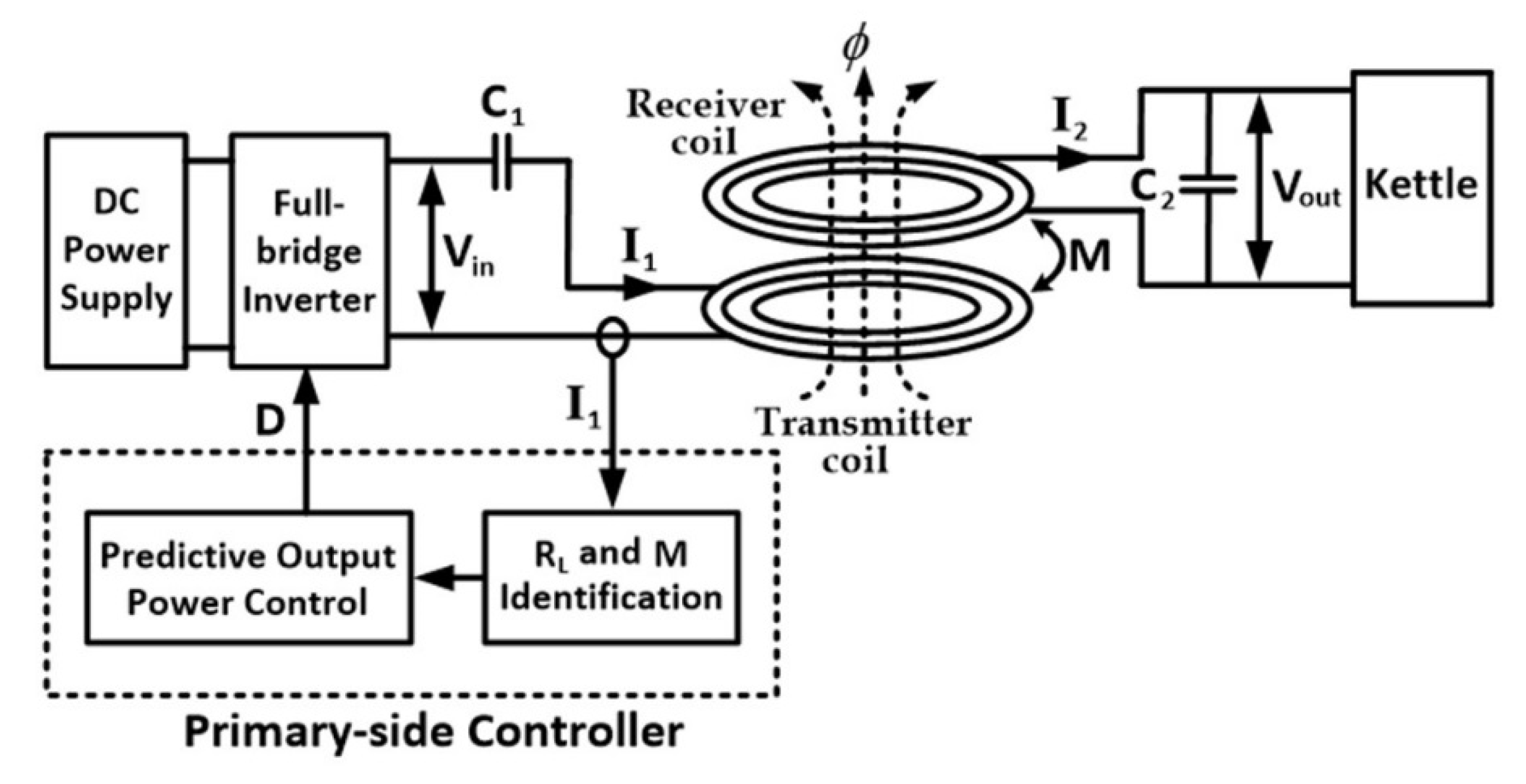

A Novel Output Power Control of Wireless Powering Kitchen Appliance System with Free-Positioning Feature

Abstract

1. Introduction

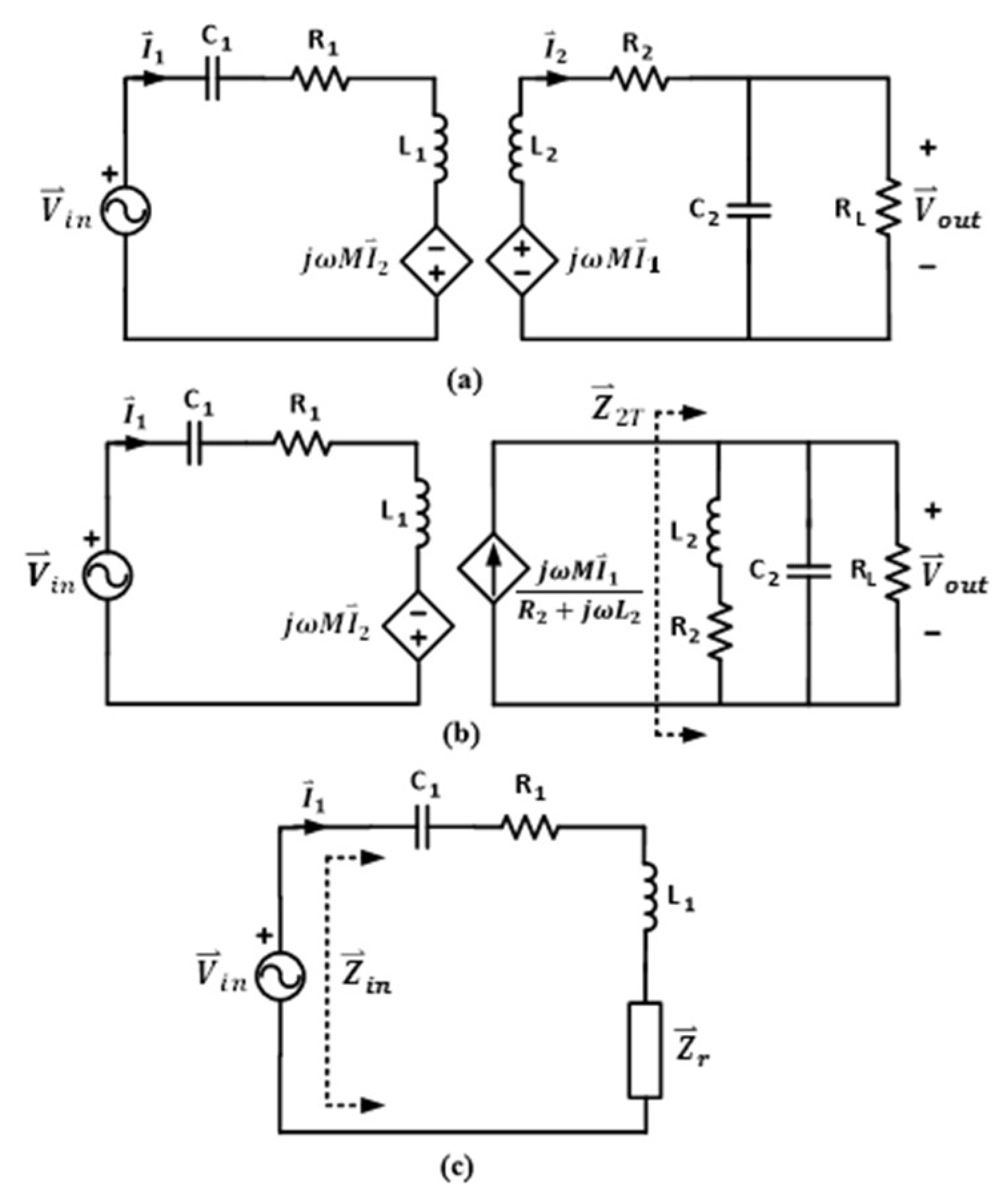

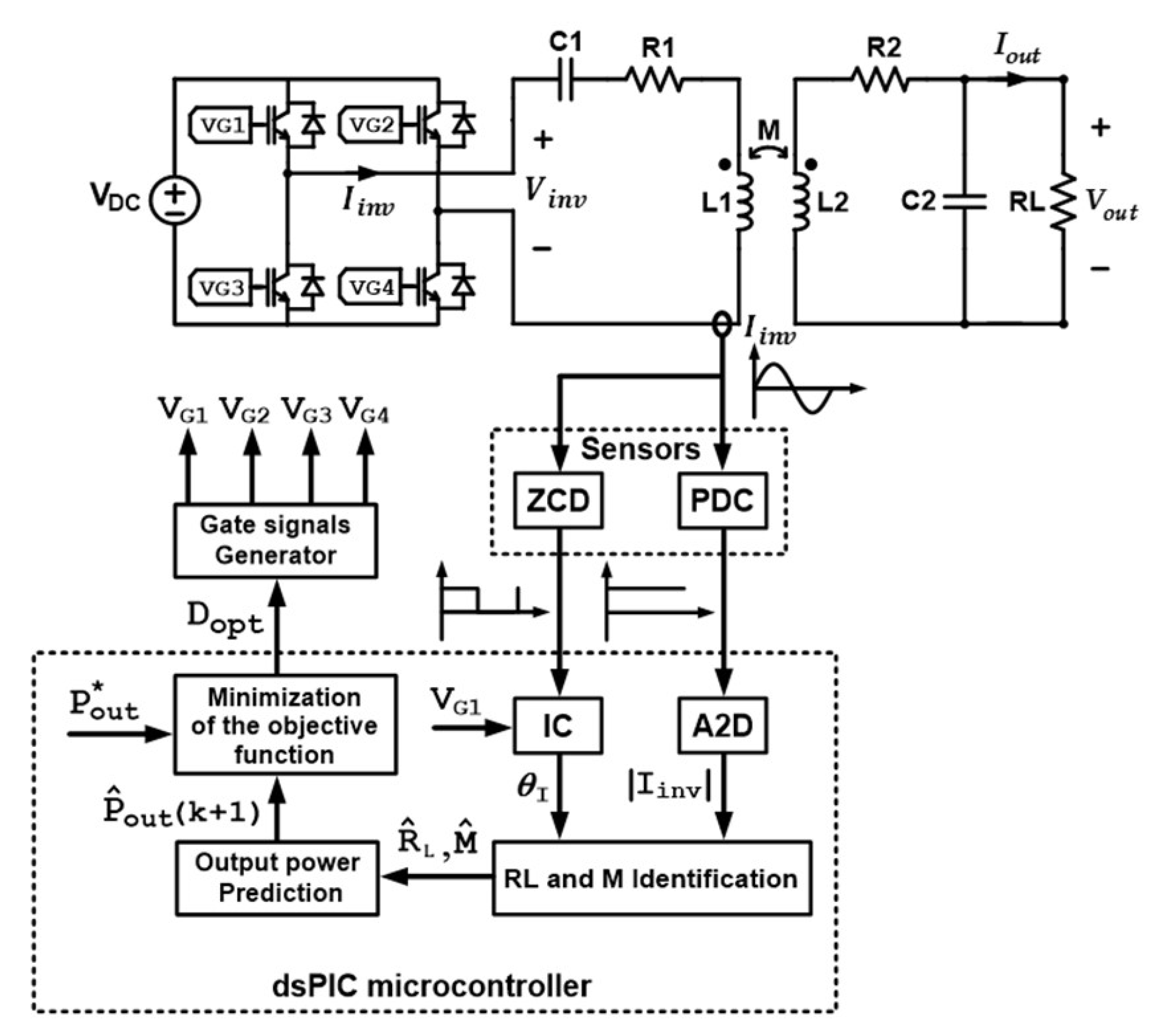

2. Theoretical Analysis

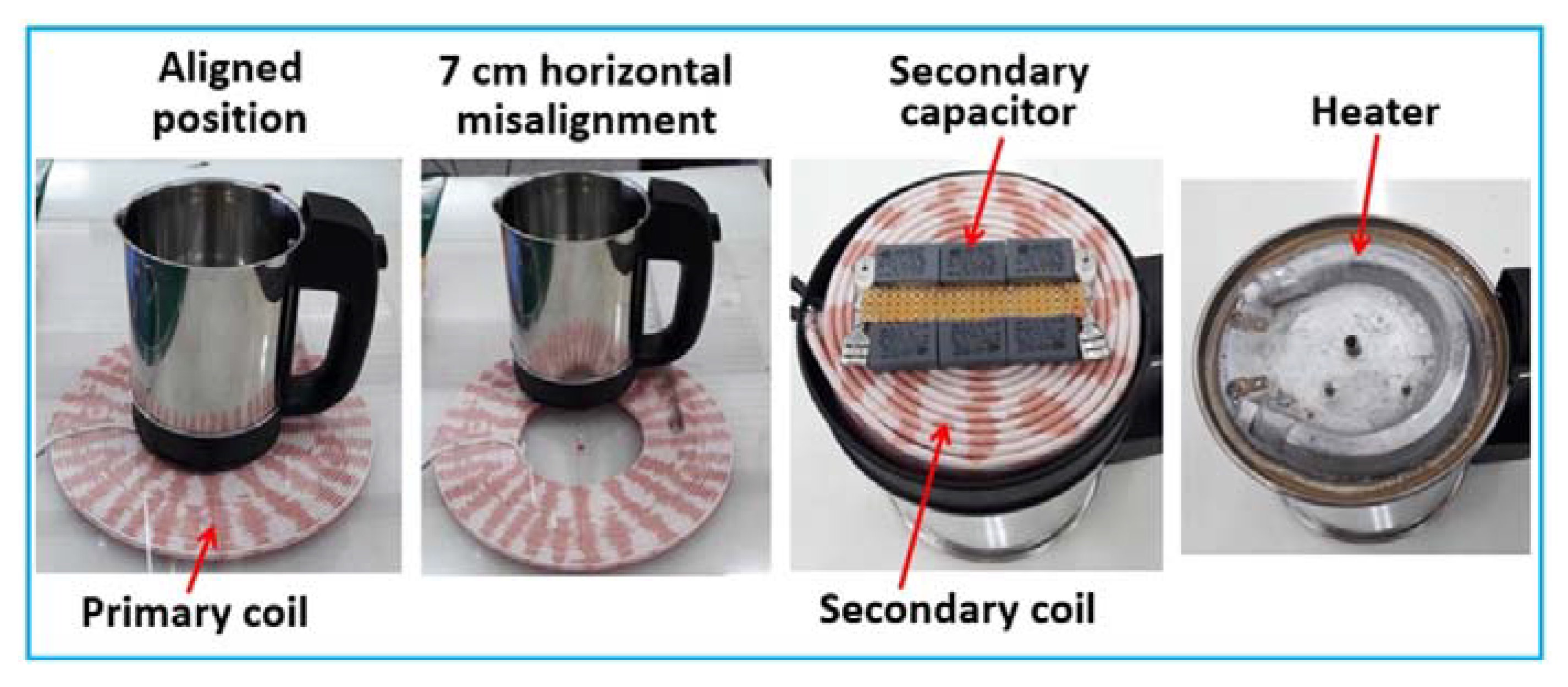

2.1. System Characteristic

- (1)

- Both self-inductances, L1 and L2, are fixed and independent of misalignment. This is due to the absence of magnetic material, such as ferrite bars, along both primary and secondary coils.

- (2)

- The winding resistances, R1 and R2, of the coupled coil are constant, since the operating frequency is fixed and the heating effect on the windings is negligible.

- (3)

- The compensation capacitors, C1 and C2, are constant under normal operating condition.

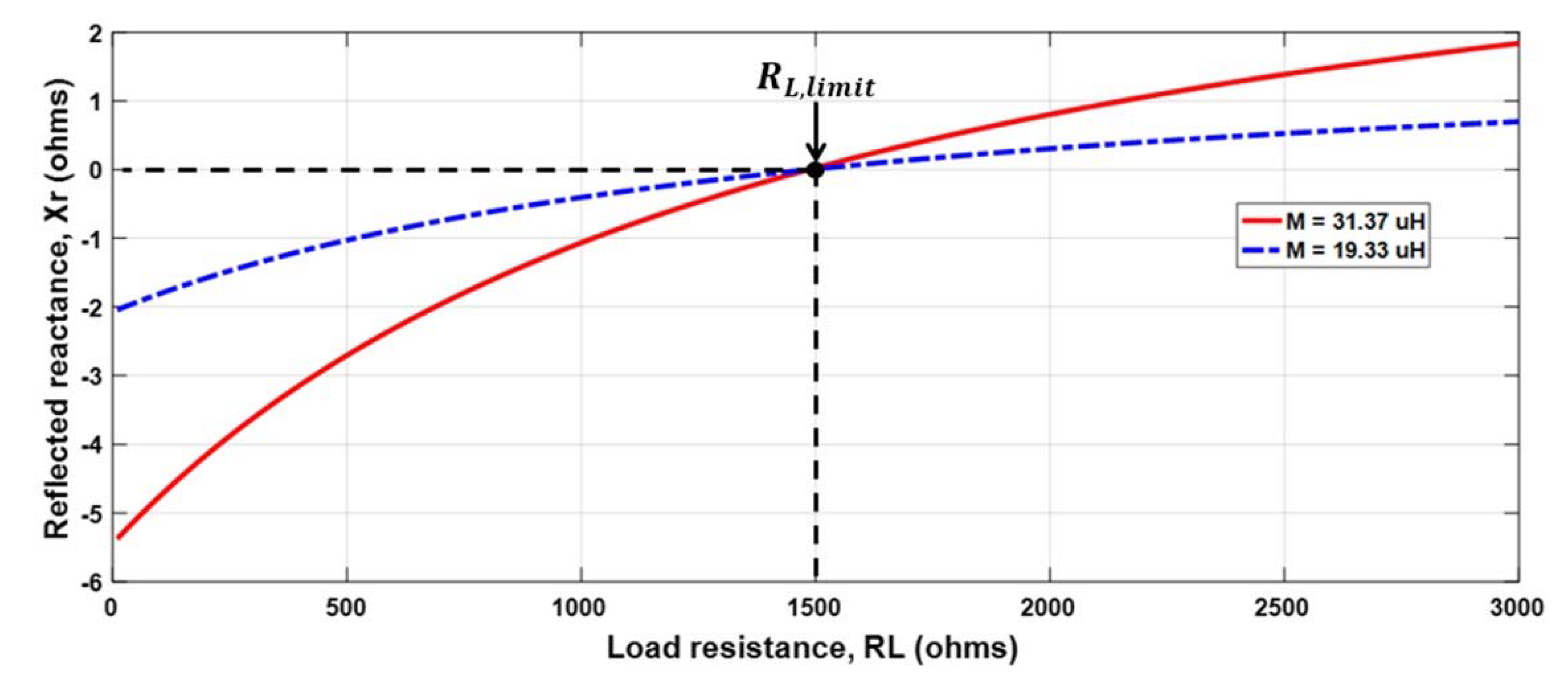

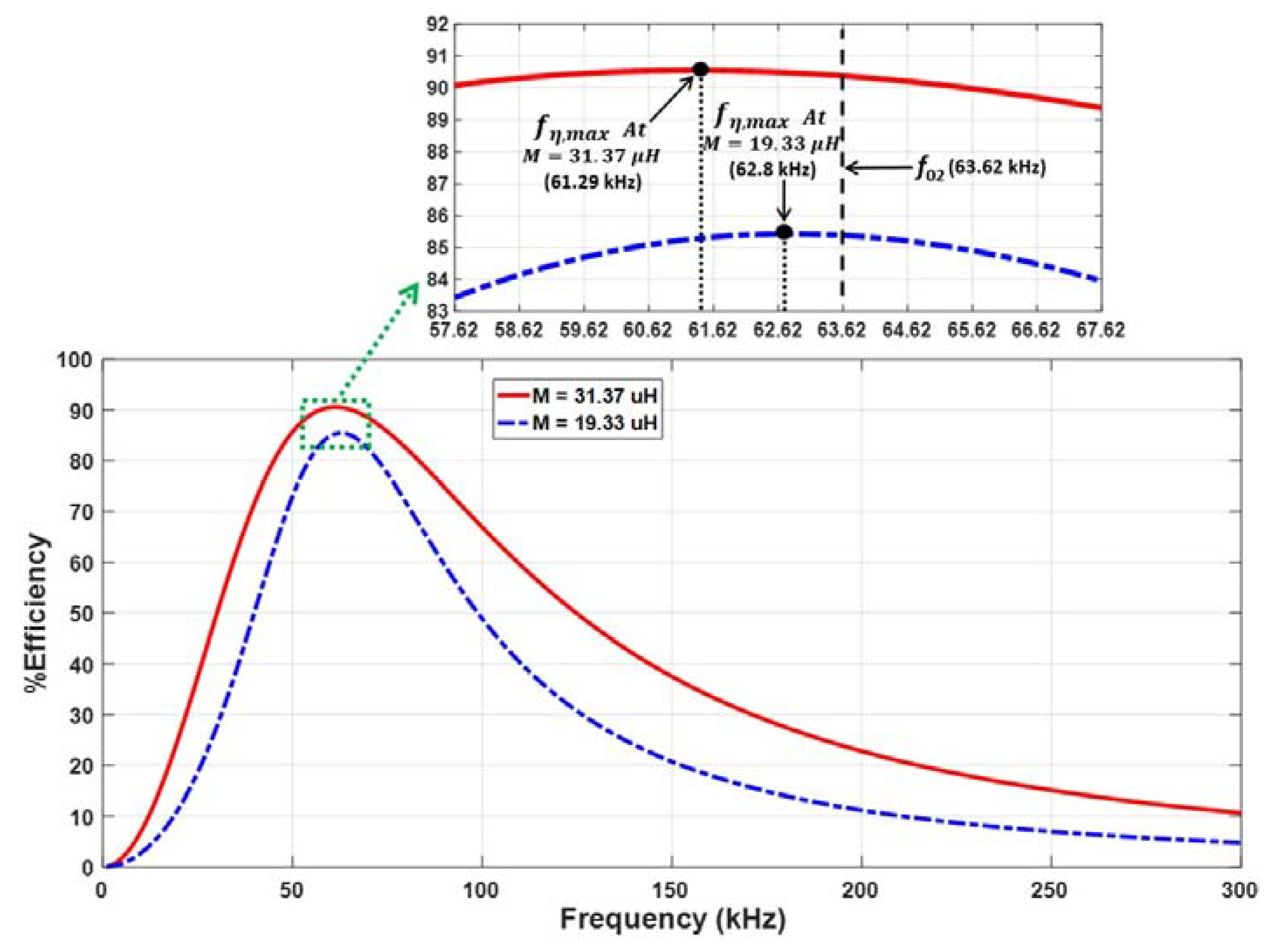

2.2. Optimal Operating Frequency

2.3. Load Resistance and Mutual Inductance Identification

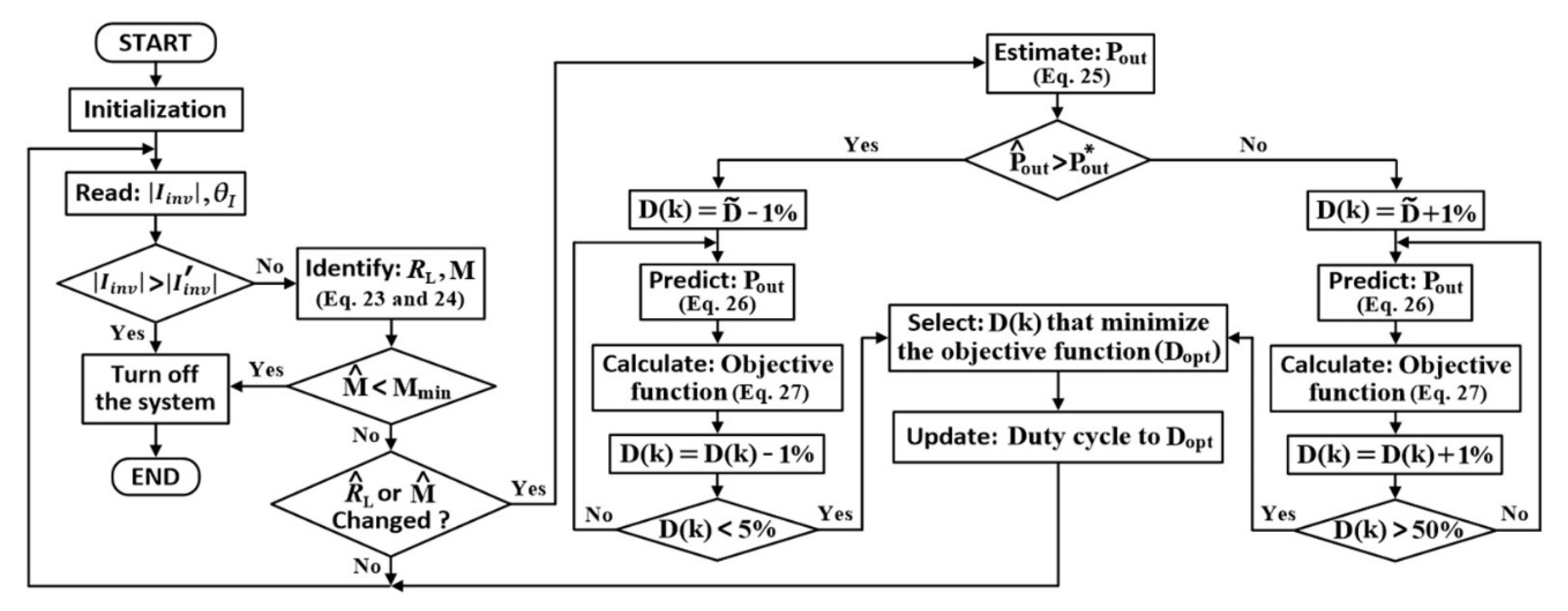

3. Proposed Controller

3.1. Full-Bridge Inverter with Phase-Shift Control

3.2. Model Predictive Control

3.3. Protection

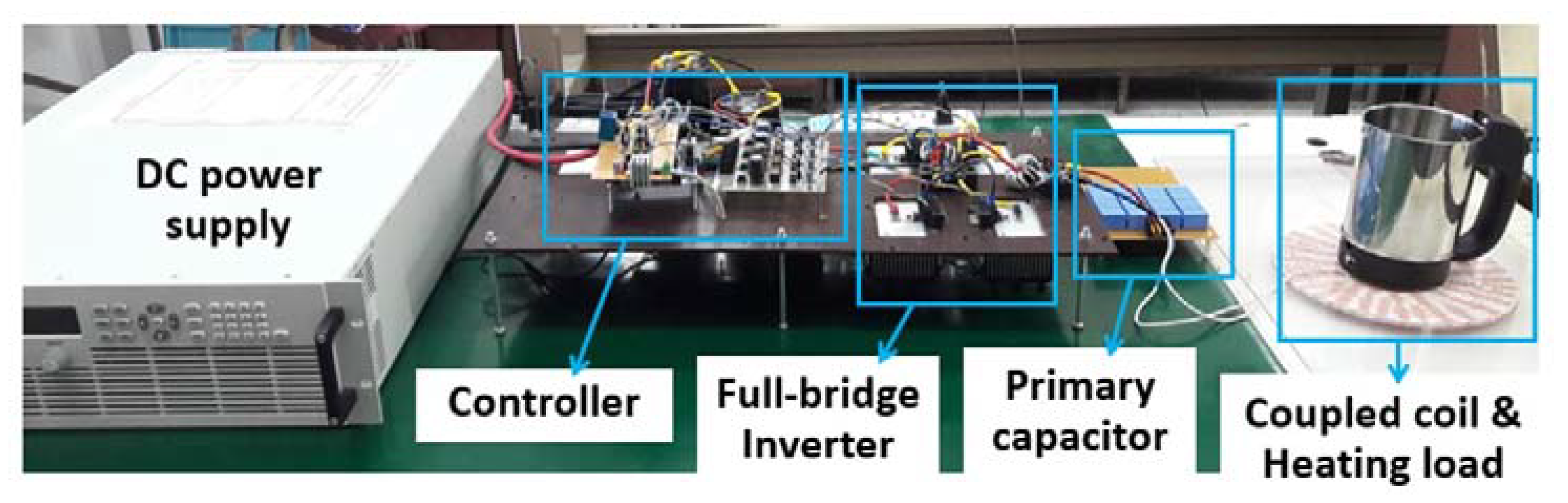

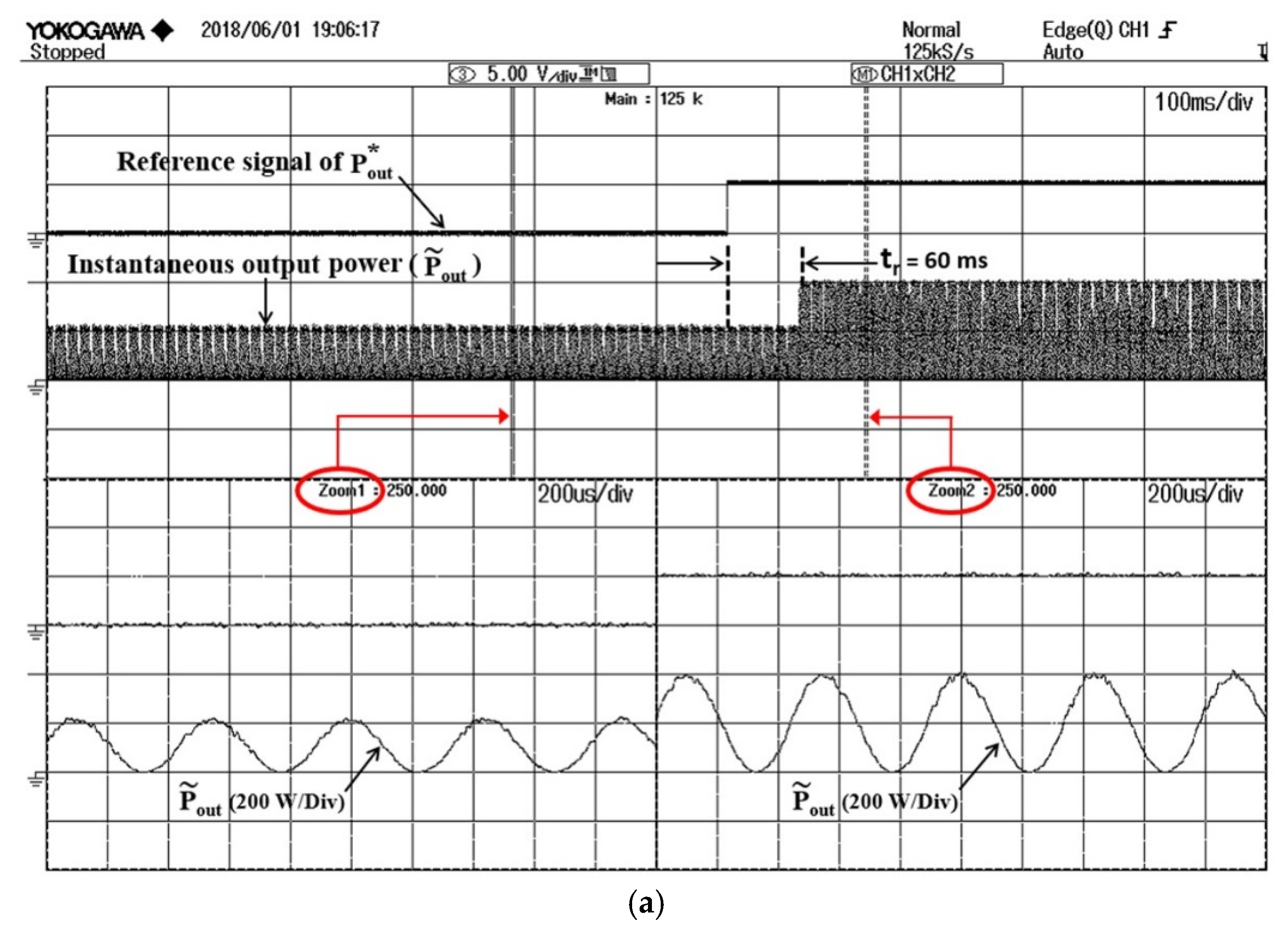

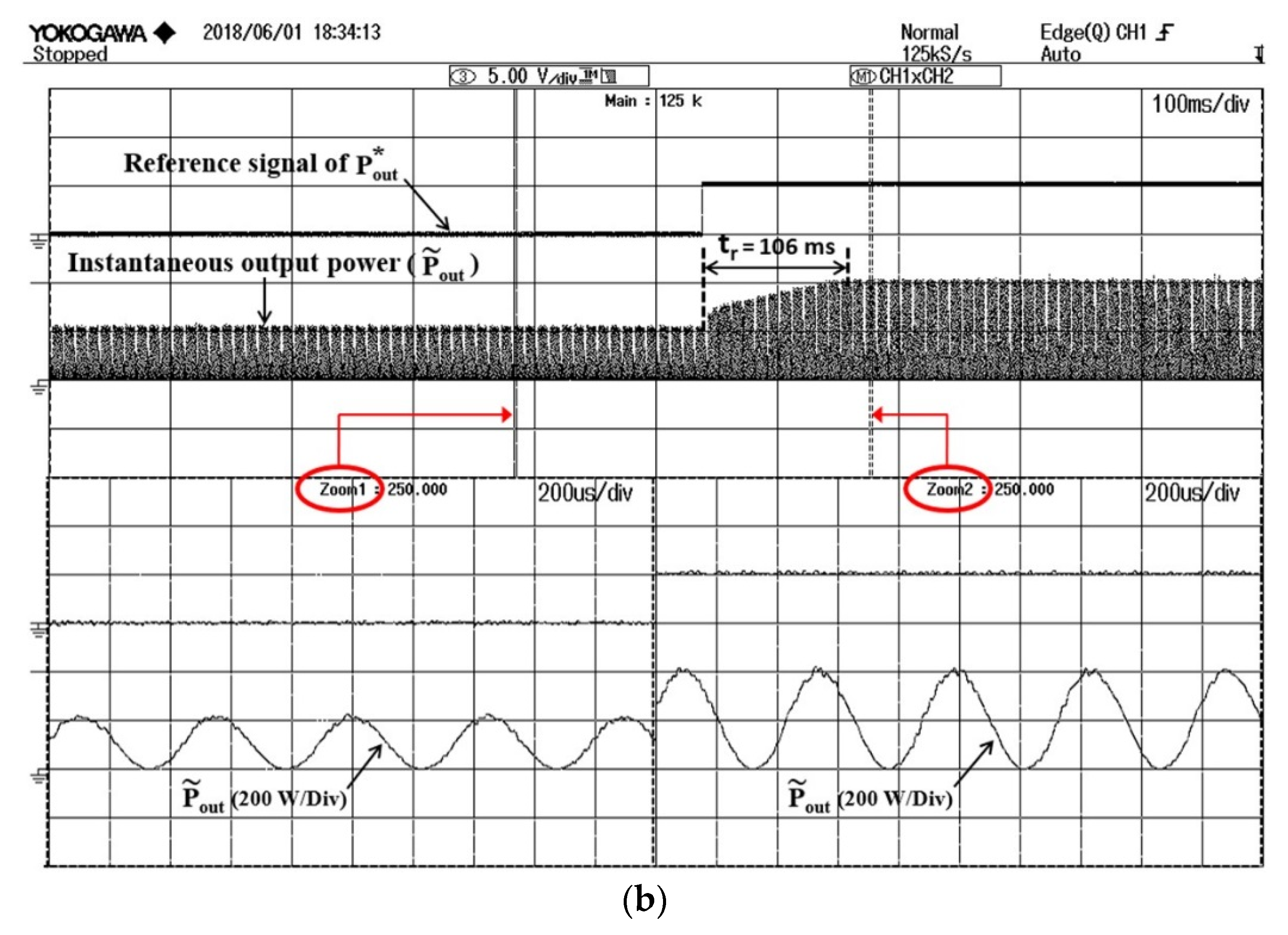

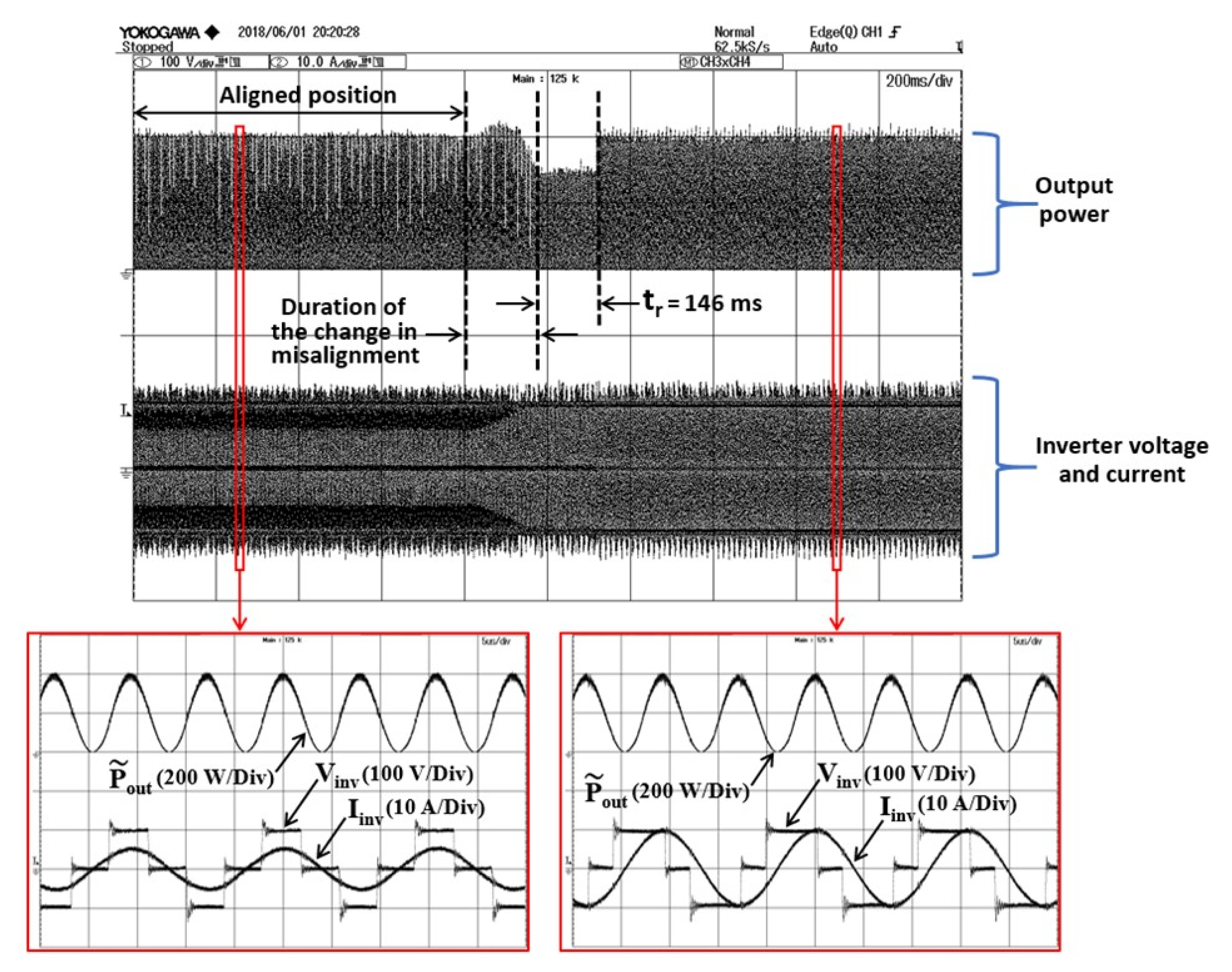

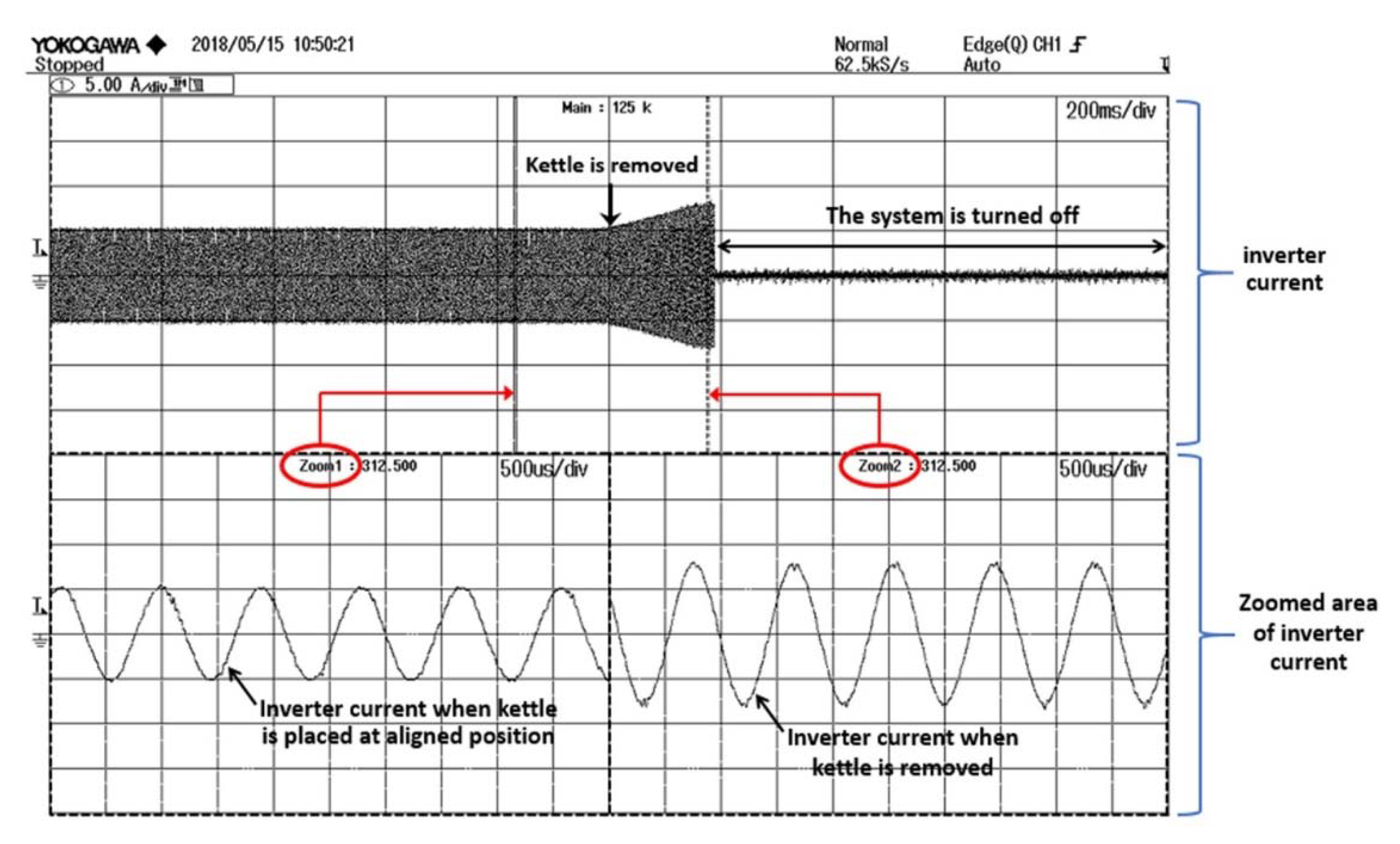

4. Experimental Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hui, S.Y.R.; Zhong, W.; Lee, C.K. A Critical Review of Recent Progress in Mid-Range Wireless Power Transfer. IEEE Trans. Power Electron. 2014, 29, 4500–4511. [Google Scholar] [CrossRef]

- Musavi, F.; Eberle, W. Overview of wireless power transfer technologies for electric vehicle battery charging. IET Power Electron. 2014, 7, 60–66. [Google Scholar] [CrossRef]

- Dai, J.; Ludois, D.C. A Survey of Wireless Power Transfer and a Critical Comparison of Inductive and Capacitive Coupling for Small Gap Applications. IEEE Trans. Power Electron. 2015, 30, 6017–6029. [Google Scholar] [CrossRef]

- Ahn, D.; Hong, S. Wireless Power Transmission with Self-Regulated Output Voltage for Biomedical Implant. IEEE Trans. Ind. Electron. 2014, 61, 2225–2235. [Google Scholar] [CrossRef]

- Roshan, Y.M.; Park, E.J. Design approach for a wireless power transfer system for wristband wearable devices. IET Power Electron. 2017, 10, 931–937. [Google Scholar] [CrossRef]

- Falkenstein, E.; Costinett, D.; Costinett, R.; Popovic, Z. Far-Field RF-Powered Variable Duty Cycle Wireless Sensor Platform. IEEE Trans. Circuits Syst. II 2011, 58, 822–826. [Google Scholar] [CrossRef]

- Lu, Y.; Ma, D.B. Wireless Power Transfer System Architectures for Portable or Implantable Applications. Energies 2016, 9, 1087. [Google Scholar] [CrossRef]

- Liu, H.; Huang, X.; Tan, L.; Guo, J.; Wang, W.; Yan, C.; Xu, C. Dynamic Wireless Charging for Inspection Robots Based on Decentralized Energy Pickup Structure. IEEE Trans. Ind. Informat. 2018, 14, 1786–1797. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, X.; Dai, H. Design and Control of a 3 kW Wireless Power Transfer System for Electric Vehicles. Energies 2015, 9, 1–18. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, J.H.; Lee, J.H. Development of a 60 kHz, 180 kW, Over 85% Efficiency Inductive Power Transfer System for a Tram. Energies 2016, 9, 1075. [Google Scholar] [CrossRef]

- Kim, J.W.; Son, H.C.; Kim, D.H.; Park, Y.J. Optimal Design of a Wireless Power Transfer System with Multiple Self-Resonators for an LED TV. IEEE Trans. Consum. Electron. 2012, 58, 775–780. [Google Scholar] [CrossRef]

- Wang, Z.H.; Li, Y.P.; Sun, Y.; Tang, C.S.; Lv, X. Load Detection Model of Voltage-Fed Inductive Power Transfer System. IEEE Trans. Power Electron. 2013, 28, 5233–5243. [Google Scholar] [CrossRef]

- James, J.E.; Robertson, D.J.; Covic, G.A. Improved AC Pickups for IPT Systems. IEEE Trans. Power Electron. 2014, 29, 6361–6374. [Google Scholar] [CrossRef]

- Tsiropoulou, E.E.; Mitis, G.; Papavassiliou, S. Interest-aware energy collection & resource management in machine to machine communications. Ad Hoc Netw. 2018, 68, 48–57. [Google Scholar] [CrossRef]

- Kim, T.H.; Yun, G.H.; Lee, W.Y.; Yook, J.G. Asymmetric Coil Structures for Highly Efficient Wireless Power Transfer Systems. IEEE Trans. Microw. Theory Tech. 2018, 1–9. [Google Scholar] [CrossRef]

- Vamvakas, P.; Tsiropoulou, E.E.; Vomvas, M.; Papavassiliou, S. Adaptive Power Management in Wireless Powered Communication Networks: A User-Centric Approach. In Proceedings of the IEEE 38th Sarnoff Symposium, Newark, NJ, USA, 18–20 September 2017; pp. 1–6. [Google Scholar]

- Kim, T.H.; Yoon, S.; Yook, J.G.; Yun, G.H.; Lee, W.Y. Evaluation of Power Transfer Efficiency with Ferrite Sheets in WPT System. In Proceedings of the IEEE Wireless Power Transfer Conference (WPTC), Taipei, Taiwan, 10–12 May 2017; pp. 1–4. [Google Scholar]

- Costanzo, A.; Masotti, D. Energizing 5G: Near- and Far-Field Wireless Energy and Data Trantransfer as an Enabling Technology for the 5G IoT. IEEE Microw. Mag. 2017, 18, 125–136. [Google Scholar] [CrossRef]

- Zhong, W.X.; Liu, X.; Hui, S.Y.R. A Novel Single-Layer Winding Array and Receiver Coil Structure for Contactless Battery Charging Systems with Free-Positioning and Localized Charging Features. IEEE Trans. Ind. Electron. 2011, 58, 4136–4144. [Google Scholar] [CrossRef]

- Yeo, T.D.; Kim, D.H.; Chae, S.C.; Khang, S.T.; Yu, J.W. Design of Free-Positioning Wireless Power Charging System for AAA Rechargeable Battery. In Proceedings of the 46th European Microwave Conference, London, UK, 4–6 October 2016; pp. 759–762. [Google Scholar]

- Madawala, U.K.; Thrimawithana, D.J. New technique for inductive power transfer using a single controller. IET Power Electron. 2012, 5, 248–256. [Google Scholar] [CrossRef]

- Chan, T.S.; Chen, C.L. A Primary Side Control Method for Wireless Energy Transmission System. IEEE Trans. Circuits Syst. 2012, 59, 1805–1814. [Google Scholar] [CrossRef]

- Yin, J.; Lin, D.; Lee, C.K.; Hui, S.Y.R. A Systematic Approach for Load Monitoring and Power Control in Wireless Power Transfer Systems without Any Direct Output Measurement. IEEE Trans. Power Electron. 2015, 30, 1657–1667. [Google Scholar] [CrossRef]

- Cai, H.; Shi, L.; Li, Y. Harmonic-Based Phase-Shifted Control of Inductively Coupled Power Transfer. IEEE Trans. Power Electron. 2014, 29, 594–602. [Google Scholar] [CrossRef]

- Matsumoto, H.; Neba, Y.; Asahara, H. Switched Compensator for Contactless Power Transfer Systems. IEEE Trans. Power Electron. 2015, 30, 6120–6129. [Google Scholar] [CrossRef]

- Nutwong, S.; Sangswang, A.; Naetiladdanon, S. Output voltage control of the SP topology IPT system using a primary side controller. In Proceedings of the IEEE International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology, Chiang Mai, Thailand, 28 June–1 July 2016; pp. 1–5. [Google Scholar]

- Aditya, K.; Williamson, S. Linearization and Control of Series-Series Compensated Inductive Power Transfer System Based on Extended Describing Function Concept. Energies 2016, 9, 962. [Google Scholar] [CrossRef]

- Su, Y.G.; Zhang, H.Y.; Wang, Z.H.; Hu, A.P.; Chen, L.; Sun, Y. Steady-State Load Identification Method of Inductive Power Transfer System Based on Switching Capacitors. IEEE Trans. Power Electron. 2015, 30, 6349–6355. [Google Scholar] [CrossRef]

- Chow, J.P.W.; Chung, H.S.H.; Cheng, C.S. Use of Transmitter-Side Electrical Information to Estimate Mutual Inductance and Regulate Receiver-Side Power in Wireless Inductive Link. IEEE Trans. Power Electron. 2016, 31, 6079–6091. [Google Scholar] [CrossRef]

- Yin, J.; Lin, D.; Parisini, T.; Hui, S.Y.R. Front-End Monitoring of the Mutual Inductance and Load Resistance in a Series–Series Compensated Wireless Power Transfer System. IEEE Trans. Power Electron. 2016, 31, 7339–7352. [Google Scholar] [CrossRef]

- Darba, A.; Belie, F.D.; D’haese, P.; Melkebeek, J.A. Improved Dynamic Behavior in BLDC Drives Using Model Predictive Speed and Current Control. IEEE Trans. Ind. Electron. 2016, 63, 728–740. [Google Scholar] [CrossRef]

- Mora, A.; Orellana, A.; Juliet, J.; Cárdenas, R. Model Predictive Torque Control for Torque Ripple Compensation in Variable-Speed PMSMs. IEEE Trans. Ind. Electron. 2016, 63, 4584–4592. [Google Scholar] [CrossRef]

- Hu, J.; Zhu, J.; Dorrell, D.G. Model Predictive Control of Grid-Connected Inverters for PV Systems with Flexible Power Regulation and Switching Frequency Reduction. IEEE Trans. Ind. Appl. 2015, 51, 587–594. [Google Scholar] [CrossRef]

- Scoltock, J.; Geyer, T.; Madawala, U.K. Model Predictive Direct Power Control for Grid-Connected NPC Converters. IEEE Trans. Ind. Electron. 2015, 62, 5319–5328. [Google Scholar] [CrossRef]

- Kranprakon, P.; Sangswang, A.; Naetiladdanon, S.; Mujjalinwimut, E. A Model Predictive Control of an LLC Resonant Inverter for Tin Melting Application. In Proceedings of the 43rd Annual Conference of the IEEE Industrial Electronics Society (IECON), Beijing, China, 29 October–1 November 2017; pp. 3773–3778. [Google Scholar]

- Niyomthai, S.; Sangswang, A.; Naetiladdanon, S.; Mujjalinwimut, E. A Predictive Control of Class E Resonant Inverter for Ultrasonic Cleaners. In Proceedings of the 43rd Annual Conference of the IEEE Industrial Electronics Society (IECON), Beijing, China, 29 October–1 November 2017; pp. 6319–6324. [Google Scholar]

- Wang, C.S.; Stielau, O.H.; Covic, G.A. Design Considerations for a Contactless Electric Vehicle Battery Charger. IEEE Trans. Ind. Electron. 2005, 52, 1308–1314. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| L1 | 290.1 µH |

| L2 | 72.14 µH |

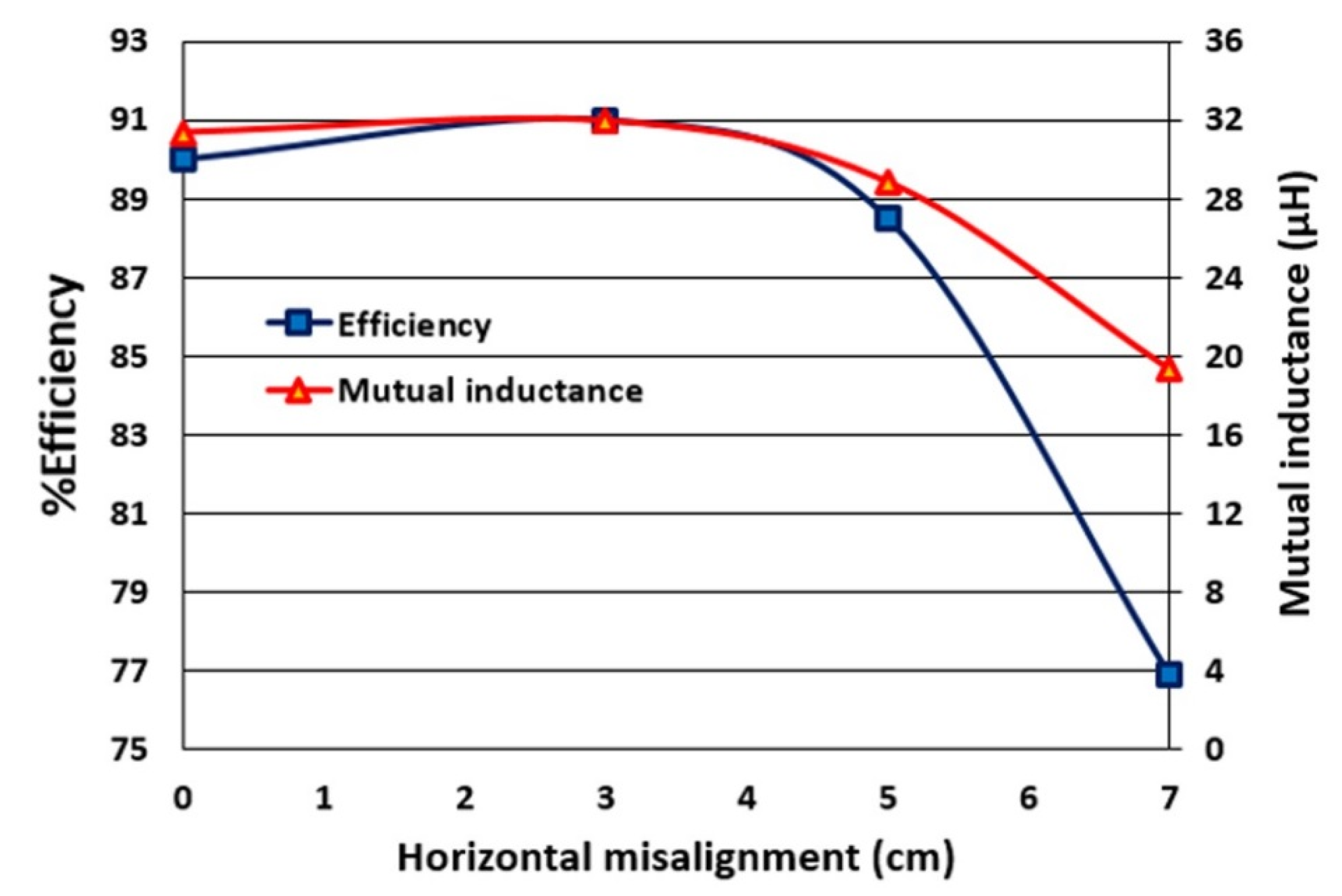

| M (at aligned position) | 31.37 µH |

| M (at 7 cm horizontal misalignment) | 19.33 µH |

| C1 | 22.51 nF |

| C2 | 86.72 nF |

| R1 | 0.6 Ω |

| R2 | 0.56 Ω |

| RL | 90.2 Ω |

| f02 | 63.62 kHz |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nutwong, S.; Sangswang, A.; Naetiladdanon, S.; Mujjalinvimut, E. A Novel Output Power Control of Wireless Powering Kitchen Appliance System with Free-Positioning Feature. Energies 2018, 11, 1671. https://doi.org/10.3390/en11071671

Nutwong S, Sangswang A, Naetiladdanon S, Mujjalinvimut E. A Novel Output Power Control of Wireless Powering Kitchen Appliance System with Free-Positioning Feature. Energies. 2018; 11(7):1671. https://doi.org/10.3390/en11071671

Chicago/Turabian StyleNutwong, Supapong, Anawach Sangswang, Sumate Naetiladdanon, and Ekkachai Mujjalinvimut. 2018. "A Novel Output Power Control of Wireless Powering Kitchen Appliance System with Free-Positioning Feature" Energies 11, no. 7: 1671. https://doi.org/10.3390/en11071671

APA StyleNutwong, S., Sangswang, A., Naetiladdanon, S., & Mujjalinvimut, E. (2018). A Novel Output Power Control of Wireless Powering Kitchen Appliance System with Free-Positioning Feature. Energies, 11(7), 1671. https://doi.org/10.3390/en11071671