Reduction of Electric Power Consumption in CO2-PSA with Zeolite 13X Adsorbent

Abstract

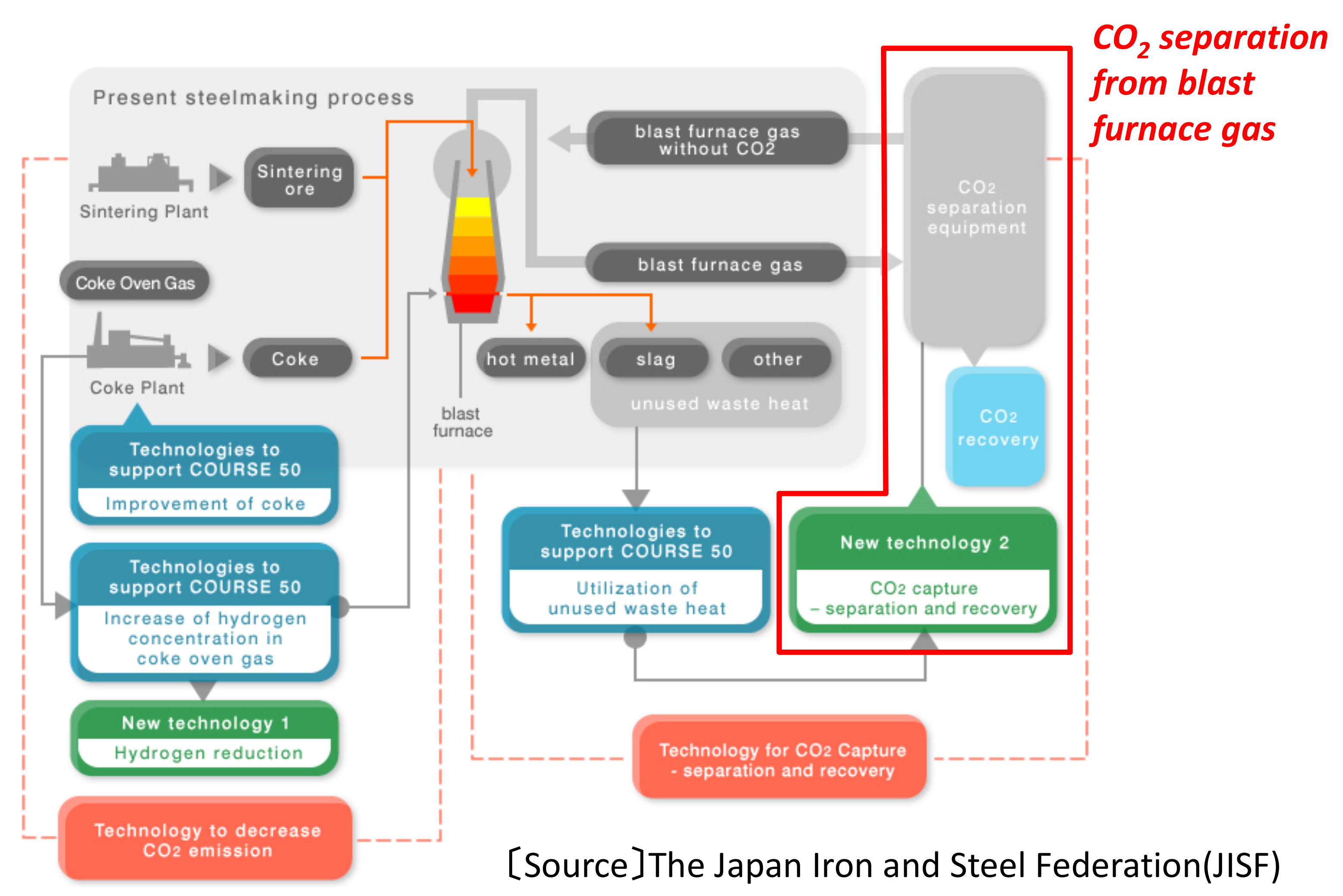

:1. Introduction

2. Experimental

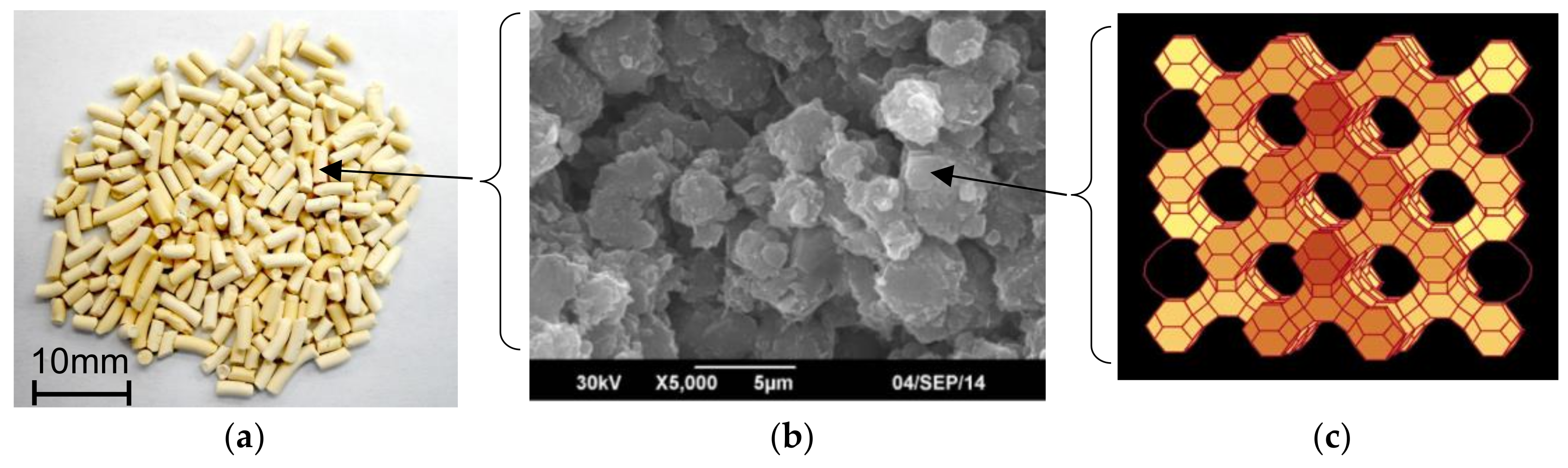

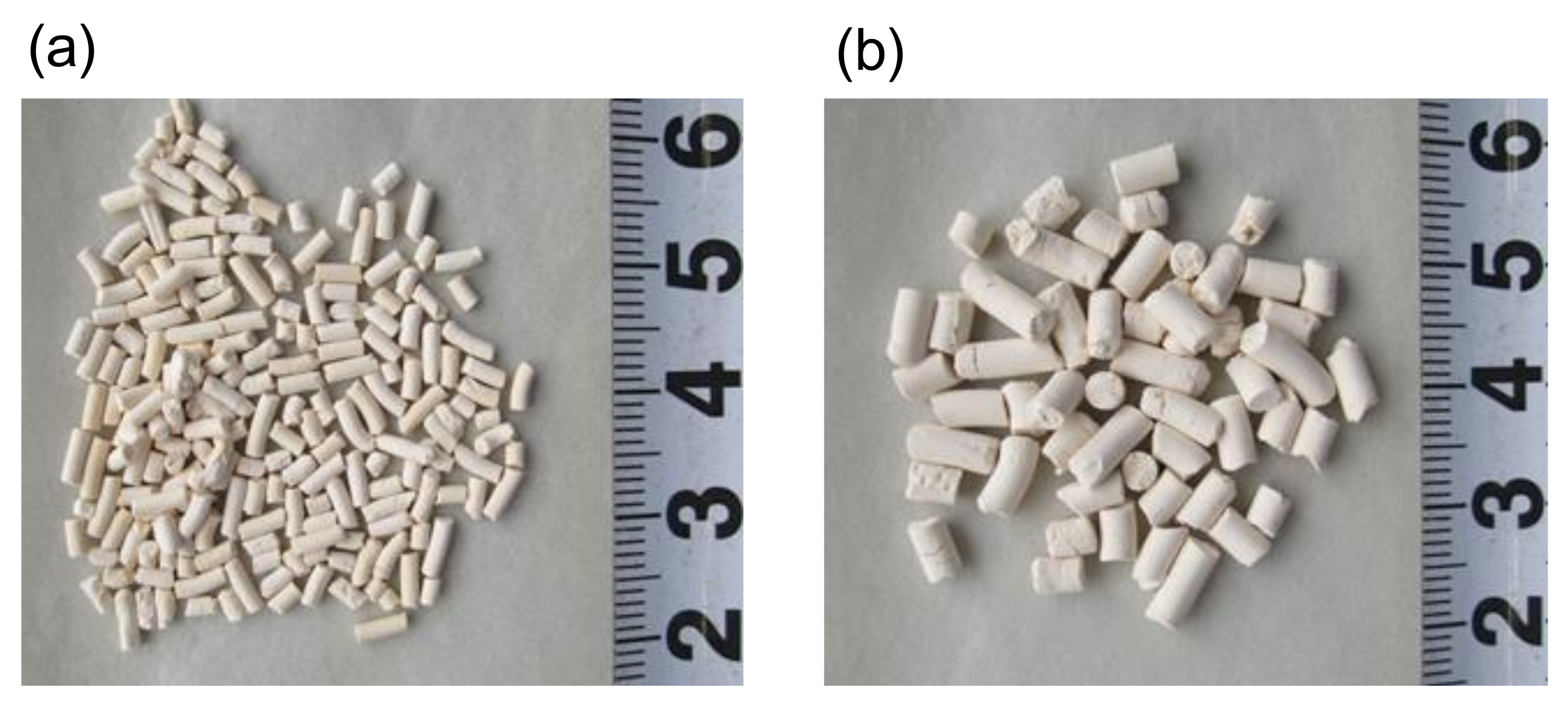

2.1. Preparation of Various Shapes of Adsorbents

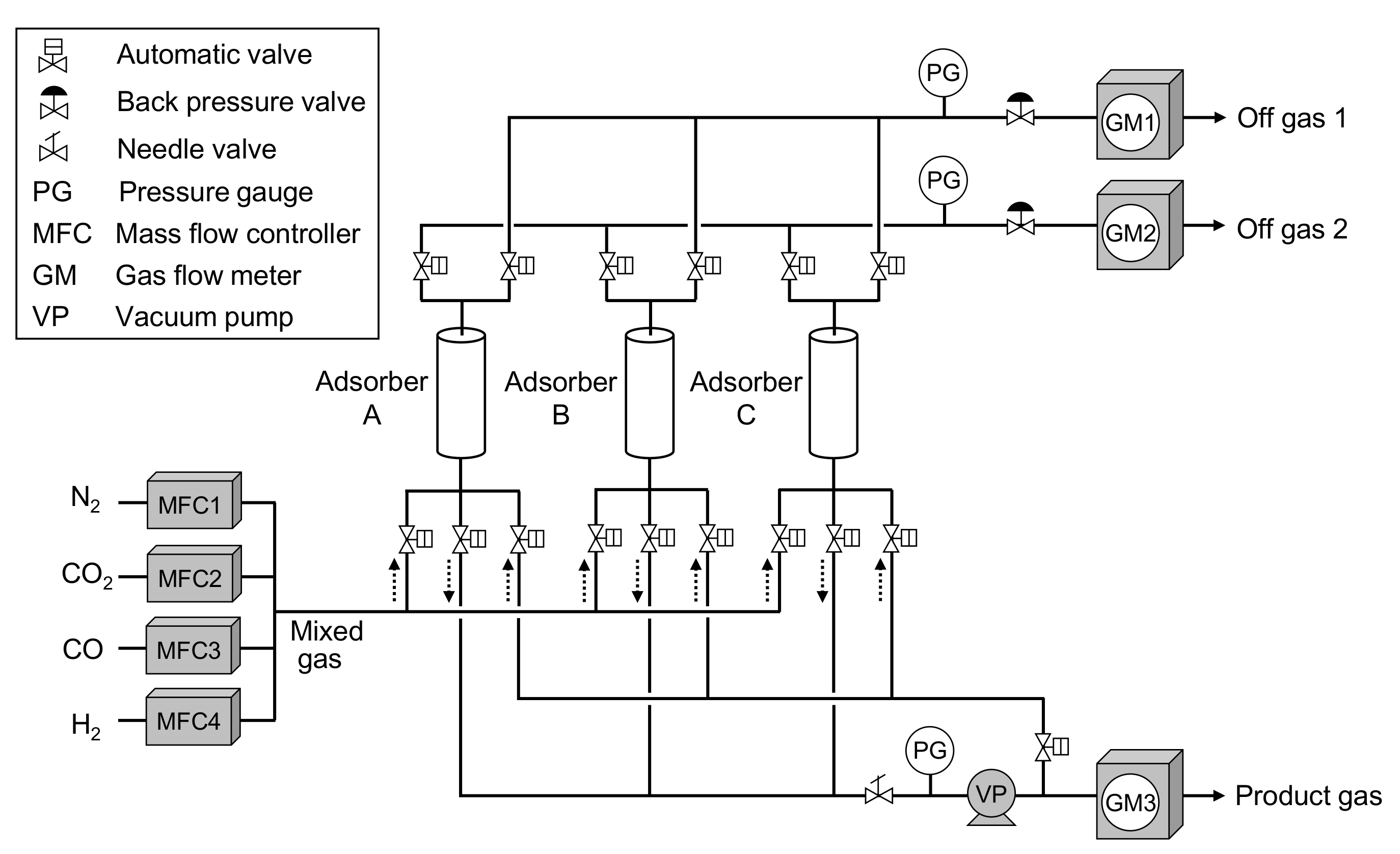

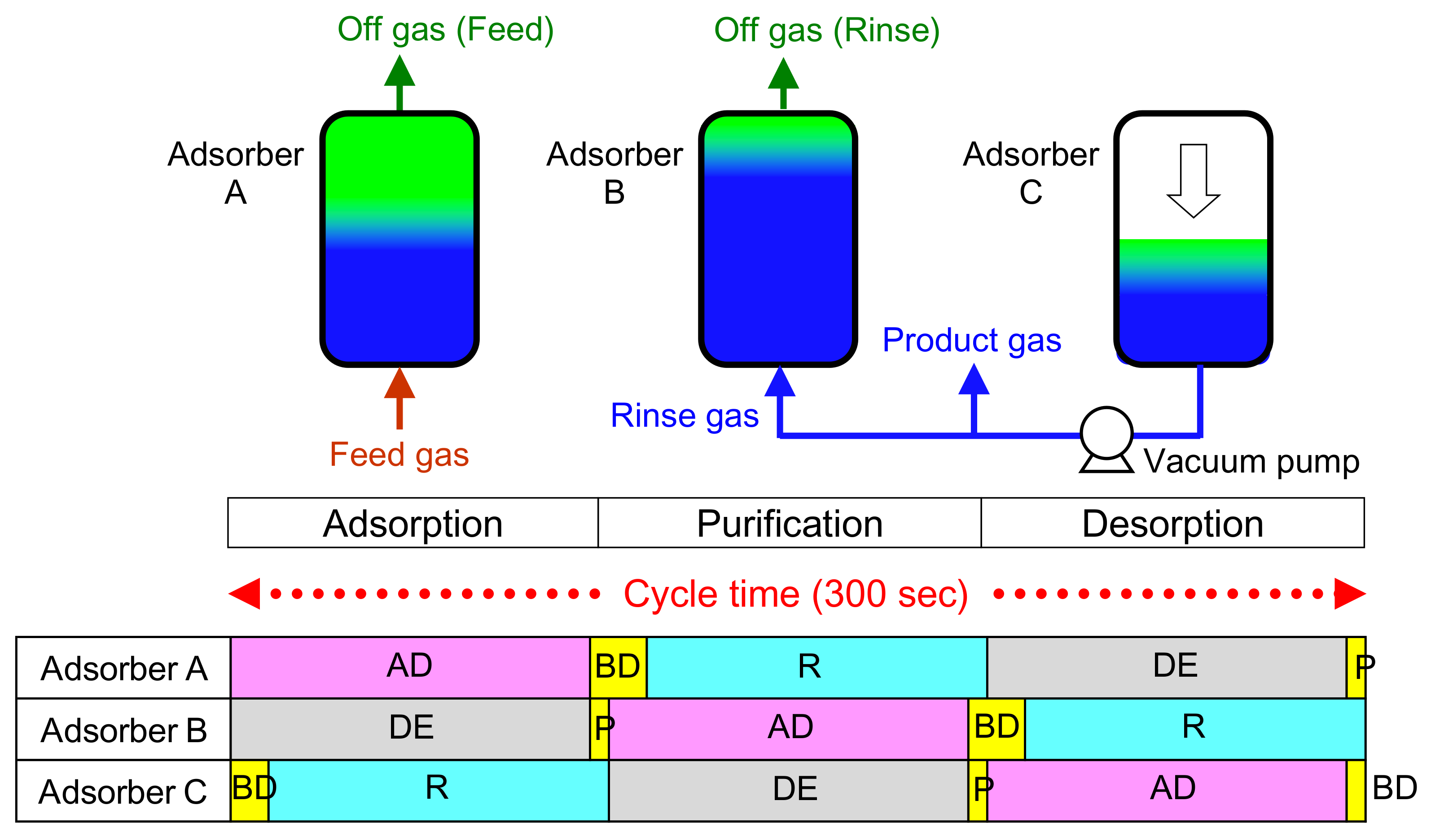

2.2. Laboratory-Scale CO2-PSA Experiment

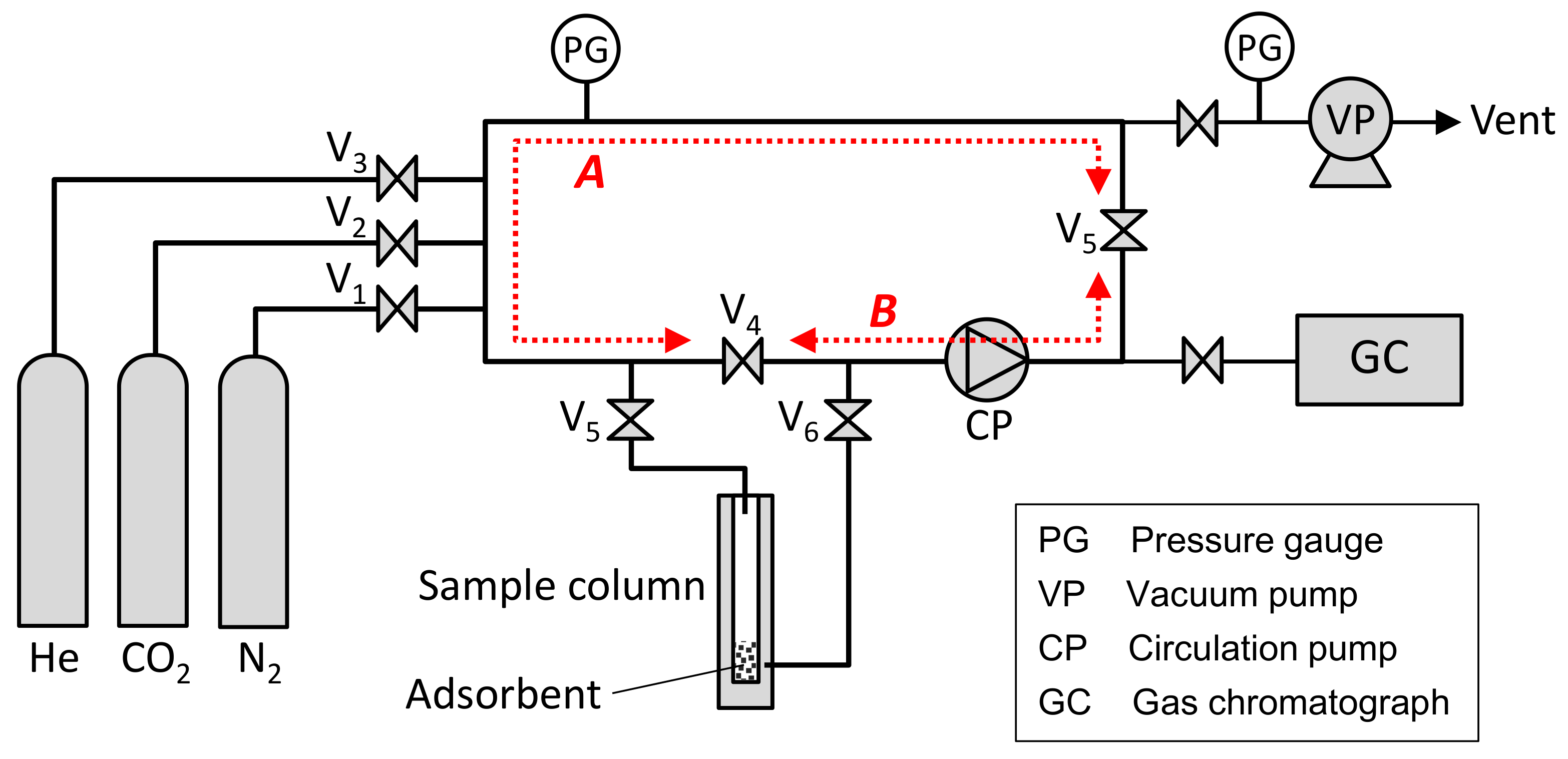

2.3. Measurement of CO2 Adsorption Rate in Early Stage of Adsorption

3. Results

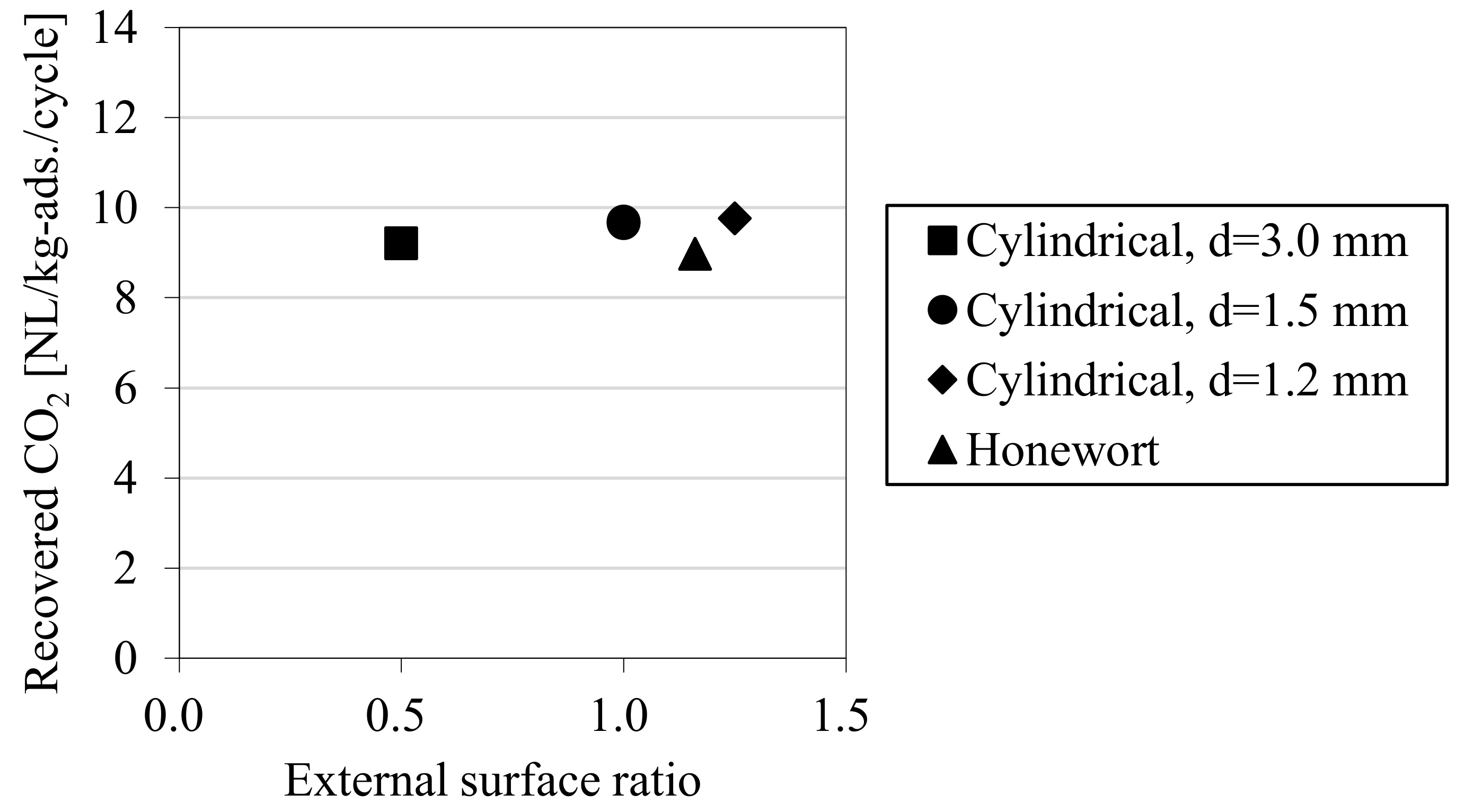

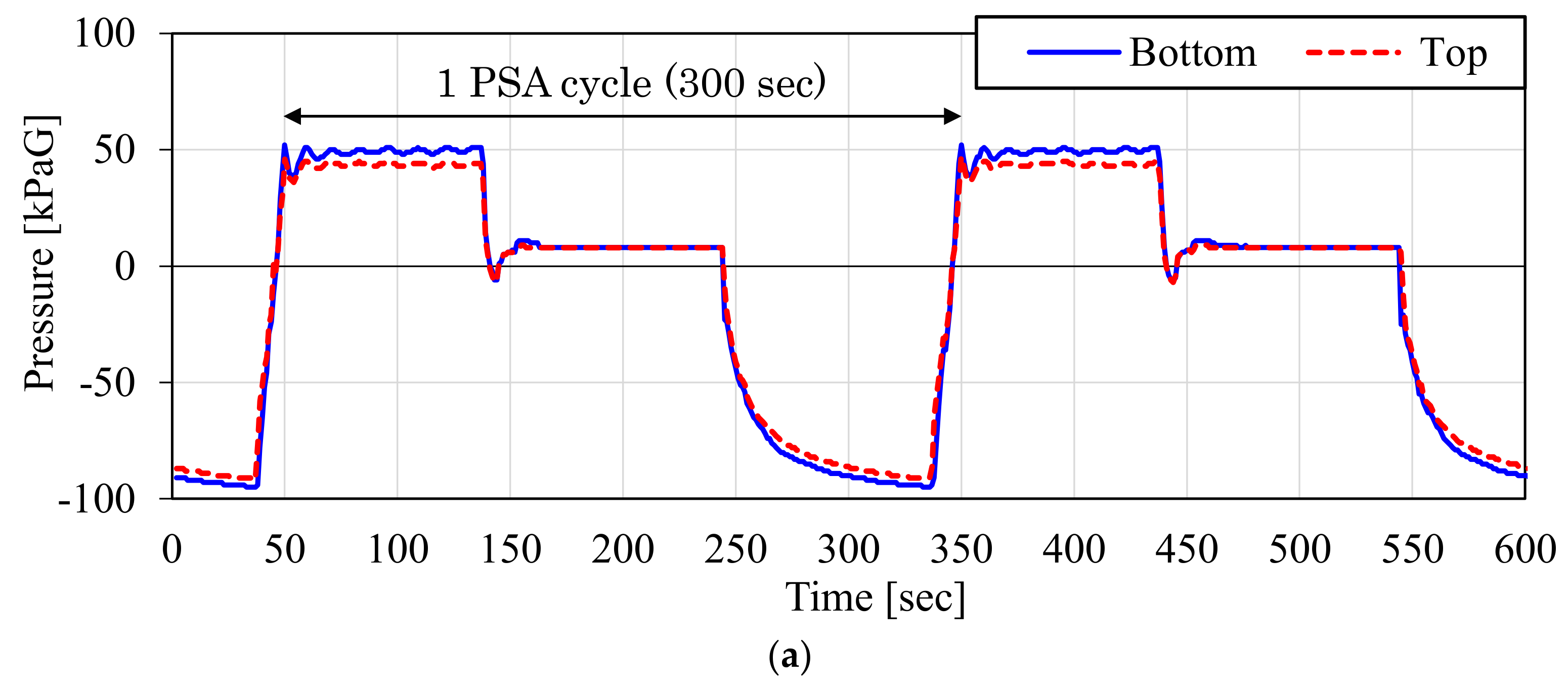

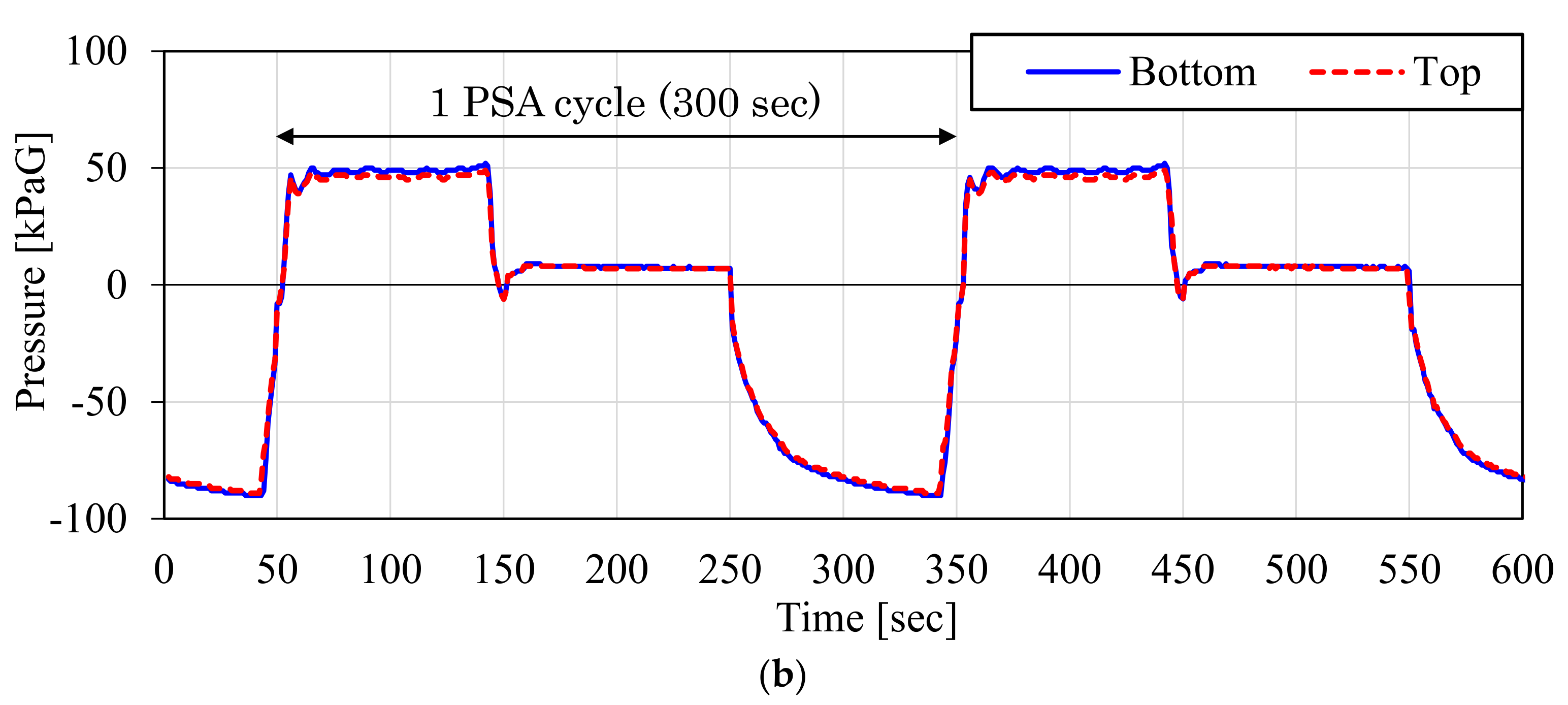

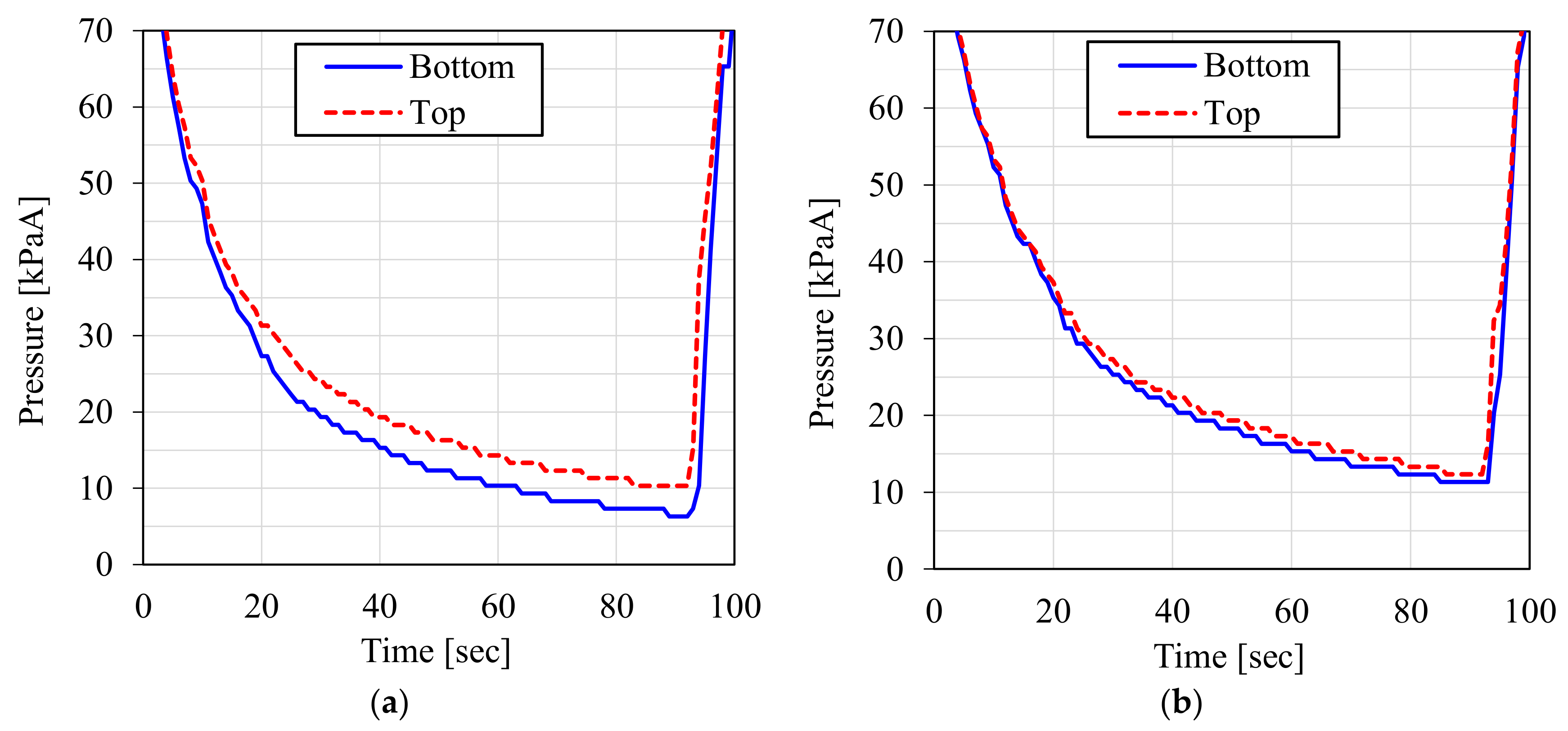

3.1. Result of the Laboratory-Scale CO2-PSA Experiment

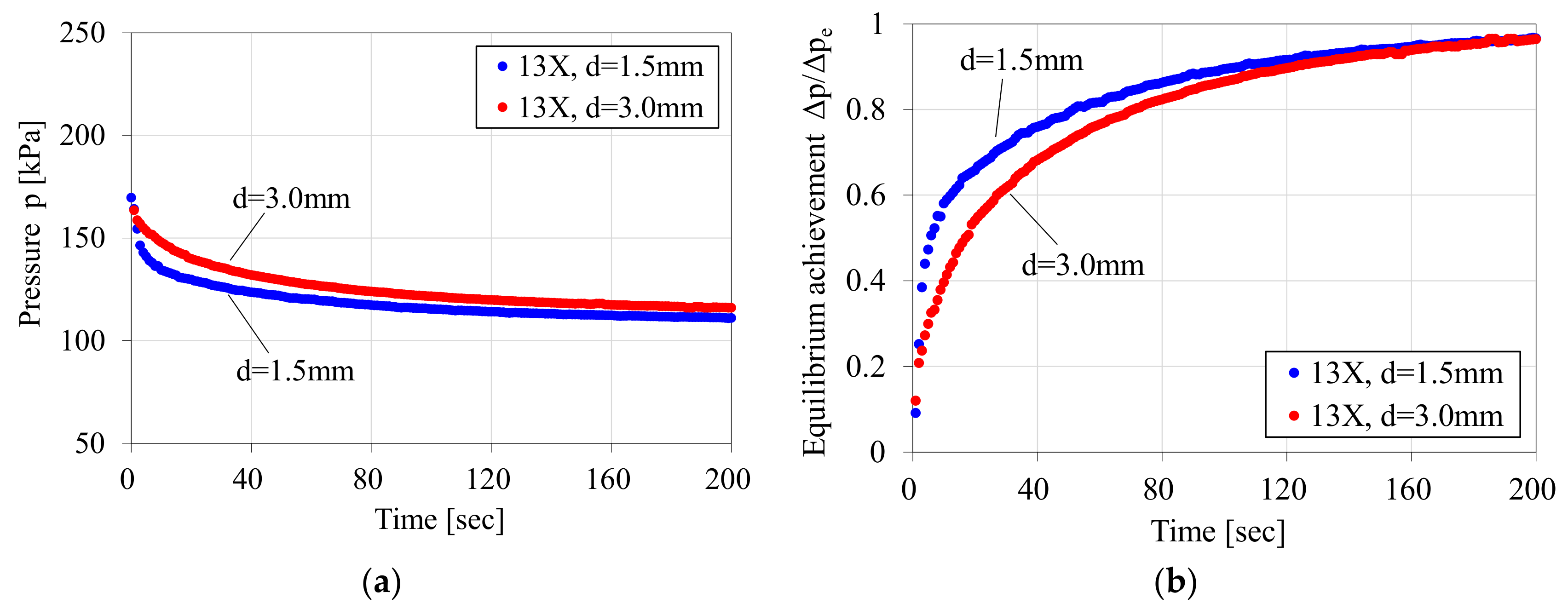

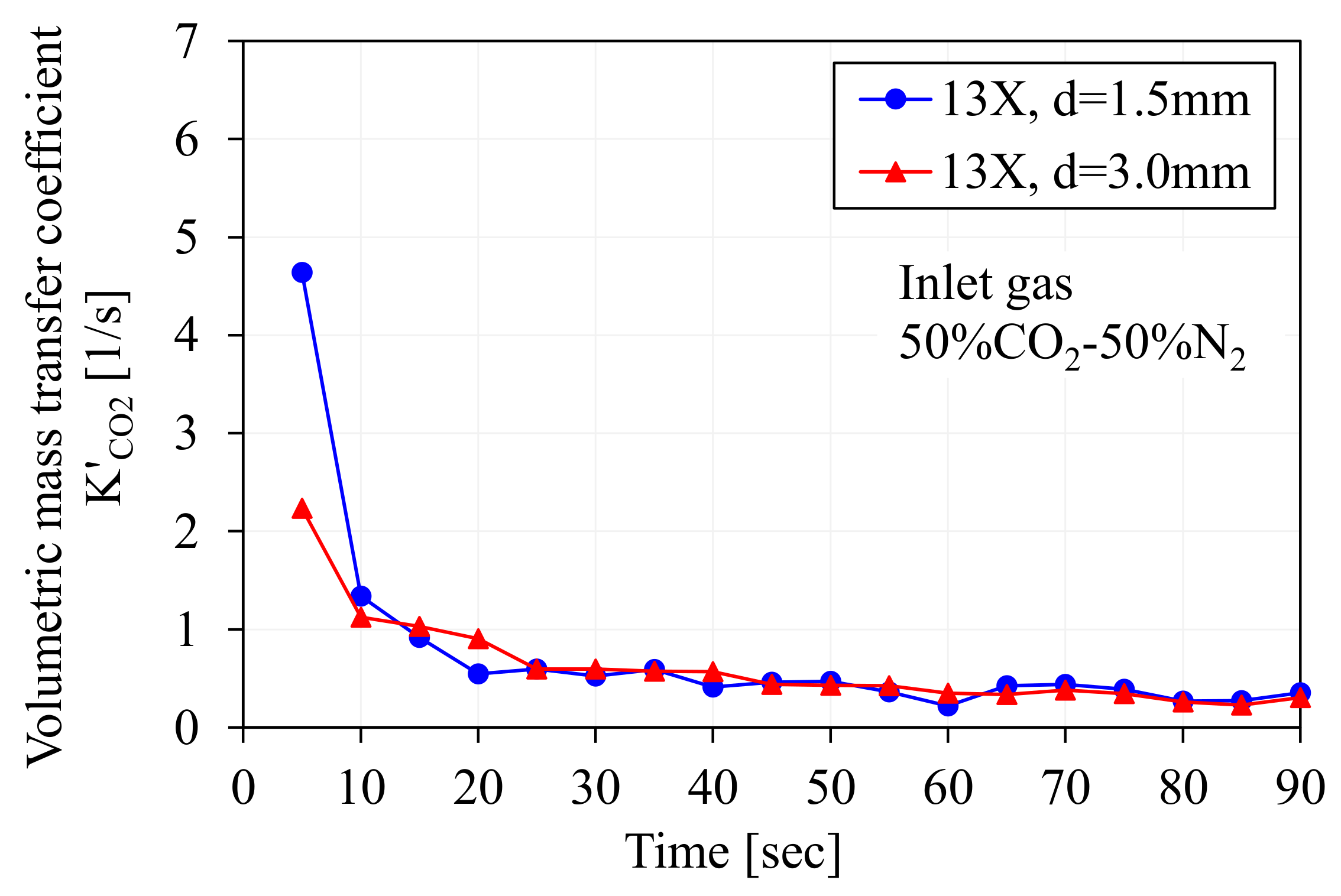

3.2. Result of the Measured CO2 Adsorption Rate in Early Stage of Adsorption

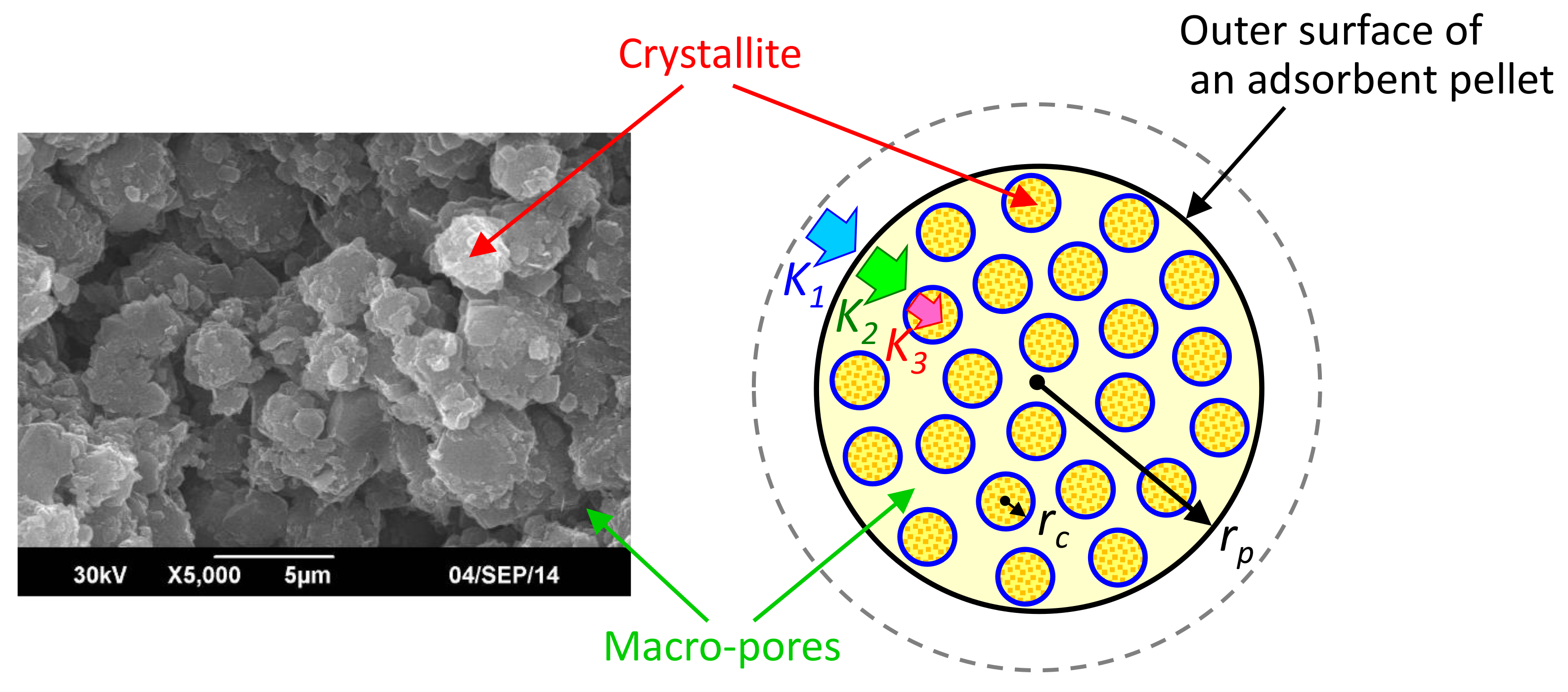

3.3. Discussion

4. Pilot Scale CO2-PSA Experiment

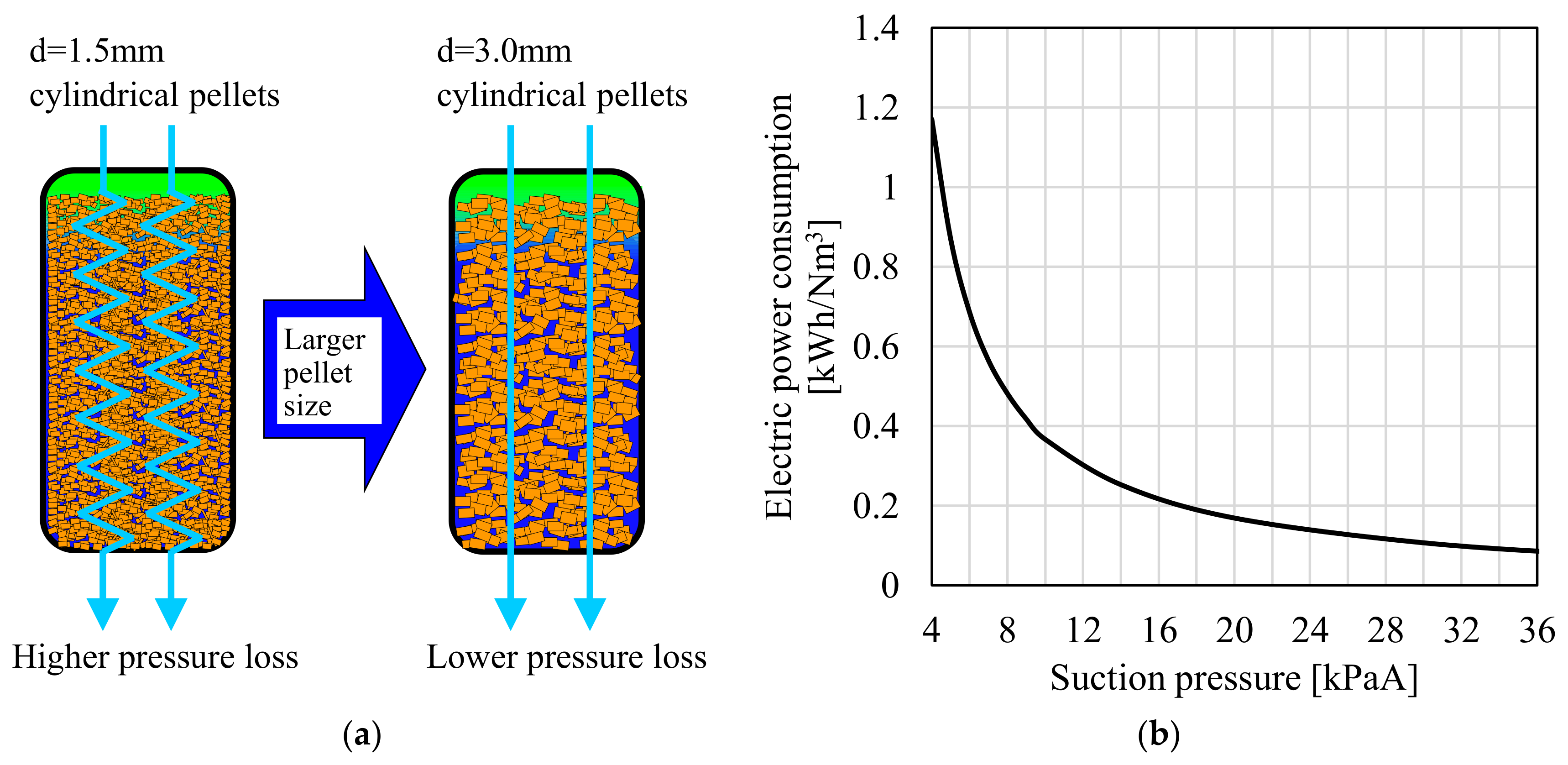

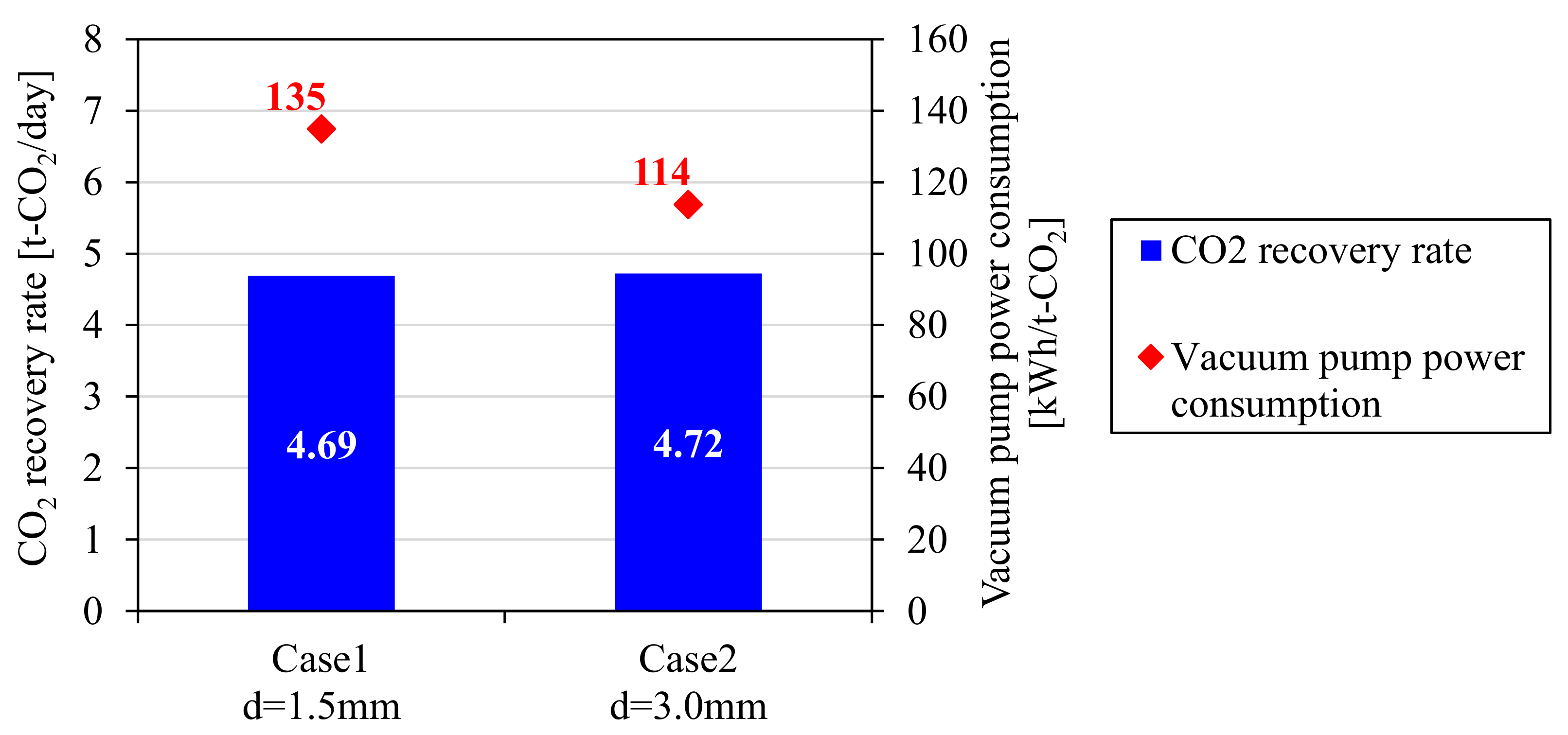

4.1. Reduction of Power Consumption by Effect of Adsorbent Shape

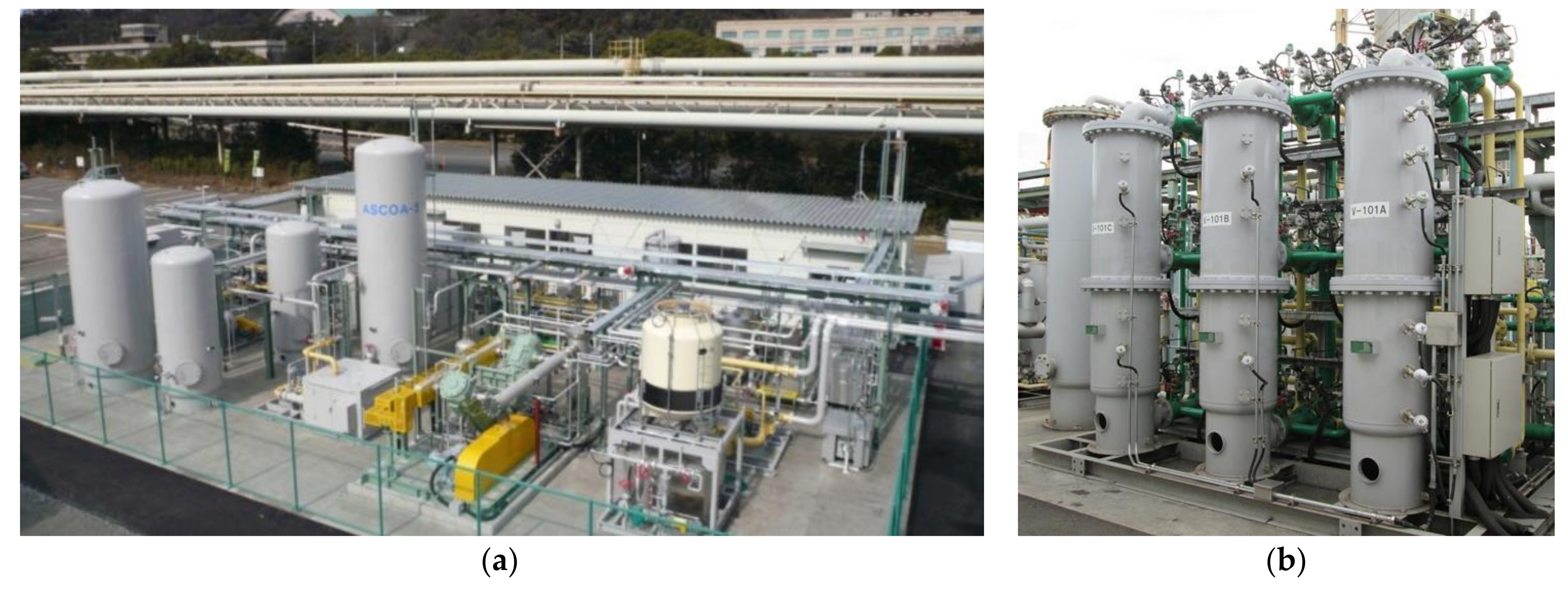

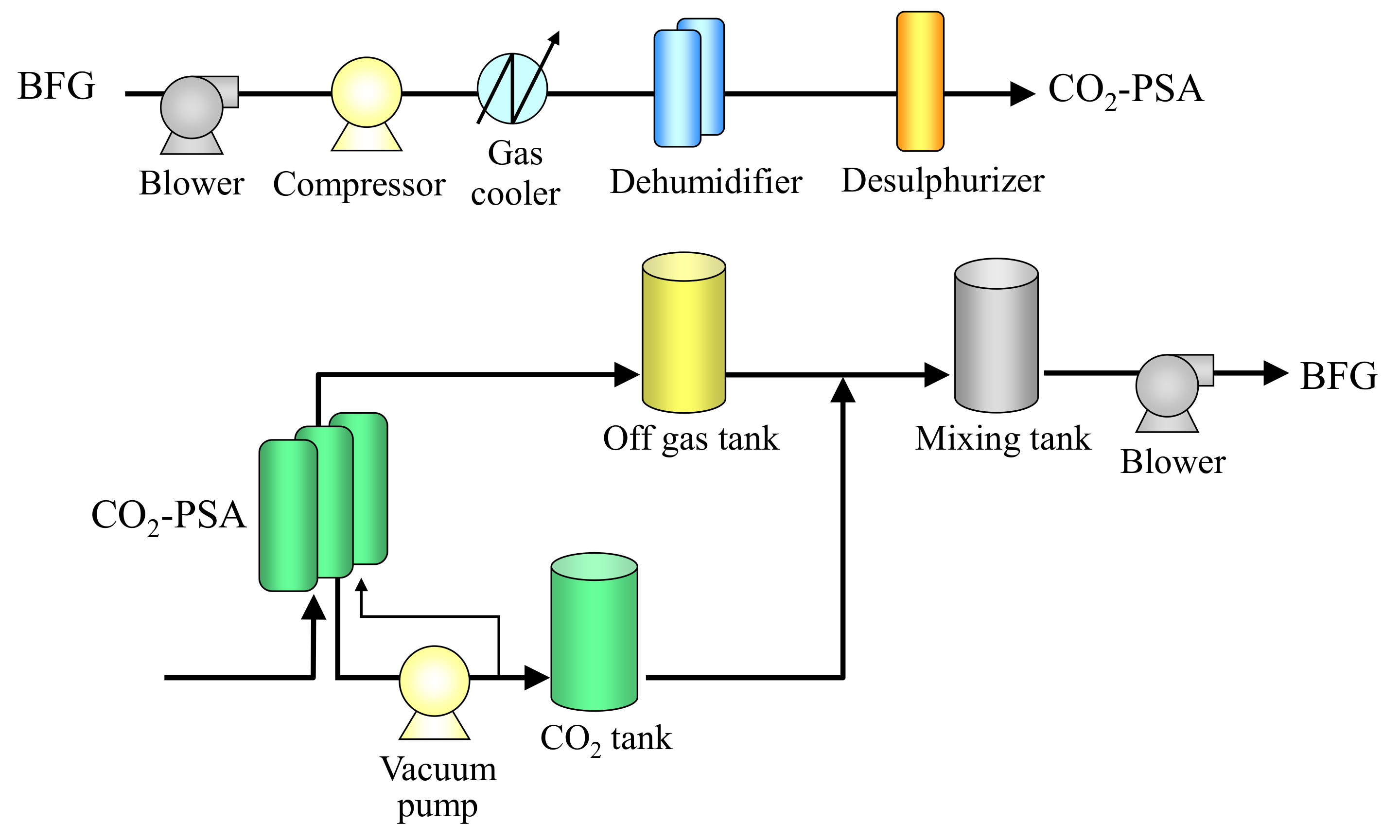

4.2. CO2-PSA Pilot Tests

5. Conclusions

Acknowledgment

Author Contributions

Conflicts of Interest

Nomenclature

| q | Adsorbed gas amount per unit adsorbent weight (g/g) |

| t | Time (s) |

| γ | Packing density of adsorbents (g/m3) |

| KF | Overall mass transfer coefficient (m/s) |

| aV | Surface area per unit volume (m2/m3) |

| c | Gas concentration (g/m3) |

| c* | Equivalent gas concentration (g/m3) |

| K′ | Overall volumetric mass transfer coefficient (1/s) |

| K1 | Volumetric mass transfer coefficient in outer layer of pellet (1/s) |

| K2 | Volumetric mass transfer coefficient in macro-pore of pellet (1/s) |

| K3 | Volumetric mass transfer coefficient in micro-pore of crystallite (1/s) |

| b | Correction factor |

| kF | Mass transfer coefficient in outer layer of pellet (m/s) |

| Sc | Schmidt number |

| Re | Reynolds number |

| μ | Gas viscosity (Pa·S) |

| ρ | Gas density (kg/m3) |

| u | Gas superficial velocity (m/s) |

| Dm | Gas molecular diffusion coefficient (m2/s) |

| T | Temperature (K) |

| Mi | Molecular weight (K) |

| P | Pressure (atm) |

| σ12 | Collision diameter (Å) |

| ΩD | Collision integral |

| R | Gas constant (J/mol K) |

| Dep | Effective diffusion coefficient in macro-pore of pellet (m2/s) |

| Dkp | Knudsen diffusion coefficient in macro-pore of pellet (m2/s) |

| Dec | Effective diffusion coefficient in micro-pore of crystallite (m2/s) |

| Dkc | Knudsen diffusion coefficient in micro-pore of crystallite (m2/s) |

| dp | Adsorbent pellet diameter (m) |

| x | Crystallite diameter (m) |

| εp | Marco-pore porosity inside pellet |

| εc | Micro-pore porosity inside crystallite |

| τp | Tortuosity factor inside pellet |

| τc | Tortuosity factor inside crystallite |

| dmacro | Macro-pore diameter in pellet (m) |

| dmicro | Micro-pore diameter in crystallite (m) |

| Subscripts | |

| p | Pellet |

| c | Crystallite |

| macro | Macro-pore |

| micro | Micro-pore |

| i | Gas species |

References

- Miwa, T.; Okuda, H. CO2 Ultimate Reduction in Steelmaking Process by Innovative Technology for Cool Earth 50 (COURSE50). J. Jpn. Inst. Energy 2010, 89, 28–35. [Google Scholar]

- Tonomura, S. Outline of Course 50. Energy Procedia 2013, 37, 7160–7167. [Google Scholar] [CrossRef]

- Ujisawa, Y.; Tonomura, S.; Ishiwata, N.; Nabeshima, Y.; Saito, K. CO2 breakthrough program by COURSE50 in Japanese steel industry sector. In Energy Technology Roadmaps of Japan: Future Energy Systems Based on Feasible Technologies Beyond 2030; Springer: Berlin, Germany, 2016; pp. 431–439. [Google Scholar]

- Hayashi, M.; Mimura, T. Steel Industries in Japan Achieve Most Efficient Energy Cut-off Chemical Absorption Process for Carbon Dioxide Capture from Blast Furnace Gas. Energy Procedia 2013, 37, 7134–7138. [Google Scholar] [CrossRef]

- Saima, H.; Mogi, Y.; Haraoka, T. Development of PSA Technology for the Separation of Carbon Dioxide from Blast Furnace Gas. JFE Tech. Rep. 2014, 19, 133–138. [Google Scholar]

- Shigaki, N.; Tobo, H.; Ozawa, S.; Ta, Y.; Hagiwara, K. Heat Recovery Process from Packed Bed of Hot Slag Plates. ISIJ Int. 2015, 55, 2258–2265. [Google Scholar] [CrossRef]

- Shigaki, N.; Ozawa, S.; Ikuhiro, S. Effect of gas velocity distribution on heat recovery process in packed bed of plate-shaped slag. Energies 2017, 10, 755. [Google Scholar] [CrossRef]

- Goto, K.; Okabe, H.; Chowdhury, F.A.; Shimizu, S.; Fujioka, Y.; Onoda, M. Development of novel absorbents for CO2 capture from blast furnace gas. Int. J. Greenh. Gas Control 2011, 5, 1214–1219. [Google Scholar] [CrossRef]

- Chowdhury, F.A.; Okabe, H.; Shimizu, S.; Onoda, M.; Fujioka, Y. Development of novel tertiary amine absorbents for CO2 capture. Energy Procedia 2009, 1, 1241–1248. [Google Scholar] [CrossRef]

- Chowdhury, F.A.; Yamada, H.; Matsuzaki, Y.; Goto, K.; Higashii, T.; Onoda, M. Development of Novel Synthetic Amine Absorbents for CO2 capture. Energy Procedia 2014, 63, 572–579. [Google Scholar] [CrossRef]

- Chowdhury, F.A.; Goto, K.; Yamada, H.; Matsuzaki, Y.; Yamamoto, S.; Higashii, T.; Onoda, M. Results of RITE’s Advanced Liquid Absorbents Develop for Low Temperature CO2 Capture. Energy Procedia 2017, 114, 1716–1720. [Google Scholar] [CrossRef]

- Rashidi, N.A.; Yusup, S.; Borhan, A. Isotherm and Thermodynamic Analysis of Carbon Dioxide on Activated Carbon. Procedia Eng. 2016, 148, 630–637. [Google Scholar] [CrossRef]

- Hosseini, S.; Bayesti, I.; Marahel, E.; Babadi, F.E.; Abdullah, L.C.; Choong, T.S.Y. Adsorption of carbon dioxide using activated carbon impregnated with Cu promoted by zinc. J. Taiwan Inst. Chem. Eng. 2015, 52, 109–117. [Google Scholar] [CrossRef]

- Plaza, M.G.; Pevida, C.; Pis, J.J.; Rubiera, F. Evaluation of the cyclic capacity of low-cost carbon adsorbents for post-combustion CO2 capture. Energy Procedia 2011, 4, 1228–1234. [Google Scholar] [CrossRef]

- Sarker, A.I.; Aroonwilas, A.; Veawab, A. Equilibrium and Kinetic Behaviour of CO2 Adsorption onto Zeolites, Carbon Molecular Sieve and Activated Carbons. Energy Procedia 2017, 114, 2450–2459. [Google Scholar] [CrossRef]

- Mendes, P.A.P.; Ribeiro, A.M.; Gleichmann, K.; Ferreira, A.F.P.; Rodrigues, A.E. Separation of CO2/N2 on binderless 5A zeolite. J. CO2 Util. 2017, 20, 224–233. [Google Scholar] [CrossRef]

- McEwen, J.; Hayman, J.D.; Yazaydin, A.O. A comparative study of CO2, CH4 and N2 adsorption in ZIF-8, Zeolite-13X and BPL activated carbon. Chem. Phys. 2013, 412, 72–76. [Google Scholar] [CrossRef]

- Walton, K.S.; Abney, M.B.; LeVan, M.D. CO2 adsorption in Y and X zeolites modified by alkali metal cation exchange. Microporous Mesoporous Mater. 2006, 91, 78–84. [Google Scholar] [CrossRef]

- Campo, M.C.; Ribeiro, A.M.; Ferreira, A.F.P.; Santos, J.C.; Lutz, C.; Loureiro, J.M.; Rodrigues, A.E. Carbon dioxide removal for methane upgrade by a VSA process using an improved 13X zeolite. Fuel Process. Technol. 2016, 143, 185–194. [Google Scholar] [CrossRef]

- Khunpolgrang, J.; Yosantea, S.; Kongnoo, A.; Phalakornkule, C. Alternative PSA process cycle with combined vacuum regeneration and nitrogen purging for CH4/CO2 separation. Fuel 2015, 140, 171–177. [Google Scholar] [CrossRef]

- Ga, S.; Jang, H.; Lee, J.H. New Performance Indicators for Evaluation of Adsorbents for CO2 Capture with PSA processes. IFAC-PapersOnLine 2016, 49, 651–656. [Google Scholar] [CrossRef]

- Ga, S.; Jang, H.; Lee, J.H. New performance indicators for adsorbent evaluation derived from a reduced order model of an idealized PSA process for CO2 capture. Comput. Chem. Eng. 2017, 102, 188–212. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, P.; Li, G.; Webley, P.A. Effect of Flue Gas Impurities on CO2 Capture Performance from Flue Gas at Coal-fired Power Stations by Vacuum Swing Adsorption. Energy Procedia 2009, 1, 1115–1122. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Rübner, K.; Hoffmann, D. Characterization of Mineral Building Materials by Mercury Intrusion Porosimetry. Part. Part. Syst. Charact. 2006, 23, 20–28. [Google Scholar] [CrossRef]

- Yoshida, F.; Ramaswami, D.; Hougen, O.A. Temperatures and partial pressures at the surfaces of catalyst particles. AIChE J. 1962, 8, 5–11. [Google Scholar] [CrossRef]

- Ye, G.; Duan, X.; Zhu, K.; Zhou, X.; Coppens, M.O.; Yuan, W. Optimizing spatial pore-size and porosity distributions of adsorbents for enhanced adsorption and desorption performance. Chem. Eng. Sci. 2015, 132, 108–117. [Google Scholar] [CrossRef]

- Silva, J.A.C.; Schumann, K.; Rodrigues, A.E. Sorption and kinetics of CO2 and CH4 in binderless beads of 13X zeolite. Microporous Mesoporous Mater. 2012, 158, 219–228. [Google Scholar] [CrossRef]

- Sun, Z.; Tang, X.; Cheng, G. Numerical simulation for tortuosity of porous media. Microporous Mesoporous Mater. 2013, 173, 37–42. [Google Scholar] [CrossRef]

- Itoh, T.; Wanibe, Y.; Sakao, H. Analysis of Packing Density by Randomly Packed Models of Binary Powders. J. Jpn. Inst. Met. 1986, 50, 475–479. [Google Scholar] [CrossRef]

- Zhao, J.; Li, S.; Lu, P.; Meng, L.; Li, T.; Zhu, H. Shape influences on the packing density of frustums. Powder Technol. 2011, 214, 500–505. [Google Scholar] [CrossRef]

- Meng, L.; Lu, P.; Li, S.; Zhao, J.; Li, T. Shape and size effects on the packing density of binary spherocylinders. Powder Technol. 2012, 228, 284–294. [Google Scholar] [CrossRef]

| Shape | Cylindrical d = 3.0 mm | Cylindrical d = 1.5 mm | Cylindrical d = 1.2 mm | Honewort d = 1.63 mm |

|---|---|---|---|---|

| External surface ratio | 0.50 | 1.00 | 1.25 | 1.16 |

| Pellet shape drawing |  |  |  |  |

| Adsorbent Type | Zeolite13X (NaX) |

|---|---|

| Macro-Meso pore volume (cm3/g) | 0.27 |

| Average macro-meso pore diameter (nm) | 126 |

| BET surface area (m2/g) | 802 |

| Packing density (g/cm3) | 0.67 |

| Particle density (g/cm3) | 1.58 |

| Si/Al ratio | 1.4 |

| Parameter | Value | |

|---|---|---|

| Adsorber | Number of adsorbers | 3 |

| Weight of adsorbent in an adsorber (g) | 120 | |

| Inner diameter (mm) | 40 | |

| PSA operation | Feed gas volume in 1 cycle (NL/kg-adsorbent/cycle) | 40 |

| Feed gas composition (vol %) | 32CO2, 33CO, 30N2, 5H2 | |

| Pressure at the bottom of the adsorber (kPaA) | Adsorption 151 | |

| Desorption 9 | ||

| Cycle time (sec/cycle) | 300 | |

| CO2 concentration of recovered gas (vol %) | 90 | |

| Property | Symbol | Value | |

|---|---|---|---|

| Adsorbent pellet diameter (mm) | Dp | 1.5 | 3.0 |

| Equivalent adsorbent pellet diameter (mm) | dp′ | 1.82 | 3.44 |

| Surface area per unit volume (m2/m3) | av | 2052 | 1088 |

| Crystallite diameter (m) | dc | 3.00 × 10−6 | |

| Macro-pore diameter in the pellet (m) | dmacro | 1.26 × 10−7 | |

| Micro-pore diameter in the crystallite (m) | dmicro | 7.35 × 10−10 | |

| Pressure (Pa) | P | 151,000 | |

| Gas constant (J/mol K) | R | 8.314 | |

| Temperature (K) | T | 298.15 | |

| Molecular weight of CO2 (g/mol) | M1 | 44.01 | |

| Molecular weight of N2 (g/mol) | M2 | 28.01 | |

| Collision diameter (m) | σ12 | 3.87 × 10−10 | |

| Marco-pore porosity inside the pellet | εp | 0.314 | |

| Micro-pore porosity inside the crystallite | εc | 0.274 | |

| Gas density (kg/m3) | ρ | 1.613735 | |

| Gas superficial velocity (m/s) | u | 0.003 | |

| Gas viscosity (Pa·s) | μ | 1.62 × 10−5 | |

| Property | Symbol | Value | |

|---|---|---|---|

| Gas molecular diffusion coefficient (C-E eq.) (m2/s) | Dm | 8.699 × 10−6 | |

| Knudsen diffusion coefficient (m2/s) | macro-pore of the pellet | Dkp | 1.591 × 10−5 |

| micro-pore of the crystallite | Dkc | 9.281 × 10−8 | |

| Effective diffusion coefficient (m2/s) | macro-pore of the pellet | Dep | 8.828 × 10−7 |

| micro-pore of the crystallite | Dec | 1.258 × 10−8 | |

| Property | Symbol | Value | ||

|---|---|---|---|---|

| d = 1.5 mm | d = 3.0 mm | |||

| Volumetric mass transfer coefficient (1/s) | outer layer of the pellet | K1 | 12.2 | 4.7 |

| macro-pore of the pellet | K2 | 9.9 | 2.8 | |

| micro-pore of the crystallite | K3 | 35,857 | 35,857 | |

| Overall volumetric mass transfer coefficient (1/s) | K′calc | 5.47 | 1.75 | |

| Equipment | Units/System | Specifications | |

|---|---|---|---|

| Blower | 1 | Type | Centrifugal type |

| Flow rate | 500 Nm3/h | ||

| Pressure | Outlet 4.9 kPaG | ||

| Gas compressor | 1 | Type | Reciprocating type |

| Flow rate | 500 Nm3/h | ||

| Pressure | Outlet 300 kPaG | ||

| Gas cooler | 1 | Type | Refrigerator cooling type |

| Temperature | Outlet gas 283 K | ||

| Dehumidifier | 2 | Type | Heating regeneration type |

| Desiccant | Silica gel, Alumina gel | ||

| Dew point | Outlet gas < 213 K | ||

| Adsorber | 3 | Dimensions | 600 ID × 1500 TTH |

| Volume | 0.42 m3 | ||

| Vacuum pump | 1 | Type | Roots type dry pump |

| Pumping speed | 1284 m3/h | ||

| Rated output | 45 kW | ||

| Pellet Shape | Length (mm) | Bulk Density of Packed Bed(kg/L) | Crushing Strength (N) | ||||

|---|---|---|---|---|---|---|---|

| Max. | Min. | Ave. | Max./Min. | Standard Deviation | |||

| Cylindrical, d = 1.5 mm | 5.66 | 1.62 | 3.19 | 3.49 | 1.02 | 0.64 | 40 |

| Cylindrical, d = 3.0 mm | 6.80 | 2.69 | 4.84 | 2.53 | 0.89 | 0.63 | 89 |

| Parameter | Value | |||

|---|---|---|---|---|

| Case 1 | Case 2 | |||

| Adsorbent | Type | Zeolite13X | ||

| Shape | Cylindrical | |||

| Pellet diameter (mm) | 1.5 | 3.0 | ||

| Adsorber | Number of adsorbers | 3 | ||

| Total weight of adsorbent in an adsorber (kg) | 240 | |||

| Packing height of adsorbent (mm) | 1350 | |||

| Inner diameter (mm) | 600 | |||

| PSA operation | Feed gas flow rate (Nm3/h) | 400 | ||

| Dew point of the feed gas (K) | <213 | |||

| Pressure at the bottom of the adsorber (kPaA) | Adsorption | 151 | ||

| Desorption | From 6 to 10 | |||

| Cycle time (sec/cycle) | 300 | |||

| CO2 recovery rate (t-CO2/day) | 4.7 | |||

| CO2 concentration of recovered gas (%) | 90 | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shigaki, N.; Mogi, Y.; Haraoka, T.; Sumi, I. Reduction of Electric Power Consumption in CO2-PSA with Zeolite 13X Adsorbent. Energies 2018, 11, 900. https://doi.org/10.3390/en11040900

Shigaki N, Mogi Y, Haraoka T, Sumi I. Reduction of Electric Power Consumption in CO2-PSA with Zeolite 13X Adsorbent. Energies. 2018; 11(4):900. https://doi.org/10.3390/en11040900

Chicago/Turabian StyleShigaki, Nobuyuki, Yasuhiro Mogi, Takashi Haraoka, and Ikuhiro Sumi. 2018. "Reduction of Electric Power Consumption in CO2-PSA with Zeolite 13X Adsorbent" Energies 11, no. 4: 900. https://doi.org/10.3390/en11040900

APA StyleShigaki, N., Mogi, Y., Haraoka, T., & Sumi, I. (2018). Reduction of Electric Power Consumption in CO2-PSA with Zeolite 13X Adsorbent. Energies, 11(4), 900. https://doi.org/10.3390/en11040900