Analysis of Integration of MEA-Based CO2 Capture and Solar Energy System for Coal-Based Power Plants Based on Thermo-Economic Structural Theory

Abstract

1. Introduction

2. System Description

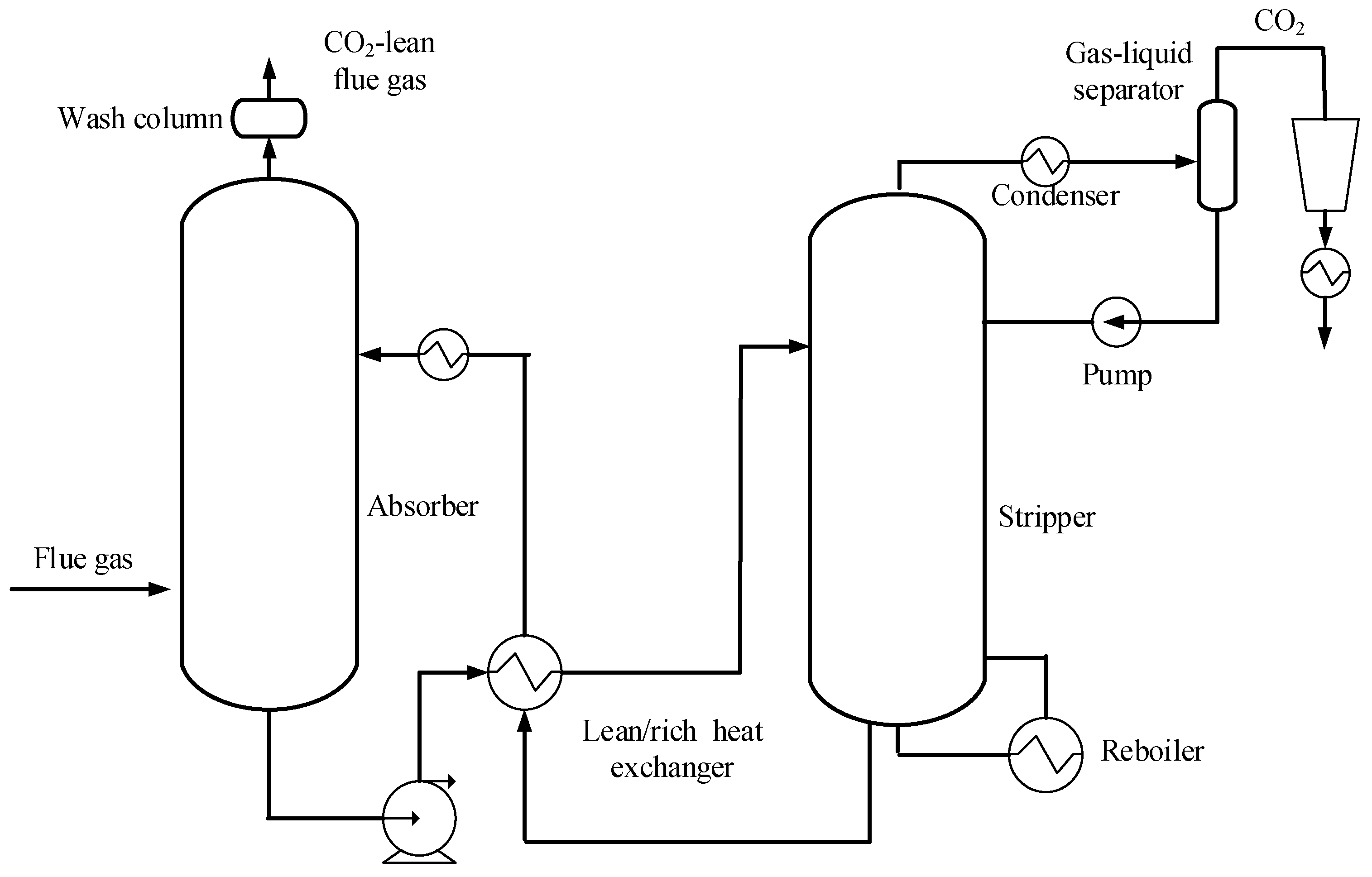

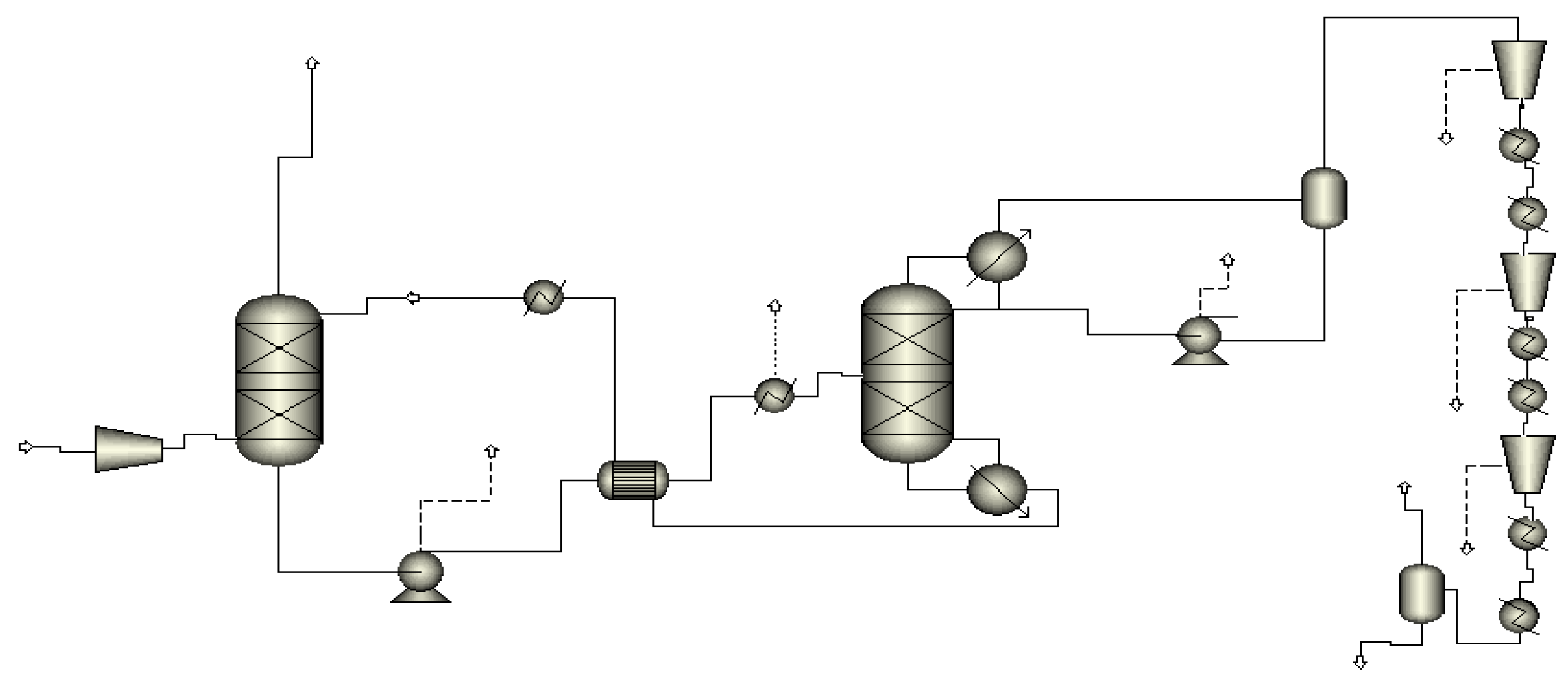

2.1. MEA-Based Post-Combustion CO2 Capture Process

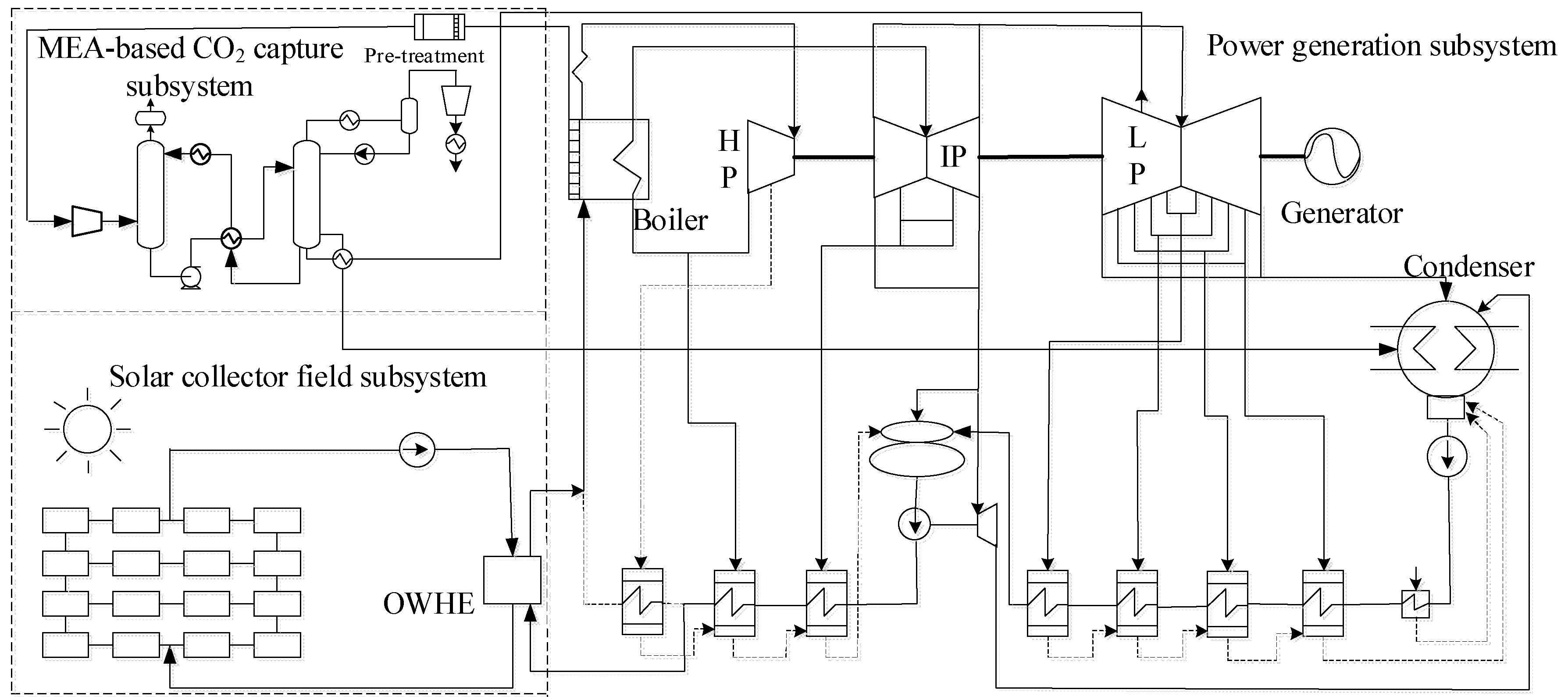

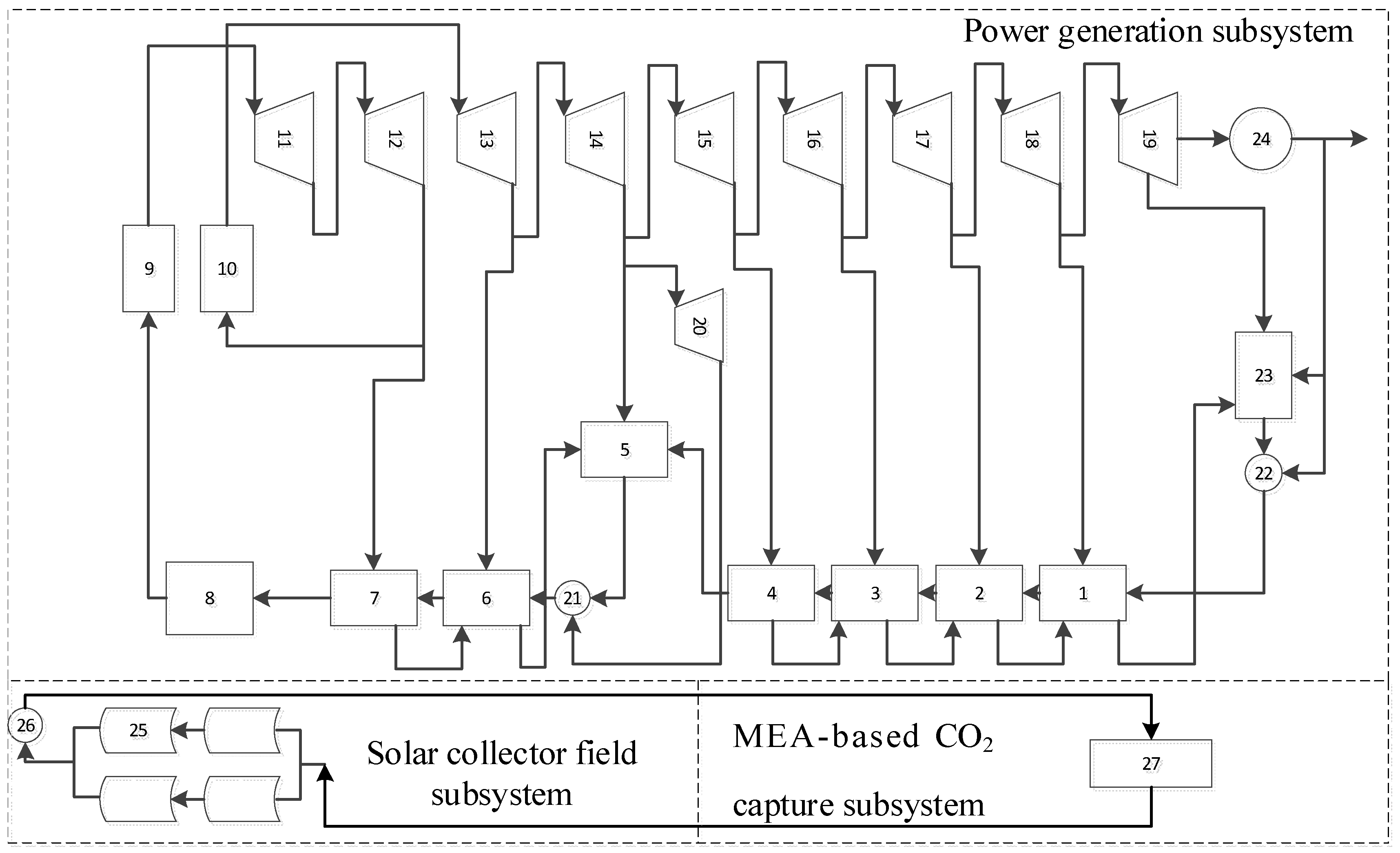

2.2. Solar-Aided Coal-Fired Power Generation with CO2 Capture

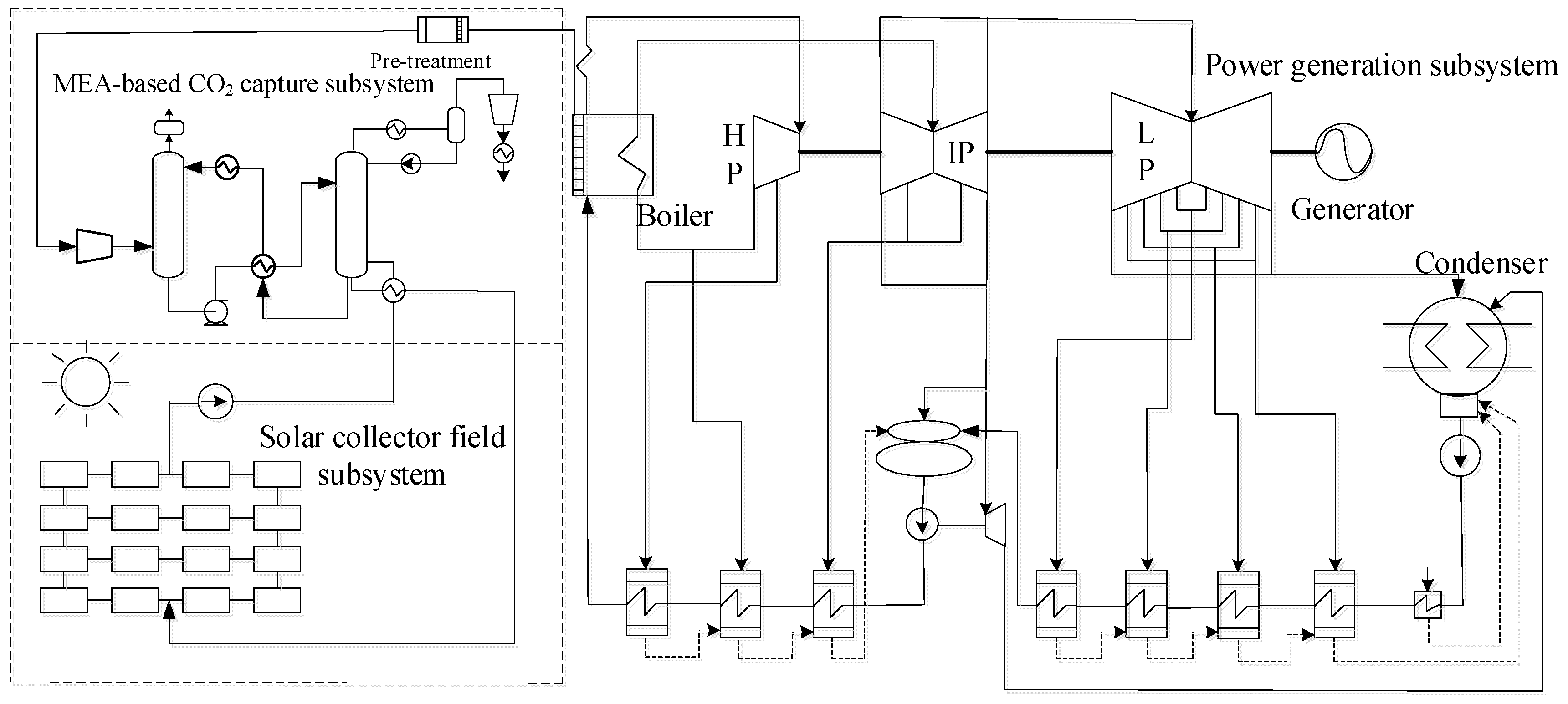

2.3. Solar-Aided CO2 Capture Coal-Fired Power-Generation System

2.4. Reference System

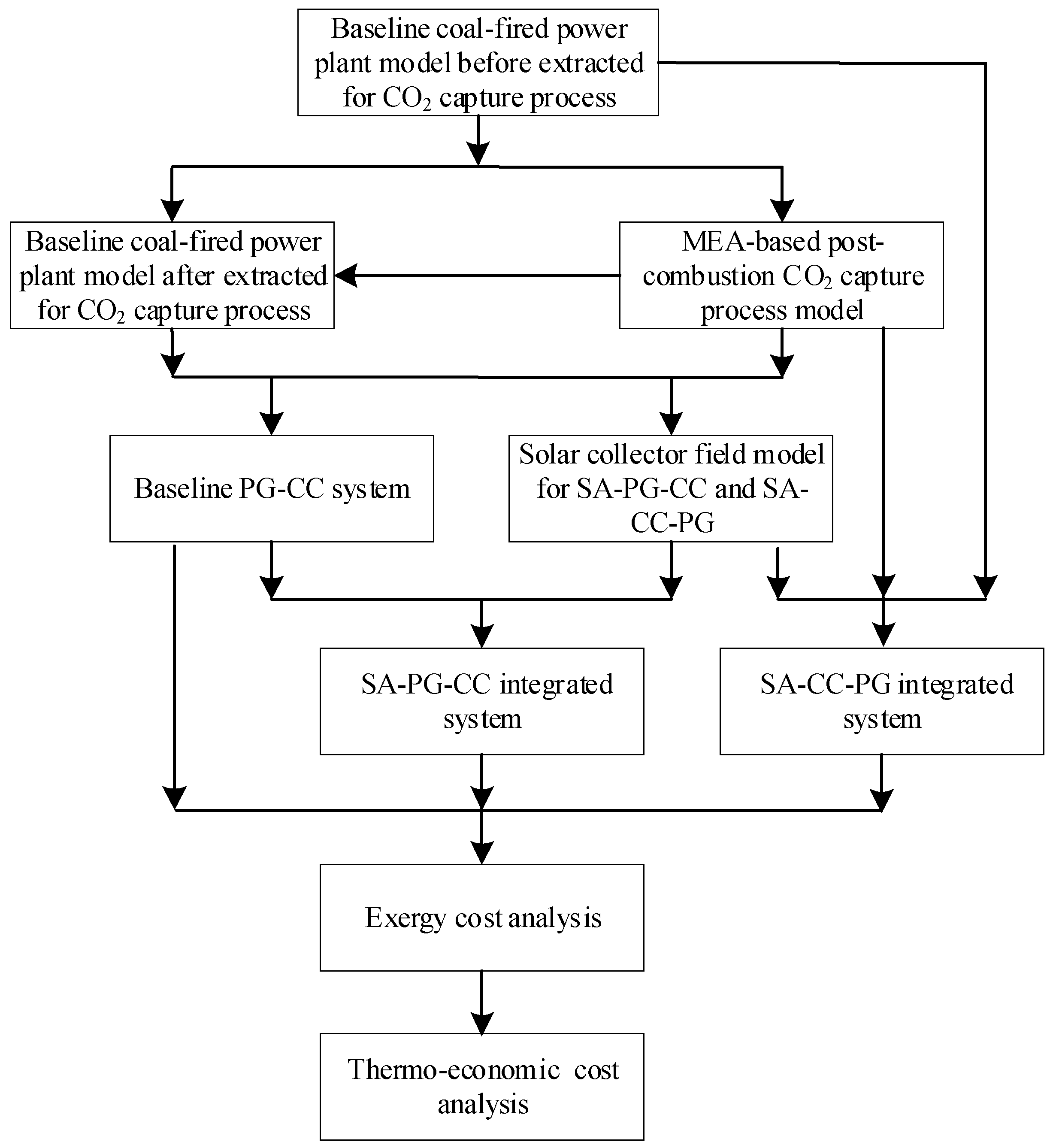

3. Modelling and Method

3.1. System Modelling

3.1.1. Solar Field Subsystem

3.1.2. Power-Generation Subsystem

3.1.3. MEA-Based CO2 Capture Subsystem

3.2. Thermo-Economic Structural Theory

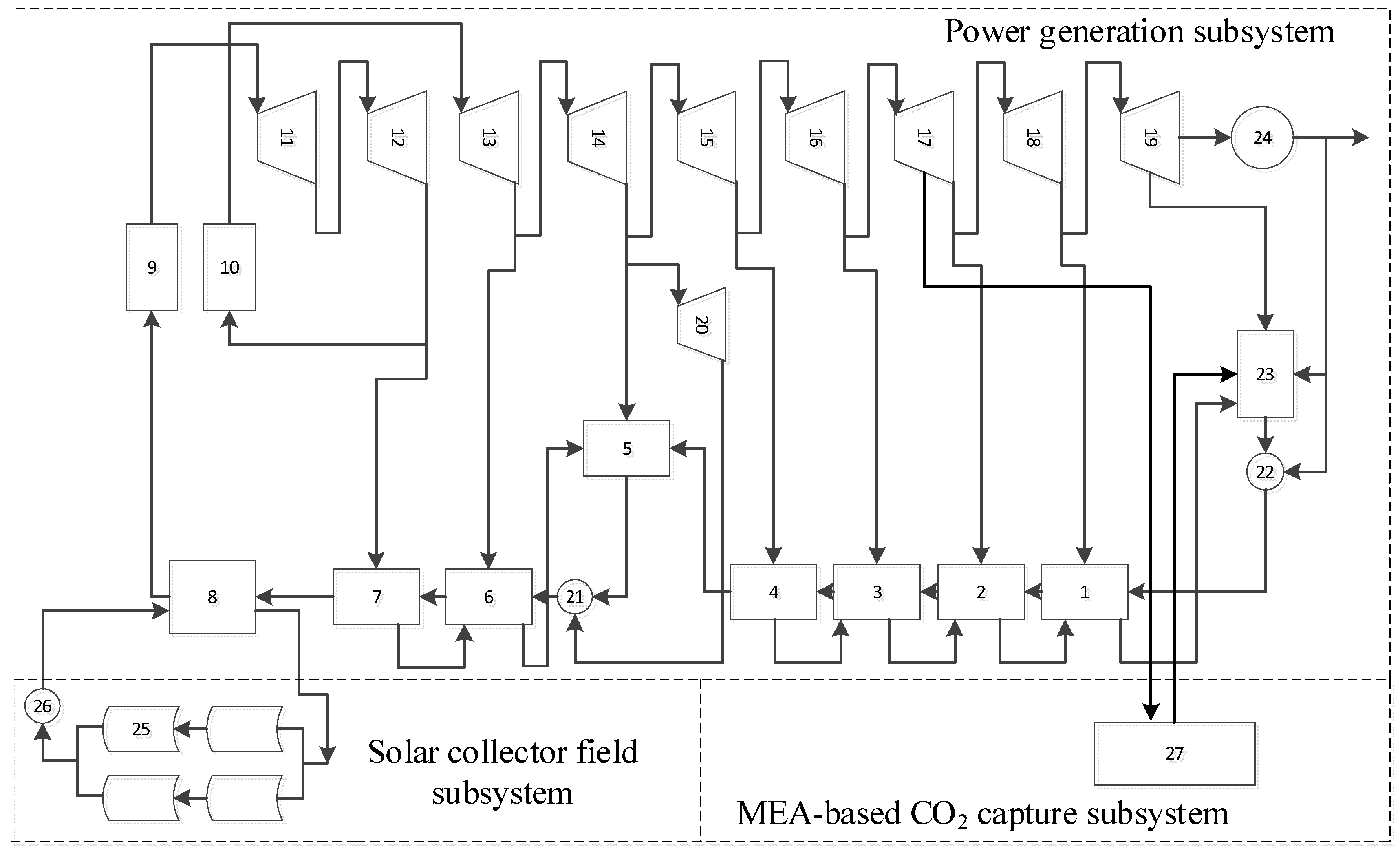

3.2.1. Physical and Productive Structures

3.2.2. Exergy Cost Model

3.2.3. Thermo-Economic Cost Model

3.2.4. Levelized Cost of Electricity Model

3.2.5. Model Solution

4. Case Study

4.1. Basic Data

4.1.1. Technical Parameters

4.1.2. Economic Parameters

4.2. Results and Discussion

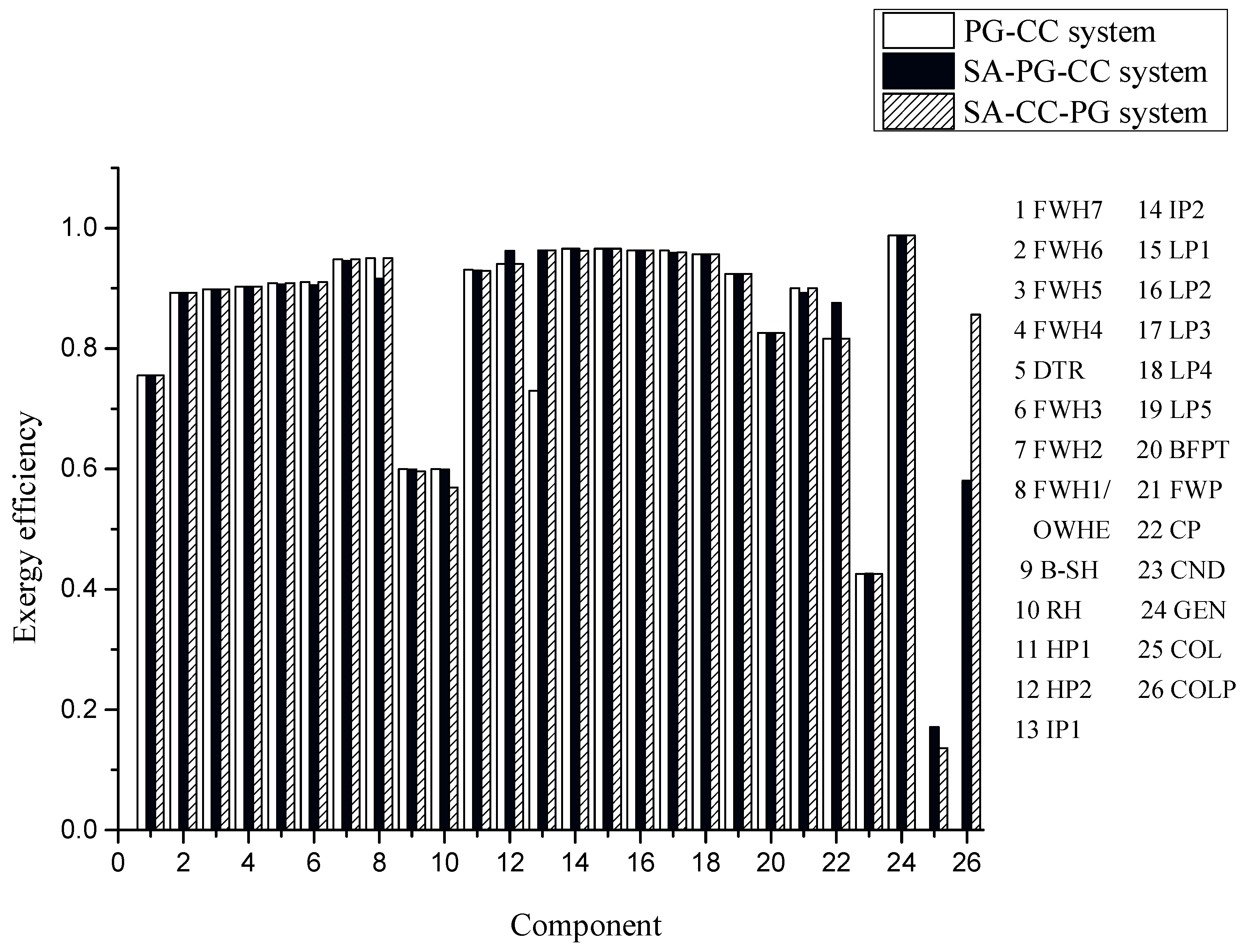

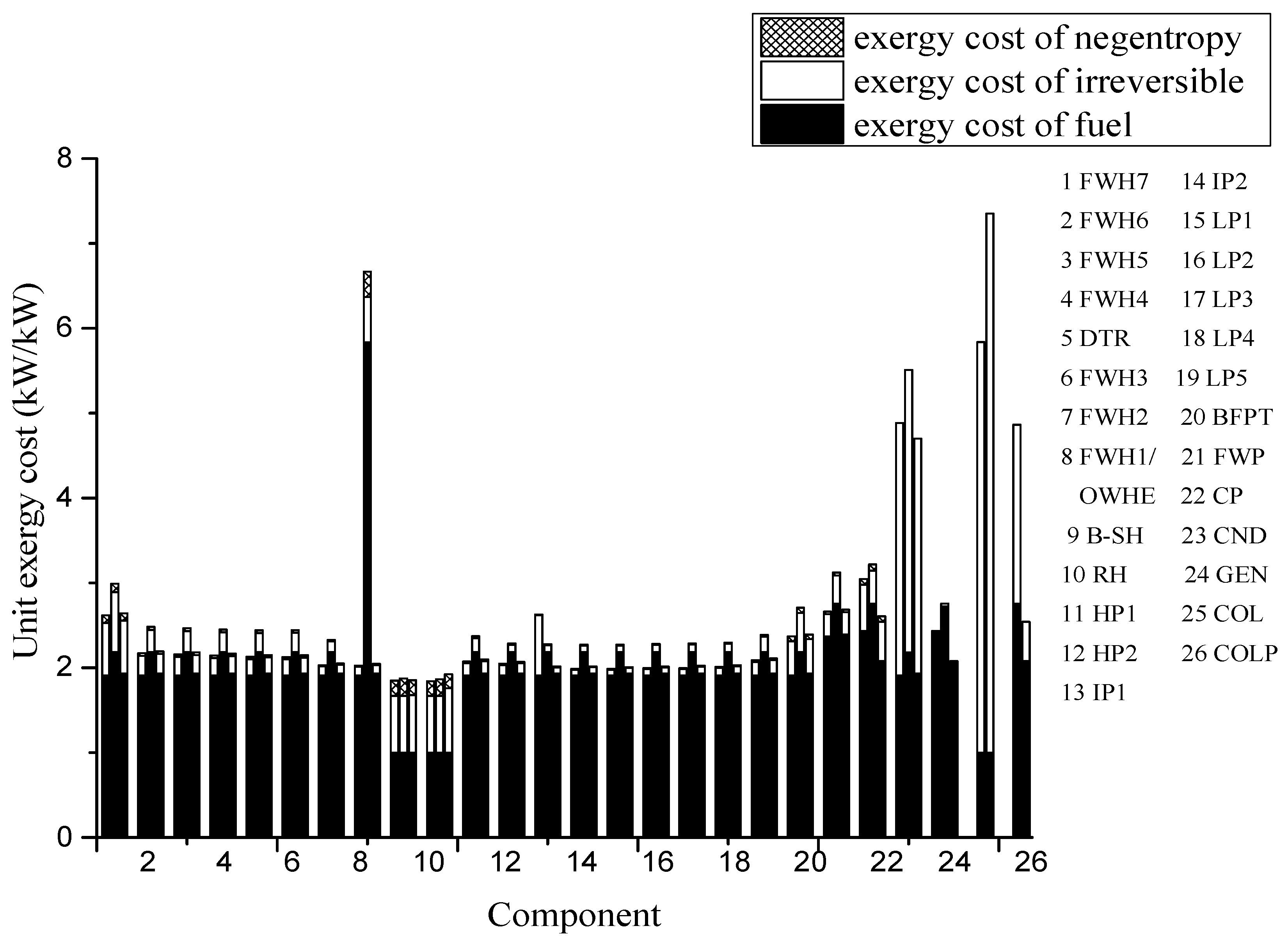

4.2.1. Exergy Cost

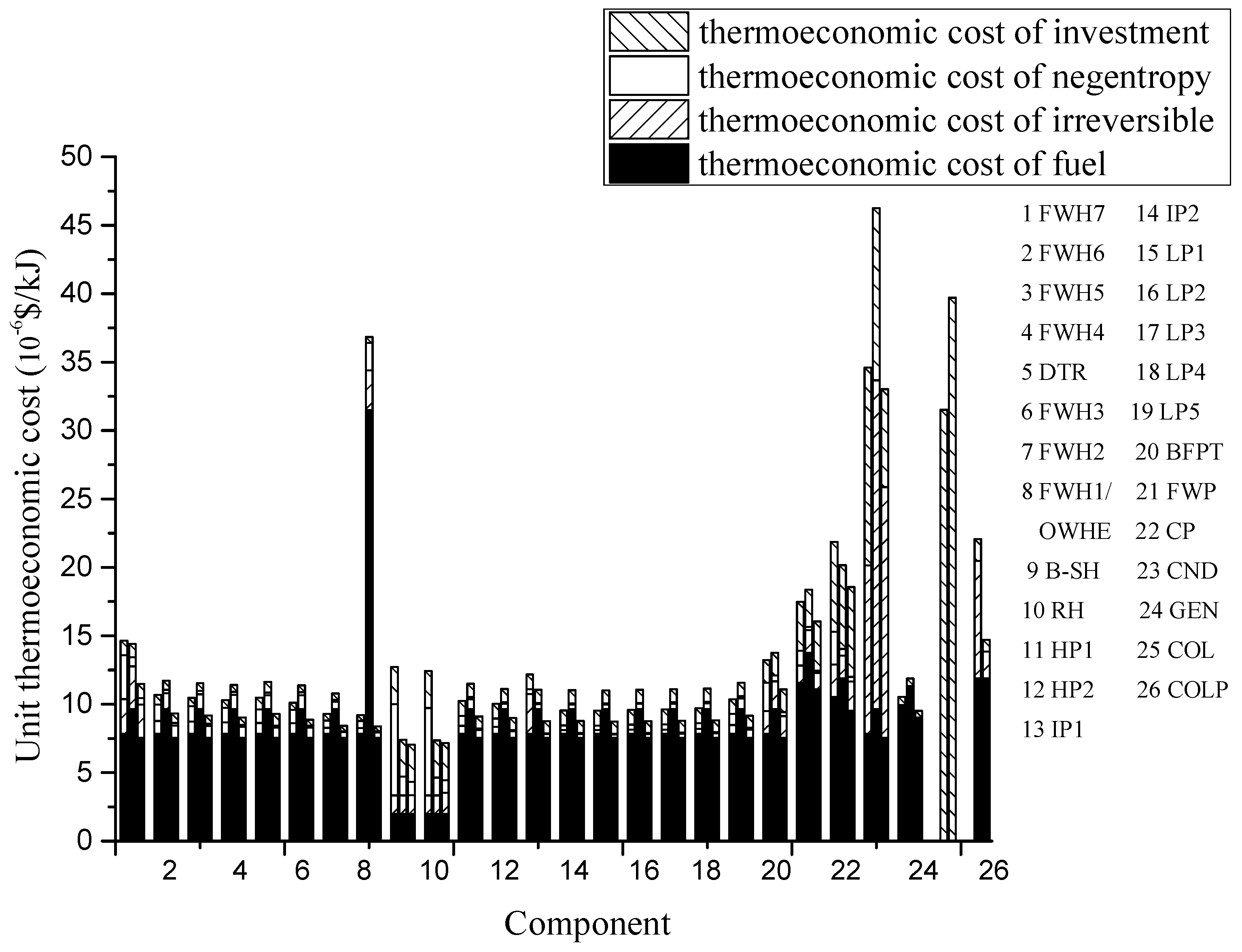

4.2.2. Thermo-Economic Cost

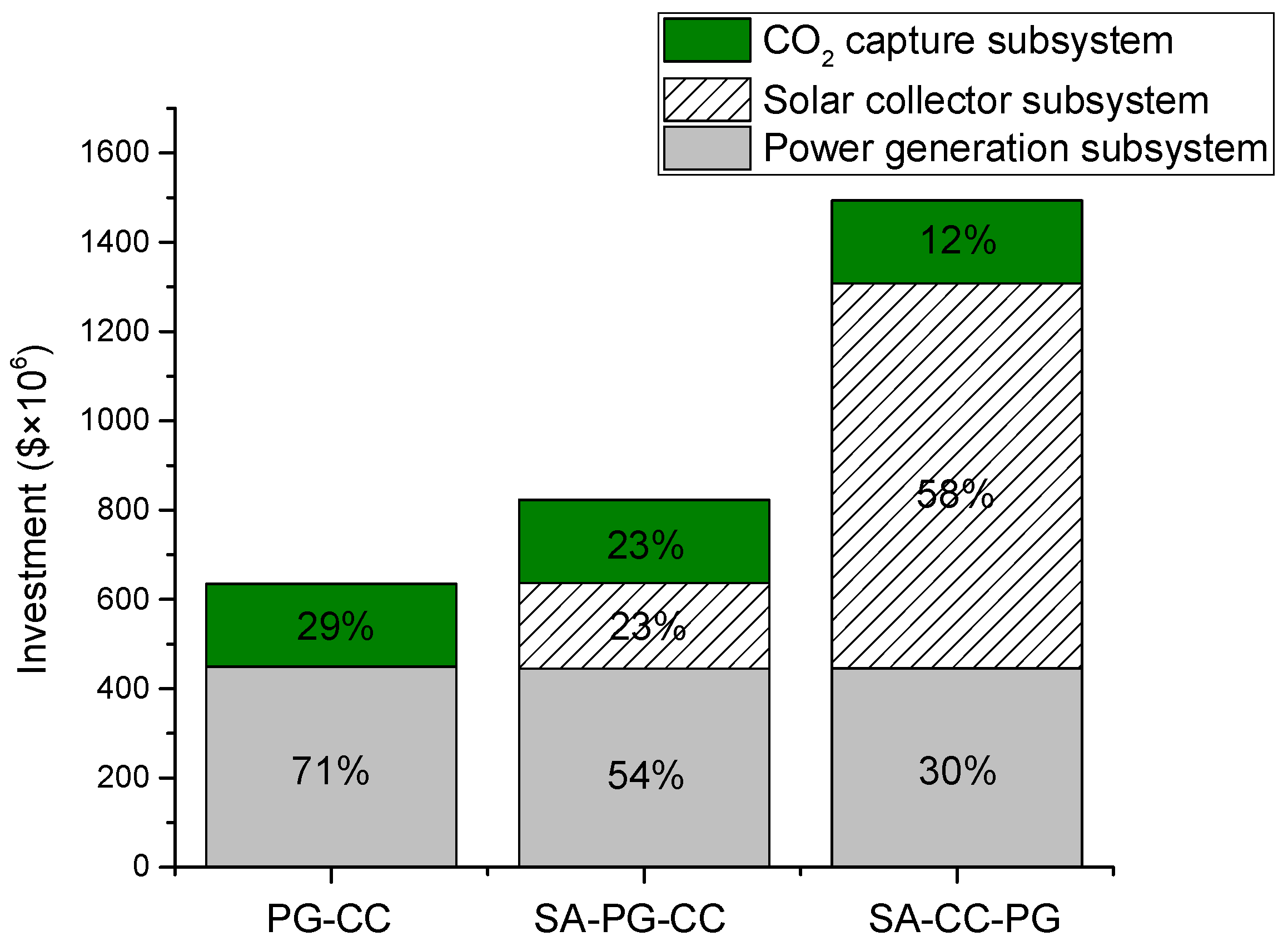

4.2.3. Levelized Cost of Electricity

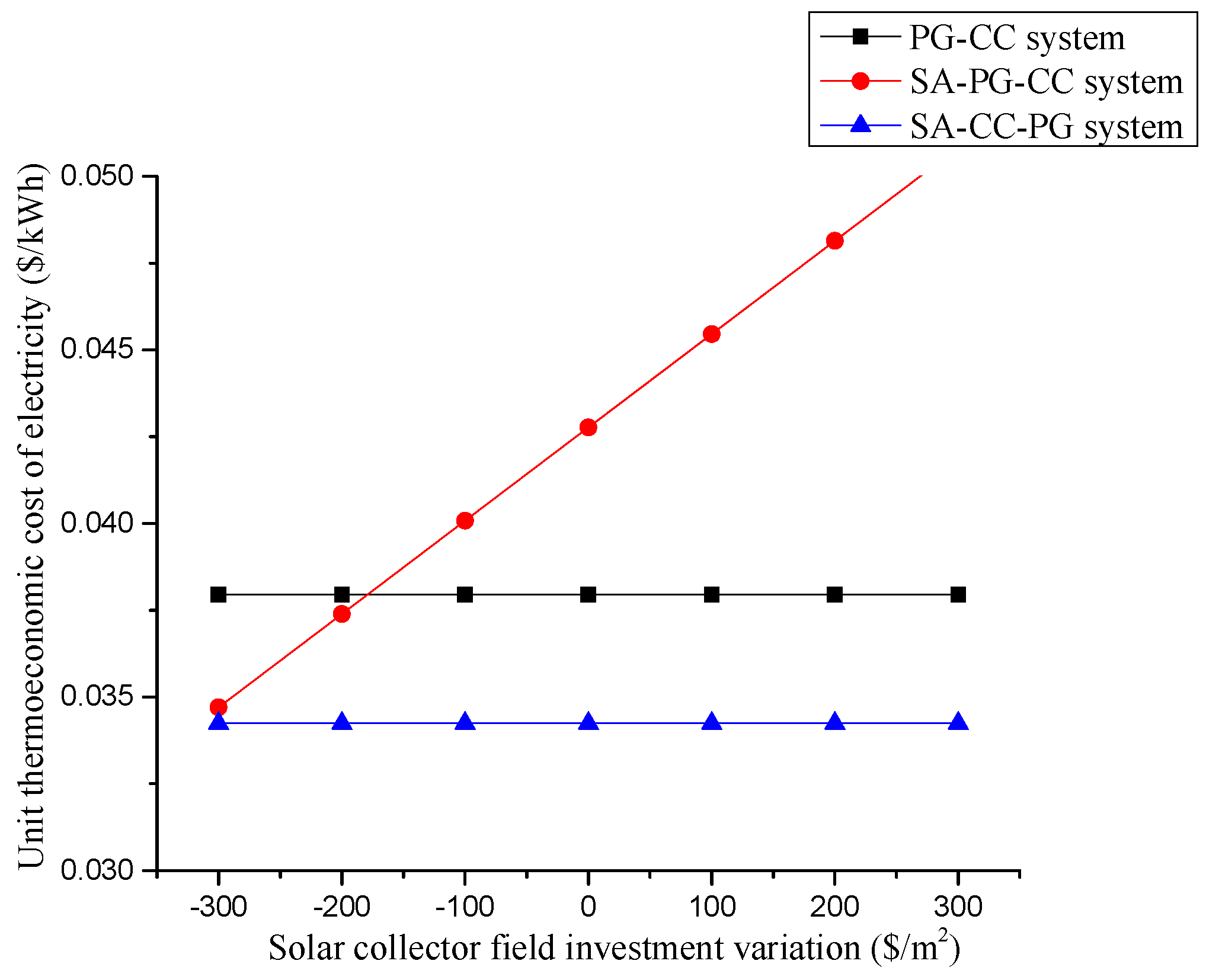

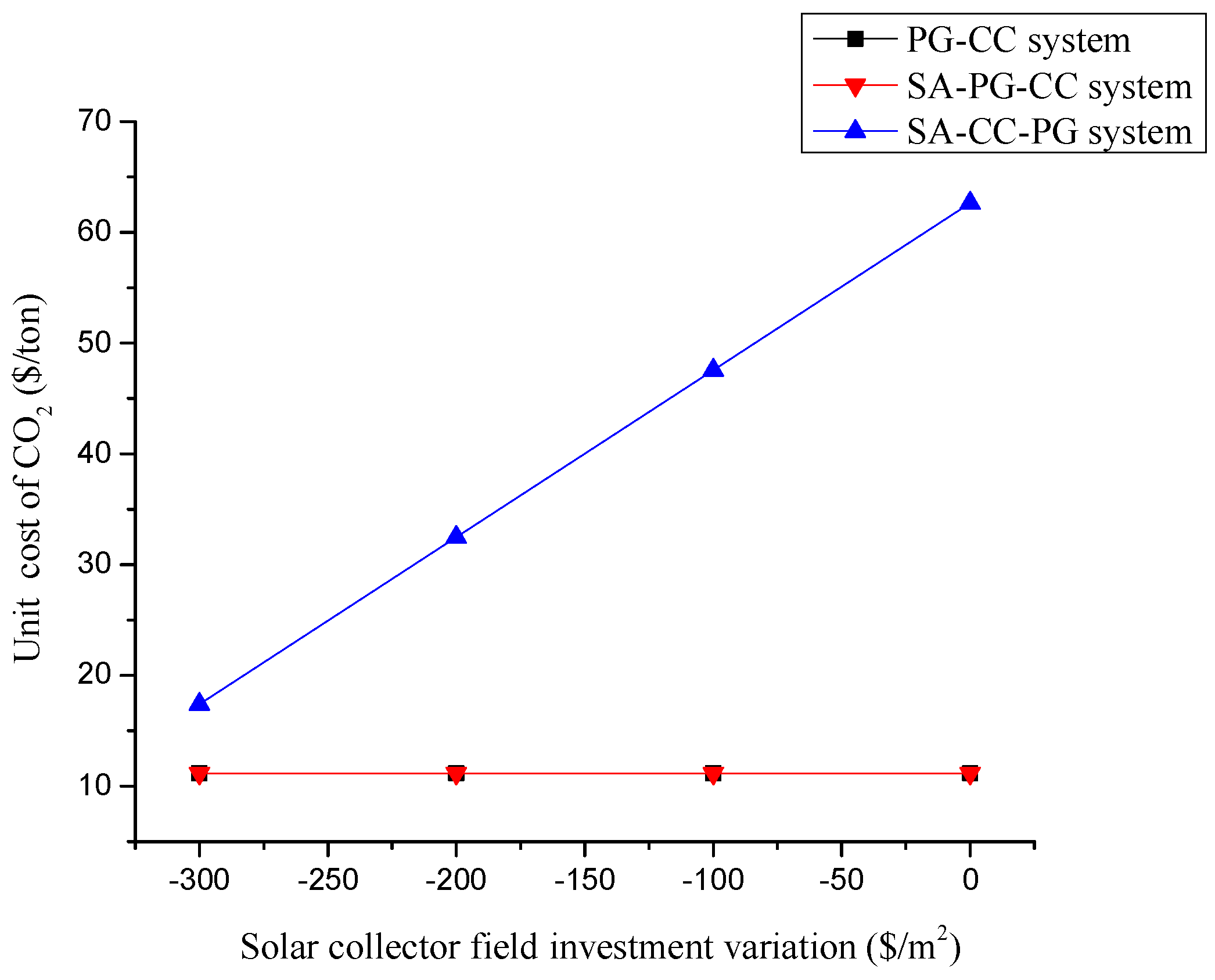

4.2.4. Sensitivity Analysis

5. Conclusions

- Both SA-PG-CC and SA-CC-PG systems have greater power generation than the PG-CC system, and greater system efficiency. Compared with PG-CC, the coal consumption rate of SA-PG-CC and SA-CC-PG fell by 15.31 and 51.41 g/kWh, respectively. In this research, only the first high-pressure extraction steam was replaced by solar thermal. The other extraction steam can also be replaced with more solar thermal energy. The higher equivalent solar-power generation efficiency in SA-PG-CC indicates that the solar thermal energy is more fully used in SA-PG-CC system than in SA-CC-PG; therefore, the SA-PG-CC is a better configuration than SA-CC-PG.

- In SA-PG-CC, the additional exergy cost of the solar-collector subsystem was distributed to other components in the power-generation process. Therefore, the unit exergy cost of each component increased slightly compared with PG-CC, and the unit exergy cost of the electricity increased by 13.2%. SA-CC-PG had a greater amount of power generation than PG-CC, and therefore slightly lower unit exergy costs of electricity and coal combustion rate in SA-CC-PG. However, the increased low-pressure steam also increased the exergy cost of other components. In SA-CC-PG, the heat required for the stripper reboiler is provided by solar thermal with higher exergy cost. Therefore, the unit exergy cost of CO2 in SA-CC-PG was significantly greater than in PG-CC and SA-PG-CC.

- Compared with PG-CC, the thermo-economic cost of electricity increased by 12.71% in SA-PG-CC and decreased by 9.77% in SA-CC-PG. The unit thermo-economic cost of CO2 was much higher in SA-CC-PG because of the large thermo-economic cost of solar thermal energy.

- The increased solar thermal energy improved the efficiency of the system in SA-PG-CC compared to PG-CC, indicating a high efficiency of solar exergy to electricity in this integration. The increased exergy cost shows the great exergy loss of the solar field. The increase of the unit thermo-economic cost of electricity indicates the enormous investment in solar fields. Therefore, to improve the thermo-economic performance of the solar energy system, the exergy efficiency of the solar field should be promoted and investment should be reduced.

- Only two integration configurations are studied in this research, and there might be better methods for the integration of solar energy systems and CO2 capture processes in coal-fired power plants. Using a general approach to optimize the solar thermal energy distribution in power generation and CO2 capture process could be studied in future research.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbol | Meaning | Unit |

| A | Total net aperture area of solar collector field | m2 |

| B | Exergy flow | kW |

| B* | External exergy consumed for the product | kW |

| Unit thermo-economic cost | $/kJ | |

| Thermo-economic cost of fuel | $/kJ | |

| Thermo-economic cost caused by irreversible | $/kJ | |

| Thermo-economic cost caused by negentropy | $/kJ | |

| The thermo-economic cost caused by investment | $/kJ | |

| DNI | Solar direct normal irradiation | W/m2 |

| Coal exergy | kW | |

| F | Flue flow | kJ |

| P | Product flow | kJ |

| FB | Exergy fuel | kW |

| FS | Negentropy fuel | kW |

| k* | Unit exergy cost | kW/kW |

| kB | Fuel exergy of unit of product | kW/kW |

| kI | Irreversible exergy lost of unit production | kW/kW |

| kS | Negentropy fuel of unit of product | kW/kW |

| KZ | Capital costs of unit production | $/kJ |

| I | Irreversible exergy loss of production | kW/kW |

| Z | Non-energy costs of the component | $ |

| Energy costs of the component | $/kJ | |

| i | Component number of input flow | - |

| j | Component number of output flow | - |

| CO2 removal ratio | – | |

| CO2 loading ratio | – |

Appendix A

| ID | Abbreviation | Component |

|---|---|---|

| 1–4,6–8 | FWH | Feed-water heater |

| 8 | OWHE | Oil–water heat exchanger |

| 5 | DTR | Deaerator |

| 9 | SH | Boiler superheater |

| 10 | RH | Reheater |

| 11,12 | HP | High-pressure turbine |

| 13,14 | IP | Intermediate-pressure turbine |

| 15–19 | LP | Low-pressure turbine |

| 20 | BFPT | Feed-water pump turbine |

| 21 | FWP | Feed-water pump |

| 22 | CP | Condenser water pump |

| 23 | CND | Condenser |

| 24 | GEN | Generator |

| 25 | COL | Collector |

| 26 | COLP | Collector oil-pump |

| 27 | CCS | MEA-based CO2 capture subsystem |

Appendix B

| ID | Component | PG-CC ($) | SA-PG-CC ($) | SA-CC-PG ($) |

|---|---|---|---|---|

| 1 | FWH7 | 1,871,692 | 1,871,692 | 1,855,075 |

| 2 | FWH6 | 884,416 | 884,416 | 876,554 |

| 3 | FWH5 | 934,189 | 934,189 | 925,895 |

| 4 | FWH4 | 862,262 | 862,262 | 854,604 |

| 5 | DTR | 1,886,061 | 1,886,061 | 1,886,061 |

| 6 | FWH3 | 1,752,092 | 1,735,706 | 1,485,249 |

| 7 | FWH2 | 2,649,115 | 2,637,052 | 2,245,656 |

| 8 | FWH1/OWHE | 2,427,635 | 2,456,082 | 2,057,915 |

| 9 | SH | 224,373,329 | 220,422,356 | 223,888,459 |

| 10 | RH | 52,032,176 | 55,983,149 | 52,517,046 |

| 11 | HP1 | 20,010,303 | 17,572,405 | 16,317,348 |

| 12 | HP2 | 8,301,811 | 7,979,165 | 6,769,733 |

| 13 | IP1 | 11,829,994 | 11,362,524 | 9,646,736 |

| 14 | IP2 | 11,629,111 | 11,169,992 | 9,482,927 |

| 15 | LP1 | 7,420,385 | 7,142,714 | 6,050,932 |

| 16 | LP2 | 6,633,423 | 6,386,493 | 5,409,206 |

| 17 | LP3 | 4,200,176 | 4,218,248 | 5,598,987 |

| 18 | LP4 | 2,408,251 | 2,578,164 | 4,951,836 |

| 19 | LP5 | 4,309,719 | 4,756,450 | 10,433,958 |

| 20 | BFPT | 3,902,195 | 3,902,195 | 3,902,195 |

| 21 | FWP | 7,641,799 | 7,641,799 | 7,641,799 |

| 22 | CP | 357,701 | 357,701 | 357,701 |

| 23 | CND | 29,835,535 | 29,835,535 | 29,835,535 |

| 24 | GEN | 40,647,868 | 40,647,868 | 40,647,868 |

| 25 | COL | - | 191,624,287 | 862,309,293 |

| 26 | COLP | - | 6401 | 6401 |

| 27 | CCS | 186,025,000 | 186,025,000 | 186,025,000 |

Appendix C

| Component | 500-MW CO2 Capture System ($) | 1000-MW CO2 Capture System ($) |

|---|---|---|

| Flue gas blower | 2,172,000 | 3,291,000 |

| Absorber | 30,690,000 | 46,516,000 |

| Rich solution pump | 4,480,000 | 6,789,000 |

| Lean/rich solution heat exchanger | 2,175,000 | 3,295,000 |

| Lean solution cooler | 3,684,000 | 5,583,000 |

| Stripper | 16,410,000 | 24,873,000 |

| Reboiler | 10,180,000 | 15,429,000 |

| Circulating water pump | 3,684,000 | 5,583,000 |

| Drying and compression device | 32,217,616 | 54,128,000 |

| MEA solution | 13,850,000 | 17,113,000 |

| Corrosion inhibitor | 2,771,000 | 3,425,000 |

Appendix D

| ID | Component | PG-CC | SA-PG-CC | SA-CC-PG | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | FWH7 | 2.62 | 1.91 | 0.62 | 0.09 | 2.99 | 2.18 | 0.71 | 0.10 | 2.64 | 1.93 | 0.63 | 0.08 |

| 2 | FWH6 | 2.17 | 1.91 | 0.23 | 0.03 | 2.48 | 2.18 | 0.26 | 0.04 | 2.19 | 1.93 | 0.23 | 0.03 |

| 3 | FWH5 | 2.16 | 1.91 | 0.22 | 0.03 | 2.47 | 2.18 | 0.25 | 0.03 | 2.18 | 1.93 | 0.22 | 0.03 |

| 4 | FWH4 | 2.14 | 1.91 | 0.21 | 0.03 | 2.45 | 2.18 | 0.23 | 0.03 | 2.16 | 1.93 | 0.21 | 0.03 |

| 5 | DTR | 2.13 | 1.91 | 0.19 | 0.03 | 2.44 | 2.18 | 0.22 | 0.03 | 2.15 | 1.93 | 0.19 | 0.03 |

| 6 | FWH3 | 2.12 | 1.91 | 0.19 | 0.03 | 2.44 | 2.18 | 0.23 | 0.03 | 2.15 | 1.93 | 0.19 | 0.03 |

| 7 | FWH2 | 2.03 | 1.91 | 0.10 | 0.01 | 2.33 | 2.18 | 0.13 | 0.02 | 2.05 | 1.93 | 0.11 | 0.01 |

| 8 | FWH1/OWHE | 2.02 | 1.91 | 0.10 | 0.01 | 6.67 | 5.84 | 0.53 | 0.30 | 2.05 | 1.93 | 0.10 | 0.01 |

| 9 | SH | 1.85 | 1.00 | 0.67 | 0.18 | 1.87 | 1.00 | 0.67 | 0.20 | 1.85 | 1.00 | 0.68 | 0.18 |

| 10 | RH | 1.84 | 1.00 | 0.67 | 0.17 | 1.86 | 1.00 | 0.67 | 0.20 | 1.92 | 1.00 | 0.76 | 0.17 |

| 11 | HP1 | 2.07 | 1.91 | 0.14 | 0.02 | 2.37 | 2.18 | 0.16 | 0.02 | 2.10 | 1.93 | 0.15 | 0.02 |

| 12 | HP2 | 2.05 | 1.91 | 0.12 | 0.02 | 2.29 | 2.18 | 0.09 | 0.02 | 2.07 | 1.93 | 0.12 | 0.02 |

| 13 | IP1 | 2.63 | 1.91 | 0.71 | 0.01 | 2.28 | 2.18 | 0.08 | 0.01 | 2.01 | 1.93 | 0.07 | 0.01 |

| 14 | IP2 | 1.99 | 1.91 | 0.07 | 0.01 | 2.27 | 2.18 | 0.08 | 0.01 | 2.02 | 1.93 | 0.08 | 0.01 |

| 15 | LP1 | 1.99 | 1.91 | 0.07 | 0.01 | 2.27 | 2.18 | 0.08 | 0.01 | 2.01 | 1.93 | 0.07 | 0.01 |

| 16 | LP2 | 1.99 | 1.91 | 0.07 | 0.01 | 2.28 | 2.18 | 0.08 | 0.01 | 2.01 | 1.93 | 0.07 | 0.01 |

| 17 | LP3 | 1.99 | 1.91 | 0.07 | 0.01 | 2.29 | 2.18 | 0.09 | 0.01 | 2.02 | 1.93 | 0.08 | 0.01 |

| 18 | LP4 | 2.01 | 1.91 | 0.09 | 0.01 | 2.30 | 2.18 | 0.10 | 0.01 | 2.03 | 1.93 | 0.09 | 0.01 |

| 19 | LP5 | 2.09 | 1.91 | 0.16 | 0.02 | 2.39 | 2.18 | 0.18 | 0.02 | 2.11 | 1.93 | 0.16 | 0.02 |

| 20 | BFPT | 2.37 | 1.91 | 0.40 | 0.06 | 2.71 | 2.18 | 0.46 | 0.06 | 2.39 | 1.93 | 0.41 | 0.05 |

| 21 | FWP | 2.66 | 2.37 | 0.26 | 0.03 | 3.12 | 2.75 | 0.33 | 0.04 | 2.68 | 2.39 | 0.26 | 0.03 |

| 22 | CP | 3.05 | 2.43 | 0.55 | 0.06 | 3.22 | 2.75 | 0.39 | 0.07 | 2.61 | 2.08 | 0.47 | 0.06 |

| 23 | CND | 4.89 | 1.91 | 2.97 | 0.00 | 5.52 | 2.18 | 3.33 | 0.00 | 4.70 | 1.93 | 2.77 | 0.00 |

| 24 | GEN | 2.43 | 2.40 | 0.03 | 0.00 | 2.75 | 2.72 | 0.03 | 0.00 | 2.08 | 2.05 | 0.02 | 0.00 |

| 25 | COL | - | - | - | - | 5.84 | 1.00 | 4.84 | 0.00 | 7.35 | 1.00 | 6.35 | 0.00 |

| 26 | COLP | - | - | - | - | 4.74 | 2.75 | 2.11 | 0.00 | 3.22 | 2.75 | 0.46 | 0.00 |

Appendix E

| PG-CC | SA-PG-CC | SA-CC-PG | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | Component | |||||||||||||||

| 1 | FWH7 | 14.64 | 7.84 | 2.54 | 3.21 | 1.05 | 14.41 | 9.65 | 3.13 | 0.66 | 0.98 | 11.48 | 7.54 | 2.44 | 0.46 | 1.04 |

| 2 | FWH6 | 10.70 | 7.84 | 0.94 | 1.19 | 0.72 | 11.72 | 9.65 | 1.16 | 0.24 | 0.67 | 9.33 | 7.54 | 0.91 | 0.17 | 0.71 |

| 3 | FWH5 | 10.47 | 7.84 | 0.89 | 1.12 | 0.61 | 11.54 | 9.65 | 1.09 | 0.23 | 0.57 | 9.17 | 7.54 | 0.85 | 0.17 | 0.61 |

| 4 | FWH4 | 10.29 | 7.84 | 0.84 | 1.06 | 0.54 | 11.41 | 9.65 | 1.04 | 0.22 | 0.51 | 9.04 | 7.54 | 0.81 | 0.15 | 0.54 |

| 5 | DTR | 10.48 | 7.84 | 0.79 | 0.99 | 0.85 | 11.64 | 9.65 | 0.99 | 0.21 | 0.79 | 9.29 | 7.54 | 0.76 | 0.14 | 0.85 |

| 6 | FWH3 | 10.10 | 7.84 | 0.77 | 0.97 | 0.52 | 11.39 | 9.65 | 1.01 | 0.21 | 0.52 | 8.86 | 7.54 | 0.74 | 0.15 | 0.43 |

| 7 | FWH2 | 9.29 | 7.84 | 0.43 | 0.54 | 0.47 | 10.79 | 9.65 | 0.55 | 0.12 | 0.48 | 8.43 | 7.54 | 0.41 | 0.08 | 0.40 |

| 8 | FWH1/OWHE | 9.21 | 7.84 | 0.41 | 0.52 | 0.44 | 36.83 | 31.51 | 2.88 | 2.00 | 0.44 | 8.38 | 7.54 | 0.40 | 0.08 | 0.36 |

| 9 | SH | 12.72 | 2.00 | 1.33 | 6.68 | 2.71 | 7.41 | 2.00 | 1.34 | 1.37 | 2.70 | 7.02 | 2.00 | 1.36 | 0.97 | 2.69 |

| 10 | RH | 12.44 | 2.00 | 1.33 | 6.39 | 2.71 | 7.35 | 2.00 | 1.34 | 1.31 | 2.70 | 7.16 | 2.00 | 1.51 | 0.93 | 2.72 |

| 11 | HP1 | 10.24 | 7.84 | 0.58 | 0.73 | 1.08 | 11.49 | 9.65 | 0.73 | 0.15 | 0.97 | 9.10 | 7.54 | 0.57 | 0.11 | 0.88 |

| 12 | HP2 | 10.03 | 7.84 | 0.50 | 0.61 | 1.08 | 11.11 | 9.65 | 0.38 | 0.12 | 0.97 | 8.99 | 7.54 | 0.48 | 0.09 | 0.88 |

| 13 | IP1 | 12.18 | 7.84 | 2.90 | 0.35 | 1.08 | 11.05 | 9.65 | 0.37 | 0.07 | 0.97 | 8.76 | 7.54 | 0.29 | 0.05 | 0.88 |

| 14 | IP2 | 9.54 | 7.84 | 0.28 | 0.34 | 1.08 | 11.02 | 9.65 | 0.34 | 0.07 | 0.97 | 8.78 | 7.54 | 0.30 | 0.06 | 0.88 |

| 15 | LP1 | 9.52 | 7.84 | 0.28 | 0.32 | 1.08 | 11.02 | 9.65 | 0.34 | 0.07 | 0.97 | 8.74 | 7.54 | 0.27 | 0.05 | 0.88 |

| 16 | LP2 | 9.59 | 7.84 | 0.30 | 0.36 | 1.08 | 11.06 | 9.65 | 0.37 | 0.07 | 0.97 | 8.77 | 7.54 | 0.29 | 0.05 | 0.89 |

| 17 | LP3 | 9.61 | 7.84 | 0.30 | 0.38 | 1.08 | 11.10 | 9.65 | 0.41 | 0.08 | 0.97 | 8.80 | 7.54 | 0.32 | 0.06 | 0.88 |

| 18 | LP4 | 9.70 | 7.84 | 0.35 | 0.42 | 1.08 | 11.14 | 9.65 | 0.44 | 0.09 | 0.97 | 8.82 | 7.54 | 0.34 | 0.06 | 0.88 |

| 19 | LP5 | 10.37 | 7.84 | 0.64 | 0.80 | 1.08 | 11.57 | 9.65 | 0.79 | 0.16 | 0.97 | 9.16 | 7.54 | 0.62 | 0.12 | 0.88 |

| 20 | BFPT | 13.22 | 7.84 | 1.65 | 2.07 | 1.66 | 13.76 | 9.65 | 2.03 | 0.42 | 1.66 | 11.08 | 7.54 | 1.59 | 0.30 | 1.65 |

| 21 | FWP | 17.50 | 11.55 | 1.28 | 1.07 | 3.60 | 18.36 | 13.76 | 1.66 | 0.24 | 2.71 | 16.05 | 11.08 | 1.22 | 0.15 | 3.60 |

| 22 | CP | 21.85 | 10.54 | 2.37 | 2.39 | 6.56 | 20.16 | 11.88 | 1.68 | 0.49 | 6.12 | 18.56 | 9.51 | 2.14 | 0.35 | 6.56 |

| 23 | CND | 34.60 | 7.84 | 12.30 | 0.00 | 14.46 | 36.92 | 9.65 | 24.01 | 0.00 | 12.59 | 25.63 | 7.54 | 18.32 | 0.00 | 7.15 |

| 24 | GEN | 10.54 | 9.83 | 0.12 | 0.00 | 0.58 | 11.88 | 11.20 | 0.13 | 0.00 | 0.54 | 9.51 | 8.92 | 0.11 | 0.00 | 0.48 |

| 25 | COL | - | - | - | - | - | 31.51 | 0.00 | 0.00 | 0.00 | 31.51 | 39.70 | 0.00 | 0.00 | 0.00 | 39.70 |

| 26 | COLP | - | - | - | - | - | 22.08 | 11.88 | 8.58 | 0.00 | 1.62 | 14.71 | 11.88 | 1.99 | 0.00 | 0.84 |

References

- Rogelj, J.; den Elzen, M.; Hohne, N.; Fransen, T.; Fekete, H.; Winkler, H.; Schaeffer, R.; Sha, F.; Riahi, K.; Meinshausen, M. Paris Agreement climate proposals need a boost to keep warming well below 2 degrees C. Nature 2016, 534, 631–639. [Google Scholar] [CrossRef] [PubMed]

- International Energy Agency (IEA). World Energy Outlook 2017; Organisation for Economic Co-operation and Development: Paris, France, 2017. [Google Scholar]

- International Energy Agency (IEA). Key World Energy Statistics; International Energy Agency: Paris, France, 2017. [Google Scholar]

- Karimi, F.; Khalilpour, R. Evolution of carbon capture and storage research: Trends of international collaborations and knowledge maps. Int. J. Greenh. Gas Control 2015, 37, 362–376. [Google Scholar]

- Li, K.; Yu, H.; Yan, S.; Feron, P.; Wardhaugh, L.; Tade, M. Technoeconomic Assessment of an Advanced Aqueous Ammonia-Based Postcombustion Capture Process Integrated with a 650-MW Coal-Fired Power Station. Environ. Sci. Technol. 2016, 50, 10746–10755. [Google Scholar] [CrossRef] [PubMed]

- Mumford, A.; Wu, Y.; Smith, H.; Geoffrey, S. Review of solvent based carbon-dioxide capture technologies. Front. Chem. Sci. Eng. 2015, 9, 125–141. [Google Scholar] [CrossRef]

- Zhao, S.; Feron, P.H.M.; Deng, L.; Favre, E.; Chabanon, E.; Yan, S.; Hou, J.; Chen, V.; Qi, H. Status and progress of membrane contactors in post-combustion carbon capture: A state-of-the-art review of new developments. J. Membr. Sci. 2016, 511, 180–206. [Google Scholar] [CrossRef]

- Theo, W.L.; Lim, J.S.; Hashim, H.; Mustaffa, A.A.; Ho, W.S. Review of pre-combustion capture and ionic liquid in carbon capture and storage. Appl. Energy 2016, 183, 1633–1663. [Google Scholar] [CrossRef]

- Li, K.; Leigh, W.; Feron, P.; Yu, H.; Tade, M. Systematic study of aqueous monoethanolamine (MEA)-based CO2 capture process: Techno-economic assessment of the MEA process and its improvements. Appl. Energy 2016, 165, 648–659. [Google Scholar] [CrossRef]

- Oh, S.-Y.; Binns, M.; Cho, H.; Kim, J.-K. Energy minimization of MEA-based CO2 capture process. Appl. Energy 2016, 169, 353–362. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, H.; Sun, Y.; Cakstins, J.; Sun, C.; Snape, C.E. Parametric study on the regeneration heat requirement of an amine-based solid adsorbent process for post-combustion carbon capture. Appl. Energy 2016, 168, 394–405. [Google Scholar] [CrossRef]

- Final Report for the Project ‘Development of an Aqueous Ammonia-Based PCC Technology for Australian Conditions’. Available online: http://anlecrd.com.au/wp-content/uploads/2016/08/Aqueous-Ammonia-Final-Report.pdf (accessed on 9 October 2017).

- CO2 Capture Technologies—Post Combustion Capture (PCC). Available online: http://www.globalccsinstitute.com/publications/CO2-capture-technologies-post-combustion-capture-pcc (accessed on 9 October 2017).

- Petra Nova Carbon Capture. Available online: https://www.globalccsinstitute.com/projects/petra-nova-carbon-capture-project (accessed on 24 July 2017).

- Lemaire, E.; Bouillon, P.A.; Lettat, K. Development of HiCapt+ TM Process for CO2 Capture from Lab to Industrial Pilot Plant. Oil Gas Sci. Technol. Rev. IFP Energies Nouv. 2014, 69, 1069–1080. [Google Scholar] [CrossRef]

- Li, K.; Cousins, A.; Yu, H.; Feron, P.; Tade, M.; Luo, W.; Chen, J. Systematic study of aqueous monoethanolamine-based CO2capture process: Model development and process improvement. Energy Sci. Eng. 2016, 4, 23–39. [Google Scholar] [CrossRef]

- Øi, L.E.; Bråthen, T.; Berg, C.; Brekne, S.K.; Flatin, M.; Johnsen, R.; Moen, I.G.; Thomassen, E. Optimization of Configurations for Amine based CO2 Absorption Using Aspen HYSYS. Energy Procedia 2014, 51, 224–233. [Google Scholar] [CrossRef]

- Chen, E.; Zhang, Y.; Sachde, D.; Lin, Y.J.; Rochelle, G.T. Evaluated Pilot Plant Results for 5 m Piperazine with the Advanced Flash Stripper. 2015. Available online: http://ieaghg.org/docs/General_Docs/PCCC3_PDF/5_PCCC3_6_Chen.pdf (accessed on 9 October 2017).

- Jiang, K.; Li, K.; Yu, H.; Chen, Z.; Wardhaugh, L.; Feron, P. Advancement of ammonia based post-combustion CO2 capture using the advanced flash stripper process. Appl. Energy 2017, 202, 496–506. [Google Scholar] [CrossRef]

- Zhang, Y.; Ji, X.; Xie, Y.; Lu, X. Screening of conventional ionic liquids for carbon dioxide capture and separation. Appl. Energy 2016, 162, 1160–1170. [Google Scholar] [CrossRef]

- Kunze, A.-K.; Dojchinov, G.; Haritos, V.S.; Lutze, P. Reactive absorption of CO2 into enzyme accelerated solvents: From laboratory to pilot scale. Appl. Energy 2015, 156, 676–685. [Google Scholar] [CrossRef]

- Wang, X.; Akhmedov, N.G.; Hopkinson, D.; Hoffman, J.; Duan, Y.; Egbebi, A.; Resnik, K.; Li, B. Phase change amino acid salt separates into CO2-rich and CO2-lean phases upon interacting with CO2. Appl. Energy 2016, 161, 41–47. [Google Scholar] [CrossRef]

- Le Moullec, Y.; Kanniche, M. Screening of flowsheet modifications for an efficient monoethanolamine (MEA) based post-combustion CO2 capture. Int. J. Greenh. Gas Control 2011, 5, 727–740. [Google Scholar] [CrossRef]

- Ahn, H.; Luberti, M.; Liu, Z.; Brandani, S. Process configuration studies of the amine capture process for coal-fired power plants. Int. J. Greenh. Gas Control 2013, 16, 29–40. [Google Scholar] [CrossRef]

- Cousins, A.; Wardhaugh, L.T.; Feron, P.H.M. Preliminary analysis of process flow sheet modifications for energy efficient CO2 capture from flue gases using chemical absorption. Chem. Eng. Res. Des. 2011, 89, 1237–1251. [Google Scholar] [CrossRef]

- Cousins, A.; Wardhaugh, L.T.; Feron, P.H.M. A survey of process flow sheet modifications for energy efficient CO2 capture from flue gases using chemical absorption. Int. J. Greenh. Gas Control 2011, 5, 605–619. [Google Scholar] [CrossRef]

- Bui, M.; Gunawan, I.; Verheyen, V.; Feron, P.; Meuleman, E.; Adeloju, S. Dynamic modelling and optimisation of flexible operation in post-combustion CO2 capture plants—A review. Comput. Chem. Eng. 2014, 61, 245–265. [Google Scholar] [CrossRef]

- Bui, M.; Fajardy, M.; Mac Dowell, N. Bio-Energy with CCS (BECCS) performance evaluation: Efficiency enhancement and emissions reduction. Appl. Energy 2017, 195, 289–302. [Google Scholar] [CrossRef]

- Harkin, T.; Hoadley, A.; Hooper, B. Process integration analysis of a brown coal-fired power station with CO2 capture and storage and lignite drying. Energy Procedia 2009, 1, 3817–3825. [Google Scholar] [CrossRef]

- Harkin, T.; Hoadley, A.; Hooper, B. Reducing the energy penalty of CO2 capture and compression using pinch analysis. J. Clean. Prod. 2010, 18, 857–866. [Google Scholar] [CrossRef]

- Xu, G.; Hu, Y.; Tang, B.; Yang, Y.; Zhang, K.; Liu, W. Integration of the steam cycle and CO2 capture process in a decarbonization power plant. Appl. Therm. Eng. 2014, 73, 277–286. [Google Scholar] [CrossRef]

- Xu, G.; Huang, S.; Yang, Y.; Wu, Y.; Zhang, K.; Xu, C. Techno-economic analysis and optimization of the heat recovery of utility boiler flue gas. Appl. Energy 2013, 112, 907–917. [Google Scholar] [CrossRef]

- Hu, Y.; Xu, G.; Xu, C.; Yang, Y. Thermodynamic analysis and techno-economic evaluation of an integrated natural gas combined cycle (NGCC) power plant with post-combustion CO2 capture. Appl. Therm. Eng. 2017, 111, 308–316. [Google Scholar] [CrossRef]

- Pfaff, I.; Oexmann, J.; Kather, A. Optimised integration of post-combustion CO2 capture process in greenfield power plants. Energy 2010, 35, 4030–4041. [Google Scholar] [CrossRef]

- Liu, X.; Chen, J.; Luo, X.; Wang, M.; Meng, H. Study on heat integration of supercritical coal-fired power plant with post-combustion CO2 capture process through process simulation. Fuel 2015, 158, 625–633. [Google Scholar] [CrossRef]

- Wang, D.; Bao, A.; Kunc, W.; Liss, W. Coal power plant flue gas waste heat and water recovery. Appl. Energy 2012, 91, 341–348. [Google Scholar] [CrossRef]

- Bui, M.; Fajardy, M.; Mac Dowell, N. Bio-energy with carbon capture and storage (BECCS): Opportunities for performance improvement. Fuel 2018, 213, 164–175. [Google Scholar] [CrossRef]

- Mokhtar, M.; Ali, M.T.; Khalilpour, R.; Abbas, A.; Shah, N.; Hajaj, A.A.; Armstrong, P.; Chiesa, M.; Sgouridis, S. Solar-assisted Post-combustion Carbon Capture feasibility study. Appl. Energy 2012, 92, 668–676. [Google Scholar] [CrossRef]

- Zhao, Y.; Hong, H.; Zhang, X.; Jin, H. Integrating mid-temperature solar heat and post-combustion CO2-capture in a coal-fired power plant. Sol. Energy 2012, 86, 3196–3204. [Google Scholar] [CrossRef]

- Zhai, R.; Qi, J.; Zhu, Y.; Zhao, M.; Yang, Y. Novel system integrations of 1000 MW coal-fired power plant retrofitted with solar energy and CO2 capture system. Appl. Therm. Eng. 2017, 125, 1133–1145. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, J.; Wang, Y.; Deng, S.; Sun, T.; Li, K. Application potential of solar-assisted post-combustion carbon capture and storage (CCS) in China: A life cycle approach. J. Clean. Prod. 2017, 154, 541–552. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, J.; Li, H.; Deng, S.; Yan, J. Preliminary experimental study of post-combustion carbon capture integrated with solar thermal collectors. Appl. Energy 2017, 185, 1471–1480. [Google Scholar] [CrossRef]

- Rezazadeh, F.; Gale, W.F.; Lin, Y.-J.; Rochelle, G.T. Energy Performance of Advanced Reboiled and Flash Stripper Configurations for CO2 Capture Using Monoethanolamine. Ind. Eng. Chem. Res. 2016, 55, 4622–4631. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, J.; Deng, S.; An, Q. A technical and economic study on solar-assisted ammonia-based post-combustion CO2 capture of power plant. Appl. Therm. Eng. 2016, 102, 412–422. [Google Scholar] [CrossRef]

- Lassagne, O.; Iliuta, M.C.; Gosselin, L.; Désilets, M. Techno-economic assessment of CO2capture from aluminum smelter emissions using PZ activated AMP solutions. Can. J. Chem. Eng. 2016, 94, 761–770. [Google Scholar] [CrossRef]

- Raksajati, A.; Ho, M.T.; Wiley, D.E. Techno-economic Evaluation of CO2 Capture from Flue Gases Using Encapsulated Solvent. Ind. Eng. Chem. Res. 2017, 56, 1604–1620. [Google Scholar] [CrossRef]

- Gao, J.; Yin, J.; Zhu, F.; Chen, X.; Tong, M.; Kang, W.; Zhou, Y.; Lu, J. Environmental Effects Comparison of absorption and regeneration performance for post-combustion CO2 capture by mixed MEA solvents. Energy Sources Part A 2016, 38, 2530–2535. [Google Scholar] [CrossRef]

- Zhai, R.; Liu, H.; Li, C.; Zhao, M.; Yang, Y. Analysis of a solar-aided coal-fired power generation system based on thermo-economic structural theory. Energy 2016, 102, 375–387. [Google Scholar] [CrossRef]

- Lozano, M.A.; Valero, A. Theory of the exergetic cost. Energy 1993, 18, 939–960. [Google Scholar] [CrossRef]

- Chao, Z. Thermoeconomic Analysis and Optimization of Complex Energy Systems. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2006. (In Chinese). [Google Scholar]

- Tsatsaronis, G. Thermoeconomic analysis and optimization of energy systems. Prog. Energy Combust. Sci. 1993, 19, 227–257. [Google Scholar] [CrossRef]

- Booras, G.; Davison, J.; Ekstrom, C.; Matuszewski, M.; Short, C. Toward a Common Method of Cost Estimation for CO2 Capture and Storage at Fossil Fuel Power Plants; Global CCS Institute: Docklands, Australia, 2013. [Google Scholar]

- Ehlers, S.; Roeder, V.; Liebenthal, U.; Kather, I.A. Techno Economic Evaluation Different Post Combustion CO2 Capture Process Flow Sheet; Hamburg University of Technology: Hamburg, Germany, 2014. [Google Scholar]

- Valero, A.; Serra, L.; Uche, J. Fundamentals of Exergy Cost Accounting and Thermoeconomics. Part II: Applications. J. Energy Resour. Technol. 2006, 128, 9–15. [Google Scholar] [CrossRef]

- Han, Y.; Xu, G.; Zheng, Q.; Xu, C.; Hu, Y.; Yang, Y.; Lei, J. New heat integration system with bypass flue based on the rational utilization of low-grade extraction steam in a coal-fired power plant. Appl. Therm. Eng. 2017, 113, 460–471. [Google Scholar] [CrossRef]

- Wang, L.; Yang, Y.; Dong, C.; Morosuk, T.; Tsatsaronis, G. Multi-objective optimization of coal-fired power plants using differential evolution. Appl. Energy 2014, 115, 254–264. [Google Scholar] [CrossRef]

- Gewald, D.; Karellas, S.; Schuster, A.; Spliethoff, H. Integrated system approach for increase of engine combined cycle efficiency. Energy Convers. Manag. 2012, 60, 36–44. [Google Scholar] [CrossRef]

- Burin, E.K.; Vogel, T.; Multhaupt, S.; Thelen, A.; Oeljeklaus, G.; Görner, K.; Bazzo, E. Thermodynamic and economic evaluation of a solar aided sugarcane bagasse cogeneration power plant. Energy 2016, 117, 416–428. [Google Scholar] [CrossRef]

- Al-Maliki, W.A.K.; Alobaid, F.; Kez, V.; Epple, B. Modelling and dynamic simulation of a parabolic trough power plant. J. Process Control 2016, 39, 123–138. [Google Scholar] [CrossRef]

- Krüger, M.; Bartsch, P.; Pointner, H.; Zunft, S. Solar tower power plant using a particle-heated steam generator: Modeling and parametric study. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2016; Volume 1734, p. 050025. [Google Scholar]

- Pei, X.; He, B.; Yan, L.; Wang, C.; Song, W.; Song, J. Process simulation of oxy-fuel combustion for a 300 MW pulverized coal-fired power plant using Aspen Plus. Energy Convers. Manag. 2013, 76, 581–587. [Google Scholar] [CrossRef]

- Li, K.; Yu, H.; Feron, P.; Wardhaugh, L.; Tade, M. Techno-economic assessment of stripping modifications in an ammonia-based post-combustion capture process. Int. J. Greenh. Gas Control 2016, 53, 319–327. [Google Scholar] [CrossRef]

- Rezazadeh, F.; Gale, W.F.; Akram, M.; Hughes, K.J.; Pourkashanian, M. Performance evaluation and optimisation of post combustion CO2 capture processes for natural gas applications at pilot scale via a verified rate-based model. Int. J. Greenh. Gas Control 2016, 53, 243–253. [Google Scholar] [CrossRef]

- Baghernejad, A.; Yaghoubi, M. Exergoeconomic analysis and optimization of an Integrated Solar Combined Cycle System (ISCCS) using genetic algorithm. Energy Convers. Manag. 2011, 52, 2193–2203. [Google Scholar] [CrossRef]

- Miao, Z. Research on Performance of Carbon Capture System for Solar-Added Coal Fired Power Generation; North China Electric Power University: Beijing, China, 2016. [Google Scholar]

- Electric Power Planning & Engineering Institute. The Reference Cost Index of Thermal Power Engineering Rationed Design; China Electric Power Press: Beijing, China, 2012; pp. 257–331. [Google Scholar]

- Xiong, J. Thermo-Economic Cost Analysis and Optimization of Conventional Coal-Fired Power Generation System and CO2 Capture System; Huazhong University of Science and Technology: Wuhan, China, 2007. [Google Scholar]

- Rao, A. A Technical, Environmental, and Economic Assessment of Amine-Based Carbon Capture Technologies for Greenhouse Gas Control; Department of Engineering and Public Policy: Washington, DC, USA, 2003. [Google Scholar]

- Hong, H.; Peng, S.; Zhao, Y.; Liu, Q.; Jin, H. A Typical Solar-coal Hybrid Power Plant in China. Energy Procedia 2014, 49, 1777–1783. [Google Scholar] [CrossRef]

| Component | Number | Exergy Cost Equation | Thermo-Economic Cost Equation |

|---|---|---|---|

| FWH, OWHE, DTR | 1–8 | ||

| SH, RH | 9,10 | ||

| HP, IP, LP, BFPT | 11–20 | ||

| FWP, CP | 21,22 | ||

| CND | 23 | ||

| GEN | 24 | ||

| COL | 25 | ||

| COLP | 26 | ||

| J1 | 27 | ||

| J2 | 28 | ||

| J3 | 29 | ||

| O1 | 30 | ||

| O2 | 31 |

| Parameter | Value | Unit |

|---|---|---|

| Capacity | 1000 | MW |

| Parameters of main steam | 25/600/600 | MPa/°C/°C |

| Feed-water mass flow rate | 2733.43 | t/h |

| Condenser pressure | 5 | kPa |

| Feed-water temperature | 294.75 | °C |

| Designed coal consumption rate | 268 | g/kWh |

| Parameter | Values | Unit |

|---|---|---|

| Direct normal irradiation (DNI) | 805 | W/m2 |

| Inlet temperature of the solar collector field | 280/123 | °C |

| Outlet temperature of the solar collector field | 387/217 | °C |

| Peak optical efficiency of collector | 0.73 | – |

| Endloss factor | 0.97 | – |

| Shading factor | 1 | – |

| Wind factor | 0.98 | – |

| Focal length | 1.71 | m |

| Flue Gas Composition | Mole per Cent | Unit | Flue Gas Composition | Mole per Cent | Unit |

| H2O | 10 | % | O2 | 3.6 | % |

| CO2 | 14 | % | Temperature | 40 | °C |

| N2 | 72.4 | % | Pressure | 0.12 | Mpa |

| Absorber | Value | Unit | Stripper | Value | Unit |

| Number of stages | 8 | – | Number of stages | 8 | – |

| Top pressure | 101 | kPa | Reboiler pressure | 220 | kPa |

| Bottom pressure | 111 | kPa | Condenser pressure | 210 | kPa |

| Inlet flue gas temperature | 40 | °C | Reboiler heat duty | 637,647.92 | kW |

| Inlet lean solvent temperature | 40 | °C | Rich solvent loading | 0.42 | – |

| Liquid-to-gas ratio | 2.8 | kg/kg | Inlet temperature * | 140/217 | °C |

| Lean solvent loading | 0.29 | – | Outlet temperature * | 120/123 | °C |

| Parameter | Value | Unit |

|---|---|---|

| System maintenance factor | 1.06 | – |

| Annual operating hours | 8000 | Hour |

| Amortise factor | 1 | – |

| Amortise cycle | 5 | Year |

| Annual inflation rate | 0.05 | – |

| Construction time | 3 | Year |

| Lifetime | 30 | Year |

| Interest rate | 0.08 | – |

| Parameter | SA-PG-CC | SA-CC-PG | Unit |

|---|---|---|---|

| Collector field area | 558,351 | 2,518,165 | m2 |

| Floor area | 1,500,000 | 6,000,000 | m2 |

| Cost of unit collector field area | 308 | 308 | $/m2 |

| Cost of unit floor area | 19.3 | 19.3 | $/m2 |

| Component | PG-CC | SA-PG-CC | SA-CC-PG | Unit |

|---|---|---|---|---|

| Power output | 838.7 | 895.9 | 1000.7 | MW |

| Solar exergy | 0 | 72.9 | 327.9 | MW |

| Share of solar exergy | 0 | 3.45 | 13.83 | % |

| Coal exergy | 2042.6 | 2042.6 | 2042.6 | MW |

| Share of coal exergy | 100 | 96.55 | 86.17 | % |

| Coal consumption rate | 319.15 | 303.84 | 267.74 | g/kWh |

| Efficiency of the system | 41.06 | 42.35 | 42.21 | % |

| Equivalent power output of solar | – | 57.2 | 162 | MW |

| Equivalent solar-power generation efficiency | – | 78.5 | 49.4 | % |

| Share of solar-energy power output | – | 6.38 | 16.19 | % |

| Unit exergy cost of electricity | 2.43 | 2.75 | 2.08 | kW/kW |

| Unit exergy cost of FWH1 | 2.02 | – | 2.05 | kW/kW |

| Unit exergy cost of OWHE | – | 6.67 | – | kW/kW |

| Efficiency of solar-collector field | – | 31 | 31 | % |

| Component | PG-CC | SA-PG-CC | SA-CC-PG | Unit |

|---|---|---|---|---|

| Output power penalty | 161.92 | 161.97 | - | MW |

| Removal CO2 | 199.67 | 199.67 | 199.67 | kg/s |

| CO2 removal rate | 80.72 | 80.72 | 80.72 | % |

| Unit CO2 thermal consumption | 3193.51 | 3193.51 | 3193.51 | kJ/kg |

| Unit CO2 exergy consumption | 1119.75 | 1119.75 | 1303.40 | kJ/kg |

| Unit exergy cost of heat source | 1.99 | 2.29 | 5.84 | kW/kW |

| Unit exergy cost of CO2 | 2228.30 | 2564.23 | 7609.52 | kJ/kg |

| Component | PG-CC | SA-PG-CC | SA-CC-PG | Unit |

|---|---|---|---|---|

| Total system investment | 674.83 | 822.86 | 1493.92 | M$ |

| Investment of coal-fired side | 448.80 | 445.22 | 445.64 | M$ |

| Share of investment of coal-fired subsystem | 70.70 | 54.11 | 29.83 | % |

| Investment of solar side | – | 191.61 | 862.25 | M$ |

| Share of investment of solar subsystem | – | 23.29 | 57.72 | % |

| Investment of CO2 capture system | 186.03 | 186.03 | 186.03 | M$ |

| Share of investment of CO2 capture system | 29.30 | 22.61 | 12.45 | % |

| Unit thermo-economic cost of feed-water heater 1 (FHW1) | 8.79 | – | 8.38 | 10−6$/kJ |

| Unit thermo-economic cost of oil–water heat exchanger (OWHE) | – | 36.83 | – | 10−6$/kJ |

| Unit thermo-economic cost of electricity | 10.54 | 11.88 | 9.51 | 10−6$/kJ |

| Unit thermo-economic cost of CO2 | 11.16 | 11.16 | 62.64 | $/t |

| Base | Factor | PG-CC | SA-PG-CC | SA-CC-PG | |

|---|---|---|---|---|---|

| Purchased equipment delivered costs (PEDC/M$) | 674.83 | 822.86 | 1493.92 | ||

| Installation | PEDC | 0.40 | 269.93 | 329.14 | 597.57 |

| Piping | PEDC | 0.68 | 458.89 | 559.54 | 1015.87 |

| Service facilities | PEDC | 0.30 | 202.45 | 246.86 | 448.18 |

| Instrumentation and controls | PEDC | 0.43 | 290.18 | 353.83 | 642.39 |

| Total direct costs (TDC/M$) | 1221.44 | 1489.38 | 2703.99 | ||

| Engineering and supervision | PEDC | 0.33 | 222.69 | 271.54 | 492.99 |

| Construction expenses | PEDC | 0.41 | 276.68 | 337.37 | 612.51 |

| Total indirect costs (TIC/M$) | 499.37 | 608.92 | 1105.5 | ||

| Profit/M$ | TDC + TIC | 0.05 | 86.04 | 104.91 | 190.47 |

| Contingency/M$ | TDC + TIC | 0.10 | 172.08 | 209.83 | 380.95 |

| Total capital requirement (TCR/M$) | 2653.76 | 3235.9 | 5874.84 | ||

| Levelized cost of electricity ($/MWh) | 83.32 | 98.23 | 165.82 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, R.; Liu, H.; Wu, H.; Yu, H.; Yang, Y. Analysis of Integration of MEA-Based CO2 Capture and Solar Energy System for Coal-Based Power Plants Based on Thermo-Economic Structural Theory. Energies 2018, 11, 1284. https://doi.org/10.3390/en11051284

Zhai R, Liu H, Wu H, Yu H, Yang Y. Analysis of Integration of MEA-Based CO2 Capture and Solar Energy System for Coal-Based Power Plants Based on Thermo-Economic Structural Theory. Energies. 2018; 11(5):1284. https://doi.org/10.3390/en11051284

Chicago/Turabian StyleZhai, Rongrong, Hongtao Liu, Hao Wu, Hai Yu, and Yongping Yang. 2018. "Analysis of Integration of MEA-Based CO2 Capture and Solar Energy System for Coal-Based Power Plants Based on Thermo-Economic Structural Theory" Energies 11, no. 5: 1284. https://doi.org/10.3390/en11051284

APA StyleZhai, R., Liu, H., Wu, H., Yu, H., & Yang, Y. (2018). Analysis of Integration of MEA-Based CO2 Capture and Solar Energy System for Coal-Based Power Plants Based on Thermo-Economic Structural Theory. Energies, 11(5), 1284. https://doi.org/10.3390/en11051284