | 0.26 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.-H.; Xu, Q.; He, Y.-N.; Wang, Y.-F.; Sun, Y.-F.; Sun, C.-Y.; Chen, G.-J. The Acoustic Properties of Sandy and Clayey Hydrate-Bearing Sediments. Energies 2019, 12, 1825. https://doi.org/10.3390/en12101825

Wang X-H, Xu Q, He Y-N, Wang Y-F, Sun Y-F, Sun C-Y, Chen G-J. The Acoustic Properties of Sandy and Clayey Hydrate-Bearing Sediments. Energies. 2019; 12(10):1825. https://doi.org/10.3390/en12101825

Chicago/Turabian StyleWang, Xiao-Hui, Qiang Xu, Ya-Nan He, Yun-Fei Wang, Yi-Fei Sun, Chang-Yu Sun, and Guang-Jin Chen. 2019. "The Acoustic Properties of Sandy and Clayey Hydrate-Bearing Sediments" Energies 12, no. 10: 1825. https://doi.org/10.3390/en12101825

APA StyleWang, X.-H., Xu, Q., He, Y.-N., Wang, Y.-F., Sun, Y.-F., Sun, C.-Y., & Chen, G.-J. (2019). The Acoustic Properties of Sandy and Clayey Hydrate-Bearing Sediments. Energies, 12(10), 1825. https://doi.org/10.3390/en12101825