Experimental and Numerical Thermal Analysis of Multi-Layered Microchannel Heat Sink for Concentrating Photovoltaic Application

Abstract

1. Introduction

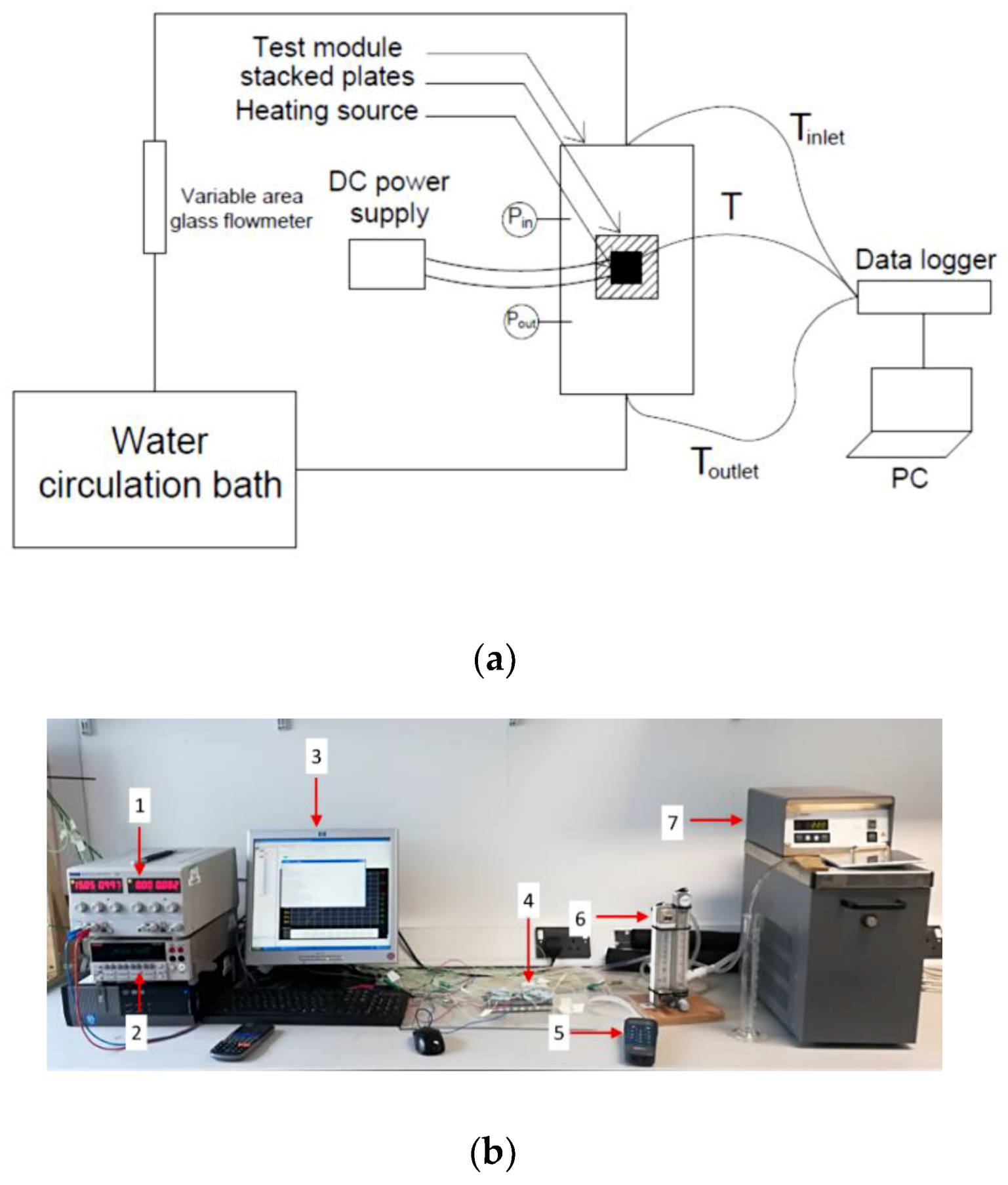

2. Experimental Setup and Procedure

2.1. Test Loop

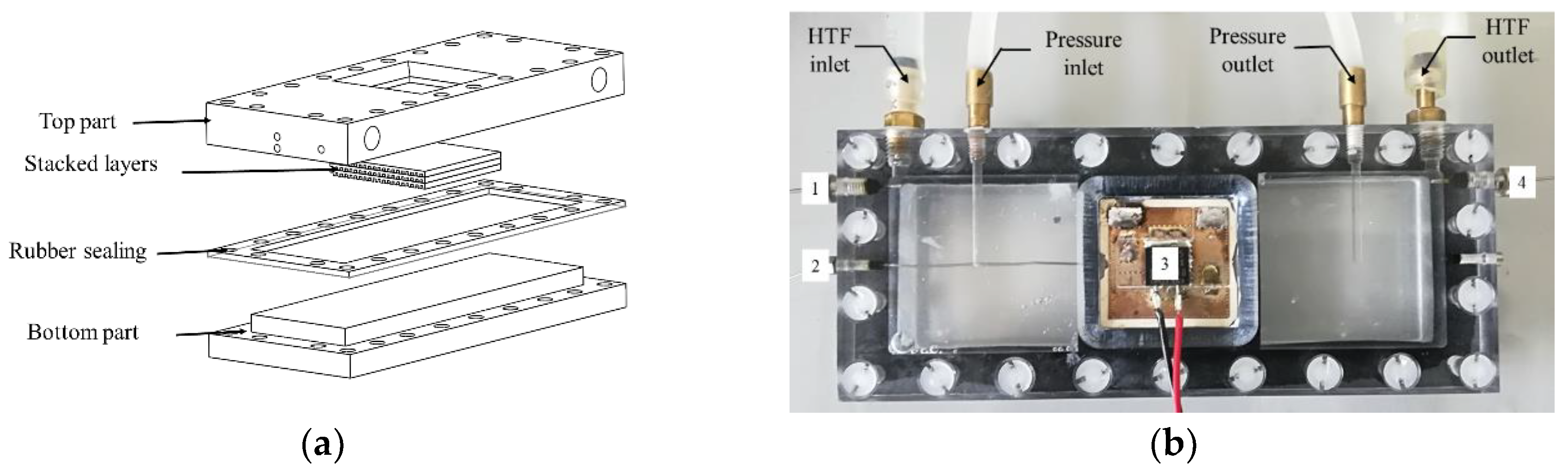

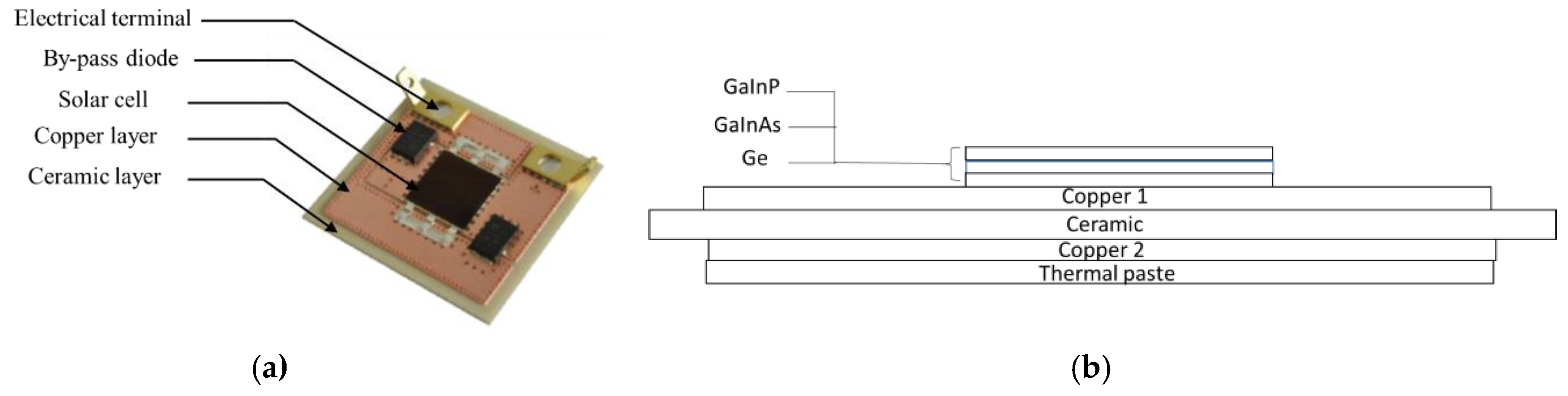

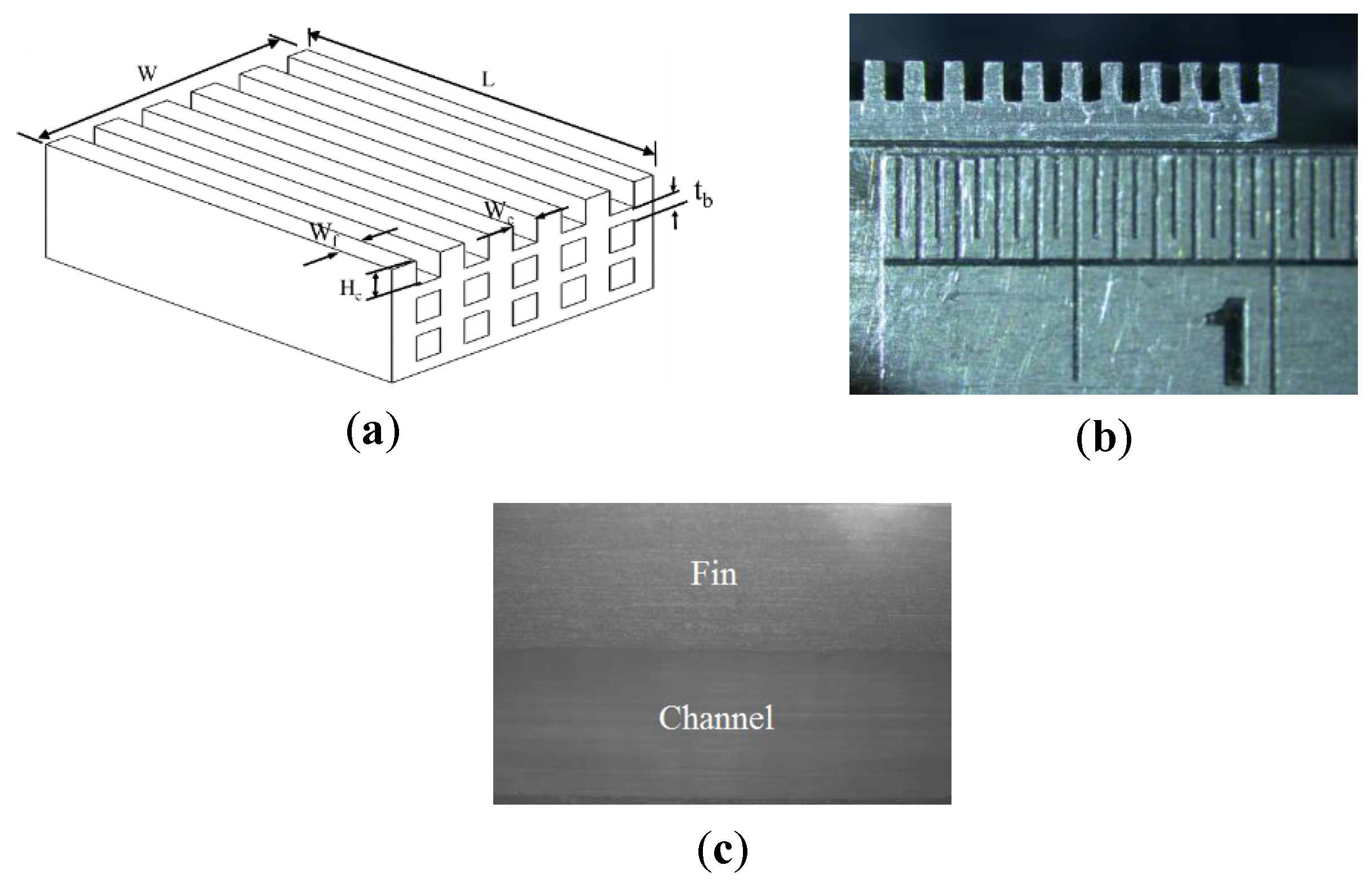

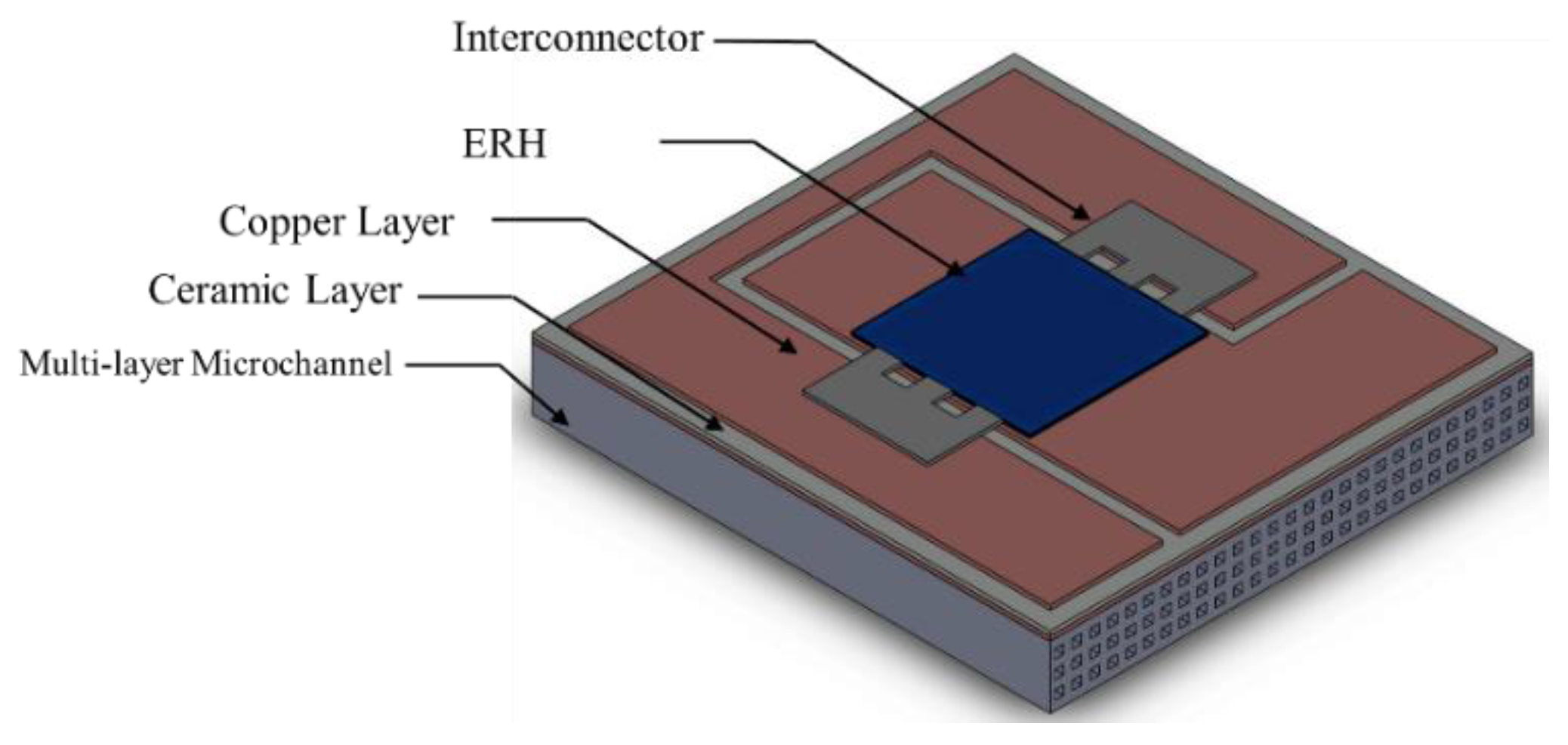

2.2. Test Module

2.3. Test Procedures and Uncertainty Analysis

3. Numerical Study

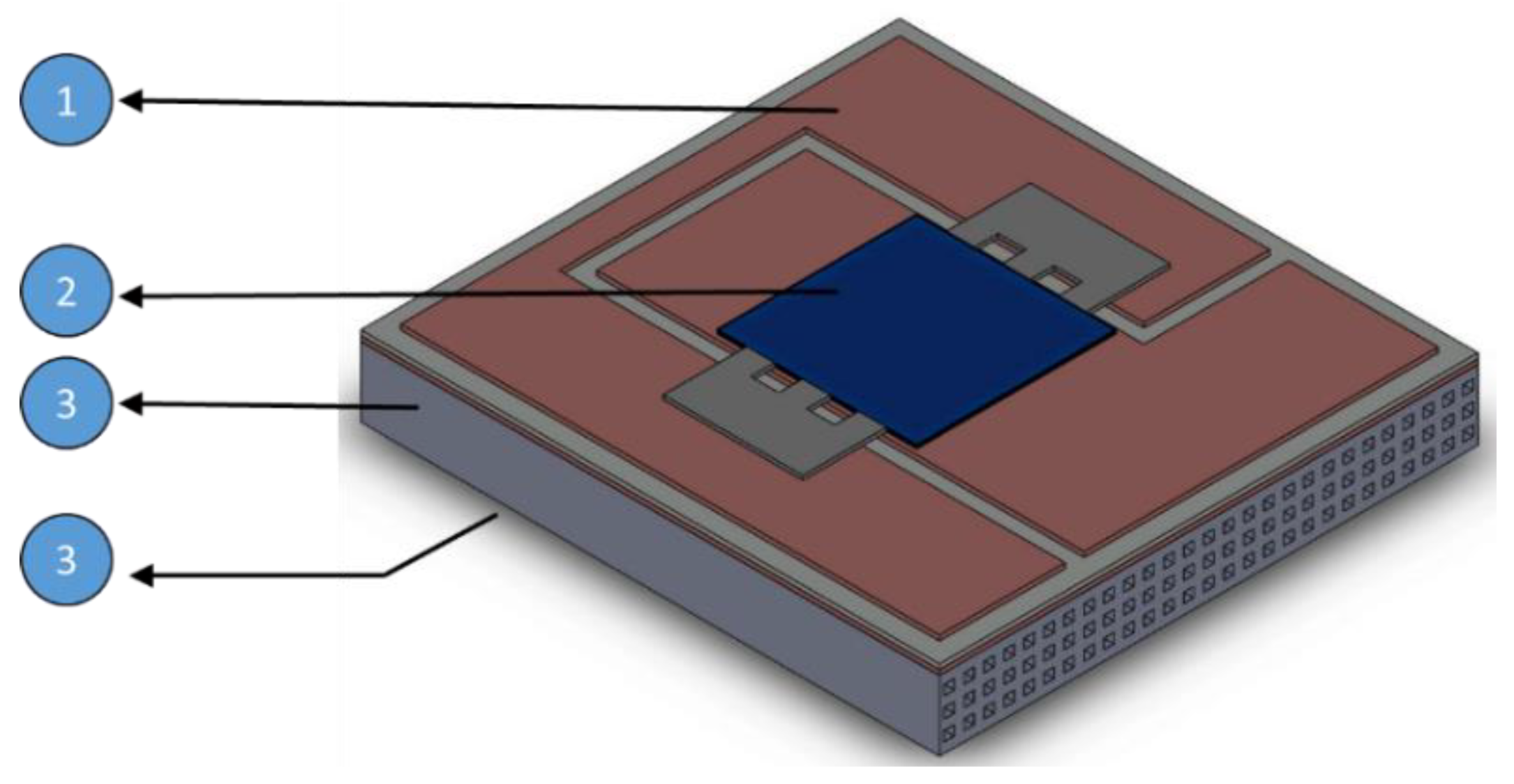

3.1. Model Description and Mathematical Formulation

- The heat source is uniform.

- The ambient temperature is 25 °C.

- HTF varies between 30 and 60 mL/min which corresponds to a low Reynolds numbers. The flow is assumed to be steady, laminar and fully developed in each channel.

3.2. Grid Independence Study

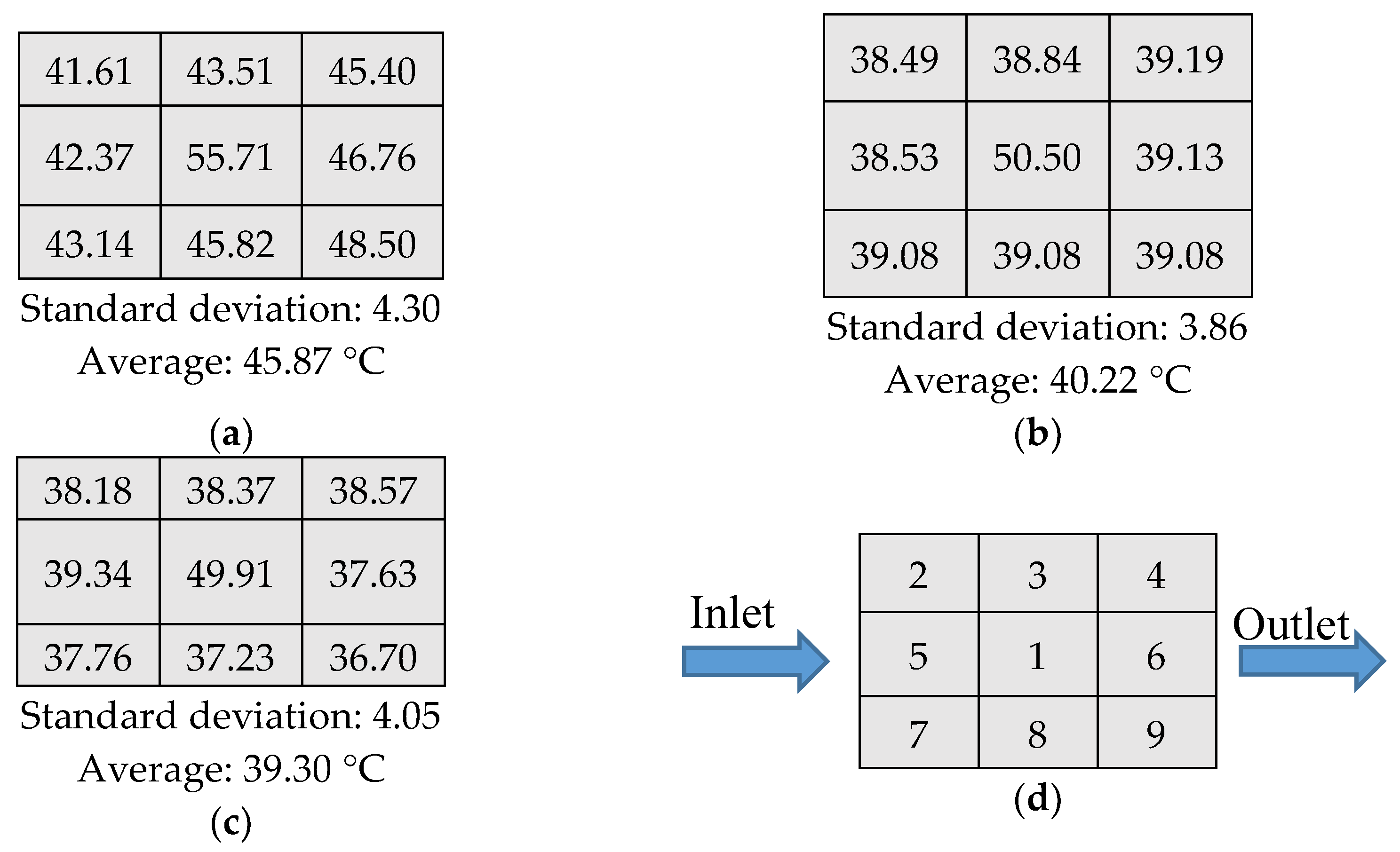

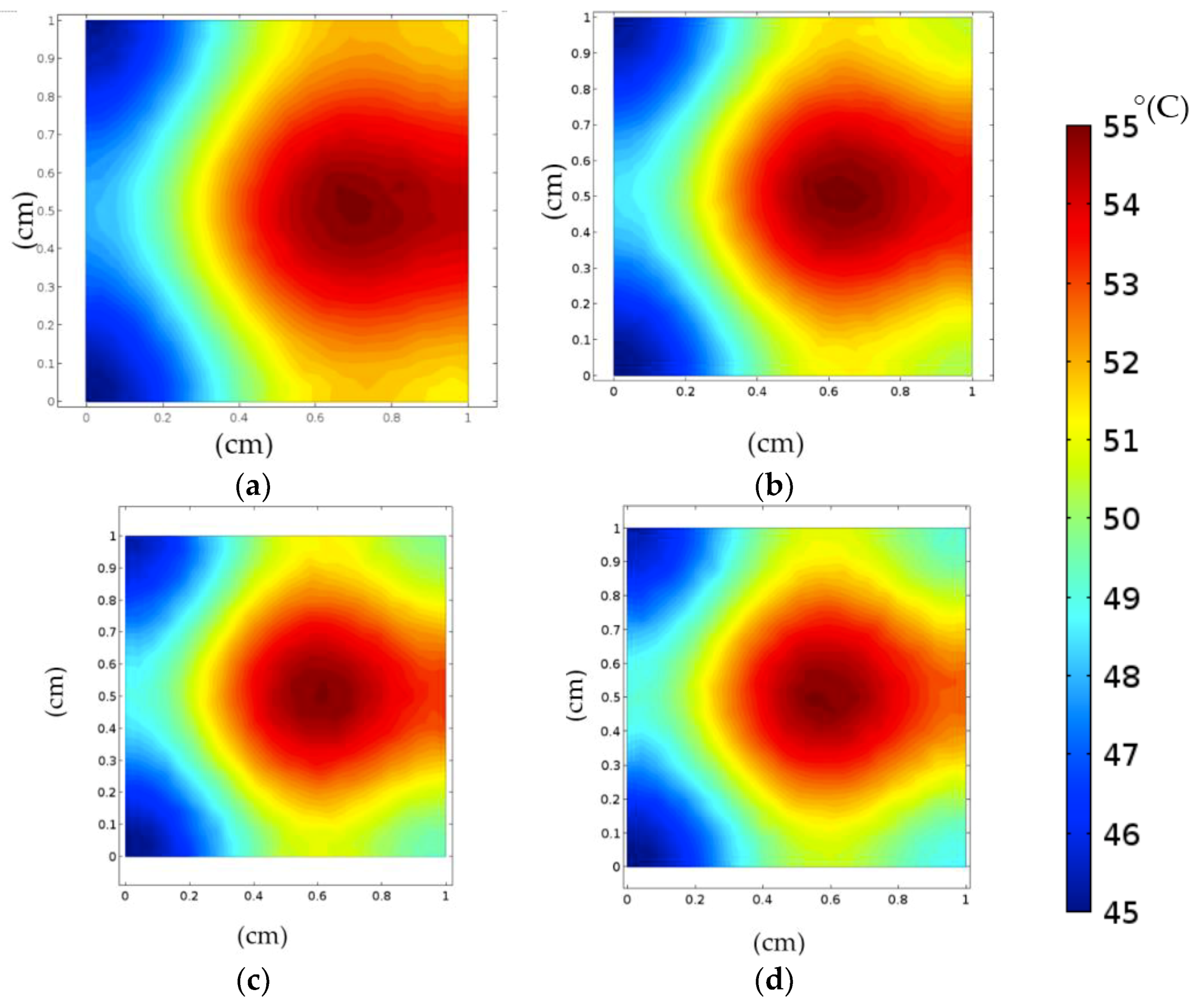

3.3. Model Validation

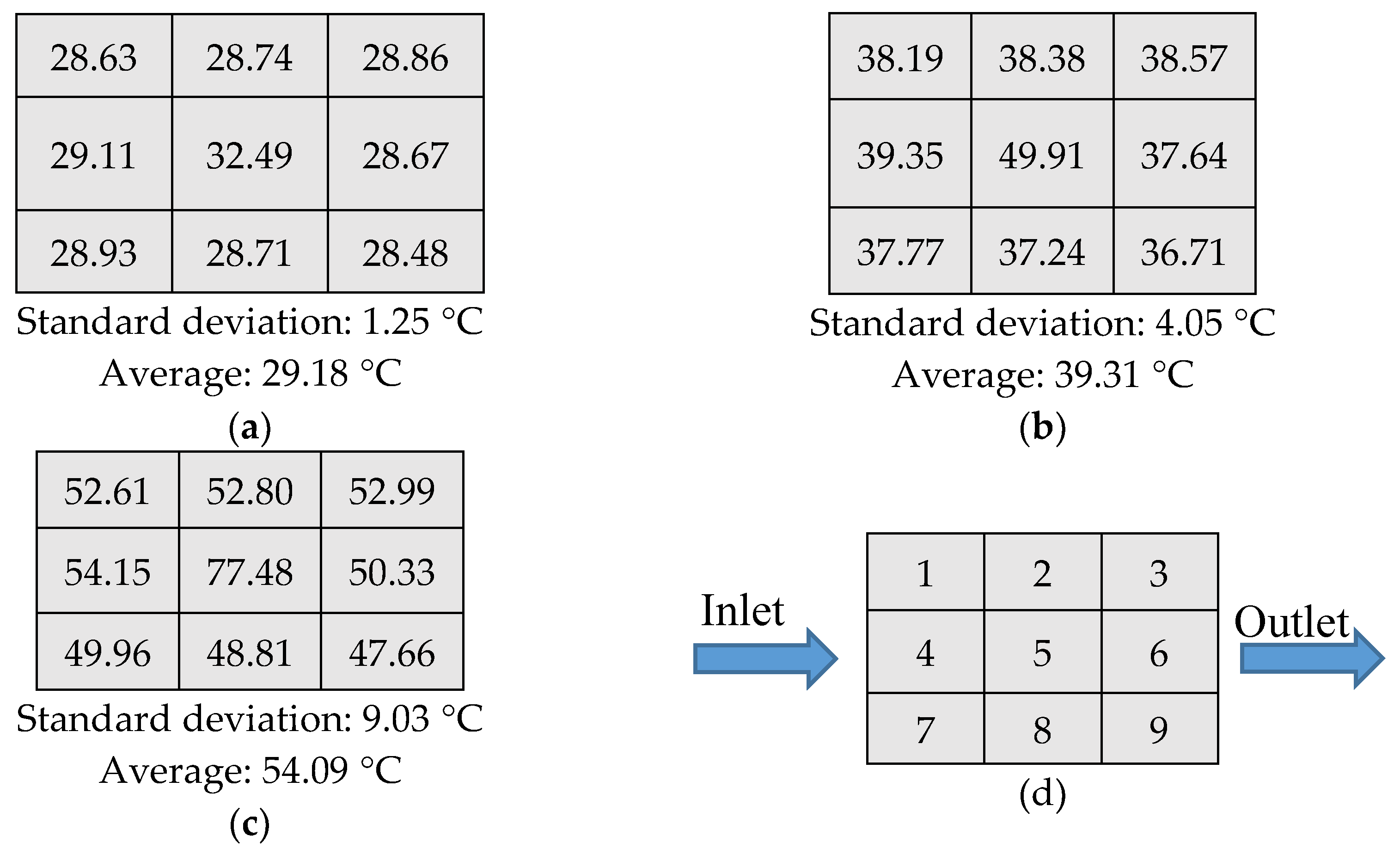

4. Results and Discussion

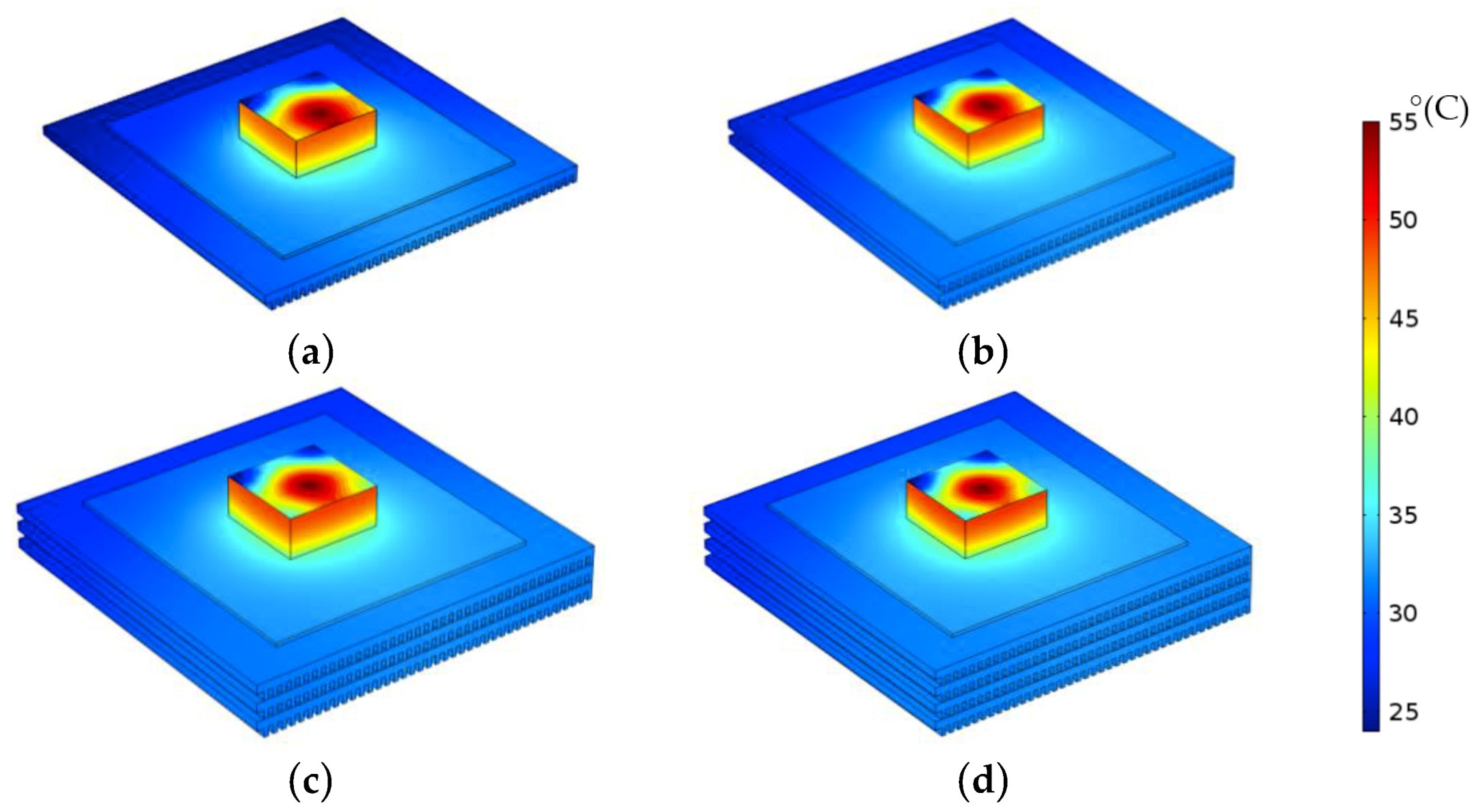

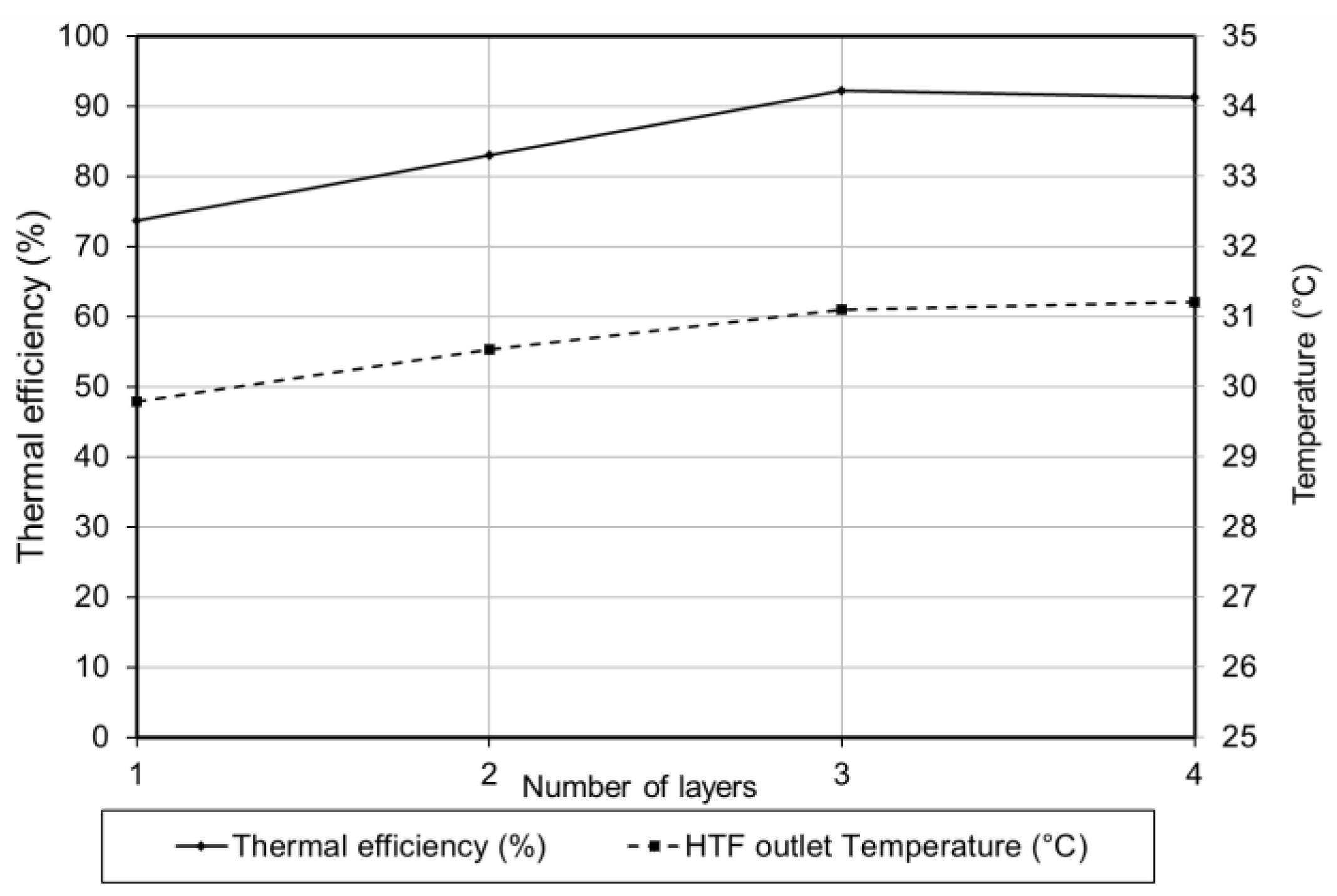

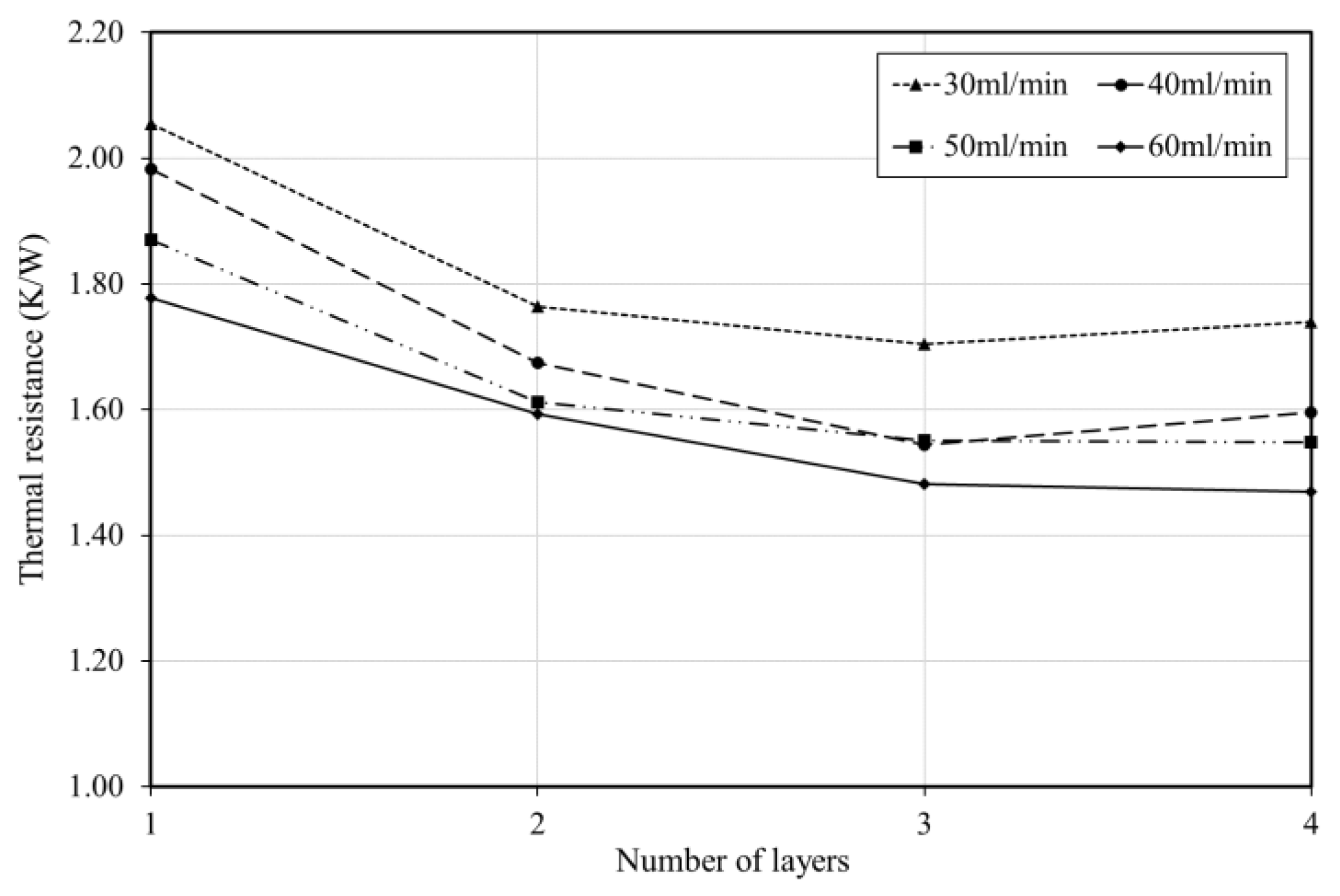

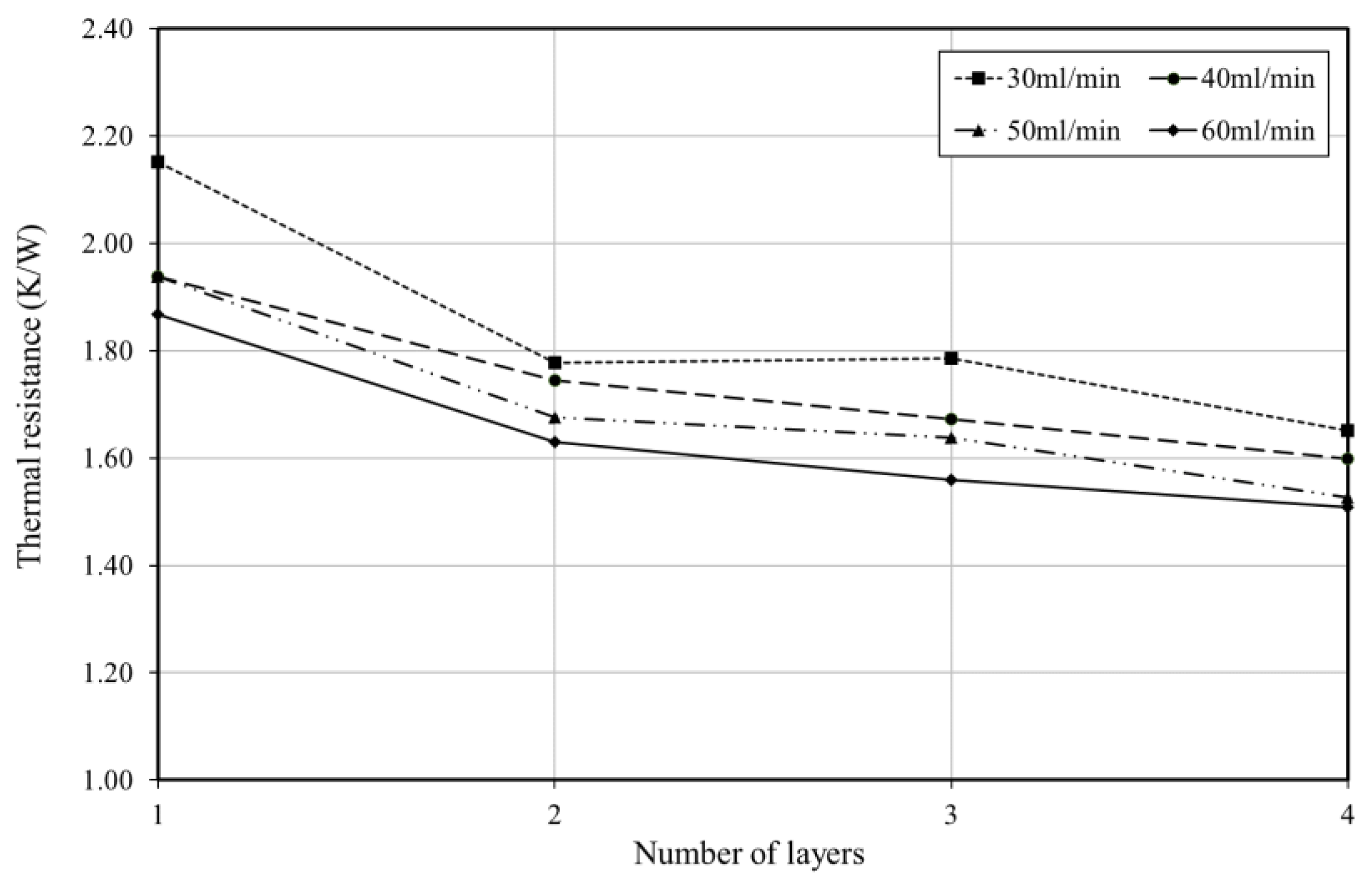

4.1. Effects of Number of Layers

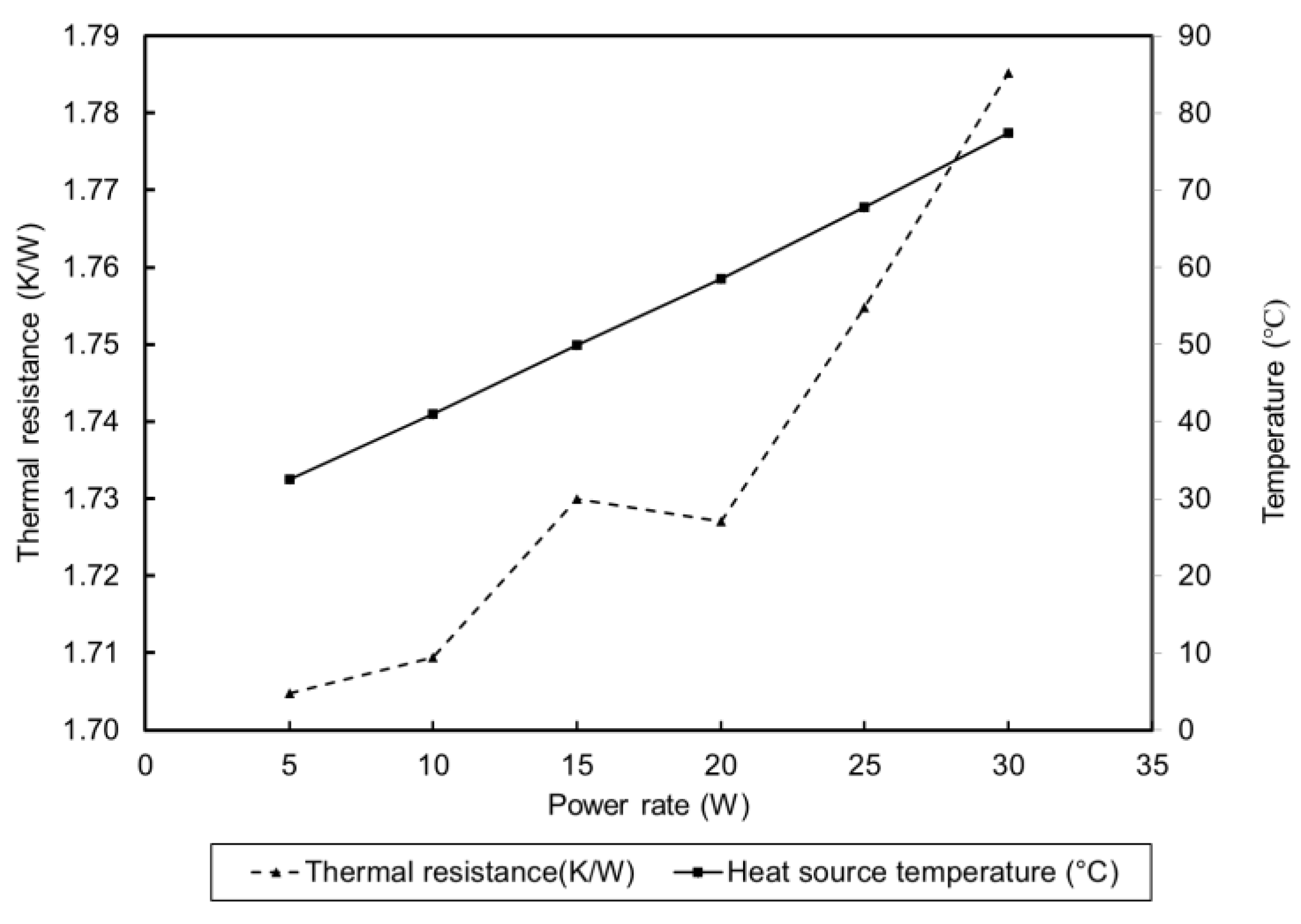

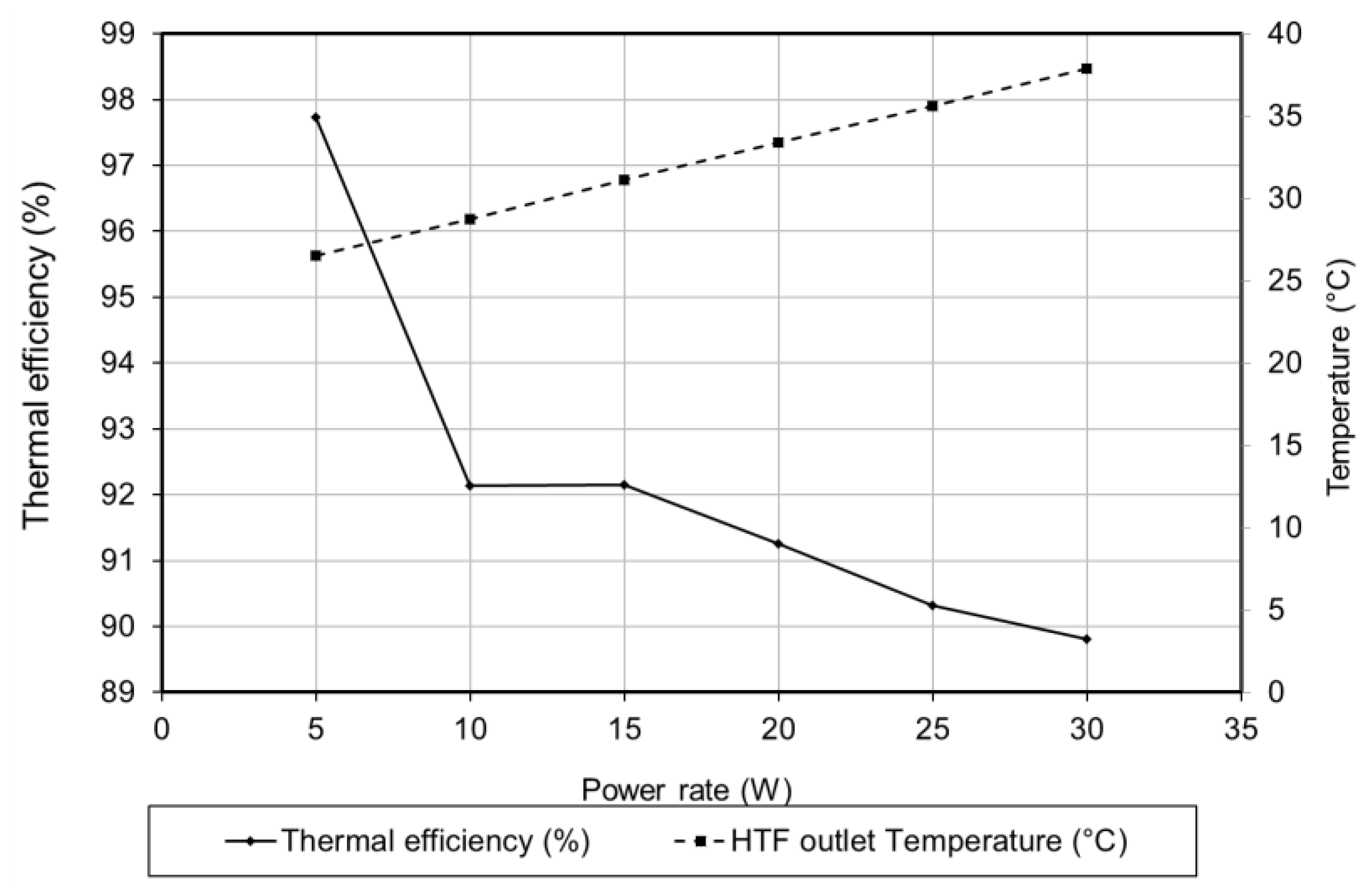

4.2. Effects of Power Rates

4.3. Effects of HTF Flow Rates

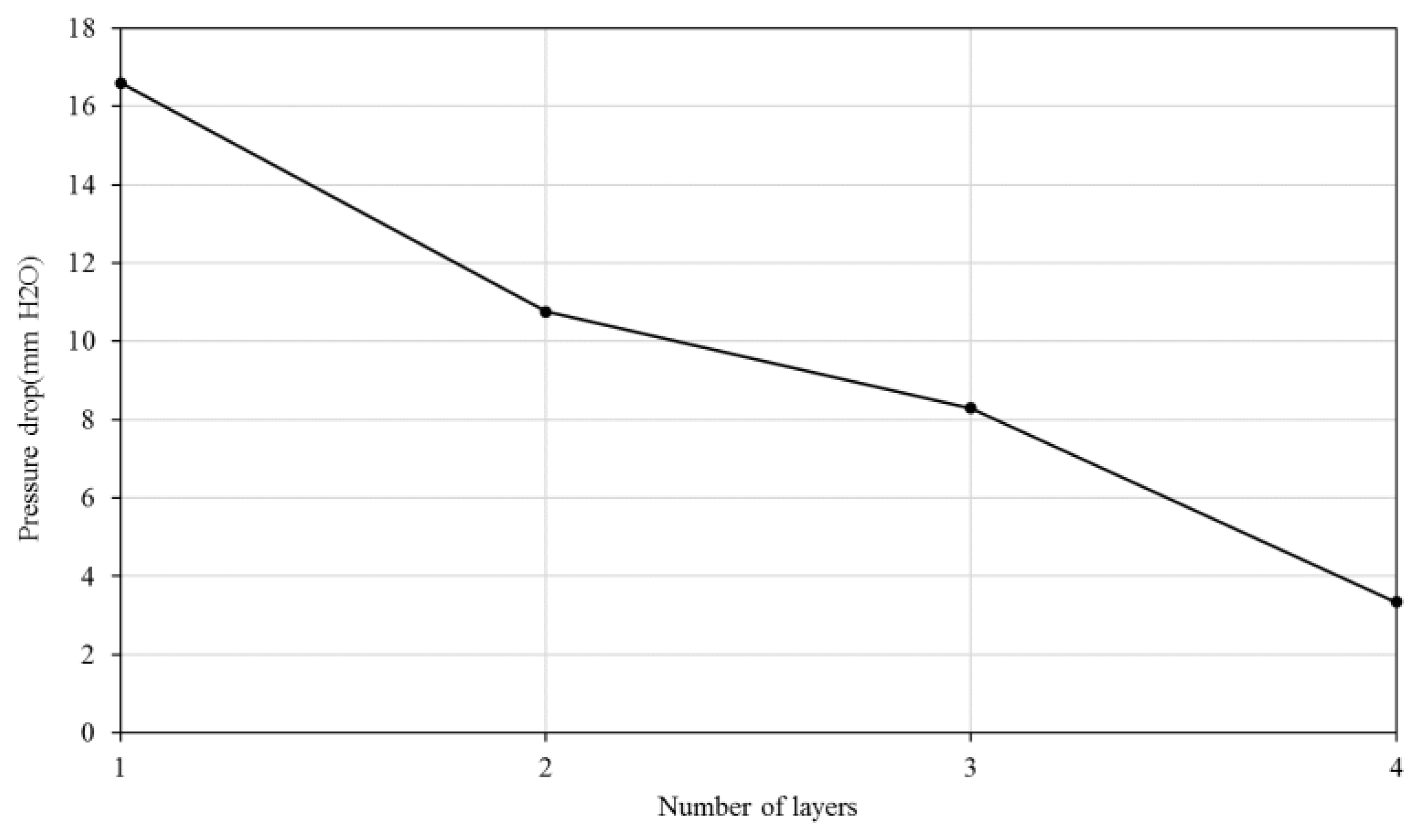

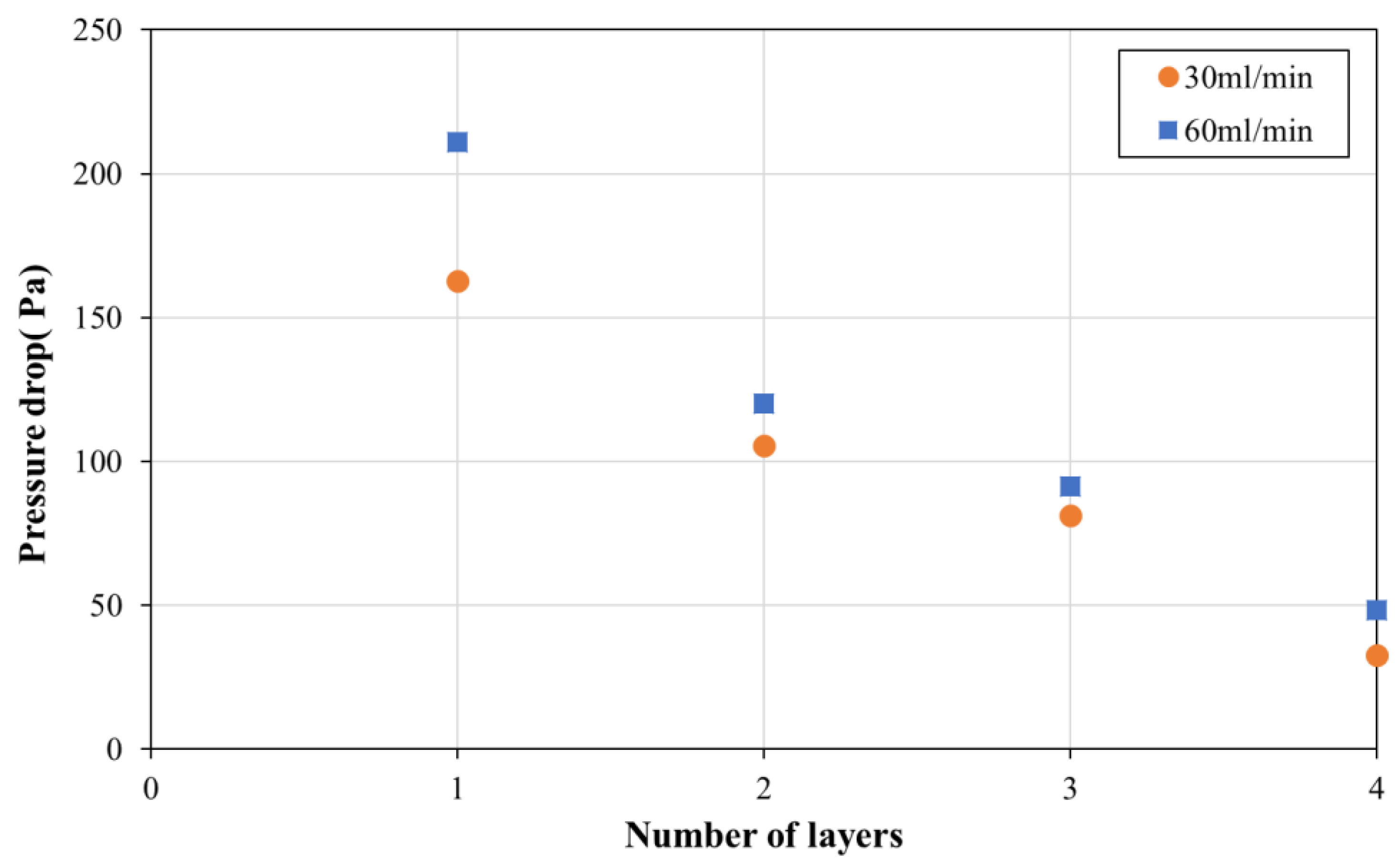

4.4. Effects of Number of Layers on the Pressure Drop

5. Conclusions

- Increasing the number of layers has a major impact in reducing the heat sink thermal resistance and the heat source maximum temperature. The thermal resistance decreases by 17% as the number of layers increases from one-layer to two-layers. A slight decrease of the thermal resistance is observed when the number of layers increased to three and four.

- The temperature non-uniformity decreases by 0.5 °C when the number of layers increases from one-layer to two-layers. However, the two-layers MLM heat sink experiences less temperature non-uniformity compared to the three-layers.

- The thermal efficiency is improved significantly by increasing the number of layers from one-layer to three-layers by 20%, due to the increase in the HTF outlet temperature.

- Increasing the input power from 5 to 30 W slightly increases the heat sink total thermal resistance and the heat source temperature increases. This shows the ability of the heat sink to accommodate a wide range of power rates with a slight change in the thermal resistance.

Author Contributions

Funding

Conflicts of Interest

References

- Micheli, L.; Micheli, L.; Fernandez, E.F.; Almonacid, F. Enhancing Ultra-High CPV Passive Cooling Using Least-Material Finned Heat Sinks. AIP Conf. Proc. 2015, 1679, 130003. [Google Scholar]

- Khanna, S.; Sundaram, S.; Reddy, K.S.; Mallick, T.K. Performance analysis of perovskite and dye-sensitized solar cells under varying operating conditions and comparison with monocrystalline silicon cell. Appl. Therm. Eng. 2017, 127, 559–565. [Google Scholar] [CrossRef]

- Khanna, S.; Reddy, K.S.; Mallick, T.K. Optimization of finned solar photovoltaic phase change material (finned pv pcm) system. Int. J. Therm. Sci. 2018, 130, 313–322. [Google Scholar] [CrossRef]

- Araki, K.; Uozumi, H.; Yamaguchi, M. A Simple Passive Cooling Structure and Its Heat Analysis for 500 X concentrator PV module. In Proceedings of the 2002 IEEE 29th Photovoltaic Specialist Conference (PVSC), New Orleans, LA, USA, 19–24 May 2002; pp. 1568–1571. [Google Scholar]

- Du, D.; Darkwa, J.; Kokogiannakis, G. Thermal management systems for Photovoltaics (PV) installations: A critical review. Sol. Energy 2013, 97, 238–254. [Google Scholar] [CrossRef]

- Ye, Z.; Li, Q.; Zhu, Q.; Pan, W. The cooling technology of solar cells under concentrated system. In Proceedings of the 2009 IEEE 6th International Power Electronics and Motion Control Conference IPEMC ’09, Wuhan, China, 17–20 May 2009; pp. 2193–2197. [Google Scholar] [CrossRef]

- Bahaidarah, H.M.S.; Baloch, A.A.B.; Gandhidasan, P. Uniform cooling of photovoltaic panels: A review. Renew. Sustain. Energy Rev. 2016, 57, 1520–1544. [Google Scholar] [CrossRef]

- Royne, A.; Dey, C.J.; Mills, D.R. Cooling of photovoltaic cells under concentrated illumination: A critical review. Sol. Energy Mater. Sol. Cells 2005, 86, 451–483. [Google Scholar] [CrossRef]

- Theristis, M.; Donovan, T.S.O. An integrated thermal electrical model for single cell photovoltaic receivers under concentration. In Proceedings of the 15th International Heat Transfer Conference (IHTC-15), Kyoto, Japan, 10–15 August 2014; pp. 1–12. [Google Scholar] [CrossRef]

- Aldossary, A.; Mahmoud, S.; Al-Dadah, R. Technical feasibility study of passive and active cooling for concentrator PV in harsh environment. Appl. Therm. Eng. 2016, 100, 490–500. [Google Scholar] [CrossRef]

- Wei, X.; Joshi, Y. Stacked Microchannel Heat Sinks for Liquid Cooling of Microelectronic Components. J. Electron. Packag. 2004, 126, 60. [Google Scholar] [CrossRef]

- Vafai, K.; Zhu, L. Analysis of two-layered micro-channel heat sink concept in electronic cooling. Int. J. Heat Mass Transf. 1999, 42, 2287–2297. [Google Scholar] [CrossRef]

- Wei, X.; Joshi, Y. Optimization study of stacked micro-channel heat sinks for micro-electronic cooling, Intersoc. In Proceedings of the Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITHERM 2002), San Diego, CA, USA, 30 May–1 June 2002; pp. 441–448. [Google Scholar] [CrossRef]

- Lin, L.; Deng, M.-X.; Zhang, X.-X.; Wang, X.-D. Numerical analysis and parametric study of multilayered microchannel heat sinks. Adv. Mech. Eng. 2015, 7. [Google Scholar] [CrossRef]

- Leng, C.; Wang, X.D.; Wang, T.H.; Yan, W.M. Optimization of thermal resistance and bottom wall temperature uniformity for double-layered microchannel heat sink. Energy Convers. Manag. 2015, 93, 141–150. [Google Scholar] [CrossRef]

- Leng, C.; Wang, X.D.; Wang, T.H.; Yan, W.M. Multi-parameter optimization of flow and heat transfer for a novel double-layered microchannel heat sink. Int. J. Heat Mass Transf. 2015, 84, 359–369. [Google Scholar] [CrossRef]

- Lu, B.; Meng, W.J.; Mei, F. Experimental investigation of Cu-based, double-layered, microchannel heat exchangers. J. Micromech. Microeng. 2013, 23. [Google Scholar] [CrossRef]

- Wang, S.L.; Li, X.Y.; Wang, X.D.; Lu, G. Flow and heat transfer characteristics in double-layered microchannel heat sinks with porous fins. Int. Commun. Heat Mass Transf. 2018, 93, 41–47. [Google Scholar] [CrossRef]

- Ahmed, H.E.; Ahmed, M.I.; Seder, I.M.F.; Salman, B.H. Experimental investigation for sequential triangular double-layered microchannel heat sink with nanofluids. Int. Commun. Heat Mass Transf. 2016, 77, 104–115. [Google Scholar] [CrossRef]

- Pang, L.; Wang, M.; Wang, W.; Liu, M.; Wang, J. Optimal thermal design of a stacked mini-channel heat sink cooled by a low flow rate coolant. Entropy 2013, 15, 4716–4731. [Google Scholar] [CrossRef]

- Hung, T.C.; Yan, W.M.; Wang, X.D.; Huang, Y.X. Optimal design of geometric parameters of double-layered microchannel heat sinks. Int. J. Heat Mass Transf. 2012, 55, 3262–3272. [Google Scholar] [CrossRef]

- Chen, K.C.; Wang, C.C. Performance improvement of high power liquid-cooled heat sink via non-uniform metal foam arrangement. Appl. Therm. Eng. 2015, 87, 41–46. [Google Scholar] [CrossRef]

- Chong, S.H.; Ooi, K.T.; Wong, T.N. Optimisation of single and double layer counter flow microchannel heat sinks. Appl. Therm. Eng. 2002, 22, 1569–1585. [Google Scholar] [CrossRef]

- Jeevan, K.; Azid, I.A.; Seetharamu, K.N.; Tehal, N. Optimization of double layer counter flow (DLCF) micro-channel heat sink used for cooling chips directly. In Proceedings of the 6th Electronics Packaging Technology Conference, Singapore, 8–10 December 2004; pp. 553–558. [Google Scholar]

- Lin, L.; Chen, Y.Y.; Zhang, X.X.; Wang, X.D. Optimization of geometry and flow rate distribution for double-layer microchannel heat sink. Int. J. Therm. Sci. 2014, 78, 158–168. [Google Scholar] [CrossRef]

- Wu, J.M.; Zhao, J.Y.; Tseng, K.J. Parametric study on the performance of double-layered microchannels heat sink. Energy Convers. Manag. 2014, 80, 550–560. [Google Scholar] [CrossRef]

- Levac, M.L.-J.; Soliman, H.M.; Ormiston, S.J. Three-dimensional analysis of fluid flow and heat transfer in single- and two-layered micro-channel heat sinks. Heat Mass Transf. 2011, 47, 1375–1383. [Google Scholar] [CrossRef]

- Wong, K.C.; Muezzin, F.N.A. Heat transfer of a parallel flow two-layered microchannel heat sink. Int. Commun. Heat Mass Transf. 2013, 49, 136–140. [Google Scholar] [CrossRef]

- Xie, G.; Liu, Y.; Sunden, B.; Zhang, W. Computational Study and Optimization of Laminar Heat Transfer and Pressure Loss of Double-Layer Microchannels for Chip Liquid Cooling. J. Therm. Sci. Eng. Appl. 2013, 5, 011004. [Google Scholar] [CrossRef]

- Al-Bakhit, H.; Fakheri, A. Numerical simulation of heat transfer in simultaneously developing flows in parallel rectangular ducts. Appl. Therm. Eng. 2006, 26, 596–603. [Google Scholar] [CrossRef]

- Cheng, Y.J. Numerical simulation of stacked microchannel heat sink with mixing-enhanced passive structure. Int. Commun. Heat Mass Transf. 2007, 34, 295–303. [Google Scholar] [CrossRef]

- Shi, B.; Srivastava, A.; Wang, P.; Circuits, B.I.; Aids, D. Non-Uniform Micro-Channel Design for Stacked 3D-ICs. In Proceedings of the 48th Design Automation Conference, San Diego, CA, USA, 5–10 June 2011; pp. 658–663. [Google Scholar]

- Hung, T.C.; Yan, W.M. Enhancement of thermal performance in double-layered microchannel heat sink with nanofluids. Int. J. Heat Mass Transf. 2012, 55, 3225–3238. [Google Scholar] [CrossRef]

- Sakanova, A.; Yin, S.; Zhao, J.; Wu, J.M.; Leong, K.C. Optimization and comparison of double-layer and double-side micro-channel heat sinks with nanofluid for power electronics cooling. Appl. Therm. Eng. 2014, 65, 124–134. [Google Scholar] [CrossRef]

- Hung, T.C.; Yan, W.M.; Li, W.P. Analysis of heat transfer characteristics of double-layered microchannel heat sink. Int. J. Heat Mass Transf. 2012, 55, 3090–3099. [Google Scholar] [CrossRef]

- Ng, E.Y.K.; Poh, S.T. CFD analysis of double-layer microchannel conjugate parallel liquid flows with electric double-layer effects. Numer. Heat Transf. Part A Appl. 2001, 40, 735–749. [Google Scholar] [CrossRef]

- Dixit, P.; Lin, N.; Miao, J.; Wong, W.K.; Choon, T.K. Silicon nanopillars based 3D stacked microchannel heat sinks concept for enhanced heat dissipation applications in MEMS packaging. Sens. Actuators A Phys. 2008, 141, 685–694. [Google Scholar] [CrossRef]

- Gong, L.; Zhao, J.; Huang, S. Numerical study on layout of micro-channel heat sink for thermal management of electronic devices. Appl. Therm. Eng. 2015, 88, 480–490. [Google Scholar] [CrossRef]

- Skandakumaran, P.; Ortega, A.; Jamal-Eddine, T.; Vaidyanathan, R. Multi-layered SiC microchannel heat sinks—Modeling and experiment. In Proceedings of the Ninth Intersociety Conference on Thermal and Thermomechanical Phenomena In Electronic Systems, Las Vegas, NV, USA, 1–4 June 2004; Volume 1, pp. 352–360. [Google Scholar] [CrossRef]

- Lei, N.; Ortega, A.; Vaidyanathan, R. Modeling and optimization of multilayer minichannel heat sinks in single-phase flow. In Proceedings of the ASME InterPACK Conference, Vancouver, BC, Canada, 8–12 July 2007; pp. 29–43. [Google Scholar] [CrossRef]

- Xie, G.; Chen, Z.; Sunden, B.; Zhang, W. Numerical predictions of the flow and thermal performance of water-cooled single-layer and double-layer wavy microchannel heat sinks. Numer. Heat Transf. Part A Appl. 2013, 63, 201–225. [Google Scholar] [CrossRef]

- Wei, X.; Joshi, Y.; Patterson, M.K. Experimental and Numerical Study of a Stacked Microchannel Heat Sink for Liquid Cooling of Microelectronic Devices. J. Heat Transf. 2007, 129, 1432. [Google Scholar] [CrossRef]

- Ansari, D.; Kim, K.Y. Performance analysis of double-layer microchannel heat sinks under non-uniform heating conditions with random hotspots. Micromachines 2017, 8, 54. [Google Scholar] [CrossRef]

- Shao, B.; Wang, L.; Cheng, H.; Li, J. Optimization and numerical simulation of multi-layer microchannel heat sink. Procedia Eng. 2012, 31, 928–933. [Google Scholar] [CrossRef]

- al Siyabi, I.; Shanks, K.; Mallick, T.; Sundaram, S. Thermal analysis of a multi-layer microchannel heat sink for cooling concentrator photovoltaic (CPV) cells. AIP Conf. Proc. 2017, 1881, 070001. [Google Scholar] [CrossRef]

- Radwan, A.; Ahmed, M. The influence of microchannel heat sink configurations on the performance of low concentrator photovoltaic systems. Appl. Energy 2017, 206, 594–611. [Google Scholar] [CrossRef]

- al Siyabi, I.; Sharma, S.; Mallick, T.K.; Sundaram, S. Thermal regulation of building-integrated concentrating photovoltaic system using phase change material. AIP Conf. Proc. 2016, 1766, 090001. [Google Scholar] [CrossRef]

- Ohadi, M.; Choo, K.; Dessiatoun, S.; Cetegen, E. Next Generation Microchannel Heat Exchangers; Springer: New York, NY, USA, 2013. [Google Scholar]

- COMSOL Multiphysics Reference Guide. Available online: http://www.lmn.pub.ro/~daniel/ElectromagneticModelingDoctoral/Books/COMSOL4.3/mph/COMSOLMultiphysicsReferenceGuide.pdf (accessed on 30 December 2018).

- Khanna, S.; Sharma, V. Effect of number of supports on the bending of absorber tube of parabolic trough concentrator. Energy 2015, 93, 1788–1803. [Google Scholar] [CrossRef]

- Khanna, S.; Sharma, V. Explicit Analytical Expression for Solar Flux Distribution on an Undeflected Absorber Tube of Parabolic Trough Concentrator Considering Sun-Shape and Optical Errors. J. Sol. Energy Eng. 2016, 138, 011010. [Google Scholar] [CrossRef]

- Sharma, V.; Khanna, S.; Nayak, J.K.; Kedare, S.B. Effects of shading and blocking in compact linear fresnel reflector field. Energy 2016, 94, 633–653. [Google Scholar] [CrossRef]

- Ong, C.L.; Escher, W.; Paredes, S.; Khalil, A.S.G.; Michel, B. A novel concept of energy reuse from high concentration photovoltaic thermal (HCPVT) system for desalination. Desalination 2012, 295, 70–81. [Google Scholar] [CrossRef]

| Ref. | Type of Study | Number of Layers | Type of Coolant | Flow Directions | Type of Heat Source | Heat Sink Materials | Shape of Channel | Objectives | Important Findings |

|---|---|---|---|---|---|---|---|---|---|

| [23] | Modelling | 1 and 2 | Water | Counter flow | Uniform (1.3 × 107 W/m2) | Rectangle |

|

| |

| [13] | Modelling | 1–6 | Water | Parallel flow | Uniform | Rectangle |

|

| |

| [24] | Modelling | 2 | Water | Counter flow | Uniform | Rectangle |

|

| |

| [39] | Analytical, numerical and experimental | 1–4 | Water | Parallel flow | Uniform | Silicon carbide (SiC) | Square |

|

|

| [11] | Numerical simulation | 1–5 | Water | Parallel flow | Uniform | Steel, Silicon, copper and diamond | Square |

|

|

| [30] | Numerical simulation | 2 | Water | Parallel flow | Uniform | - | Square |

|

|

| [31] | Numerical simulation | 2 | Air and water | Counter flow | Uniform | - | Rectangle |

|

|

| [40] | Modelling and experimental | 1–5 | Water | Parallel flow | Uniform | Copper | Square |

|

|

| [37] | Modelling and experiment | 3 | Water | - | Uniform | Silicon | Rectangle |

|

|

| [27] | Modelling | 1–2 | Water | Parallel and counter flow | Uniform | Silicon | Rectangle |

|

|

| [32] | Modelling and experiment | 1–2 | Air | Parallel flow | Uniform | Silicon | Rectangle |

|

|

| [21] | Modelling | 2 | Water | Parallel flow | Uniform | Silicon | Rectangle |

|

|

| [33] | Numerical modelling | 2 | Nanofluid (Al2O3–water) | Counter flow | Uniform | Silicon | Rectangle |

|

|

| [44] | Numerical modelling | 2 | Deionized water | Parallel flow | Uniform | - | Rectangle |

|

|

| [35] | Numerical modelling | 2 | Glycerol Ethylene glycol Distilled water | Counter flow | Uniform | Steel Silicon Aluminum Copper | Rectangle |

|

|

| [41] | Numerical | 1 and 2 | Water | Uniform (100 W/cm2) | Rectangle and wavy |

|

| ||

| [17] | Experiment | 1–2 | Water | Counter flow | - | Copper | Rectangle |

|

|

| [20] | Modelling | 2 | Water | Counter flow | Uniform | Copper | Rectangle |

| |

| [29] | Modelling | 2 | Water | Parallel and counter flow | Uniform | Silicon | Rectangle |

|

|

| [28] | Modelling | 2 | Water | Parallel and counter flow | Uniform | Silicon | Rectangle |

|

|

| [25] | Modelling | 2 | Water | Counter flow | Uniform | Silicon | Rectangle |

|

|

| [34] | Modelling | 2 | Water Nanofluid (Al2O3–water) | Counter flow | Uniform | copper | Rectangle |

|

|

| [26] | Modelling | 2 | Water | Counter flow | Uniform | Silicon | Rectangle |

|

| Thickness of Fins Wf (μm) | Width of Channel Wc (μm) | Height of Channels and Fins Hc (μm) | Base Thickness tb (μm) |

|---|---|---|---|

| 500 | 500 | 1000 | 1000 |

| Parameters | Value |

|---|---|

| Heating power (W) | 5, 10, 15, 20, 25 and 30 |

| HTF flow rate (mL/min) | 30, 40, 50 and 60 |

| Number of layers | 1, 2, 3 and 4 |

| Volume Flow Rate Using Flowmeter mL/min | Volume Flow Rate Using Water Column mL/min | Variation % | Mass Flow Rate g/min |

|---|---|---|---|

| 30 | 29 | 3 | 29.99 |

| 40 | 39 | 2.5 | 40.00 |

| 50 | 48 | 4 | 46.31 |

| 60 | 58 | 3.33 | 56.90 |

| Layer | Dimension (mm) | Thickness (mm) | Thermal Conductivity (W/m·K) | Heat Capacity (J/kg·K) | Density (kg/m3) |

|---|---|---|---|---|---|

| ERH | 10 × 10 | 4.5 | 400 | 730 | 3965 |

| Copper I | 27 × 25 | 0.250 | 400 | 385 | 8700 |

| Ceramic | 29 × 27 | 0.320 | 27 | 900 | 3900 |

| Copper II | 29 × 27 | 0.250 | 400 | 385 | 8700 |

| Aluminum | - | - | 160 | 900 | 2700 |

| Solder | - | 0.125 | 50 | 150 | 9000 |

| Silver | - | 0.20 | 430 | 235 | 10,490 |

| No | Region | Boundary Condition |

|---|---|---|

| 1 | Top surfaces | Natural convection (15 W/m2K) |

| 2 | ERH | Heat source (Qh) |

| 3 | Surfaces on bottom and sides | Thermally insulated |

| Number of Elements | 560,765 | 712,539 | 879,992 | 1,510,497 | 1,669,580 | |

| Element Size of Domain | Water (Fluid Dynamics) | Normal | fine | Fine | Finer | Extra fine |

| Remaining (General Physics) | Normal | fine | Extra fine | Extra fine | Extremely fine | |

| Calculated Parameters | Maximum Heat Source Temperature (°C) | 49.315 | 49.306 | 49.294 | 49.292 | 49.92 |

| Fluid Outlet Temperature (°C) | 31.704 | 31.702 | 31.701 | 31.701 | 31.701 | |

| Number of Layers | HTF Flow Rate (mL/min) | Power Rate (W) | |||||

|---|---|---|---|---|---|---|---|

| 5 | 10 | 15 | 20 | 25 | 30 | ||

| Temperature (°C) | |||||||

| 1 | 30 | 34.32 | 44.27 | 55.72 | 65.98 | 79.93 | 88.55 |

| 40 | 33.91 | 43.49 | 53.44 | 62.51 | 74.11 | 82.27 | |

| 50 | 33.41 | 42.52 | 52.18 | 61.80 | 71.78 | 82.15 | |

| 60 | 32.77 | 42.03 | 51.18 | 60.95 | 70.30 | 80.02 | |

| 2 | 30 | 32.79 | 41.76 | 50.51 | 60.52 | 68.91 | 77.39 |

| 40 | 32.43 | 40.46 | 49.03 | 56.98 | 66.60 | 76.32 | |

| 50 | 32.12 | 39.95 | 48.21 | 56.60 | 65.56 | 74.30 | |

| 60 | 31.94 | 39.69 | 47.60 | 54.77 | 64.26 | 72.88 | |

| 3 | 30 | 32.49 | 41.04 | 49.91 | 58.50 | 67.81 | 77.48 |

| 40 | 31.78 | 40.15 | 48.47 | 56.06 | 64.88 | 74.16 | |

| 50 | 31.73 | 39.58 | 47.73 | 55.88 | 64.29 | 73.23 | |

| 60 | 31.38 | 38.94 | 46.86 | 54.67 | 62.16 | 70.70 | |

| 4 | 30 | 32.63 | 40.55 | 49.35 | 57.75 | 66.00 | 73.57 |

| 40 | 31.87 | 39.41 | 46.98 | 55.30 | 63.06 | 71.99 | |

| 50 | 31.66 | 39.13 | 46.38 | 53.62 | 60.83 | 69.74 | |

| 60 | 31.42 | 38.94 | 45.75 | 53.07 | 60.99 | 69.31 | |

| Number of Layers | HTF Flow Rate (mL/min) | Power Rate (W) | |||||

|---|---|---|---|---|---|---|---|

| 5 | 10 | 15 | 20 | 25 | 30 | ||

| Temperature (°C) | |||||||

| 1 | 30 | 26.08 | 27.54 | 29.79 | 32.22 | 33.66 | 36.66 |

| 40 | 25.59 | 26.87 | 28.23 | 29.55 | 30.72 | 31.81 | |

| 50 | 25.18 | 26.03 | 26.90 | 27.89 | 29.03 | 29.74 | |

| 60 | 24.82 | 25.70 | 26.41 | 27.15 | 27.91 | 28.82 | |

| 2 | 30 | 26.38 | 28.47 | 30.53 | 32.83 | 35.35 | 37.03 |

| 40 | 25.82 | 27.30 | 28.69 | 30.23 | 31.84 | 33.24 | |

| 50 | 25.52 | 26.61 | 27.68 | 28.77 | 29.84 | 31.11 | |

| 60 | 25.19 | 26.05 | 26.95 | 27.96 | 28.95 | 29.98 | |

| 3 | 30 | 26.49 | 28.72 | 31.10 | 33.39 | 35.63 | 37.88 |

| 40 | 25.78 | 27.50 | 29.24 | 30.97 | 32.85 | 34.77 | |

| 50 | 25.37 | 26.81 | 28.22 | 29.74 | 31.25 | 32.95 | |

| 60 | 25.23 | 26.35 | 27.54 | 28.75 | 29.96 | 31.16 | |

| 4 | 30 | 26.43 | 28.77 | 31.20 | 33.65 | 36.26 | 38.36 |

| 40 | 25.80 | 27.39 | 29.26 | 31.12 | 32.89 | 34.71 | |

| 50 | 25.49 | 26.68 | 28.15 | 29.71 | 31.25 | 32.66 | |

| 60 | 25.30 | 26.35 | 27.50 | 28.75 | 30.01 | 31.26 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Siyabi, I.; Khanna, S.; Sundaram, S.; Mallick, T. Experimental and Numerical Thermal Analysis of Multi-Layered Microchannel Heat Sink for Concentrating Photovoltaic Application. Energies 2019, 12, 122. https://doi.org/10.3390/en12010122

Al Siyabi I, Khanna S, Sundaram S, Mallick T. Experimental and Numerical Thermal Analysis of Multi-Layered Microchannel Heat Sink for Concentrating Photovoltaic Application. Energies. 2019; 12(1):122. https://doi.org/10.3390/en12010122

Chicago/Turabian StyleAl Siyabi, Idris, Sourav Khanna, Senthilarasu Sundaram, and Tapas Mallick. 2019. "Experimental and Numerical Thermal Analysis of Multi-Layered Microchannel Heat Sink for Concentrating Photovoltaic Application" Energies 12, no. 1: 122. https://doi.org/10.3390/en12010122

APA StyleAl Siyabi, I., Khanna, S., Sundaram, S., & Mallick, T. (2019). Experimental and Numerical Thermal Analysis of Multi-Layered Microchannel Heat Sink for Concentrating Photovoltaic Application. Energies, 12(1), 122. https://doi.org/10.3390/en12010122