Performance Prediction Based on Effects of Wrapping Angle of a Side Channel Pump

Abstract

:1. Introduction

2. Pump Model

3. Numerical Simulations

3.1. Governing Equations

3.2. Turbulence Model

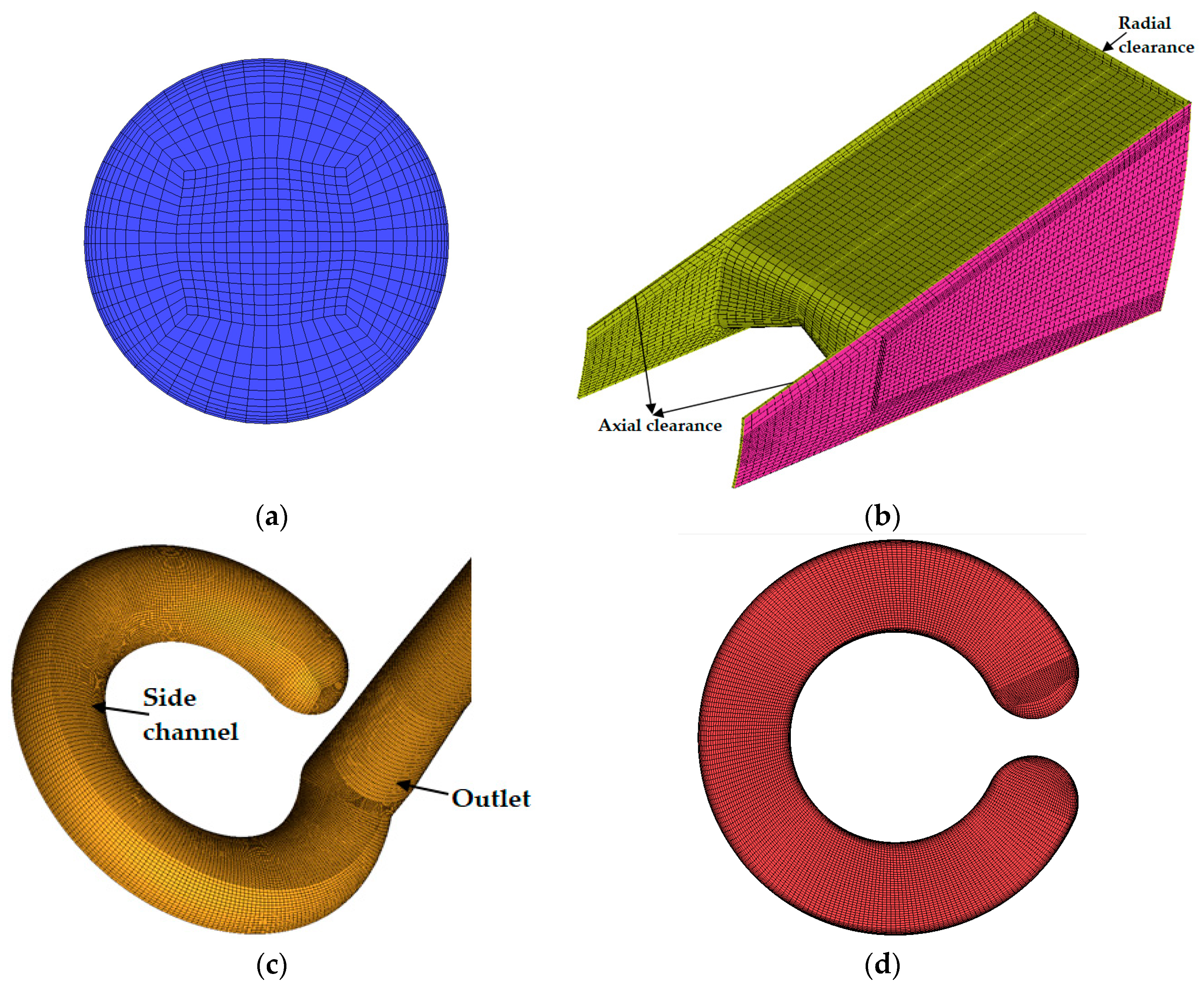

3.3. Grid Generation

3.4. Steady and Unsteady Simulations Step-Up

4. Numerical Results

4.1. Head Fluctuation Curves

4.2. Exchanged Mass Flow

4.3. Pressure Distribution Analysis

4.4. Velocity Distribution Analysis

5. Experimental Apparatus and Validation

5.1. Experimental Apparatus

5.2. Comparison of CFD and Experimental Performances

5.3. Hydraulic Performance under CFD Data

6. Conclusions

- (1)

- The size of wrapping angle has a significant effect on the head performance with a slight increase in the efficiency of the side channel pump. In industrial situations where high heads are required, the size of the wrapping angle can be reduced. Pump case 1 with the smallest wrapping angle records head improvement at all operating conditions compared to case 2 and case 3. Although the size of the wrapping angle slightly affected the efficiency of the side channel pump, case 1 still predicted a marginal increase compared to the other two pump cases at all operating conditions.

- (2)

- The pressure growth in the tangential direction from inflow to the outflow mainly depends on flow exchange times between the impeller and side channel. A small wrapping angle produces stronger static pressure in both the impeller and side channel flow passage than a larger wrapping angle.

- (3)

- The radial vortex flow at the outer radius has negative effects on the pump performance and increases as the size of the wrapping angle increases. Pump case 3 experienced the strongest vortices at the outer radius. Furthermore, the mass flow exchange view shows the energy conversion and zones of irregular flow patterns within the side channel pump. Pump cases 1 and 2 perform better energy conversion whereas pump case 3 has many irregular flow characteristics along the flow passage; thus, the size of the wrapping angle affects the energy conversion in side channel pumps.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| d | diameter of impeller, mm |

| H | head, m |

| P | pressure, Pa |

| Q | flow rate, m3/h |

| ω | angular speed, rad/s |

| n | rotational speed, r/min |

| η | efficiency |

| φ | wrapping angle, deg |

| ρ | density, kg/m3 |

| θ | blade suction angle, deg |

| h | height of the side height, mm |

| b | blade thickness, mm |

| s | axial clearance, mm |

| σ | radial clearance, mm |

| y+ | non-dimensional wall distance |

| t | time, s |

| M | torque, Nm |

| z | height of axial plane in z-direction, m |

| ϕ | angular position, deg |

| g | acceleration due to gravity, m/s2 |

| ψ | head coefficient |

| y+ | non-dimensional wall distance |

| M | torque, Nm |

| k | kinetic energy of turbulence, m2/s2 |

| ϵ | dissipation of kinetic energy of turbulence, m2/s3 |

| ω | specific dissipation of turbulence kinetic energy, s−1 |

| Reynolds-stress tensor | |

| β’ | turbulence-model coefficients |

| μ | dynamic viscosity, Pa.s |

| μt | turbulent viscosity, m2/s |

| σk | turbulence-model coefficients |

| σω | turbulence-model coefficients |

| F1, F2 | blending or auxiliary functions in turbulence model |

| Kronecker delta | |

| auxiliary variable in turbulence model | |

| S | scalar measure of the vorticity tensor |

| Subscript | |

| xi | cartesian coordinates: x, y, z |

| i, j | components in different directions |

| Abbreviations | |

| CFD | computational fluid dynamics |

| SST | shear stress transport |

| URANS | unsteady Reynolds-averaged Navier-Stokes equations |

| BEP | best efficiency point |

References

- Appiah, D.; Zhang, F.; Yuan, S.; Osman, M.K. Effects of the Geometrical Conditions on the Performance of a Side Channel Pump: A review. Int. J. Energy Res. 2018, 42, 416–428. [Google Scholar] [CrossRef]

- Siemen, O.; Hinsch, J. A Circulation Pump Which Acts Partially with Sealing Circling Auxiliary Liquid. Germany Patent 413435, 3 March 1920. [Google Scholar]

- Senoo, Y. Researches on Peripheral Pumps. Rep. Res. Inst. Appl. Mech. 1954, 3, 53–113. [Google Scholar]

- Iverson, H.W. Performance of the Periphery Pump. J. Fluids Eng. Trans. ASME 1955, 77, 19–28. [Google Scholar]

- Engels, H. Investigations of Ring Pumps; Tech Hoch Hannover: Hannover, Germany, 1940. [Google Scholar]

- Wilson, W.A.; Santalo, M.A.; Oelrich, J.A. A Theory of the Fluid Dynamic Mechanism of Regenerative Pumps. J. Fluids Eng. Trans. ASME 1955, 77, 1303–1316. [Google Scholar]

- Grabow, G. Influence of the Number of Vanes and Vane Angle on the Suction Behaviour of Regenerative Pumps. In Proceedings of the 5th Conference on Fluid Machinery, Budapest, Hungary, 15–20 September 1975; Volume 1, pp. 351–364. [Google Scholar]

- Song, J.W.; Engeda, A.; Chung, M.K. A Modified Theory for the Flow Mechanism in a Regenerative Flow Pump. Proc. Inst. Mech. Eng. Part A J. Power Energy 2003, 217, 311–322. [Google Scholar] [CrossRef]

- Quail, F.A. One Dimensional Numerical Model for the Momentum Exchange in Regenerative Pumps. J. Eng. Gas Turbines Power 2011, 133, 093001. [Google Scholar] [CrossRef]

- Yoo, I.; Park, M.; Chung, M. Improved Momentum Exchange Theory for Incompressible Regenerative Turbomachines. Proc. Inst. Mech. Part A J. Power Energy 2005, 219, 567–581. [Google Scholar] [CrossRef]

- Shimosaka, M.; Yamazaki, S. Research on the Characteristics of Regenerative Pump. 1st Report, Influences of Flow Channel and Impeller. Bull. JSME 1960, 3, 185–190. [Google Scholar] [CrossRef]

- Yamazaki, S.; Tomita, Y.; Sasahara, T. Research on the Performance of the Regenerative Pump with Non-Radial Vanes. Bull. JSME 1972, 15, 337–343. [Google Scholar] [CrossRef]

- Badami, M. Theoretical and Experimental Analysis of Traditional and New Periphery Pumps. SAE Tech. Pap. Ser. 1997, 971074. [Google Scholar] [CrossRef]

- Surek, D. Influence of the Blade Geometry on the Characteristic Curve Gradient of Side Channel Machines. Res. Eng. 1998, 64, 173–182. [Google Scholar]

- Choi, W.C.; Yoo, I.S.; Park, M.R.; Chung, M.K. Experimental Study on the Effect of Blade Angle on Regenerative Pump Performance. Proc. Inst. Mech. Eng. Part A J. Power Energy 2013, 227, 585–592. [Google Scholar] [CrossRef]

- Meakhail, T.; Seung, O.P.; Lee, D.A.; Meakhail, S. A study of circulating flow in regenerative pump. In Proceedings of the KSAS 1st International Session, Gyeongju, Korea, 14–15 November 2003; pp. 19–26. [Google Scholar]

- Meakhail, T.; Park, S. An Improved Theory for Regenerative Pump Performance. Proc. Inst. Mech. Part A J. Power Energy 2005, 219, 213–222. [Google Scholar] [CrossRef]

- Shirinov, A.; Oberbeck, S. Optimisation of the High Vacuum Side Channel Pump. In Proceedings of the 7th International Conference on Compressors and their Systems, London, UK, 5–6 September 2011; pp. 5–6. [Google Scholar]

- Bӧhle, M.; Muller, T. Evaluation of the Flow Inside a Side Channel Pump by the Application of an Analytical Model and CFD. In Proceedings of the ASME 2009 Fluids Engineering Division Summer Meeting, Vail, CO, USA, 2–6 August 2009. Paper No. FEDSM2009-78023. [Google Scholar]

- Quail, F.; Scanlon, T.; Stickland, M. Design Optimisation of a Regenerative Pump using Numerical and Experimental Techniques. Int. J. Numer. Methods Heat Fluid Flow 2011, 21, 95–111. [Google Scholar] [CrossRef]

- Fleder, A.; Muller, T.; Bӧhle, M. A Theoretical Method to Improve the Side Channel Pump Efficiency. In Proceedings of the 9th European Conference on Turbomachinery, Istanbul, Turkey, 21–25 March 2011; Volume 1, pp. 711–720. [Google Scholar]

- Fleder, A.; Bӧhle, M. A Study of the Internal Flow Structure in a Side Channel Pump. In Proceedings of the ISROMAC-14, Honolulu, HI, USA, 27 February–2 March 2012. Paper ID 1133. [Google Scholar]

- Fleder, A.; Bӧhle, M. A Systematical Study of the Influence of Blade Length, Blade Width and Side Channel Height on the Performance of a Side Channel Pump. ASME J. Fluid Eng. 2015, 137, 121102. [Google Scholar] [CrossRef]

- Zhang, F.; Fleder, A.; Bӧhle, M.; Yuan, S. Effect of Suction Side Blade Profile on the Performance of a Side Channel Pump. Proc. Inst. Mech. Part A J. Power Energy 2016, 230, 586–597. [Google Scholar] [CrossRef]

- Zhang, F.; Appiah, D.; Yuan, S.; Osman, M.K.; Ke, C. Transient Flow Characterization in Energy Conversion of a Side Channel Pump under Different Blade Suction Angles. Energy 2018, 161, 635–648. [Google Scholar] [CrossRef]

- Senoo, Y. Influences of the Suction Nozzle on the Characteristic of a Peripheral Pump and an Effective Method of their Removal. In Reports of Research Institute for Applied Mechanic; Kyusku University: Fukuoka, Japan, 1954; Volume 3, pp. 129–142. [Google Scholar]

- Sixsmith, H.; Altmann, H. A Regenerative Compressor. Trans. ASME 1977, 99, 637–647. [Google Scholar] [CrossRef]

- Sixsmith, H. The Theory and Design of a Regenerative Compressor. In Vacuum and Ultravacuum: Physics and Technology; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Gao, B.; Du, W.; Yang, L. Influences of volute cross-section area profile on performance of low-specific-speed centrifugal pump. J. Drain Irrigat. Mach. Eng. 2017, 35, 749–754. [Google Scholar]

- Cao, W.; Zhang, Y.; Yao, L. Influence of outlet blade angle on performance of centrifugal pump and correction of slip factor. J. Drain Irrigat. Mach. Eng. 2017, 35, 755–760. [Google Scholar]

- Menter, F.R. Two-Equation Eddy Viscosity Models for Engineering Applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Menter, F. Zonal Two Equation Turbulence Models for Aerodynamic Flows. In Proceedings of the 24th Fluid Dynamics Conference, Orlando, FL, USA, 6–9 July 1993; AIAA Paper. pp. 93–2906. [Google Scholar]

- Wilcox, D. Turbulence Modeling for CFD; DCW Industries Inc.: La Canada, CA, USA, 1993; p. 4. [Google Scholar]

- Wilcox, D. Reassessment of the Scale-Determining Equation for Advanced Turbulence Models. AIAA J. 1988, 26, 1299. [Google Scholar] [CrossRef]

- Celik, I.B.; Ghia, U.; Roache, P.J.; Freitas, C.J.; Coleman, H.; Raad, P.E. Procedure for Estimation and Reporting of Uncertainty due to Discretization in CFD applications. J. Fluids Eng. 2008, 130, 078001. [Google Scholar]

- Gülich, J.F. Centrifugal Pumps; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2008. [Google Scholar]

| Parameter | Value |

|---|---|

| Impeller outer diameter, d2 (mm) | 150 |

| Impeller inner diameter, d1 (mm) | 80 |

| Blade width, w (mm) | 15 |

| Blade thickness, b (mm) | 2 |

| Blade suction angle (°) | 30 |

| Rotational speed, n (r/min) | 1500 |

| Blade number | 24 |

| Radial clearance, σ (mm) | 0.2 |

| Axial clearance, s (mm) | 0.2 |

| Side channel radius, r (mm) | 17.6 |

| Wrapping angle, φ (°) | 15, 30, 45 |

| Grid | Grid Number (×106) | Head (m) | Grid Convergence Index (GCI) (%) |

|---|---|---|---|

| A | 3.7 | 17.0 | 9.8431 |

| B | 4.0 | 17.9 | 8.3531 |

| C | 4.5 | 18.3 | 1.7957 |

| Domain | Grid Number (×106) | Grid Quality Criterion | Ave. y+ | ||

|---|---|---|---|---|---|

| Determinant 3 × 3 × 3 | Angle | Aspect Ratio | |||

| Inlet | 0.1 | 0.60–1 | 46.89–89.64 | 1.27–40.1 | 18.54 |

| Impeller | 3.4 | 0.62–1 | 20.62–87.91 | 1.10–23.0 | 34.28 |

| Side channel | 1.0 | 0.57–1 | 37.78–89.90 | 1.28–42.4 | 43.94 |

| Pump | Mass Flow-In (kg·s−1) | Mass Flow-In (kg·s−1) |

|---|---|---|

| Case 1 | 13.8438 | −11.0998 |

| Case 2 | 13.1637 | −10.3925 |

| Case 3 | 12.4384 | −9.6593 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pei, J.; Zhang, F.; Appiah, D.; Hu, B.; Yuan, S.; Chen, K.; Asomani, S.N. Performance Prediction Based on Effects of Wrapping Angle of a Side Channel Pump. Energies 2019, 12, 139. https://doi.org/10.3390/en12010139

Pei J, Zhang F, Appiah D, Hu B, Yuan S, Chen K, Asomani SN. Performance Prediction Based on Effects of Wrapping Angle of a Side Channel Pump. Energies. 2019; 12(1):139. https://doi.org/10.3390/en12010139

Chicago/Turabian StylePei, Ji, Fan Zhang, Desmond Appiah, Bo Hu, Shouqi Yuan, Ke Chen, and Stephen Ntiri Asomani. 2019. "Performance Prediction Based on Effects of Wrapping Angle of a Side Channel Pump" Energies 12, no. 1: 139. https://doi.org/10.3390/en12010139

APA StylePei, J., Zhang, F., Appiah, D., Hu, B., Yuan, S., Chen, K., & Asomani, S. N. (2019). Performance Prediction Based on Effects of Wrapping Angle of a Side Channel Pump. Energies, 12(1), 139. https://doi.org/10.3390/en12010139