Experimental Study on Breakdown Characteristics of Transformer Oil Influenced by Bubbles

Abstract

:1. Introduction

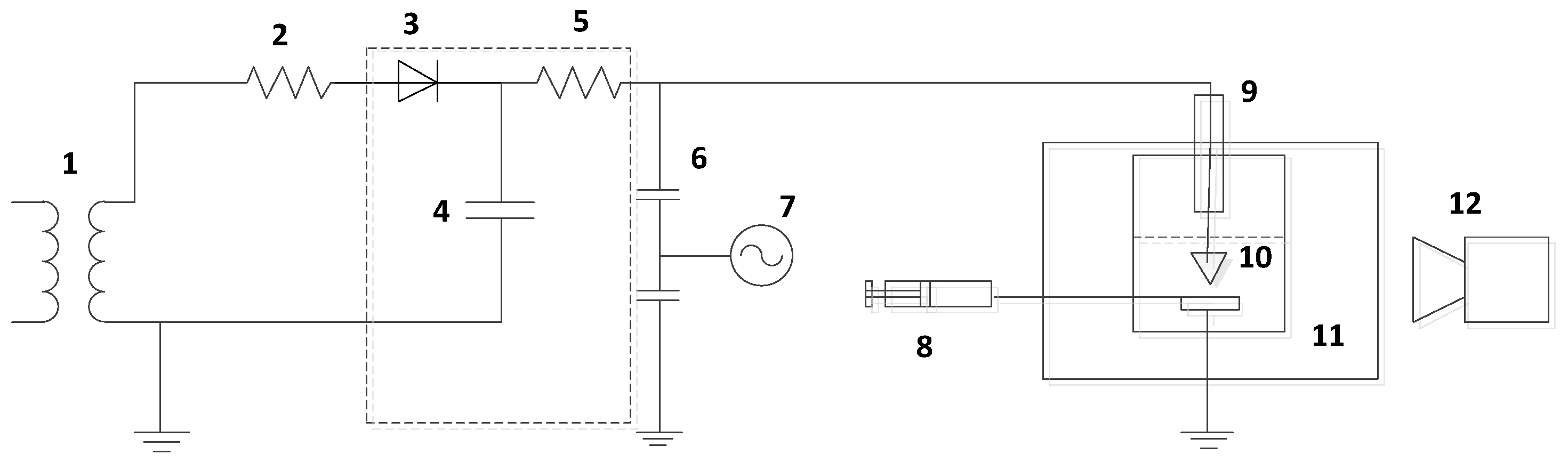

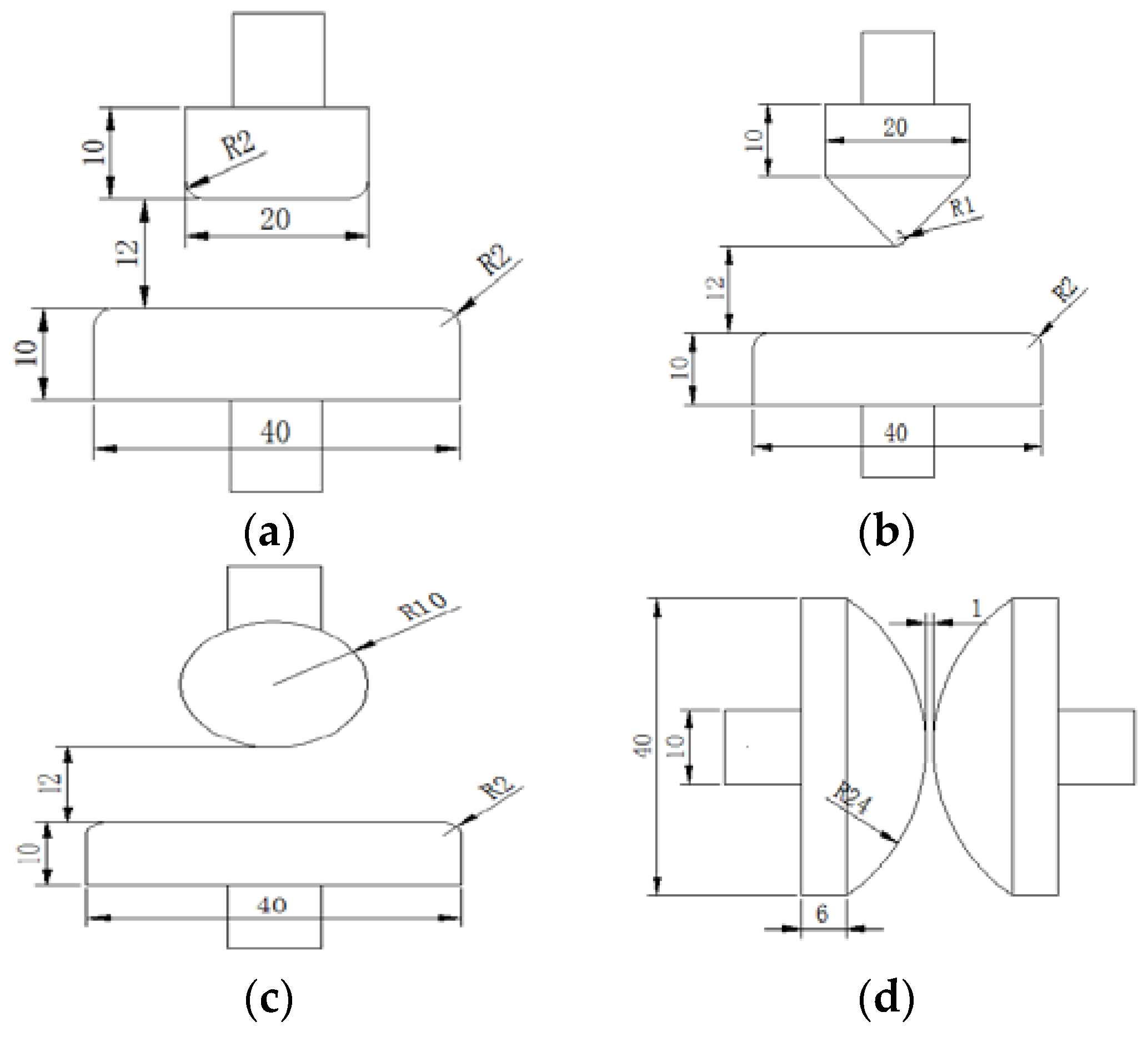

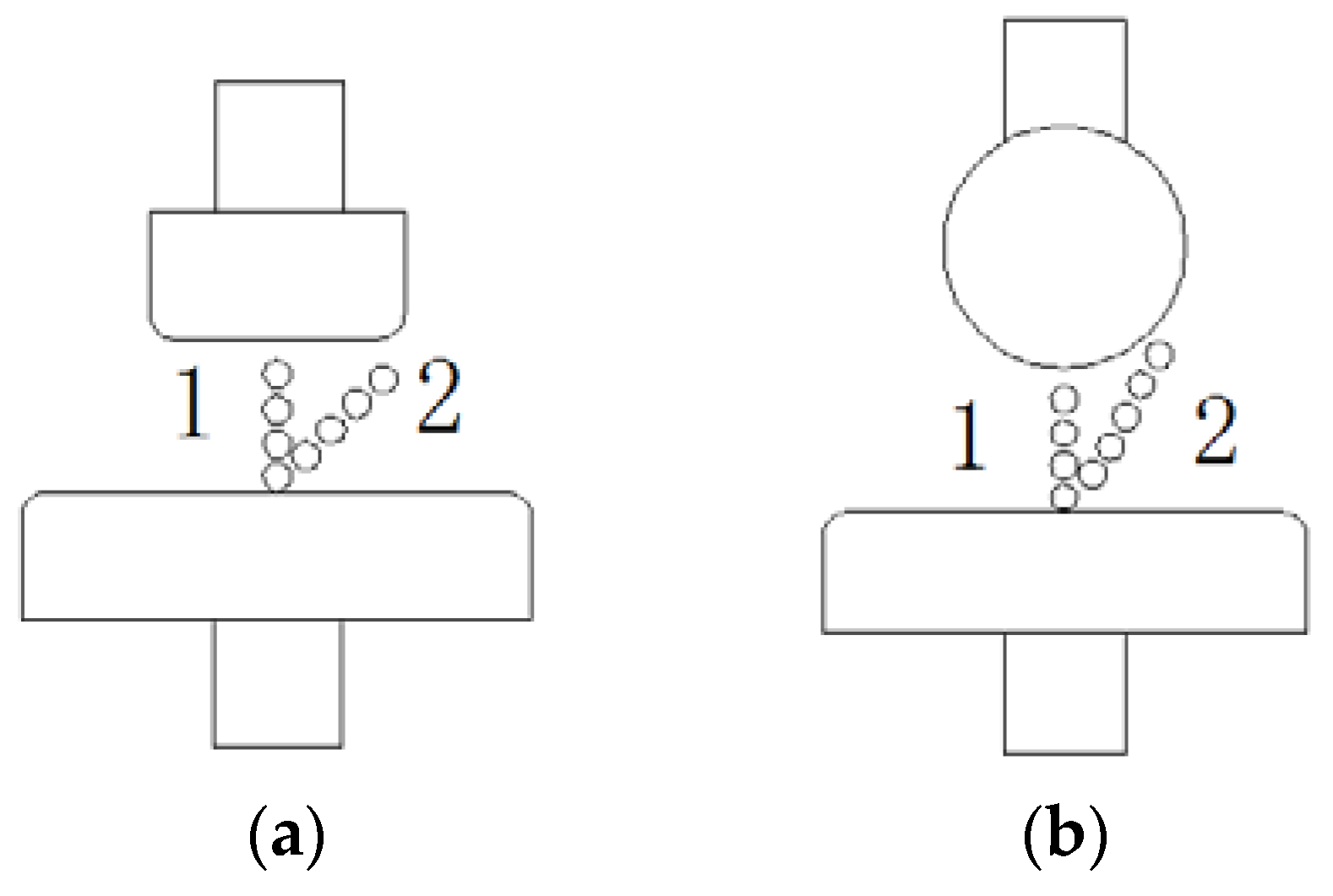

2. Experimental Methods

2.1. Experimental System

2.2. Test Method

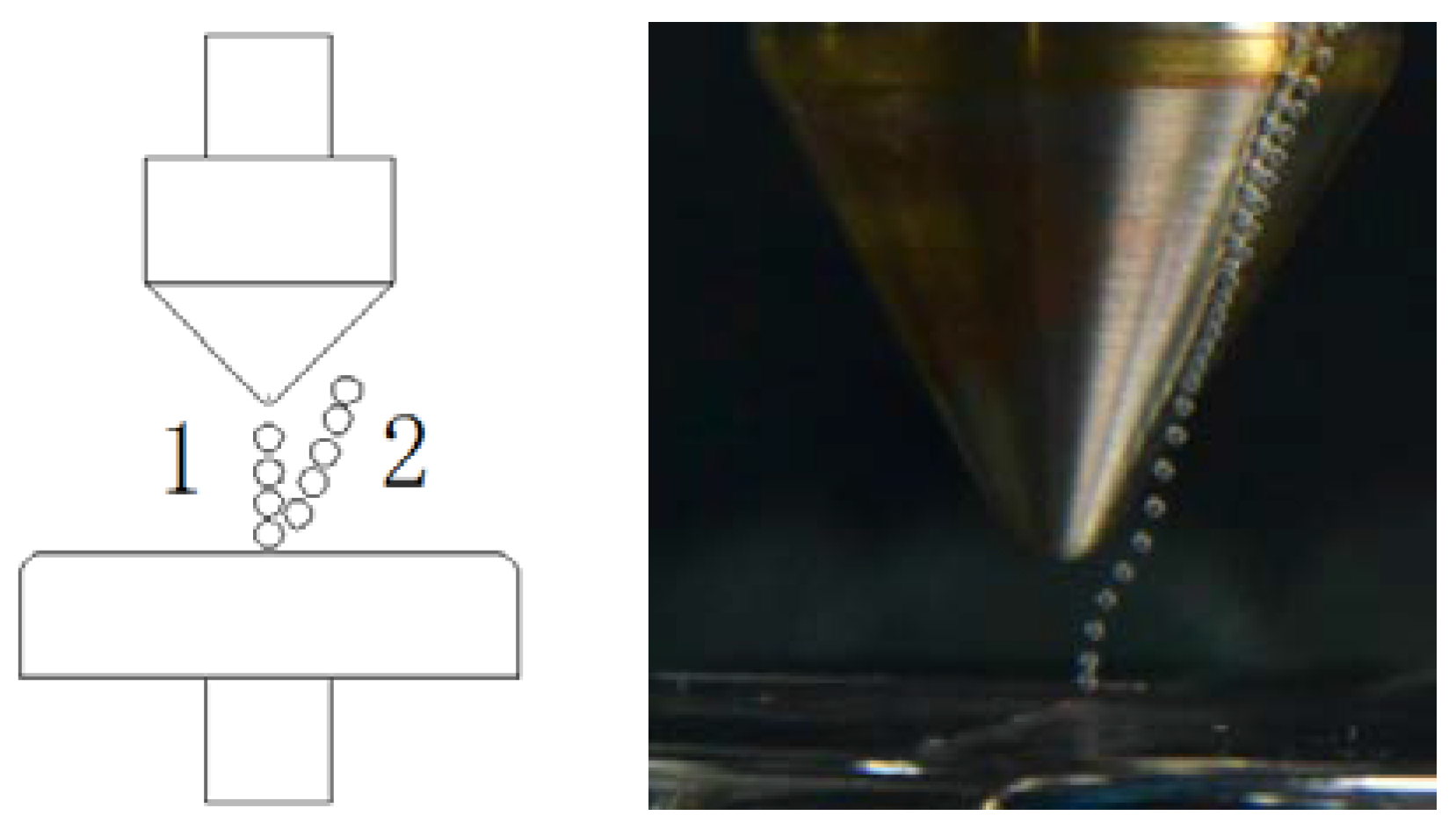

2.2.1. The Breakdown of the Oil

- Before voltage was applied, about 7 L of initial oil was put into the electrode systems, and the oil’s surface is 5 cm above the electrodes. After 30 min’ standing, the bubbles were injected by a syringe at a speed of three bubbles per second, and the bubbles linked the two electrodes. The bubbles were injected all the time until the breakdown occurred.

- Then, AC or DC voltages were applied on the electrodes at the rate of voltage rise of 1 kV/s until breakdown of the oil. We then waited 0.5 h.

- We changed the oil and repeated the tests.

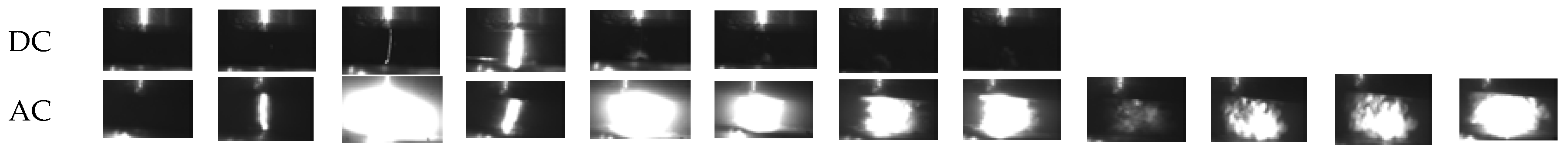

- All of the discharges were recorded by the high-speed camera.

2.2.2. The Breakdown of the Oil-Impregnated Pressboard

- AC or DC voltages were applied on the electrodes and the rate of voltage rise was 1 kV/s until breakdown. We changed the pressboard, mixed the oil, and then waited 0.5 h.

- Using a vacuum to reduce air pressure to 100 Pa, the bubbles appeared on the oil-impregnated pressboard. AC or DC voltages were applied to the electrodes and the rate of voltage rise was 1 kV/s until breakdown of the insulation.

- We mixed the oil, changed the oil-impregnated pressboard, and repeated steps 1 and 2.

- All of the discharges were recorded by the high-speed camera.

3. Results and Discussion

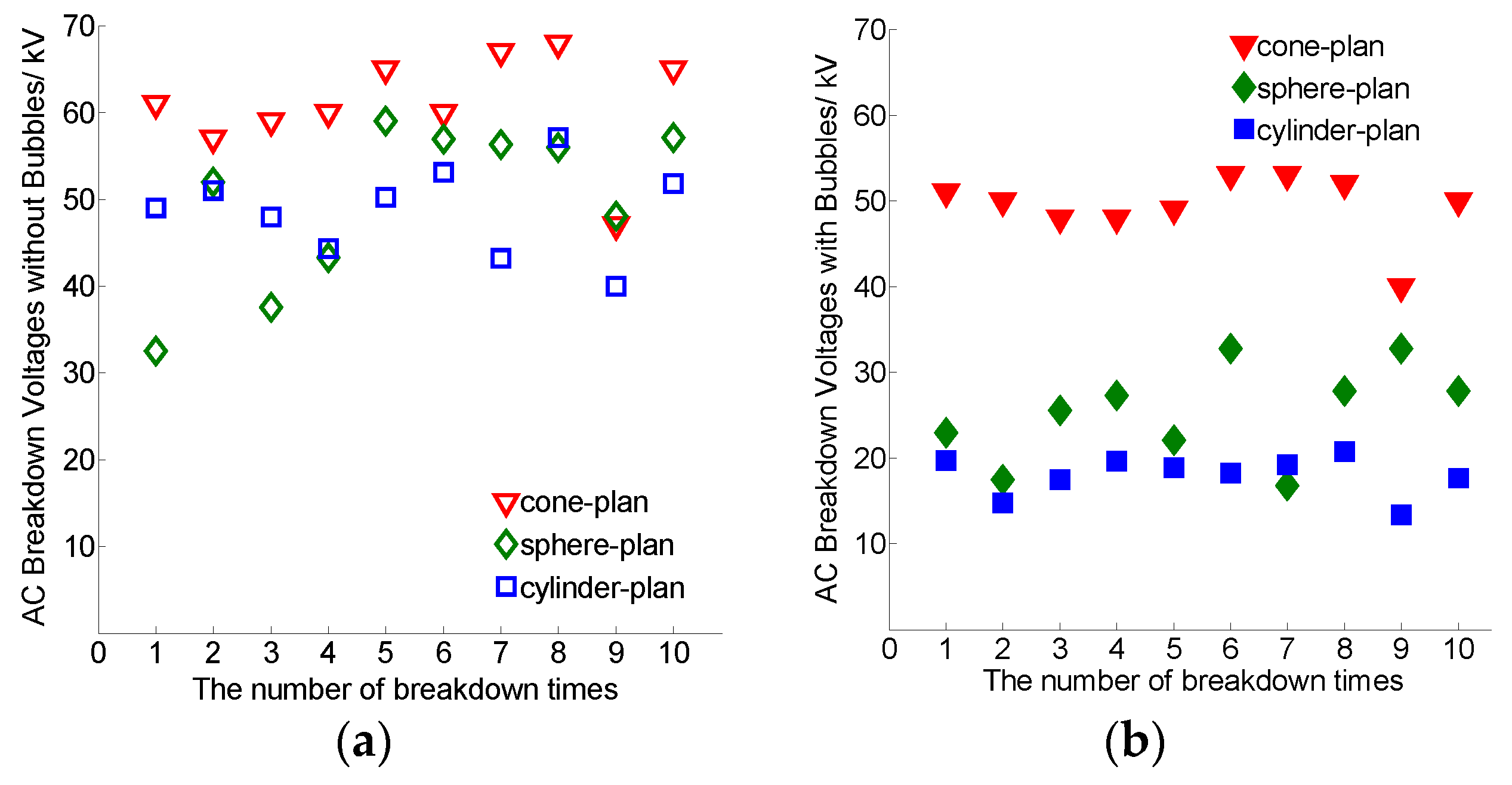

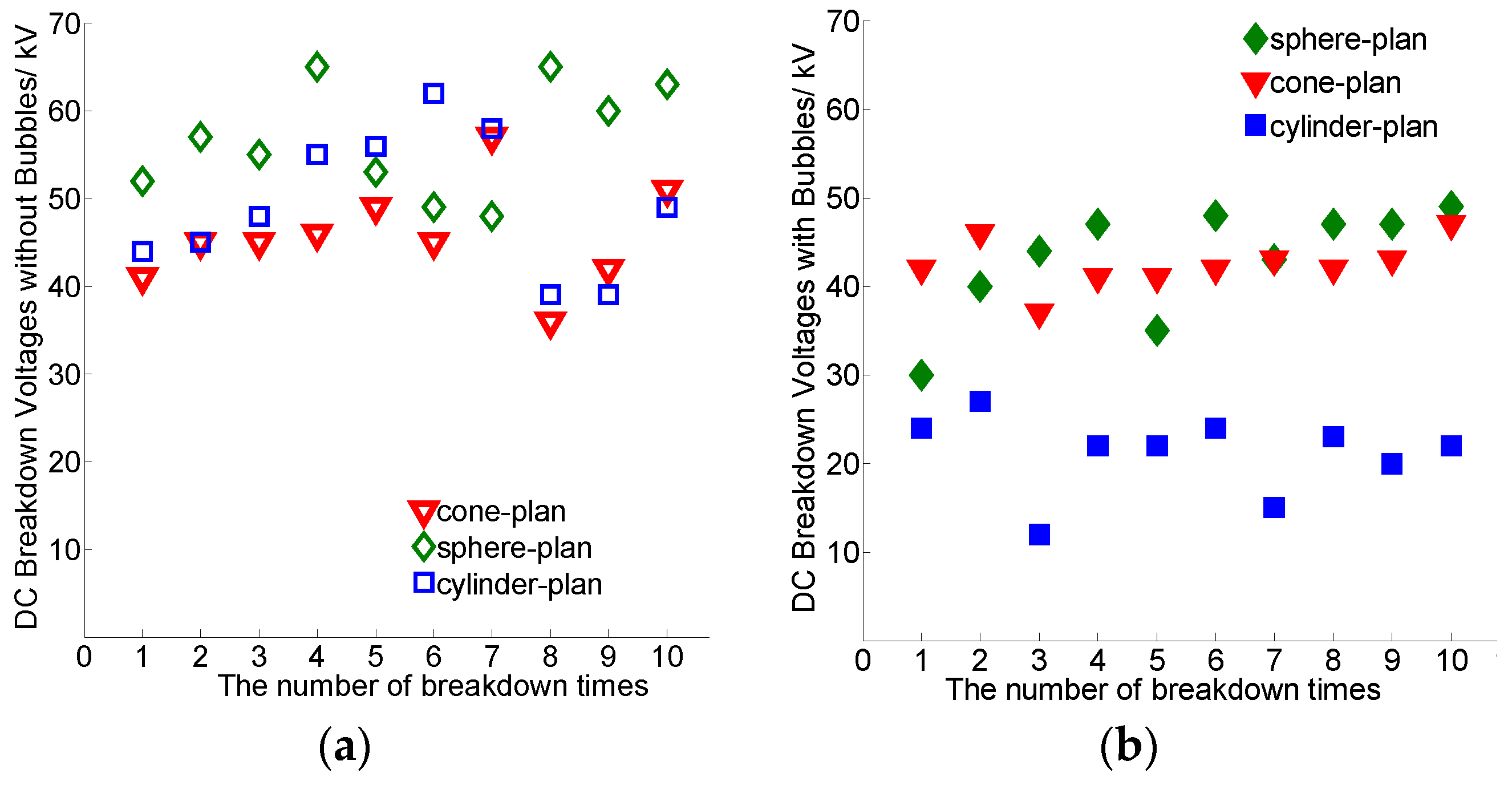

3.1. AC Breakdown Voltages of the Transformer Oil

3.2. Positive DC Breakdown Voltages of the Transformer Oil

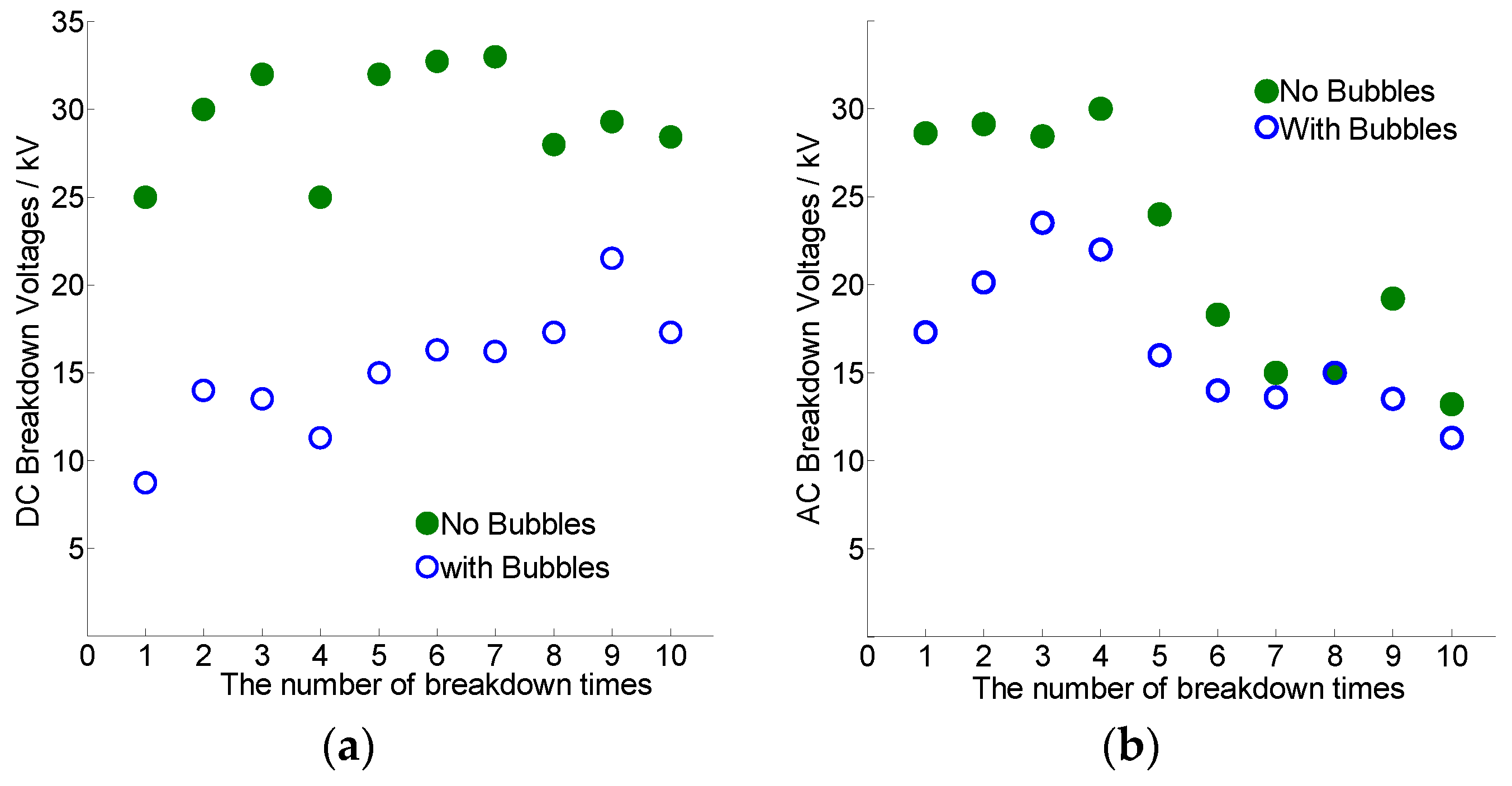

3.3. The Breakdown Voltages of the Oil-Impregnated Pressboard

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Liao, R.; Ying, L.; Zheng, H.; Ma, Z. Reviews on oil-paper insulation thermal aging in power transformers. Trans. China Elctrotech. Soc. 2012, 27, 1–12. [Google Scholar]

- Yin-biao, S. Present status and prospect of HVDC transmission in China. High Volt. Eng. 2004, 30, 1–2. [Google Scholar]

- You-liang, S.; Qing-pu, W.; Wen-ping, L. R&D ofconverter transformer for ±800 kV HVDC power transmission project. Electr. Equip. 2006, 7, 17–20. [Google Scholar]

- Tao, Z.; Yunpeng, L.; Fangcheng, L.; Ruihong, D. Study on dynamics of the bubble in transformer oil under non-uniform electric field. IET Sci. Meas. Technol. 2016, 10, 498–504. [Google Scholar] [CrossRef]

- Ushakov, V.Y.; Klimkin, V.F.; Korobeynikov, S.M. Impulse Breakdown of Liquids, 1st ed.; Springer: Berlin/Heidelberg, German; GmbH & Co. K: Berlin, German, 2007; ISBN 9783642091858. [Google Scholar]

- Heinrichs, F.W. Bubble formation in power transformer windings at overload temperatures. IEEE Trans. Power Appar. Syst. 1979, PAS-98, 1576–1582. [Google Scholar] [CrossRef]

- Kaufmann, G.H.; McMillen, C.J. Gas bubble studies and impulse tests on distribution transformers during loading-above nameplate rating. IEEE Trans. Power Appar. Syst. 1983, PAS-102, 2531–2542. [Google Scholar] [CrossRef]

- Oommen, T.V.; Lindgren, S.R. Bubble evolution from transformer overload. Transm. Distrib. Conf. Expo. 2001, 1, 137–142. [Google Scholar]

- Koch, M.; Tenbohlen, S. Evolution of bubbles in oil-pressboard insulation influenced by material quality and ageing. IET Electr. Power Appl. 2011, 5, 168–174. [Google Scholar] [CrossRef]

- Przybylek, P. The influence of cellulose insulation aging degree on its water sorption properties and bubble evolution. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 906–912. [Google Scholar] [CrossRef]

- Przybylek, P.; Nadolny, Z.; Moscicka-Grzesiak, H. Bubble effect as a consequence of dielectric losses in cellulose insulation. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 913–919. [Google Scholar] [CrossRef]

- Przybylek, P.; Moranda, H.; Walczak, K.; Moscicka-Grzesiak, H. Can the bubble effect occur in an oil-impregnated pressboard bushing. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1879–1883. [Google Scholar] [CrossRef]

- Perkasa, C.Y.; Nick, L.; Tadeusz, C.; Jaury, W.; Daniel, M. A Comparison of the Formation of Bubbles and Water Droplets in Vegetable and Mineral Oil Impregnated Transformer pressboard. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2111–2118. [Google Scholar] [CrossRef]

- Sharbaugh, H.; Devins, J.S.; Rzad, S.J. Progress in the field of electric breakdown in dielectric liquids. IEEE Trans. Electr. Insul. 1978, 13, 249–276. [Google Scholar] [CrossRef]

- Ogata, S.; Shigehara, K.; Yoshida, T.; Shinohara, H. Small bubble formation by using strong non-uniform electric field. IEEE Trans. Ind. Appl. 1980, IA-16, 766–770. [Google Scholar] [CrossRef]

- Hara, M.; Koishihara, H.; Saita, K. Breakdown behavior of cryogenic liquids in the presence of thermal bubbles under ramped voltage. IEEE Trans. Dielectr. Electr. Insul. 1991, 26, 685–691. [Google Scholar] [CrossRef]

- Seok, B.Y.; Tamuro, N.; Hara, M. A study of thermal bubble behavior in the simulated electrode system of HT superconducting coils. IEEE Trans. Dielectr. Electr. Insul. 1999, 6, 109–116. [Google Scholar] [CrossRef]

- Hara, M.; Kubuki, M. Effect of thermally induced bubbles on the electrical breakdown characteristics of liquid nitrogen. Proc. IEE 1990, 137, 209–216. [Google Scholar]

- Hara, M.; Wang, Z.; Saito, H. Thermal Bubble Breakdown in Liquid Nitrogen under Nonuniform Fields. IEEE Trans Dielectr. Electr. Insul. 1994, 4, 709–716. [Google Scholar] [CrossRef]

- Gan, D.; Liu, F.; Liu, P.; Hu, C. Calculation Method of Oil-Paper Insulation Moisture Content Based on Oil-Paper Moisture Equilibrum of Transformer. Transformer 2009, 8, 21–24. [Google Scholar]

- Dissado, L.A. Theoretical basis for the statistics of dielectric breakdown. J. Phys. D Appl. Phys. 1990, 23, 1582–1591. [Google Scholar] [CrossRef]

- Peppas, G.D.; Charalampakos, V.P.; Pyrgioti, E.C.; Danikas, M.G.; Bakandritsos, A.; Gonos, I.F. Statistical investigation of AC breakdown voltage of nanofluids compared with mineral and natural ester oil. IET Sci. Meas. Technol. 2016, 10, 644–652. [Google Scholar] [CrossRef]

- You, Z.; Jun, J.; Yingting, L.; Hao, W.; Yuzhen, L.; Chengrong, L. Statistical Analysis of AC Breakdown Voltage for Transformer Oil. Insul. Mater. 2015, 48, 73–77. [Google Scholar]

- Wang, Y.; Wei, X.; Chen, Q. Breakdown Characteristics of Oil-pressboard Insulation in Converter Transformer under Composite Electric Field and Its Test Method. High Volt. Eng. 2011, 37, 2005–2011. [Google Scholar]

| Dielectric Liquid | Moisture (ppm) | Viscosity (mm2/s), 40 °C | Flash Point (°C) | Tan δ (90 °C, 50 Hz) | Acid Number (mg∙KOH/g) |

|---|---|---|---|---|---|

| KI25X | ≤40 | 10.13 | 142 | 0.0006 | 0.05 |

| Electrode Systems | Cone-Plan | Sphere-Plan | Cylinder-Plan | |

|---|---|---|---|---|

| With bubbles | Mean BDV (kV) | 49.4 | 25.3 | 18 |

| Std. Deviation (kV) | 3.8 | 5.5 | 2.3 | |

| Min BDV (kV) | 40 | 16.8 | 13.4 | |

| Max BDV0 (kV) | 53 | 32.8 | 20.8 | |

| Without bubbles | Mean BDV (kV) | 60.9 | 49.9 | 48.8 |

| Std. Deviation (kV) | 6.1 | 9.2 | 5.1 | |

| Min BDV (kV) | 47 | 32.5 | 40 | |

| Max BDV (kV) | 68 | 59 | 57.1 | |

| Electrode Systems | Cone-Plan | Sphere-Plan | Cylinder-Plan | |

|---|---|---|---|---|

| With bubbles | Mean BDV (kV) | 42.4 | 43 | 21.1 |

| Std. Deviation (kV) | 2.7 | 6.2 | 4.4 | |

| Min BDV (kV) | 37 | 30 | 12 | |

| Max BDV (kV) | 47 | 49 | 27 | |

| Without bubbles | Mean BDV (kV) | 45.7 | 56.7 | 49.5 |

| Std. Deviation (kV) | 5.7 | 6.3 | 8.0 | |

| Min BDV (kV) | 36 | 48 | 39 | |

| Max BDV (kV) | 42.4 | 43 | 21.1 | |

| Electrode Systems | AC | AC* | DC | |

|---|---|---|---|---|

| With bubbles | Mean BDV (kV) | 16.6 | 19 | 15.1 |

| Std. Deviation (kV) | 4.0 | 3.1 | 3.5 | |

| Min BDV (kV) | 11.3 | 16 | 8.7 | |

| Max BDV (kV) | 23.5 | 23.5 | 21.5 | |

| Without bubbles | Mean BDV (kV) | 22.8 | 28 | 29.5 |

| Std. Deviation (kV) | 6.6 | 2.3 | 2.9 | |

| Min BDV (kV) | 13.2 | 29.1 | 25 | |

| Max BDV (kV) | 30 | 16 | 33 | |

| Voltages | AC | DC | ||

|---|---|---|---|---|

| Test No. | No Bubbles | Bubbles | No Bubbles | Bubbles |

| 1 | Breakdown | Breakdown | Breakdown | Flashover |

| 2 | Breakdown | Breakdown | Breakdown | Flashover |

| 3 | Breakdown | Breakdown | Breakdown | Flashover |

| 4 | Breakdown | Breakdown | Breakdown | Flashover |

| 5 | Breakdown | Breakdown | Breakdown | Flashover |

| 6 | Breakdown | Flashover | Breakdown | Flashover |

| 7 | Breakdown | Breakdown | Breakdown | Flashover |

| 8 | Breakdown | Breakdown | Breakdown | Flashover |

| 9 | Breakdown | Breakdown | Breakdown | Breakdown |

| 10 | Breakdown | Breakdown | Breakdown | Flashover |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, C.; He, Y.; Shi, B.; Zhao, T.; Lv, F.; Cheng, X. Experimental Study on Breakdown Characteristics of Transformer Oil Influenced by Bubbles. Energies 2018, 11, 634. https://doi.org/10.3390/en11030634

Qin C, He Y, Shi B, Zhao T, Lv F, Cheng X. Experimental Study on Breakdown Characteristics of Transformer Oil Influenced by Bubbles. Energies. 2018; 11(3):634. https://doi.org/10.3390/en11030634

Chicago/Turabian StyleQin, Chunxu, Yan He, Bing Shi, Tao Zhao, Fangcheng Lv, and Xiangrui Cheng. 2018. "Experimental Study on Breakdown Characteristics of Transformer Oil Influenced by Bubbles" Energies 11, no. 3: 634. https://doi.org/10.3390/en11030634

APA StyleQin, C., He, Y., Shi, B., Zhao, T., Lv, F., & Cheng, X. (2018). Experimental Study on Breakdown Characteristics of Transformer Oil Influenced by Bubbles. Energies, 11(3), 634. https://doi.org/10.3390/en11030634