Comprehensive Thermodynamic Analysis of the Humphrey Cycle for Gas Turbines with Pressure Gain Combustion

Abstract

1. Introduction

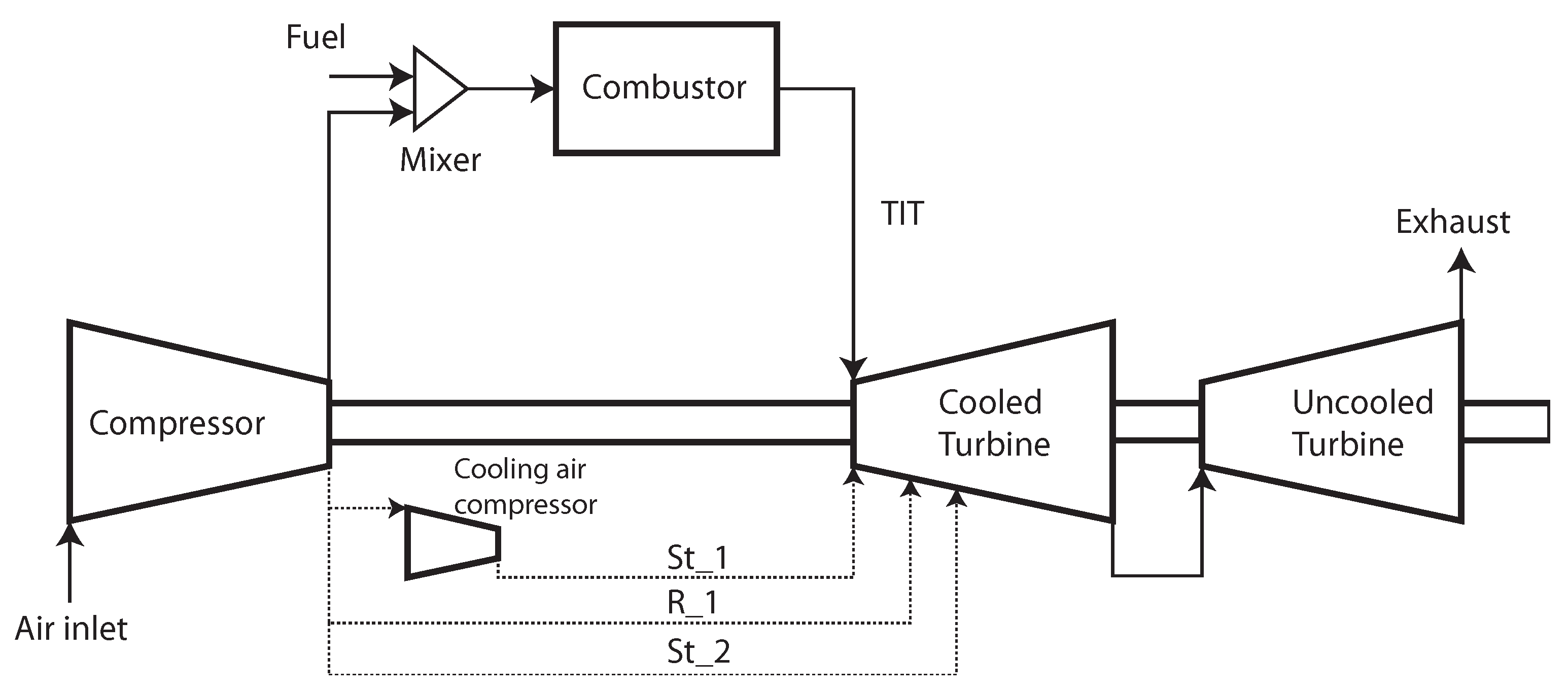

2. Methods and Modeling Approach

2.1. Combustor Model

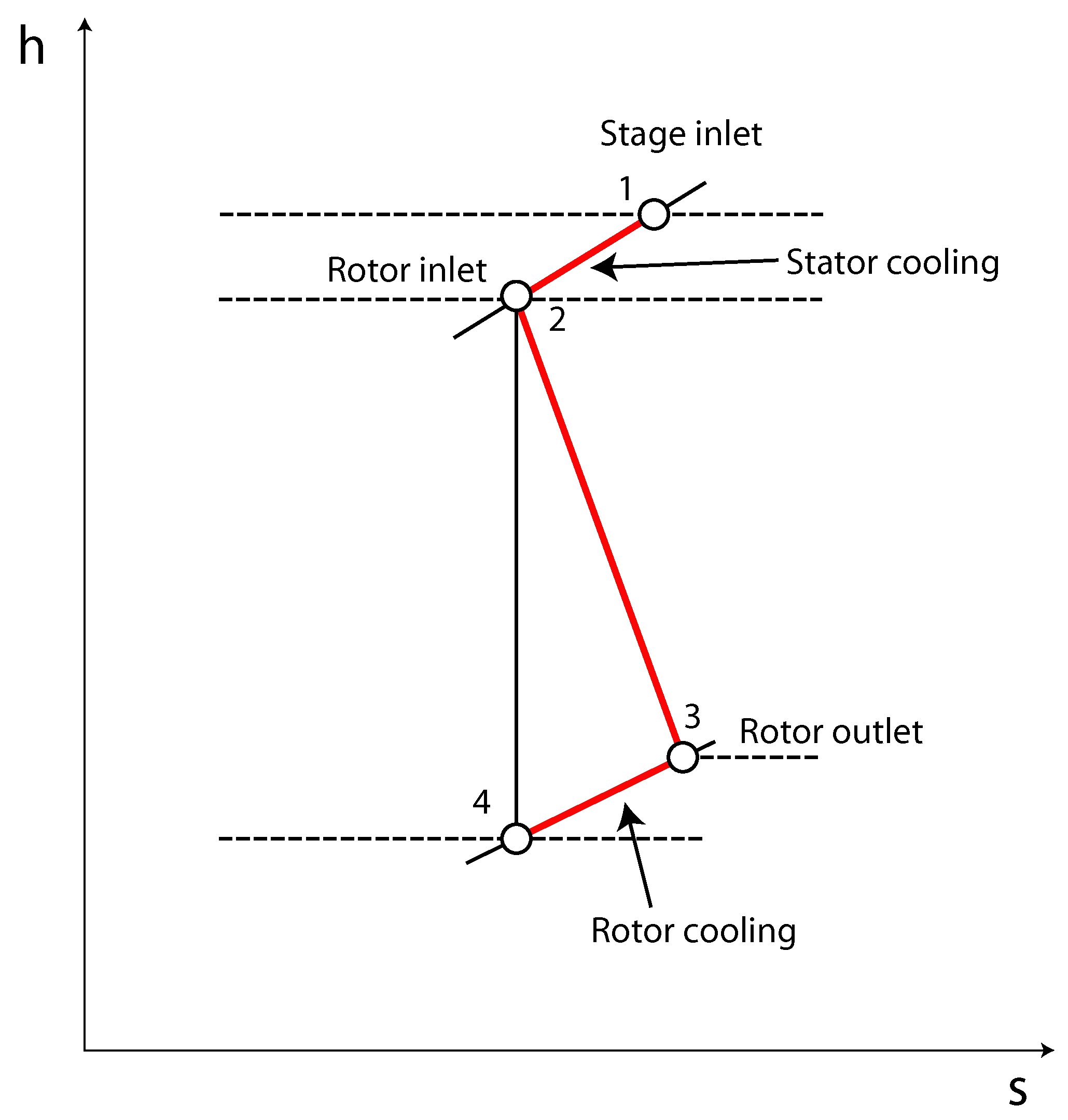

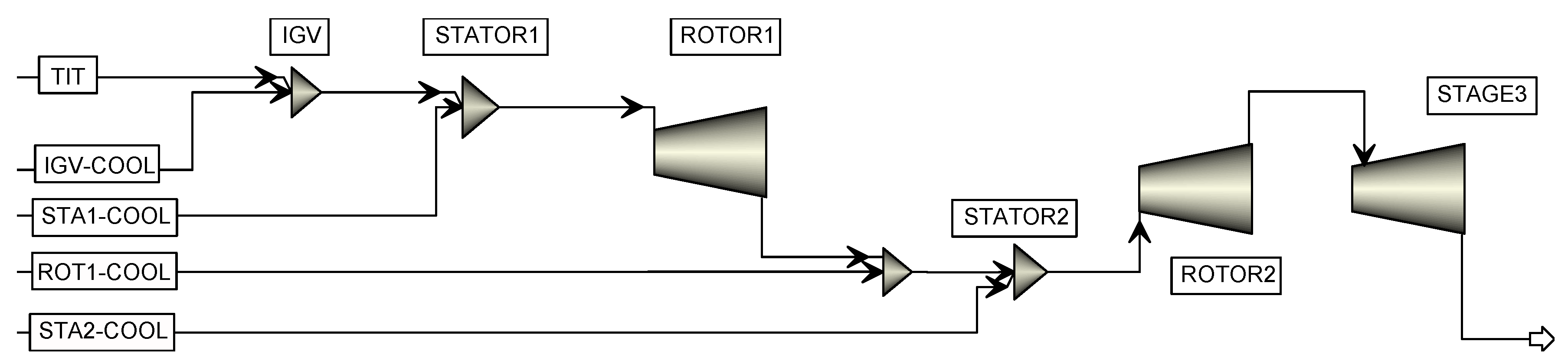

2.2. Secondary Air System Model

2.3. Gas Turbine Model

- The working fluid was considered a real gas and its properties were computed by the Aspen Properties database (the RK-BS model has been used for that). Only the processes in the combustion chamber were computed with the average properties at its inlet and outlet.

- The compression process was adiabatic with a given constant isentropic efficiency.

- The combustion products (and not air) were taken as the working fluid of the turbine expander.

2.4. Simulation Procedure

3. Cycle Analysis Results

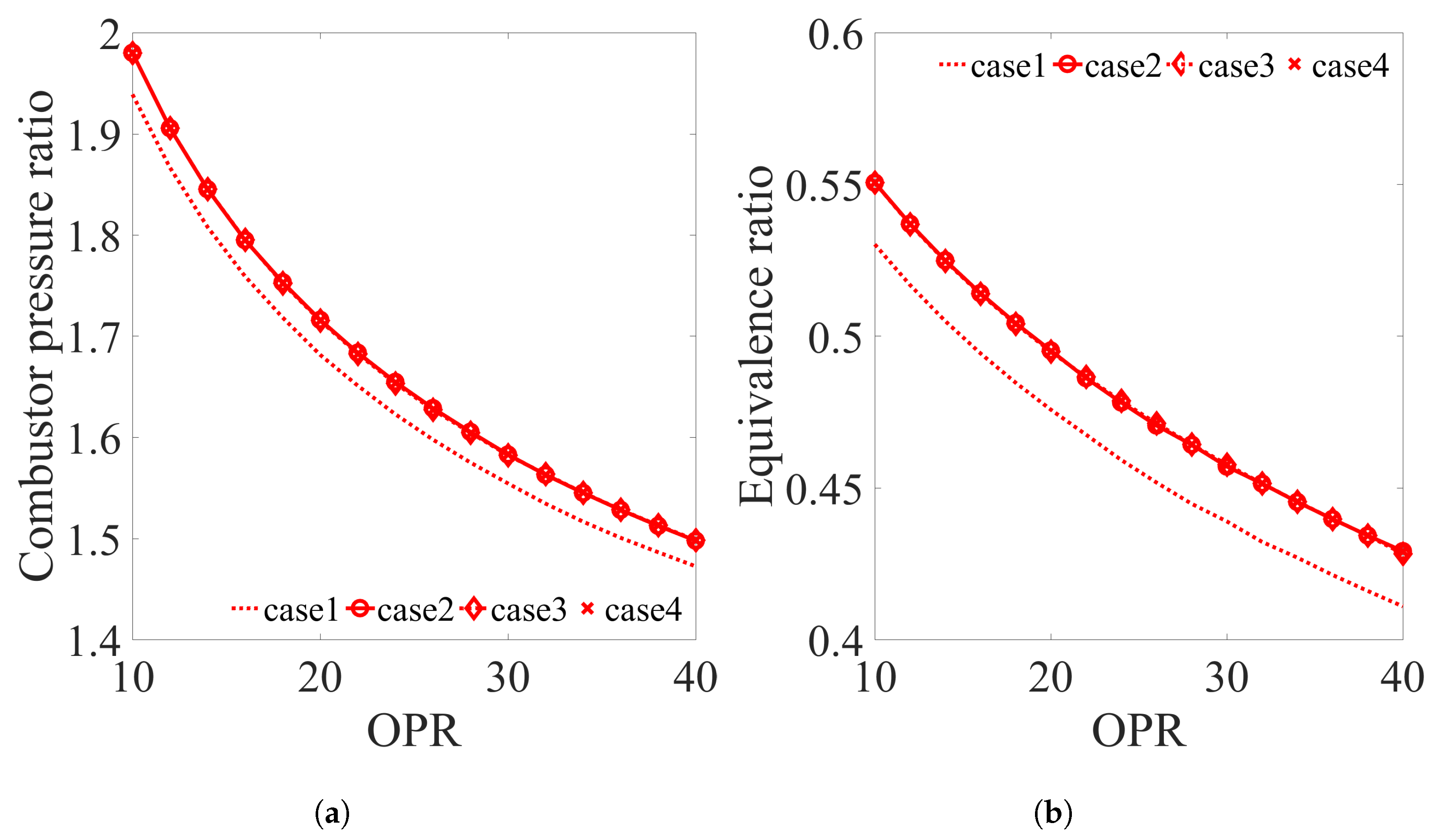

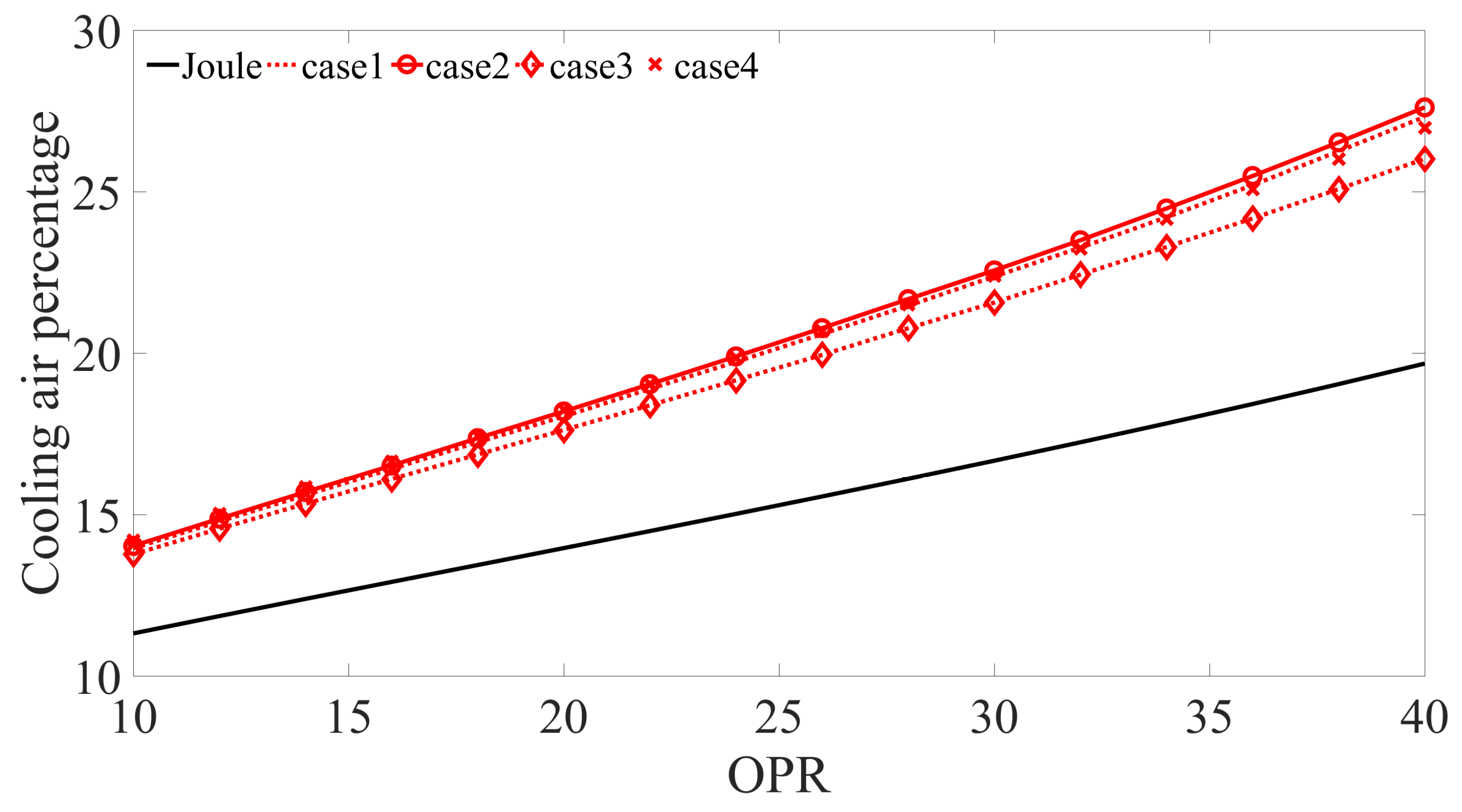

3.1. Basic Thermodynamic Analysis

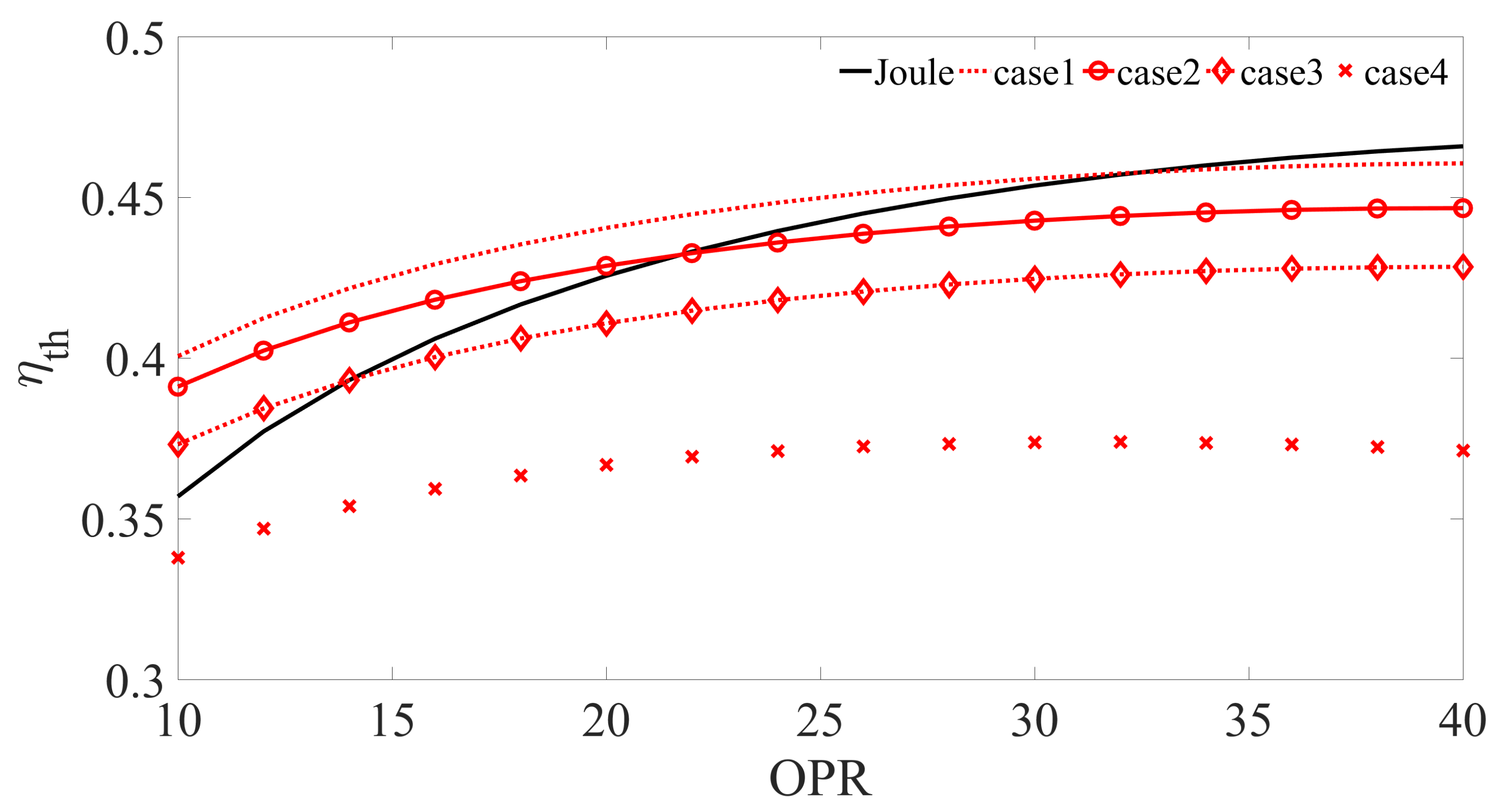

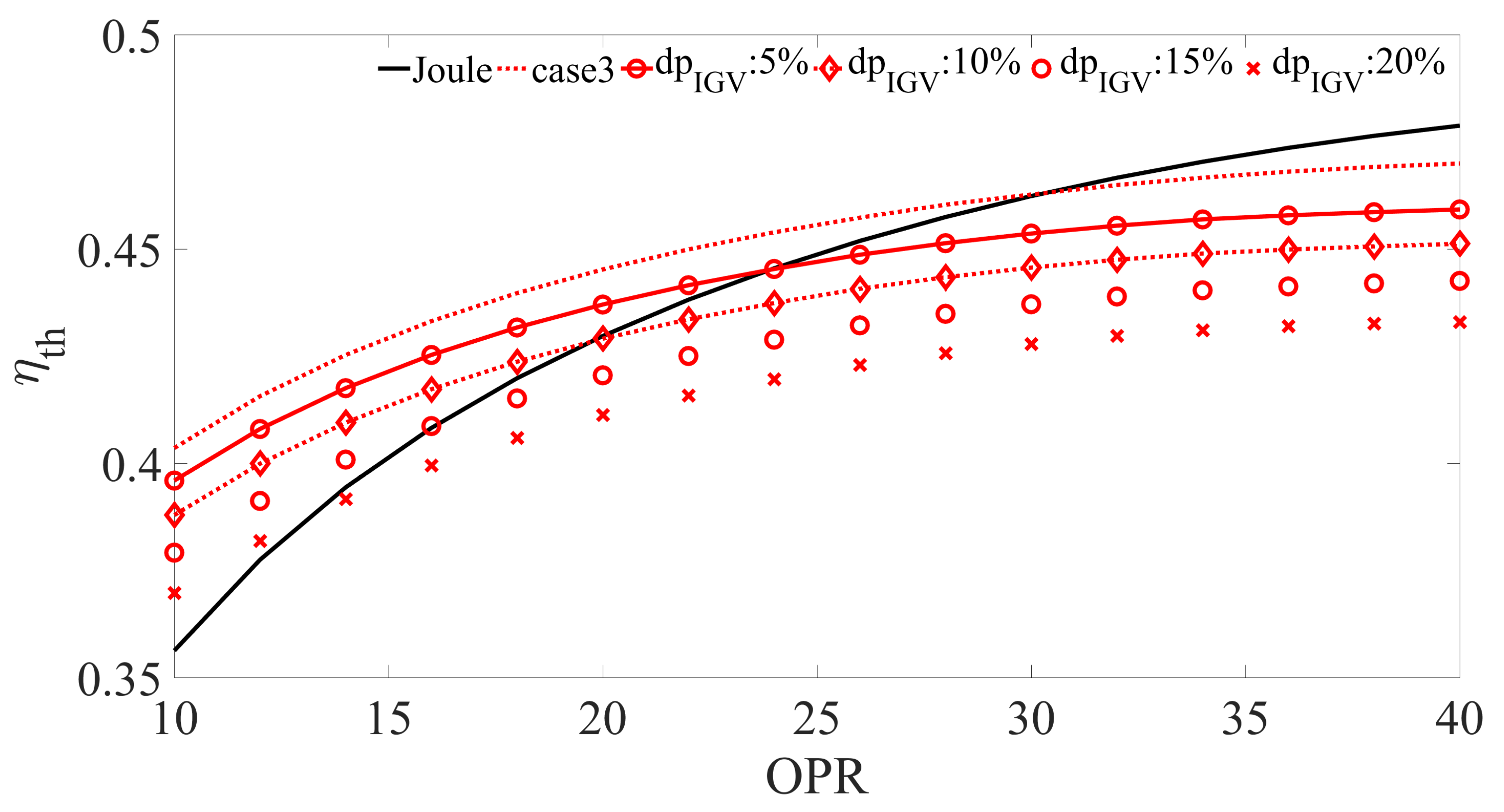

3.1.1. Thermal Efficiency Results

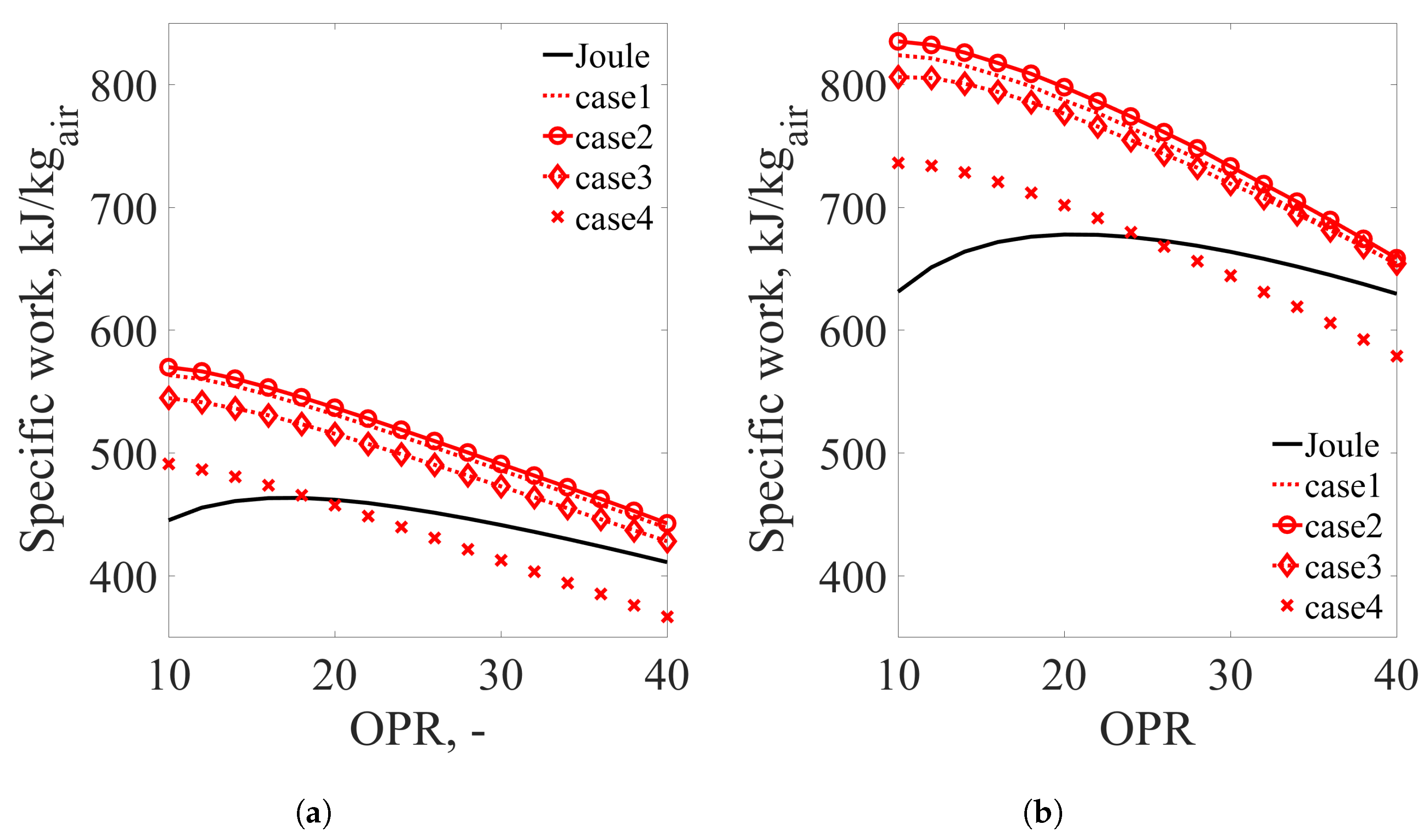

3.1.2. Specific Work Results

3.1.3. Gas Turbine Outlet Temperature

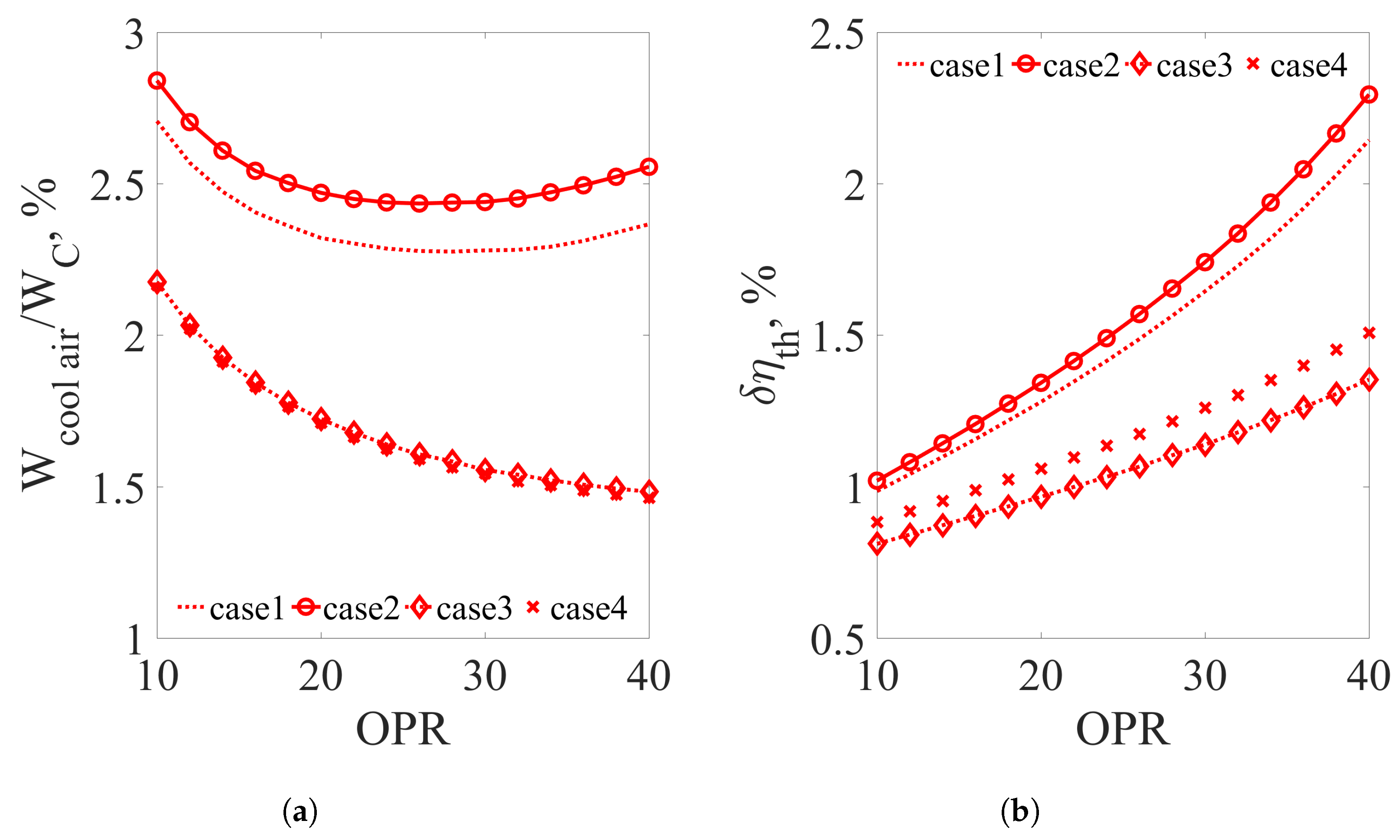

3.1.4. On the Effect of the Cooling Air Compressor

3.1.5. On the Effect of Combustor Exhaust Gas Conditioning

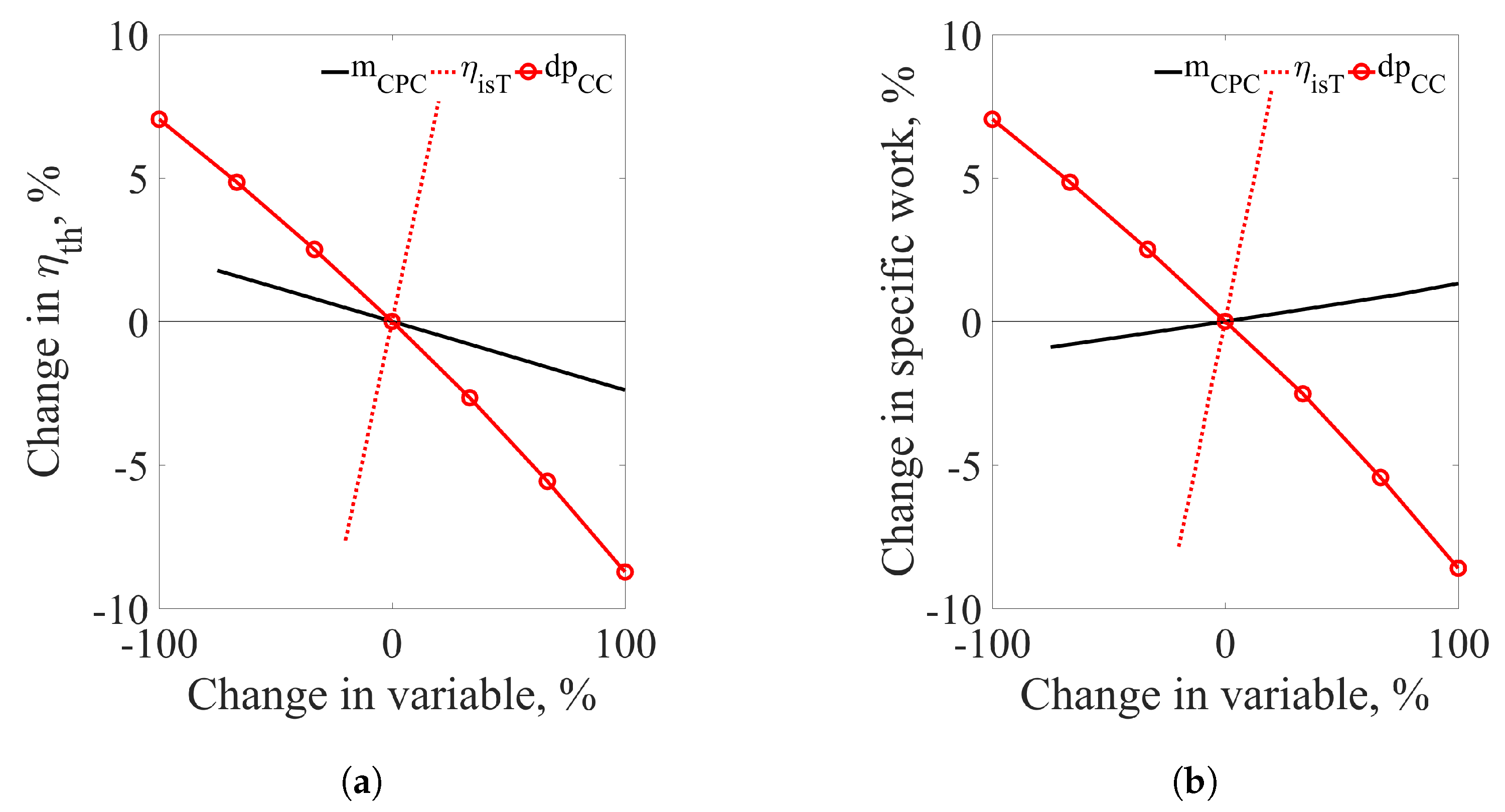

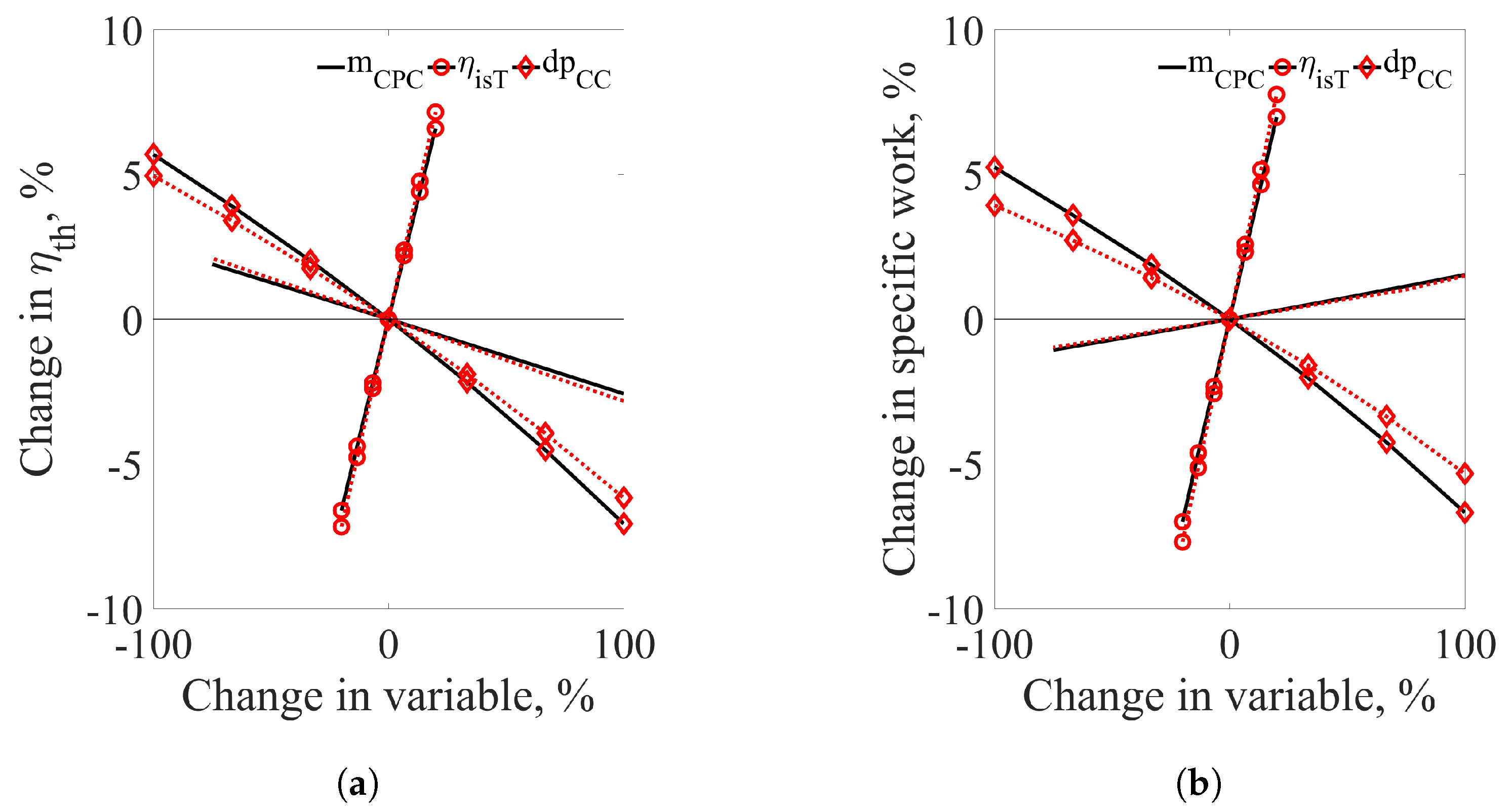

3.2. Sensitivity Analysis

4. Conclusions

- If realistic assumptions are made on the combustor inlet pressure drop, the turbine efficiency and the fuel mass consumed under constant pressure conditions, the Humphrey cycle will most probably make sense for mass averaged turbine inlet temperatures above 1500 C and pressure ratios below 25.

- For a combustor inlet pressure drop of 15% and if 20% of the fuel mass is consumed under constant pressure conditions, the isentropic efficiency of the first turbine stage must be higher than 0.7. In any other case, the Humphrey cycle will not be able to compete with the Joule cycle of a similar technological level (i.e., turbine cooling effectiveness level).

- For the same cycle setting as before, the maximum pressure drop of an exhaust gas conditioning device that results in efficiency parity with the respective Joule cycle (provided that the turbine isentropic efficiency is 0.9) is approximately 15%. This parity is observed for this case at relatively low cycle pressure ratios. For higher pressure ratios, the allowable pressure loss is lower.

- For low cycle pressure ratios, the Humphrey cycle has a considerably higher specific work than the equivalent Joule cycle, even for low isentropic efficiencies of the turbine. Above pressure ratios of 20, this result changes if the turbine does not have an isentropic efficiency above 0.7.

- The Humphrey cycle generally results in lower turbine outlet temperatures for the same TIT with an equivalent Joule cycle. This is expected due to the higher turbine expansion ratio in the Humphrey cycle. This finding must be accounted for, when the Humphrey (but also other PGC gas turbine cycles) is considered the topping cycle of a combined cycle power plant.

- Generally, the Humphrey cycle (and to this effect most probably other PGC gas turbine cycles) has a considerably higher secondary air consumption than a Joule cycle of the same technological level. The fact that the cooling air of the first stator row has to be further compressed before its inlet in the turbine results in higher cooling air temperatures and thus increased secondary air consumption. This effect could be limited by compressor intercooling, cooling down the cooling air or improving the cooling effectiveness in the first stator row (i.e., improving the cooling technological level). It must be stressed here that the current study did not take into account the possible increase of the convective heat transfer coefficient at the hot gas blade side. This might be the case due to unsteady flow phenomena that are not accounted for here. In this case, an even higher mass flow rate of cooling air would be necessary, for the same technological level.

- An initial study on the effect of the extra cooling air compressor showed that its integration results in an cycle efficiency decrease between one and three percentage points, depending on the cycle pressure ratio and settings.

Funding

Acknowledgments

Conflicts of Interest

Symbols

| Latin Characters | ||

| C | Turbine cooling technology level constant | |

| Specific heat capacity under constant volume | ||

| Specific heat capacity under constant pressure | ||

| Combustor inlet pressure drop | % of | |

| IGV pressure drop | % of | |

| K | Cooling air injection pressure loss constant | |

| Mixture mass flow rate | ||

| Mixture mass percentage combusted under constant pressure | ||

| Combustor inlet temperature | K | |

| Combustor temperature at the end of the constant volume heat addition process | K | |

| Combustor outlet temperature | K | |

| Combustor inlet pressure | bar | |

| Combustor pressure at the end of the constant volume heat addition process | bar | |

| Combustor outlet pressure | bar | |

| Q | Heat added through combustion | W |

| Expansion ratio of each turbine stage | ||

| Relative pressure drop due to cooling air mixing in the main exhaust stream | % of | |

| Blade temperature used for cooling air calculations | K | |

| Turbine outlet temperature | K | |

| Main compressor work consumption | W | |

| Cooling air compressor work consumption | W | |

| Greek Letters | ||

| Specific heat capacity ratio | ||

| Turbine stage film cooling effectiveness | ||

| Compressor isentropic efficiency | ||

| Cooling air compressor isentropic efficiency | ||

| Cooling air efficiency | ||

| Turbine stage isentropic efficiency | ||

| Cycle thermal efficiency | ||

| Specific volume | ||

| Combustion chamber pressure loss coefficient | ||

| Turbine stage cooling pressure loss | ||

| Density | ||

Abbreviations

| Constant pressure combustion | |

| Constant volume combustion | |

| Inlet guide vanes | |

| Operational (compressor) pressure ratio | |

| Pressure gain combustion | |

| Pulsed detonation combustion | |

| Rotating detonation combustion | |

| Turbine Inlet Temperature | |

| Zeldovich, von Neumann, Dörring |

References

- International Air Transport Association. Annual Review; Technical report; International Air Transport Association: Montreal, QC, Canada, 2017. [Google Scholar]

- Zhang, A.; Gudmundsson, S.V.; Oum, T.H. Air transport, global warming and the environment. Transp. Res. Part D Transp. Environ. 2010, 15, 1–4. [Google Scholar] [CrossRef]

- Styczynski, B.M.B.Z. Smart Grids—Fundamentals and Technologies in Electricity Networks; Springer: Berlin, Germany, 2014. [Google Scholar]

- European Network of Transmission System Operators for Electricity. Scenario Outlook and Adequacy Forecast; Technical Report June; European Network of Transmission System Operators for Electricity: Brussels, Belgium, 2015. [Google Scholar]

- Bratkovich, T.; Bussing, T. A Pulse Detonation Engine performance model. In Proceedings of the 31st Joint Propulsion Conference and Exhibit, San Diego, CA, USA, 10–12 July 1995. [Google Scholar]

- Wolański, P. Detonative propulsion. Proc. Combust. Inst. 2013, 34, 125–158. [Google Scholar] [CrossRef]

- Berndt, P.; Klein, R. Modeling the kinetics of the Shockless Explosion Combustion. Combust. Flame. 2016. [Google Scholar] [CrossRef]

- Paxson, D.; Dougherry, K. Operability of an Ejector Enhanced Pulse Combustor in a Gas Turbine Environment. In Proceedings of the 46th AIAA Aerospace Sciences Meeting and Exhibit, Reston, VA, USA, 7–10 January 2008. [Google Scholar]

- Heiser, W.; Pratt, D. Thermodynamic cycle analysis of pulse detonation engines. J. Propul. Power 2002, 18, 68–76. [Google Scholar] [CrossRef]

- Nalim, M.R. Thermodynamic limits of work and pressure gain in combustion and evaporation processes. J. Propul. Power 2002, 18, 1176–1182. [Google Scholar] [CrossRef]

- Paxson, D.; Kaemming, T. Foundational Performance Analyses of Pressure Gain Combustion Thermodynamic Benefits for Gas Turbines. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012. [Google Scholar]

- Stathopoulos, P.; Vinkeloe, J.; Paschereit, C.O. Thermodynamic Evaluation of Constant Volume Combustion for Gas Turbine Power Cycles. In Proceedings of the 11th International Gas Turbine Congress, Tokyo, Japan, 15–20 November 2015. [Google Scholar]

- Rähse, T.S.; Stathopoulos, P.; Berndt, P.; Klein, R.; Paschereit, C.O. Gas Dynamic Simulation of Shockless Explosion Combustion for Gas Turbine Power Cycles. In Proceedings of the ASME Turbomachinery technical conference and Exposition, Charlotte, NC, USA, 26–30 June 2017. [Google Scholar]

- Rähse, T.S.; Stathopoulos, P.; Schäpel, J.S.; Arnold, F.; King, R. On the influence of fuel stratification and its control on the efficiency of the shockless explosion combustion cycle. In Proceedings of ASME Turbo Expo; ASME International: Oslo, Norway, 2018. [Google Scholar]

- Nordeen, C.A. Thermodynamics of a Rotating Detonation Engine. Ph.D. Thesis, University of Connecticut, Storrs, CT, USA, 2013. [Google Scholar]

- Ma, F.; Choi, J.Y.; Yang, V. Thrust chamber dynamics and propulsive performance of multible pulse detonation engines. J. Propul. Power 2005, 21, 512–526. [Google Scholar] [CrossRef]

- Bach, E.; Bohon, M.; Paschereit, C.O.; Stathopoulos, P. Development of an Instrumented Guide Vane Set for RDC Exhaust Flow Characterization. In 2018 Joint Propulsion Conference; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2018. [Google Scholar]

- Suresh, A.; Hofer, D.C.; Tangirala, V.E. Turbine Efficiency for Unsteady, Periodic Flows. J. Turbomach. 2012, 134, 034501. [Google Scholar] [CrossRef]

- Fernelius, M. Experimental and Computational Analysis of an Axial Turbine Driven by Pulsing Flow. Ph.D. Thesis, Brigham Young University, Provo, UT, USA, 2017. [Google Scholar]

- Rouser, K. Unsteady Specific Work and Isentropic Efficiency of a Radial Turbine Driven by Pulsed Detonations. Ph.D. Thesis, Department of the air force, Air University, Islamabad, Pakistan, 2012. [Google Scholar]

- Frolov, S.M.; Dubrovskii, A.V.; Ivanov, V.S. Three-dimensional numerical simulation of a continuously rotating detonation in the annular combustion chamber with a wide gap and separate delivery of fuel and oxidizer. In Progress in Propulsion Physics; Calabro, M., DeLuca, L., Frolov, S., Galfetti, L., Haidn, O., Eds.; EDP Sciences: Les Ulis, France, 2016; pp. 375–388. [Google Scholar]

- Zhou, R.; Wu, D.; Wang, J. Progress of continuously rotating detonation engines. Chin. J. Aeronaut. 2016, 29, 15–29. [Google Scholar] [CrossRef]

- Schwer, D.A.; Kailasanath, K. Characterizing NOx Emissions for Air-Breathing Rotating Detonation Engines. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Reston, VA, USA, 25–27 July 2016. [Google Scholar]

- Zander, L.; Tornow, G.; Klein, R.; Djordjevic, N. Knock Control in Shockless Explosion Combustion by Extension of Excitation Time; Springer: Cham, Switzerland, 2018; pp. 151–166. [Google Scholar]

- Kurzke, J. Performance Modeling Methodology: Efficiency Definitions for Cooled Single and Multistage Turbines. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002; pp. 85–92. [Google Scholar]

- Horlock, J.H. Advanced Gas Turbine Cycles; Elsevier Science and Technology: London, UK, 2003. [Google Scholar]

- Stathopoulos, P.; Paschereit, C. Retrofitting micro gas turbines for wet operation. A way to increase operational flexibility in distributed CHP plants. Appl. Energy 2015, 154, 438–446. [Google Scholar] [CrossRef]

- Stathopoulos, P.; Paschereit, C.O. Operational Strategies of Wet-Cycle Micro Gas Turbines and Their Economic Evaluation. J. Eng. Gas Turbines Power 2016, 138, 122301. [Google Scholar] [CrossRef]

- Gray, J.A.T.; Vinkeloe, J.; Moeck, J.; Paschereit, C.O.; Stathopoulos, P. Thermodynamic Evaluation of Pulse Detonation Combustion for Gas Turbine Power Cycles. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition GT2016, Seoul, South Korea, 13–17 June 2016. [Google Scholar]

- Fernelius, M.H.; Gorrell, S.E. Predicting Efficiency of a Turbine Driven by Pulsing Flow. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, Charlotte, NA, USA, 26–30 June 2017. [Google Scholar]

- Naples, A.; Battelle, R.; Hoke, J.; Schauer, F. T63 Turbine Response to Rotating Detonation Combustor Exhaust Flow. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Endo, T.; Fujiwara, T. A Simplified Analysis on a Pulse Detonation Engine Model. Trans. Jpn. Soc. Aeronautn Space Sci. 2002, 44, 217–222. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| Cooling efficiency | 0.9 | |

| Film cooling effectiveness | 0.4 | |

| Level of technology constant | C | 0.045 |

| Pressure loss constant | K | 0.07 |

| Component | Symbol | Value |

|---|---|---|

| Compressor | 0.9 | |

| Cooling air compressor | 0.9 | |

| Turbine | 0.7–0.9, variable | |

| 0.9, fixed | ||

| 0.9, fixed | ||

| Cooling system | 1100 K | |

| 1% |

| Case | Mass through CPC (%) | Inlet Pressure Drop, % of | , % |

|---|---|---|---|

| Case 1 | 0 | 5 | 0.9 |

| Case 2 | 20 | 5 | 0.9 |

| Case 3 | 20 | 15 | 0.9 |

| Case 4 | 20 | 15 | 0.7 |

| Parameter | Symbol | Reference Value | Variance Region |

|---|---|---|---|

| Mass through CPC (%) | m | 20 | 5–40 |

| Combustor inlet pressure drop, % of | dp | 15 | 0–30 |

| Turbine first stage isentropic efficiency, - | 0.75 | 0.6–0.9 | |

| IGV pressure drop, % of | dp | - | 5–20 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stathopoulos, P. Comprehensive Thermodynamic Analysis of the Humphrey Cycle for Gas Turbines with Pressure Gain Combustion. Energies 2018, 11, 3521. https://doi.org/10.3390/en11123521

Stathopoulos P. Comprehensive Thermodynamic Analysis of the Humphrey Cycle for Gas Turbines with Pressure Gain Combustion. Energies. 2018; 11(12):3521. https://doi.org/10.3390/en11123521

Chicago/Turabian StyleStathopoulos, Panagiotis. 2018. "Comprehensive Thermodynamic Analysis of the Humphrey Cycle for Gas Turbines with Pressure Gain Combustion" Energies 11, no. 12: 3521. https://doi.org/10.3390/en11123521

APA StyleStathopoulos, P. (2018). Comprehensive Thermodynamic Analysis of the Humphrey Cycle for Gas Turbines with Pressure Gain Combustion. Energies, 11(12), 3521. https://doi.org/10.3390/en11123521