A High-Precision Adaptive Thermal Network Model for Monitoring of Temperature Variations in Insulated Gate Bipolar Transistor (IGBT) Modules

Abstract

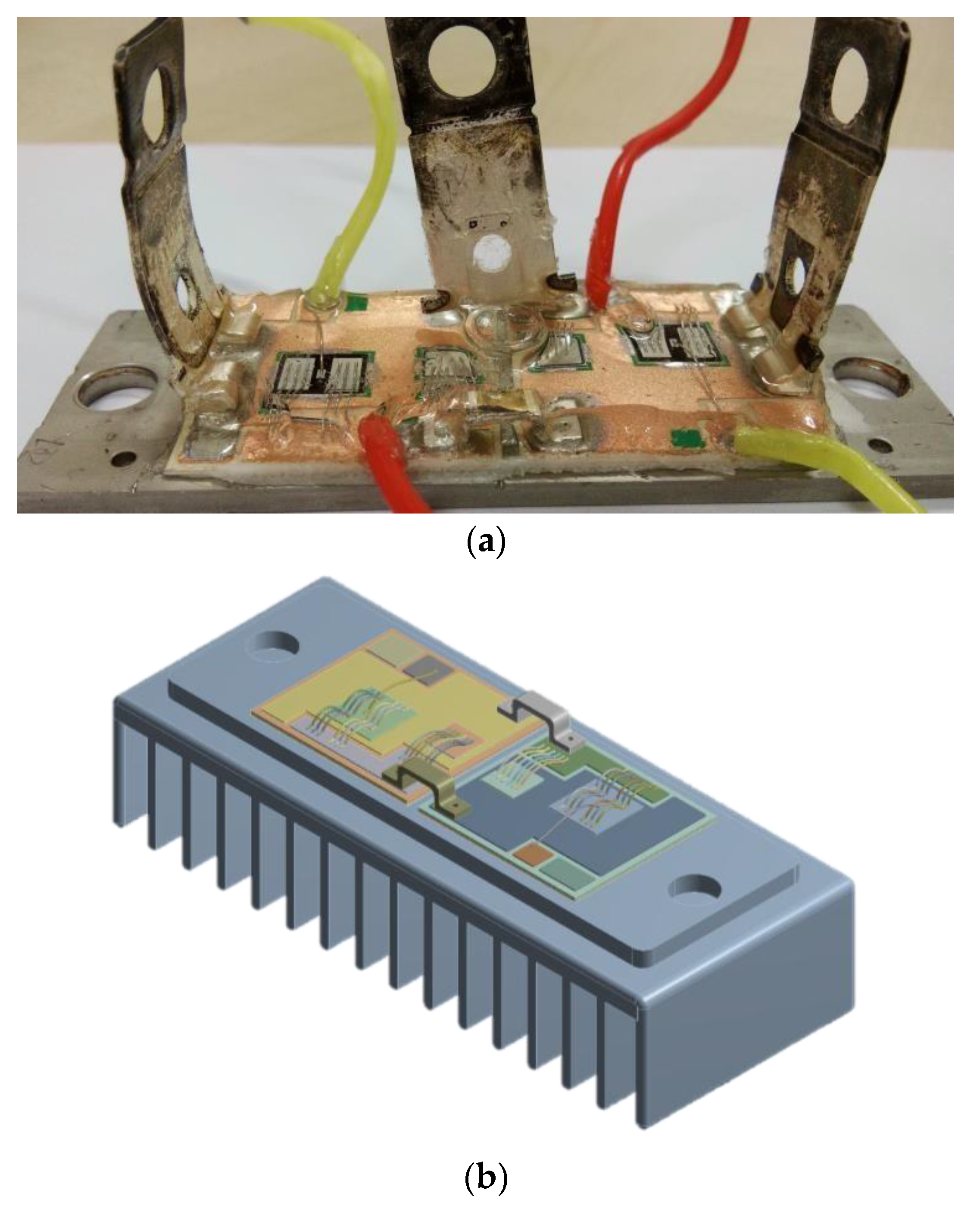

1. Introduction

- (a)

- Obvious improvement of the accuracy of the prediction of the steady-state junction temperature, considering the influence of temperature.

- (b)

- Efficient improvement of the prediction performance of the transient junction temperature by redefining the hierarchical Cauer-type architecture for the internal structure of the module.

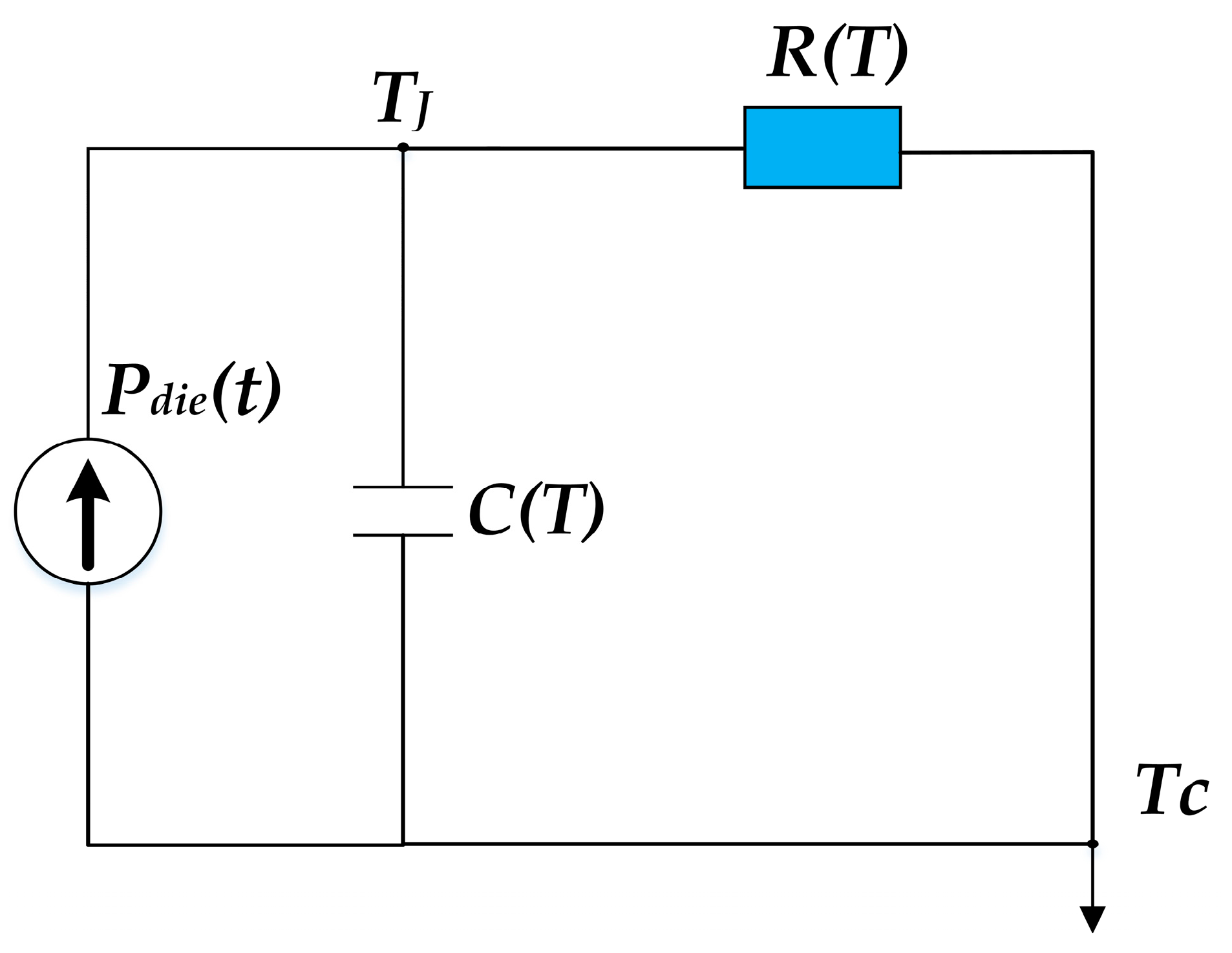

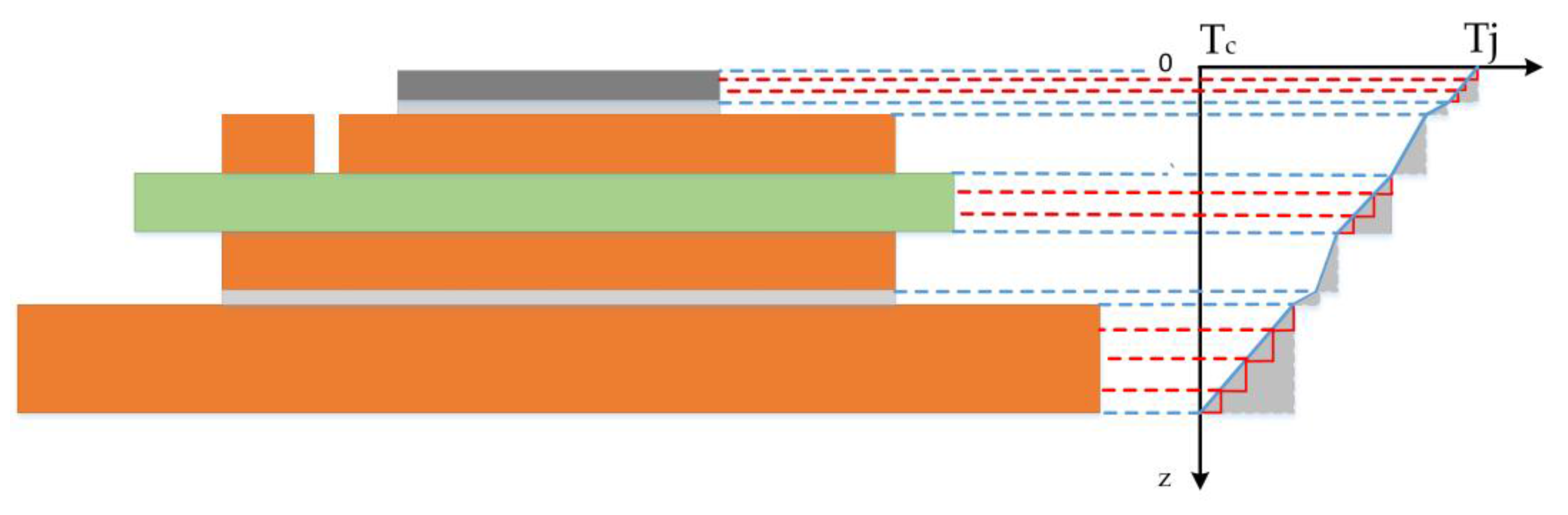

2. Methods

- (a)

- Tjcs is determined by the power loss when the time constant is same. The larger power loss, the higher Tjcs.

- (b)

- Compared with the results about ts1, the deviation of ts2 calculated by Equation (12) is always kept in a small range.

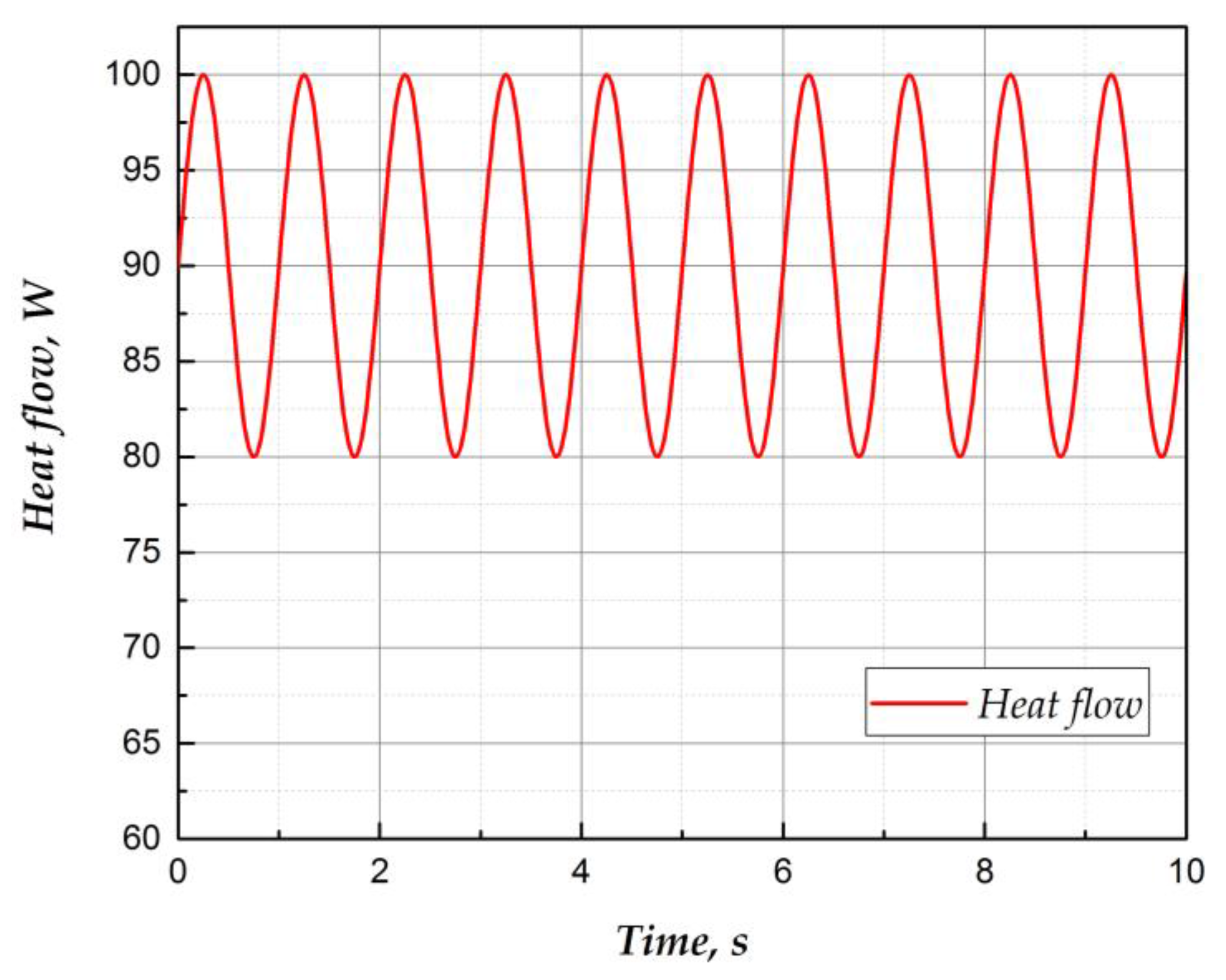

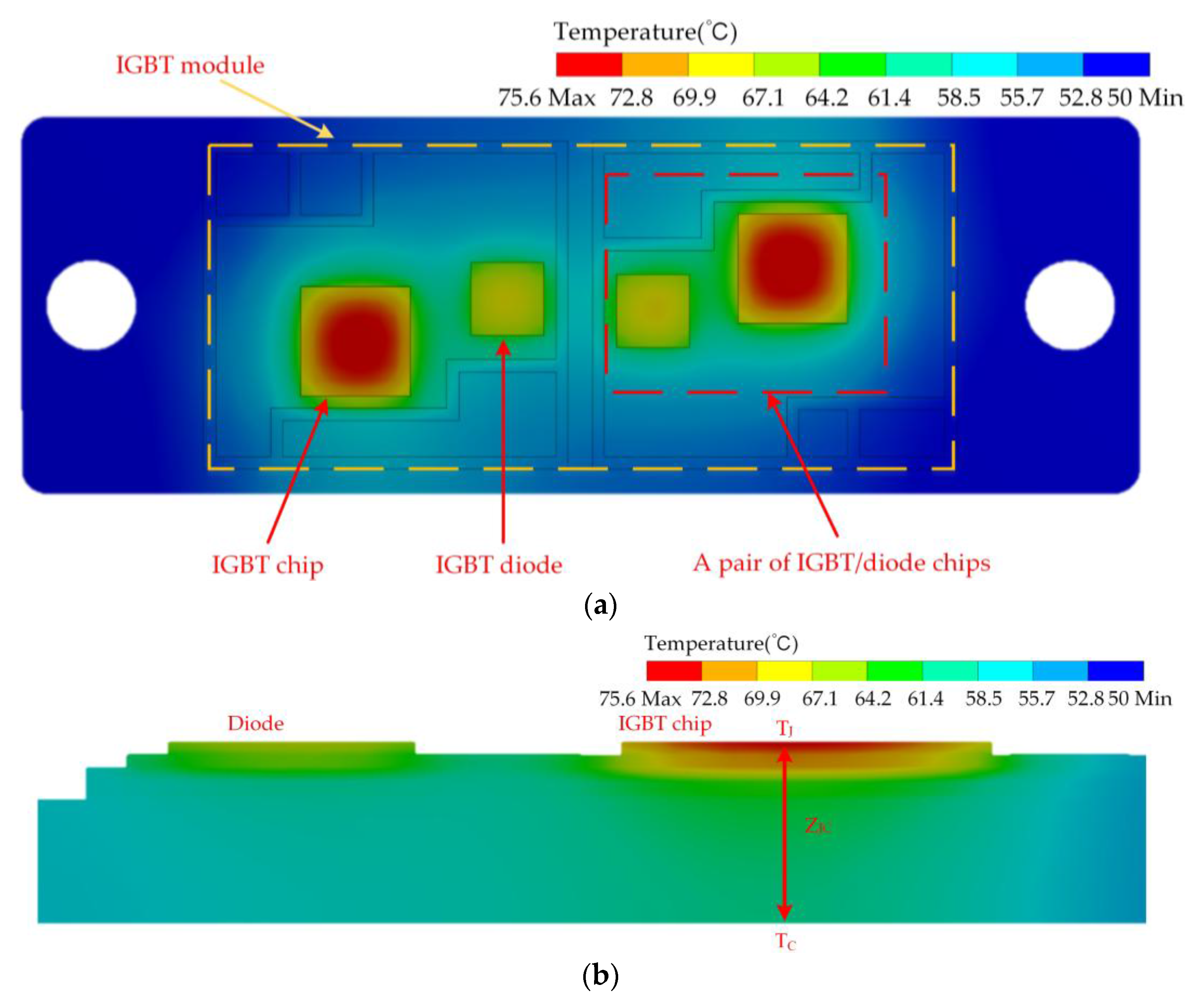

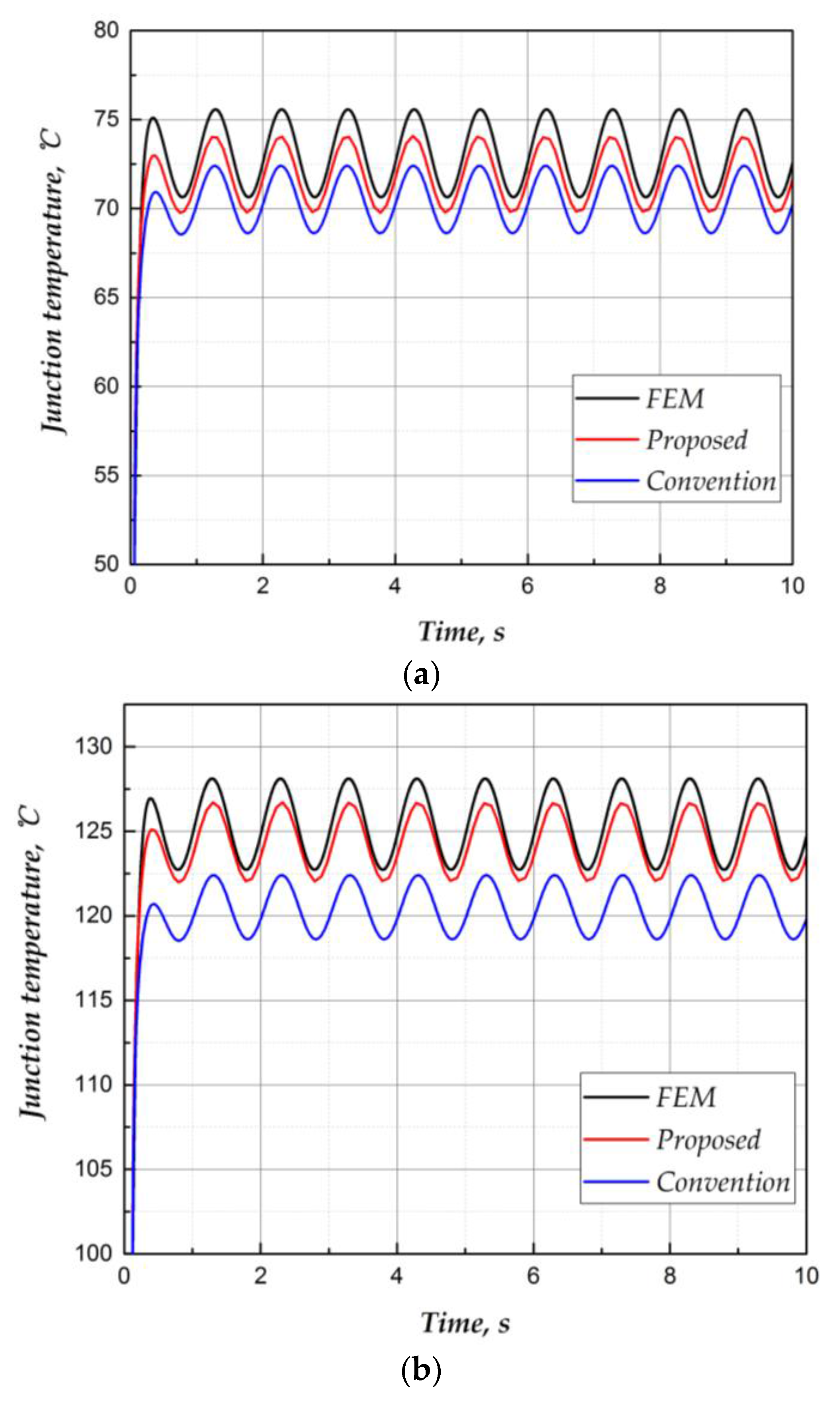

3. Simulation Validation

4. Experimental Validation

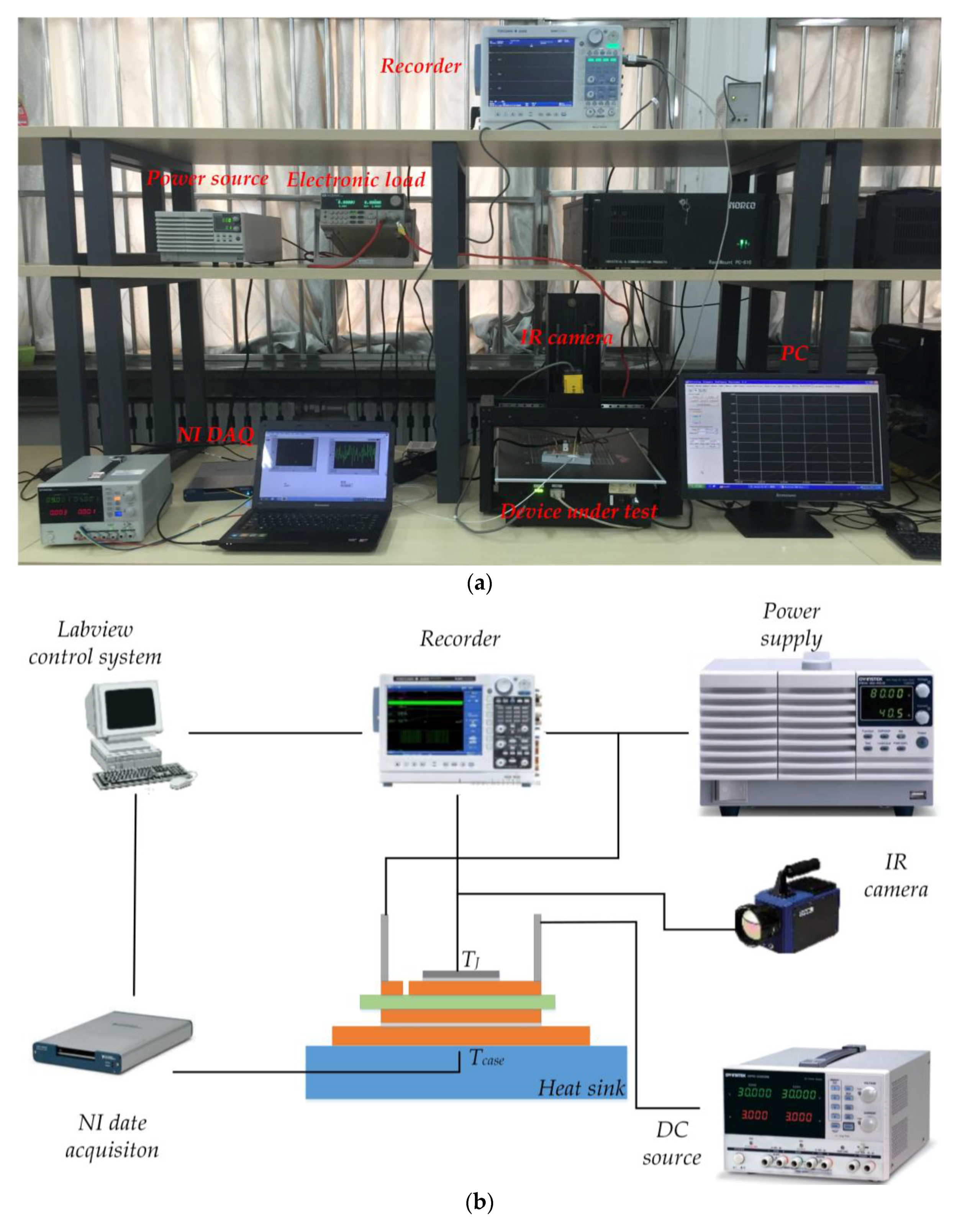

4.1. Experiment Setup

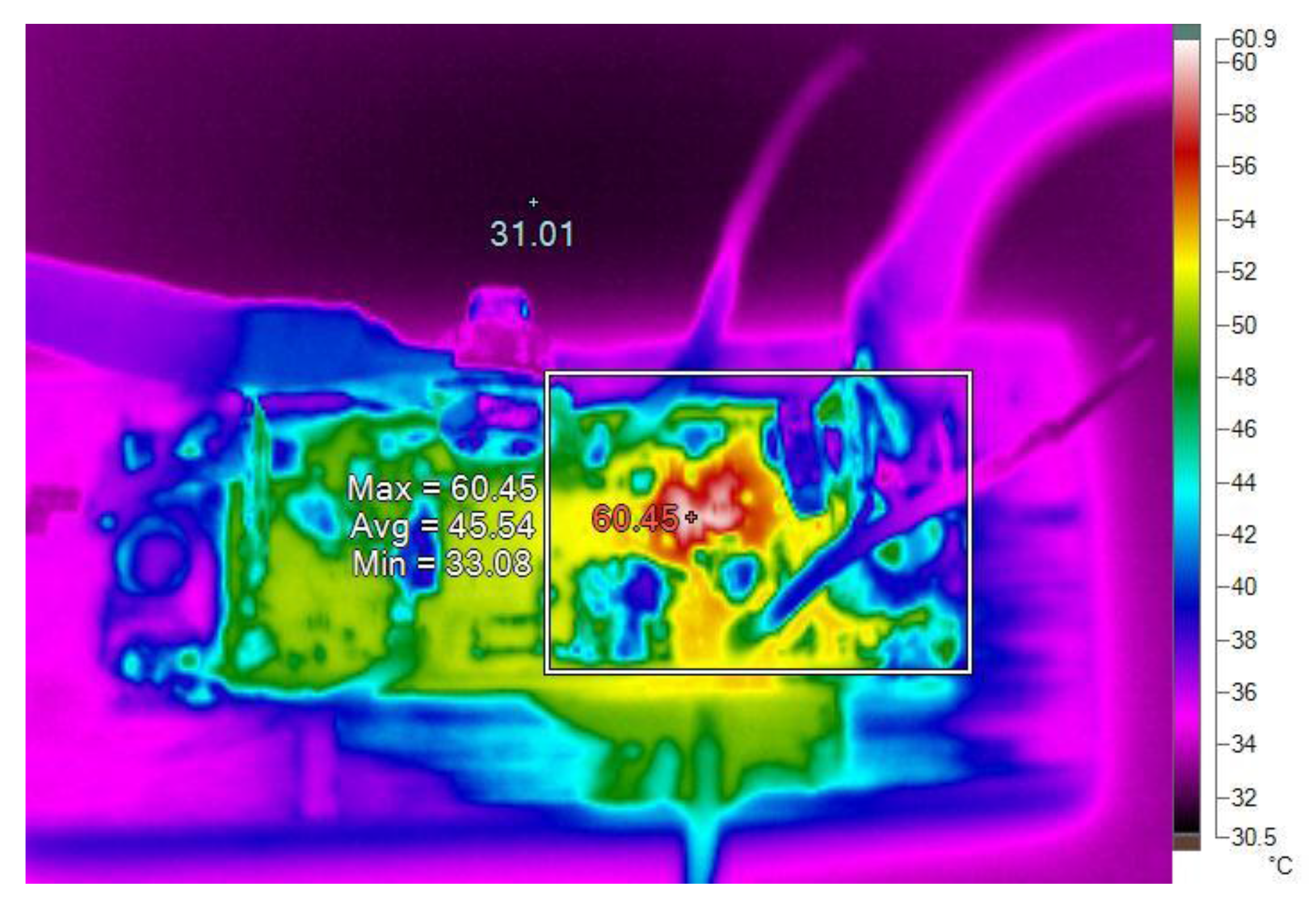

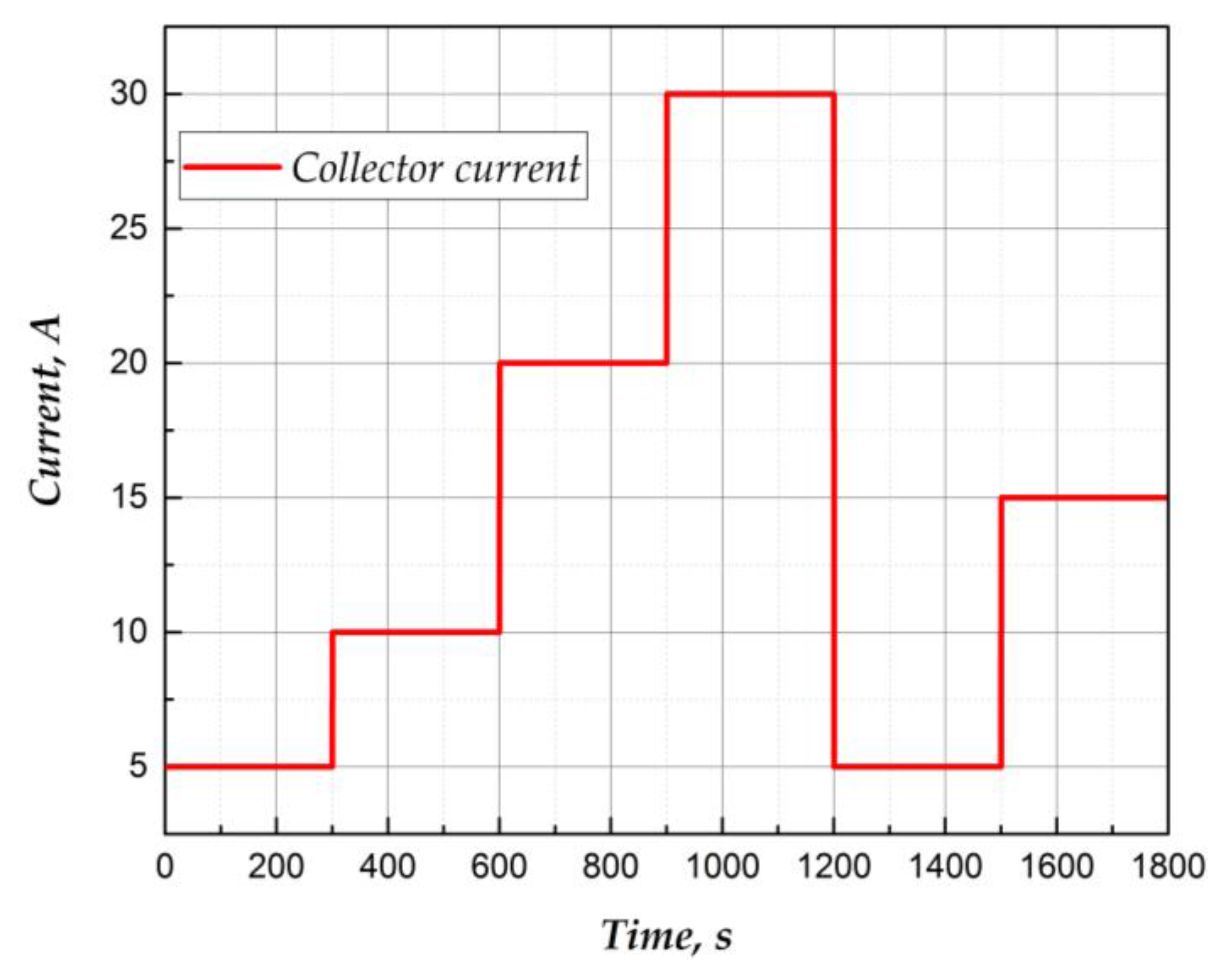

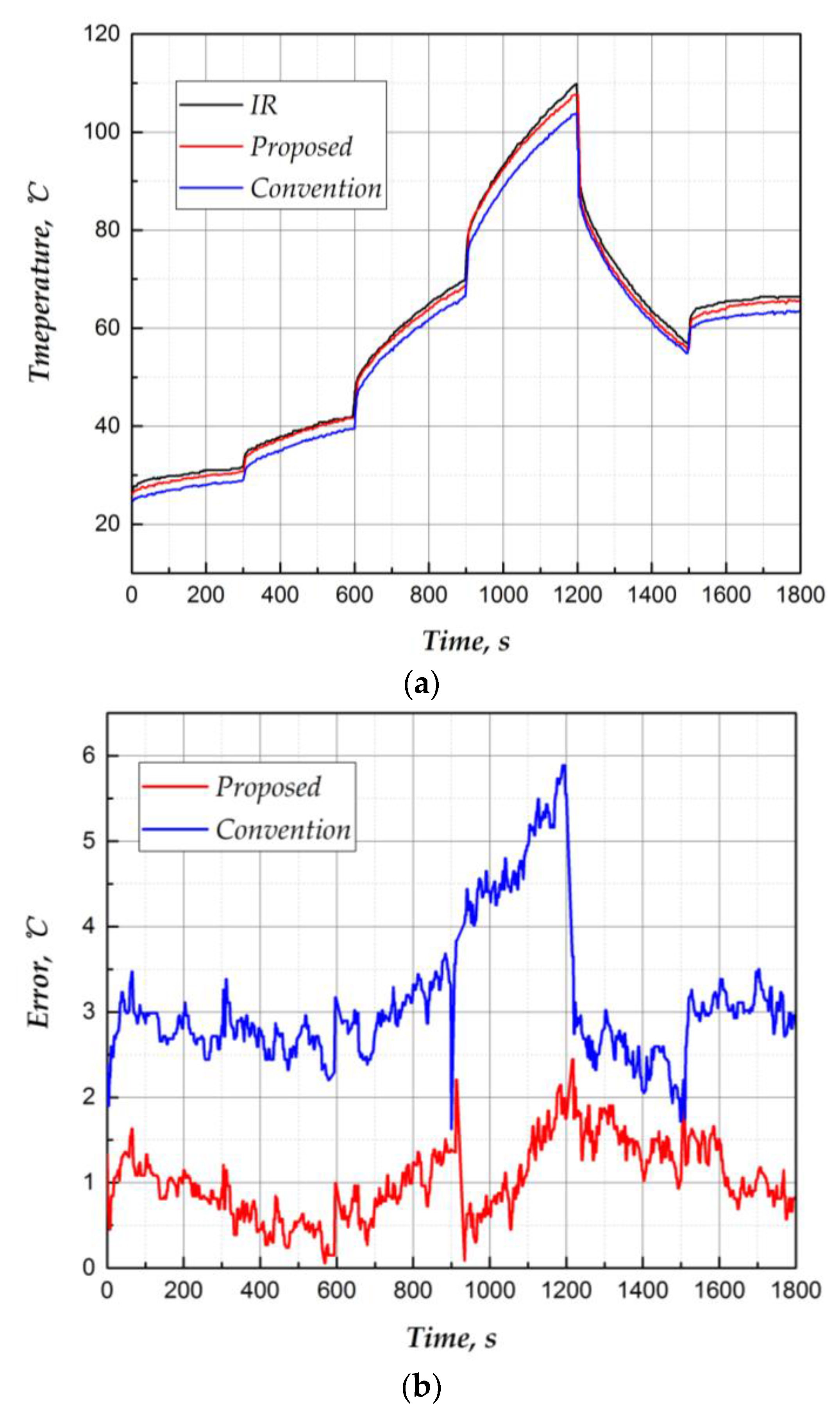

4.2. Variable Current Test

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Blaabjerg, F.; Ma, K. Future on power electronics for wind turbine systems. IEEE Trans. Power Electron. 2013, 1, 139–152. [Google Scholar] [CrossRef]

- Ji, B.; Pickert, V.; Cao, W. In situ diagnostics and prognostics of wire bonding faults in IGBT modules for electric vehicle. IEEE Trans. Power Electron. 2013, 28, 5568–5577. [Google Scholar] [CrossRef]

- Xu, Z.; Li, M.; Wang, F. Investigation of Si IGBT operation at 200°C for traction application. IEEE Trans. Power Electron. 2013, 28, 2604–2615. [Google Scholar] [CrossRef]

- Cao, W.; Mevrow, B.; Atkinson, G.J. Overview of electric motor technologies used for more electric aircraft (MEA). IEEE Trans. Ind. Electron. 2012, 59, 3523–3531. [Google Scholar]

- Senturk, O.; Helle, L.; Munk-Nielsen, S. Power capability investigation based on electrothermal models of press-pack IGBT three-level NPC and ANPC VSCs for multimegawatt wind turbines. IEEE Trans. Power Electron. 2012, 27, 3195–3206. [Google Scholar] [CrossRef]

- Li, H.; Hu, Y.; Liu, S. An improved thermal network model of the IGBT module for wind power converters considering the effects of base plate solder fatigue. IEEE Trans. Device Mater. Reliab. 2016, 16, 570–575. [Google Scholar] [CrossRef]

- Gong, X.; Ferreira, J.A. Comparison and reduction of conducted EMI in SiC JFET and Si IGBT-based motor drives. IEEE Trans. Power Electron. 2014, 29, 1757–1767. [Google Scholar] [CrossRef]

- Kexin, W.; Mingxing, D.; Linlin, X. Study of bonding wire faliure effects on external measurable signals of IGBT module. IEEE Trans. Device Mater. Reliab. 2014, 14, 83–89. [Google Scholar] [CrossRef]

- Shaoyong, Y.; Angus, B.; Philip, M.; Dawei, X.; Li, R.; Peter, T. An industry-based survey of reliability in power electronic converter. IEEE Trans. Ind. Appl. 2011, 47, 3151–3157. [Google Scholar] [CrossRef]

- Ismail, M.A.; Tamchek, N. A fiber bragg grating—Bimetal temperature sensor for solar panel inverters. Sensors 2011, 11, 8665–8673. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Mei, W.; Zeng, X.; Zhou, X. Remaining useful life estimation of insulated gate bipolar transistors (IGBTs) based on a novel volterra k-nearest neighbor optimally pruned extreme learning machine (VKOPP) model using degradation data. Sensors 2017, 17, 2524. [Google Scholar] [CrossRef] [PubMed]

- Zhen, H.; Mingxing, D.; Kexin, W. Online calculation of the increase in thermal resistance caused by solder fatigue for IGBT modules. IEEE Trans. Device Mater. Reliab. 2017, 17, 785–794. [Google Scholar]

- Riccio, M.; Carli, M.; Rossi, L.; Irace, A. Compact electro-thermal modeling and simultaion of large aera multicellular Trench-IGBT. In Proceedings of the 2010 27th International Conference on Microelectronics Proceedings (MIEL), Nis, Serbia, 16–19 May 2010; pp. 379–382. [Google Scholar]

- Dupont, L.; Avenas, Y.; Jeannin, P.-O. Comparison of junction temperature evaluations in a power IGBT module using an IR camera and three thermosensitive electrical parameters. IEEE Trans. Ind. Appl. 2013, 49, 1599–1608. [Google Scholar] [CrossRef]

- Irace, A. Infrared thermography application to functional and failure analysis of electron devices and circuits. Microelectron. Reliab. 2012, 52, 2019–2023. [Google Scholar] [CrossRef]

- Khatir, Z.; Dupont, L.; Ibrahim, A. Investigation on junction temperature estimation based on junction voltage measurements. Microelectron. Reliab. 2010, 50, 1506–1510. [Google Scholar] [CrossRef]

- Cao, X.; Wang, T. Characterization of lead-free solder and sintered nano-silver die-attach layers using thermal impedance. IEEE Trans. Compon. Packag. Manuf. Technol. 2011, 1, 495–501. [Google Scholar] [CrossRef]

- Avenas, Y.; Dupont, L.; Khatir, Z. Temperature measurement of power semiconductor devices by thermos-sensitive electrical parameters—A review. IEEE Trans. Power Electron. 2012, 27, 3081–3092. [Google Scholar] [CrossRef]

- Luo, H.; Chen, Y.; Sun, P. Junction temperature extraction approach with turn-off delay time for high-voltage high-power IGBT modules. IEEE Trans. Power Electron. 2016, 31, 5122–5132. [Google Scholar] [CrossRef]

- Perdersen, K.B.; Kristensen, P.K. Vce as early indicator of IGBT module failure mode. In Proceedings of the IEEE Reliability Physics Symposium, Aalborg, Denmark, 2–6 April 2017; pp. FA-1.1–FA-1.6. [Google Scholar]

- Shabany, Y. Heat Transfer: Thermal Management of Electronics; CRC Press: France, Francis, 2010; pp. 61–65. ISBN 9781439814673. [Google Scholar]

- Codecasa, L.; Dalessandro, V.; Magnani, A.; Irace, A. Circuit-based electrothermal simulation of power devices by an ultrafast nonlinear mor approach. IEEE Trans. Power Electron. 2016, 31, 5906–5916. [Google Scholar] [CrossRef]

- Chen, M.; Hu, A.; Yang, X. Predicting IGBT junction temperature with thermal network component model. In Proceedings of the Asia-Pacific Power and Energy Engineering Conference, Washington, DC, USA, 25–28 March 2011; pp. 1–4. [Google Scholar]

- Ma, K.; He, N.; Liserre, M. Frequency-domain thermal modeling and characterization of power semiconductor devices. IEEE Trans. Power Electron. 2016, 31, 7183–7193. [Google Scholar] [CrossRef]

- Dutta, S.; Parkhideh, B.; Subhashish, D. Development of a predictive observer thermal model for power semiconductor devices for overload monitoring in high power high frequency converters. In Proceedings of the Applied Power Electronics Conference and Exposition, Raleigh, NC, USA, 5–9 February 2012; pp. 2305–2310. [Google Scholar]

- Luo, Z.; Ahn, H. A thermal model for Insulated Gate Bipolar Transistor module. IEEE Trans. Power Electron. 2004, 19, 902–907. [Google Scholar] [CrossRef]

- Ma, K.; Liserre, M.; Blaabjerg, F.; Kerekes, T. Thermal loading and lifetime estimation for power device considering mission profiles in wind power converter. IEEE Trans. Power Electron. 2015, 30, 590–602. [Google Scholar] [CrossRef]

- Bahman, A.S.; Ma, K.; Ghimire, P. A 3-D-Lumped thermal network model for long-term load profiles analysis in high-power IGBT modules. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 1050–1063. [Google Scholar] [CrossRef]

- Tang, Y.; Ma, H. Dynamic electrothermal model of paralleled IGBT modules with unbalanced stray parameters. IEEE Trans. Power Electron. 2017, 32, 1385–1399. [Google Scholar] [CrossRef]

- Tian, B.; Qiao, W.; Wang, Z. Monitoring IGBT’s health condition via junction temperature variations. In Proceedings of the Applied Power Electronics Conference and Exposition, Lincoln, NE, USA, 16–20 March 2014; pp. 2550–2555. [Google Scholar]

- Batard, C.; Ginot, N.; Antonios, J. Lumped dynamic electrothermal model of IGBT module of inverters. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 355–364. [Google Scholar] [CrossRef]

- Yun, C.; Malberti, P.; Ciappa, M.; Fichtner, W. Thermal component model for electrothermal analysis of IGBT module systems. IEEE Trans. Adv. Packag. 2001, 24, 401–406. [Google Scholar]

- Vermeersch, B.; Demey, G. A fixed-angle heat spreading model for dynamic thermal characterization of rear-cooled substrates. In Proceedings of the Semiconductor Thermal Measurement and Management Symposium, San Jose, CA, USA, 18–22 March 2007; pp. 95–101. [Google Scholar]

- Material Home. Available online: http://www.efunda.com/materials/materials_home/materials.cfm (accessed on 18 January 2018).

- Du, B.; Hudgins, J.; Santi, E. Transient electrothermal simulation of power semiconductor devices. IEEE Trans. Power Electron. 2010, 25, 237–248. [Google Scholar]

| Rth (°C/W) | Cth (J/°C) | Power (W) | Tjcs (°C) | ts1 (ms) | ts2 (ms) |

|---|---|---|---|---|---|

| 0.03 | 0.50 | 50 | 1.5 | 58.7 | 58.7 |

| 0.05 | 0.30 | 50 | 2.5 | 58.7 | 58.7 |

| 0.06 | 0.30 | 50 | 3 | 70.4 | 70.4 |

| 0.10 | 0.10 | 100 | 10 | 39.1 | 39.1 |

| 0.30 | 0.05 | 100 | 30 | 58.7 | 58.7 |

| 0.50 | 0.03 | 100 | 50 | 58.7 | 58.7 |

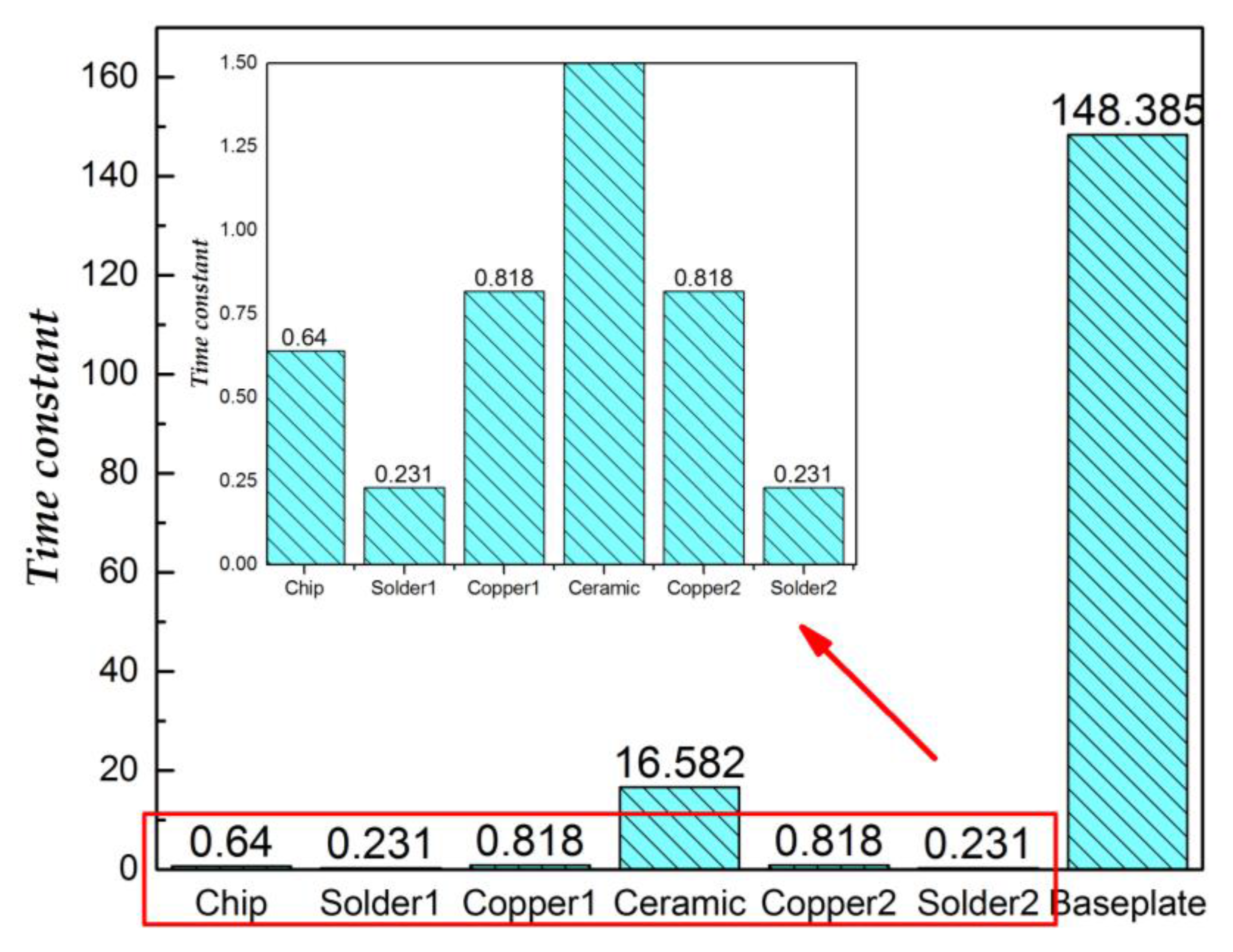

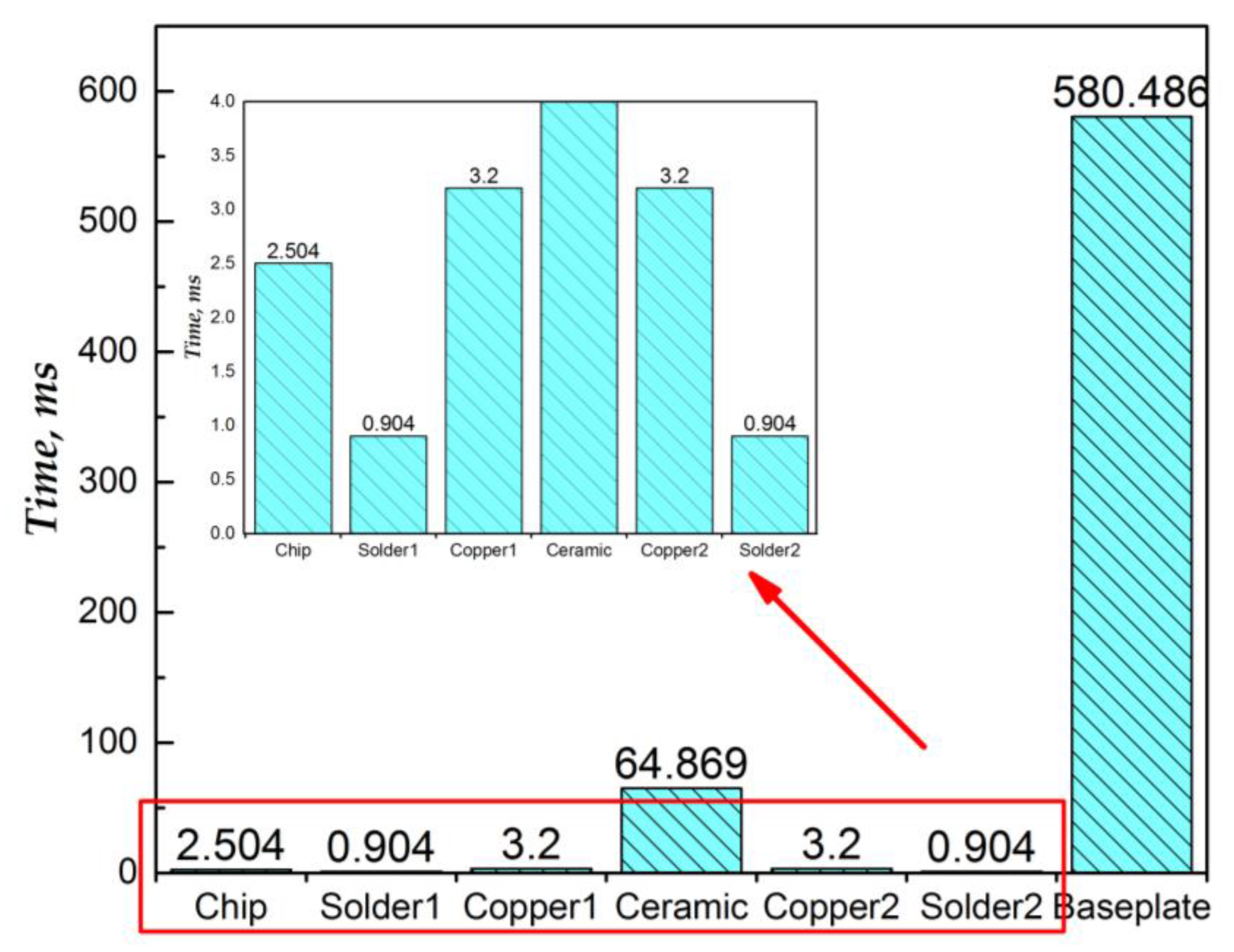

| Material Layer | Thickness (mm) | Density (kg/m3) | Length (mm) | Width (mm) | Rth (°C/W) | Cth (J/°C) |

|---|---|---|---|---|---|---|

| Silicon | 0.15 | 2329 | 7.24 | 6.9 | 1.65e−2 | 2.60e−2 |

| Solder | 0.12 | 7300 | 7.24 | 6.9 | 2.26e−2 | 9.51e−3 |

| Copper | 0.3 | 8960 | 28.5 | 25.8 | 9.17e−3 | 8.55e−2 |

| Alumina | 0.38 | 3780 | 30.65 | 28 | 0.112 | 0.104 |

| Copper | 0.3 | 8960 | 28.5 | 25.8 | 8.18e−3 | 9.56e−2 |

| Solder | 0.12 | 7300 | 28.5 | 25.8 | 1.93e−2 | 1.12e−2 |

| Copper | 2.8 | 8960 | 91.4 | 31.4 | 7.71e−2 | 1.44 |

| Model | Chip | Chip Solder | Copper | Ceramic | Copper | Substrate Solder | Baseplate |

|---|---|---|---|---|---|---|---|

| Convention | 1.65 × 10−2; 2.60 × 10−2 | 2.26 × 10−2; 9.51 × 10−3 | 9.17 × 10−3; 8.55 × 10−2 | 0.112; 0.104 | 8.18 × 10−3; 9.56 × 10−2 | 1.93 × 10−2; 1.12 × 10−2 | 7.71 × 10−2; 1.44 |

| Improved (50 °C) | 1.86 × 10−2; 2.72 × 10−2 | 2.31 × 10−2; 9.51 × 10−3 | 9.27 × 10−3; 8.69 × 10−2 | 0.126; 0.108 | 8.27 × 10−3; 9.72 × 10−2 | 1.97 × 10−2; 1.12 × 10−2 | 7.80 × 10−2; 1.47 |

| Improved (100 °C) | 2.21 × 10−2; 2.90 × 10−2 | 2.43 × 10−2; 9.51 × 10−3 | 9.42 × 10−3; 8.90 × 10−2 | 0.151; 0.114 | 8.41 × 10−3; 9.96 × 10−2 | 2.07 × 10−2; 1.12 × 10−2 | 7.93 × 10−2; 1.50 |

| Model | Peak-to-Valley Value (°C) | Average Rate of Change (°C/s) |

|---|---|---|

| FEM | 4.99; 5.38 | 9.98; 10.76 |

| Improved | 4.35; 4.96 | 8.7; 9.92 |

| Convention | 3.68; 3.71 | 7.36; 7.42 |

| Model | Maximum Deviation (°C) | Error Fluctuation (°C) | Average Deviation (°C) |

|---|---|---|---|

| Improved | 2.34 | 2.30 | 1.03 |

| Convention | 5.88 | 4.25 | 3.13 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, N.; Du, M.; Hu, Z.; Wei, K. A High-Precision Adaptive Thermal Network Model for Monitoring of Temperature Variations in Insulated Gate Bipolar Transistor (IGBT) Modules. Energies 2018, 11, 595. https://doi.org/10.3390/en11030595

An N, Du M, Hu Z, Wei K. A High-Precision Adaptive Thermal Network Model for Monitoring of Temperature Variations in Insulated Gate Bipolar Transistor (IGBT) Modules. Energies. 2018; 11(3):595. https://doi.org/10.3390/en11030595

Chicago/Turabian StyleAn, Ning, Mingxing Du, Zhen Hu, and Kexin Wei. 2018. "A High-Precision Adaptive Thermal Network Model for Monitoring of Temperature Variations in Insulated Gate Bipolar Transistor (IGBT) Modules" Energies 11, no. 3: 595. https://doi.org/10.3390/en11030595

APA StyleAn, N., Du, M., Hu, Z., & Wei, K. (2018). A High-Precision Adaptive Thermal Network Model for Monitoring of Temperature Variations in Insulated Gate Bipolar Transistor (IGBT) Modules. Energies, 11(3), 595. https://doi.org/10.3390/en11030595