Energy Saving of Composite Agglomeration Process (CAP) by Optimized Distribution of Pelletized Feed

Abstract

1. Introduction

2. Experimental

2.1. Materials and Equipment

2.2. Methods

2.2.1. Heat Balance Calculation

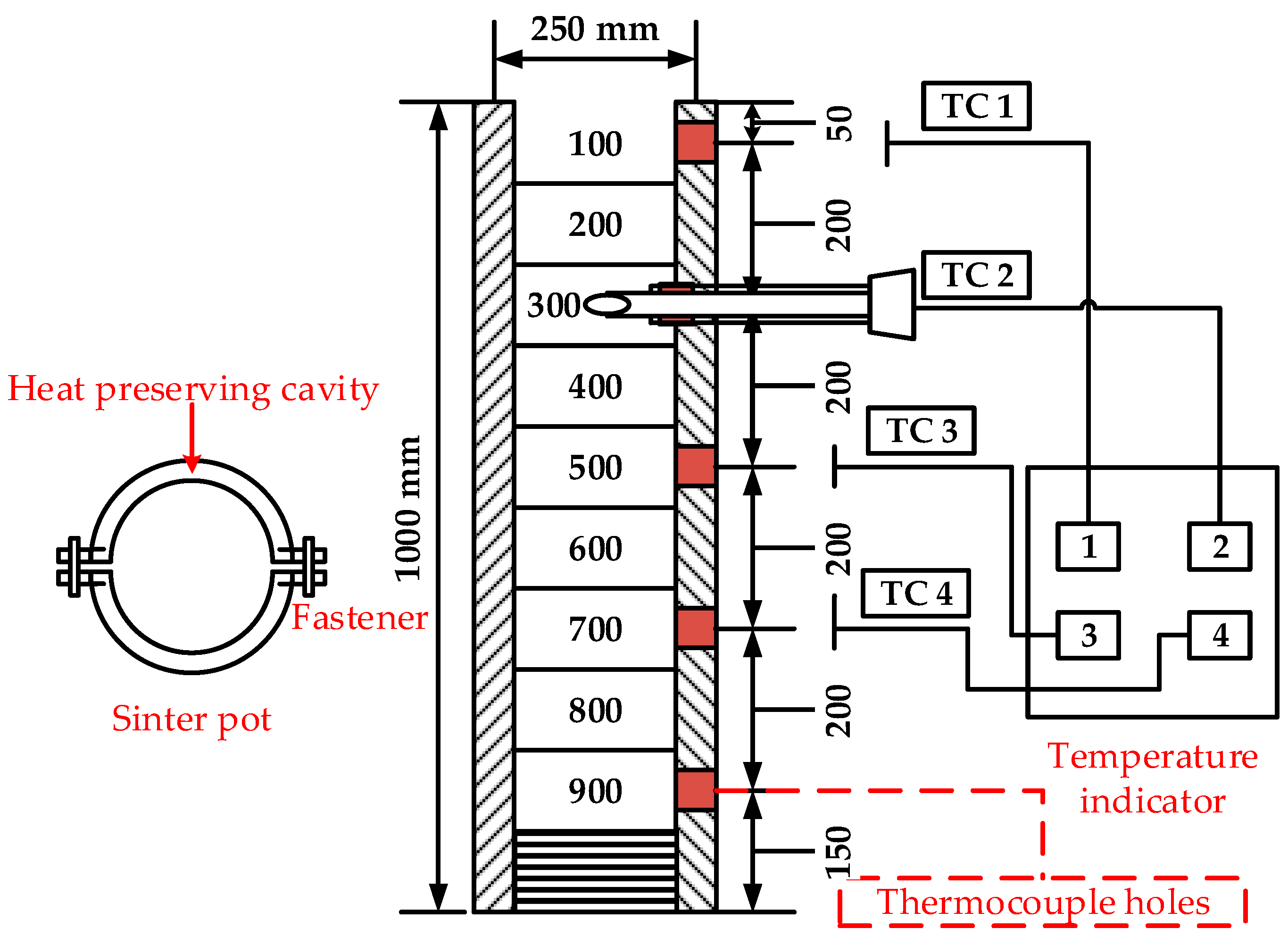

2.2.2. Sinter Pot Trials

3. Results and Discussion

3.1. Uniform Distribution of Pelletized Feed in Sinter Bed

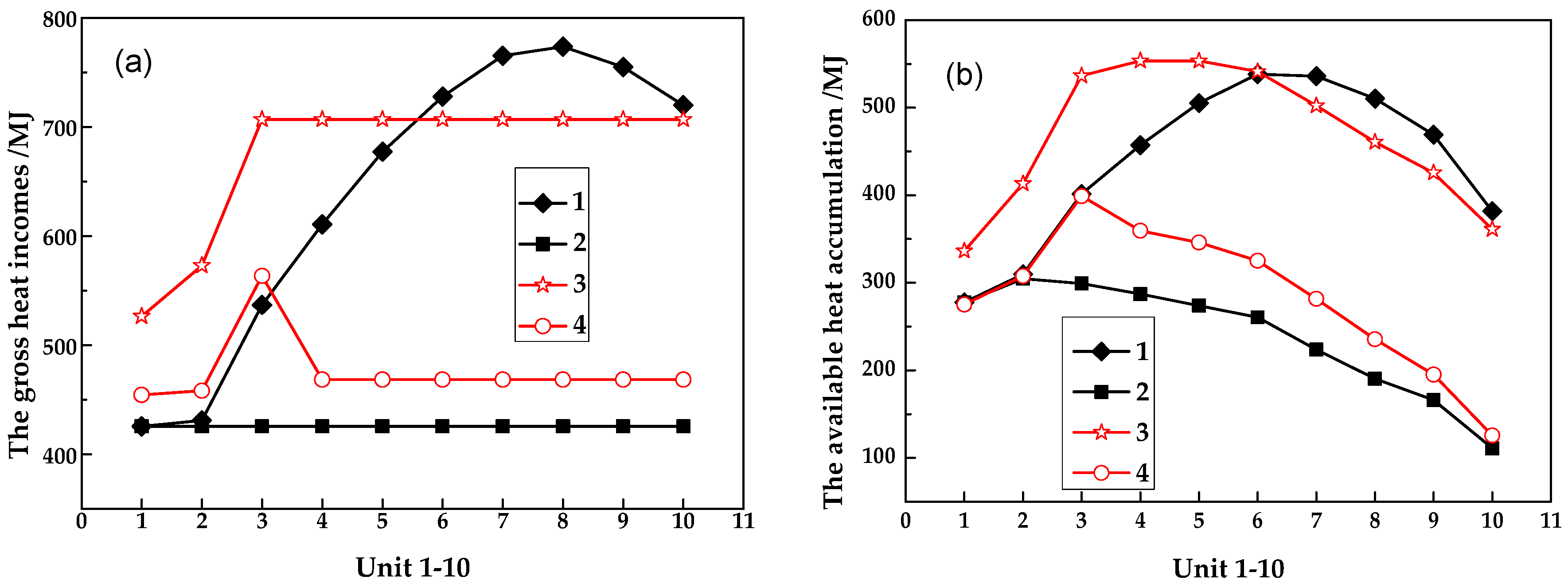

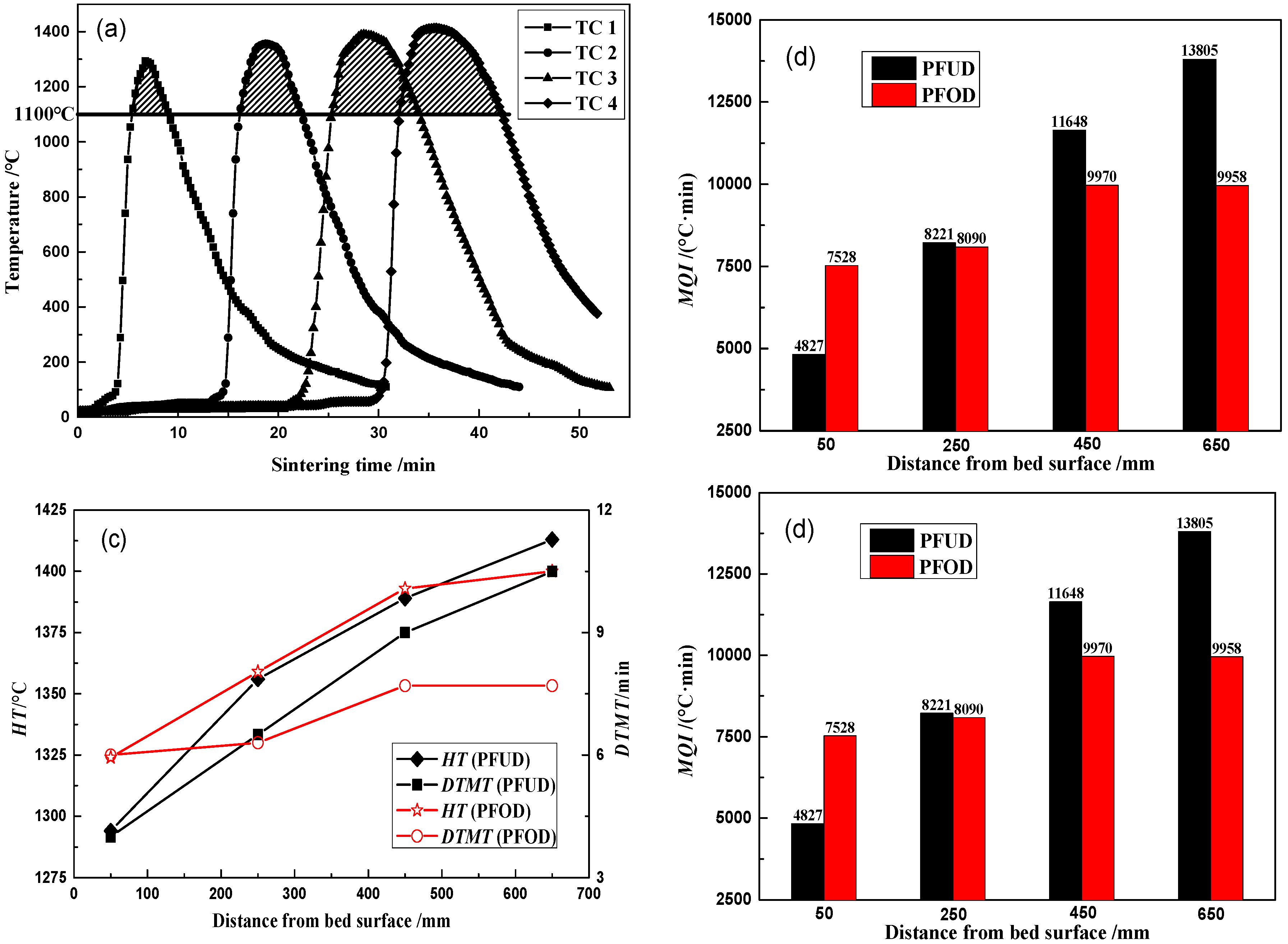

3.1.1. Heat Accumulation Regularity

3.1.2. Sinter Bed Heat-Homogenizing

3.2. Optimized Distribution of Pelletized Feed Under the Condition of Bed Heat-Homogenization

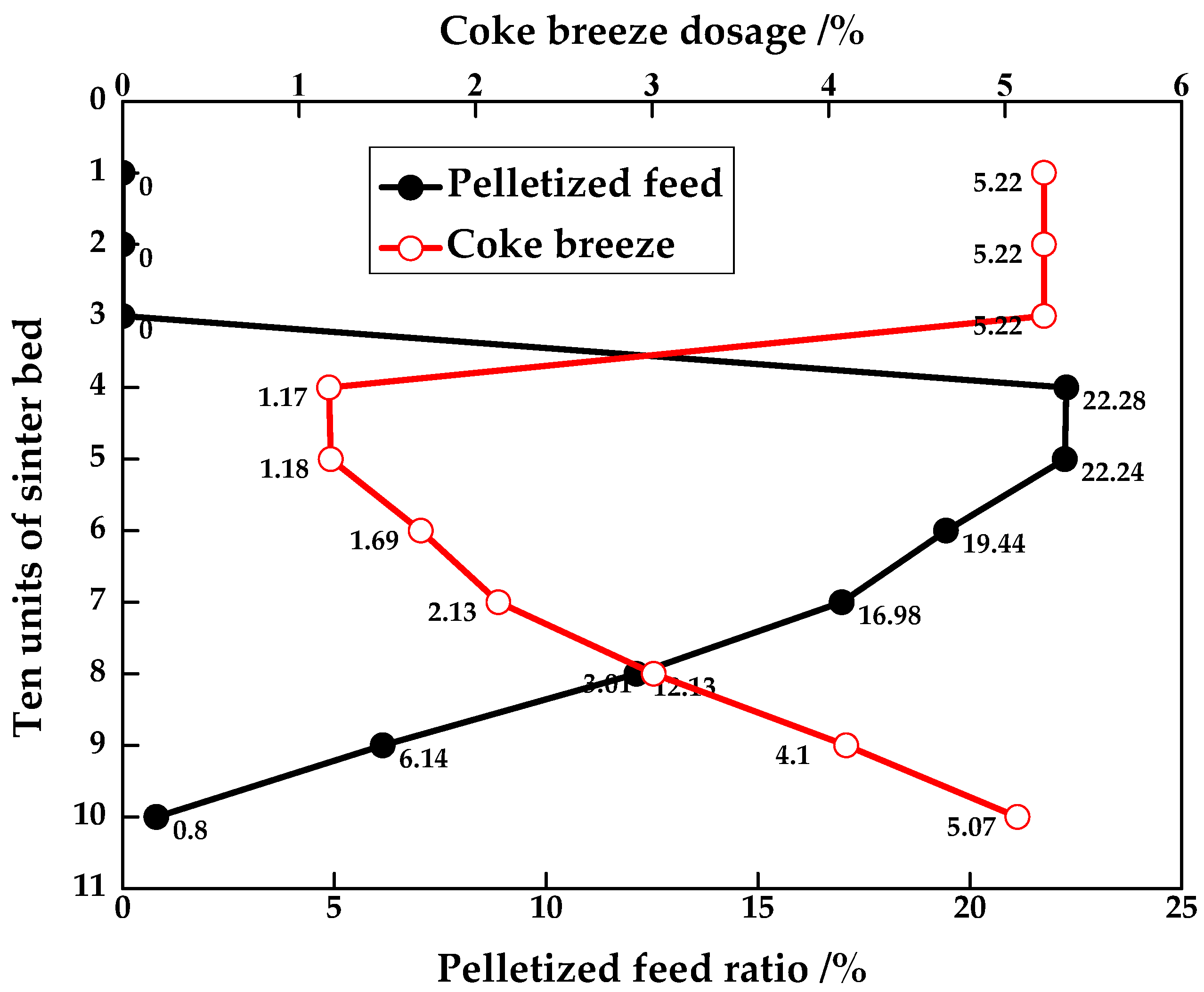

3.2.1. Heat Accumulation Regularity

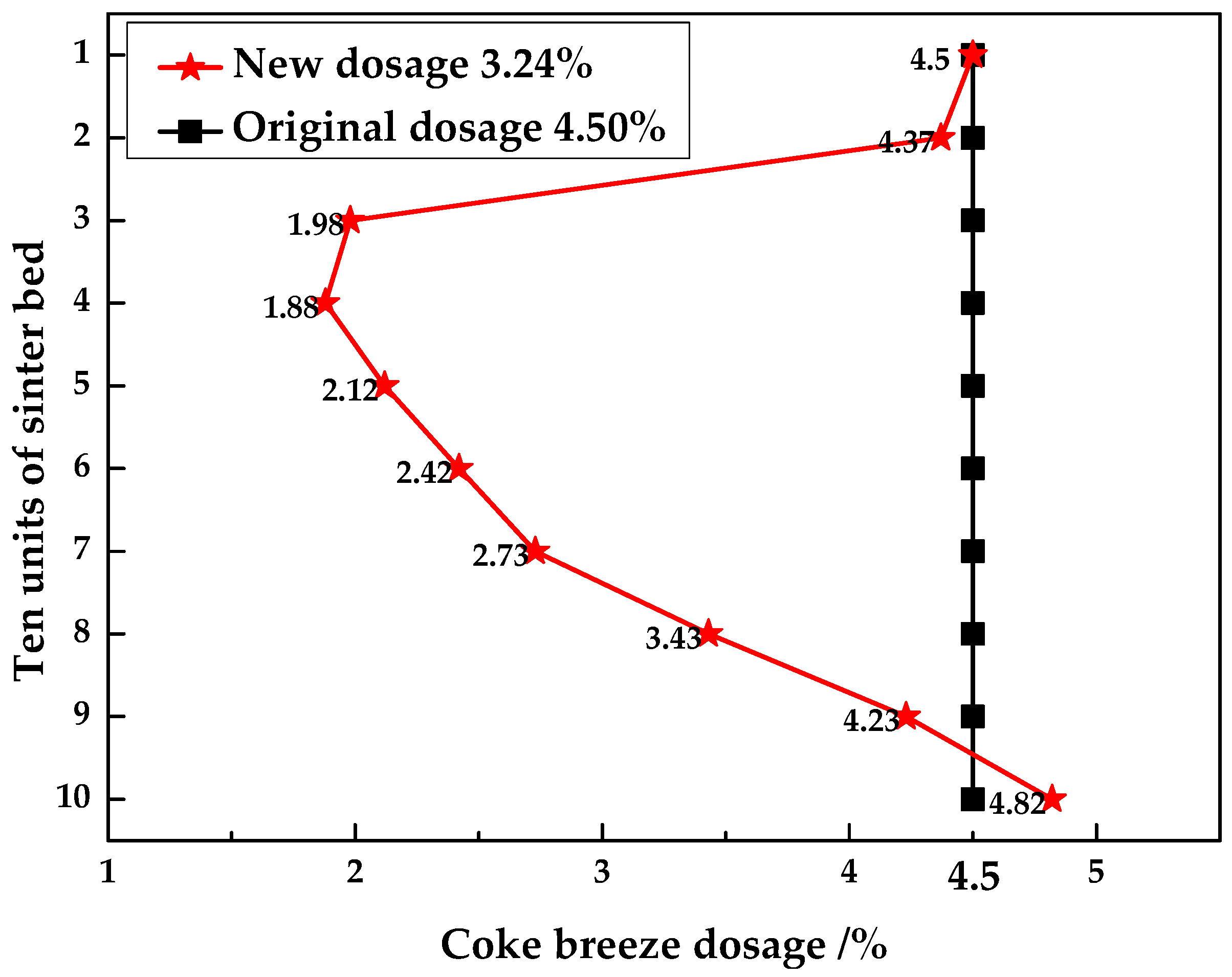

3.2.2. Coke Breeze Dosage Reduction

3.3. Comprehensive Comparison of Heat Accumulation in Two Methods

3.4. Effects of Two Methods on Thermal Behavior

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Loo, C.E.; Dukino, R.D. Laboratory iron ore sintering studies. 1. Process simulation and airflow rate. Trans. Inst. Min. Metall. C 2014, 123, 191–196. [Google Scholar] [CrossRef]

- Yang, W.; Choi, S.; Choi, E.S.; Ri, D.W.; Kim, S. Combustion characteristics in an iron ore sintering bed-evaluation of fuel substitution. Combust. Flame 2006, 145, 447–463. [Google Scholar] [CrossRef]

- Jiang, T.; Li, G.H.; Xu, B.; Zhang, Y.B. An Approach of Quality-improving and Energy-saving for Sintering Process: Heat-Homogenizing and Deep-Bed Sintering. In Proceedings of the 10th Annual Conference of China Iron and Steel-Proceedings of the 6th Baosteel Academic Annual Conference, Shanghai, China, 1 October 2015; pp. 1–10. [Google Scholar]

- Long, H.M.; Zuo, J.; Wang, P.; Li, J.M.; Shi, S.Q.; Wang, A.P. Study on homogeneity of thick layer sintering process in height direction. Sinter. Pellet. 2013, 38, 1–6. [Google Scholar]

- Jiang, Y.; Huang, Z.C.; Xu, B.; Jiang, T. Lower fuel consumption model and air-flow segregation feeding system for sintering. J. Cent. South. Univ. 2011, 18, 1917–1923. [Google Scholar] [CrossRef]

- Yu, Z.W. Researhces on bed structure and mineralization theory of composite agglomeration process (CAP) of iron ore fines and their application. Ph.D. Thesis, Central South University, Changsha, China, June 2016. [Google Scholar]

- Jiang, T.; Hu, Y.M.; Li, Q.; Li, G.H.; Yang, Y.B.; Zhang, Y.B.; Guo, Y.F. Mechanisms of composite agglomeration of fluoric iron concentrate. J. Central South Univ. Tech. 2010, 17, 1190–1195. [Google Scholar] [CrossRef]

- Jiang, T.; Li, G.H.; Wang, H.T.; Zhang, K.C.; Zhang, Y.B. Composite agglomeration process (CAP) for preparing blast furnace burden. Ironmak. Steelmak. 2013, 37, 1–7. [Google Scholar] [CrossRef]

- Jiang, T.; Yu, Z.W.; Peng, Z.W.; Rao, M.J.; Zhang, Y.B.; Li, G.H. Preparation of BF Burden from Titanomagnetite Concentrate by Composite Agglomeration Process (CAP). ISIJ Int. 2015, 55, 1599–1607. [Google Scholar] [CrossRef]

- Yu, Z.W.; Li, G.H.; Liu, C.; Zhou, F.; Peng, Z.W.; Jiang, T. Comparison of reduction disintegration characteristics of TiO2-rich burdens prepared with sintering process and composite agglomeration process. Int. J. Min. Met. Mater. 2016, 23, 389–398. [Google Scholar] [CrossRef]

- Zhao, B. Experimental research on the distribution process of hybrid sinter-pellet. Sci. Techno. Baotou Steel Corp. 2009, 35, 21–23. [Google Scholar]

- Jiang, T. Chinese Patent CN200910303235.7, 25 November 2009.

- Jiang, T. Chinese Patent CN200510032095.6, 7 March 2007.

- Machida, S.; Higuchi, T.; Oyama, N.; Sato, H.; Takeda, K.; Yamashita, K.; Tamura, K. Optimization of Coke Breeze Segregation in Sintering Bed under High Pisolite Ore Ratio. ISIJ Int. 2009, 49, 667–675. [Google Scholar] [CrossRef]

- Hou, P.; Choi, S.; Choi, E.; Kang, H. Improved distribution of fuel particles in iron ore sintering process. Ironmak. Steelmak. 2011, 38, 379–385. [Google Scholar] [CrossRef]

- Cheng, Z.; Yang, J.; Zhou, L.; Liu, Y.; Wang, Q. Sinter strength evaluation using process parameters under different conditions in iron ore sintering process. Appl. Therm. Eng. 2016, 105, 894–904. [Google Scholar] [CrossRef]

- Huang, X.X.; Fan, X.H.; Chen, X.L.; Zhao, X.Z.; Gan, M. Optimisation model of fuel distribution in materials bed of iron ore sintering process. Ironmak. Steelmak. 2018, 1–7. [Google Scholar] [CrossRef]

- Oyama, N.; Iwami, Y.; Yamamoto, T.; Machida, S.; Higuchi, T.; Sato, H.; Sato, M.; Takeda, K.; Watanabe, Y.; Shimizu, M.; et al. Development of Secondary-fuel Injection Technology for Energy Reduction in the Iron Ore Sintering Process. ISIJ Int. 2011, 51, 913–921. [Google Scholar] [CrossRef]

- Iwami, Y.; Yamamoto, T.; Higuchi, T.; Oyama, N.; Sato, M.; Sodani, Y. Effect of Oxygen Enrichment on Mineral Texture in Sintered Ore with Gaseous Fuel Injection. ISIJ Int. 2015, 55, 2350–2357. [Google Scholar] [CrossRef]

- Cheng, Z.L.; Wang, J.Y.; Wei, S.S.; Guo, Z.G.; Yang, J.; Wang, Q.W. Optimization of gaseous fuel injection for saving energy consumption and improving imbalance of heat distribution in iron ore sintering. Appl. Energy 2017, 207, 230–242. [Google Scholar] [CrossRef]

- Cheng, Z.L.; Wei, S.S.; Guo, Z.G.; Yang, J.; Wang, Q.W. Improvement of heat pattern and sinter strength at high charcoal proportion by applying ultra-lean gaseous fuel injection in iron ore sintering process. J. Clean. Prod. 2017, 161, 1374–1384. [Google Scholar] [CrossRef]

- Xu, B.; Wang, J.C.; Chang, L.L.; Jiang, T.; Li, Q.; Hou, T. Investigation on Air-Injection Feeding for Sintering of Iron Ores. J. Iron. Steel. Res. Int. 2009, 35, 263–266. [Google Scholar]

- Xu, B. Research on Fundamental and Technology of Heat-Homogenizing Sintering of Iron Ores. Ph.D. Thesis, Central South University, Changsha, China, December 2011. [Google Scholar]

- Huang, Z.C.; Jiang, Y.; Mao, X.M.; Xu, B.; Guo, Y.F.; Jiang, T. Fuel appropriate distribution in iron ore sintering. J. Cent. South. Univ. 2006, 37, 884–890. [Google Scholar]

- Mitterlehner, J.; Loeffler, G.; Winter, F.; Hofbauer, H.; Schmid, H.; Zwittag, E.; Buergler, T.H.; Pammer, O.; Stiasny, H. Modeling and simulation of heat front propagation in the iron ore sintering process. ISIJ Int. 2004, 44, 11–20. [Google Scholar] [CrossRef]

- Yang, W.; Ryu, C.; Choi, S.M.; Choi, E.S.; Lee, D.; Huh, W. Modeling of combustion and heat transfer in an iron ore sintering bed with considerations of multiple solid phases. ISIJ Int. 2004, 44, 492–499. [Google Scholar] [CrossRef]

- Bai, C.G.; Xie, H.; Qiu, G.B.; Lv, X.W.; Xu, G.; Pu, X.D. An accumulation heat model and its application in iron ore sintering. J. Chongqing Univ. 2008, 31, 1002–1007. [Google Scholar]

- Hayashi, N.; Komarov, S.V.; Kasai, E. Heat transfer analysis of the mosaic embedding iron ore sintering (MEBIOS) process. ISIJ Int. 2009, 49, 681–686. [Google Scholar] [CrossRef]

- Wang, J.F.; Wang, Z.; Wang, Y.Z. Heat-balanced sintering method numerical simulation and experimental verification. Sustain. Energy 2017, 7, 18–30. [Google Scholar] [CrossRef]

- Cheng, Z.L.; Yang, J.; Zhou, L.; Liu, Y.; Guo, Z.G.; Wang, Q.W. Experimental study of commercial charcoal as alternative fuel for coke breeze in iron ore sintering process. Energy Convers. Manag. 2016, 125, 254–263. [Google Scholar] [CrossRef]

| Unit | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Temperature/°C | 25 | 50 | 100 | 200 | 300 | 400 | 650 | 850 | 1000 | 1300 |

| Sensible heat/MJ | 2.55 | 5.25 | 10.82 | 22.87 | 36.16 | 49.45 | 86.38 | 119.53 | 143.71 | 198.88 |

| Unit | ||||

|---|---|---|---|---|

| 1 | 425.72 | 277.57 | - | - |

| 2 | 431.15 | 309.66 | 45.06 | 45.29 |

| 3 | 536.89 | 401.38 | 55.88 | 56.34 |

| 4 | 610.72 | 457.25 | 61.22 | 62.04 |

| 5 | 677.34 | 505.25 | 65.03 | 66.48 |

| 6 | 727.70 | 538.29 | 67.45 | 69.73 |

| 7 | 765.23 | 535.89 | 69.05 | 72.27 |

| 8 | 773.46 | 510.31 | 69.38 | 74.28 |

| 9 | 754.84 | 468.99 | 68.62 | 75.93 |

| 10 | 719.86 | 381.64 | 66.87 | 77.17 |

| Unit | |||

|---|---|---|---|

| 1 | 277.57 | - | - |

| 2 | 304.67 | 45.64 | 45.87 |

| 3 | 299.10 | 69.65 | 70.05 |

| 4 | 287.05 | 70.65 | 71.54 |

| 5 | 273.76 | 68.28 | 70.32 |

| 6 | 260.47 | 65.24 | 69.20 |

| 7 | 223.54 | 62.12 | 68.66 |

| 8 | 190.39 | 55.11 | 66.67 |

| 9 | 166.21 | 47.06 | 65.58 |

| 10 | 111.04 | 40.75 | 66.39 |

| Unit | ||||

|---|---|---|---|---|

| 1 | 526.51 | 336.33 | –– | –– |

| 2 | 573.07 | 413.32 | 41.08 | 41.27 |

| 3 | 706.84 | 536.44 | 55.21 | 55.56 |

| 4 | 706.84 | 553.55 | 70.67 | 71.21 |

| 5 | 706.84 | 553.32 | 77.59 | 78.48 |

| 6 | 706.84 | 541.36 | 78.29 | 79.85 |

| 7 | 706.84 | 502.17 | 77.10 | 79.65 |

| 8 | 706.84 | 460.75 | 72.71 | 77.42 |

| 9 | 706.84 | 425.68 | 66.94 | 75.04 |

| 10 | 706.84 | 361.08 | 61.71 | 73.77 |

| Unit | ||||

|---|---|---|---|---|

| 1 | 454.52 | 275.15 | –– | –– |

| 2 | 458.26 | 307.70 | 42.03 | 42.25 |

| 3 | 563.59 | 399.03 | 52.86 | 53.33 |

| 4 | 468.56 | 359.49 | 79.31 | 79.88 |

| 5 | 468.56 | 346.10 | 79.25 | 80.48 |

| 6 | 468.56 | 325.27 | 74.72 | 77.36 |

| 7 | 468.56 | 281.73 | 70.75 | 75.41 |

| 8 | 468.56 | 235.54 | 62.91 | 71.80 |

| 9 | 468.56 | 195.23 | 53.23 | 68.59 |

| 10 | 468.56 | 125.69 | 44.25 | 67.07 |

| Pelletized Feed Distribution with Coke Breeze Mass/kg/t | Uniform Distribution | Optimized Distribution | ||

|---|---|---|---|---|

| 56.93 | 41.08 | 56.93 | 43.02 | |

| Total heat inputs/MJ | 6422.93 | 4257.23 | 6754.27 | 4756.30 |

| Percentage variation of heat inputs/% | 0 | −33.72 | 5.16 | −25.95 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Liu, C.; Yu, Z.; Rao, M.; Zhong, Q.; Zhang, Y.; Jiang, T. Energy Saving of Composite Agglomeration Process (CAP) by Optimized Distribution of Pelletized Feed. Energies 2018, 11, 2382. https://doi.org/10.3390/en11092382

Li G, Liu C, Yu Z, Rao M, Zhong Q, Zhang Y, Jiang T. Energy Saving of Composite Agglomeration Process (CAP) by Optimized Distribution of Pelletized Feed. Energies. 2018; 11(9):2382. https://doi.org/10.3390/en11092382

Chicago/Turabian StyleLi, Guanghui, Chen Liu, Zhengwei Yu, Mingjun Rao, Qiang Zhong, Yuanbo Zhang, and Tao Jiang. 2018. "Energy Saving of Composite Agglomeration Process (CAP) by Optimized Distribution of Pelletized Feed" Energies 11, no. 9: 2382. https://doi.org/10.3390/en11092382

APA StyleLi, G., Liu, C., Yu, Z., Rao, M., Zhong, Q., Zhang, Y., & Jiang, T. (2018). Energy Saving of Composite Agglomeration Process (CAP) by Optimized Distribution of Pelletized Feed. Energies, 11(9), 2382. https://doi.org/10.3390/en11092382