The performance of various power and electronic systems in conditions where harmonic voltages and currents appear has been an important aspect of various research and functional works for a long time. Such performance involves minimizing the adverse effects of higher harmonics on various elements of the power infrastructure. The occurrence of various electromagnetic disturbances protruding in the supplied electric energy is associated mainly with the constantly developing methods of processing the energy into other useful forms. Both electricity suppliers and consumers insist that the provided energy is of the appropriate quality. The quality of electric energy is usually determined on the basis of conditions related to the adopted standards, as well as measurements of accepted descriptive parameters and legal requirements. In addition, energy suppliers, upon concluded contracts, often limit the possibility of using reactive power from the electrical power system which, at the same time, introduces a significant financial burden for the energy recipient who does not meet the adopted requirements. Under the presented conditions, the energy supplier has included in the contract the stipulation of not collecting the capacitive reactive power from the network. Nonetheless, energy recipients often employ systems of continuous monitoring and compensation of the consumed reactive power. As a rule, such systems are typically assembled in newly built or modernized facilities. Currently, it is emphasized that the facilities should be characterized by low energy demands for their own needs. The newly designed facilities are, at the initial stage of being put into operation, already adapted to the installation of intelligent control steering systems that ensure the optimization of control, such as lighting sources and air conditioning. In most cases, users of such facilities are obliged to use devices, characterized by specific parameters that meet certain requirements that are recommended by designers. Such an approach should result, on one hand, in limiting operating costs. On the other hand, it should also reduce the risk resulting from, among others, introducing additional disturbances to the mains. However, on these facilities appears also a significant amount of the cheapest LED light sources that may significantly affect the introduced disturbances and the nature of the power factor (PF). The PF coefficient presented in this article allows one to determine, in a concise way, the impact of all receivers working on the supply network. On the other hand, the fundamental power factor determines the demand for reactive power, which, in the case of LED receivers, is of capacitive nature. For facilities equipped with a large number of LED light sources with unit powers lower than 25 W, there occurs the accumulation of the following phenomena: an increase in the number of current and voltage harmonics and the generation of capacitive reactive power. A similar approach is presented, among others, in papers [

1,

2,

3]. It is commonly known that a high value of disturbances may cause various power devices (residual current devices, control devices, signal transmission devices) to operate incorrectly [

3,

4]. Frequently, harmonics occurring from various nonlinear electric energy receivers may lead to various damages. Their occurrence usually results in the overheating of circuits with magnetic cores or, in critical situations, may even lead to an overload of the capacitor battery used in inductive reactive power compensation systems [

5,

6]. However, these are usually single and rare cases when supervision of disturbances occurring in a given facility is not being carried out properly. The paper presents results of measurements and tests carried out on a newly built facility, which, to large extent, uses energy-saving LED lighting sources. Vast introduction of LED lighting, in addition to the expected further decrease in demand for consumed power in relation to used luminaries with gas-discharge light sources (approximately 30%) [

7,

8], also leads to deterioration of the power factor and an increase in the capacitive reactive power. Basic information on their application can be found inter alia in [

9,

10,

11,

12]. Additionally, a number of publications [

13,

14] contain information on the safety of the use of lighting based on LED sources and emerging hazards associated with the use of such lighting. Though, aspects related to spectral efficiency and its safety are not addressed in this article.

The hypotheses for introducing LED lighting sources are assumed and the systems should be highly efficient. However, apart from introducing additional harmonics caused by non-sinusoidal currents, there is often a change in the nature of the consumed reactive power, which may result in a negative impact on the network [

15]. The nature of these interactions was also presented in a paper [

12], which suggested the possibility of occurrence of indicated problems related to the impact of lighting systems on the power factor.

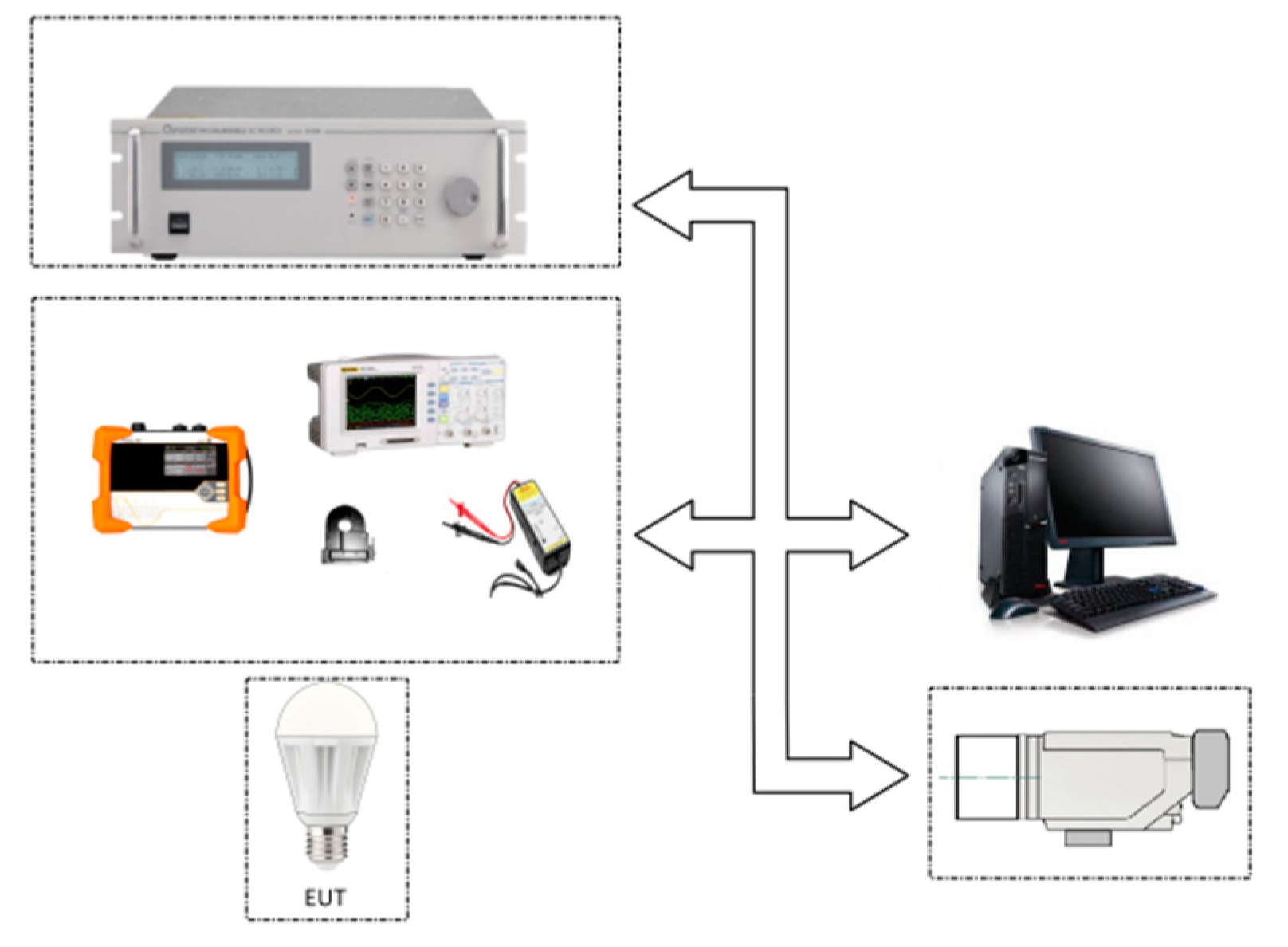

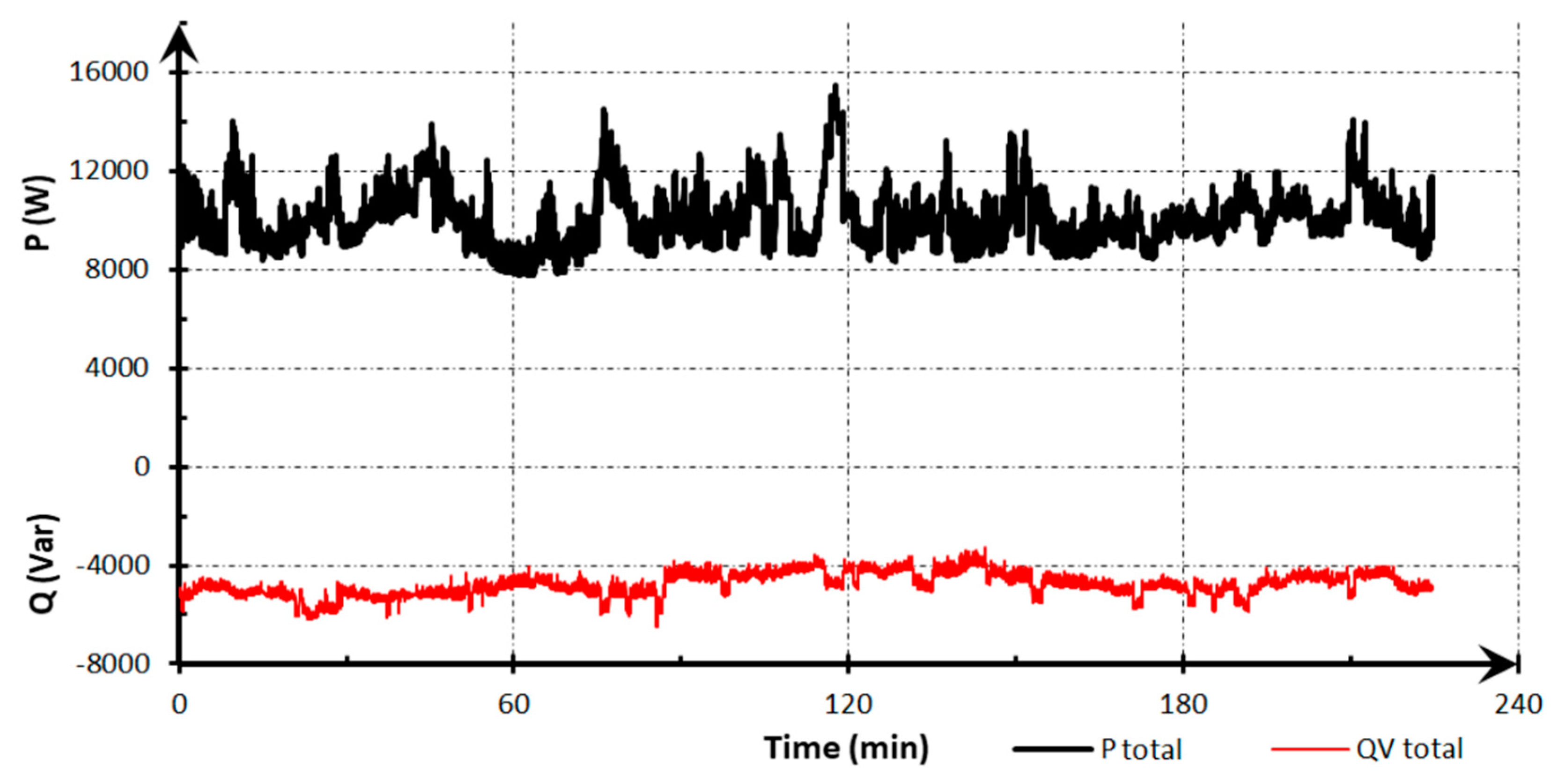

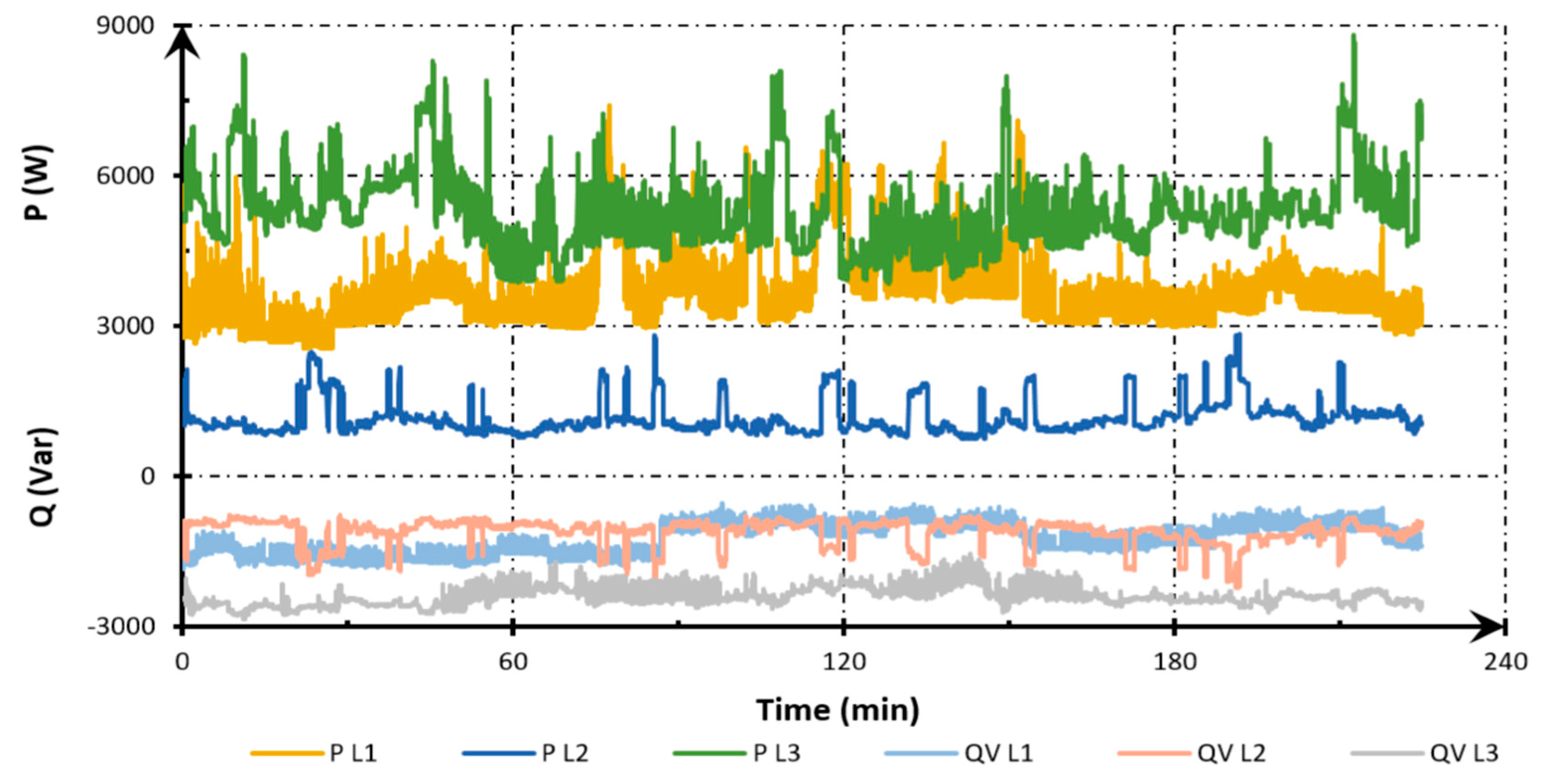

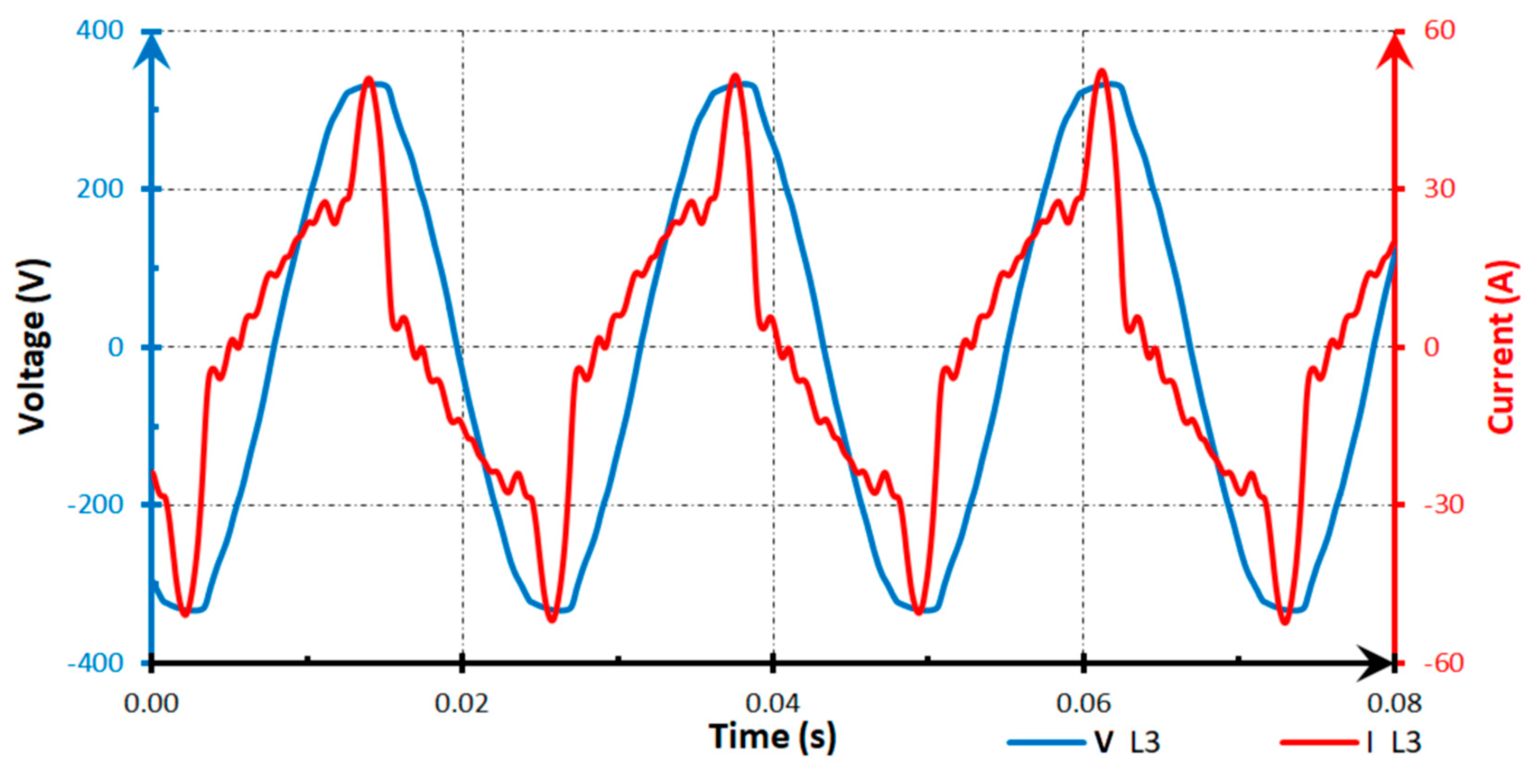

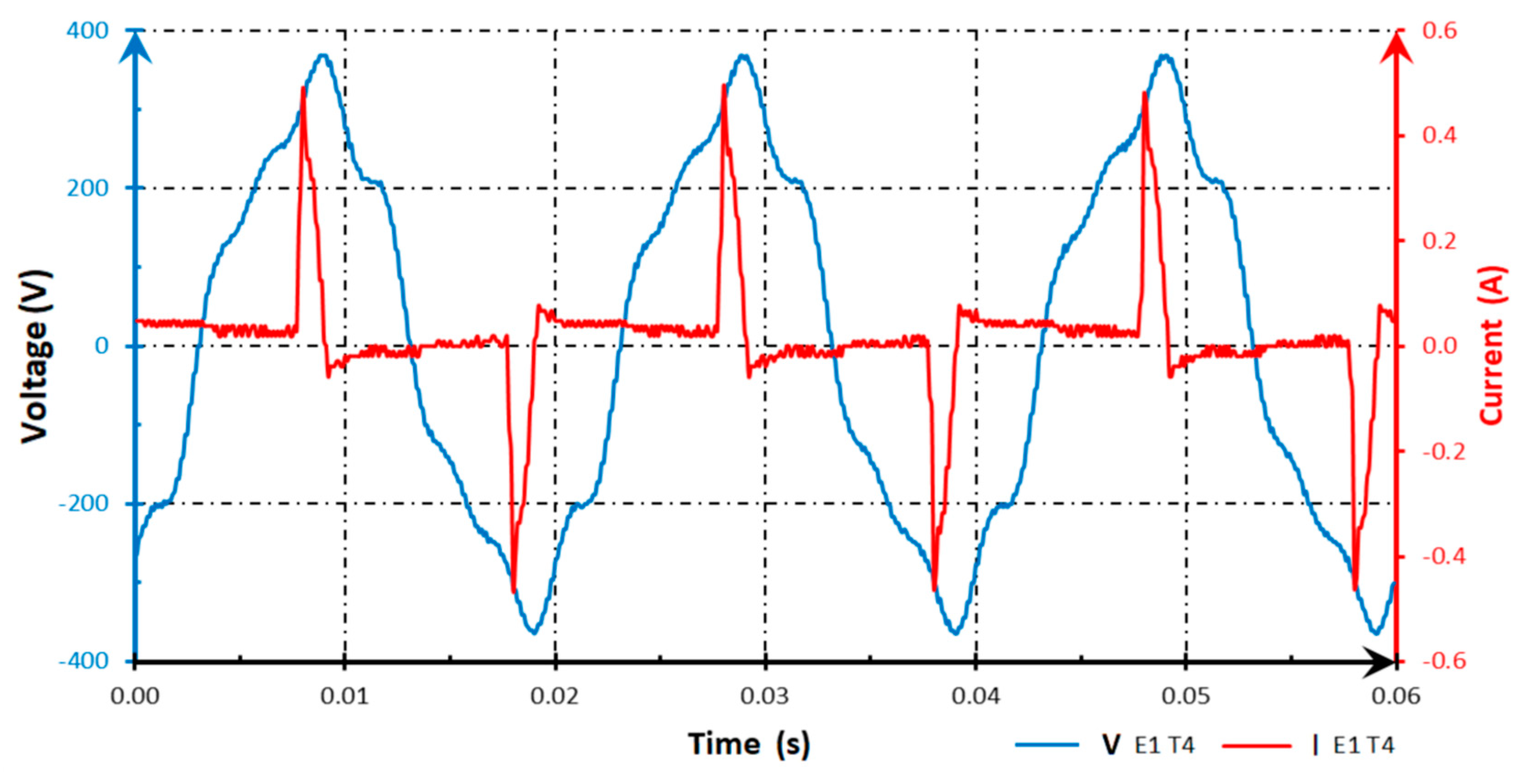

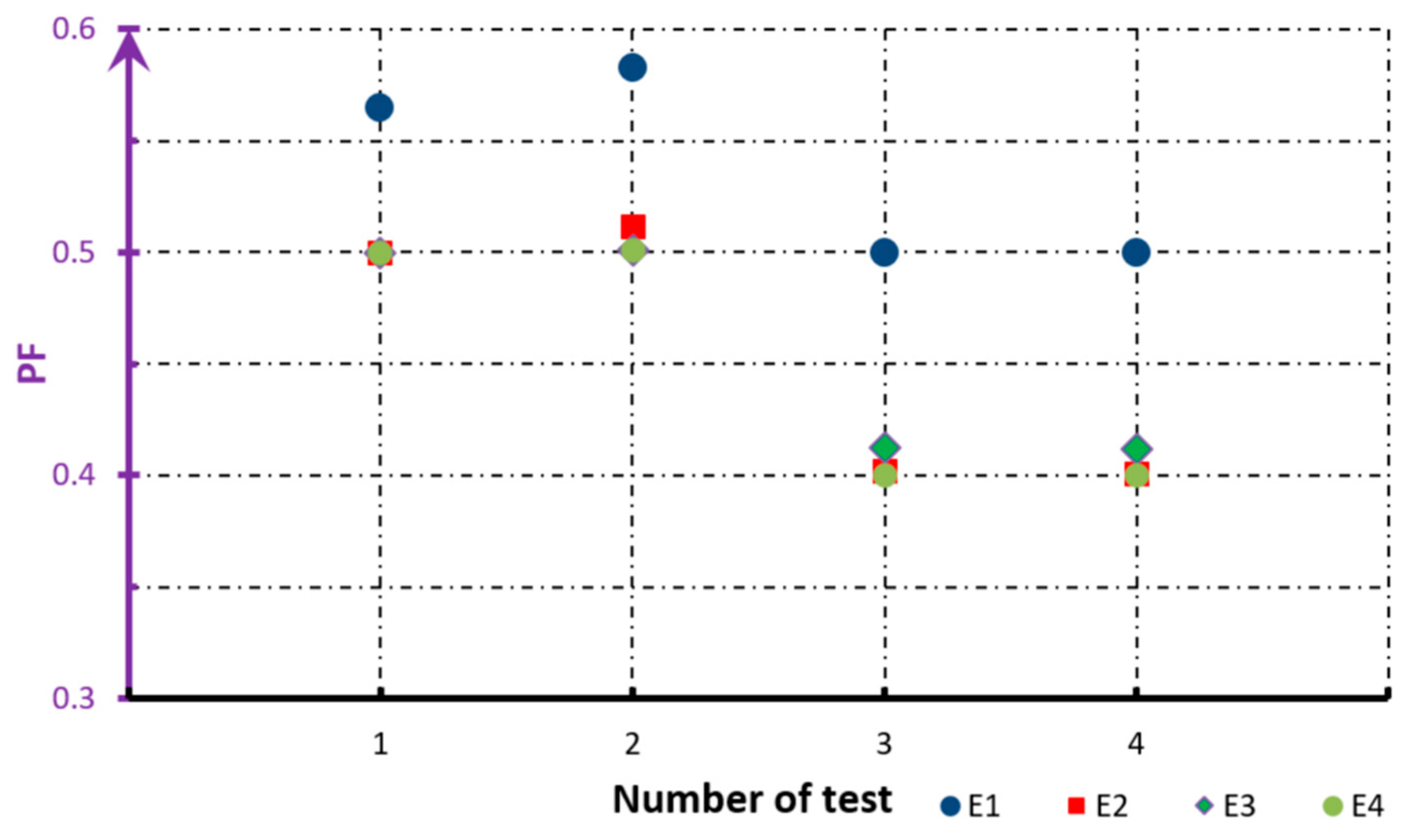

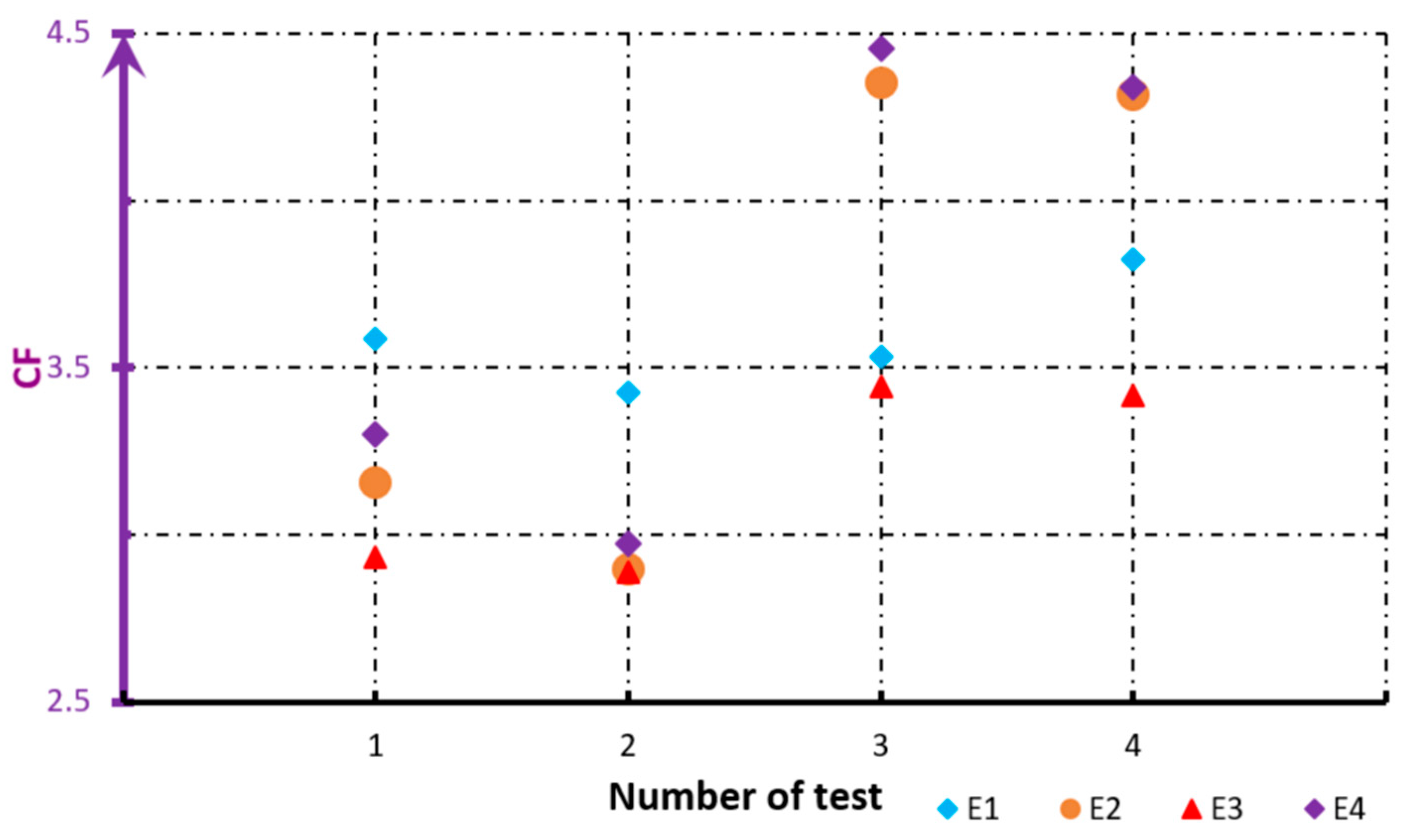

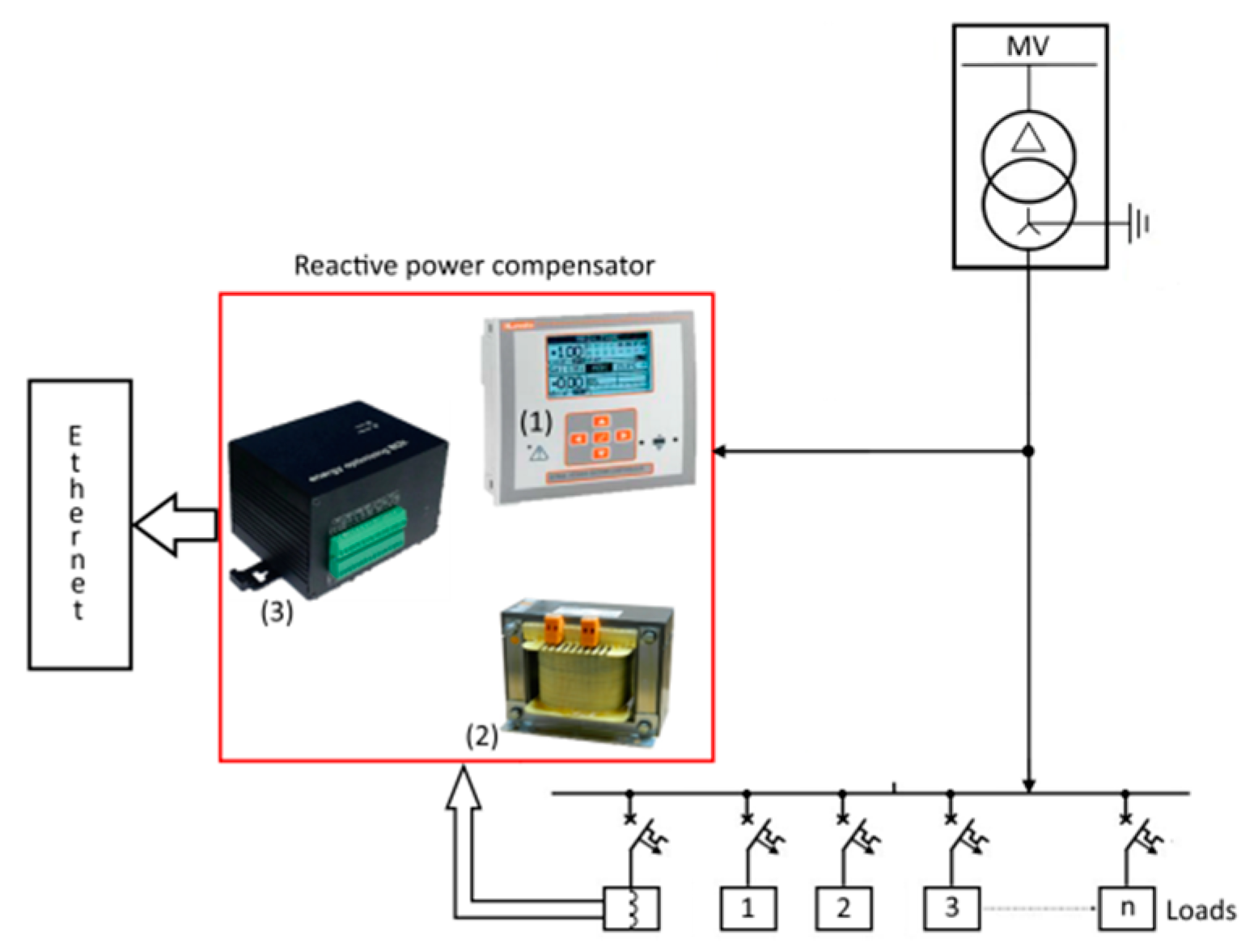

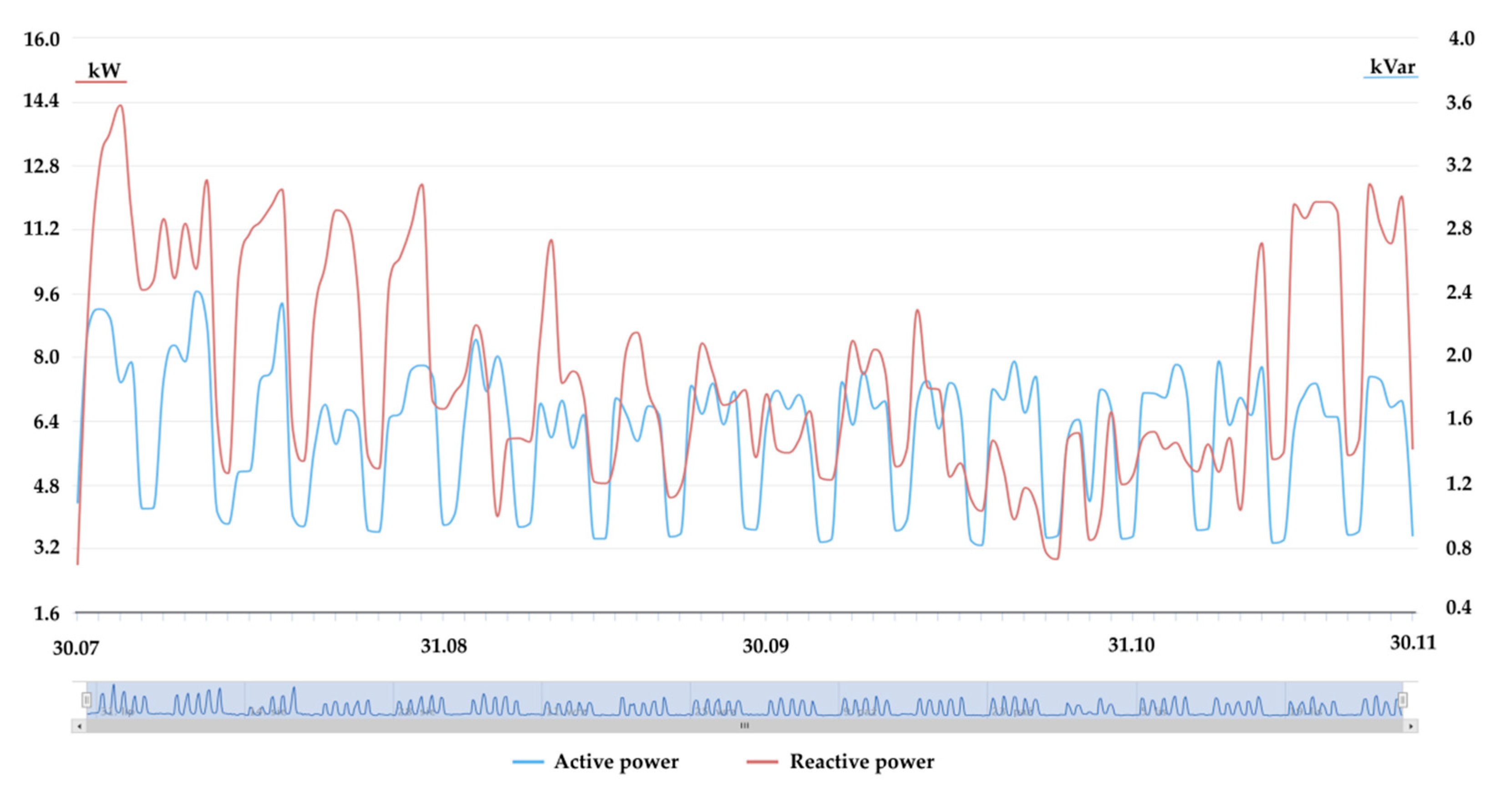

The conclusion presented above was formulated on the basis of measurements carried out in a newly opened facility and measurements of selected LED lighting sources available on the market, during which a low power factor was found. The measurements were performed at the request of the facility user, who bore additional costs related to the consumption of reactive capacitive energy (over 42% of the costs on the invoice accounted for the cost of reactive capacitive energy). Yet, in the design phase, it was assumed that the facility should consume it at the minimum level. The measurement results are presented with the consent of the person who ordered them—“Research and Development Center for Renewable Energy Sources”. The work presents applied measurement systems for on-site testing and for LED lighting source tests. The implemented system for monitoring and compensation of reactive power, which allows the quality of selected electrical energy parameters on the facility’s network to be determined, is also described.