Calculation of Equivalent Resistance for Ground Wires Twined with Armor Rods in Contact Terminals

Abstract

1. Introduction

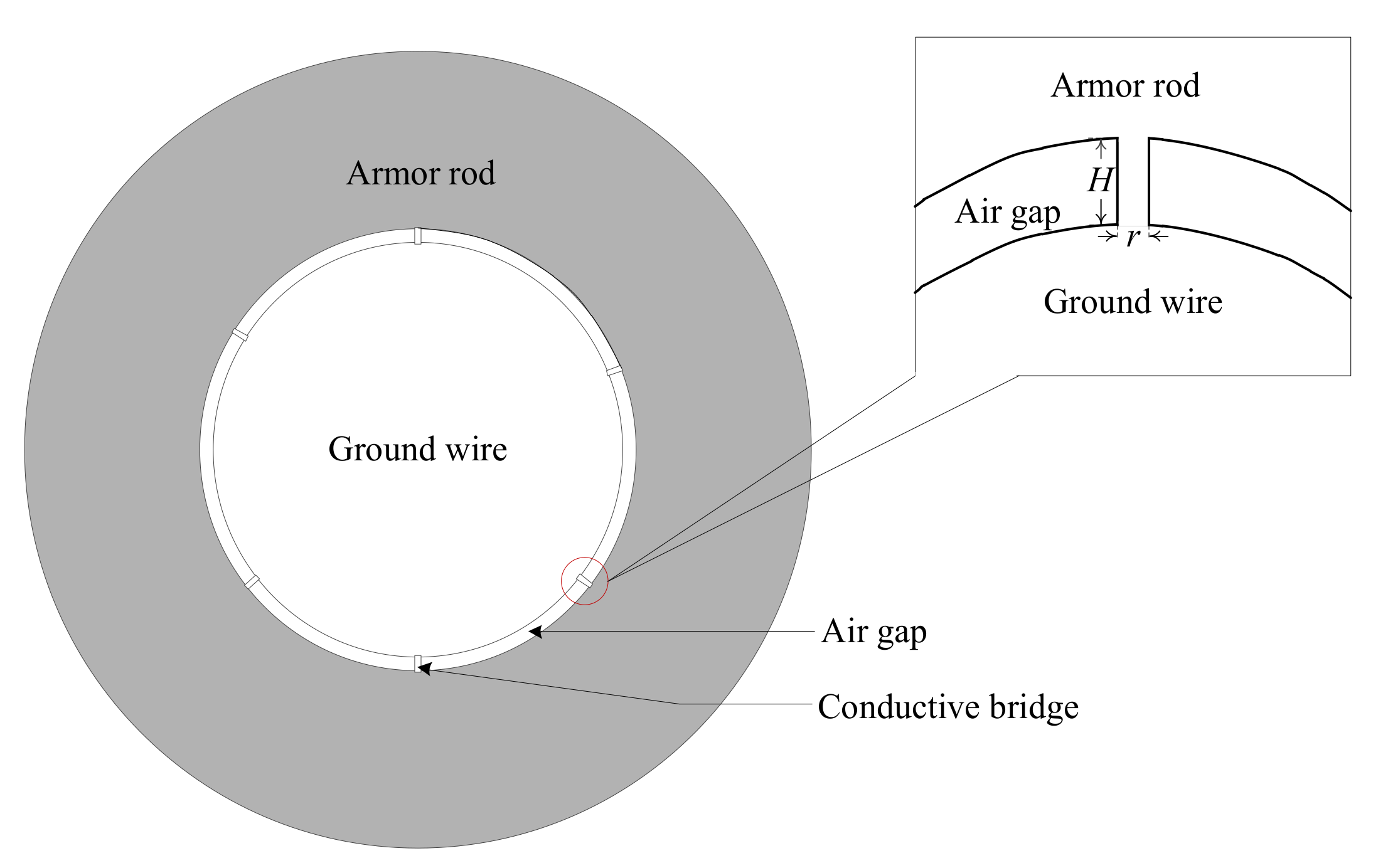

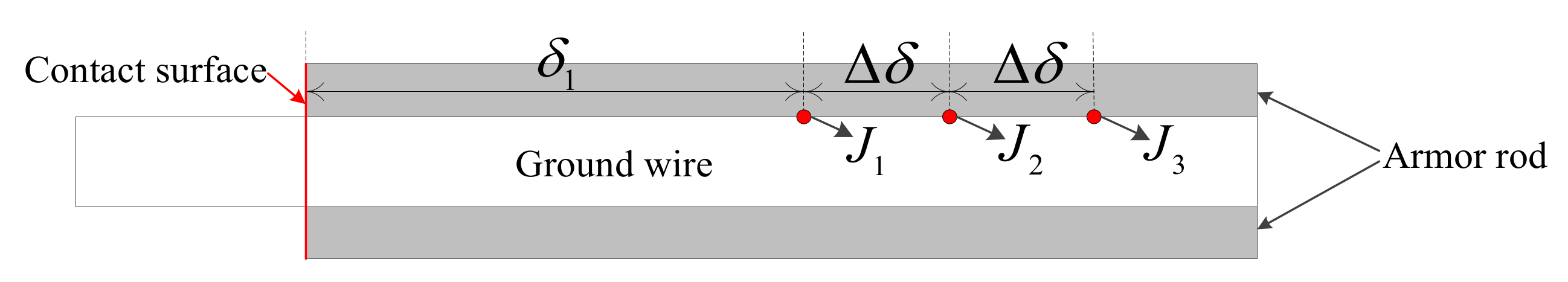

2. Multiple Contact Points Model of the Contact Terminal Consisting of Ground Wire and Armor Rod

2.1. Spatial Distribution of the Contact Points between the Ground Wire and the Armor Rod

2.2. Equivalent Treatment of the Contact Points between the Ground Wire and the Armor Rod in the FEA Model

3. FEA Computation of the Electromagnetic Field for the Contact Terminal Based on the Multiple Contact Points Model

3.1. Geometric Model of the Contact Terminal

3.2. The Physical Parameters and the Boundary Conditions of the Model

3.3. Determination of the Axial Length of the Model

3.4. Simulation Results and Analysis

3.5. Output Quantities of the Model

4. Experimental Verification

4.1. The Steady-State Temperature Rise Experiments of the Contact Terminal

4.2. The Equivalent Resistance Measuring Experiments for the Armor Rod Segment in the Contact Terminal

- 1)

- The output voltage U of the adjustable constant alternating current source, i.e., total voltage of the constant-current source leads, the parallel groove clamps, and the measurement segment of the experimental contact terminal, was measured. Then, the equivalent output AC resistance of the adjustable constant alternating current source (i.e., R) was computed with Equation (7). In Equation (7), cosφ is the power factor of the measuring loop. R consisted of three parts: the AC resistance of the measurement segment of the experimental contact terminal (i.e., Rd1), the total AC resistance of L1 and the corresponding parallel groove clamp (i.e., Rf1), and the total AC resistance of L2 and the corresponding parallel groove clamp (i.e., Rf2), as shown in Equation (8):

- 2)

- Under the condition of no load on the equivalent resistance measurement loop, the total DC resistance of L1 (L2) and the corresponding parallel groove clamp, i.e., Rf1′ (Rf2′), was measured by the digital DC bridge PC36C (accuracy of 0.01 μΩ). The materials of the constant-current source leads and the parallel groove clamps were copper and aluminum alloy, respectively, which belonged to the non-ferromagnetic materials. Therefore, the differences between the AC resistance and the DC resistance of the constant-current source leads and the parallel groove clamps were very slight. Rf1′ and Rf2′ were adopted to approximately substitute Rf1 and Rf2.

- 3)

- Rd1 was obtained using Equation (8) on the basis of the measurement results of the alternating current voltage drop method and the digital DC bridge measuring method.

4.3. Determination of the Conductive Bridge Radius r

- For Boundary I1 and I3, which belong to the horizontal boundaries, their natural heat transfer coefficients, h1 and h3, respectively, were automatically computed by COMSOL after inputting the ambient temperature and the diameters of the ground wire and the armor rod to COMSOL.

- For Boundary I2, which belongs to the vertical boundaries, the natural heat transfer coefficient h2 was automatically computed by COMSOL after inputting the ambient temperature and the vertical height of Boundary I2 to COMSOL.

- Boundary I4 was set as the axial adiabatic plane, i.e., the second type of thermal boundary condition.

- 1)

- The geometric models of the contact terminal in the electromagnetic field simulation model and the thermal field simulation model were the same.

- 2)

- In the thermal field simulation model, the third type of thermal boundary condition was used to simulate the air domain wrapped around the ground wire and the armor rod in the 3D-EM model.

- 3)

- There was a conversion relationship between the electromagnetic loss power of various components computed by the 3D-EM model and the heat source of corresponding components in the thermal simulation model.

4.4. Discussion

- 1)

- The value of the Rz1 output by the 3D-EM model of contact terminal was dependent on the value of the conductive bridge radius r, and the value of conductive bridge radius r was dependent on the error between the calculation results of thermal simulation model and the measuring results of the steady-state temperature rise experiments. Therefore, the calculation error of the conductive bridge radius r accumulated in the calculation error of Rz1 inevitably.

- 2)

- Table 4 shows that for the experimental contact terminal, the calculation error of Rz1 in the 3D-EM model was 3.0%. Thus, the 3D-EM model of contact terminal was sufficiently accurate to be practically applied to calculate the value of Rz1.

5. Analysis of Factors Influencing Rz1

6. Conclusions

- 1)

- This paper adopted the cylindrical conductive bridge model to simulate the conductive contact points between the ground wire and armor rod, and subsequently established a 3D-EM model of the contact terminal based on the actual characteristics of contact points. The 3D-EM model was successfully applied to obtain the current distribution in the contact terminal.

- 2)

- The simulation results of the 3D-EM model showed that the current diffusion occurred near the contact surface and the severe current contraction phenomenon happened in the conductive bridges within the diffusion range. However, outside the current diffusion range, there was no current exchange between the ground wire and armor rod. As a result, the contact resistance generating heat effect near the contact surface was only determined by the conductive bridges within the current diffusion range.

- 3)

- This paper proposed a method for determining the conductive bridge radius r, which was based on the criterion of the minimum sum of squared error between the simulation results and experimental results at the temperature measurement points of contact terminal. The results of the steady state temperature rise experiments for contact terminal verified that the conductive bridge radius r determined by the proposed method could have sufficient accuracy for application in the 3D-EM model and the thermal simulation model of contact terminal.

- 4)

- Rz1 could be regarded as an indicator to evaluate the temperature rise of the armor rod segment in the contact terminal. The results of the equivalent resistance measuring experiments for the armor rod segment verified that the 3D-EM model of contact terminal developed in this paper was sufficiently accurate to be practically applied to calculate the value of Rz1 .This meant that the 3D-EM model could provide reliable data for analyzing breakage accidents of the armor rod segment in contact terminal caused by temperature rise.

- 5)

- Based on the 3D-EM model of contact terminal, the values of Rz1 under different μr, θ, and l were calculated, respectively. The results showed that the value of Rz1 hardly varied with θ. However, the increasing l and μr resulted in a larger Rz1, which could increase the breakage possibility of the armor rod segment in contact terminal.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Variables | |

| l | Axial distance between adjacent two radial cross section of the armor rod segment with contact points (mm). |

| l1 | Axial distance between adjacent two radial cross section of the armor rod segment with contact points when the stranding directions of the outermost layer of the ground wire and the armor rod are identical (mm). |

| l2 | Axial distance between adjacent two radial cross section of the armor rod segment with contact points when the stranding directions of the outermost layer of the ground wire and the armor rod are opposite (mm). |

| s1 | Lay length of the outermost layer of the ground wire (mm). |

| s2 | Lay length of the outermost layer of the armor rod (mm). |

| θ | Rotation angle of the adjacent two contact points on the stranded conductor of the outermost layer of the same strand of ground wire. |

| θ1 | Rotation angle of the two adjacent contact points on the stranded conductor of the outermost layer of the same strand of ground when the stranding directions of the outermost layer of the ground wire and the armor rod are identical. |

| θ2 | Rotation angle of the two adjacent contact points on the stranded conductor of the outermost layer of the same strand of ground when the stranding directions of the outermost layer of the ground wire and the armor rod are opposite. |

| smin | Minimum value between s1 and s2 (mm). |

| H | Height of cylindrical conductive bridge model (mm). |

| r | Radius of cylindrical conductive bridge model (mm). |

| R1 | DC resistance of the ground wire (Ω). |

| R2 | Power frequency AC resistance of the ground wire (Ω). |

| S1 | Equivalent sectional areas of the ground wire through which direct current pass (m2). |

| S2 | Equivalent sectional areas of the ground wire through which power frequency alternating current pass (m2). |

| rg | Radius of the ground wire (m). |

| d | Skin depth of steel under the power frequency of 50 Hz (m). |

| ω | Angular frequency (rad/s). |

| μr | Relative permeability of steel. |

| μ0 | Vacuum magnetic conductivity (N/A2). |

| γ | Conductivity of steel (S/m). |

| L | Axial length of the current diffusion range of the armor rod segment (mm). |

| Rz1 | Equivalent resistance of the armor rod segment (Ω). |

| Rz | Total resistance of the simulation model (Ω). |

| R20 | Resistance of the bare ground wire segment in the simulation model (Ω). |

| U | Output voltage of the adjustable constant alternating current source (V). |

| cosφ | Power factor of measuring loop. |

| I | Output current of the adjustable constant alternating current source (A). |

| R | Total resistance of the constant-current source lead, parallel groove clamp, and the measurement segment of the experimental ground wire (Ω). |

| Rd1 | Resistance of the measurement segment of the experimental ground wire (Ω). |

| Rf1 | Total AC resistance of the constant-current source lead L1 and the corresponding parallel groove clamp (Ω). |

| Rf2 | Total AC resistance of the constant-current source lead L2 and the corresponding parallel groove clamp (Ω). |

| Rf1′ | Total measured DC resistance of the constant-current source lead L1 and the corresponding parallel groove clamp (Ω). |

| Rf2′ | Total measured DC resistance of the constant-current source lead L2 and the corresponding parallel groove clamp (Ω). |

| TW | Surface temperature of the contact terminal (°C). |

| Tf | Temperature of the surrounding air (°C). |

| h | Natural heat transfer coefficient (W/(m2·K)). |

| PT | Heat source power at the temperature T (W). |

| T | Conductor temperature (°C). |

| i | Load current (A). |

| r20 | Resistance at 20 °C (Ω). |

| α | Temperature coefficient of steel (°C−1). |

| P20 | Heat source power at 20 °C, i.e., the electromagnetic loss power output by the 3D-EM model (W). |

| Ssqu | Sum of square for the simulation result error at various temperature measuring points. |

| Tai | Simulated surface temperature at temperature measuring point i (°C). |

| Tbi | Measured surface temperature at temperature measuring point i (°C). |

| Parameters and Constants | |

| FEA | Finite element analysis. |

| 3D-EM model | Three-dimensional electromagnetic field simulation model based on the multiple contact points model. |

| A1 | Terminal of the bare ground wire segment. |

| A2 | Terminal of the armor rod segment. |

| A | Current density sampling path at the radial terminal of the armor rod segment away from the contact surface. |

| B | Current density sampling path at the radial terminal of the bare ground wire segment away from the contact surface. |

| L1 | A constant-current source Lead. |

| L2 | The other constant-current source Lead. |

| n | Outer normal of the heat exchange surface. |

| W | External surface of the contact terminal. |

| I1 | Horizontal surface boundary of the bare ground wire segment in the thermal model. |

| I2 | Vertical surface boundary of the armor rod segment at the contact surface in the thermal model. |

| I3 | Horizontal surface boundary of the armor rod segment in the thermal model. |

| I4 | Both of the two radial cross sections at the ends of the thermal model. |

References

- Jiang, X.; Meng, Z.; Zhang, Z.; Hu, J.; Lei, Y. DC ice-melting and temperature variation of optical fiber for ice-covered overhead ground wire. IET Gener. Transm. Distrib. 2016, 10, 352–358. [Google Scholar] [CrossRef]

- Li, J.; Sun, D. Analysis on Lightning Strike Damages to Optical Fiber Composite Overhead Ground Wire. In Proceedings of the 2009 International Conference on Industrial and Information Systems, Haikou, China, 24–25 April 2009; pp. 39–44. [Google Scholar]

- Du, T.; Zhang, Y.; Xia, W. Study on the Problem of Lightning Strike OPGW. In Proceedings of the 2006 International Conference on Power System Technology, Chongqing, China, 22–26 October 2006; pp. 1–4. [Google Scholar]

- Karabay, S.; Guven, E.A.; Erturk, A.T. Enhancement on Al–Mg–Si alloys against failure due to lightning arc occurred in energy transmission lines. Eng. Fail. Anal. 2013, 31, 153–160. [Google Scholar] [CrossRef]

- Karabay, S. Modification of Conductive Material AA6101 of OPGW Conductors against Lightning Strikes. Strojniski Vestnik J. Mech. Eng. 2013, 59, 451–461. [Google Scholar] [CrossRef][Green Version]

- Iwata, M.; Ohtaka, T.; Goda, Y. Melting and Breaking of 80 mm2 OPGWs by DC Arc Discharge Simulating Lightning Strike. In Proceedings of the 2016 33rd International Conference on Lightning Protection (ICLP), Estoril, Portugal, 25–30 September 2016; pp. 1–4. [Google Scholar]

- Liu, G.; Li, Y.; Guo, D.; Qi, H.; Zhang, Y.; Ma, H. Experimental Investigation on the Breakage in Earth Wire Suspension String with Winding Preformed Armor Rods. In Proceedings of the 2017 IEEE International Conference on Environment and Electrical Engineering and 2017 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Milan, Italy, 6–9 June 2017; pp. 1–5. [Google Scholar]

- Andrusca, M.; Adam, M.; Burlica, R.; Munteanu, A.; Dragomir, A. Considerations regarding the Influence of Contact Resistance on the Contacts of Low Voltage Electrical Equipment. In Proceedings of the 9th International Conference and Exposition on Electrical and Power Engineering (EPE), Iasi, Romania, 20–22 October 2016; pp. 123–128. [Google Scholar]

- Holm, R. Electrical Contacts, 4th ed.; Springer: New York, NY, USA, 1979. [Google Scholar]

- Greenwood, J.A. Constriction Resistance and the Real Area of Contact. Br. J. Appl. Phys. 1966, 17, 1621–1632. [Google Scholar] [CrossRef]

- Kogut, L.; Komvopoulos, K. Electrical contact resistance theory for conductive rough surfaces. J. Appl. Phys. 2003, 94, 3153–3162. [Google Scholar] [CrossRef]

- Laor, A.; Herrell, P.J.; Mayer, M. A Study on Measuring Contact Resistance of Ball Bonds on Thin Metallization. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 704–708. [Google Scholar] [CrossRef]

- Dhotre, M.T.; Korbel, J.; Ye, X.; Ostrowski, J.; Kotilainen, S.; Kriegel, M. CFD Simulation of Temperature Rise in High-Voltage Circuit Breakers. IEEE Trans. Power Deliv. 2017, 32, 2530–2536. [Google Scholar] [CrossRef]

- Zeng, R.; Zhou, P.; Wang, S.; Li, Z.; Zhang, B. Modeling of Contact Resistance in Ground System and Analysis on Its Influencing Factors. High Volt. Eng. 2010, 36, 2393–2397. [Google Scholar] [CrossRef]

- Ito, S.; Kawase, Y.; Mori, H. 3-D finite element analysis of repulsion forces on contact systems in low voltage circuit breakers. IEEE Trans. Magn. 1996, 32, 1677–1680. [Google Scholar] [CrossRef]

- Qiang, R.; Rong, M. Simulation of the contact resistance of high voltage apparatus with the method of coupling contact surface. In Proceedings of the 2013 2nd International Conference on Electric Power Equipment—Switching Technology (ICEPE-ST), Matsue, Japan, 20–23 October 2013; pp. 1–4. [Google Scholar]

- Li, X.; Qu, J.; Wang, Q.; Zhao, H.; Chen, D. Numerical and Experimental Study of the Short-Time Withstand Current Capability for Air Circuit Breaker. Trans. Power Deliv. 2013, 28, 2610–2615. [Google Scholar] [CrossRef]

- Li, X.; Chen, D. 3-D Finite Element Analysis and Experimental Investigation of Electrodynamic Repulsion Force in Molded Case Circuit Breakers. IEEE Trans. Compon. Packag. Manuf. Technol. 2005, 28, 877–883. [Google Scholar] [CrossRef]

- Kawase, Y.; Mori, H.; Ito, S. 3-D finite element analysis of electrodynamic repulsion forces in stationary electric contacts taking into account asymmetric shape (invited). IEEE Trans. Magn. 1997, 33, 1994–1999. [Google Scholar] [CrossRef]

- Kong, W.; Cheng, Y. Measures of Introduction and Look Forward to Prevent Breeze Vibration of Overhead Power Transmission Lines. In Proceedings of the 2011 Second International Conference on Mechanic Automation and Control Engineering, Hohhot, China, 15–17 July 2011; pp. 2299–2301. [Google Scholar]

- Dai, D.; Zhang, X.; Wang, J. Calculation of AC Resistance for Stranded Single-Core Power Cable Conductors. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- De Paulis, F.; Olivieri, C.; Orlandi, A.; Giannuzzi, G.; Bassi, F.; Morandini, C.; Fiorucci, E.; Bucci, G. Exploring Remote Monitoring of Degraded Compression and Bolted Joints in HV Power Transmission Lines. IEEE Trans. Power Deliv. 2016, 31, 2179–2187. [Google Scholar] [CrossRef]

- Hao, X.; Yin, W.; Strangwood, M.; Peyton, A.; Morris, P.; Davis, C. Characterization of Decarburization of Steels Using a Multifrequency Electromagnetic Sensor: Experiment and Modeling. Metall. Mater. Trans. A 2009, 40, 745–756. [Google Scholar] [CrossRef]

- Guo, D.; Liu, G.; Qi, H.; Zhang, Y. Experimental analysis on temperature distribution of ground wire suspension string with winding preformed armor rod. Guangdong Electr. Power 2017, 30, 1–5. [Google Scholar] [CrossRef]

- Wang, P.; Liu, G.; Ma, H.; Liu, Y.; Xu, T. Investigation of the Ampacity of a Prefabricated Straight-Through Joint of High Voltage Cable. Energies 2017, 10, 2050. [Google Scholar] [CrossRef]

- Liu, G.; Lei, M.; Ruan, B.; Zhou, F.; Li, Y.; Liu, Y. Model research of real-time calculation for single-core cable temperature considering axial heat transfer. High Volt. Eng. 2012, 38, 1877–1883. [Google Scholar] [CrossRef]

- You, L.; Wang, J.; Liu, G.; Ma, H.; Zheng, M. Thermal rating of offshore wind farm cables installed in ventilated J-tubes. Energies 2018, 11, 545. [Google Scholar] [CrossRef]

| Model Components | Geometric Parameters (mm) |

|---|---|

| Radius of the ground wire | 4.5 |

| Thickness of the armor rod | 3.6 |

| Height of the conductive bridge/air gap | 0.1 |

| Radius of the air field | 10 |

| Physical Properties | Value |

|---|---|

| Conductivity (S/m) | 6 × 106 |

| Relative permeability | 300~4000 |

| Relative permittivity | 1 |

| Thermal conductivity (W/(m·K)) | 420 |

| Current (A) | Ssqu | Conductive Bridge Radii (mm) |

|---|---|---|

| 55 | 0.0307 | 0.0340 |

| 68 | 0.0358 | 0.0335 |

| 76 | 0.0367 | 0.0340 |

| Conductive Bridge Radius r (mm) | Rd1 (μΩ) | Rz1 (μΩ) | Relative Error |

|---|---|---|---|

| 0.0340 | 655.9 | 675.3 | 3.0% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Guo, D.; Wang, P.; Deng, H.; Hong, X.; Tang, W. Calculation of Equivalent Resistance for Ground Wires Twined with Armor Rods in Contact Terminals. Energies 2018, 11, 737. https://doi.org/10.3390/en11040737

Liu G, Guo D, Wang P, Deng H, Hong X, Tang W. Calculation of Equivalent Resistance for Ground Wires Twined with Armor Rods in Contact Terminals. Energies. 2018; 11(4):737. https://doi.org/10.3390/en11040737

Chicago/Turabian StyleLiu, Gang, Deming Guo, Pengyu Wang, Honglei Deng, Xiaobin Hong, and Wenhu Tang. 2018. "Calculation of Equivalent Resistance for Ground Wires Twined with Armor Rods in Contact Terminals" Energies 11, no. 4: 737. https://doi.org/10.3390/en11040737

APA StyleLiu, G., Guo, D., Wang, P., Deng, H., Hong, X., & Tang, W. (2018). Calculation of Equivalent Resistance for Ground Wires Twined with Armor Rods in Contact Terminals. Energies, 11(4), 737. https://doi.org/10.3390/en11040737