A Review of Evaluation, Optimization and Synthesis of Energy Systems: Methodology and Application to Thermal Power Plants †

Abstract

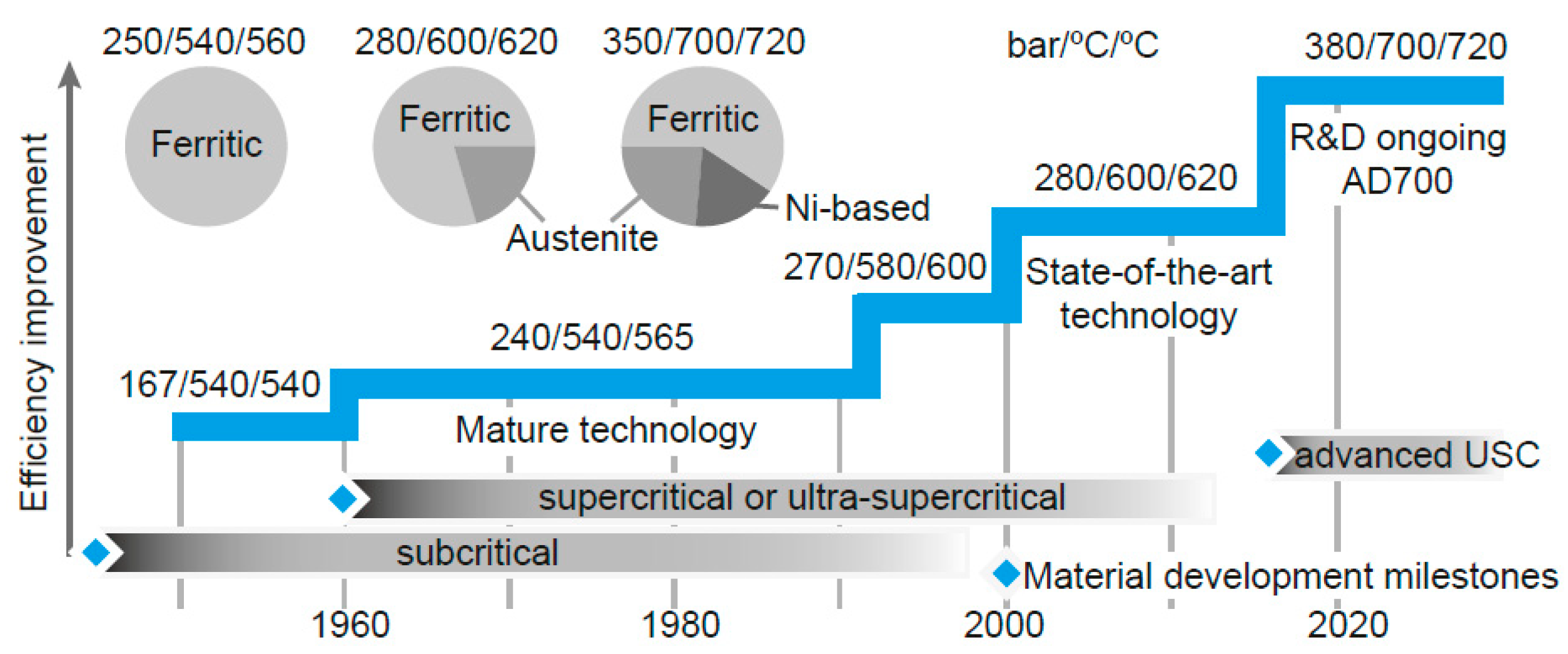

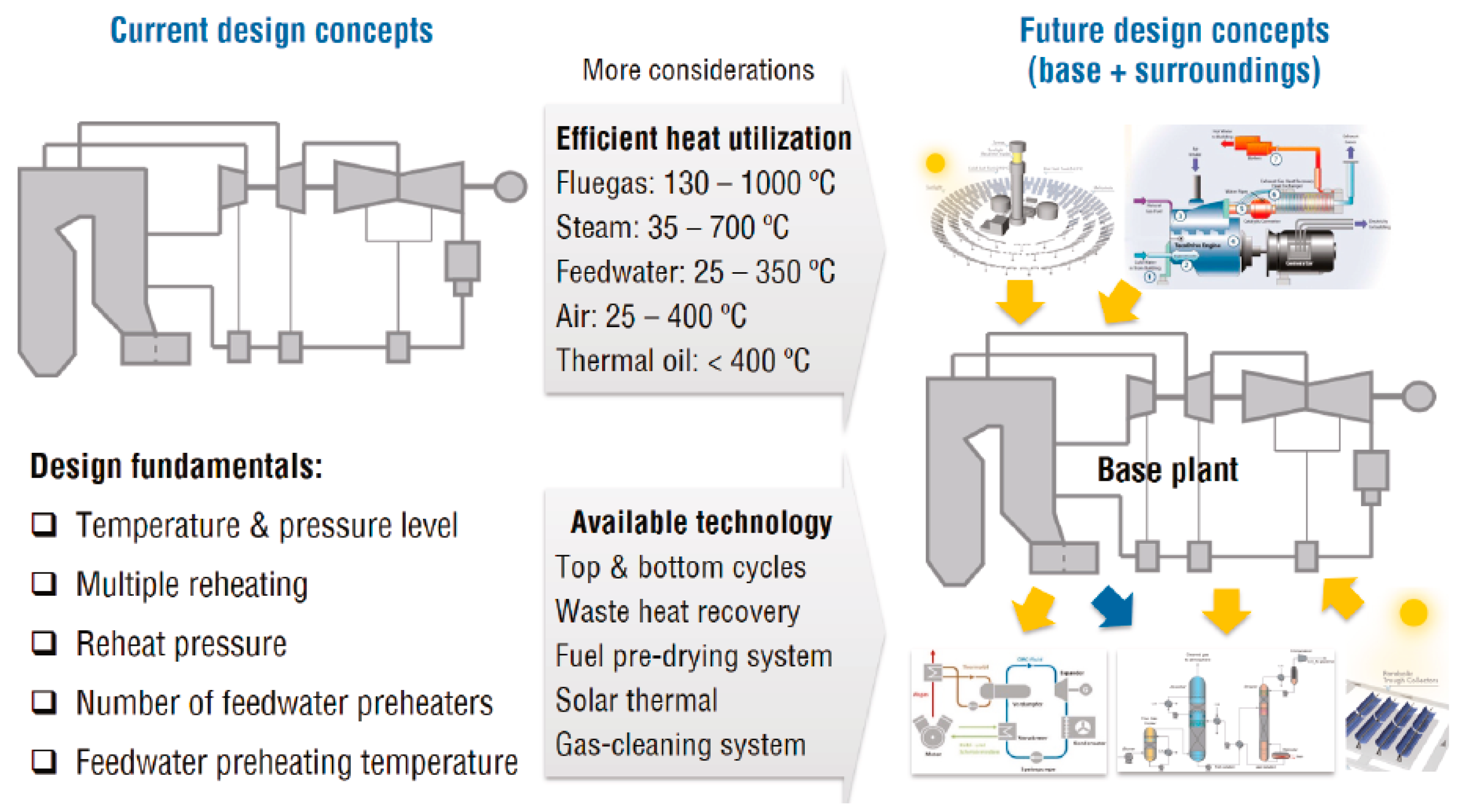

1. Introduction

2. Analysis of Energy Systems

2.1. Exergy Analysis

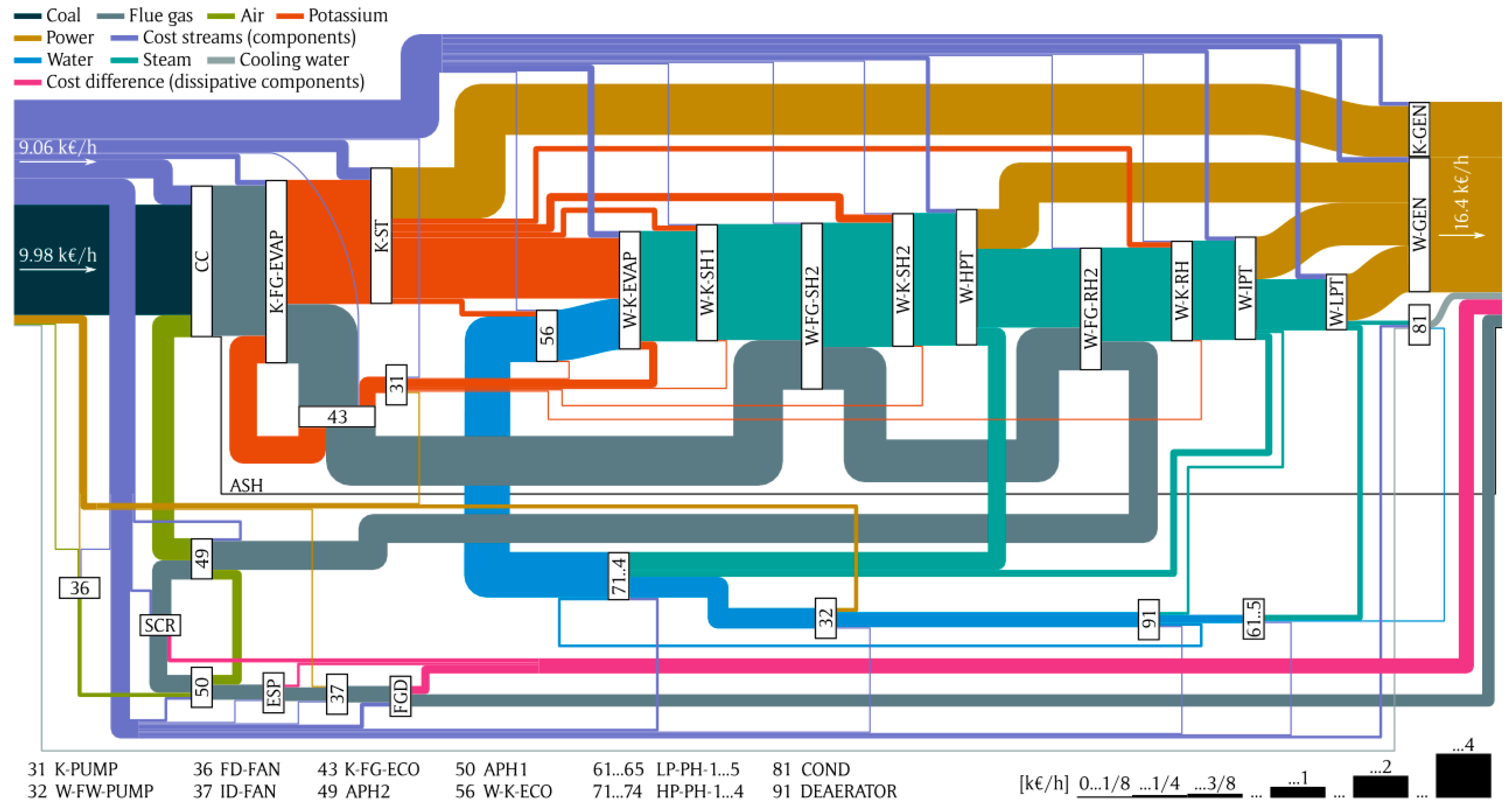

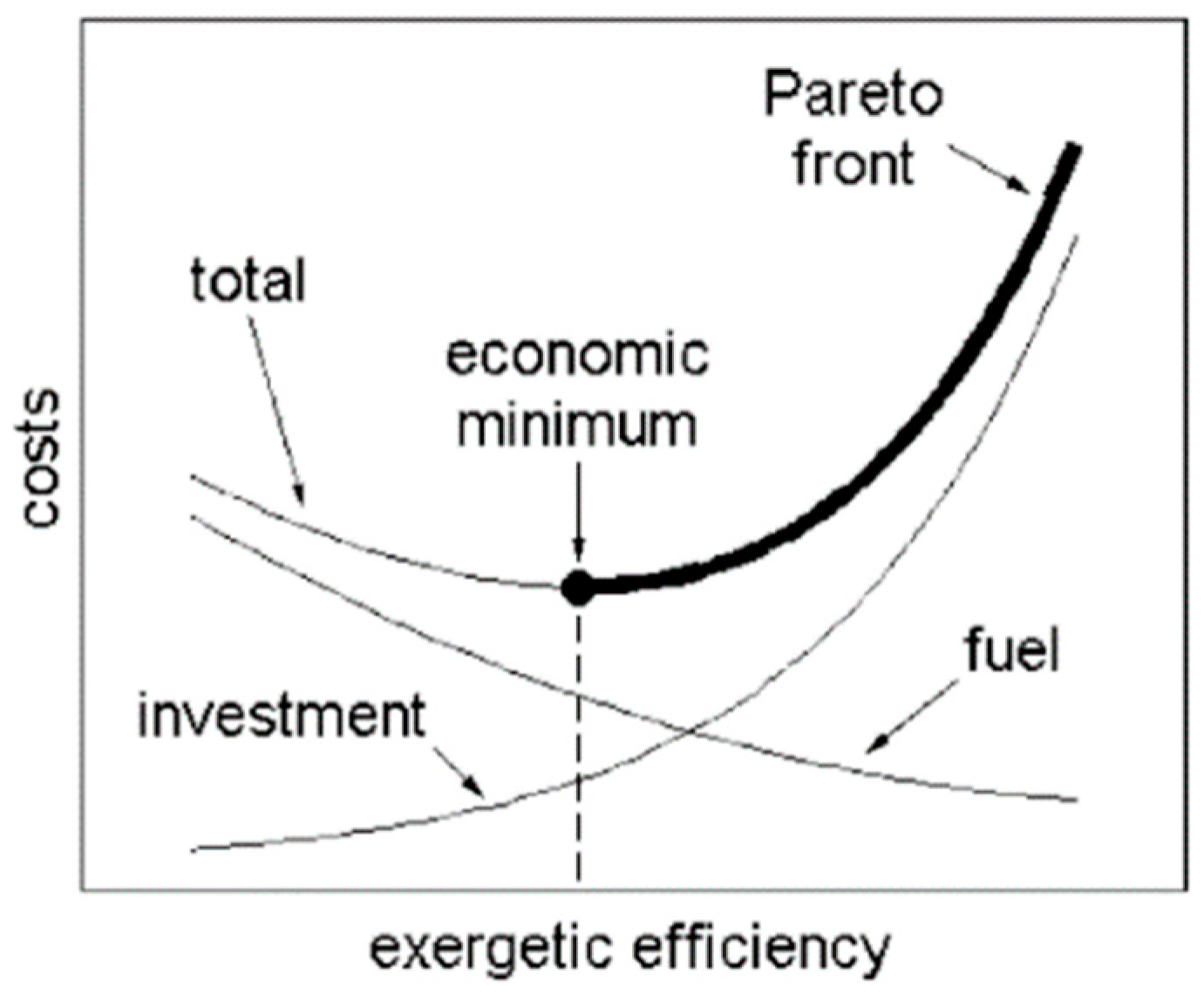

2.2. Exergoeconomic Analysis

2.2.1. Accounting Methods

2.2.2. Calculus Methods

2.2.3. Recent Developments

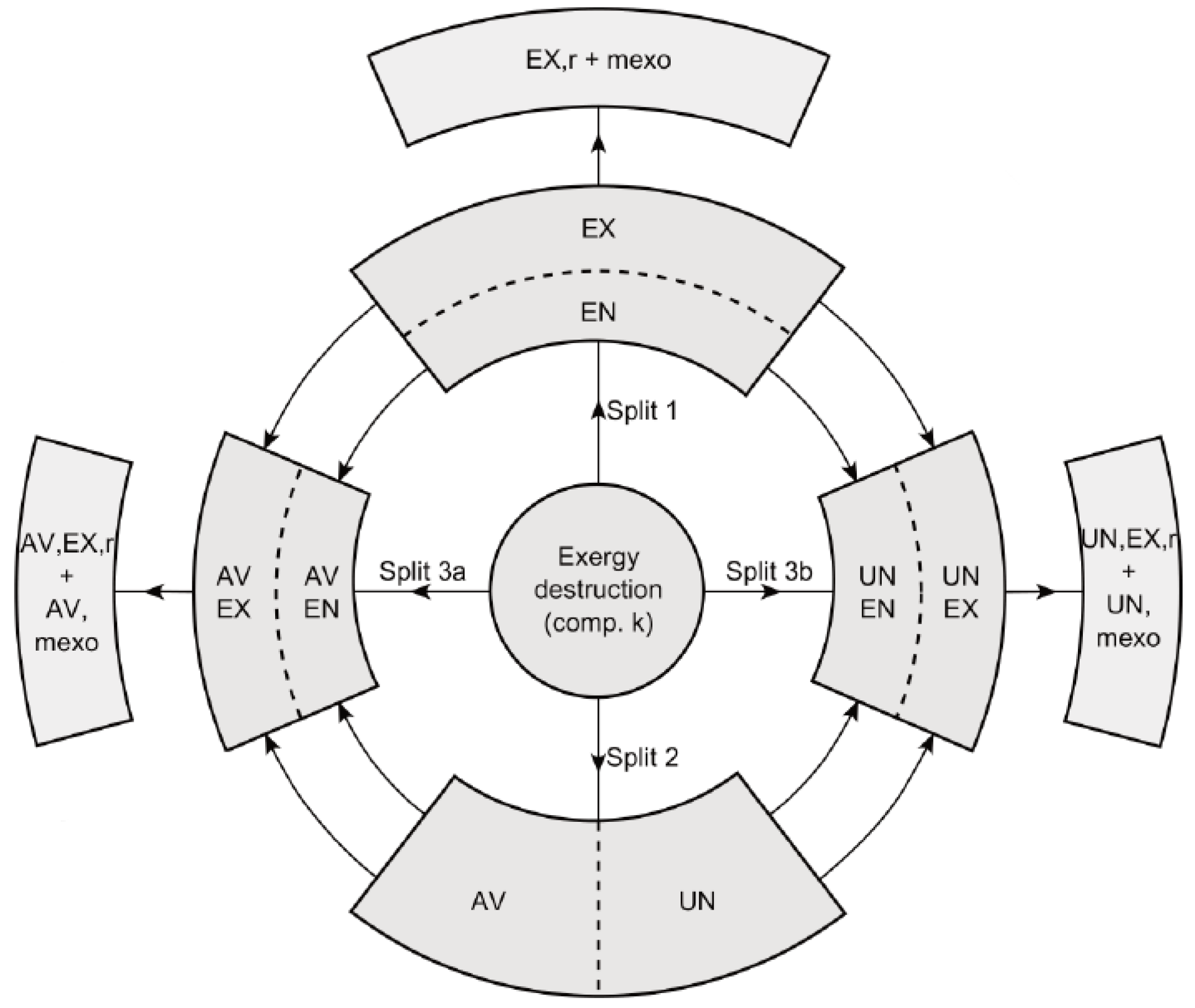

2.3. Advanced Exergy-Based Analysis

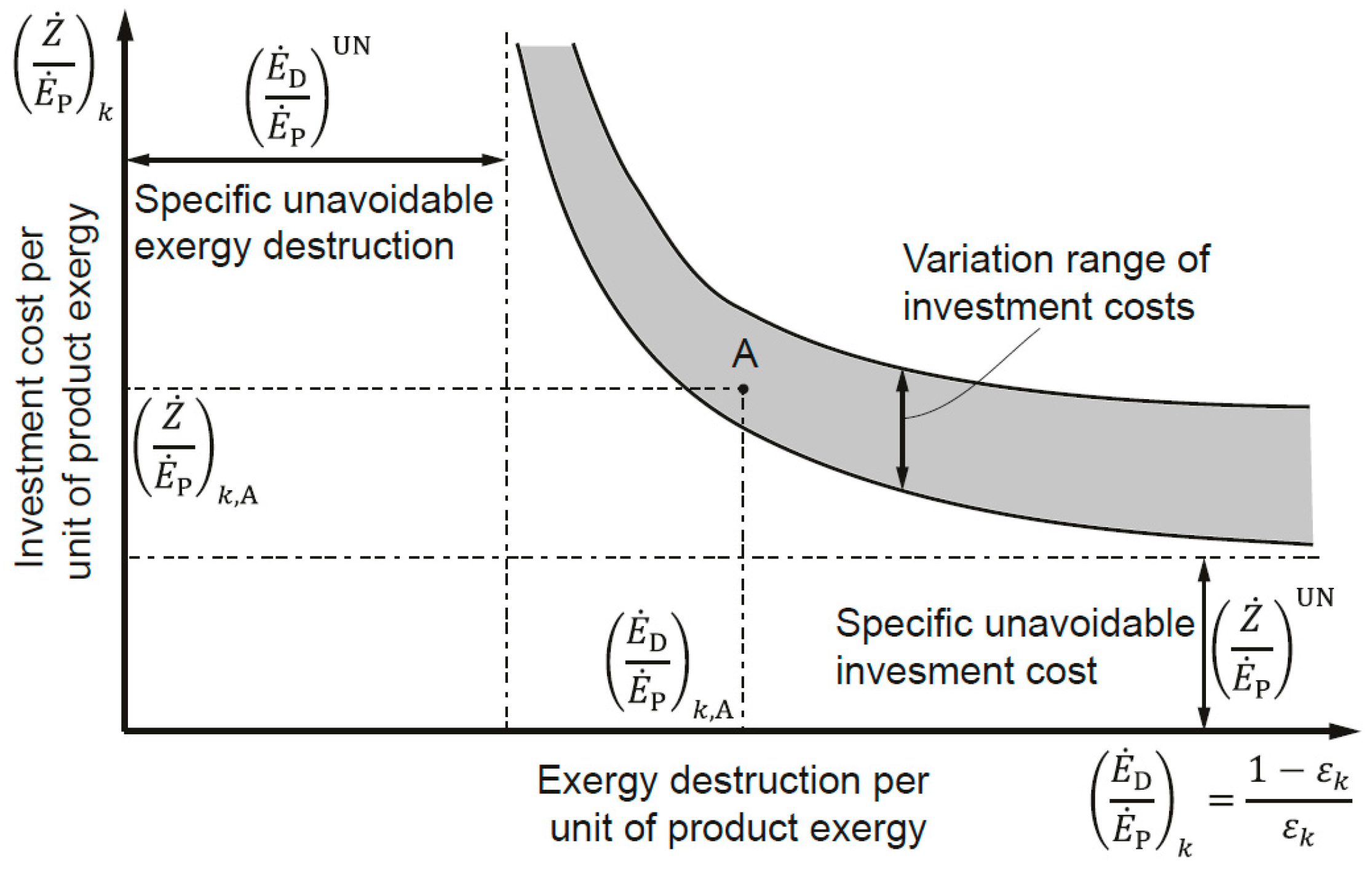

2.3.1. Avoidable/Unavoidable Exergy Destruction and Cost

2.3.2. Endogenous/Exogenous Exergy Destruction and Cost

2.3.3. Combination of the Two Exergy-Destruction Splits

2.4. Applications

2.4.1. Conventional Exergy-Based Analysis

2.4.2. Advanced Exergy-Based Analysis

2.5. Limitations

3. Optimization of Energy Systems

3.1. Mathematical Optimization

3.1.1. Deterministic Algorithms

3.1.2. Metaheuristic Algorithms

3.2. Applications to Thermal Power Plants

3.2.1. Nonlinearity and Integrity

3.2.2. Scope and Key Results

3.2.3. Limitations

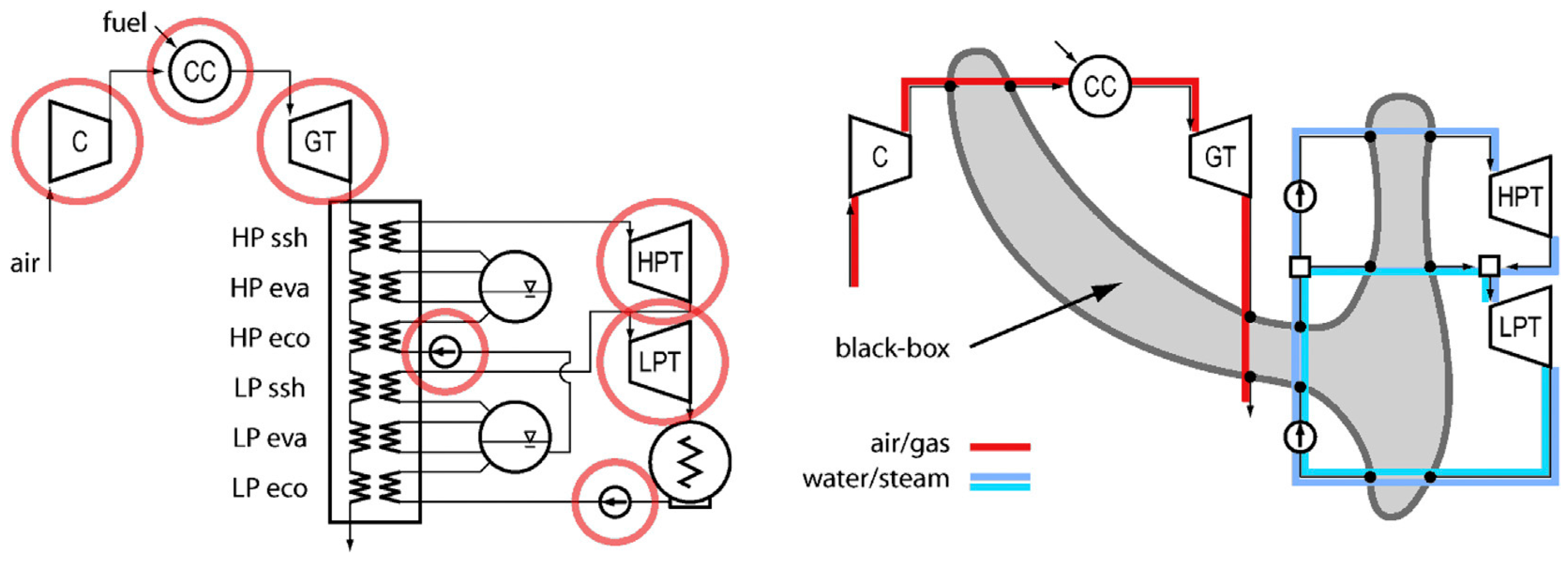

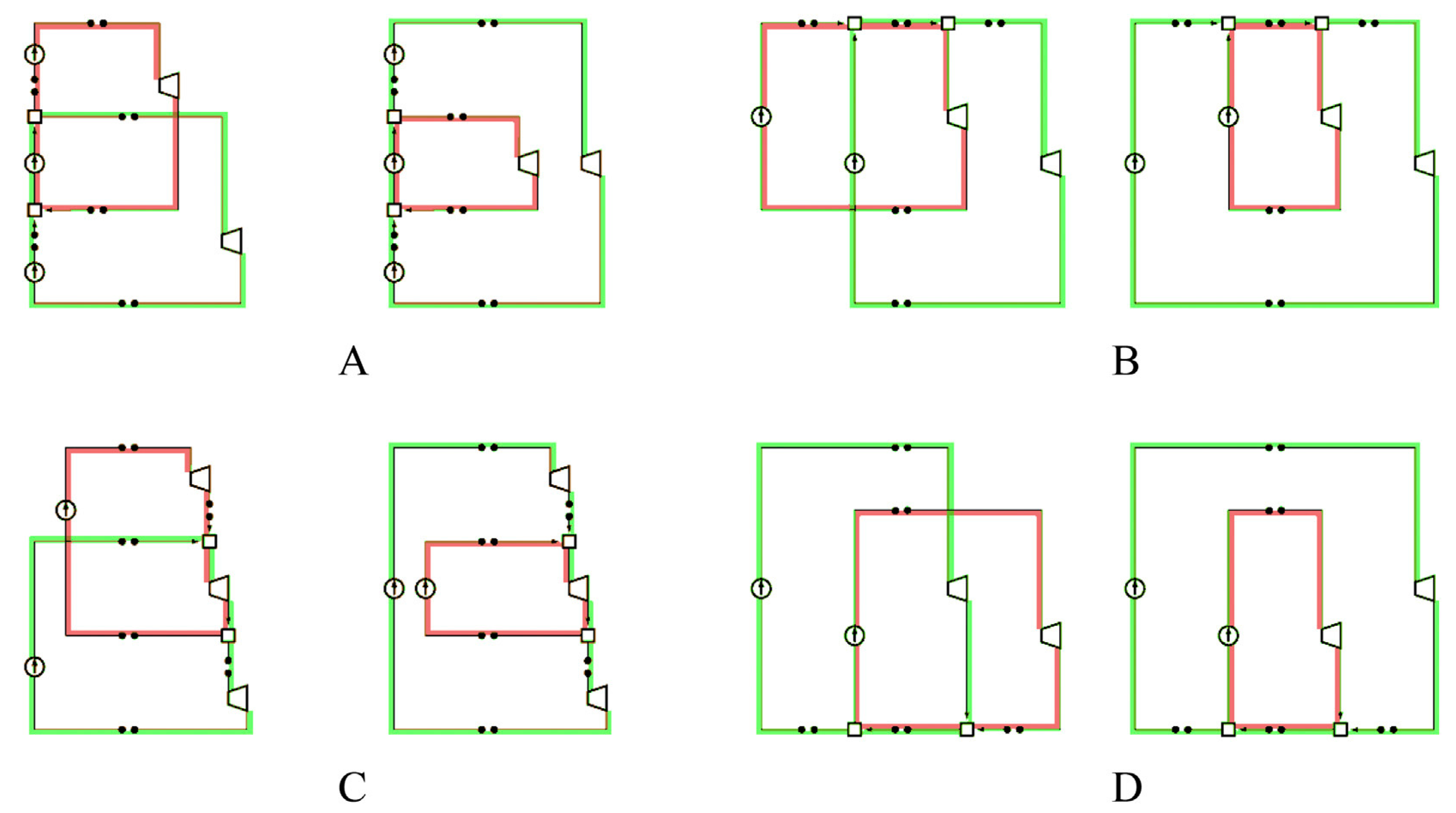

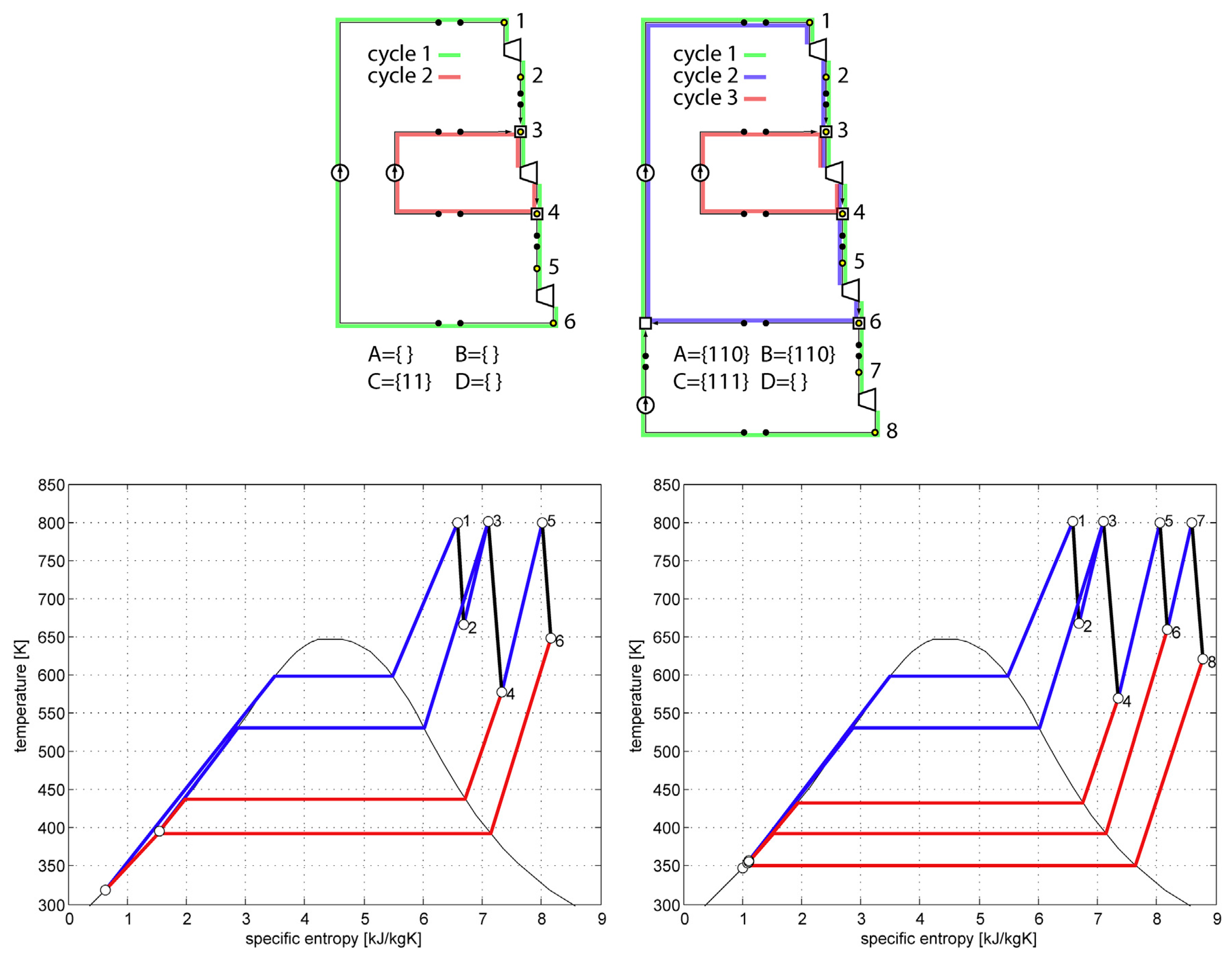

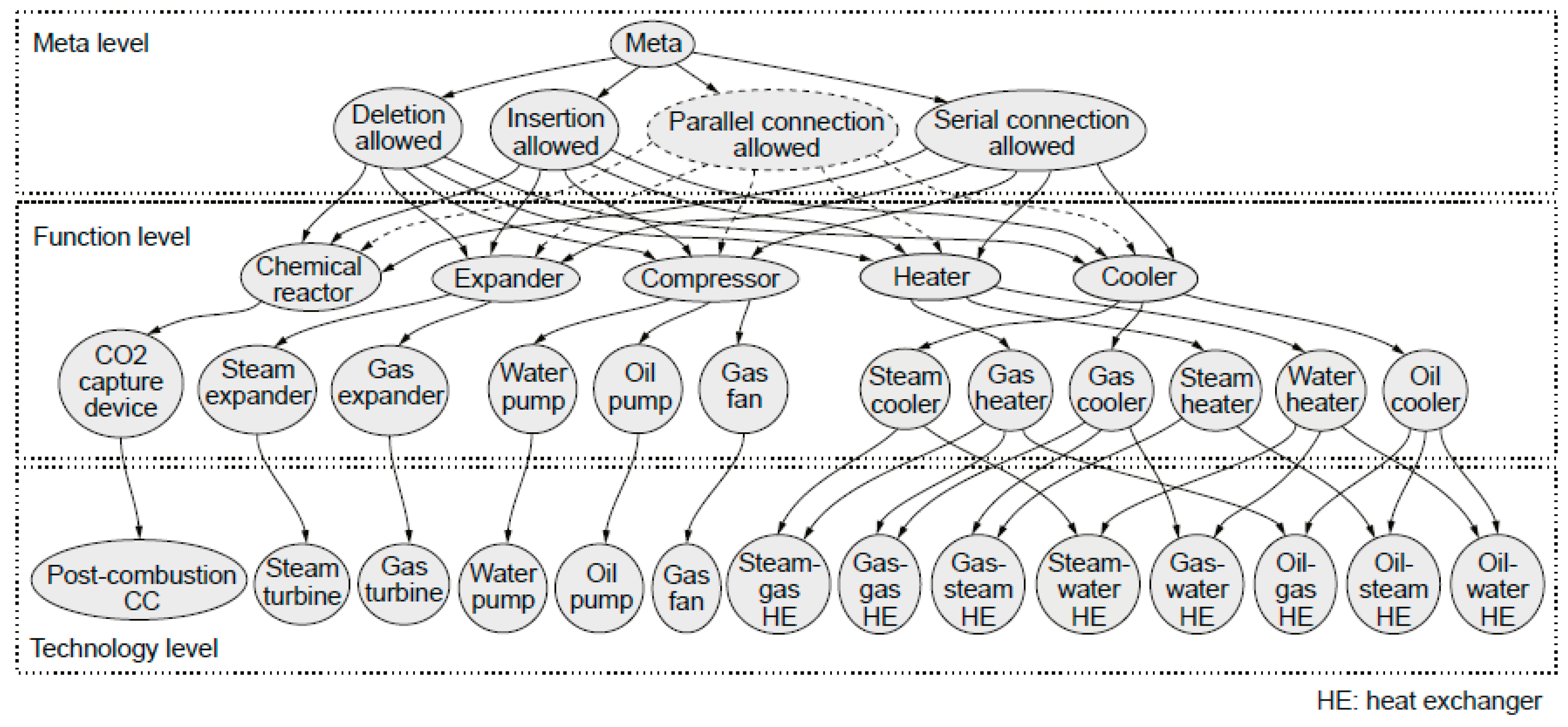

4. Synthesis of Energy Systems

4.1. Superstructure-Based Synthesis

4.1.1. Superstructure Representation

4.1.2. Superstructure Generation

4.1.3. Superstructure-Based Modeling and Solving

4.2. Superstructure-Free Synthesis

4.3. Applications

4.3.1. Superstructure-Based Synthesis

4.3.2. Superstructure-Free Synthesis

- Remove one component with all of its interconnections.

- Remove one component and short-circuit all of its interconnections.

- Delete one component and insert another component.

- Delete one component and insert a parallel connection of two other components.

- Delete one component and insert a serial connection of two other components.

- Insert one component by replacing the technology-related stream.

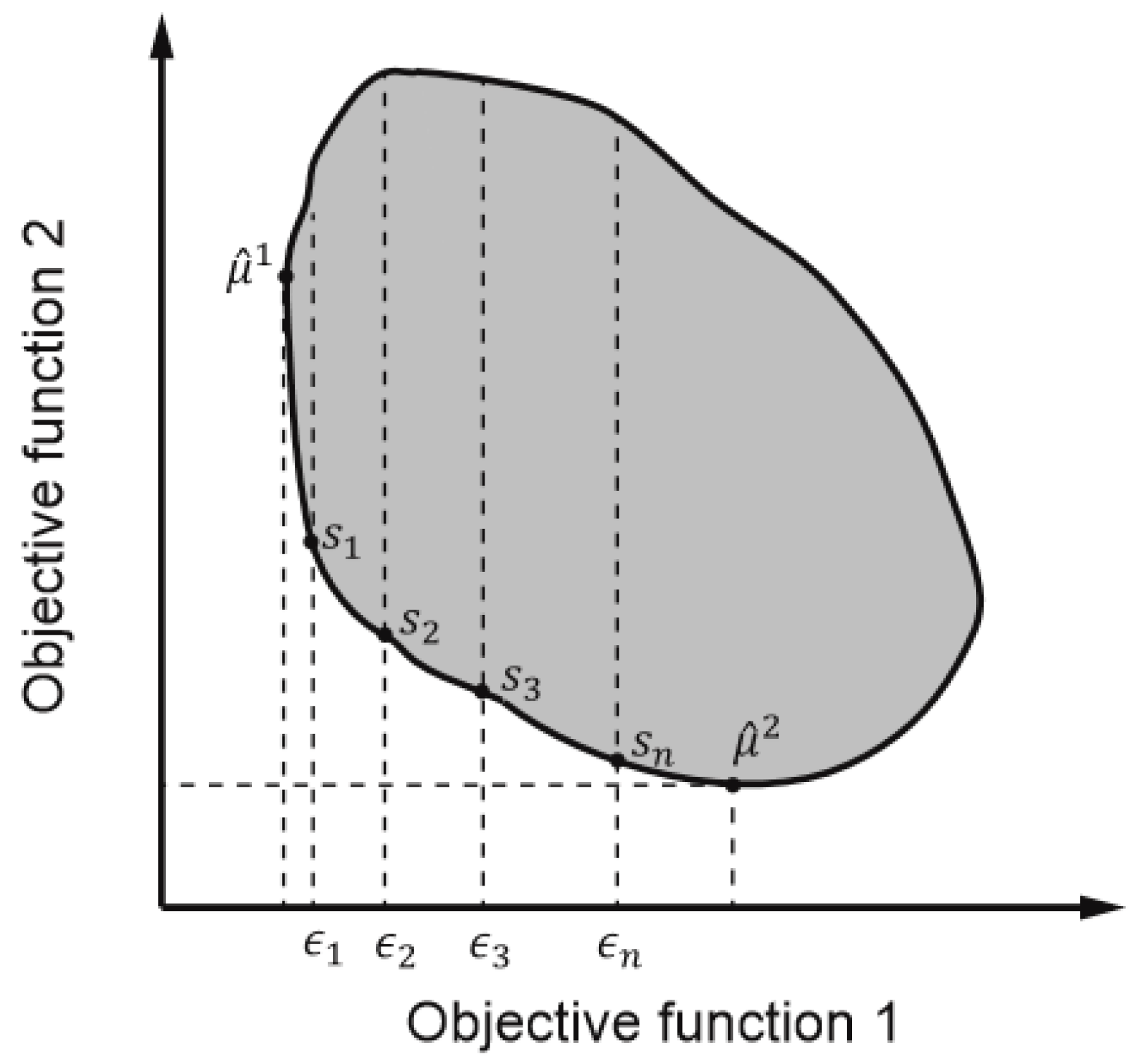

5. Multi-Objective Optimization

5.1. Multi-Objective Optimization Techniques

5.1.1. The Weighted Sum Method

5.1.2. The -Constraint Method

5.1.3. The Normalized Normal Constraint Method

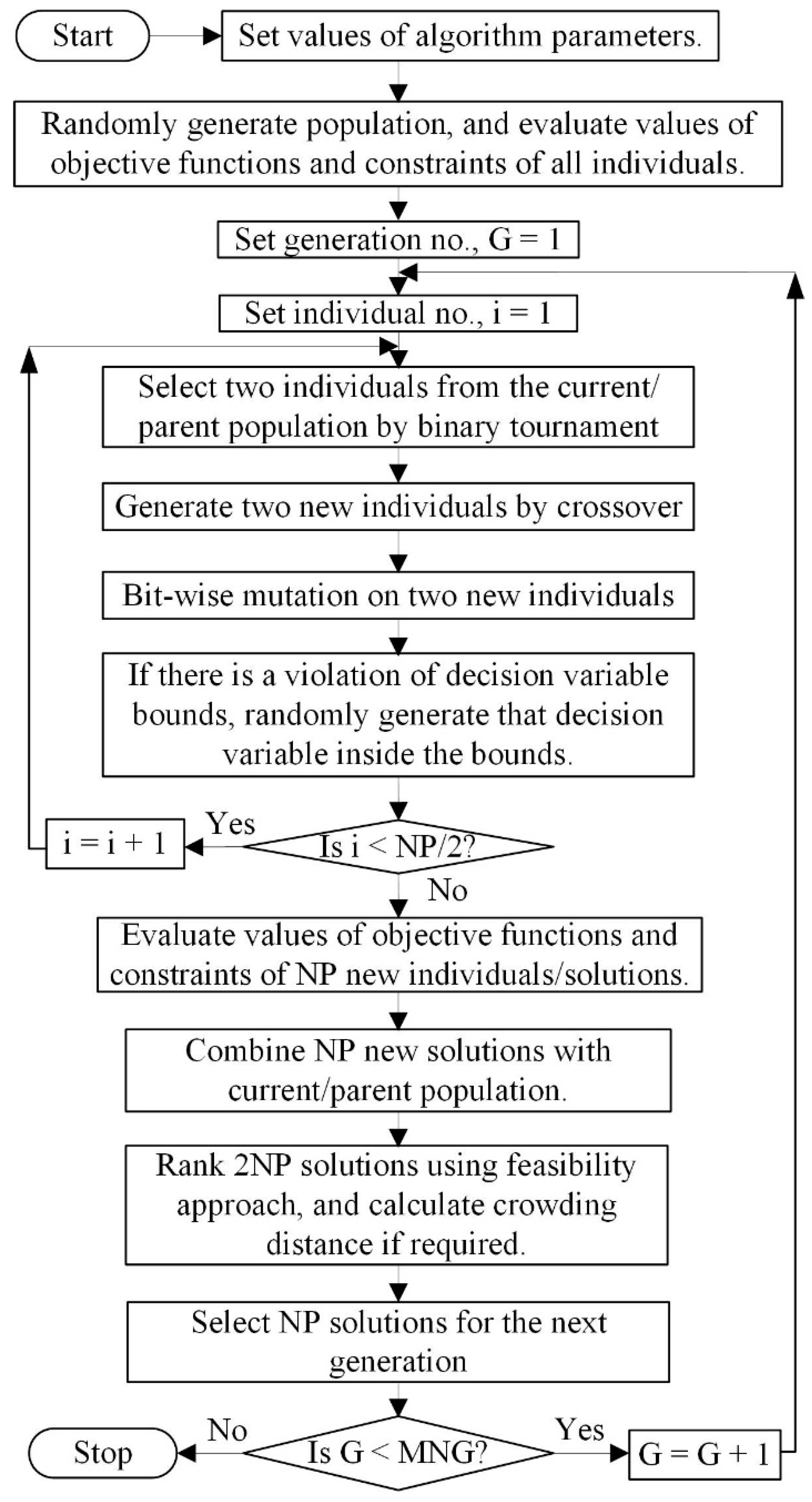

5.1.4. Evolutionary Multi-Objective Optimization Algorithms (EMOAs)

- Both solutions are feasible, and for all objective functions.

- Solution is feasible and solution is infeasible.

- Both solutions are infeasible, but solution has a smaller number of violated constraints (and lesser total absolute constraint violation if both have the same number of violated constraints) compared to solution .

5.2. Applications

6. Comparison and Perspectives

6.1. Comparison of the Identified Methodologies

6.2. Future Perspectives

6.2.1. Real-World Optimal Designs and Retrofits

6.2.2. Evaluation and Synthesis Methodologies

6.2.3. Mathematical Modeling Practice

7. Conclusions

- For system analysis, the advanced exergy-based analyses aim at paving a step further above traditional exergy analysis to reveal the sources and avoidability of exergy destruction and costs within different components and their interactions. The related methods are still under development and remain several fundamental problems to be addressed, e.g., validation of the splits of exergy dissipation.

- For superstructure-based synthesis, the steam network, incorporating algorithmic generation of the steam-cycle superstructure for a predefined number of pressure levels and bi-level hybrid solving algorithm (EA+MILP), is flexible to be employed as standalone thermal power plants or a utility for process integration. However, the method must combine with superstructure-based heat exchanger network for synthesizing complete flowsheets.

- For superstructure-free synthesis, both SYNTHSEP and ECH-based method performs evolutionary structural alternation of given structures based on different concepts. The SYNTHSEP, not for complete flowsheet synthesis, employs elementary cycles and the share of multiple elementary cycles, which limits its use for other processes. The ECH-based method can perform total flowsheet synthesis and can be flexibly extended with well-defined ECH and component models. Both methods employ bi-level decomposition techniques combining EA and mathematical programming.

- A straightforward comparison of these chosen methods on a common basis of a benchmarking problem should be made, since the applications given in literature aimed at solving specific optimization problems.

- Three directions of method development and implementation are recommended: real-world designs and retrofits, further methodology development, particularly synthesis methodologies, and good modeling practice.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| DE | differential evolution |

| EA | evolutionary algorithm |

| ECH | energy conversion hierarchy |

| GDP | generalized disjunctive programming |

| GRG | generalized reduced gradient |

| HPT | high-pressure turbine |

| ICC | Integer cut constraint |

| IP | integer programming |

| IPT | intermedia pressure turbine |

| LP | linear programming |

| LPT | low-pressure turbine |

| MILP | mixed integer linear programming |

| MINLP | mixed integer nonlinear programming |

| MOO | multi-objective optimization |

| NLP | nonlinear programming |

| NNC | normalized normal constraint |

| SOO | single objective optimization |

| SPECO | specific exergy costing |

| SQP | successive quadratic programming |

| TRR | total revenue requirement |

| exergy flow, MW | |

| design variable | |

| objective function | |

| objective function | |

| Pareto front | |

| the best Pareto front | |

| inequality constraint | |

| equality constraint; or enthalpy, kJ/kg | |

| mass flow, kg/s | |

| operational variable | |

| structural variable | |

| temperature, ℃ | |

| () | continuous nonconvex bilinear term |

| weighting factor | |

| vector in the feasible solution space | |

| solution space | |

| variable to replace the bilinear term | |

| Z | investment cost, M$ |

| Greek letters | |

| space of all structure alternatives | |

| crowding distance | |

| efficiency | |

| size of offspring population | |

| solution structure evolved by mutation | |

| size of parent population; or solution | |

| anchor solution | |

| objective function | |

| Subscripts and superscripts | |

| A | average |

| abs | absorption |

| AV | avoidable |

| D | destruction |

| EN | endogenous |

| EX | exogenous |

| F | fuel |

| i, j, k | index |

| L | loss |

| N | independent decision variable |

| P | product |

| rel | release |

| UN | unavoidable |

References

- Sieminski, A. International Energy Outlook; Energy Information Administration (EIA): Washington, DC, USA, 2014.

- Iodice, P.; Senatore, A. Atmospheric pollution from point and diffuse sources in a National Interest Priority Site located in Italy. Energy Environ. 2016, 27, 586–596. [Google Scholar] [CrossRef]

- Iodice, P.; Adamo, P.; Capozzi, F.; Di Palma, A.; Senatore, A.; Spagnuolo, V.; Giordano, S. Air pollution monitoring using emission inventories combined with the moss bag approach. Sci. Total Environ. 2016, 541, 1410–1419. [Google Scholar] [CrossRef] [PubMed]

- Qazi, H.W.; Flynn, D. Synergetic frequency response from multiple flexible loads. Electr. Power Syst. Res. 2017, 145, 185–196. [Google Scholar] [CrossRef]

- Wang, L.; Pérez-Fortes, M.; Madi, H.; Diethelm, S.; Herle, J.V.; Maréchal, F. Optimal design of solid-oxide electrolyzer based power-to-methane systems: A comprehensive comparison between steam electrolysis and co-electrolysis. Appl. Energy 2018, 211, 1060–1079. [Google Scholar] [CrossRef]

- Jensen, S.H.; Graves, C.; Mogensen, M.; Wendel, C.; Braun, R.; Hughes, G.; Gao, Z.; Barnett, S.A. Correction: Large-scale electricity storage utilizing reversible solid oxide cells combined with underground storage of CO2 and CH4. Energy Environ. Sci. 2015, 8, 2471–2479. [Google Scholar] [CrossRef]

- Fukuda, Y. Development of Advanced Ultra Supercritical Fossil Power Plants in Japan: Materials and High Temperature Corrosion Properties. Mater. Sci. Forum 2010, 696, 236–241. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Technology Roadmap: High-Efficiency, Low-Emissions Coal-Fired Power Generation; International Energy Agency: Paris, France, 2012. [Google Scholar]

- Wang, L. Thermo-Economic Evaluation, Optimization and Synthesis of Large-Scale Coal-Fired Power Plants. Ph.D. Thesis, Technical University of Berlin, Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Rukes, B.; Taud, R. Status and perspectives of fossil power generation. Energy 2004, 29, 1853–1874. [Google Scholar] [CrossRef]

- Spliethoff, H. Steam Power Stations for Electricity and Heat Generation. In Power Generation from Solid Fuels; Springer: Berlin/Heidelberg, Germany, 2010; pp. 73–219. [Google Scholar]

- Silvestri, G.J., Jr.; Westinghouse Electric Corp. Boiler Feedpump Turbine Drive/Feedwater Train Arrangement. U.S. Patent 5,404,724, 11 April 1995. [Google Scholar]

- Blum, R.; Kjaer, S.; Bugge, J. Development of a pf fired high efficiency power plant AD700. In Proceedings of the Riso International Energy Conference: “Energy Solutions for Sustainable Development”, Roskilde, Denmark, 22–24 May 2007. [Google Scholar]

- Stępczyńska, K.; Kowalczyk, Ł.; Dykas, S.; Elsner, W. Calculation of a 900 MW conceptual 700/720°C coal-fired power unit with an auxiliary extraction-backpressure turbine. J. Power Technol. 2012, 92, 266–273. [Google Scholar]

- Eaves, J.; Palmer, F.D.; Wallace, J.; Wilson, S. The Value of Our Existing Coal Fleet: An Assessment of Measures to Improve Reliability & Efficiency While Reducing Emissions; The National Coal Council: Washington, DC, USA, 2014. [Google Scholar]

- Espatolero, S.; Cortés, C.; Romeo, L.M. Optimization of boiler cold-end and integration with the steam cycle in supercritical units. Appl. Energy 2010, 87, 1651–1660. [Google Scholar] [CrossRef]

- Karthikeyan, M.; Zhonghua, W.; Mujumdar, A.S. Low-rank coal drying technologies--Current status and new developments. Dry. Technol. 2009, 27, 403–415. [Google Scholar] [CrossRef]

- Turchi, C.S.; Langle, N.; Bedilion, R.; Libby, C. Solar-augment potential of US fossil-fired power plants. In Proceedings of the ASME 2011 5th International Conference on Energy Sustainability, Washington, DC, USA, 7–10 August 2011; pp. 641–651. [Google Scholar]

- Popov, D. An option for solar thermal repowering of fossil fuel fired power plants. Sol. Energy 2011, 85, 344–349. [Google Scholar] [CrossRef]

- Yang, Y.; Yan, Q.; Zhai, R.; Kouzani, A.; Hu, E. An efficient way to use medium-or-low temperature solar heat for power generation—Integration into conventional power plant. Appl. Therm. Eng. 2011, 31, 157–162. [Google Scholar] [CrossRef]

- Sansaniwal, S.K.; Sharma, V.; Mathur, J. Energy and exergy analyses of various typical solar energy applications: A comprehensive review. Renew. Sustain. Energy Rev. 2018, 82, 1576–1601. [Google Scholar] [CrossRef]

- Tsatsaronis, G. Thermodynamics and the Destruction of Resources; Cambridge University Press: New York, NY, USA, 2011; pp. 377–401. [Google Scholar]

- Moran, M.J.; Shapiro, H.N.; Boettner, D.D.; Bailey, M.B. Fundamentals of Engineering Thermodynamics, 7th ed.; John Wiley Sons: New York, NY, USA, 2010. [Google Scholar]

- Iodice, P.; Langella, G.; Amoresano, A.; Senatore, A. Comparative exergetic analysis of solar integration and regeneration in steam power plants. J. Energy Eng. 2017, 143, 04017042. [Google Scholar] [CrossRef]

- Cornelissen, R.L. Thermodynamics and Sustainable Development: The Use of Exergy Analysis and the Reduction of Irreversibility; Universiteit Twente: Enschede, The Netherlands, 1997. [Google Scholar]

- Tsatsaronis, G. Energy Economics and Management in Industry. In Energy Economics and Management in Industry; Pergamon Press: Oxford, UK, 1984; pp. 151–157. [Google Scholar]

- Kotas, T.J. The Exergy Method of Thermal Plant Analysis; Butterworth Publishers: Stoneham, MA, USA, 1985. [Google Scholar]

- Singh, O.K.; Kaushik, S. Energy and exergy analysis and optimization of Kalina cycle coupled with a coal fired steam power plant. Appl. Therm. Eng. 2013, 51, 787–800. [Google Scholar] [CrossRef]

- Sengupta, S.; Datta, A.; Duttagupta, S. Exergy analysis of a coal-based 210 MW thermal power plant. Int. J. Energy Res. 2007, 31, 14–28. [Google Scholar] [CrossRef]

- Aljundi, I.H. Energy and exergy analysis of a steam power plant in Jordan. Appl. Therm. Eng. 2009, 29, 324–328. [Google Scholar] [CrossRef]

- Erdem, H.H.; Akkaya, A.V.; Cetin, B.; Dagdas, A.; Sevilgen, S.H.; Sahin, B.; Teke, I.; Gungor, C.; Atas, S.; et al. Comparative energetic and exergetic performance analyses for coal-fired thermal power plants in Turkey. Int. J. Therm. Sci. 2009, 48, 2179–2186. [Google Scholar] [CrossRef]

- Ray, T.K.; Datta, A.; Gupta, A.; Ganguly, R. Exergy-based performance analysis for proper O&M decisions in a steam power plant. Energy Convers. Manag. 2010, 51, 1333–1344. [Google Scholar]

- Zhao, Z.; Su, S.; Si, N.; Hu, S.; Wang, Y.; Xu, J.; Jiang, L.; Chen, G.; Xiang, J. Exergy analysis of the turbine system in a 1000 MW double reheat ultra-supercritical power plant. Energy 2017, 119, 540–548. [Google Scholar] [CrossRef]

- Tsatsaronis, G. Thermodynamic Optimization of Complex Energy Systems. In Thermodynamic Optimization of Complex Energy Systems; Bejan, A., Mamut, E., Eds.; Springer: Amsterdam, The Netherlands, 1999; pp. 93–100. [Google Scholar]

- Tsatsaronis, G.; Winhold, M. Exergoeconomic analysis and evaluation of energy-conversion plants—I. Analysis of a coal-fired steam power plant. Energy 1985, 10, 81–94. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Winhold, M. Exergoeconomic analysis and evaluation of energy-conversion plants—II. A new general methodology. Energy 1985, 10, 69–80. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Pisa, J. Exergoeconomic evaluation and optimization of energy systems—Application to the CGAM problem. Energy 1994, 19, 287–321. [Google Scholar] [CrossRef]

- Tsatsaronis, G. Thermoeconomic analysis and optimization of energy systems. Prog. Energy Combust. Sci. 1993, 19, 227–257. [Google Scholar] [CrossRef]

- Lazzaretto, A.; Tsatsaronis, G. On the calculation of efficiencies and costs in thermal systems. In Proceedings of the ASME Advanced Energy Systems Division 1999, Nashville, TN, USA, 14–19 November 1999; American Society of Mechanical Engineers: New York, NY, USA, 1999; Volume 39, pp. 421–430. [Google Scholar]

- Lazzaretto, A.; Tsatsaronis, G. On the quest for objective equations in exergy costing. In Proceedings of the ASME Advanced Energy Systems Division 1997, Dallas, TX, USA, 16–21 November 1997; American Society of Mechanical Engineers: New York, NY, USA, 1997; Volume 37, pp. 197–210. [Google Scholar]

- Valero, A.; Lozano, M.; Muñoz, M. A general theory of exergy saving. III. Energy savings and thermodynamics. In Computer-Aided Engineering and Energy Systems Second Law Analysis and Modelling; Gaggioli, R., Ed.; American Society of Mechanical Engineers: New York, NY, USA, 1986; Volume 3, pp. 16–21. [Google Scholar]

- Valero, A.; Lozano, M.; Muñoz, M. A general theory of exergy saving. II. On the thermodynamic cost. In Computer-Aided Engineering and Energy Systems Second Law Analysis and Modelling; Gaggioli, R., Ed.; American Society of Mechanical Engineers: New York, NY, USA, 1986; Volume 3, pp. 9–15. [Google Scholar]

- Valero, A.; Lozano, M.; Muñoz, M. A general theory of exergy saving. I. On the exergetic cost. In Computer-Aided Engineering and Energy Systems Second Law Analysis and Modelling; Gaggioli, R., Ed.; American Society of Mechanical Engineers: New York, NY, USA, 1986; Volume 3, pp. 1–8. [Google Scholar]

- Valero, A.; Torres, C. Algebraic thermodynamic analysis of energy systems. In Proceedings of the Approaches to the Design and Optimization of Thermal Systems AES; American Society of Mechanical Engineers: New York, NY, USA, 1988; Volume 7, pp. 13–23. [Google Scholar]

- Valero, A.; Lozano, M.A.; Serra, L.; Torres, C. Application of the exergetic cost theory to the CGAM problem. Energy 1994, 19, 365–381. [Google Scholar] [CrossRef]

- Lozano, M.A.; Valero, A. Theory of the exergetic cost. Energy 1993, 18, 939–960. [Google Scholar] [CrossRef]

- Frangopoulos, C.A. Application of the thermoeconomic functional approach to the CGAM problem. Energy 1994, 19, 323–342. [Google Scholar] [CrossRef]

- Frangopoulos, C.A. Optimal Synthesis and Operation of Thermal Systems by the Thermoeconomic Functional Approach. ASME J. Eng. Gas Turb. Power 1992, 114, 707–714. [Google Scholar] [CrossRef]

- Frangopoulos, C.A. Functional decomposition for optimal design of complex thermal systems. Energy 1988, 13, 239–244. [Google Scholar] [CrossRef]

- Frangopoulos, C.A. Thermoeconomic Functional Analysis: A Method for Optimal Design or Improvement of Complex Thermal Systems; Georgia Institute of Technology: Atlanta, GA, USA, 1983. [Google Scholar]

- Von Spakovsky, M.R. A Practical Generalized Analysis Approach to the Optimal Thermoeconomic Design and Improvement of Real-World Thermal Systems; Georgia Institute of Technology: Atlanta, GA, USA, 1986. [Google Scholar]

- Von Spakovsky, M.R.; Evans, R.B. The Design and Performance Optimization of Thermal Systems. ASME J. Eng. Gas Turb. Power 1990, 112, 86–93. [Google Scholar] [CrossRef]

- Von Spakovsky, M.R. Application of engineering functional analysis to the analysis and optimization of the CGAM problem. Energy 1994, 19, 343–364. [Google Scholar] [CrossRef]

- Gaggioli, R.A.; El-Sayed, Y.M. A critical review of second law costing method--II: Calculus procedures. ASME J. Energy Resour. Technol. 1989, 111, 8–15. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Lin, L.; Pisa, J. Exergy Costing in Exergoeconomics. ASME J. Energy Resour. Technol. 1993, 115, 9–16. [Google Scholar] [CrossRef]

- Lazzaretto, A.; Tsatsaronis, G. SPECO: A systematic and general methodology for calculating efficiencies and costs in thermal systems. Energy 2006, 31, 1257–1289. [Google Scholar] [CrossRef]

- Kanoglu, M.; Ayanoglu, A.; Abusoglu, A. Exergoeconomic assessment of a geothermal assisted high temperature steam electrolysis system. Energy 2011, 36, 4422–4433. [Google Scholar] [CrossRef]

- Kalinci, Y.; Hepbasli, A.; Dincer, I. Exergoeconomic analysis of hydrogen production from plasma gasification of sewage sludge using specific exergy cost method. Int. J. Hydrogen Energy 2011, 36, 11408–11417. [Google Scholar] [CrossRef]

- Al-Sulaiman, F.A.; Dincer, I.; Hamdullahpur, F. Thermoeconomic optimization of three trigeneration systems using organic Rankine cycles: Part I--Formulations. Energy Convers. Manag. 2013, 69, 199–208. [Google Scholar] [CrossRef]

- Alkan, M.A.; Keçebaş, A.; Yamankaradeniz, N. Exergoeconomic analysis of a district heating system for geothermal energy using specific exergy cost method. Energy 2013, 60, 426–434. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Moran, M.J. Exergy-aided cost minimization. Energy Convers. Manag. 1997, 38, 1535–1542. [Google Scholar] [CrossRef]

- Cziesla, F.; Tsatsaronis, G. Iterative exergoeconomic evaluation and improvement of thermal power plants using fuzzy inference systems. Energy Convers. Manag. 2002, 43, 1537–1548. [Google Scholar] [CrossRef]

- Seyyedi, S.M.; Ajam, H.; Farahat, S. A new approach for optimization of thermal power plant based on the exergoeconomic analysis and structural optimization method: Application to the CGAM problem. Energy Convers. Manag. 2010, 51, 2202–2211. [Google Scholar] [CrossRef]

- Frangopoulos, C.A. Intelligent functional approach: A method for analysis and optimal synthesis-design-operation of complex systems. Int. J. Energy Environ. Econ. 1991, 4, 267–274. [Google Scholar]

- Hua, B.; Yin, Q.; Wu, G. Energy optimization through exergy-economic evaluation. ASME J. Energy Resour. Technol. 1989, 111, 148–153. [Google Scholar] [CrossRef]

- Hua, B.; Chen, Q.L.; Wang, P. A new exergoeconomic approach for analysis and optimization of energy systems. Energy 1997, 22, 1071–1078. [Google Scholar] [CrossRef]

- Valero, A.; Serra, L.; Lozano, M.A. Structural Theory of Thermoeconomics; ASME: New York, NY, USA, 1993; Volume 30, pp. 189–198. [Google Scholar]

- Torres, C.; Valero, A.; Rangel, V.; Zaleta, A. On the cost formation process of the residues. Energy 2008, 33, 144–152. [Google Scholar] [CrossRef]

- Seyyedi, S.M.; Ajam, H.; Farahat, S. A new criterion for the allocation of residues cost in exergoeconomic analysis of energy systems. Energy 2010, 35, 3474–3482. [Google Scholar] [CrossRef]

- Piacentino, A.; Cardona, E. Scope-Oriented Thermoeconomic analysis of energy systems. Part II: Formation Structure of Optimality for robust design. Appl. Energy 2010, 87, 957–970. [Google Scholar] [CrossRef]

- Piacentino, A.; Cardona, F. Scope-Oriented Thermoeconomic analysis of energy systems. Part I: Looking for a non-postulated cost accounting for the dissipative devices of a vapour compression chiller. Is it feasible? Appl. Energy 2010, 87, 943–956. [Google Scholar] [CrossRef]

- Banerjee, A.; Tierney, M.J.; Thorpe, R.N. Thermoeconomics, cost benefit analysis, and a novel way of dealing with revenue generating dissipative units applied to candidate decentralised energy systems for Indian rural villages. Energy 2012, 43, 477–488. [Google Scholar] [CrossRef]

- Paulus, D.M.; Tsatsaronis, G. Auxiliary equations for the determination of specific exergy revenues. Energy 2006, 31, 3235–3247. [Google Scholar] [CrossRef]

- Cardona, E.; Piacentino, A. A new approach to exergoeconomic analysis and design of variable demand energy systems. Energy 2006, 31, 490–515. [Google Scholar] [CrossRef]

- Kelly, S. Energy Systems Improvement based on Endogenous and Exogenous Exergy Destruction; Technische Universit at Berlin: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Kelly, S.; Tsatsaronis, G.; Morosuk, T. Advanced exergetic analysis: Approaches for splitting the exergy destruction into endogenous and exogenous parts. Energy 2009, 34, 384–391. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Morosuk, T. A General Exergy-Based Method for Combining a Cost Analysis with an Environmental Impact Analysis: Part I--Theoretical Development. ASME Conf. Proc. 2008, 2008, 453–462. [Google Scholar]

- Gaggioli, R.; Reini, M. Panel I: Connecting 2nd Law Analysis with Economics, Ecology and Energy Policy. Entropy 2014, 16, 3903–3938. [Google Scholar] [CrossRef]

- Rashidi, J.; Yoo, C.K. Exergetic and exergoeconomic studies of two highly efficient power-cooling cogeneration systems based on the Kalina and absorption refrigeration cycles. Appl. Therm. Eng. 2017, 124, 1023–1037. [Google Scholar] [CrossRef]

- Sahin, A.Z.; Al-Sharafi, A.; Yilbas, B.S.; Khaliq, A. Overall performance assessment of a combined cycle power plant: An exergo-economic analysis. Energy Convers. Manag. 2016, 116, 91–100. [Google Scholar] [CrossRef]

- Ahmadzadeh, A.; Salimpour, M.R.; Sedaghat, A. Thermal and exergoeconomic analysis of a novel solar driven combined power and ejector refrigeration (CPER) system. Int. J. Refrig. 2017, 83, 143–156. [Google Scholar] [CrossRef]

- Baghsheikhi, M.; Sayyaadi, H. Real-time exergoeconomic optimization of a steam power plant using a soft computing-fuzzy inference system. Energy 2016, 114, 868–884. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Dong, C.; Yang, Z.; Xu, G.; Wu, L. Exergoeconomic Evaluation of a Modern Ultra-Supercritical Power Plant. Energies 2012, 5, 3381–3397. [Google Scholar] [CrossRef]

- Cziesla, F.; Tsatsaronis, G.; Gao, Z. Avoidable thermodynamic inefficiencies and costs in an externally fired combined cycle power plant. Energy 2006, 31, 1472–1489. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, L.; Dong, C.; Xu, G.; Morosuk, T.; Tsatsaronis, G. Comprehensive exergy-based evaluation and parametric study of a coal-fired ultra-supercritical power plant. Appl. Energy 2013, 112, 1087–1099. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Park, M.-H. On avoidable and unavoidable exergy destructions and investment costs in thermal systems. Energy Convers. Manag. 2002, 43, 1259–1270. [Google Scholar] [CrossRef]

- Morosuk, T.; Tsatsaronis, G. Advanced exergy analysis for chemically reacting systems—Application to a simple open gas-turbine system. Int. J. Thermophys. 2009, 12, 105–111. [Google Scholar]

- Morosuk, T.; Tsatsaronis, G. Advanced exergetic evaluation of refrigeration machines using different working fluids. Energy 2009, 34, 2248–2258. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Morosuk, T. Advanced exergetic analysis of a novel system for generating electricity and vaporizing liquefied natural gas. Energy 2010, 35, 820–829. [Google Scholar] [CrossRef]

- Petrakopoulou, F.; Tsatsaronis, G.; Morosuk, T.; Carassai, A. Advanced Exergoeconomic Analysis Applied to a Complex Energy Conversion System. ASME J. Eng. Gas Turb. Power 2011, 134, 243–250. [Google Scholar]

- Morosuk, T.; Tsatsaronis, G. Exergoeconomic evaluation of refrigeration machines based on avoidable endogenous and exogenous costs. In Proceedings of the 20th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Padova, Italy, 25–28 June 2007; pp. 1459–1467. [Google Scholar]

- Morosuk, T.; Tsatsaronis, G. A new approach to the exergy analysis of absorption refrigeration machines. Energy 2008, 33, 890–907. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Kelly, S.O.; Morosuk, T.V. Endogenous and exogenous exergy destruction in thermal systems. In Proceedings of the ASME 2006 International Mechanical Engineering Congress and Exposition, Chicago, IL, USA, 5–10 November 2006; pp. 311–317. [Google Scholar]

- Tsatsaronis, G.; Morosuk, T.; Kelly, S. Approaches for Splitting the Exergy Destruction into Endogenous and Exogenous Parts. In Proceedings of the 5th Workshop Advances in Energy Studies, Porto Venere, Italy, 12–16 September 2006; pp. 12–16. [Google Scholar]

- Penkuhn, M.; Tsatsaronis, G. A decomposition method for the evaluation of component interactions in energy conversion systems for application to advanced exergy-based analyses. Energy 2017, 133, 388–403. [Google Scholar] [CrossRef]

- Sorgenfrei, M. Analysis of IGCC-Based Plants with Carbon Capture for an Efficient and Flexible Electric Power Generation; Technical University of Berlin: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Kaushik, S.C.; Reddy, V.S.; Tyagi, S.K. Energy and exergy analyses of thermal power plants: A review. Renew. Sustain. Energy Rev. 2011, 15, 1857–1872. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhai, R.; Peng, H.; Yang, Y. Exergy destruction analysis of solar tower aided coal-fired power generation system using exergy and advanced exergetic methods. Appl. Therm. Eng. 2016, 108, 339–346. [Google Scholar] [CrossRef]

- Ertesvåg, I.S.; Kvamsdal, H.M.; Bolland, O. Exergy analysis of a gas-turbine combined-cycle power plant with precombustion CO2 capture. Energy 2005, 30, 5–39. [Google Scholar] [CrossRef]

- Reddy, V.S.; Kaushik, S.C.; Tyagi, S.K. Exergetic analysis and performance evaluation of parabolic trough concentrating solar thermal power plant (PTCSTPP). Energy 2012, 39, 258–273. [Google Scholar] [CrossRef]

- Xu, C.; Wang, Z.; Li, X.; Sun, F. Energy and exergy analysis of solar power tower plants. Appl. Therm. Eng. 2011, 31, 3904–3913. [Google Scholar] [CrossRef]

- Hofmann, M.; Tsatsaronis, G. Comparative exergoeconomic assessment of coal-fired power plants – Binary Rankine cycle versus conventional steam cycle. Energy 2018, 142, 168–179. [Google Scholar] [CrossRef]

- Petrakopoulou, F. Comparative Evaluation of Power Plants with CO2 Capture: Thermodynamic, Economic and Environmental Performance; Technical University of Berlin: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Petrakopoulou, F.; Boyano, A.; Cabrera, M.; Tsatsaronis, G. Exergoeconomic and exergoenvironmental analyses of a combined cycle power plant with chemical looping technology. Int. J. Greenh. Gas Control 2011, 5, 475–482. [Google Scholar] [CrossRef]

- Petrakopoulou, F.; Tsatsaronis, G.; Morosuk, T. Advanced Exergoenvironmental Analysis of a Near-Zero Emission Power Plant with Chemical Looping Combustion. Environ. Sci. Technol. 2012, 46, 3001–3007. [Google Scholar] [CrossRef] [PubMed]

- Petrakopoulou, F.; Tsatsaronis, G.; Morosuk, T.; Carassai, A. Conventional and advanced exergetic analyses applied to a combined cycle power plant. Energy 2012, 41, 146–152. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Morosuk, T.; Tsatsaronis, G. Advanced Thermodynamic Analysis and Evaluation of a Supercritical Power Plant. Energies 2012, 5, 1850–1863. [Google Scholar] [CrossRef]

- Wang, L.; Fu, P.; Wang, N.; Morosuk, T.; Yang, Y.; Tsatsaronis, G. Malfunction diagnosis of thermal power plants based on advanced exergy analysis: The case with multiple malfunctions occurring simultaneously. Energy Convers. Manag. 2017, 148, 1453–1467. [Google Scholar] [CrossRef]

- Fu, P.; Wang, N.; Wang, L.; Morosuk, T.; Yang, Y.; Tsatsaronis, G. Performance degradation diagnosis of thermal power plants: A method based on advanced exergy analysis. Energy Convers. Manag. 2016, 130, 219–229. [Google Scholar] [CrossRef]

- Açıkkalp, E.; Aras, H.; Hepbasli, A. Advanced exergy analysis of an electricity-generating facility using natural gas. Energy Convers. Manag. 2014, 82, 146–153. [Google Scholar] [CrossRef]

- Gökgedik, H.; Yürüsoy, M.; Keçebaş, A. Improvement potential of a real geothermal power plant using advanced exergy analysis. Energy 2016, 112, 254–263. [Google Scholar] [CrossRef]

- Petrakopoulou, F.; Tsatsaronis, G.; Morosuk, T. Evaluation of a power plant with chemical looping combustion using an advanced exergoeconomic analysis. Sustain. Energy Technol. Assess. 2013, 3, 9–16. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Dong, C.; Xu, G. Improvement and primary application of theory of fuel specific consumption. Zhongguo Dianji Gongcheng Xuebao (Proc. Chin. Soc. Electr. Eng.) 2012, 32, 16–21. [Google Scholar]

- Wang, L.; Wu, L.; Xu, G.; Dong, C.; Yang, Y. Calculation and analysis of energy consumption interactions in thermal systems of large-scale coal-fired steam power generation units. Zhongguo Dianji Gongcheng Xuebao (Proc. Chin. Soc. Electr. Eng.) 2012, 32, 9–14. [Google Scholar]

- Manesh, M.K.; Navid, P.; Marigorta, A.B.; Amidpour, M.; Hamedi, M. New procedure for optimal design and evaluation of cogeneration system based on advanced exergoeconomic and exergoenvironmental analyses. Energy 2013, 59, 314–333. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Morosuk, T. Understanding the Formation of Costs and Environmental Impacts Using Exergy-Based Methods. Energy Security and Development; Springer: Berlin/Heidelberg, Germany, 2015; pp. 271–291. [Google Scholar]

- Bolatturk, A.; Coskun, A.; Geredelioglu, C. Thermodynamic and exergoeconomic analysis of Çayırhan thermal power plant. Energy Convers. Manag. 2015, 101, 371–378. [Google Scholar] [CrossRef]

- Frangopoulos, C.A. Methods of energy systems optimization. In Summer school. In Proceedings of the Summer School: Optimization of Energy Systems and Processes, Gliwice, Poland, 24–27 June 2003. [Google Scholar]

- Glover, F.; Kochenberger, G.A. Handbook of Metaheuristics; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Uhlenbruck, S.; Lucas, K. Exergy-Aided Cost Optimization Using Evolutionary Algorithm. Int. J. Appl. Thermodyn. 2000, 3, 121–127. [Google Scholar]

- Nocedal, J.; Wright, S. Numerical Optimization, 2rd ed.; Springer: New York, NY, USA, 2006. [Google Scholar]

- Biegler, L.T.; Grossmann, I.E. Retrospective on optimization. Comput. Chem. Eng. 2004, 28, 1169–1192. [Google Scholar] [CrossRef]

- Grossmann, I.E.; Biegler, L.T. Part II. Future perspective on optimization. Comput. Chem. Eng. 2004, 28, 1193–1218. [Google Scholar] [CrossRef]

- Floudas, C.A.; Gounaris, C.E. A review of recent advances in global optimization. J. Glob. Optim. 2009, 45, 3–38. [Google Scholar] [CrossRef]

- More, J.; Wild, S. Benchmarking Derivative-Free Optimization Algorithms. SIAM J. Optim. 2009, 20, 172–191. [Google Scholar] [CrossRef]

- Rios, L.M.; Sahinidis, N.V. Derivative-free optimization: A review of algorithms and comparison of software implementations. J. Glob. Optim. 2013, 56, 1247–1293. [Google Scholar] [CrossRef]

- Drud, A. CONOPT Documentation; ARKI Consulting and Development A/S: Bagsvaerd, Denmark, 2004. [Google Scholar]

- Nocedal, J.; Wright, S. Conjugate Gradient Methods; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Nesterov, Y.; Nemirovskii, A.; Ye, Y. Interior-Point Polynomial Algorithms in Convex Programming; SIAM: Philadelphia, PA, USA, 1994. [Google Scholar]

- Matthias, K. On the Complexity of Nonlinear Mixed-Integer Optimization; Mixed Integer Nonlinear Programming; Springer: Berlin/Heidelberg, Germany, 2012; pp. 533–557. [Google Scholar]

- Bonami, P.; Kilincc, M.; Linderoth, J. Algorithms and Software for Convex Mixed Integer Nonlinear Programs; Mixed Integer Nonlinear Programming; Springer: Berlin/Heidelberg, Germany, 2012; pp. 1–39. [Google Scholar]

- Grossmann, I.E.; Guillén-Gosálbez, G. Scope for the application of mathematical programming techniques in the synthesis and planning of sustainable processes. Comput. Chem. Eng. 2010, 34, 1365–1376. [Google Scholar] [CrossRef]

- Grossmann, I.; Ruiz, J. Generalized Disjunctive Programming: A Framework for Formulation and Alternative Algorithms for MINLP Optimization. In The IMA Volumes in Mathematics and Its Applications; Lee, J., Leyffer, S., Eds.; Springer: New York, NY, USA, 2012; pp. 93–115. [Google Scholar]

- Grossmann, I.E.; Trespalacios, F. Systematic modeling of discrete-continuous optimization models through generalized disjunctive programming. AIChE J. 2013, 59, 3276–3295. [Google Scholar] [CrossRef]

- Vecchietti, A.; Grossmann, I.E. LOGMIP: A disjunctive 0--1 non-linear optimizer for process system models. Comput. Chem. Eng. 1999, 23, 555–565. [Google Scholar] [CrossRef]

- Voll, P. Automated Optimization-Based Synthesis of Distributed Energy Supply Systems; RWTH Aachen Univeristy: Aachen, Germany, 2014. [Google Scholar]

- Beyer, H.G.; Schwefel, H.P. Evolution strategies—A comprehensive introduction. Nat. Comput. 2002, 1, 3–52. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential evolution--A simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Wagner, W.; Cooper, J.R.; Dittmann, A.; Kijima, J.; Kretzschmar, H.J.; Kruse, A. The IAPWS Industrial Formulation 1997 for the Thermodynamic Properties of Water and Steam. ASME J. Eng. Gas Turb. Power 2000, 122, 150–184. [Google Scholar] [CrossRef]

- Savola, T. Modeling Biomass-Fuelled Small-Scale CHP Plants for Process Synthesis and Optimization; Helsinki University of Technology: Espoo, Finland, 2007. [Google Scholar]

- Angira, R.; Babu, B.V. Optimization of process synthesis and design problems: A modified differential evolution approach. Chem. Eng. Sci. 2006, 61, 4707–4721. [Google Scholar] [CrossRef]

- Luo, X.; Zhang, B.; Chen, Y.; Mo, S. Modeling and optimization of a utility system containing multiple extractions steam turbines. Energy 2011, 36, 3501–3512. [Google Scholar] [CrossRef]

- Manassaldi, J.I.; Mussati, S.F.; Scenna, N.A.J. Optimal synthesis and design of Heat Recovery Steam Generation (HRSG) via mathematical programming. Energy 2011, 36, 475–485. [Google Scholar] [CrossRef]

- Judes, M. MINLP Optimization of Design and Steady-State Operation of Power Plants Considering Several Operating Points; Technical University of Berlin: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- TILMedia Suite. Available online: https://www.tlk-thermo.com/index.php/en/tilmedia-suite (accessed on 26 December 2018).

- Freesteam. Available online: http://freesteam.sourceforge.net/ (accessed on 26 December 2018).

- Pacherneggm, S.J. A Closer Look at the Willans-Line; SAE: Troy, MI, USA, 1969. [Google Scholar]

- Mavromatis, S.P.; Kokossis, A.C. Hardware composites: A new conceptual tool for the analysis and optimisation of steam turbine networks in chemical process industries: Part II: Application to operation and design. Chem. Eng. Sci. 1998, 53, 1435–1461. [Google Scholar] [CrossRef]

- Cooke, D.H. Modeling of Off-Design Multi-Stage Turbine Pressures by Stodola’s Ellipse; Energy Incoportated (PEPSE) User’s Group Meeting: Richmond, VA, USA, 1983. [Google Scholar]

- Paterson, W.R. A replacement for the logarithmic mean. Chem. Eng. Sci. 1984, 39, 1635–1636. [Google Scholar] [CrossRef]

- Drud, A.S. CONOPT—A large-scale GRG code. ORSA J. Comput. 1994, 6, 207–216. [Google Scholar] [CrossRef]

- Fair Isaac Corporation (FICO). XPRESS Optimization Suite: MIP Formulations and Linearizations; Fair Isaac Corporation: San Jose, CA, USA, 2009. [Google Scholar]

- Tomlin, J.A. Special Ordered Sets and an Application to Gas Supply Operations Planning; Mathematical Programming; Springer: Berlin/Heidelberg, Germany, 1988; Volume 42, pp. 69–84. [Google Scholar]

- Tsoukalas, A.; Mitsos, A. Multivariate mccormick relaxations. J. Glob. Optim. 2014, 59, 633–662. [Google Scholar] [CrossRef]

- Haywood, R.W. A generalized analysis of the regenerative steam cycle for a finite number of heaters. Proc. Inst. Mech. Eng. 1949, 161, 157–164. [Google Scholar] [CrossRef]

- Weir, C.D. Optimization of heater enthalpy rises in feed-heating trains. Proc. Inst. Mech. Eng. 1960, 174, 769–796. [Google Scholar] [CrossRef]

- Espatolero, S.; Romeo, L.M.; Cortés, C. Efficiency improvement strategies for the feedwater heaters network designing in supercritical coal-fired power plants. Appl. Therm. Eng. 2014, 73, 449–460. [Google Scholar] [CrossRef]

- Uche, J.; Serra, L.; Valero, A. Thermoeconomic optimization of a dual-purpose power and desalination plant. Desalination 2001, 136, 147–158. [Google Scholar] [CrossRef]

- Xiong, J.; Zhao, H.; Zhang, C.; Zheng, C.; Luh, P.B. Thermoeconomic operation optimization of a coal-fired power plant. Energy 2012, 42, 486–496. [Google Scholar] [CrossRef]

- Conradie, A.; Buys, J.; Kröger, D. Performance optimization of dry-cooling systems for power plants through SQP methods. Appl. Therm. Eng. 1998, 18, 25–45. [Google Scholar] [CrossRef]

- Li, X.; Wang, N.; Wang, L.; Yang, Y.; Maréchal, F. Identification of optimal operating strategy of direct air-cooling condenser for Rankine cycle based power plants. Appl. Energy 2018, 209, 153–166. [Google Scholar] [CrossRef]

- Suresh, M.V.J.J.; Reddy, K.S.; Kolar, A.K. ANN-GA based optimization of a high ash coal-fired supercritical power plant. Appl. Energy 2011, 88, 4867–4873. [Google Scholar] [CrossRef]

- Hajabdollahi, F.; Hajabdollahi, Z.; Hajabdollahi, H. Soft computing based multi-objective optimization of steam cycle power plant using NSGA-II and ANN. Appl. Soft Comput. 2012, 12, 3648–3655. [Google Scholar] [CrossRef]

- Montes, M.J.; Abánades, A.; Martínez-Val, J.M.; Valdés, M. Solar multiple optimization for a solar-only thermal power plant, using oil as heat transfer fluid in the parabolic trough collectors. Sol. Energy 2009, 83, 2165–2176. [Google Scholar] [CrossRef]

- Desai, N.B.; Bandyopadhyay, S. Optimization of concentrating solar thermal power plant based on parabolic trough collector. J. Clean. Prod. 2015, 89, 262–271. [Google Scholar] [CrossRef]

- Biegler, L.T.; Grossmann, I.E.; Westerberg, A.W.; Kravanja, Z. Systematic Methods of Chemical Process Design; Prentice Hall PTR: Upper Saddle River, NJ, USA, 1997. [Google Scholar]

- Westerberg, A.W. A retrospective on design and process synthesis. Comput. Chem. Eng. 2004, 28, 447–458. [Google Scholar] [CrossRef]

- Frangopoulos, C.A.; von Spakovsky, M.R.; Sciubba, E. A Brief Review of Methods for the Design and Synthesis Optimization of Energy Systems. Int. J. Thermodyn. 2002, 5, 151–160. [Google Scholar]

- Kaibel, G.; Schoenmakers, H. Process synthesis and design in industrial practice. Comput. Aid. Chem. Eng. 2002, 10, 9–22. [Google Scholar]

- Li, X.; Kraslawski, A. Conceptual process synthesis: Past and current trends. Chem. Eng. Process. Process Intensif. 2004, 43, 583–594. [Google Scholar] [CrossRef]

- Barnicki, S.D.; Siirola, J.J. Process synthesis prospective. Comput. Chem. Eng. 2004, 28, 441–446. [Google Scholar] [CrossRef]

- Douglas, J.M. A hierarchical decision procedure for process synthesis. AIChE J. 1985, 31, 353–362. [Google Scholar] [CrossRef]

- Jaksland, C.A.; Gani, R.; Lien, K.M. Separation process design and synthesis based on thermodynamic insights. Chem. Eng. Sci. 1995, 50, 511–530. [Google Scholar] [CrossRef]

- Kravanja, Z.; Grossmann, I.E. Multilevel-hierarchical MINLP synthesis of process flowsheets. Comput. Chem. Eng. 1997, 21, S421–S426. [Google Scholar] [CrossRef]

- Douglas, J.M. Conceptual Design of Chemical Processes; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Douglas, J.M. Synthesis of Separation System Flowsheets. AIChE J. 1995, 41, 2522–2536. [Google Scholar] [CrossRef]

- Linnhoff, B. Pinch analysis: A state-of-the-art overview: Techno-economic analysis. Chem. Eng. Res. Des. 1993, 71, 503–522. [Google Scholar]

- Matsuda, K.; Hirochi, Y.; Tatsumi, H.; Shire, T. Applying heat integration total site based pinch technology to a large industrial area in Japan to further improve performance of highly efficient process plants. Energy 2009, 34, 1687–1692. [Google Scholar] [CrossRef]

- Siirola, J.J.; Rudd, D.F. Computer-Aided Synthesis of Chemical Process Designs: From Reaction Path Data to the Process Task Network. Ind. Eng. Chem. Fund. 1971, 10, 353–362. [Google Scholar] [CrossRef]

- Mahalec, V.; Motard, R.L. Procedures for the initial design of chemical processing systems. Comput. Chem. Eng. 1977, 1, 57–68. [Google Scholar] [CrossRef]

- Kirkwood, R.L.; Locke, M.H.; Douglas, J.M. A prototype expert system for synthesizing chemical process flowsheets. Comput. Chem. Eng. 1988, 12, 329–343. [Google Scholar] [CrossRef]

- Sciubba, E. Toward Automatic Process Simulators: Part II--An Expert System for Process Synthesis. ASME J. Eng. Gas Turb. Power 1998, 120, 9–16. [Google Scholar] [CrossRef]

- Manolas, D.A.; Efthimeros, G.A.; Tsahalis, D.T. Development of an Expert System Shell Based on Genetic Algorithms for the Selection of the Energy Best Available Technologies and their Optimal Operating Conditions for the Process Industry. Expert Syst. 2001, 18, 124–130. [Google Scholar] [CrossRef]

- Matelli, J.A.; Bazzo, E.; da Silva, J.C. An expert system prototype for designing natural gas cogeneration plants. Expert Syst. Appl. 2009, 36, 8375–8384. [Google Scholar] [CrossRef]

- Chen, F.; Duic, N.; Manuel Alves, L.; da Graça Carvalho, M. Renewisland--Renewable energy solutions for islands. Renew. Sustain. Energy Rev. 2007, 11, 1888–1902. [Google Scholar] [CrossRef]

- Siirola, J.J. Strategic process synthesis: Advances in the hierarchical approach. Comput. Chem. Eng. 1996, 20 (Suppl. 2), S1637–S1643. [Google Scholar] [CrossRef]

- Surma, J.; Braunschweig, B. Case-base retrieval in process engineering: Supporting design by reusing flowsheets. Eng. Appl. Artif. Intell. 1996, 9, 385–391. [Google Scholar] [CrossRef]

- Duran, M.A.; Grossmann, I.E. An outer-approximation algorithm for a class of mixed-integer nonlinear programs. Math. Program. 1986, 36, 307–339. [Google Scholar] [CrossRef]

- Yee, T.F.; Grossmann, I.E. Simultaneous optimization models for heat integration--II. Heat exchanger network synthesis. Comput. Chem. Eng. 1990, 14, 1165–1184. [Google Scholar] [CrossRef]

- Grossmann, I.E.; Caballero, J.A.; Yeomans, H. Advances in mathematical programming for the synthesis of process systems. Latin Am. Appl. Res. 2000, 30, 263–284. [Google Scholar]

- Westerberg, A.W. Process Engineering. In Perspectives in Chemical Engineering Research and Education; Colton, C.K., Ed.; Academic Press: Cambridge, MA, USA, 1991; pp. 499–523. [Google Scholar]

- Luo, X.; Wen, Q.-Y.; Fieg, G. A hybrid genetic algorithm for synthesis of heat exchanger networks. Comput. Chem. Eng. 2009, 33, 1169–1181. [Google Scholar] [CrossRef]

- Escobar, M.; Trierweiler, J.O.; Grossmann, I.E. A heuristic Lagrangean approach for the synthesis of multiperiod heat exchanger networks. Appl. Therm. Eng. 2014, 63, 177–191. [Google Scholar] [CrossRef]

- Skiborowski, M.; Harwardt, A.; Marquardt, W. Conceptual design of distillation-based hybrid separation processes. Annu. Rev. Chem. Biomol. Eng. 2012, 4, 45–68. [Google Scholar] [CrossRef] [PubMed]

- Ahmetović, E.; Grossmann, I.E. Global superstructure optimization for the design of integrated process water networks. AIChE J. 2011, 57, 434–457. [Google Scholar] [CrossRef]

- Liu, P.; Georgiadis, M.C.; Pistikopoulos, E.N. Advances in energy systems engineering. Ind. Eng. Chem. Res. 2010, 50, 4915–4926. [Google Scholar] [CrossRef]

- Luo, X.; Zhang, B.; Chen, Y.; Mo, S. Operational planning optimization of multiple interconnected steam power plants considering environmental costs. Energy 2012, 37, 549–561. [Google Scholar] [CrossRef]

- Jiang, L.; Lin, R.; Jin, H.; Cai, R.; Liu, Z. Study on thermodynamic characteristic and optimization of steam cycle system in IGCC. Energy Convers. Manag. 2002, 43, 1339–1348. [Google Scholar] [CrossRef]

- Grekas, D.N.; Frangopoulos, C.A. Automatic synthesis of mathematical models using graph theory for optimisation of thermal energy systems. Energy Convers. Manag. 2007, 48, 2818–2826. [Google Scholar] [CrossRef]

- Ahadi-Oskui, T.; Alperin, H.; Nowak, I.; Cziesla, F.; Tsatsaronis, G. A relaxation-based heuristic for the design of cost-effective energy conversion systems. Energy 2006, 31, 1346–1357. [Google Scholar] [CrossRef]

- Ahadi-Oskui, T.; Vigerske, S.; Nowak, I.; Tsatsaronis, G. Optimizing the design of complex energy conversion systems by Branch and Cut. Comput. Chem. Eng. 2010, 34, 1226–1236. [Google Scholar] [CrossRef]

- Friedler, F.; Tarjan, K.; Huang, Y.W.; Fan, L.T. Graph-theoretic approach to process synthesis: Axioms and theorems. Chem. Eng. Sci. 1992, 47, 1973–1988. [Google Scholar] [CrossRef]

- Emmerich, M.; Grötzner, M.; Schütz, M. Design of Graph-Based Evolutionary Algorithms: A Case Study for Chemical Process Networks. Evol. Comput. 2001, 9, 329–354. [Google Scholar] [CrossRef] [PubMed]

- Book, R.V.; Otto, F. String-Rewriting Systems; Springer: Berlin/Heidelberg, Germany, 1993. [Google Scholar]

- Fraga, E.S. A rewriting grammar for heat exchanger network structure evolution with stream splitting. Eng. Optim. 2009, 41, 813–831. [Google Scholar] [CrossRef]

- Lam, H.L.; Klemeš, J.J.; Kravanja, Z.; Varbanov, P.S. Software tools overview: Process integration, modelling and optimisation for energy saving and pollution reduction. Asia-Pac. J. Chem. Eng. 2011, 6, 696–712. [Google Scholar] [CrossRef]

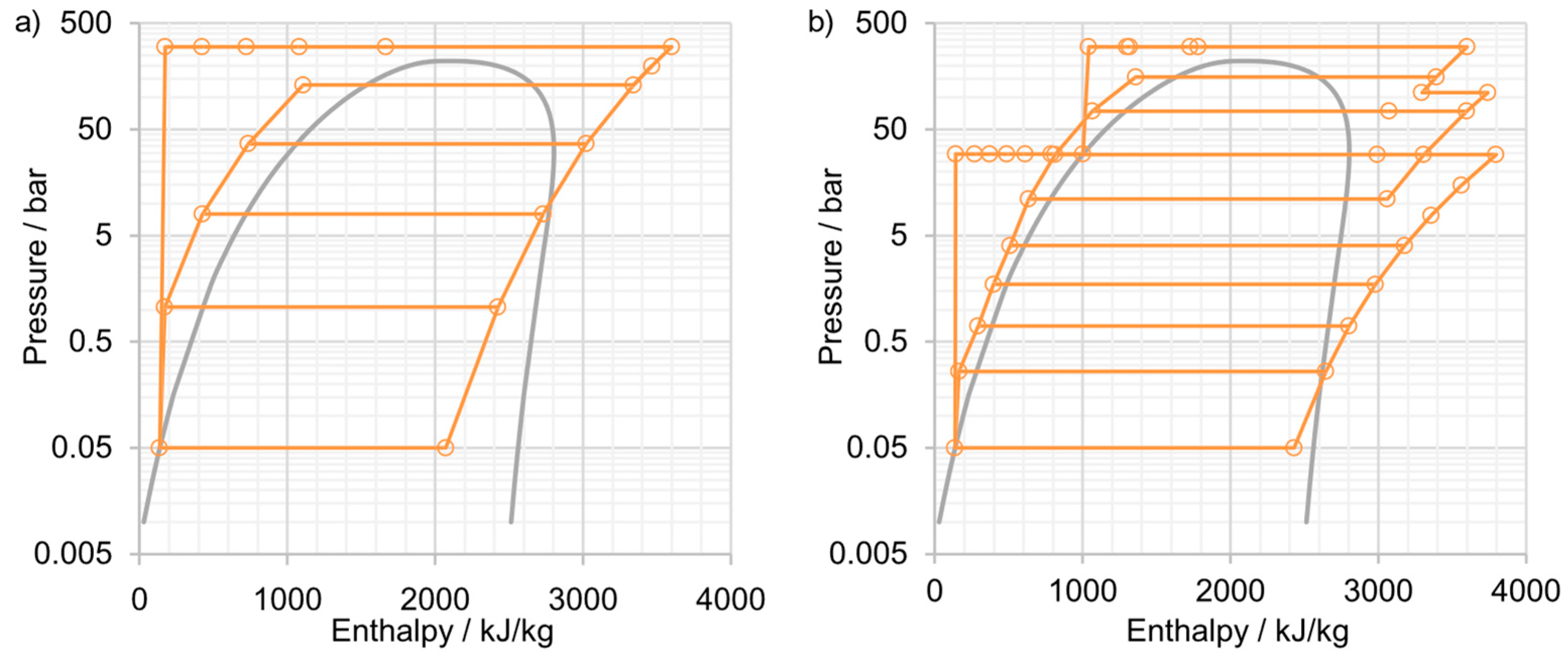

- Wang, L.; Yang, Y.; Dong, C.; Morosuk, T.; Tsatsaronis, G. Systematic Optimization of the Design of Steam Cycles Using MINLP and Differential Evolution. ASME J. Energy Resour. Technol. 2014, 136, 031601. [Google Scholar] [CrossRef]

- Bertok, B.; Barany, M.; Friedler, F. Generating and Analyzing Mathematical Programming Models of Conceptual Process Design by P-graph Software. Ind. Eng. Chem. Res. 2012, 52, 166–171. [Google Scholar] [CrossRef]

- Hostrup, M.; Gani, R.; Kravanja, Z.; Sorsak, A.; Grossmann, I. Integration of thermodynamic insights and MINLP optimization for the synthesis, design and analysis of process flowsheets. Comput. Chem. Eng. 2001, 25, 73–83. [Google Scholar] [CrossRef]

- Fraga, E.S. The generation and use of partial solutions in process synthesis. Chem. Eng. Res. Des. 1998, 76, 45–54. [Google Scholar] [CrossRef]

- Seferlis, P.; Grievink, J. Optimal Design and Sensitivity Analysis of Reactive Distillation Units Using Collocation Models. Ind. Eng. Chem. Res. 2001, 40, 1673–1685. [Google Scholar] [CrossRef]

- Hillermeier, C.; Hüster, S.; Märker, W.; Sturm, T.F. Optimization of Power Plant Design: Stochastic and Adaptive Solution Concepts. In Evolutionary Design and Manufacture; Parmee, I.C., Ed.; Springer: London, UK, 2000; pp. 3–18. [Google Scholar]

- Daichendt, M.M.; Grossmann, I.E. Preliminary screening procedure for the MINLP synthesis of process systems--II. Heat exchanger networks. Comput. Chem. Eng. 1994, 18, 679–709. [Google Scholar] [CrossRef]

- Daichendt, M.M.; Grossmann, I.E. Integration of hierarchical decomposition and mathematical programming for the synthesis of process flowsheets. Comput. Chem. Eng. 1998, 22, 147–175. [Google Scholar] [CrossRef]

- Manninen, J.; Zhu, X.X. Level-by-level flowsheet synthesis methodology for thermal system design. AIChE J. 2001, 47, 142–159. [Google Scholar] [CrossRef]

- Yeomans, H.; Grossmann, I.E. A systematic modeling framework of superstructure optimization in process synthesis. Comput. Chem. Eng. 1999, 23, 709–731. [Google Scholar] [CrossRef]

- Chen, K.; Parmee, I.C.; Gane, C.R. Dual mutation strategies for mixed-integer optimisation in power station design. In Proceedings of the 1997 IEEE International Conference on Evolutionary Computation (ICEC ’97), Indianapolis, IN, USA, 13–16 April 1997; pp. 385–390. [Google Scholar]

- Friedler, F.; Tarjan, K.; Huang, Y.W.; Fan, L.T. Graph-theoretic approach to process synthesis: Polynomial algorithm for maximal structure generation. Comput. Chem. Eng. 1993, 17, 929–942. [Google Scholar] [CrossRef]

- Friedler, F.; Varga, J.B.; Fan, L.T. Decision-mapping: A tool for consistent and complete decisions in process synthesis. Chem. Eng. Sci. 1995, 50, 1755–1768. [Google Scholar] [CrossRef]

- Vance, L.; Cabezas, H.; Heckl, I.; Bertok, B.; Friedler, F. Synthesis of Sustainable Energy Supply Chain by the P-graph Framework. Ind. Eng. Chem. Res. 2012, 52, 266–274. [Google Scholar] [CrossRef]

- Bertok, B.; Kalauz, K.; Sule, Z.; Friedler, F. Combinatorial Algorithm for Synthesizing Redundant Structures to Increase Reliability of Supply Chains: Application to Biodiesel Supply. Ind. Eng. Chem. Res. 2012, 52, 181–186. [Google Scholar] [CrossRef]

- Voll, P.; Klaffke, C.; Hennen, M.; Bardow, A. Automated superstructure-based synthesis and optimization of distributed energy supply systems. Energy 2013, 50, 374–388. [Google Scholar] [CrossRef]

- Martelli, E.; Amaldi, E.; Consonni, S. Numerical optimization of heat recovery steam cycles: Mathematical model, two-stage algorithm and applications. Comput. Chem. Eng. 2011, 35, 2799–2823. [Google Scholar] [CrossRef]

- Bagajewicz, M.J.; Manousiouthakis, V. Mass/heat-exchange network representation of distillation networks. AIChE J. 1992, 38, 1769–1800. [Google Scholar] [CrossRef]

- Papalexandri, K.P.; Pistikopoulos, E.N. Generalized modular representation framework for process synthesis. AIChE J. 1996, 42, 1010–1032. [Google Scholar] [CrossRef]

- Lang, Y.D.; Biegler, L.T. Distributed stream method for tray optimization. AIChE J. 2002, 48, 582–595. [Google Scholar] [CrossRef]

- Stein, O.; Oldenburg, J.; Marquardt, W. Continuous reformulations of discrete-continuous optimization problems. Comput. Chem. Eng. 2004, 28, 1951–1966. [Google Scholar] [CrossRef]

- Urselmann, M.; Barkmann, S.; Sand, G.; Engell, S. A Memetic Algorithm for Global Optimization in Chemical Process Synthesis Problems. IEEE Trans. Evol. Comput. 2011, 15, 659–683. [Google Scholar] [CrossRef]

- Urselmann, M.; Engell, S. Design of memetic algorithms for the efficient optimization of chemical process synthesis problems with structural restrictions. Comput. Chem. Eng. 2015, 72, 87–108. [Google Scholar] [CrossRef]

- Stephanopoulos, G.; Westerberg, A.W. Studies in process synthesis-II: Evolutionary synthesis of optimal process flowsheets. Chem. Eng. Sci. 1976, 31, 195–204. [Google Scholar] [CrossRef]

- Seader, J.D.; Westerberg, A.W. A combined heuristic and evolutionary strategy for synthesis of simple separation sequences. AIChE J. 1977, 23, 951–954. [Google Scholar] [CrossRef]

- Toffolo, A. The synthesis of cost optimal heat exchanger networks with unconstrained topology. Appl. Therm. Eng. 2009, 29, 3518–3528. [Google Scholar] [CrossRef]

- Wright, J.; Zhang, Y.; Angelov, P.; Hanby, V.; Buswell, R. Evolutionary synthesis of HVAC system configurations: Algorithm development. Hvac R Res. 2008, 14, 33–55. [Google Scholar] [CrossRef]

- Toffolo, A. A synthesis/design optimization algorithm for Rankine cycle based energy systems. Energy 2014, 66, 115–127. [Google Scholar] [CrossRef]

- Toffolo, A.; Rech, S.; Lazzaretto, A. Generation of Complex Energy Systems by Combination of Elementary Processes. J. Energy Resour. Technol. 2018, 140, 112005. [Google Scholar] [CrossRef]

- Lazzaretto, A.; Toffolo, A. A method to separate the problem of heat transfer interactions in the synthesis of thermal systems. Energy 2008, 33, 163–170. [Google Scholar] [CrossRef]

- Urselmann, M.; Emmerich, M.T.M.; Till, J.; Sand, G.; Engell, S. Design of problem-specific evolutionary algorithm/mixed-integer programming hybrids: Two-stage stochastic integer programming applied to chemical batch scheduling. Eng. Optim. 2007, 39, 529–549. [Google Scholar] [CrossRef]

- Emmerich, M.T.M. Optimisation of Thermal Power Plant Designs: A Graph-based Adaptive Search Approach. In Adaptive Computing in Design and Manufacture V; Parmee, I.C., Ed.; Springer: London, UK, 2002; pp. 87–98. [Google Scholar]

- Voll, P.; Lampe, M.; Wrobel, G.; Bardow, A. Superstructure-free synthesis and optimization of distributed industrial energy supply systems. Energy 2012, 45, 424–435. [Google Scholar] [CrossRef]

- Wang, L.; Voll, P.; Lampe, M.; Yang, Y.; Bardow, A. Superstructure-free synthesis and optimization of thermal power plants. Energy 2015, 91, 700–711. [Google Scholar] [CrossRef]

- Wang, L.; Lampe, M.; Voll, P.; Yang, Y.; Bardow, A. Multi-objective superstructure-free synthesis and optimization of thermal power plants. Energy 2016, 116, 1104–1116. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Dong, C.; Morosuk, T.; Tsatsaronis, G. Parametric optimization of supercritical coal-fired power plants by MINLP and differential evolution. Energy Convers. Manag. 2014, 85, 828–838. [Google Scholar] [CrossRef]

- Maréchal, F.; Kalitventzeff, B. Targeting the optimal integration of steam networks: Mathematical tools and methodology. Comput. Chem. Eng. 1999, 23, S133–S136. [Google Scholar] [CrossRef]

- Kermani, M.; Wallerand, A.S.; Kantor, I.D.; Maréchal, F. Generic superstructure synthesis of organic Rankine cycles for waste heat recovery in industrial processes. Appl. Energy 2018, 212, 1203–1225. [Google Scholar] [CrossRef]

- Wallerand, A.S.; Kermani, M.; Kantor, I.; Maréchal, F. Optimal heat pump integration in industrial processes. Appl. Energy 2018, 219, 68–92. [Google Scholar] [CrossRef]

- Gassner, M.; Maréchal, F. Thermo-economic optimisation of the polygeneration of synthetic natural gas (SNG), power and heat from lignocellulosic biomass by gasification and methanation. Energy Environ. Sci. 2012, 5, 5768–5789. [Google Scholar] [CrossRef]

- Gassner, M.; Maréchal, F. Methodology for the optimal thermo-economic, multi-objective design of thermochemical fuel production from biomass. Comput. Chem. Eng. 2009, 33, 769–781. [Google Scholar] [CrossRef]

- Wang, L.; Düll, J.; Maréchal, F.; Jan van, H. Trade-off designs and comparative exergy evaluation of solid-oxide electrolyzer based power-to-methane plants. Int. J. Hydrogen Energy 2018. [Google Scholar] [CrossRef]

- Mian, A.; Martelli, E.; Maréchal, F. Framework for the multiperiod sequential synthesis of heat exchanger networks with selection, design, and scheduling of multiple utilities. Ind. Eng. Chem. Res. 2016, 55, 168–186. [Google Scholar] [CrossRef]

- Lazzaretto, A.; Manente, G.; Toffolo, A. SYNTHSEP: A general methodology for the synthesis of energy system configurations beyond superstructures. Energy 2018, 147, 924–949. [Google Scholar] [CrossRef]

- Rangaiah, G.P.; Sharma, S.; Sreepathi, B.K. Multi-objective optimization for the design and operation of energy efficient chemical processes and power generation. Curr. Opin. Chem. Eng. 2015, 10, 49–62. [Google Scholar] [CrossRef]

- Jubril, A.M. A nonlinear weights selection in weighted sum for convex multiobjective optimization. Facta Univ. 2012, 27, 357–372. [Google Scholar]

- Zhang, W.; Reimann, M. A simple augmented ε-constraint method for multi-objective mathematical integer programming problems. Eur. J. Oper. Res. 2014, 234, 15–24. [Google Scholar] [CrossRef]

- Messac, A.; Ismail-Yahaya, A.; Mattson, C.A. The normalized normal constraint method for generating the Pareto frontier. Struct. Multidiscip. Optim. 2003, 25, 86–98. [Google Scholar] [CrossRef]

- Rangaiah, G.P.; Sharma, S. Differential Evolution in Chemical Engineering: Developments and Applications; World Scientific: Singapore, 2017. [Google Scholar]

- Deb, K. Multi-Objective Optimization Using Evolutionary Algorithms; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Coello, C.A.C.; Lamont, G.B.; Van Veldhuizen, D.A. Evolutionary Algorithms for Solving Multi-Objective Problems; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Sharma, S.; Rangaiah, G. Hybrid Approach for Multiobjective Optimization and Its Application to Process Engineering Problems; Applications of Metaheuristics in Process Engineering; Springer: Berlin/Heidelberg, Germany, 2014; pp. 423–444. [Google Scholar]

- Beume, N.; Naujoks, B.; Emmerich, M. SMS-EMOA: Multiobjective selection based on dominated hypervolume. Eur. J. Oper. Res. 2007, 181, 1653–1669. [Google Scholar] [CrossRef]

- Zitzler, E.; Laumanns, M.; Thiele, L. SPEA2: Improving the Strength Pareto Evolutionary Algorithm; TIK-Report 103; ETH Library: Zurich, Switzerland, 2001. [Google Scholar]

- Corne, D.W.; Knowles, J.D.; Oates, M.J. The Pareto envelope-based selection algorithm for multiobjective optimization. In Proceedings of the International Conference on Parallel Problem Solving from Nature, Kraków, Poland, 11–15 September2000; Springer: Berlin/Heidelberg, Germany, 2000; pp. 839–848. [Google Scholar]

- Poloni, C.; Giurgevich, A.; Onesti, L.; Pediroda, V. Hybridization of a multi-objective genetic algorithm, a neural network and a classical optimizer for a complex design problem in fluid dynamics. Comput. Methods Appl. Mech. Eng. 2000, 186, 403–420. [Google Scholar] [CrossRef]

- Van Veldhuizen, D.A.; Lamont, G.B. Multiobjective evolutionary algorithms: Analyzing the state-of-the-art. Evol. Comput. 2000, 8, 125–147. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Pistikopoulos, E.N.; Li, Z. A multi-objective optimization approach to polygeneration energy systems design. AIChE J. 2010, 56, 1218–1234. [Google Scholar] [CrossRef]

- Lazzaretto, A.; Toffolo, A. Energy, economy and environment as objectives in multi-criterion optimization of thermal systems design. Energy 2004, 29, 1139–1157. [Google Scholar] [CrossRef]

- Kavvadias, K.C.; Maroulis, Z.B. Multi-objective optimization of a trigeneration plant. Energy Policy 2010, 38, 945–954. [Google Scholar] [CrossRef]

- Fazlollahi, S.; Mandel, P.; Becker, G.; Marechal, F. Methods for multi-objective investment and operating optimization of complex energy systems. Energy 2012, 45, 12–22. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Dong, C.; Morosuk, T.; Tsatsaronis, G. Multi-objective optimization of coal-fired power plants using differential evolution. Appl. Energy 2014, 115, 254–264. [Google Scholar] [CrossRef]

- Chen, L.; Yan, C.; Liao, Y.; Song, F.; Jia, Z. A hybrid non-dominated sorting genetic algorithm and its application on multi-objective optimal design of nuclear power plant. Ann. Nucl. Energy 2017, 100, 150–159. [Google Scholar] [CrossRef]

- Gimelli, A.; Luongo, A.; Muccillo, M. Efficiency and cost optimization of a regenerative Organic Rankine Cycle power plant through the multi-objective approach. Appl. Therm. Eng. 2017, 114, 601–610. [Google Scholar] [CrossRef]

- Boyaghchi, F.A.; Molaie, H. Advanced exergy and environmental analyses and multi objective optimization of a real combined cycle power plant with supplementary firing using evolutionary algorithm. Energy 2015, 93, 2267–2279. [Google Scholar] [CrossRef]

- Yao, E.; Wang, H.; Wang, L.; Xi, G.; Maréchal, F. Multi-objective optimization and exergoeconomic analysis of a combined cooling, heating and power based compressed air energy storage system. Energy Convers. Manag. 2017, 138, 199–209. [Google Scholar] [CrossRef]

- Yao, E.; Wang, H.; Wang, L.; Xi, G.; Maréchal, F. Thermo-economic optimization of a combined cooling, heating and power system based on small-scale compressed air energy storage. Energy Convers. Manag. 2016, 118, 377–386. [Google Scholar] [CrossRef]

- Barzegar Avval, H.; Ahmadi, P.; Ghaffarizadeh, A.; Saidi, M. Thermo-economic-environmental multiobjective optimization of a gas turbine power plant with preheater using evolutionary algorithm. Int. J. Energy Res. 2011, 35, 389–403. [Google Scholar] [CrossRef]

- Gutiérrez-Arriaga, C.G.; Serna-González, M.; Ponce-Ortega, J.M.; El-Halwagi, M.M. Multi-objective optimization of steam power plants for sustainable generation of electricity. Clean Technol. Environ. Policy 2013, 15, 551–566. [Google Scholar] [CrossRef]

- Hajabdollahi, H.; Ahmadi, P.; Dincer, I. An exergy-based multi-objective optimization of a heat recovery steam generator (HRSG) in a combined cycle power plant (CCPP) using evolutionary algorithm. Int. J. Green Energy 2011, 8, 44–64. [Google Scholar] [CrossRef]

- Li, H.; Marechal, F.; Burer, M.; Favrat, D. Multi-objective optimization of an advanced combined cycle power plant including CO2 separation options. Energy 2006, 31, 3117–3134. [Google Scholar] [CrossRef]

- Sayyaadi, H. Multi-objective approach in thermoenvironomic optimization of a benchmark cogeneration system. Appl. Energy 2009, 86, 867–879. [Google Scholar] [CrossRef]

- González-Bravo, R.; Nápoles-Rivera, F.; Ponce-Ortega, J.M.; El-Halwagi, M.M. Multiobjective Optimization of Dual-Purpose Power Plants and Water Distribution Networks. ACS Sustain. Chem. Eng. 2016, 4, 6852–6866. [Google Scholar] [CrossRef]

- Cooke, D.H. On prediction of off-design multistage turbine pressures by Stodol’s ellipse. ASME J. Eng. Gas Turb. Power 1985, 107, 596–606. [Google Scholar] [CrossRef]

- Rabek, G. Die Ermittlung der Betriebsverhaltnisse von Speisewasservorwarmern bei verschiedenen Belastungen; Energie und Technik: Winterthur, Swizerland, 1963. [Google Scholar]

- Tchanche, B.F.; Lambrinos, G.; Frangoudakis, A.; Papadakis, G. Low-grade heat conversion into power using organic Rankine cycles—A review of various applications. Renew. Sustain. Energy Rev. 2011, 15, 3963–3979. [Google Scholar] [CrossRef]

- Wright, S.A.; Radel, R.F.; Vernon, M.E.; Rochau, G.E.; Pickard, P.S. Operation and Analysis of a Supercritical CO2 Brayton Cycle; Sandia Report, No. SAND2010-0171; Sandia National Laboratories: Livermore, CA, USA, 2010.

- Harkin, T.; Hoadley, A.; Hooper, B. Using multi-objective optimisation in the design of CO2 capture systems for retrofit to coal power stations. Energy 2012, 41, 228–235. [Google Scholar] [CrossRef]

- Samanta, A.; Zhao, A.; Shimizu, G.K.H.; Sarkar, P.; Gupta, R. Post-combustion CO2 capture using solid sorbents: A review. Ind. Eng. Chem. Res. 2011, 51, 1438–1463. [Google Scholar] [CrossRef]

- Jamel, M.S.; Abd Rahman, A.; Shamsuddin, A.H. Advances in the integration of solar thermal energy with conventional and non-conventional power plants. Renew. Sustain. Energy Rev. 2013, 20, 71–81. [Google Scholar] [CrossRef]

- Morandin, M.; Maréchal, F.; Mercangöz, M.; Buchter, F. Conceptual design of a thermo-electrical energy storage system based on heat integration of thermodynamic cycle—Part B: Alternative system configurations. Energy 2012, 45, 386–396. [Google Scholar] [CrossRef]

- Morandin, M.; Maréchal, F.; Mercangöz, M.; Buchter, F. Conceptual design of a thermo-electrical energy storage system based on heat integration of thermodynamic cycles—Part A: Methodology and base case. Energy 2012, 45, 375–385. [Google Scholar] [CrossRef]

| Year | Authors | Applications | Component-Based | Advanced Exergy Analysis | Advanced Exergoeconomic Analysis | Advanced Exergoenvironmental Analysis |

|---|---|---|---|---|---|---|

| 2006–2009 | Morosuk and Tsatsaronis [88,93,94,95], Kelly et al. [76] | Absorption refrigeration machine, gas-turbine power plant | √ | √ | ||

| 2010 | Tsatsaronis [89] | Liquefied natural gas fed cogeneration system | √ | √ | ||

| 2010–2012 | Petrakopoulou et al. [90,103,104,105,106,112] | Power plants with CO2 capture | √ | √ | √ | √ |

| 2013 | Yang et al. [85,107,113,114] | Ultra-supercritical coal-fired power plants | √ | √ | ||

| 2013 | Manesh [115] | Cogeneration system | √ | √ | √ | √ |

| 2014 | Acikkalp et al. [110] | Natural gas fed power-generation facility | √ | √ | ||

| 2015 | Tsatsaronis [116] | Gas-turbine-based cogeneration system | √ | √ | √ | √ |

| 2015 | Bolatturk [117] | Coal-fired power plants | √ | √ | ||

| 2016 | Zhu et al. [98] | Solar tower aided coal-fired power plant | √ | √ | ||

| 2016 | Gökgedik et al. [111] | Degradation analysis of geothermal power plant | √ | √ | ||

| 2017 | Wang and Fu et al. [108,109] | Anomalies diagnosis of thermal power plants | √ | √ |

| Year | Authors | Application | Objective Function | Method |

|---|---|---|---|---|

| 1949, 1960 | Haywood [156] and Weir [157] | Steam cycles | Optimal heat-load distribution of feedwater preheating system | Analytical deductions |

| 1998, 2018 | Conradie et al. [161], Li et al. [162] | Cooling systems for thermal power plant | Cost or net-power increment | SQP algorithms |

| 2014 | Espatolero et al. [158] | Layouts of feedwater preheating and flue-gas heat recovery system | Steam-extraction pressures | SQP algorithms |

| 2001, 2012 | Uche et al. [159] and Xiong et al. [160] | Steam cycles | Local cost optimization | Quadratic programming (QP) approximation |

| 2011, 2012 | Suresh et al. [163] and Hajabdollahi et al. [164] | Coal-fired power plant | Plant efficiency and/or cost | Genetic algorithm and artificial neural network |

| Year | Author | Application | Structural Representation | Platform or Solving Method/Technique | Multi-Level |

|---|---|---|---|---|---|

| 2000 | Hillermeier et al. [213] | Feedwater preheater train | Modified decision tree | Bi-level hierarchical method with SQP; one-level evolutionary optimization | √/× |

| 2007 | Grekas et al. [200] | Gas-fired combined cycle | Graph theory | Object-oriented programming and application programming interface | × |

| 2010 | Ahadi-Oskui et al. [201,202] | Combined-cycle-based cogeneration plant | Directly-coded in GAMS | Outer approximation and branch-and-cut | × |

| 2014 | Wang et al. [208,243] | Coal-fired power plants | Graphical flowsheet | Commercial simulator, differential evolution | × |

| 2018 | Maréchal and Kalitventzeff [244], Kermani et al. [245], Wallerand et al. [246] | (Organic) Rankine cycle, steam network, heat pump network | Algorithmic generation | AMPL, Integer cut | √ |

| Year | Author | Application | Platform or Solving Method/Technique | Multi-Level |

|---|---|---|---|---|

| 2007–present | Toffolo, Lazzaretto, and et al. [233,235,236,251] | Thermal power plant | Genetic algorithm and SQP | √ |

| 2015–present | Wang et al. [241,242] | Thermal power plant | Energy conversion hierarchy | √ |

| Year | Authors | Applications | Objective Functions | MOO Method |

|---|---|---|---|---|

| 2010 | Liu et al. [265] | Methanol/electricity polygeneration plant | NPV, CO2 equivalent | -constraint |

| 2004 | Lazzaretto and Toffolo [266] | Thermal system design | Total cost rate, exergetic efficiency, pollution damage cost | MOEA |

| 2010 | Kavvadias and Maroulis [267] | Trigeneration (electricity, heat, cold) generation system | NPV, primary energy savings ratio, emission reduction ratio | MOEA |

| 2012 | Fazlollahi et al. [268] | Complex energy system | Total cost, CO2 emission | EMOA and -constraint method |

| 2014,2016 | Wang et al. [242,269] | Thermal power plant | Thermal efficiency and cost of electricity | MOEA |

| 2017 | Chen et al. [270] | Nuclear power plant | Primary flow rate, weight | Hybrid NSGA-II |

| 2017 | Gimelli et al. [271] | Organic Rankine cycle power plant | Electric efficiency, overall heat exchangers area | MOGA-II |

| 2015 | Boyaghchi and Molaie [272] | Combined cycle power plant | Total avoidable exergy destruction rate, CO2 emission | NSGA-II |

| 2016,2017 | Yao et al. [273,274] | Combined cooling, heating and power based compressed air energy storage system | Total product unit cost, exergy efficiency | MODE |

| 2011 | Avval et al. [275] | Gas turbine power plant | Exergy efficiency, total cost rate, CO2 emission | NSGA-II |

| 2013 | Gutierrez-Arriaga et al. [276] | Steam power plant | Annual gross profit, GHG emissions | -constraint |

| 2011 | Hajabdollahi et al. [277] | Heat recovery steam generator | Annualized cost per unit of steam, exergy efficiency | NSGA-II |

| 2006 | Li et al. [278] | Combined cycle power plant | Cost of electricity, CO2 emission rate | MOEA |

| 2009 | Sayyaadi et al. [279] | Cogeneration system | Exergetic efficiency, cost rate of products, pollution damage cost | MOEA |

| 2016 | Gonzalez-Bravo et al. [280] | Power plant and water distribution network | Profit, GHG emission | -constraint |

| Terms | Exergy-Based Analysis | Superstructure-Based | Superstructure-Free | |

|---|---|---|---|---|

| Name of the selected method | SPECO and advanced analysis | Steam network in OSMOSE | SYNTHSEP | ECH-based |

| Structure space definition | Specific structure | Superstructure defined by the number of pressure levels | Elementary cycles and number of shared processes | ECH and replacement-insertion rules |

| Structural generation | Fixed structure | Algorithmic, fixed superstructure | Algorithmic, evolutionary | Algorithmic, evolutionary |

| Structural evolution algorithm | - | - | EA (mutation, crossover) | EA (only mutation) |

| Total flowsheet | - | By integrating the synthesis of heat exchanger network | √ | |

| Evaluation of objective function | Simulation & Solving a linear equation set | MILP via AMPL with CPLEX solver | MILP by SQP solver | NLP via GAMS by CONOPT3 solver |

| Num. of meaningless structures? | - | Large | Small | Small |

| (Near-)optimal solution? | × | √ | √ | √ |

| Expert knowledge requirement | √ | × | × | × |

| Multi-objective trade-offs | - | √ | √ | √ |

| Multi-objective selection technique | - | EA | EA | EA |

| Computational effort needed | Small < 1 s for each simulation <10 s for exergoeconomic analysis | Large (hours) | Large (from hours to days) | Enormous (several days for MOO) |

| Flexibility and extensibility | - | High | High | High |

| Target problems | All types | Steam cycle and its integration with all other processes | Thermal cycle | All types after adaption |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Yang, Z.; Sharma, S.; Mian, A.; Lin, T.-E.; Tsatsaronis, G.; Maréchal, F.; Yang, Y. A Review of Evaluation, Optimization and Synthesis of Energy Systems: Methodology and Application to Thermal Power Plants. Energies 2019, 12, 73. https://doi.org/10.3390/en12010073

Wang L, Yang Z, Sharma S, Mian A, Lin T-E, Tsatsaronis G, Maréchal F, Yang Y. A Review of Evaluation, Optimization and Synthesis of Energy Systems: Methodology and Application to Thermal Power Plants. Energies. 2019; 12(1):73. https://doi.org/10.3390/en12010073

Chicago/Turabian StyleWang, Ligang, Zhiping Yang, Shivom Sharma, Alberto Mian, Tzu-En Lin, George Tsatsaronis, François Maréchal, and Yongping Yang. 2019. "A Review of Evaluation, Optimization and Synthesis of Energy Systems: Methodology and Application to Thermal Power Plants" Energies 12, no. 1: 73. https://doi.org/10.3390/en12010073

APA StyleWang, L., Yang, Z., Sharma, S., Mian, A., Lin, T.-E., Tsatsaronis, G., Maréchal, F., & Yang, Y. (2019). A Review of Evaluation, Optimization and Synthesis of Energy Systems: Methodology and Application to Thermal Power Plants. Energies, 12(1), 73. https://doi.org/10.3390/en12010073