Sealing Failure Analysis on V-Shaped Sealing Rings of an Inserted Sealing Tool Used for Multistage Fracturing Processes

Abstract

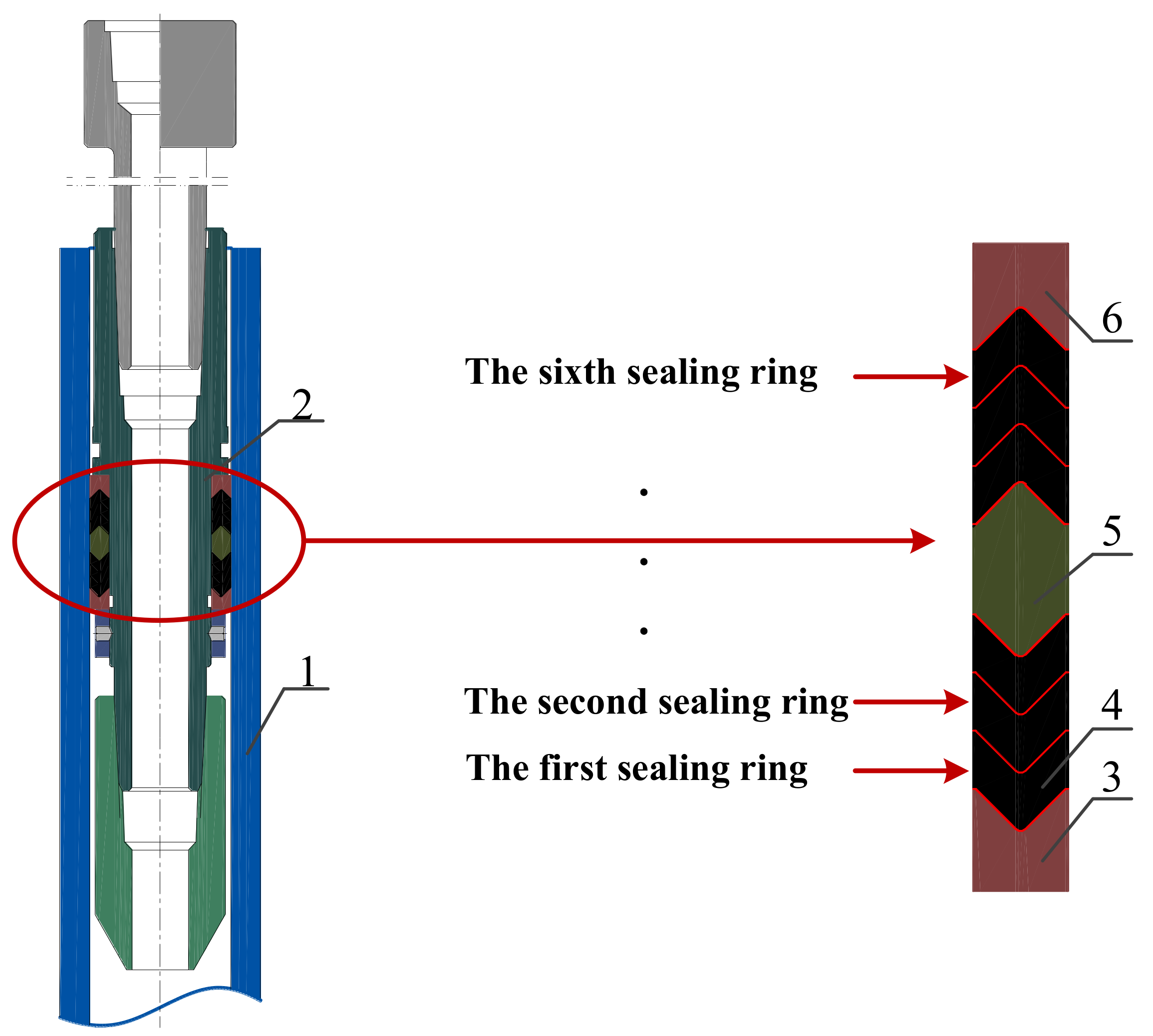

1. Introduction

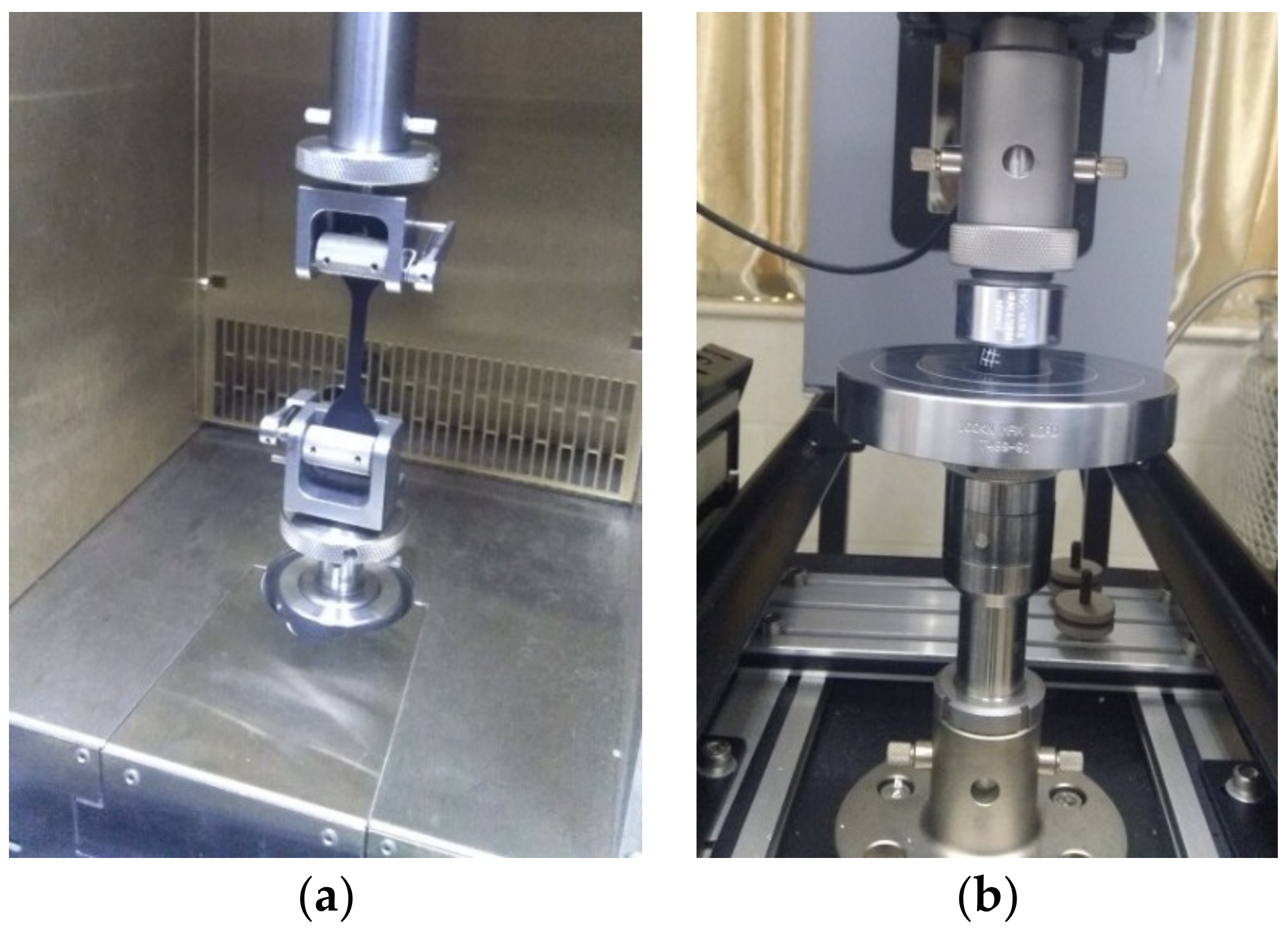

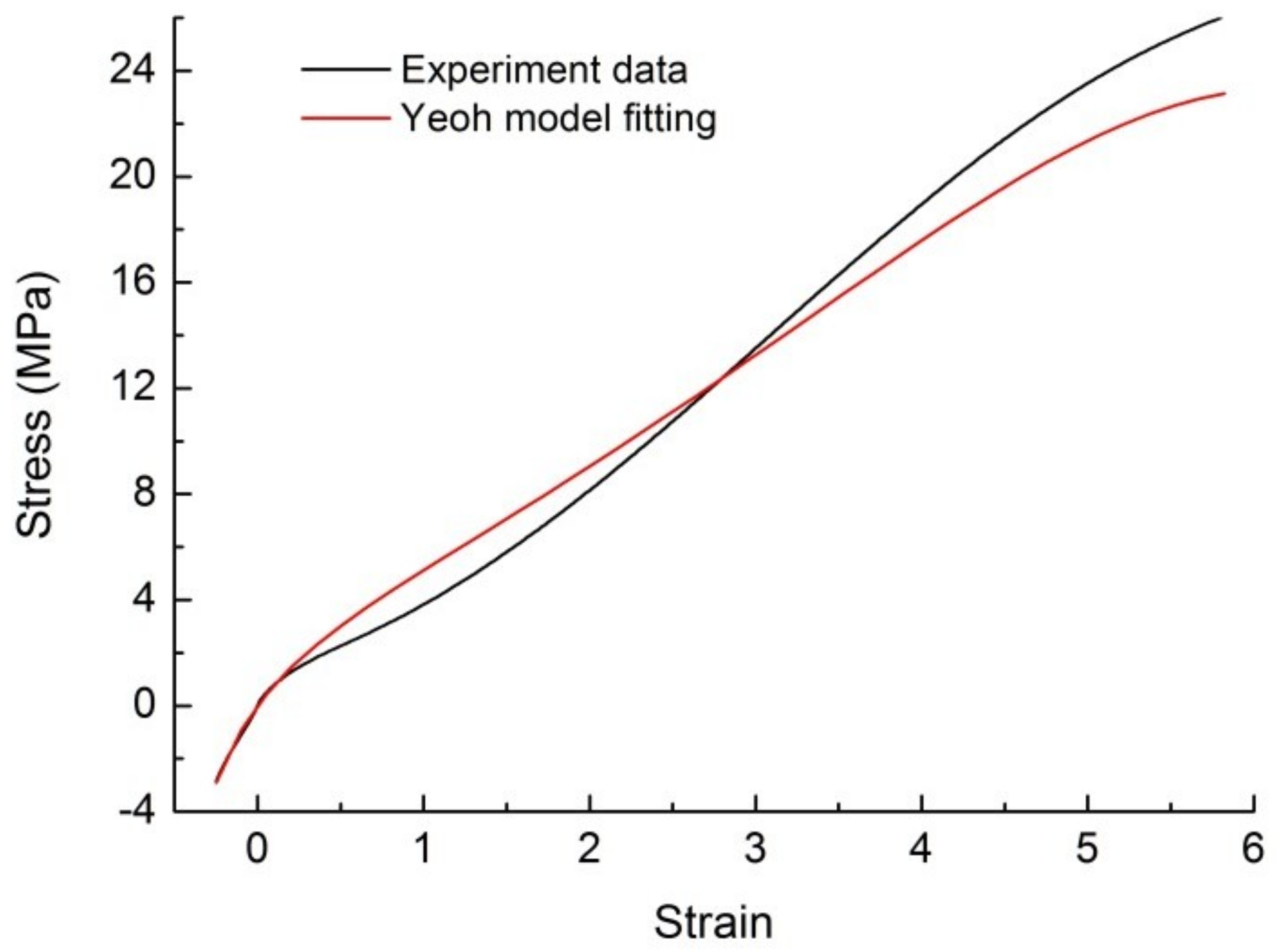

2. Hyperelastic Constitutive Model of Rubber Material

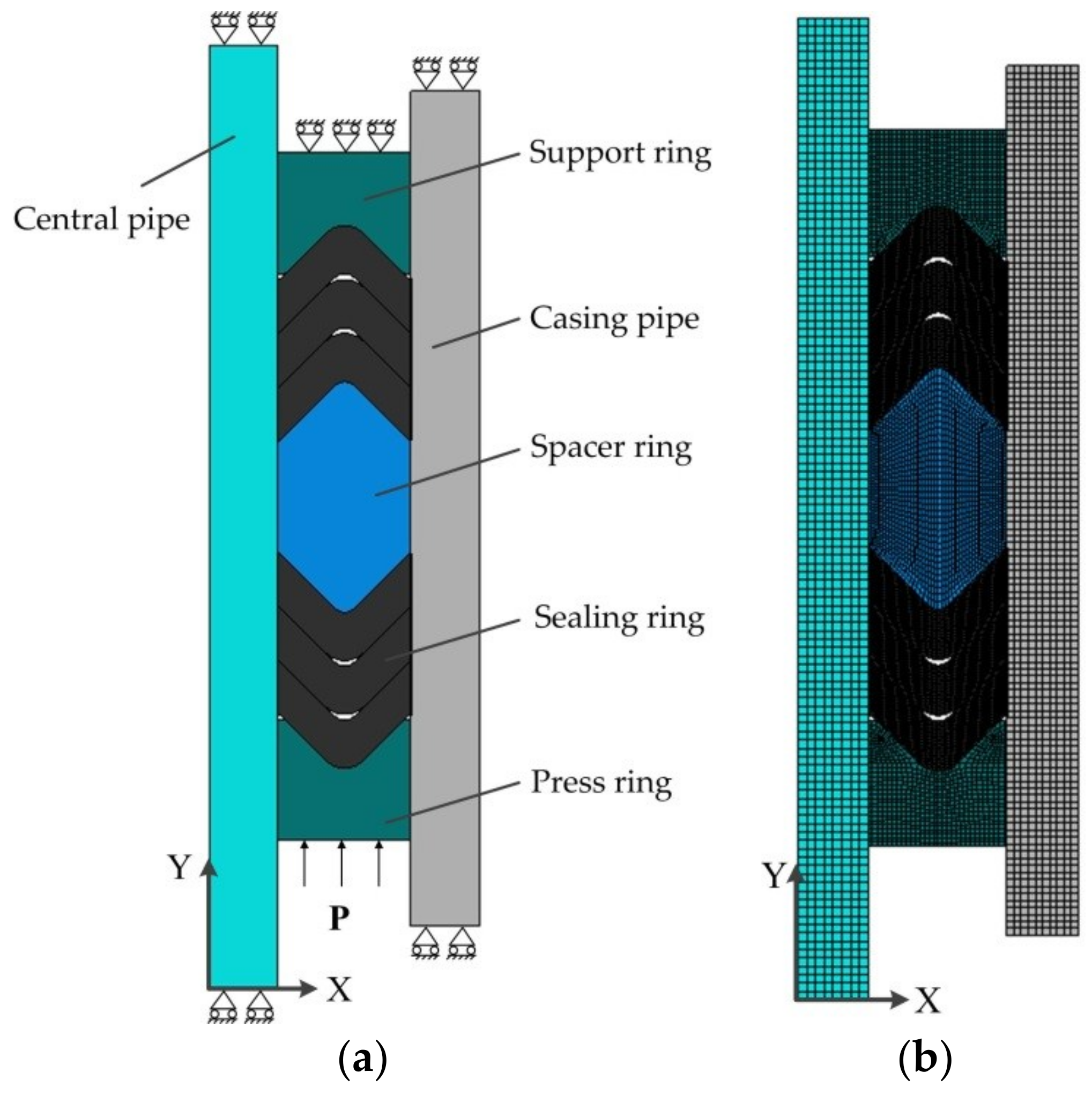

3. Two-Dimensional Axisymmetric Simulation Model

4. Results

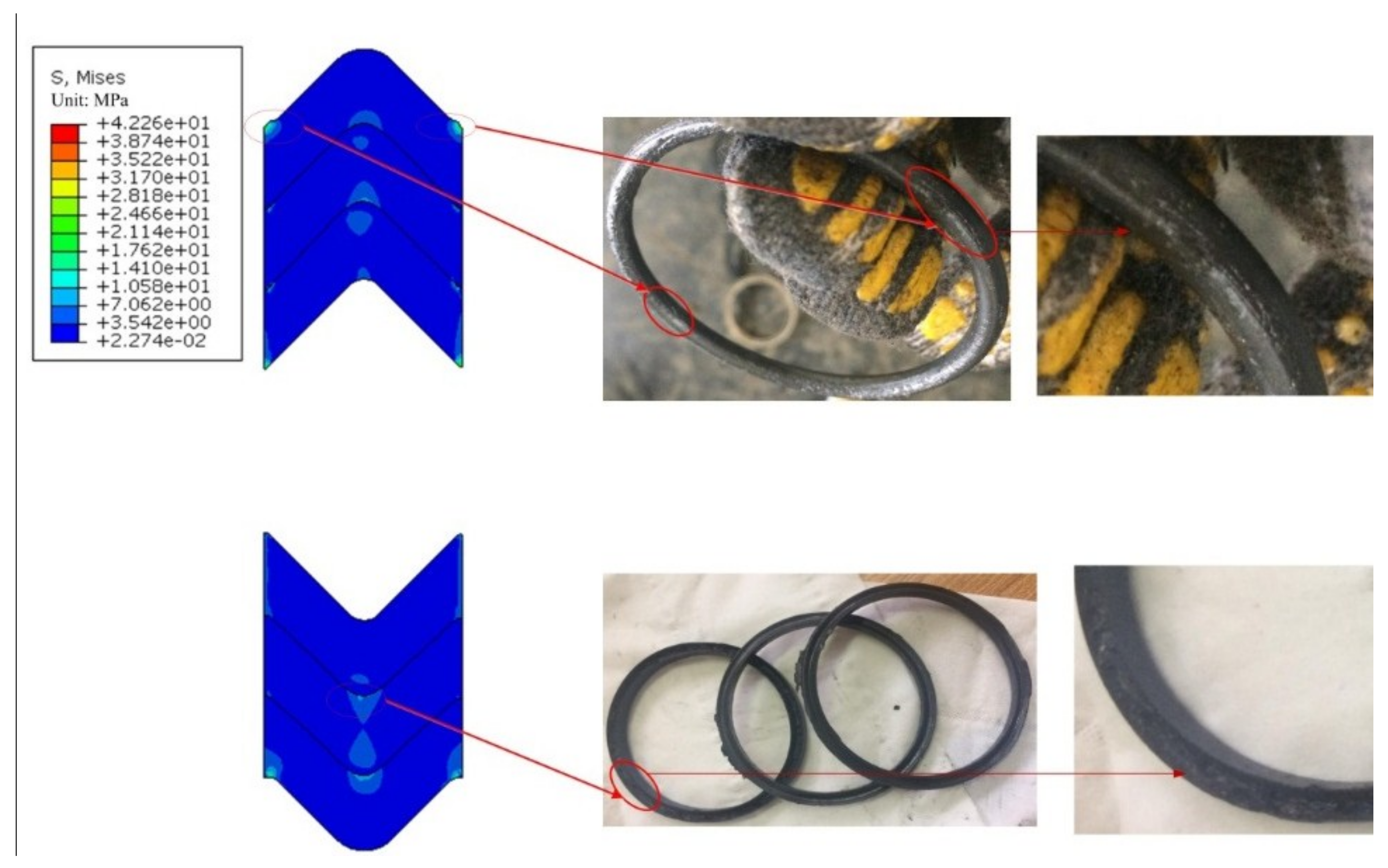

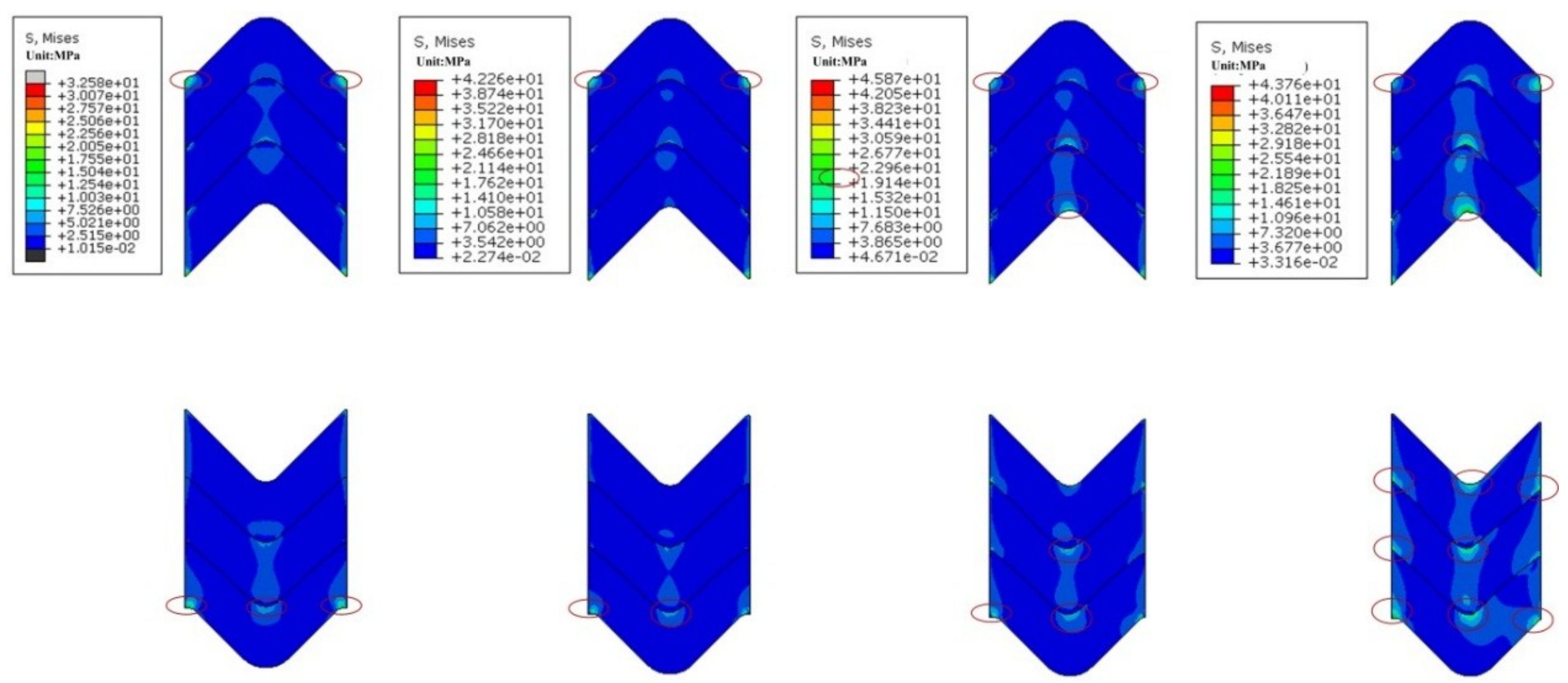

4.1. Failure Analysis and Reliability Validation

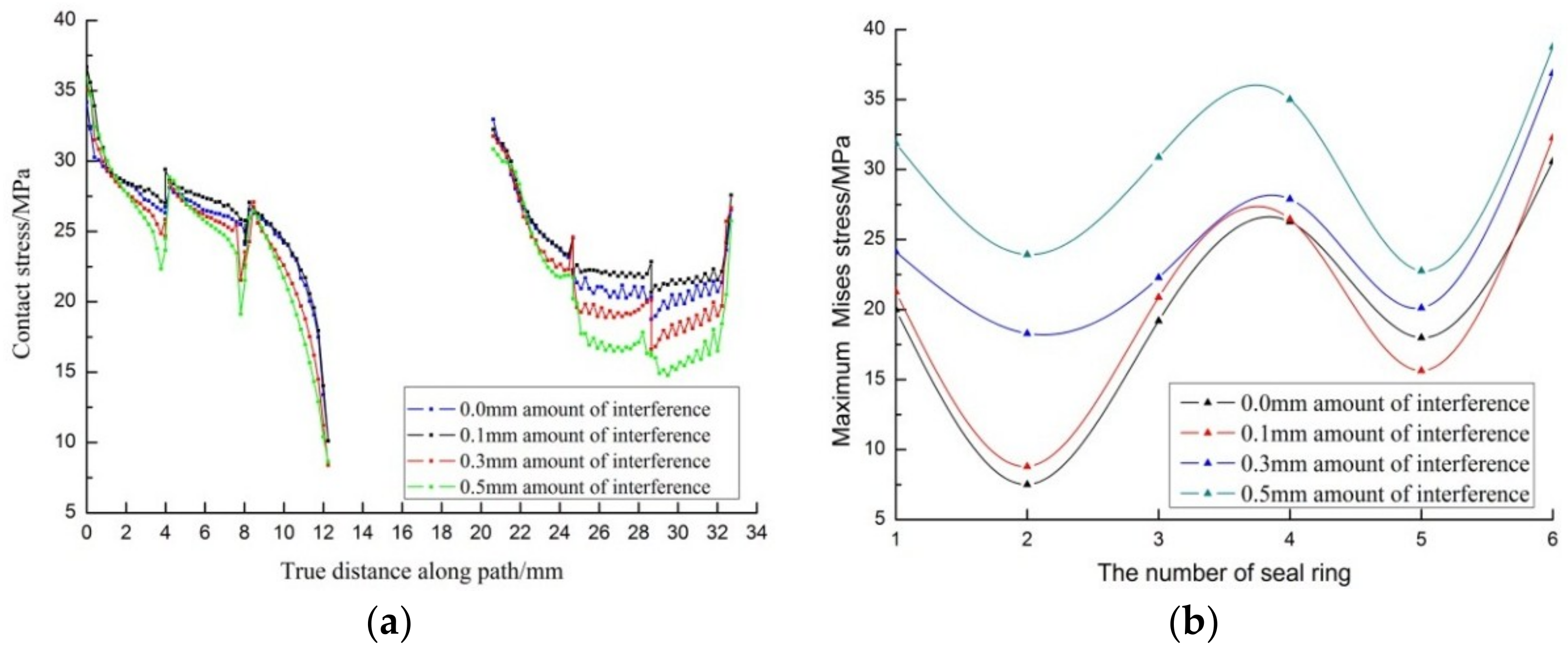

4.2. The Influence of Sealing Interference Magnitude

- (1)

- Figure 7a shows that the contact stress among the first five sealing rings decreased with the increase of the actual distance along the path, while increasing on the sixth sealing ring. As the sealing interference increased, the contact stress of the sealing assembly initially increased and then decreased, which means the sealing ability of the V-shaped sealing ring exhibited the same trend.

- (2)

- Figure 7b shows that the surfaces of the four sealing rings which directly contacted the metal components (i.e., support ring, spacer ring, and press ring—see Figure 4) had higher Mises stresses when compared with the other two sealing rings, i.e., the third and fourth sealing rings. The maximum Mises stress changing trends were similar under different sealing interferences. With the increase of the sealing interference, the maximum Mises stress of the sealing ring gradually increased and the growth became more dramatic, which shows that the sealing interference magnitude had a significant effect on the working life of V-shaped sealing rings.

- (3)

- In summary, compared with other sealing structures, the structure with 0.1 mm sealing interference had a higher contact stress and lower Mises stress, which means that it has better sealing performance and is not easily damaged.

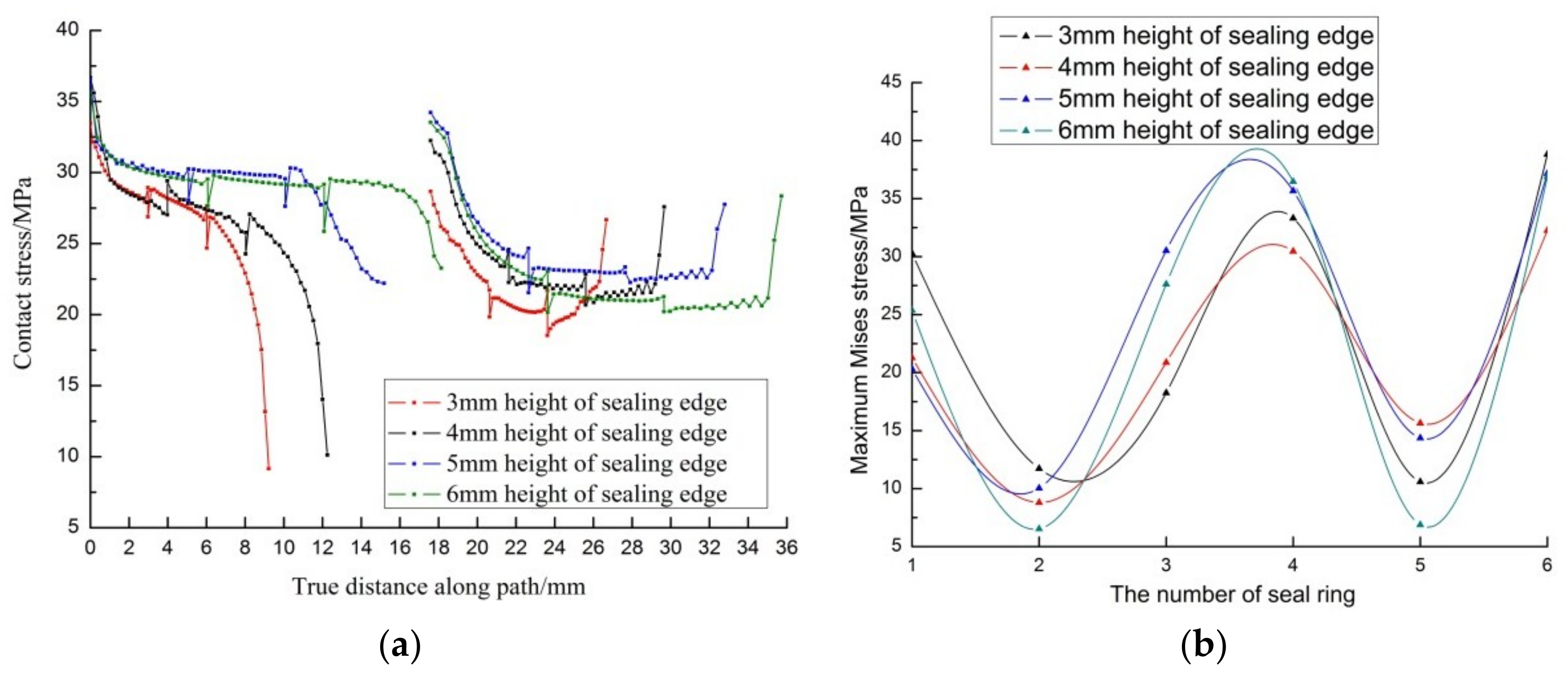

4.3. The Influence of Height of Sealing Ring Edge

- (1)

- As shown in Figure 8a, as the height of the sealing ring edge increased, the contact stress of the sealing assembly initially increased and then decreased. The attenuation rate of the contact stress decreased.

- (2)

- As shown in Figure 8b, changing the height of the sealing ring did not affect the trend of the maximum Mises stress, and it had a certain influence on each sealing ring, which means the height of the sealing ring edge had little influence on the sealing failure of the V-shaped sealing ring.

- (3)

- According to the stress distribution curve, the sealing ring with the edge height of 5 mm had higher contact stress than the others, and its attenuation rate of the contact stress was lower. Therefore, under certain conditions, the sealing ring with the edge height of 5 mm performs better than the others.

4.4. The Influence of Magnitude of Sealing Ring Vertex Angle

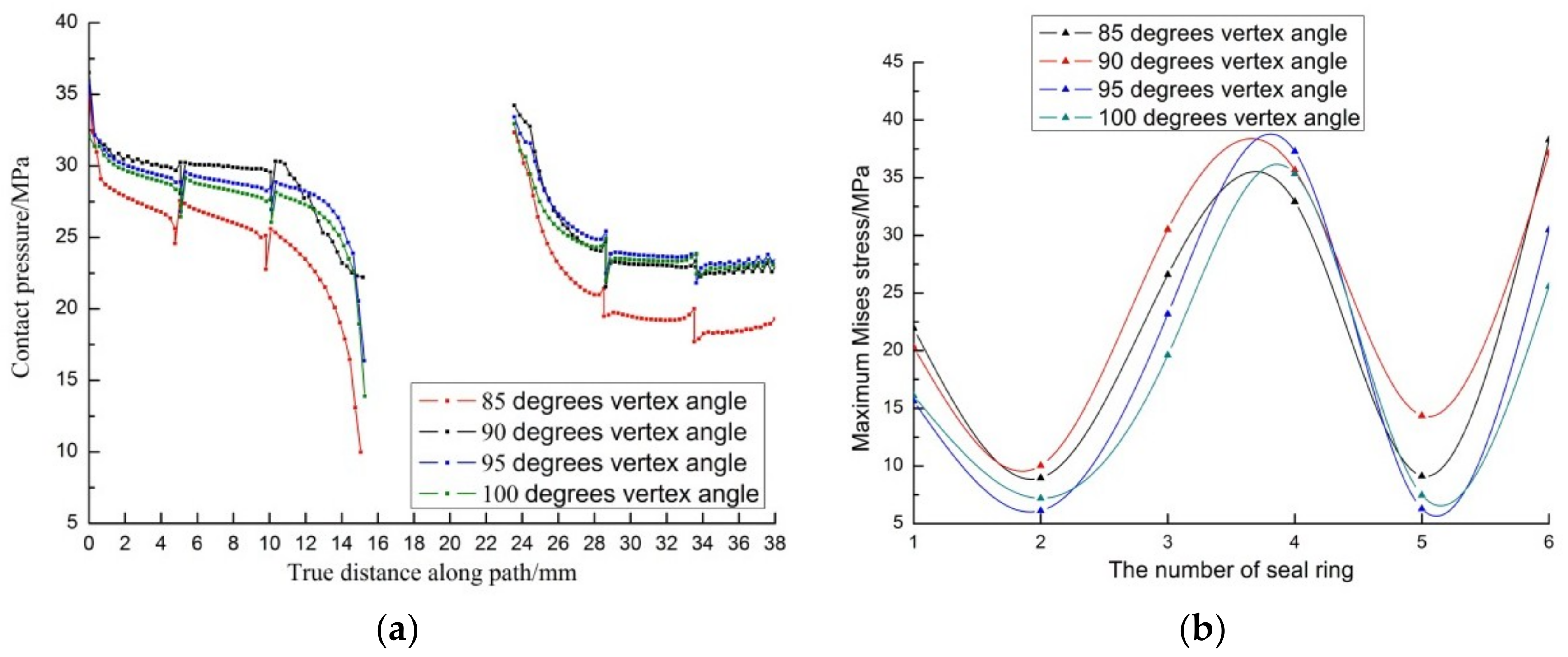

- (1)

- As shown in Figure 9a, as the vertex angle of the sealing ring increased, the contact stress of the sealing assembly gradually increased. When the vertex angle reached 90°, the contact stress barely changed and the attenuation rate remained the same.

- (2)

- As shown in Figure 9b, when the sealing ring vertex angle changed, the trend and value of the maximum Mises stress of the first, second, and fourth sealing rings only changed a little, which means the vertex angle has little influence on the sealing failure of V-shaped sealing rings.

- (3)

- When the vertex angle ranged from 90° to 100°, the values of contact stress and maximum Mises stress were very close. Considering the fact that the contact stress and the maximum Mises stress directly affect the sealing performance, this paper recommends a V-shaped sealing ring with the vertex angle in the range of 90° to 100°.

5. Discussion

- (1)

- The contact stress among the first five sealing rings gradually decreased because of the friction between the V-shape sealing ring and the casing pipe, which caused the compression deformation to decrease. However, in the sixth sealing ring, the closer it was to the support ring, the higher the contact stress was. The support ring was fixed and its deformation was minimal; therefore, the load was not able to transmit and the sealing rings were extremely deformed.

- (2)

- In the sealing process, large areas of stress concentration exists around the shoulders of the V-shaped sealing ring that contacts the metal components. The reason is that the metal components would not be deformed under loads; therefore, the entire load transmits to the shoulder of the sealing ring, causing considerable deformation. The primary reason is that the radial deformation increases while the concave design of the vertex angle prevents the stress from spreading, which leads to stress concentration and ultimately cracks with the V-shaped sealing ring damaged.

- (3)

- The height of sealing edge and vertex angle of the V-shaped sealing ring have little influence on the Mises stress because, under a given sealing interference, the axial load is fixed and the radial distortion is the same. Therefore, the deformation of the V-shaped sealing ring is almost the same, and the change in the maximum Mises stress is very limited.

6. Conclusions

- (1)

- The contact stress of the first V-shaped sealing ring was the largest, which means the first sealing ring played a predominate role in the sealing. The largest Mises stress was also found at the first ring. This implies that this ring may fail first among all the other sealing rings.

- (2)

- Stress concentrations exist at the shoulder and inner vertex of the V-shaped sealing ring. These stress concentration areas agree with what is observed in the oil/gas production field.

- (3)

- The magnitude of the sealing interference greatly influences the stress concentration and the life of the sealing ring, as per the results of the research. It suggests that the sealing interference should be seriously considered in the design of sealing rings, to be able to reduce the stress concentrations and therefore enlarge the operation life of the rings. Meanwhile, the height of sealing edge and vertex angle have little influence on the stress concentration and the life of the sealing ring.

- (4)

- Optimized ring parameters are determined in the research for designing a new V-shaped sealing ring with optimal sealing and prolonged operation life. Specifically, the optimal parameter found for the edge height is 5 mm, optimal sealing interference is 0.1 mm, and optimal range of vertex angle is between 90° and 100°, under the conditions employed in the research.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Lu, H.; Wu, X.; Huang, K. Study on the Effect of Reciprocating Pump Pipeline System Vibration on Oil Transportation Stations. Energies 2018, 11, 132. [Google Scholar] [CrossRef]

- Hu, G.; Zhang, P.; Wang, G.; Zhu, H.; Li, Q.; Zhao, S.; Qiao, K.; Wang, T. Performance study of erosion resistance on throttle valve of managed pressure drilling. J. Pet. Sci. Eng. 2017, 156, 29–40. [Google Scholar] [CrossRef]

- He, Y.; Cheng, S.; Rui, Z.; Qin, J.; Fu, L.; Shi, J.; Wang, Y.; Li, D.; Patil, S.; Yu, H.; et al. An Improved Rate-Transient Analysis Model of Multi-Fractured Horizontal Wells with Non-Uniform Hydraulic Fracture Properties. Energies 2018, 11, 393. [Google Scholar] [CrossRef]

- Zhang, D.; Dai, Y.; Ma, X.; Zhang, L.; Zhong, B.; Wu, J.; Tao, Z. An Analysis for the Influences of Fracture Network System on Multi-Stage Fractured Horizontal Well Productivity in Shale Gas Reservoirs. Energies 2018, 11, 414. [Google Scholar] [CrossRef]

- Diany, M.; Bouzid, A.H. Analytical evaluation of stresses and displacements of stuffing-box packing based on a flexibility analysis. Tribol. Int. 2009, 42, 980–986. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, Z.; Bu, Y.; Qiu, C.; Yuan, Y. Simulation studies on drilling mud pump plunger seal failure under ultrahigh pressure and ultradeep conditions. Eng. Fail. Anal. 2014, 45, 142–150. [Google Scholar] [CrossRef]

- Zhu, W.B.; Zhou, G.; Wang, H.S. Research on axial pressure distributionof plunger and seal pair in fracturing pump. Drill. Prod. Technol. 2007, 30, 91–93. [Google Scholar]

- Qin, Y.; Wang, C.; Zhou, Q.; An, Q. Mechanics calculation method for V-type sealing ring in compression process. J. East China Univ. Sci. Technol. Sci. Ed. 2013, 39, 108–114. [Google Scholar]

- Gilstad, B.C.; Gilstad, D.W. Plunger Sealing Ring. U.S. Patent 8,276,918, 2 October 2012. [Google Scholar]

- Ellerhorst, R.J.; Kraimer, R.H. Conforming Plunger Seal Assembly. U.S. Patent 5,115,979, 26 May 1991. [Google Scholar]

- Zhang, X. New sealing packing. Pump Technol. 1997, 5, 45–48. [Google Scholar]

- Zavos, A.; Nikolakopoulos, P.G. Waviness and straightness of cylinder and textured piston ring tribo pair. Int. J. Struct. Integr. 2015, 6, 300–324. [Google Scholar] [CrossRef]

- Huang, J.; Lee, Y.H. Evaluation of uni-axially expanded PTFE as a gasket material for fluid sealing applications. Mater. Chem. Phys. 2001, 70, 197–207. [Google Scholar] [CrossRef]

- Kim, J.J.; Kim, H.Y. Shape design of an engine mount by a method of parameter optimization. Comput. Struct. 1997, 65, 725–731. [Google Scholar] [CrossRef]

- Chagnon, G.; Verron, E.; Marckmann, G.; Gornet, L. Development of new constitutive equations for the Mullins effect in rubber using the network alteration theory. Int. J. Solids Struct. 2006, 43, 6817–6831. [Google Scholar] [CrossRef]

- Ogden, R.W. Non-Linear Elastic Deformations; Courier Corporation: New York, NY, USA, 1997. [Google Scholar]

- Yamashita, Y.; Kawabata, S. Approximated form of the strain energy-density function of carbon-black filled rubbers for industrial applications. Nippon Gomu Kyokaishi J. Soc. Rubber Ind. Jpn. 1992, 65, 517–528. [Google Scholar] [CrossRef]

- Yeoh, O.H. Characterization of elastic properties of carbon black-filled rubber vulcanization. Rubber Chem. Technol. 1990, 63, 792–805. [Google Scholar] [CrossRef]

- International Organization for Standardization. Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties; ISO 37; ISO: Geneva, Switzerland, 2011. [Google Scholar]

- International Organization for Standardization. Rubber, Vulcanized or Thermoplastic—Determination of Compression Stress-Strain Properties; ISO 7743; ISO: Geneva, Switzerland, 2011; ISBN 978-0-580-66331-4. [Google Scholar]

- Ma, W.; Qu, B.; Guan, F. Effect of the friction coefficient for contact pressure of packer rubber. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 228, 2881–2887. [Google Scholar] [CrossRef]

- China Machinery Industry Federation. VD-Shaped Rubber Sealing Ring; JB/T 6994; China Machine Press: Beijing, China, 2007. [Google Scholar]

| Component | Material | Elastic Modulus/MPa | Poisson’s Ratio | Density/kg*m−3 |

|---|---|---|---|---|

| Casing pipe | P110 | 206,000 | 0.280 | 7870 |

| Central pipe | 40CrNiMoA | 209,000 | 0.295 | 7870 |

| Press ring | 45 | 209,000 | 0.269 | 7890 |

| Support ring | 45 | 209,000 | 0.269 | 7890 |

| Spacer ring | 45 | 209,000 | 0.269 | 7890 |

| Sealing ring | Hydrogenated nitrile rubber | / | 0.49 | 1400 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, G.; Wang, G.; Dai, L.; Zhang, P.; Li, M.; Fu, Y. Sealing Failure Analysis on V-Shaped Sealing Rings of an Inserted Sealing Tool Used for Multistage Fracturing Processes. Energies 2018, 11, 1432. https://doi.org/10.3390/en11061432

Hu G, Wang G, Dai L, Zhang P, Li M, Fu Y. Sealing Failure Analysis on V-Shaped Sealing Rings of an Inserted Sealing Tool Used for Multistage Fracturing Processes. Energies. 2018; 11(6):1432. https://doi.org/10.3390/en11061432

Chicago/Turabian StyleHu, Gang, Guorong Wang, Liming Dai, Peng Zhang, Ming Li, and Yukun Fu. 2018. "Sealing Failure Analysis on V-Shaped Sealing Rings of an Inserted Sealing Tool Used for Multistage Fracturing Processes" Energies 11, no. 6: 1432. https://doi.org/10.3390/en11061432

APA StyleHu, G., Wang, G., Dai, L., Zhang, P., Li, M., & Fu, Y. (2018). Sealing Failure Analysis on V-Shaped Sealing Rings of an Inserted Sealing Tool Used for Multistage Fracturing Processes. Energies, 11(6), 1432. https://doi.org/10.3390/en11061432