Analysis and Optimization of Material Flow inside the System of Rotary Coolers and Intake Pipeline via Discrete Element Method Modelling

Abstract

1. Introduction

2. Theoretical Background

- Static friction coefficient μs

- Coefficient of rolling friction μr

- Coefficient of restitution e

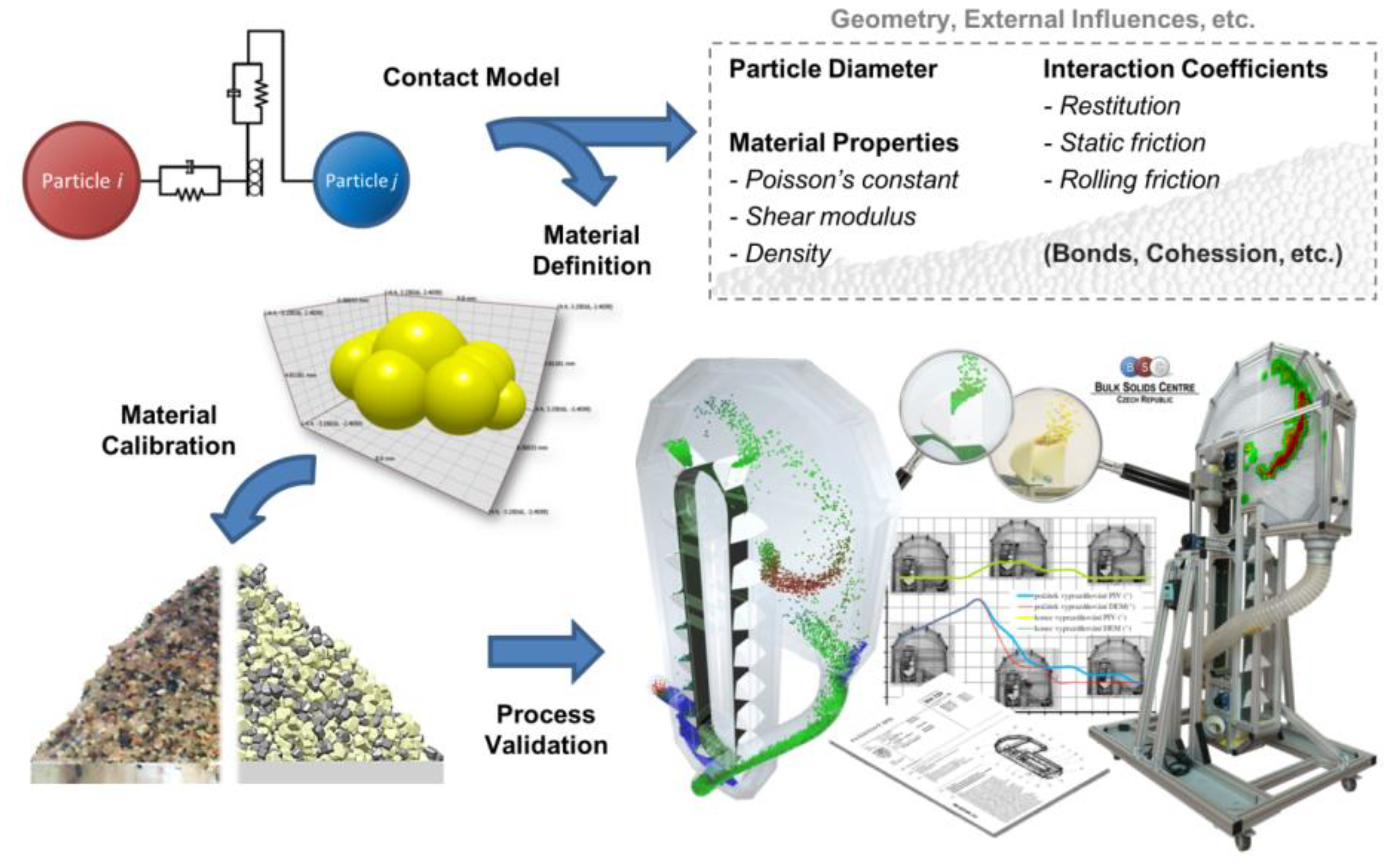

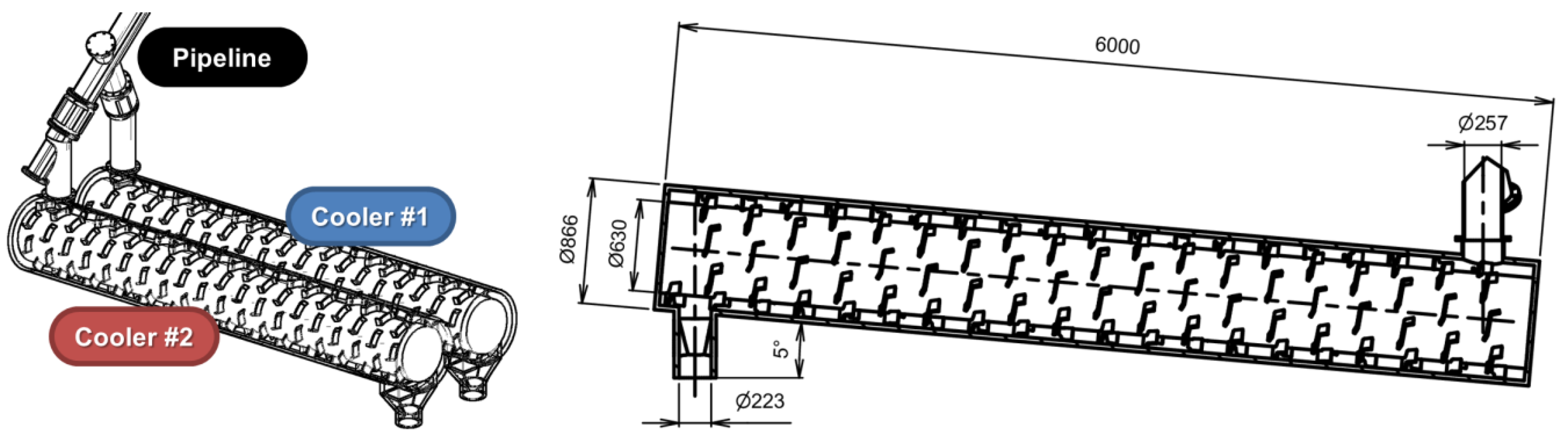

3. Material and Methods

3.1. Fly Ash Characterization

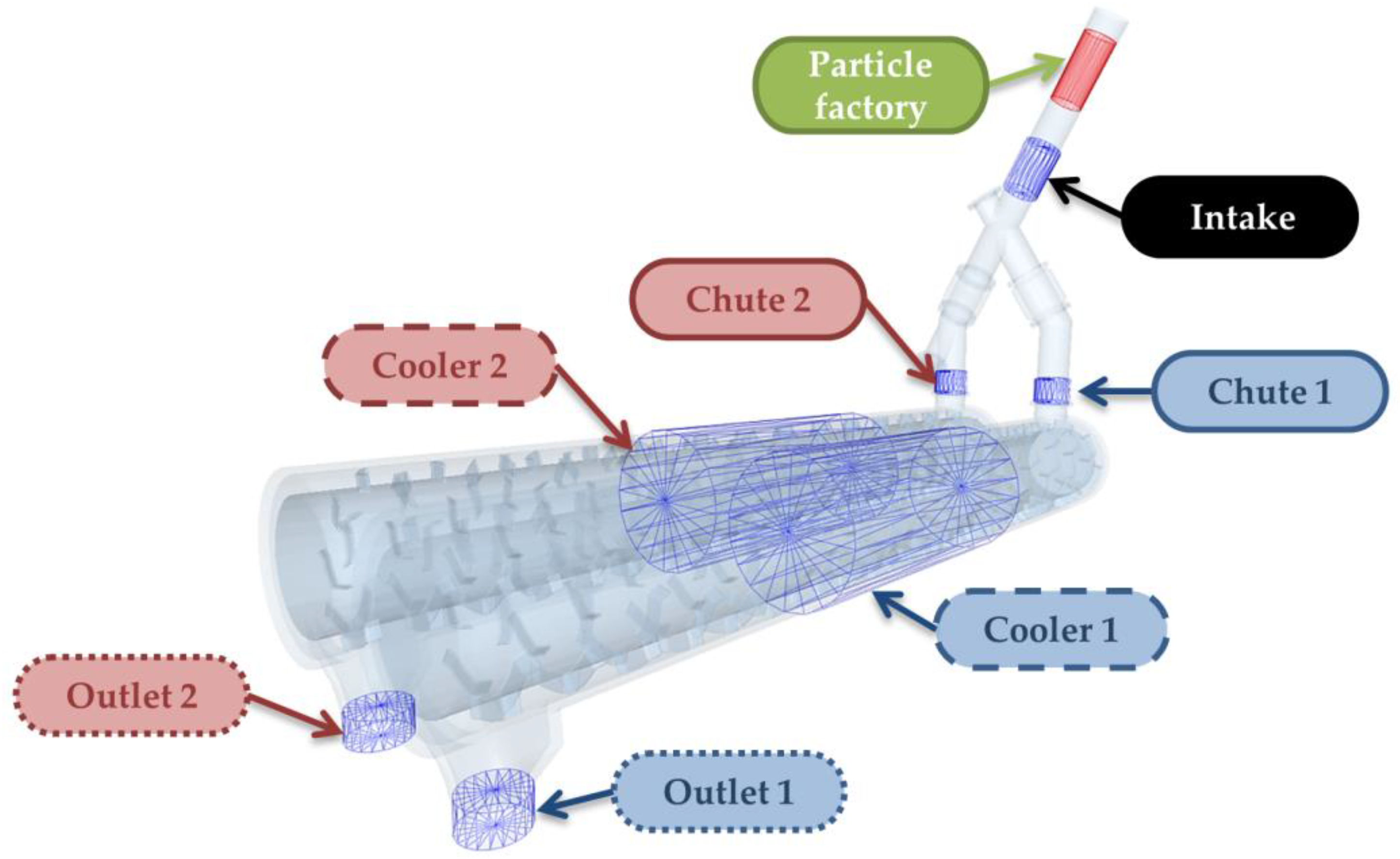

3.2. Virtual Material, Geometry Definition, and Contact Model

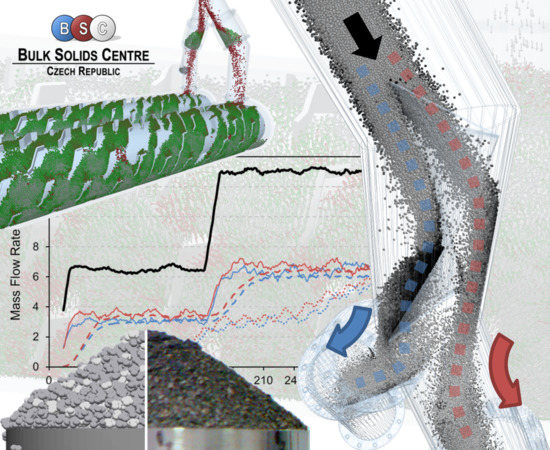

4. Results and Discussion

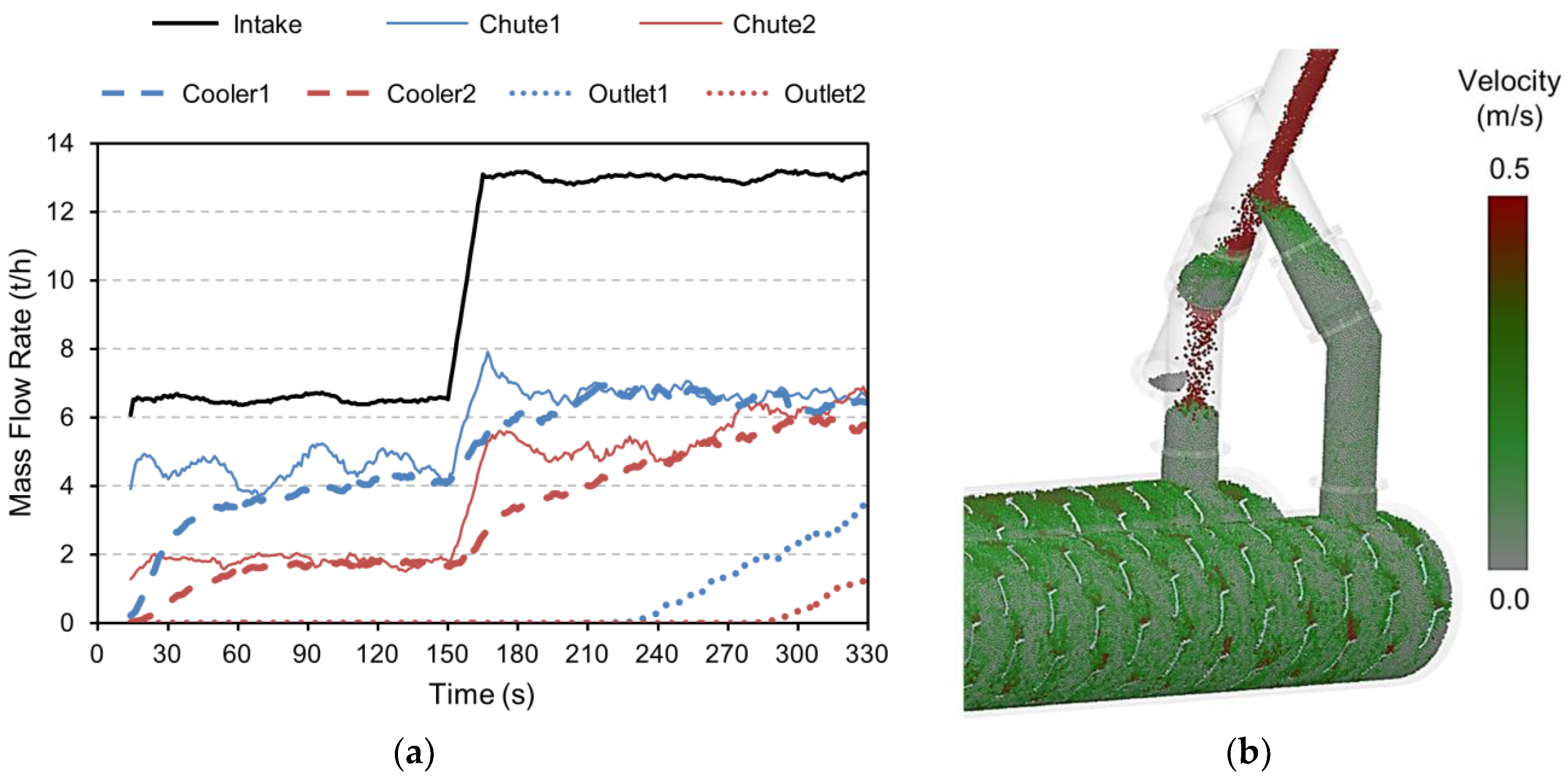

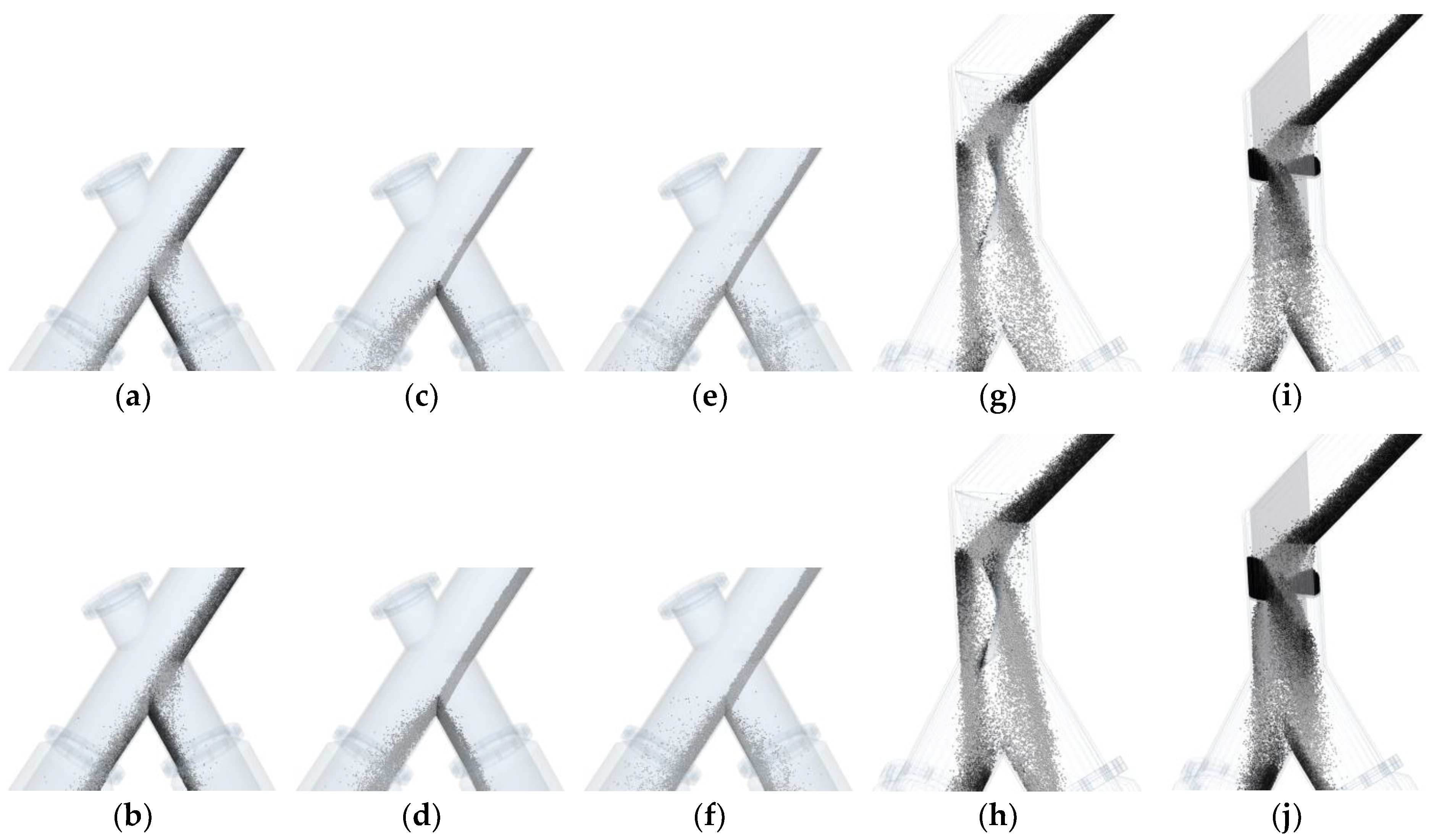

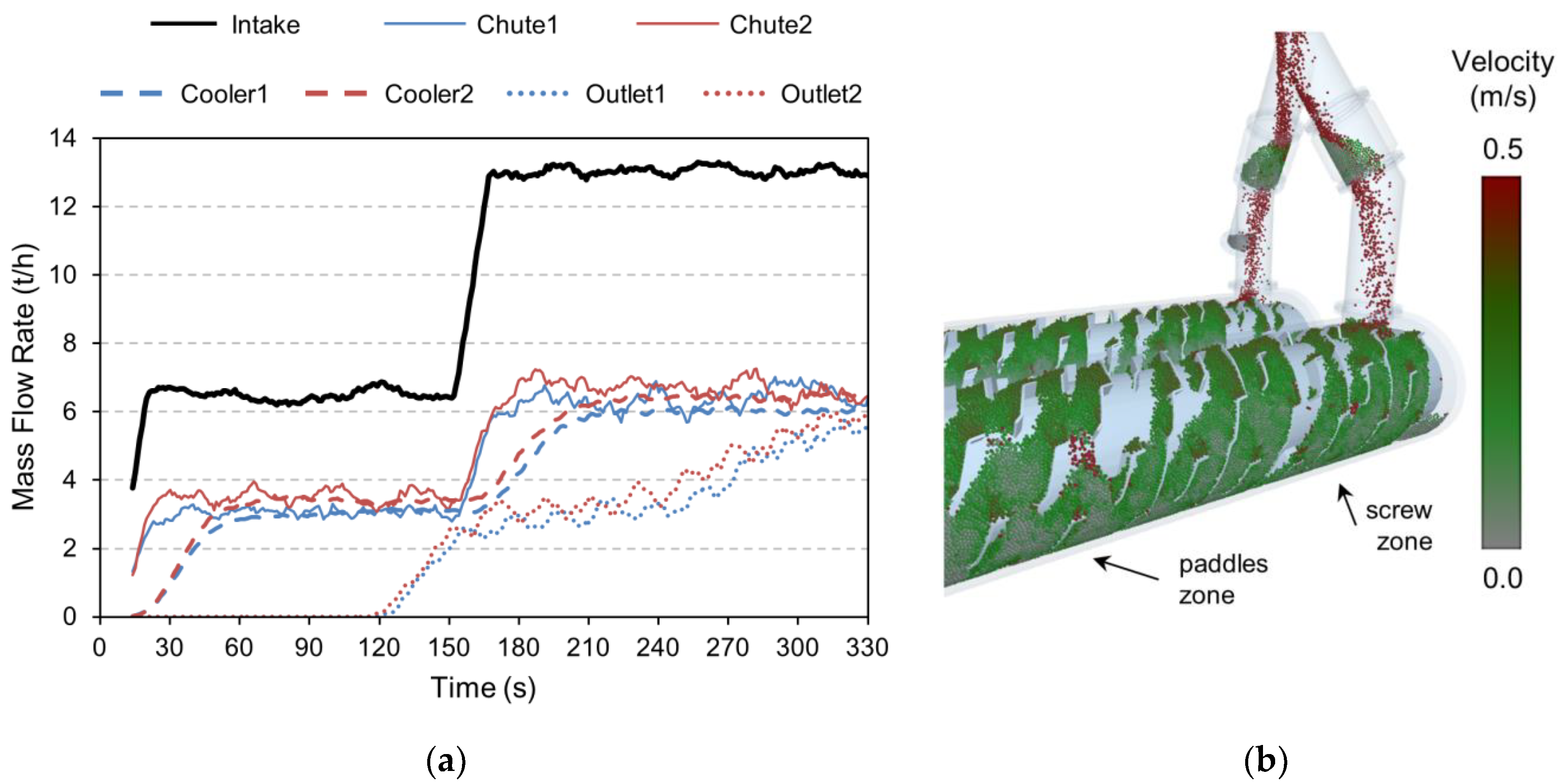

4.1. Analysis of the Current State of Operation

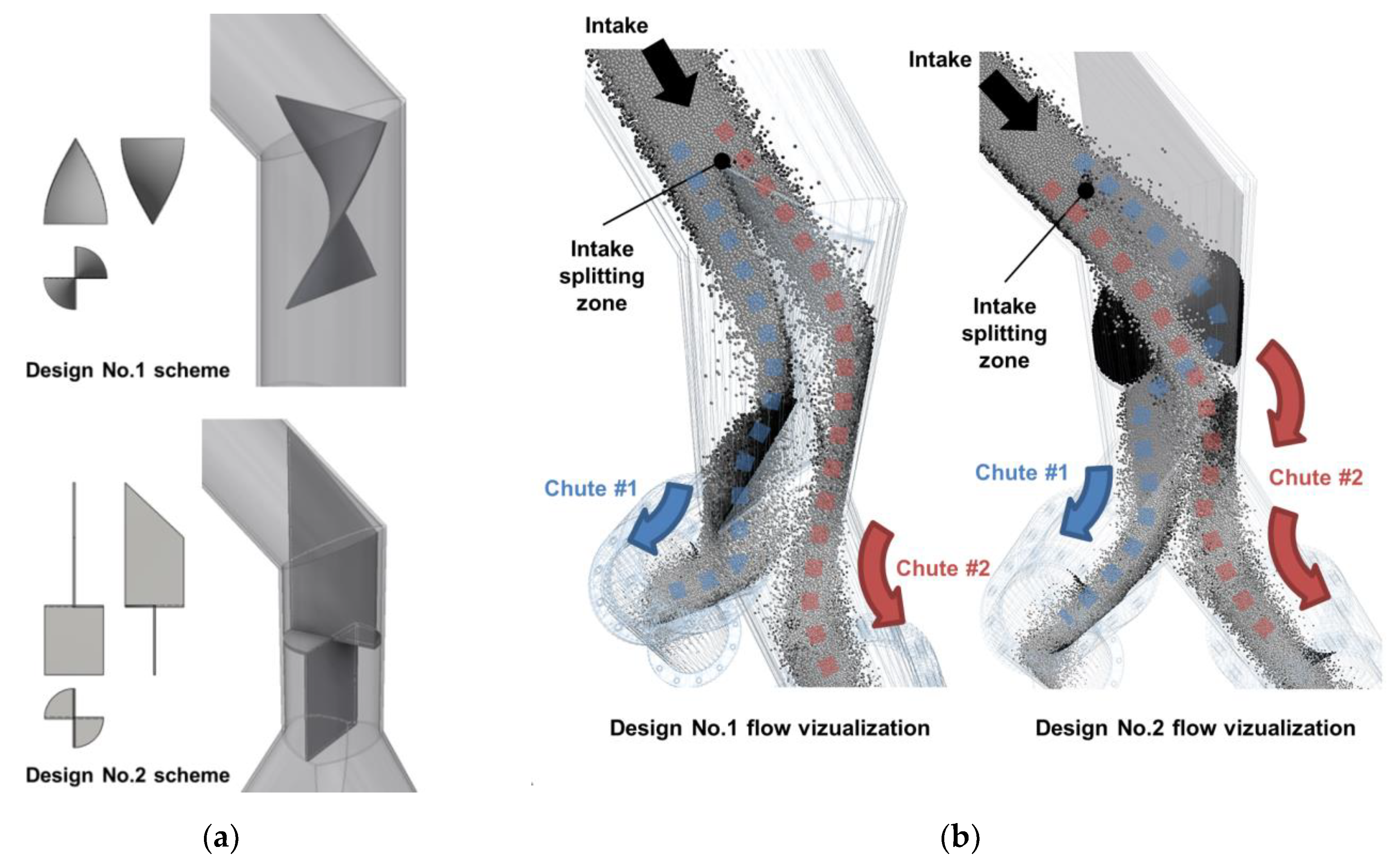

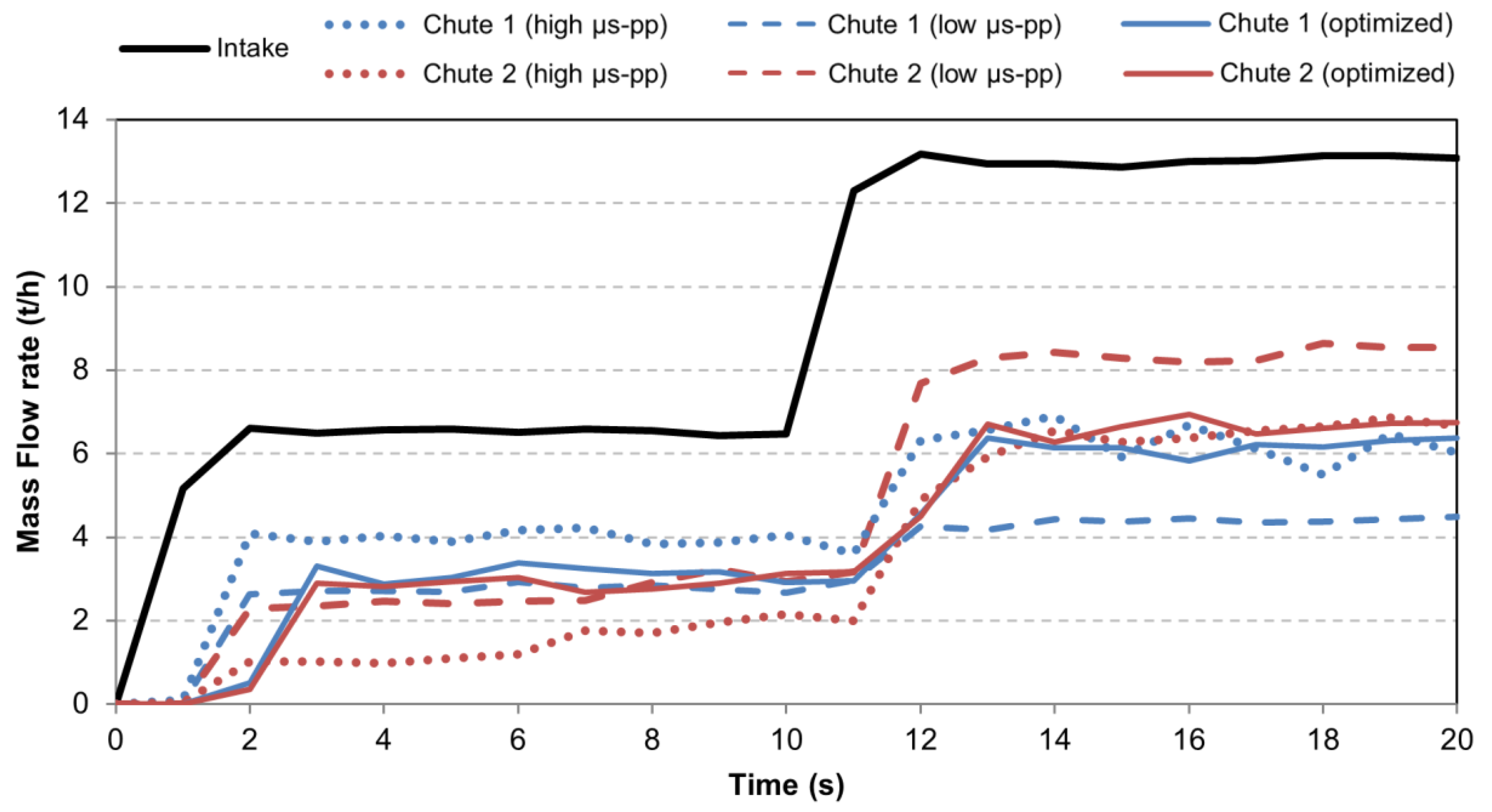

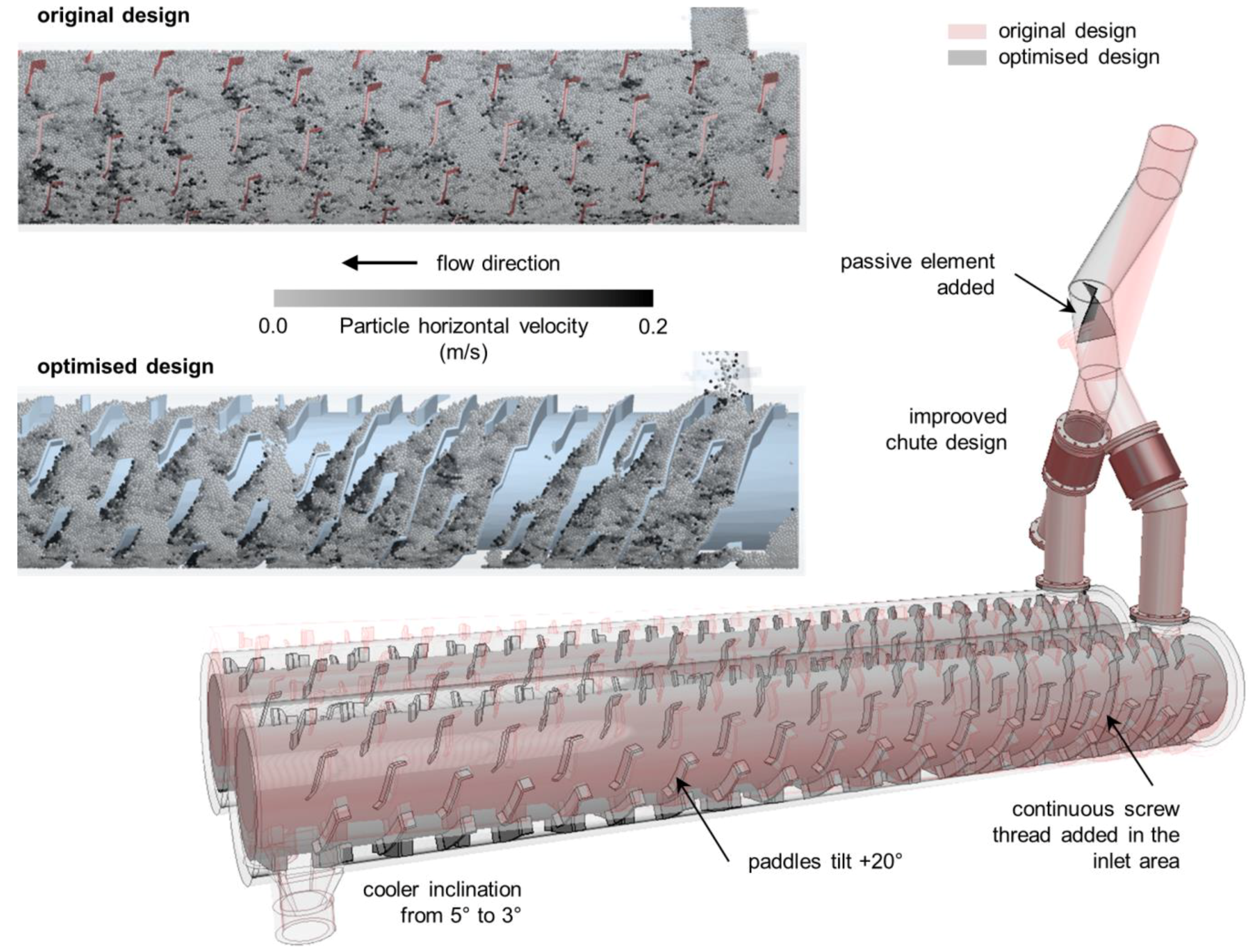

4.2. Inlet Pipeline Design Optimization

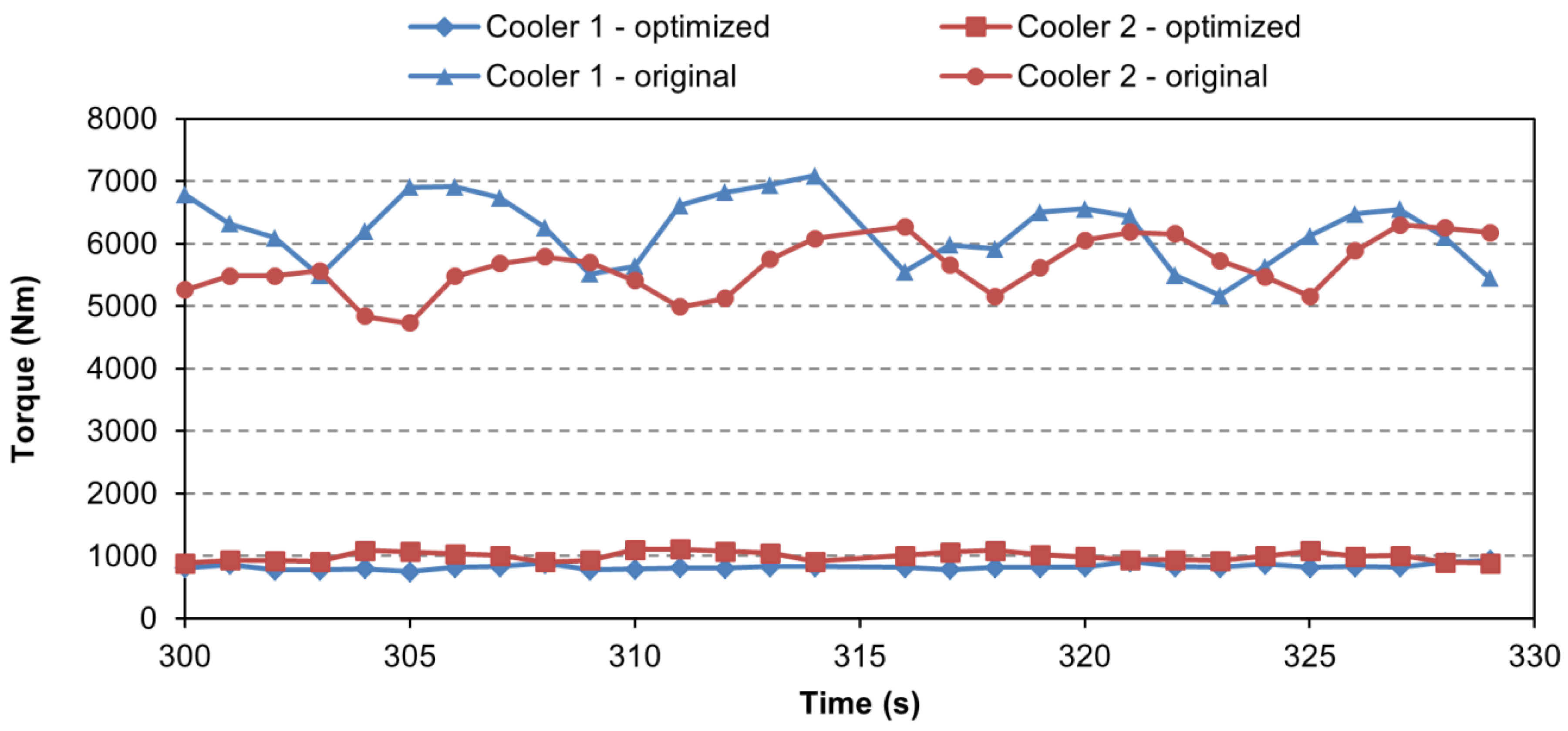

4.3. Rotary Coolers Design Optimization

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbols used | ||

| D | diameter | (m) |

| E | Young modulus | (Pa) |

| e | coefficient of restitution | (-) |

| F | force | (N) |

| G | shear modulus | (Pa) |

| I | moment of inertia | (kg∙m2) |

| k | damping | (N∙m−1) |

| m | mass | (kg) |

| R | radius | (m) |

| RV | reaction vector | (-) |

| T | time | (s) |

| v | velocity | (m∙s−1) |

| Greek letters | ||

| δ | displacement | (m) |

| μ | friction coefficient | (-) |

| ν | Poisson ratio | (-) |

| ρ | density | (kg∙m−3) |

| ψ | damping ratio | (-) |

| ω | angular velocity | (rad∙s−1) |

| Subscripts | ||

| * | equivalent | |

| i | particle i | |

| j | particle j | |

| n | normal | |

| pp | particle–particle | |

| pw | particle–wall | |

| r | rolling | |

| s | static | |

| sh | shear | |

| t | tangential | |

| Abbreviations | ||

| CAD | Computer-Aided Design | |

| CFD | Computational Fluid Dynamics | |

| CPU | Central Processing Unit | |

| DEM | Discrete Element Method | |

| FEM | Finite Element Method | |

| GPU | Graphics Processing Unit | |

| MBD | Multibody Dynamics | |

| SW | Software | |

References

- Wait, R. Discrete element models of particle flows. Math Model Anal. 2001, 6, 156–164. [Google Scholar] [CrossRef]

- Cleary, P.W. Discrete element modelling of industrial granular flow applications. Task. q.-Sci. Bull. 1998, 2, 385–416. [Google Scholar]

- Antonyuk, S.; Palis, S.; Heinrich, S. Breakage behaviour of agglomerates and crystals by static loading and impact. Powder Technol. 2011, 206, 88–98. [Google Scholar] [CrossRef]

- Owen, P.J.; Cleary, P.W. Prediction of screw conveyor performance using the Discrete Element Method (DEM). Powder Technol. 2009, 193, 274–288. [Google Scholar] [CrossRef]

- Feda, J. Mechanics of Particulate Materials—The Principles, 2nd ed.; Academia Prague: Prague, Czech Republic, 1982; ISBN 0-444-99712-X. [Google Scholar]

- Hendrik, O.; Kerst, K.; Roloff, C.; Janiga, G.; Katterfeld, A. CFD-DEM simulation and experimental investigation of the flow behavior of lunar regolith JSC-1A. Particuology 2018, in press. [Google Scholar] [CrossRef]

- Forsström, D.; Pär, J. Calibration and validation of a large scale abrasive wear model by coupling DEM-FEM: Local failure prediction from abrasive wear of tipper bodies during unloading of granular material. Eng. Fail. Anal. 2016, 66, 274–283. [Google Scholar] [CrossRef]

- Barrios, G.K.; Tavares, L.M. A preliminary model of high pressure roll grinding using the discrete element method and multi-body dynamics coupling. Int. J. Miner. Process. 2016, 156, 32–42. [Google Scholar] [CrossRef]

- Fedorko, G.; Ivančo, V. Analysis of Force Ratios in Conveyor Belt of Classic Belt Conveyor. Procedia. Eng. 2012, 48, 123–128. [Google Scholar] [CrossRef]

- Manjula, E.V.P.J.; Ariyaratne, W.K.H.; Ratnayake, C.; Melaaen, M.C. A review of CFD modelling studies on pneumatic conveying and challenges in modelling offshore drill cuttings transport. Powder Technol. 2017, 305, 782–793. [Google Scholar] [CrossRef]

- Chen, W.; Roberts, A.; Katterfeld, A.; Wheeler, C. Modelling the stability of iron ore bulk cargoes during marine transport. Powder Technol. 2018, 326, 255–264. [Google Scholar] [CrossRef]

- Markauskas, D.; Ramírez-Gómez, Á.; Kačianauskas, R.; Zdancevičius, E. Maize grain shape approaches for DEM modelling. Comput. Electron. Agric. 2015, 118, 247–258. [Google Scholar] [CrossRef]

- Bai, Y.; He, F. Modeling on the Effect of Coal Loads on kinetic Energy of Balls for Ball Mills. Energies 2015, 8, 6859–6880. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Geotech. 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Marigo, M. Discrete Element Method Modelling of Complex Granular Motion in Mixing Vessels: Evaluation and Validation. Ph.D. Thesis, The University of Birmingham, Birmingham, UK, 2012. [Google Scholar]

- Kannan, A.S.; Jareteg, K.; Lassen, N.C.K.; Carstensen, J.M.; Hansen, M.A.E.; Dam, F. Design and performance optimization of gravity tables using a combined CFD-DEM framework. Powder Technol. 2017, 318, 423–440. [Google Scholar] [CrossRef]

- Haeri, S. Optimisation of paddle type spreaders for powder bed preparation in Additive Manufacturing using DEM simulations. Powder Technol. 2017, 321, 94–104. [Google Scholar] [CrossRef]

- Zhao, L.; Zhao, Y.; Bao, C.; Hou, Q.; Yu, A. Optimisation of a circularly vibrating screen based on DEM simulation and Taguchi orthogonal experimental design. Powder Technol. 2017, 310, 307–317. [Google Scholar] [CrossRef]

- Pantaleev, S.; Yordanova, S.; Janda, A.; Marigo, M.; Ooi, J.Y. An experimentally validated DEM study of powder mixing in a paddle paddle mixer. Powder Technol. 2017, 311, 287–302. [Google Scholar] [CrossRef]

- Wang, D.; Servin, M.; Mickelsson, K.O. Outlet design optimization based on large-scale nonsmooth DEM simulation. Powder Technol. 2014, 253, 438–443. [Google Scholar] [CrossRef]

- Kulka, J.; Mantic, M.; Faltinova, E.; Molnar, V.; Fedorko, G. Failure analysis of the foundry crane to increase its working parameters. Eng. Fail. Anal. 2018, 88, 25–34. [Google Scholar] [CrossRef]

- Roberts, A.W.; Wensrich, C.M. Flow dynamics or ‘quaking’in gravity discharge from silos. Chem. Eng. Sci. 2002, 57, 295–305. [Google Scholar] [CrossRef]

- Klinzing, G.E. A review of pneumatic conveying status, advances and projections. Powder Technol. 2018, 333, 78–90. [Google Scholar] [CrossRef]

- Nečas, J.; Hlosta, J.; Žurovec, D.; Žídek, M.; Rozbroj, J.; Zegzulka, J. Feeder Type Optimisation for the Plain Flow Discharge Process of an Underground Hopper by Discrete Element Modelling. Adv. Sci. Technol. Res. J. 2017, 11, 246–252. [Google Scholar] [CrossRef]

- Roberts, A.W. Particle Technology—Reflections and Horizons. Chem. Eng. Res. Des. 1998, 76, 775–796. [Google Scholar] [CrossRef]

- Drescher, A.; Josselin, G. Photoelastic verification of a mechanical model for the flow of a granular material. J. Mech. Phys. Solids. 1972, 20, 337–340. [Google Scholar] [CrossRef]

- Raclavská, H.; Corsaro, A.; Juchelková, D.; Sassmanová, V.; Frantík, J. Effect of temperature on the enrichment and volatility of 18 elements during pyrolysis of biomass, coal, and tires. Fuel Process. Technol. 2015, 131, 330–337. [Google Scholar] [CrossRef]

- Belohlav, Z.; Brenková, L.; Hanika, J.; Durdil, P.; Rapek, P.; Tomasek, V. Effect of Drug Active Substance Particles on Wet Granulation Process. Chem. Eng. Res. Des. 2017, 85, 974–980. [Google Scholar] [CrossRef]

- Hlosta, J.; Zurovec, D.; Gelnar, D.; Zegzulka, J.; Necas, J. Thermal Conductivity Measurement of Bulk Solids. Chem. Eng. Technol. 2017, 40, 1876–1884. [Google Scholar] [CrossRef]

- Baniasadi, M.; Baniasadi, M.; Peters, B. Coupled CFD-DEM with heat and mass transfer to investigate the melting of a granular packed bed. Chem. Eng. Sci. 2018, 178, 136–145. [Google Scholar] [CrossRef]

- Bellan, S.; Matsubara, K.; Cho, H.S.; Gokon, N.; Kodama, T. A CFD-DEM study of hydrodynamics with heat transfer in a gas-solid fluidized bed reactor for solar thermal applications. Int. J. Heat Mass Transf. 2018, 116, 377–392. [Google Scholar] [CrossRef]

- Wu, H.; Gui, N.; Yang, X.; Tu, J.; Jiang, S. A smoothed void fraction method for CFD-DEM simulation of packed pebble beds with particle thermal radiation. Int. J. Heat Mass Transf. 2018, 118, 275–288. [Google Scholar] [CrossRef]

- Tsuji, Y.; Tanaka, T.; Ishida, T. Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol. 1992, 71, 239–250. [Google Scholar] [CrossRef]

- Raymus, G.J. Handling of Bulk Solids. In Chemical Engineers’ Handbook, 6th ed.; Perry, R.H., Green, D., Eds.; McGraw-Hill: New York, NY, USA, 1985; ISBN 978-0070494794. [Google Scholar]

- Schwartz, S.R.; Richardson, D.C.; Michel, P. An implementation of the soft-sphere discrete element method in a high-performance parallel gravity tree-code. Granul. Matter 2012, 14, 363–380. [Google Scholar] [CrossRef]

- Hlosta, J.; Zurovec, D.; Rozbroj, J.; Ramírez-Gómez, Á.; Necas, J.; Zegzulka, J. Experimental determination of particle-particle restitution coefficient via double pendulum method. Chem. Eng. Res. Des. 2018, in press. [Google Scholar] [CrossRef]

- Beakawi Al-Hashemi, H.M.; Baghabra Al-Amoudi, O.S. A review on the angle of repose of granular materials. Powder Technol. 2018, 330, 397–417. [Google Scholar] [CrossRef]

- Bian, X.; Wang, G.; Wang, H.; Wang, S.; Lv, W. Effect of lifters and mill speed on particle behaviour, torque, and power consumption of a tumbling ball mill: Experimental study and DEM simulation. Miner. Eng. 2017, 105, 22–35. [Google Scholar] [CrossRef]

| Material | Density | Poisson’s Ratio | Young’s Modulus | Coeff. of Restitution | Static Friction | Rolling Friction |

|---|---|---|---|---|---|---|

| (kg∙m−3) | (-) | (MPa) | (-) | (-) | (°) | |

| Fly ash | 7850 | 0.25 | 11 | 0.65 | 0.8 | 1.4 |

| Steel | 870 | 0.30 | 210 | 0.70 | 0.9 | 1.3 |

| Angle of Repose (°)—Measurement No. | Avg. | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||

| Experiment | 38.5 | 39.2 | 38.7 | 38.4 | 37.0 | 38.1 | 37.1 | 37.3 | 38.1 |

| DEM | 35.0 | 43.5 | 38.8 | 36.5 | 37.0 | 37.0 | 40.1 | 40.9 | 38.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hlosta, J.; Žurovec, D.; Rozbroj, J.; Ramírez-Gómez, Á.; Nečas, J.; Zegzulka, J. Analysis and Optimization of Material Flow inside the System of Rotary Coolers and Intake Pipeline via Discrete Element Method Modelling. Energies 2018, 11, 1849. https://doi.org/10.3390/en11071849

Hlosta J, Žurovec D, Rozbroj J, Ramírez-Gómez Á, Nečas J, Zegzulka J. Analysis and Optimization of Material Flow inside the System of Rotary Coolers and Intake Pipeline via Discrete Element Method Modelling. Energies. 2018; 11(7):1849. https://doi.org/10.3390/en11071849

Chicago/Turabian StyleHlosta, Jakub, David Žurovec, Jiří Rozbroj, Álvaro Ramírez-Gómez, Jan Nečas, and Jiří Zegzulka. 2018. "Analysis and Optimization of Material Flow inside the System of Rotary Coolers and Intake Pipeline via Discrete Element Method Modelling" Energies 11, no. 7: 1849. https://doi.org/10.3390/en11071849

APA StyleHlosta, J., Žurovec, D., Rozbroj, J., Ramírez-Gómez, Á., Nečas, J., & Zegzulka, J. (2018). Analysis and Optimization of Material Flow inside the System of Rotary Coolers and Intake Pipeline via Discrete Element Method Modelling. Energies, 11(7), 1849. https://doi.org/10.3390/en11071849