Design, Analysis, and Evaluation of a Compact Electromagnetic Energy Harvester from Water Flow for Remote Sensors

Abstract

1. Introduction

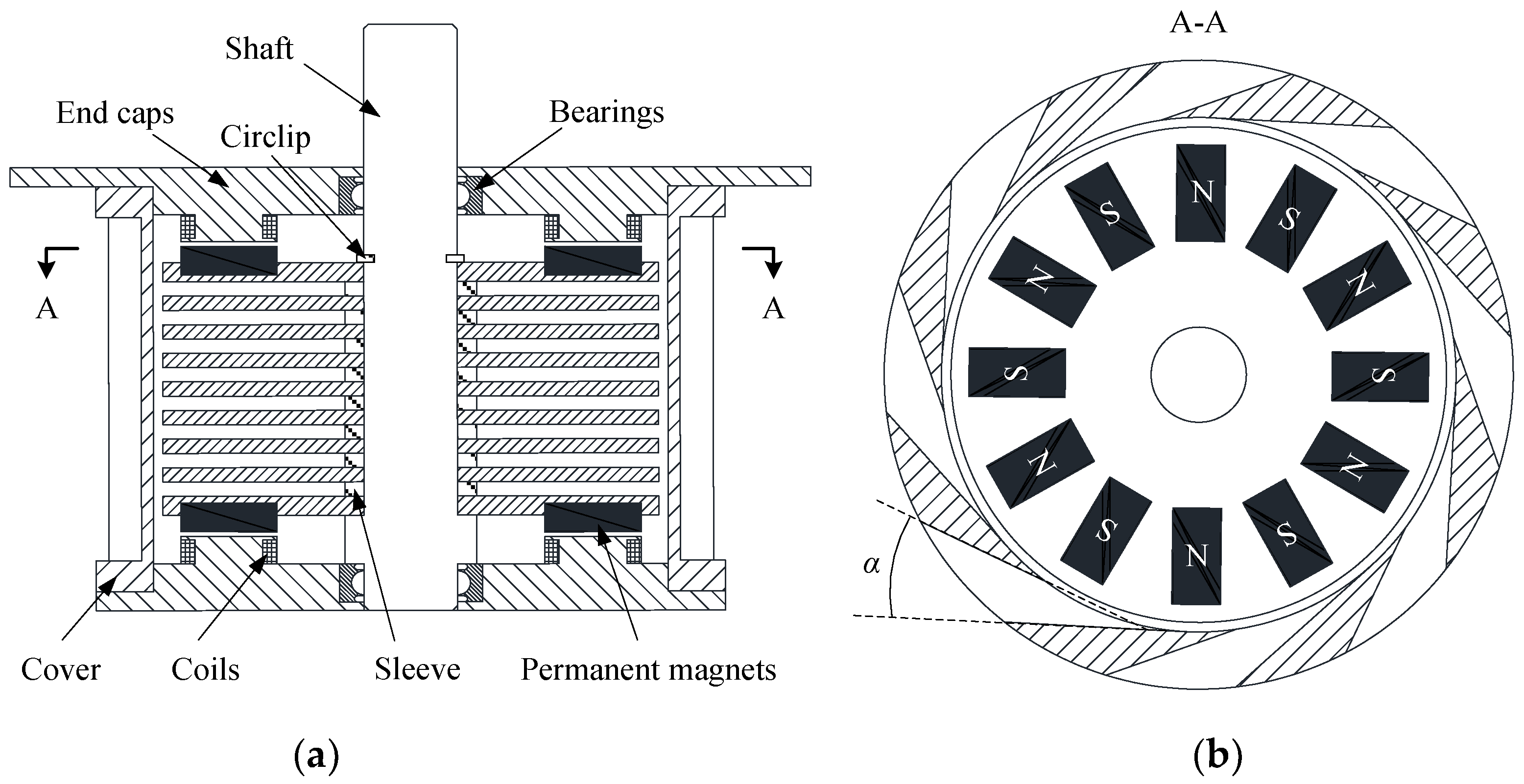

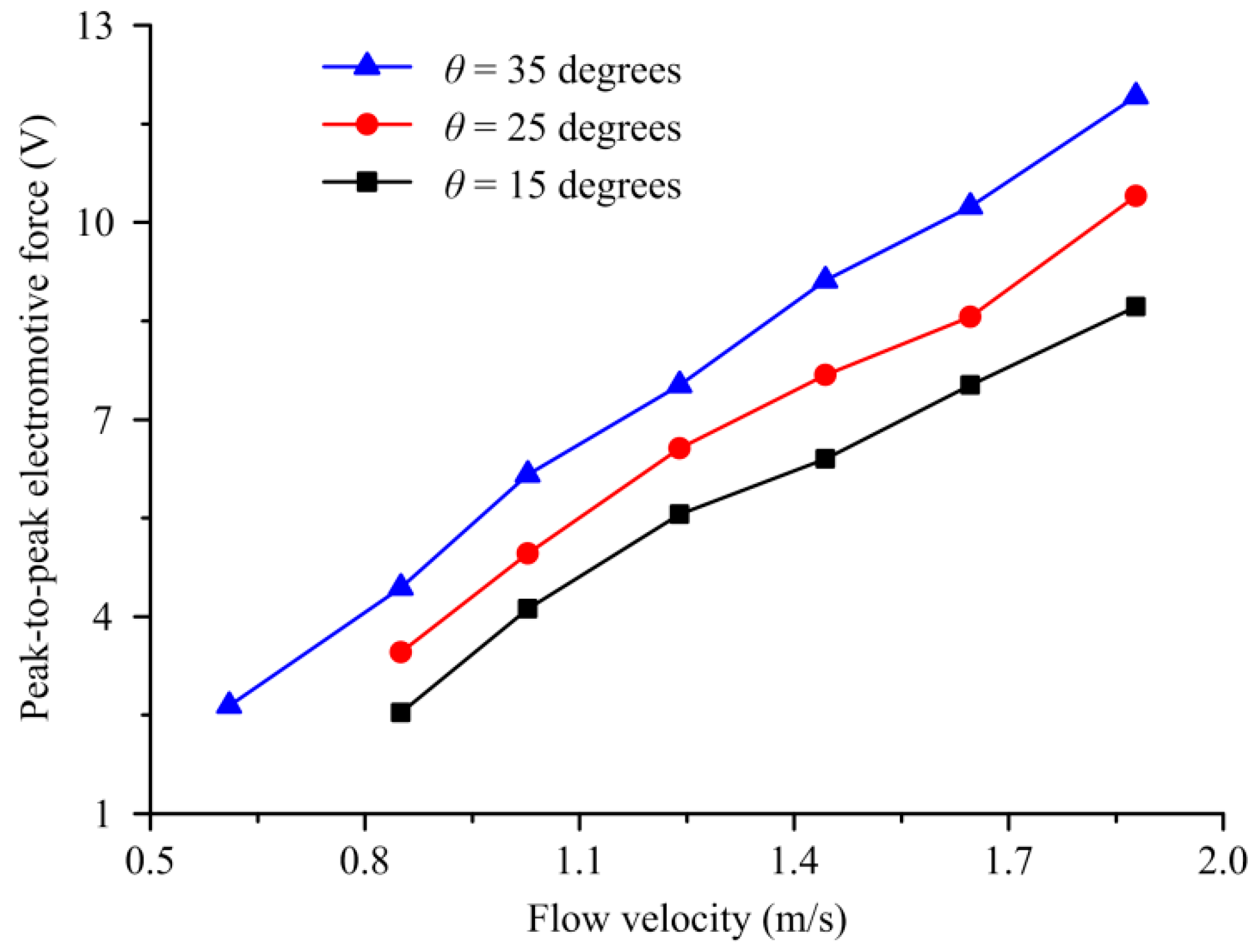

2. Machine Description and Prototype

2.1. Structure and Principle

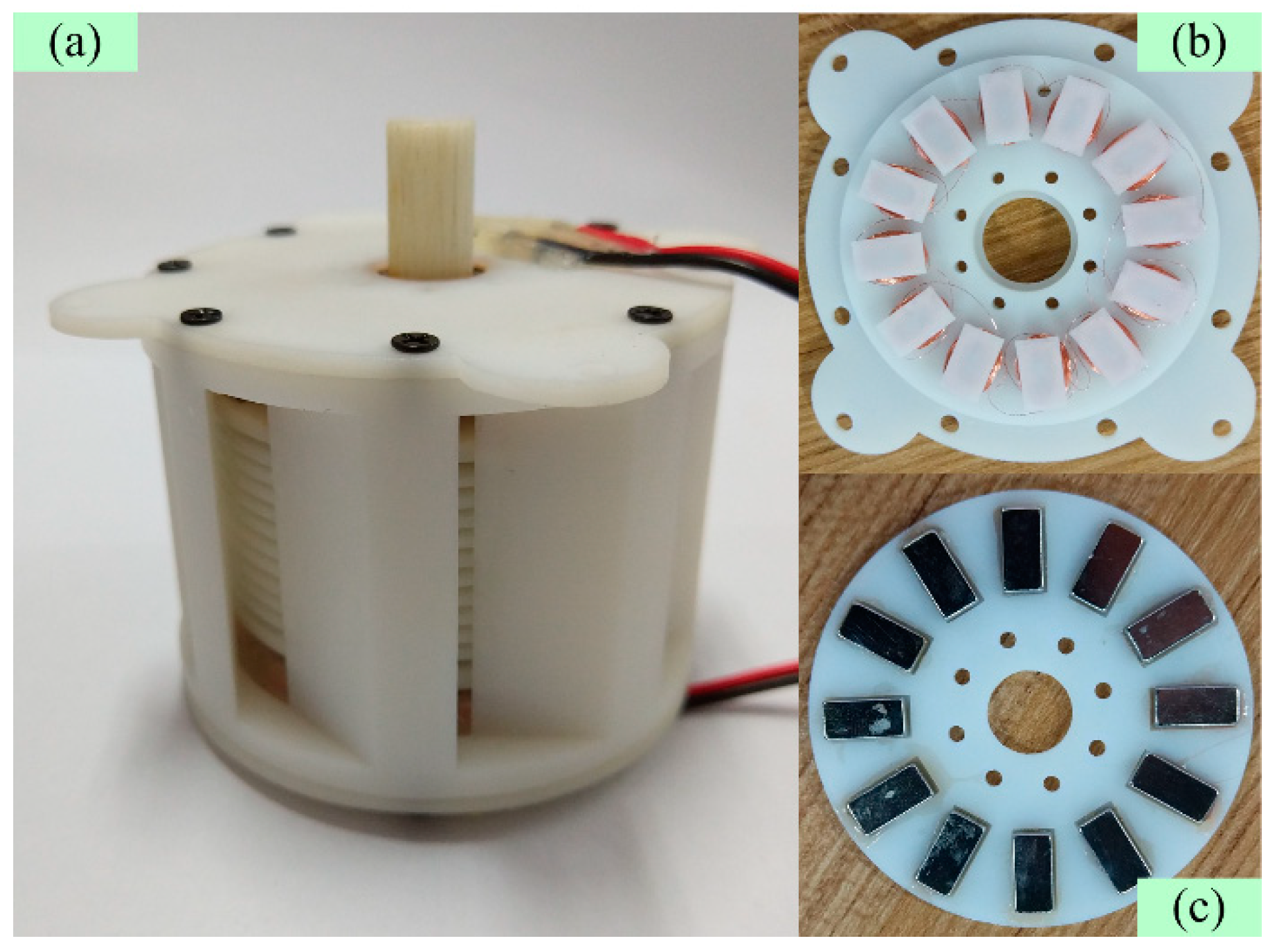

2.2. Prototype Fabrication

3. Energy Conversion Analysis

3.1. Hydrokinetic Energy

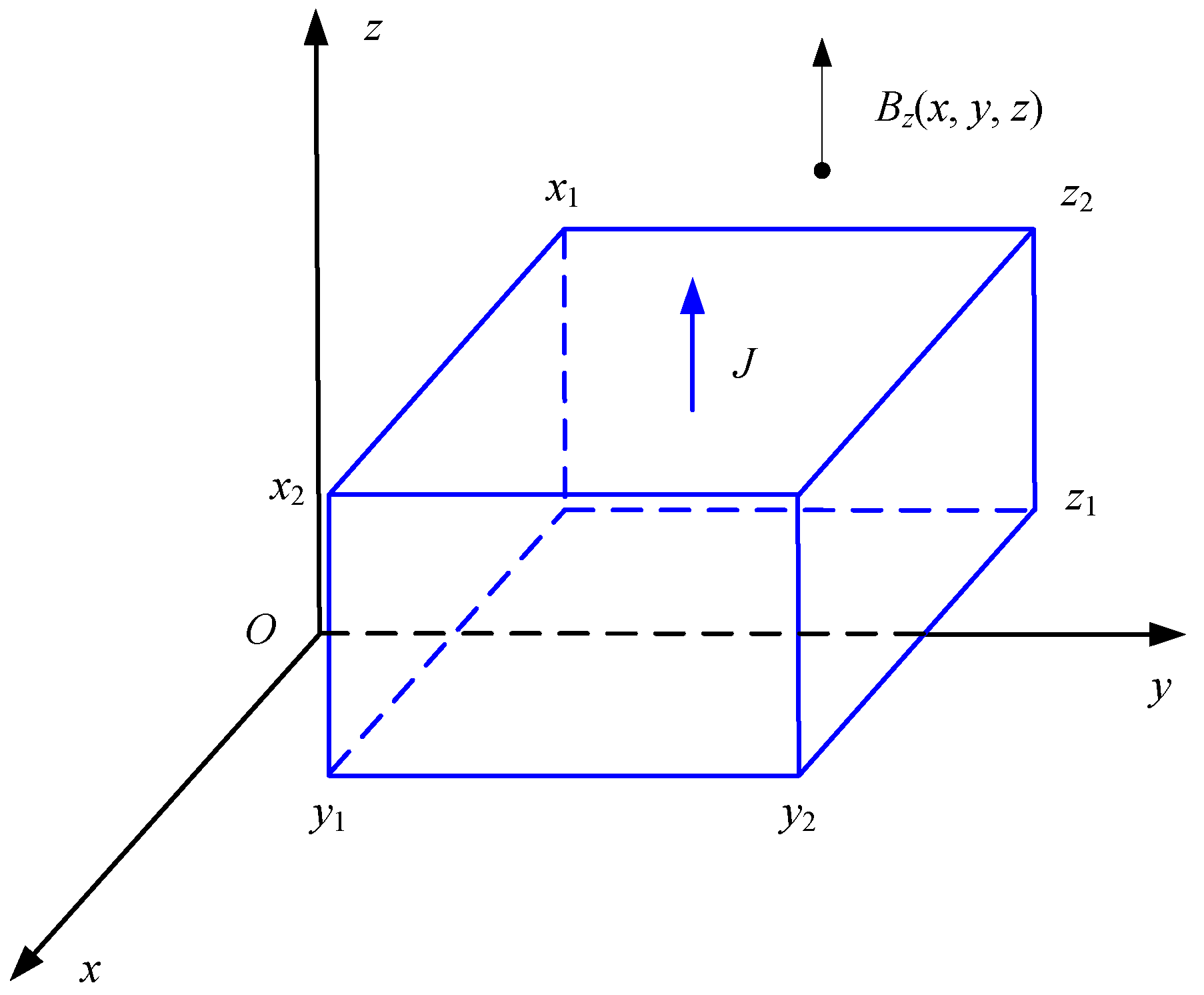

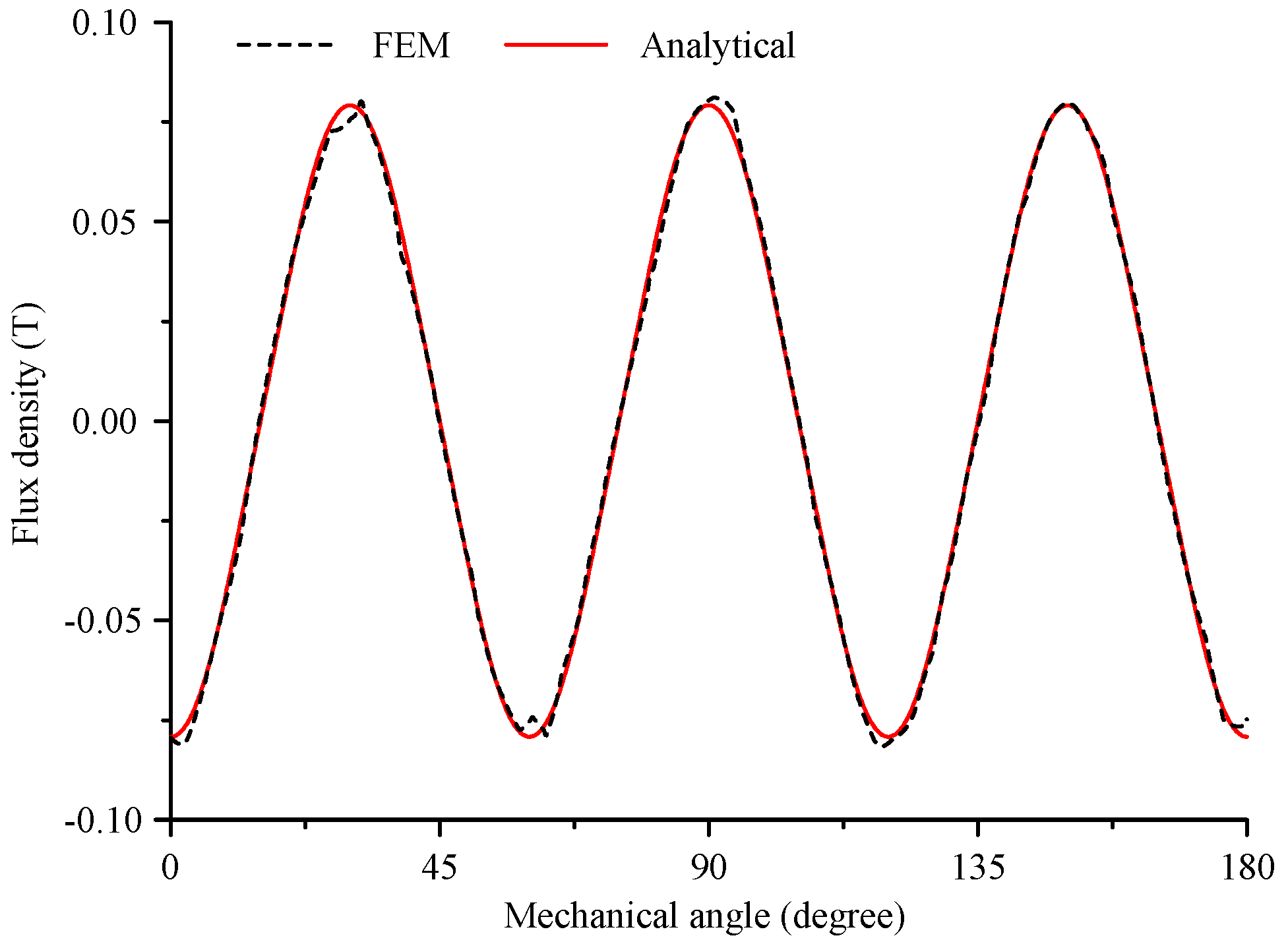

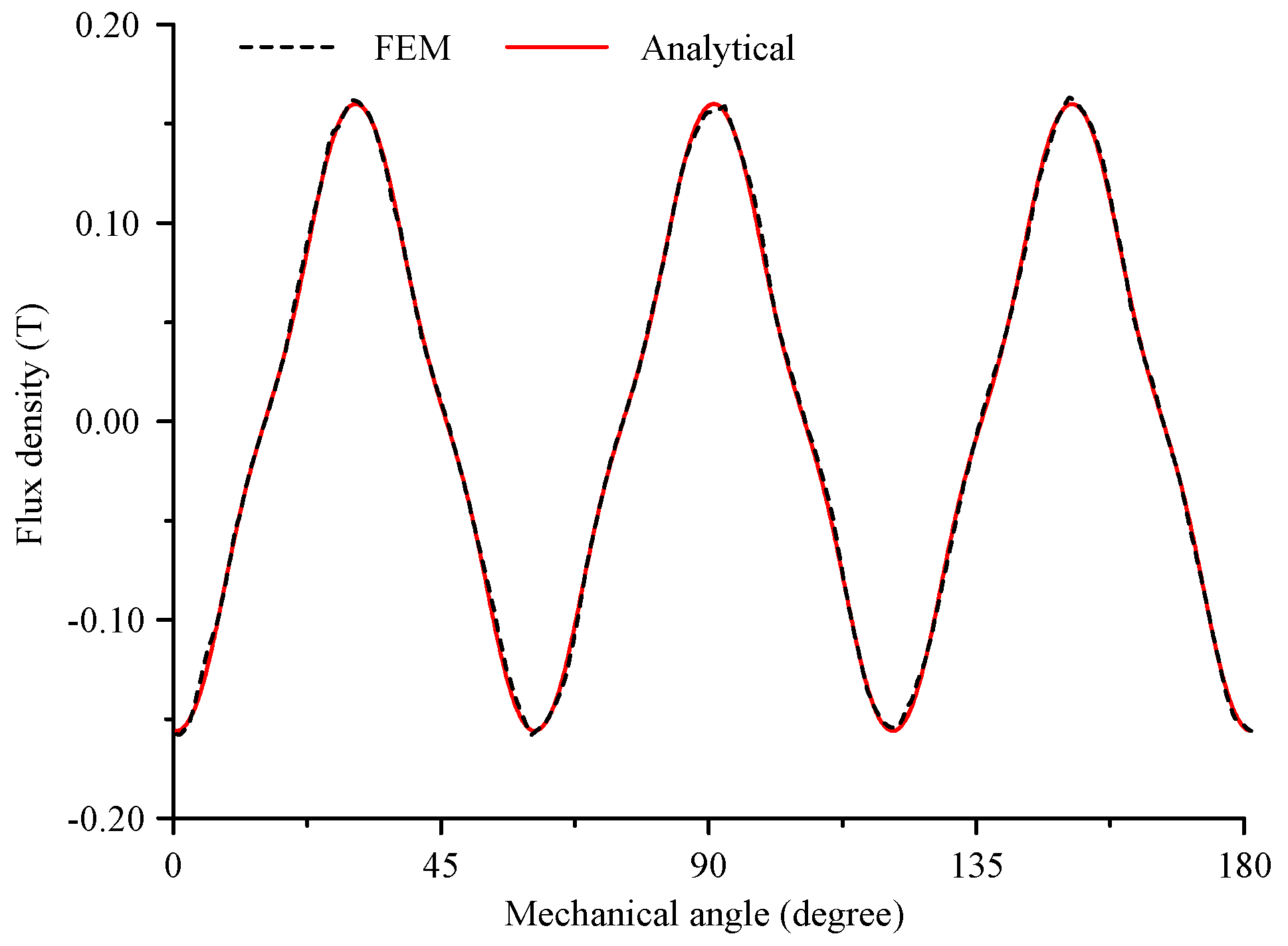

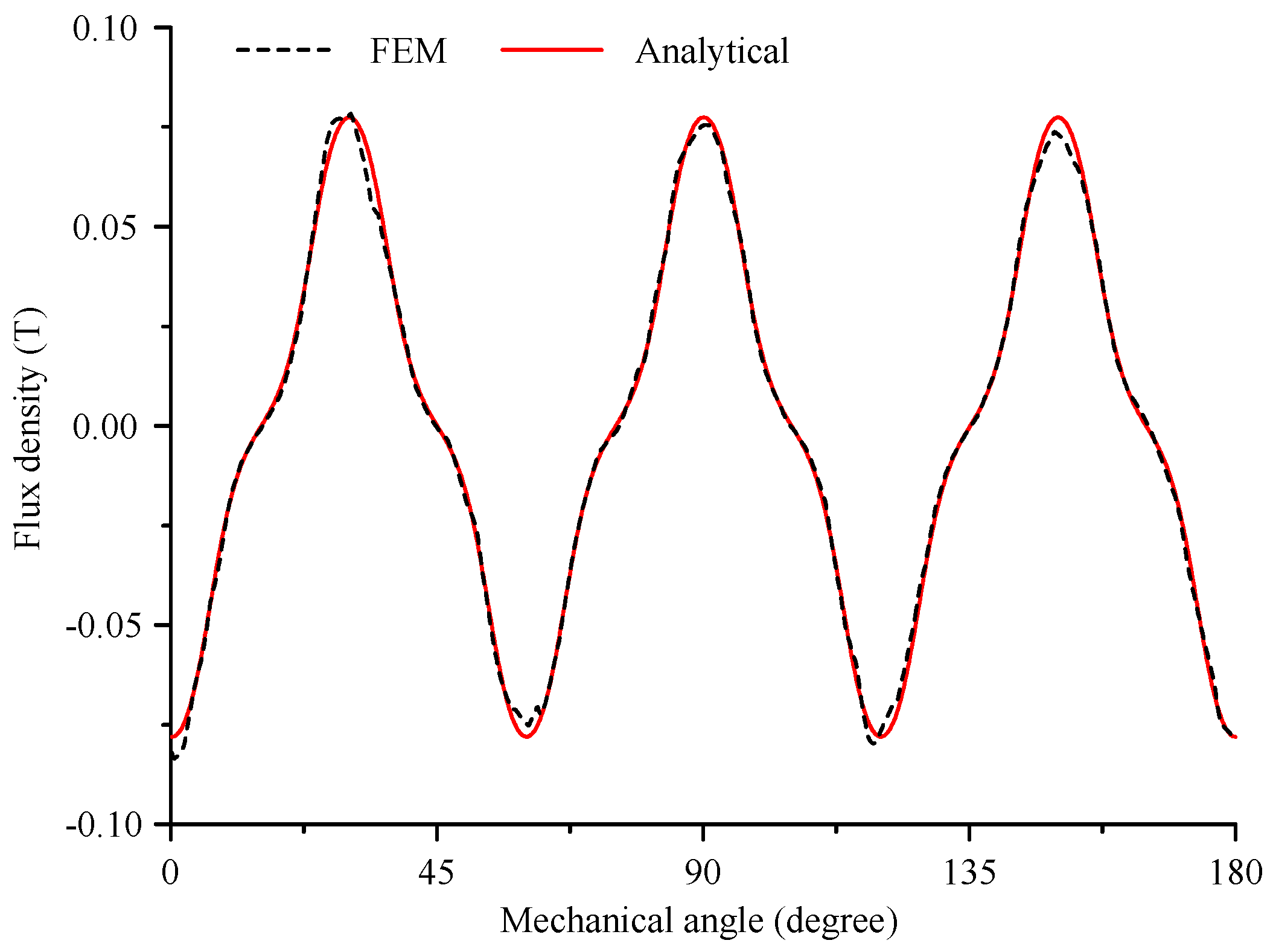

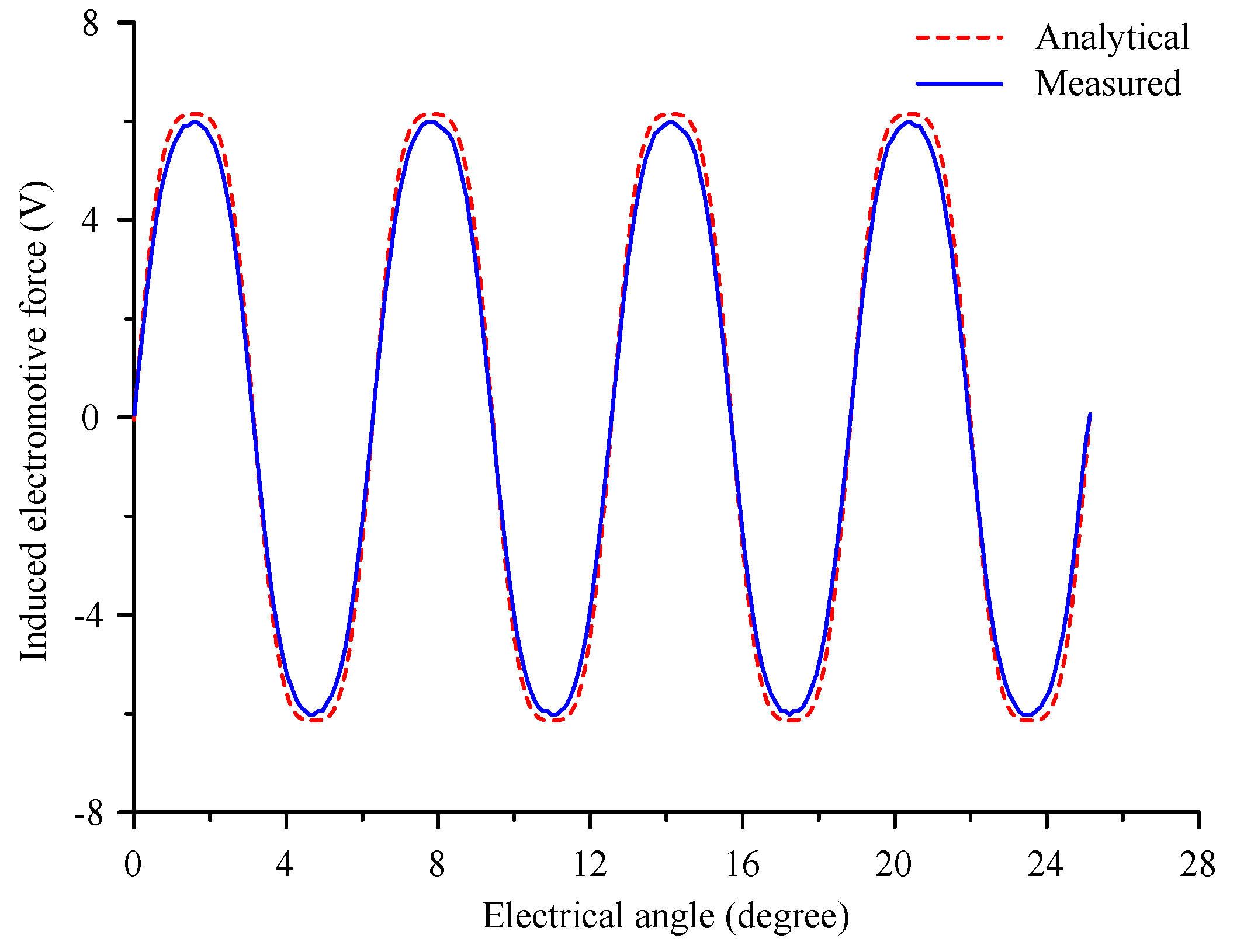

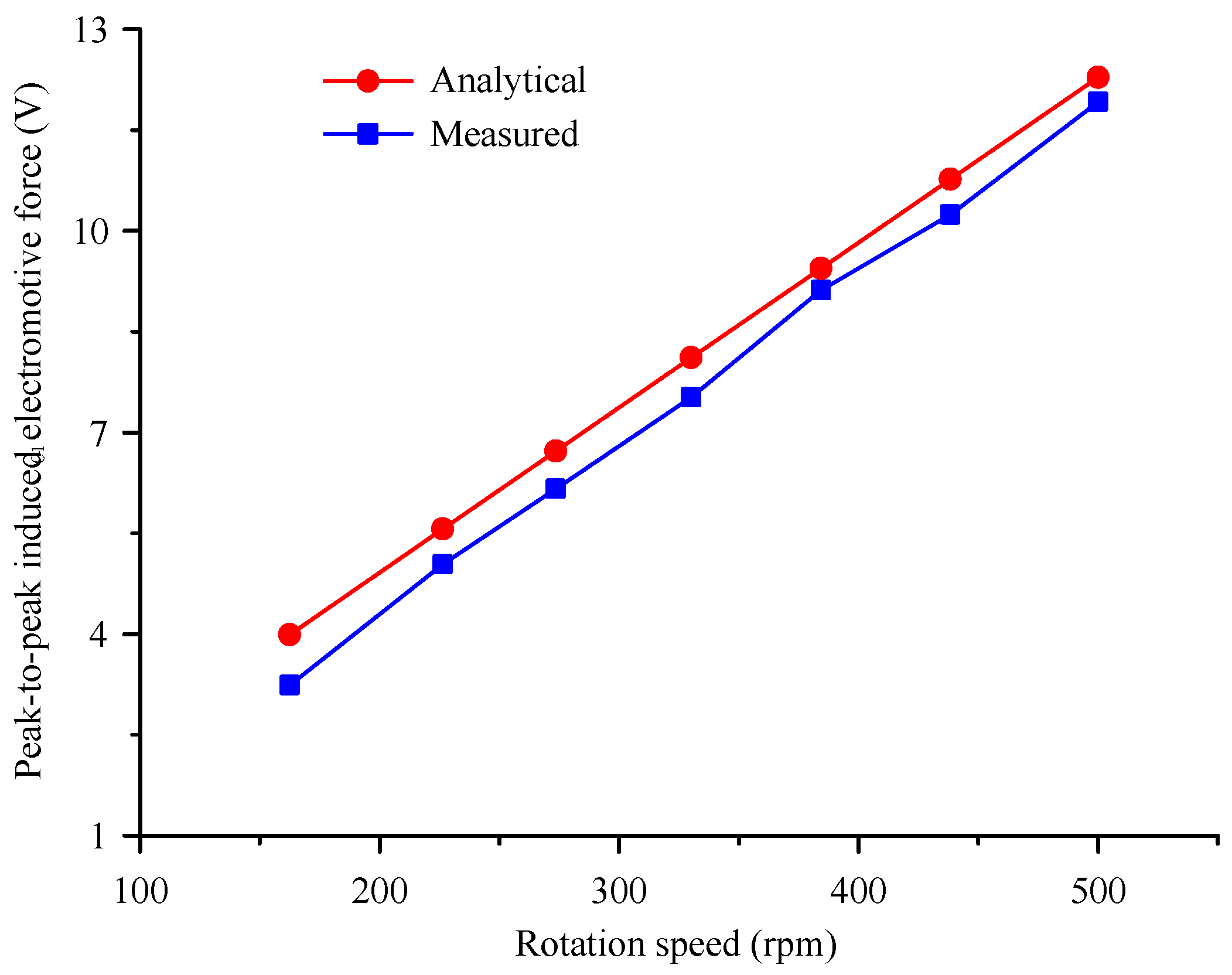

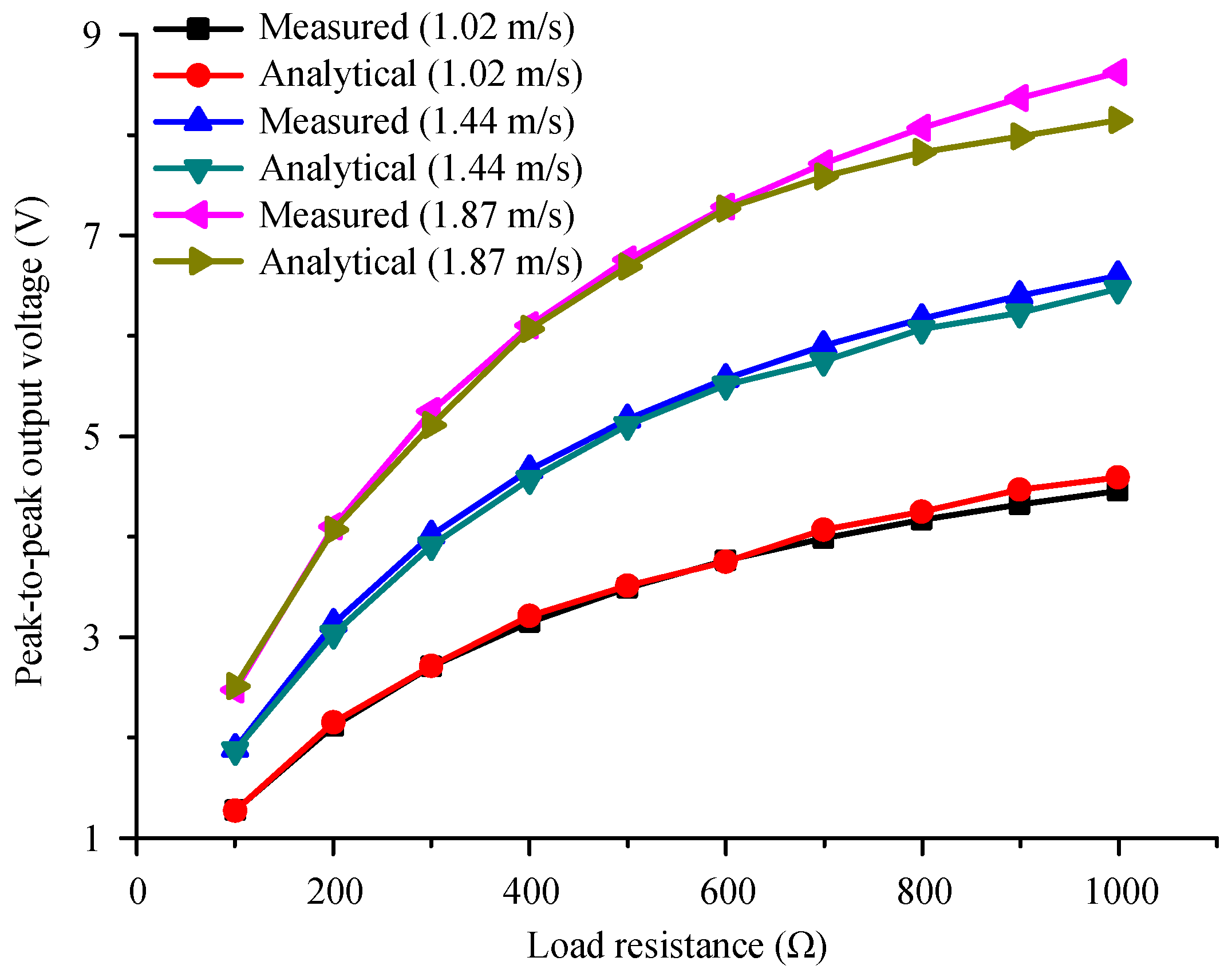

3.2. Power Generation Model

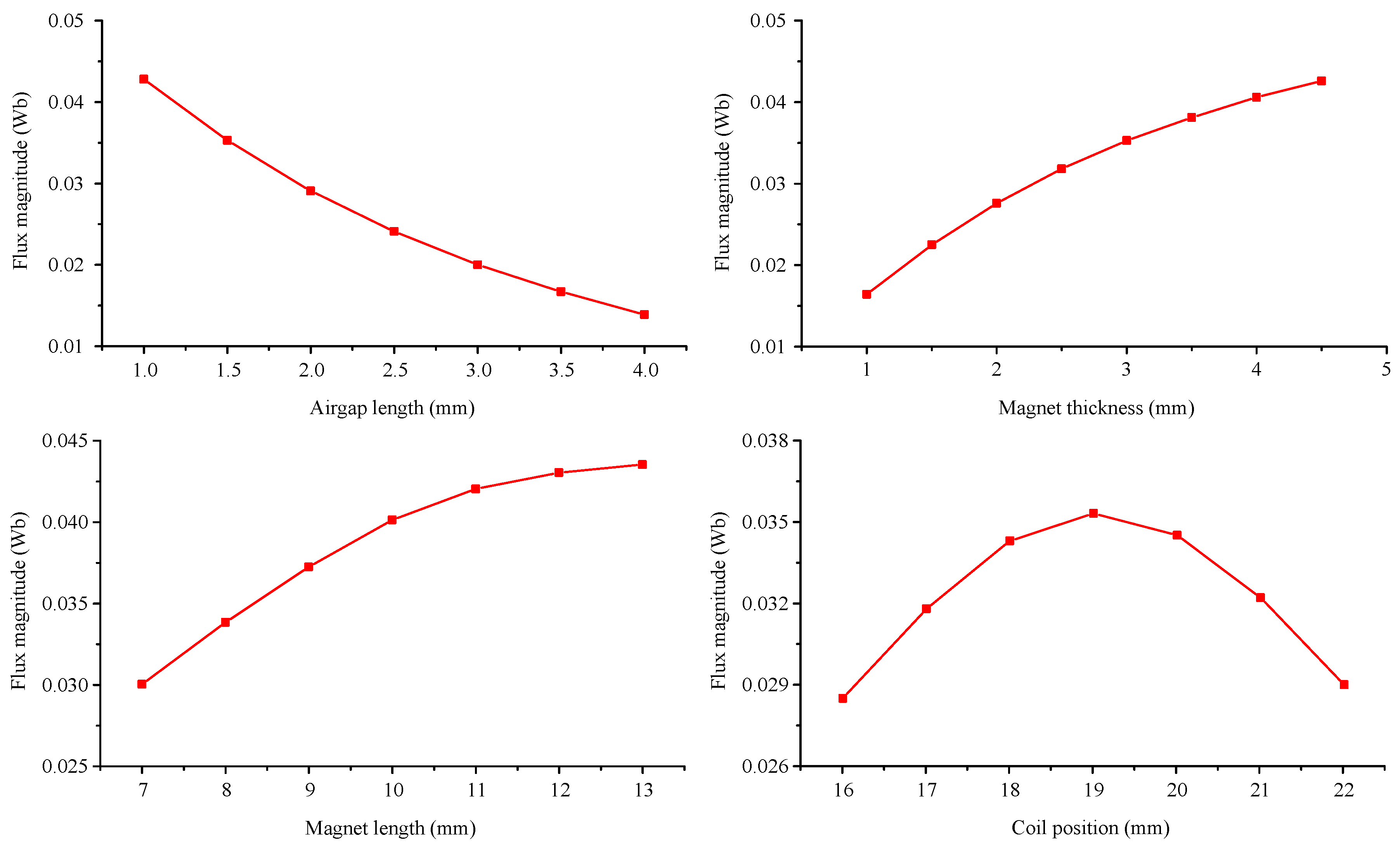

3.3. Parametric Analysis

4. Results and Discussion

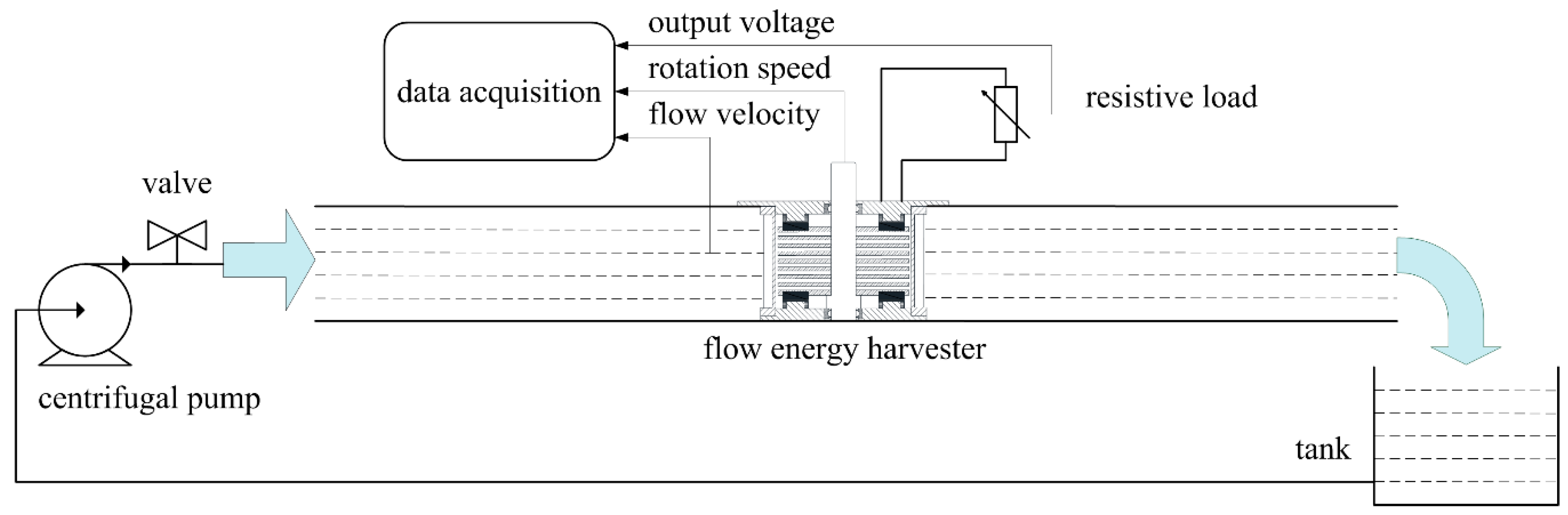

4.1. Experimental Setup

4.2. Under No-Load Condition

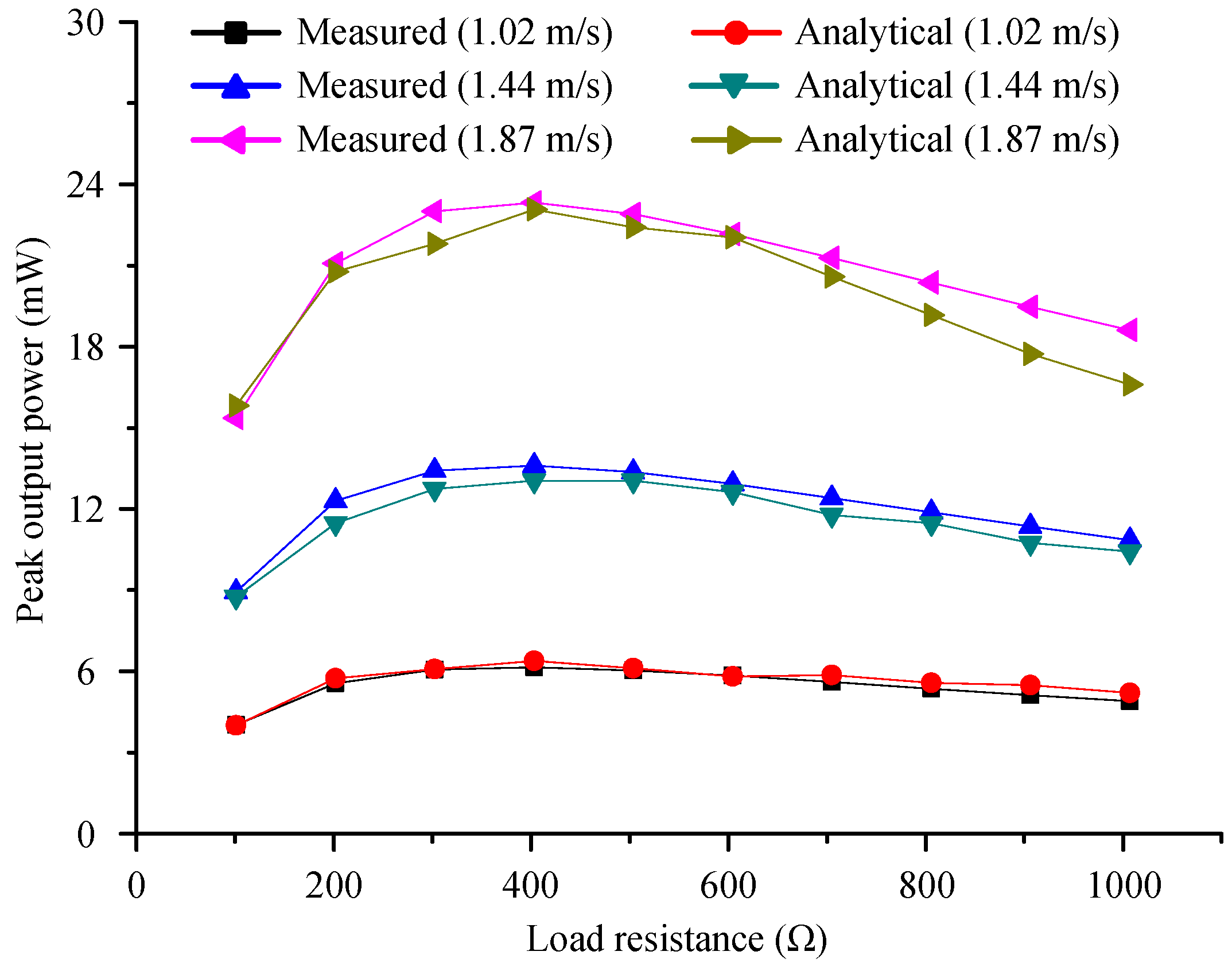

4.3. Under Loaded Condition

5. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Constantinou, P.; Mellor, P.H.; Wilcox, P.D. A magnetically sprung generator for energy harvesting applications. IEEE/ASME Trans. Mechatron. 2012, 17, 415–424. [Google Scholar] [CrossRef]

- Mansour, M.O.; Arafa, M.H.; Megahed, S.M. Resonator with magnetically adjustable natural frequency for vibration energy harvesting. Sens. Actuators A Phys. 2010, 163, 297–303. [Google Scholar] [CrossRef]

- Luo, Q.; He, X.; Jiang, S.; Wang, X. Impact-based electromagnetic energy harvester with high output voltage under low-level excitations. Energies 2017, 10, 1848. [Google Scholar] [CrossRef]

- Donelan, J.M.; Li, Q.; Naing, V.; Hoffer, J.A.; Weber, D.J.; Kuo, A.D. Biomechanical energy harvesting: Generating electricity during walking with minimal user effort. Science 2008, 319, 807–810. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.M.; Lee, M.G.; Jeon, Y. Wearable biomechanical energy harvesting technologies. Energies 2017, 10, 1483. [Google Scholar] [CrossRef]

- Kim, S.H.; Yu, C.H.; Ishiyama, K. Rotary-type electromagnetic power generator using a cardiovascular system as a power source for medical implants. IEEE/ASME Trans. Mechatron. 2016, 21, 122–129. [Google Scholar] [CrossRef]

- Pfenniger, A.; Vogel, R.; Koch, V.M.; Jonsson, M. Performance analysis of a miniature turbine generator for intracorporeal energy harvesting. Artif. Organs 2014, 38, E68–E81. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Wang, Y.; Kim, E.S. Electromagnetic energy harvester with flexible coils and magnetic spring for 1–10 Hz resonance. J. Microelectromech. Syst. 2015, 24, 1193–1206. [Google Scholar] [CrossRef]

- Mitcheson, P.D.; Yeatman, E.M.; Rao, G.K.; Holmes, A.S.; Green, T.C. Energy harvesting from human and machine motion for wireless electronic devices. Proc. IEEE 2008, 96, 1457–1486. [Google Scholar] [CrossRef]

- Berdy, D.F.; Valentino, D.J.; Peroulis, D. Kinetic energy harvesting from human walking and running using a magnetic levitation energy harvester. Sens. Actuators A Phys. 2015, 222, 262–271. [Google Scholar] [CrossRef]

- Khaligh, A.; Zeng, P.; Zheng, C. Kinetic energy harvesting using piezoelectric and electromagnetic technologies—State of the art. IEEE Trans. Ind. Electron. 2010, 57, 850–860. [Google Scholar] [CrossRef]

- Ren, H.; Wang, T. Development and modeling of an electromagnetic energy harvester from pressure fluctuations. Mechatronics 2018, 49, 36–45. [Google Scholar] [CrossRef]

- Taylor, G.W.; Burns, J.R.; Kammann, S.A.; Powers, W.B.; Welsh, T.R. The energy harvesting eel: A small subsurface ocean/river power generator. IEEE J. Ocean. Eng. 2001, 26, 539–547. [Google Scholar] [CrossRef]

- Mehmood, A.; Abdelkefi, A.; Hajj, M.R.; Nayfeh, A.H.; Akhtar, I.; Nuhait, A.O. Piezoelectric energy harvesting from vortex-induced vibrations of circular cylinder. J. Sound Vib. 2013, 332, 4656–4667. [Google Scholar] [CrossRef]

- Bernitsas, M.M.; Raghavan, K.; Ben-Simon, Y.; Garcia, E.M. VIVACE (Vortex Induced Vibration Aquatic Clean Energy): A new concept in generation of clean and renewable energy from fluid flow. J. Offsh. Mech. Arct. Eng. 2008, 130, 041101. [Google Scholar] [CrossRef]

- Lee, J.H.; Bernitsas, M.M. High-damping, high-Reynolds VIV tests for energy harnessing using the VIVACE converter. Ocean Eng. 2011, 38, 1697–1712. [Google Scholar] [CrossRef]

- Wang, D.A.; Chiu, C.Y.; Pham, H.T. Electromagnetic energy harvesting from vibrations induced by Kármán vortex street. Mechatronics 2012, 22, 746–756. [Google Scholar] [CrossRef]

- Ding, L.; Zhang, L.; Wu, C.; Mao, X.; Jiang, D. Flow induced motion and energy harvesting of bluff bodies with different cross sections. Energy Convers. Manag. 2015, 91, 416–426. [Google Scholar] [CrossRef]

- Xu-Xu, J.; Barrero-Gil, A.; Velazquez, A. Dual mass system for enhancing energy extraction from Vortex-induced Vibrations of a circular cylinder. Int. J. Mar. Energy 2016, 16, 250–261. [Google Scholar] [CrossRef]

- Li, S.; Yuan, J.; Lipson, H. Ambient wind energy harvesting using cross-flow fluttering. J. Appl. Phys. 2011, 109, 026104. [Google Scholar] [CrossRef]

- Kim, S.H.; Ji, C.H.; Galle, P.; Herrault, F.; Wu, X.; Lee, J.H.; Choi, C.A.; Allen, M.G. An electromagnetic energy scavenger from direct airflow. J. Micromech. Microeng. 2009, 19, 094010. [Google Scholar] [CrossRef]

- Wang, X.; Pan, C.L.; Liu, Y.B.; Feng, Z.H. Electromagnetic resonant cavity wind energy harvester with optimized reed design and effective magnetic loop. Sens. Actuators A Phys. 2014, 205, 63–71. [Google Scholar] [CrossRef]

- Hao, W.S.; Garcia, R. Development of a digital and battery-free smart flowmeter. Energies 2014, 7, 3695–3709. [Google Scholar] [CrossRef]

- Holmes, A.S.; Hong, G.; Pullen, K.R. Axial-flux permanent magnet machines for micropower generation. J. Microelectromech. Syst. 2005, 14, 54–62. [Google Scholar] [CrossRef]

- Tan, Y.K.; Panda, S.K. Self-autonomous wireless sensor nodes with wind energy harvesting for remote sensing of wind-driven wildfire spread. IEEE Trans. Instrum. Meas. 2011, 60, 1367–1377. [Google Scholar] [CrossRef]

- Han, N.; Zhao, D.; Schluter, J.U.; Goh, E.S.; Zhao, H.; Jin, X. Performance evaluation of 3D printed miniature electromagnetic energy harvesters driven by air flow. Appl. Energy 2016, 178, 672–680. [Google Scholar] [CrossRef]

- Rezaei-Hosseinabadi, N.; Tabesh, A.; Dehghani, R.; Aghili, A. An efficient piezoelectric windmill topology for energy harvesting from low-speed air flows. IEEE Trans. Ind. Electron. 2015, 62, 3576–3583. [Google Scholar] [CrossRef]

- Krishnan, V.G.; Romanin, V.; Carey, V.P.; Maharbiz, M.M. Design and scaling of microscale Tesla turbines. J. Micromech. Microeng. 2013, 23, 125001. [Google Scholar] [CrossRef]

- Zhao, D.; Ji, C.; Teo, C.; Li, S. Performance of small-scale bladeless electromagnetic energy harvesters driven by water or air. Energy 2014, 74, 99–108. [Google Scholar] [CrossRef]

- Zhao, D.; Khoo, J. Rainwater-and air-driven 40 mm bladeless electromagnetic energy harvester. Appl. Phys. Lett. 2013, 103, 033904. [Google Scholar] [CrossRef]

- Wang, T.; Zhou, Z. A compact hydrostatic-driven electric generator: Design, prototype, and experiment. IEEE/ASME Trans. Mechatron. 2016, 21, 1612–1619. [Google Scholar] [CrossRef]

- Wang, T.; Wang, H. Research on an integrated hydrostatic-driven electric generator with controllable load for renewable energy applications. Energies 2017, 10, 1299. [Google Scholar] [CrossRef]

- Nammari, A.; Caskey, L.; Negrete, J.; Bardaweel, H. Fabrication and characterization of non-resonant magneto-mechanical low-frequency vibration energy harvester. Mech. Syst. Signal Process. 2018, 102, 298–311. [Google Scholar] [CrossRef]

- Nammari, A.; Bardaweel, H. Design enhancement and non-dimensional analysis of magnetically-levitated nonlinear vibration energy harvesters. J. Intell. Mater. Syst. Struct. 2017, 28, 2810–2822. [Google Scholar] [CrossRef]

- Yaşar, O.; Uluşan, H.; Zorlu, Ö.; Şardan-Sukas, Ö.; Külah, H. Optimization of AA-battery sized electromagnetic energy harvesters: Reducing the resonance frequency using a non-magnetic inertial mass. IEEE Sens. J. 2018, 18, 4509–4516. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, Z.; Zhu, S. Comparison of vibration energy harvesters with fixed and unfixed magnetic springs. Electron. Lett. 2018, 54, 646–647. [Google Scholar] [CrossRef]

- Ravaud, R.; Lemarquand, G. Magnetic field produced by a parallelepipedic magnet of various and uniform polarization. Progr. Electromagn. Res. 2009, 98, 207–219. [Google Scholar] [CrossRef]

- Priya, S.; Daniel, I.D. Energy Harvesting Technologies; Springer: New York, NY, USA, 2009. [Google Scholar]

| Name | Value | Unit |

|---|---|---|

| Outer diameter | 65 | mm |

| Total height | 46 | mm |

| Total weight | 140 | G |

| Disk number | 8 | - |

| Disk thickness | 1.5 | mm |

| Sleeve thickness | 1.5 | mm |

| Magnet residual flux density | 1.25 | T |

| Magnet relative permeability | 1.06 | - |

| Total magnet number | 24 | - |

| Magnet thickness | 3 | mm |

| Magnet length | 10 | mm |

| Magnet width | 5 | mm |

| Magnet position radius | 19 | mm |

| Total coil number | 24 | - |

| Turn number per coil | 200 | - |

| Airgap length | 1.5 | mm |

| Copper wire diameter | 0.1 | mm |

| Groove number | 8 | - |

| Total coil resistance | 380 | Ω |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Zhang, Y. Design, Analysis, and Evaluation of a Compact Electromagnetic Energy Harvester from Water Flow for Remote Sensors. Energies 2018, 11, 1424. https://doi.org/10.3390/en11061424

Wang T, Zhang Y. Design, Analysis, and Evaluation of a Compact Electromagnetic Energy Harvester from Water Flow for Remote Sensors. Energies. 2018; 11(6):1424. https://doi.org/10.3390/en11061424

Chicago/Turabian StyleWang, Tao, and Yunce Zhang. 2018. "Design, Analysis, and Evaluation of a Compact Electromagnetic Energy Harvester from Water Flow for Remote Sensors" Energies 11, no. 6: 1424. https://doi.org/10.3390/en11061424

APA StyleWang, T., & Zhang, Y. (2018). Design, Analysis, and Evaluation of a Compact Electromagnetic Energy Harvester from Water Flow for Remote Sensors. Energies, 11(6), 1424. https://doi.org/10.3390/en11061424