Abstract

Leather processing for commercial purposes involves going through a set of complex and laborious operations, resulting in over 70% waste relative to the initial feedstock; a quarter of this waste is produced in Europe. Worldwide there are about 36,000 companies active in this sector, generating a turnover of almost 48 billion euros. As in any industrial sector, waste recovery is a highly researched topic, with alternatives for its use being constantly considered. One of the most interesting solutions to this problem consists of using part of the waste for power applications. For instance, the 10% fats from total animal waste could well be employed to power diesel engines, both in raw state or as biodiesel. The remainder, which contains mostly proteins, can be exploited to obtain biogas through anaerobic digestion. This paper presents the results of experimental determinations on the combustion of animal fats and compares it to other biofuels, such as vegetable oils and solid biomass. The advantages of co-firing hydrogen-rich gas (HRG) and vegetable biomass are also analyzed. According to the presented results, combustion of the investigated fuels has a lower impact on the environment, with the concentration of pollutants in the flue gases being low. Thus, the paper proves that all the proposed solutions are ecological alternatives for biomass exploitation for energy recovery purposes, based on comparing the results in terms of pollutant emissions. This paper provides qualitative and quantitative perspectives on multiple alternatives of energy recovery from biomass resources, while also briefly describing the methods and equipment used to this end.

1. Introduction

Biomass represents an important energy source and its energy harnessing potential constitutes an ongoing focus of researchers. The interest in burning biomass is due to the fact that it represents the third highest source of primary energy worldwide, following coal (first) and oil (second). Biomass, in general, is constituted from vegetal biomass (such as forestry residues and specialized agricultural crops) and animal biomass (such as fats resulting from the leather industry). In the leather processing industry, around 10% represents the finished product and more than 30% is protein residues. Animal fat wastes represent more than half of the original feedstock, and have a high energy potential, due to their good combustion properties; hence, they can be used as fuel for several thermal machines, such as internal combustion engines, and steam or hot water generators. Moreover, the European Union report, Future Transport Fuels, points out the necessity of using biofuel starting from 2050 and strongly endorses employing raw animal fats as fuel for diesel engines, in the form of diesel biofuel obtained from blending animal fat and diesel fuel [1]. This approach is also a very good solution that responds to the storage problem, as their disposal or elimination by incineration involves high associated costs of around 300–400 €/tonne [2,3].

The high heating value of animal fats (Hi) qualifies them for energy purposes, both in their raw state (under special conditions) and as derived products, resulted from specific chemical processes (e.g., biodiesel, obtained through transesterification with some alcohols). Table 1 presents a comparison between animal fat oils (methyl ester of animal fat—MEGA, ethyl ester of animal fat—EGA) and diesel fuel properties. The testing procedures followed the methodology set out in the EN 590 standard for diesel fuel, and the EN 14214 standard for animal fat-diesel fuel blends, respectively.

Table 1.

Characteristics of diesel fuel, animal fat oils and animal fats [3,4,5].

Animal fats preheated to a temperature of 40 °C and blended with diesel fuel were used by Kumar et al. to fuel a single-cylinder diesel engine [4]. Compared to diesel fuel, the use of animal fats led to a decrease in maximum pressure of 11% because the auto-ignition delay increased by 33% [4]. In a similar experiment, Kumar et al. also found that for a constant injection timing of 20 CAD (crank angle degree), the use of neat animal fat led to a decrease of maximum cycle pressure from 95 bar to 82 bar [5]. A biodiesel mixture of animal fat was used to fuel a diesel engine at full engine load, with the same injection timing and injection pressure in by the authors of [6]. Because of the lower heating value of biodiesel compared to diesel fuel, the use of biodiesel led to a reduction in maximum pressure and indicated mean effective pressure [6], under conditions of constant injection timing. Animal fats were used in a composition of diesel fuel blend in order to fuel a 2 L turbocharged diesel engine, and the effects on indicated mean effective pressure and break mean effective pressure are presented by the authors of [7]. In order to compensate for the decrease of indicated mean effective pressure, an increase in the injection rate and timing must be applied [7], with injection timing being the main engine setup parameter which can improve engine performance in this case.

The research regarding vegetal biomass has focused on combustion technologies that render the energy process efficient and concomitantly reduce noxious emissions [8,9,10]. The utilization of wood residues for energy production that meets the European Union targets in small communities in Italy was investigated by the authors of [11]. Analysis of the energy potential and environmental protection of four types of biomass (wheat straw, oat grains, larch needles and rapeseed pods) was experimentally investigated in Reference [12]. The use of alternative fuels (such as crude palm oil or crude rubber seed oil) instead of diesel for energy production in Asia, as a measure to reduce the use of nonrenewable fuels and improve energy efficiency, was experimentally analyzed by the authors of [13] and economically investigated by the authors of [14]. An efficient proven technology for the co-combustion of biomass and hydrogen-rich gas (HRG) was demonstrated in Reference [8]. Research on obtaining hydrogen-rich gas from charcoal or biomass was conducted in Reference [15]. Hydrogen production from biomass was reviewed by the authors of [16]. Other solutions for producing hydrogen-rich gas are presented in the scientific literature by the authors of [17]. However, in this paper, hydrogen-rich gas produced by an electrolytic system was used. Hydrogen-rich gas was cheaper than methane (the HRG cost was 0.35 €/1000 L while methane was 0.38 €/1000 L), based on 2016 Romanian market prices [18].

The aim of this research was to present the experimental research and results obtained through the energy utilization of animal biomass and vegetal biomass. The objective was to demonstrate the efficiency of supporting the combustion of various types of biomass by injecting HRG. In addition, the paper highlights the convergence of results for the combustion of chopped biomass for a large range of biomass types. The combustion technology was chosen based on its minimum implied costs. The results reveal that combustion of chopped materials can be applied to a large range of biomass types. This implies the convergence of technological solutions that, at this point, due to their broad spectrum, lead to technical and financial deficiencies. The biomass represented by animal fats, in combination with liquid fuel using mechanical pulverization technology, was analyzed through combustion experiments. The crude vegetable oils and animal fats combined with diesel fuel were experimentally investigated in internal combustion engines.

2. Experimental Investigations

2.1. Energy Valorization of Animal Fat Waste from the Leather Industry

2.1.1. Diesel Engines Fueled with Animal Fats

The experimental engine was upgraded by adding measuring instrumentation devices, namely:

- In-cylinder pressure transducer line—Anstalt für Verbrennungskraftmaschinen List Engineering Company (AVL), with an accuracy of ±0.05% for 0–250 bar measuring domain;

- Angle encoder—Kubler, with a resolution of 0.05 °CA (crank angle) and accuracy of ±0.1 °CA;

- Real-time data acquisition system—AVL for recording and processing of the in-cylinder data (256 RAM for Indimodul 621);

- Gas analyzer—AVL (with 1 ppm for NOx accuracy);

- Smoke meter for diesel engines—AVL (with 0.1% accuracy).

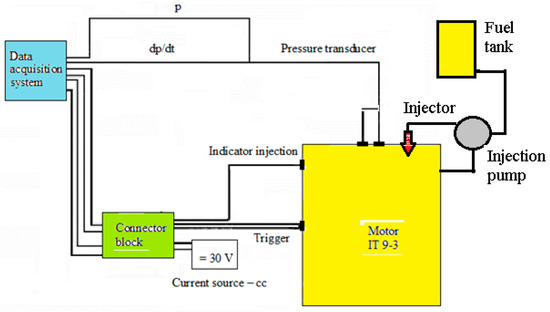

Thermo-resistances, of type Pt 100 TTR, were used to monitor the temperatures of the engine’s cooling liquid and of the inlet air, with an accuracy of ±1 °C and a response time of 0.25 ms; thermocouples, of type 100 TTC Chromel-Alumel, were used to measure the temperature of the combustion gases, with an accuracy of ±2 °C and response time of 0.25 ms. For each installation operating mode of the installation, the experimental investigations were repeated to ensure accuracy of the final results. For error analysis of the results, the variation ratio (VC) method was used and did not exceed 1% for all measurements due to the stability of the engine running. The experimental installation is shown in Figure 1.

Figure 1.

Internal combustion engine test bench.

The experimental results from combustion of a fuel mixture consisting of diesel and animal fat were obtained on a CFR-IT9-3M engine, varying the fraction of animal fat blended with diesel fuel in the range: xc = 0–125 .

The methodology used in the experiment is further described below:

- Initially, components of the installation were calibrated.

- For the animal fat-diesel fuel mixture preparation both fuels required preheating at temperatures over 40 °C. At this temperature animal fats are in a liquid state and become soluble in diesel fuel, and a finally homogenous mixture results.

- The engine was firstly fueled exclusively with diesel fuel, to set up the reference regime, defined by xc = 0. Secondly, different diesel fuel-animal fat blends were used, which were prepared as per the previously described procedure.

- For each experiment, several parameters were monitored: the auto-ignition delay; injection timing; engine compression ratio; in-cylinder pressure variation; and temperatures of the exhaust gases, cooling liquid, lubricant oil and inlet air. The concentration of pollutants emissions was also recorded.

Two cases were analyzed in order to highlight the differences between injection timing and combustion pressure variation with animal fat content blended with diesel fuel:

- Case I—constant engine parameters, namely: injection timing (β = 13 °CA, crank angle), compression ratio (ε = 13.80), and the values corresponding to a diesel fuel auto-ignition delay equal to the injection timing.

- Case II—variable engine parameters; adjustment of the injection timing from the standard value of 13 °CA to 15.8 °CA, for the same compression ratio, in order to maintain the start of the combustion process at TDC (top dead center).

2.1.2. Pilot Boiler Fed with Animal Fat

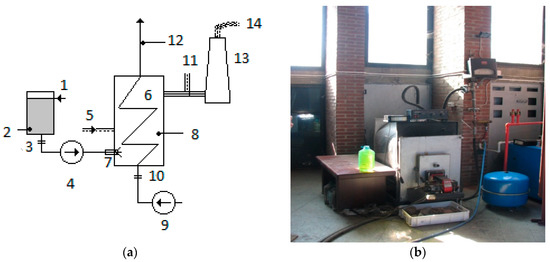

The experimental research was performed on a pilot boiler, Multiplex CL 50 model, manufactured by Thermostahl Company. Validation of the results was also considered. The pilot boiler comprised an Anyo-12 burner. The experimental installation is illustrated in Figure 2, where: 1-fuel inlet, 2-mixed fuel thermometer, 3-fuel flow meter, 4-fuel supply pump, 5-combustion air inlet, 6-boiler, 7-furnace mixed fuel, 8-radiation pyrometer, 9-water supply pump, 10-water flow meter, 11-gas analyzer, 12-hot water thermometer, 13-exhaust gases stack, and 14-exhaust gases outlet.

Figure 2.

Pilot boiler: (a) schematic diagram; (b) actual installation.

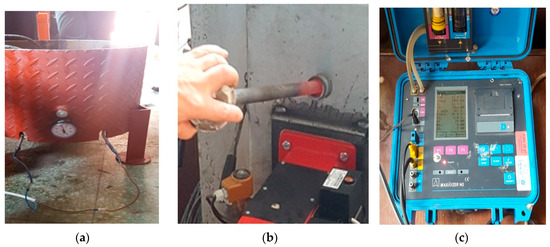

The burner used has a mechanical spray pump that ensures a maximum pressure of 22.5 bar, with a spray nozzle. The flow rate is regulated in the return and the sprayed fuel flow is air-swirled. The burner has included in its structure an electric heater that preheats the fuel spray, raising its temperature to 7.6 °C. Figure 3 shows the measuring devices.

Figure 3.

Measuring installation: (a) thermocouple for measuring the temperature of the mixture; (b) thermocouple for measuring the temperature inside the boiler; (c) MAXILYZER NG-type exhaust gas analyzer.

In order to start the burner, it is necessary to check the operating state of both camouflage and protection elements; then, the desired values must be set up. Before coupling the main switch, the separator valve has to be verified.

To obtain baseline values to which the other results relate and calibrate the equipment, first the engine was fueled exclusively with diesel. For the remainder of the experiments, a mixture of animal fat and diesel oil was used in mass ratios of 10%, 20% and 30%, respectively, of fat dissolved in diesel. The combustion blends could be made in the preheater mounted in front of the burner.

The preheating temperature of the burner was set in the range of 47–52 °C, allowing total fat dissolution in the diesel fuel, with the melting temperature of the fat being experimentally determined at approximately ≈42 °C as previously stated.

2.2. Production of Biogas from Protein Waste in the Leather Industry

Waste from the high-protein leather industry can be transformed into biogas by an anaerobic digestion process. For such waste the carbon/nitrogen ratio is C/N < 5.

Since ammonia concentrations, characterized by the ratio (/NH3), are very high, more than 9000 mg/L, an adaptation period for microorganisms used in the anaerobic digestion process is required.

The ammonia content was measured using a spectrophotometer, in agreement with ISO 6501:2800. Its operating principle is based on ammonia resulting from the reaction between ammonium ions and hypochlorite in the presence of nitrozopentacyanate (III) salicylates and sodium (nitroprusside sodium).

The experimental plant fed with biogas was designed and tested for the protein waste fraction from the leather industry, and consisted in an anaerobic digestor comprising a cascade of hydrolysis, acidogenesis and protein methanogenesis.

The optimal pH in the methanogenesis reactor’s acidogenesis section was maintained by the control system within the range of 4.7 to 7.2. As required, hydrochloric acid or sodium hydroxide was added to correct the pH to smaller (acid) or higher (basic) values.

While functioning, the pilot plant reached a conversion rate of 0.165–0.175 kg/kg producing an average gas flow of 0.28 cm3/s. The raw material of the experimental plant consisted of various animal protein waste (cattle, horses, pigs, etc.). Figure 4 shows the experimental installation.

Figure 4.

Experimental installation.

The biogas obtained had a percentage composition within the following limits:

- Methane (CH4), 42–64%;

- Carbon dioxide (CO2), 55–30%;

- Hydrogen (H2), 0.95–1.15%;

- Hydrogen sulfide (H2S), 0.01–0.8%;

- Nitrogen (N2), 2.04–4.05%.

The operation of the pilot installation, of small capacity (0.3 Nm3/h), was strongly influenced by the variation in protein quality. Thus, the obtained biogas had a time quality variation leading to the variation of concentration in the specified ranges. The gas quality was not homogenized (through storage in a recipient) as the purpose was not energy generation, but the quality of biogas delivered by this installation. Hence, it was envisaged that the research conducted was would ensure hydrogen combustion for extreme qualities, and also for average quality obtained through storage.

The lower calorific value of the biogas produced was 15,118–23,191 kJ/Nm3, obtained from:

where = 35,764 kJ/m3N, = 10,050 kJ/m3N, = 23,354 kJ/m3N.

The biogas was burned and the combustion gases were analyzed with the analyzer showed in Figure 5. The values obtained fell within the limits presented in the scientific literature, including lower calorific power, thus validating the procedure employed.

Figure 5.

Analyzer for combustion gases investigation.

2.3. Energy Use of Raw Vegetable Oils

Romania has a vegetable crop processing industry which produces various oils on a European scale. Thus, for energy applications, a research theme is the use of these vegetable oils mixed with diesel fuel (Figure 6).

Figure 6.

Experimental installation.

Just as rapeseed oil is intended as a biofuel for internal combustion engines, the use of sunflower oil for energy production is being intensively investigated in the expectation that this goal too will soon be possible, particularly as, rapeseed and sunflower are the most productive oilseeds in Europe.

Rapeseed oil blended with traditional fuel is used in internal combustion engines, following a well-established technology. For sunflower oil, its combustion when mixed with classic fuel is a direct use solution.

Experimental research was carried out with crude oils, without chemical modification, mainly oils obtained exclusively by mechanical pressing. The investigations were performed for various mass ratios between crude vegetable oils and diesel fuel. Therefore, the dosing mixture is reported in mass units and does not take into account lower calorific power differences.

The substances are completely miscible, resulting in a perfect homogenization of the combustion mixture. The experiments were carried out for two values of mass proportions: 20% and 50% vegetable oil in classic fuel. A lightweight liquid fuel (LLF) was used as classic fuel. The mixture of vegetable oil and light liquid fuel did not contain mechanical impurities or sediment. Next, we considered the mixtures subjected to combustion as follows:

- Mix 1: 20% vegetable oil and the rest LLF;

- Mix 2: 50% vegetable oil and the rest LLF;

- Mix 3: 20% vegetable oil and the rest diesel;

- Mix 4: 50% vegetable oil and the rest diesel.

The viscosity of the mixture was lower than that of light fuel, which had a positive effect on the combustion process, especially on particle dispersion. At the same time, this led to increased volatility and a reduction in coke and asphaltene content. The low calorific power (LHV) of raw vegetable oils has slightly lower values compared to lightweight fuel. On the other hand, vegetable oils have a high ignition point temperature, between 254–321 °C, much higher than that of gas oil or light fuel, with values around 81–110 °C.

Regarding vegetable oils’ kinematic viscosity dependent on temperature, Figure 7 shows that for corn and soy it decreased and tended towards a constant value around 100 °C, but for sunflower it reached a minimum at approximately 80 °C and then increased again with temperature. Increasing the preheating temperature of the sprayed liquid by 20 °C led to a halving of the kinematic viscosity; thereby, allowing for better spraying, increasing the reaction surface and resulting in better burning (reducing the unburned fraction). At the same time, it reduces energy consumption for spraying. Figure 7 also illustrates the kinematic viscosity variation with temperature for two combustion blends, one consisting of crude vegetable oils and LLF and the other composed of the same oils and diesel. Compared to the pure vegetable oil kinematic viscosity, results showed that the first combustion mix (with LLF) had higher values of viscosity, which decreased as the ratio of vegetable oil increased, on the one hand, and as the temperature increased on the other hand. For the second combustion mixture (with diesel), the differences were barely notable; varying both the temperature and the vegetable oil ratio led to the viscosity dropping slightly, although it still had lower values than the pure oil.

Figure 7.

Kinematic viscosity comparison.

Research on the combustion of mixtures of raw vegetable oil and light fuel oil has also focused on the most constructive solutions for medium power burners intended for burning crude vegetable oils.

A steam boiler with a 2 MW heat output was used for the experiment; it was equipped with a burner and the grate, both of them being specially designed and built for burning raw vegetable oils, with a maximum flow rate of vegetable oil to the burner of 90 kg/h.

A multi-function device with integrated functions, MASILYZER NG, was used to monitor the combustion gases.

2.4. Innovative Energy Vector: Clean Hydrogen-Solid Biomass

The proposed and investigated innovative energy mix combines the positive effects of hydrogen and solid biomass on carbon emissions being, therefore, a clean energy vector.

The research focused on finding an efficient co-firing technology for hydrogen-rich gas (HRG)—solid biomass and HRG was produced through an electrolytic process.

The investigations were conducted over a three-year period and the influence of HRG on the different categories of solid biomass was analyzed, including for: sawdust, energy willow, cut wood, corn cobs, vines, and straw briquettes. Experimental determinations of biomass burning, with and without HRG, were performed to highlight the beneficial effects of this technology.

The biomass of interest for energy recovery includes agricultural and wood residues. It is estimated that one third of this biomass is agricultural residues.

Figure 8 shows the experimental installation.

Figure 8.

Experimental installation.

For the solid biomass HRG co-firing experiments, HRG generation was undertaken with an industrial portable apparatus located near the firing plant. For safety reasons, the device was equipped with an anti-explosion valve and an external sensor for detection of possible HRG leakage.

By positioning the apparatus near the combustion plant, no accumulation or storage was required and the bioassay and HRG mixture were quasi-stoichiometric. The components of the HRG plant are shown in Figure 9 and Figure 10. Measurement of blackout was done with two S-type thermocouples. One of these had a measurement range from −30 °C to 180 °C, and the other from −35 °C to 400 °C.

Figure 9.

Installation components.

Figure 10.

Measuring devices: (a) gas analyzer and data acquisition system; (b) exhaust gases analyzer.

Research on solid biomass co-burning with HRG has been carried out for a very long time, about 10 years, and various types of solid biomass have been used. Table 2 presents the main energy characteristics for solid biomass: lower calorific value (LHV), initial humidity (Wt) and ash at initial state (Ai).

Table 2.

Biomass parameters.

3. Results

3.1. Animal Fat

For the interpretation of the experimental results used the method of errors analysis by the variation ratio was used. The variation ratio did not exceed 1%, due to engine running stability. For all experimental investigations, the engine parameters were maintained at the following nominal values: the injection time was setup (β = 13 °CA), which defined the self-ignition delay duration; and the compression ratio—ε = 13.80.

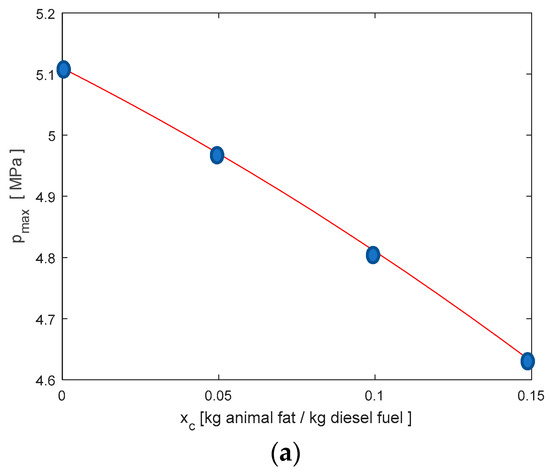

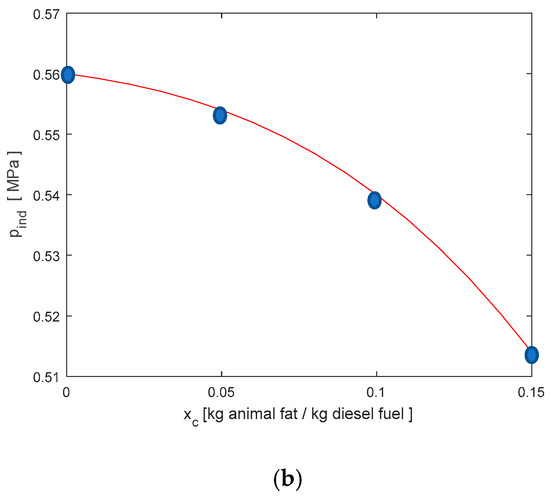

For the diesel engine, the maximum pressure (pmax) and the indicated mean effective pressure (pi) variations versus animal fat content are shown in Figure 11a,b.

Figure 11.

Maximum pressure (a) and indicated mean pressure (b) variation for different xc, at constant engine setup parameters.

Under constant engine parameter (classic injection timing) conditions, the maximum pressure (pmax) showed a linear decreasing trend of variation with the animal fat concentration; because of the auto-ignition delay increase with the rise of animal fat content in the blend with diesel fuel, the increase of animal fat content led to worsening fuel atomization, Figure 11a. Compared to diesel fueling, the maximum pressure decreased by 9% for maximum xc. With the rise of animal fat content in the blend with diesel fuel, the indicated mean effective pressure also decreased by 8% at maximum xc, because the auto-ignition delay increased with animal fat use, Figure 11b.

Similar combustion aspects were obtained in [4,5,6,7] with the use of preheated animal fats to fuel diesel engines, which led to a decrease of in-cylinder maximum pressure and indicated mean effective pressure correlated with the increase of the auto-ignition delay, at a constant value of injection timing.

In order to compensate for the increase of auto-ignition delay with the rise of animal fat content in the final fuel, the injection timing was increased from 13 °CA to 15.8 °CA with the rise of the animal fat percentage in the blend; thus the combustion process started at TDC (top dead centre), Figure 12. The variation of the injection timing, which compensated for the atomization worsening with animal fat use, led to an increase of indicated mean effective pressure (pi) of 7.19% compared to the pure diesel fuel combustion, Figure 12.

Figure 12.

Indicated mean effective pressure variation for different xc, at variable engine setup parameters.

Thus, the increase of the injection timing compensated for the negative influence of animal fat content increase on auto-ignition delay and combustion and improved the indicated mean effective pressure values (pi). Similar aspects and influences are presented in References [5,7,19] in which the adjustment of injection timing was used to increase the indicated mean effective pressure of the biodiesel-diesel blend used to fuel a diesel engine. The variation in NOx and smoke concentration depending on the mass ratio of animal fats to diesel fuel is shown in Figure 13. It emerged that, in Case 1, the NOx emission levels increased with the animal fat concentration, starting from about 60% of the pure fuel emission level. For animal fat concentrations above 0–125 emissions reached almost the same value, or slightly higher, than in the no animal fat conditions. The minimum value of the emissions was registered at the minimum value of 0.05 . In the second case, the results were inconclusive.

Figure 13.

Emission levels and smoke concentration.

It emerged that the smoke concentration decreased by half when comparing results from the combustion of exclusively diesel and the mixture with the smallest animal fat concentration; further, the smoke concentration reduced as the animal fat mass ratio increased. The observations are valid for both cases, the decrease being even larger in the second case.

The pilot combustion plant of the diesel fuel mixture had correct combustion with a flame as shown in Figure 14. The air inlet temperature, equal to the ambient of the installation location, was 30 °C. The flame of the blend of diesel-animal fat was monitored through a circular window placed above the burner on the boiler front. The flame size and its compatibility with the burner and furnace were investigated. For all three mixtures with animal fats, the flame had a clear yellow color, very close to the color of the flame obtained by burning pure diesel fuel, and the temperature was 1900–2050 °C. Figure 14 illustrates the flame image for the three mixtures with animal fats. Figure 14c shows an adequate flame even for a 30% animal fat blend with diesel fuel.

Figure 14.

Flame shape.

Experimental determinations have shown that it is technologically feasible to burn animal fats mixed with diesel fuel. Very low NOx emission values, with a mean of 26 ppm were obtained.

Combustion efficiency (yield) varied between 69% and 72.6%. The yield was determined for a chimney gas temperature between 284 °C and 337 °C. Emission of carbon monoxide, CO, was between 0.092% and 0.364%.

The overall conclusion drawn from all research into the energy recovery of raw animal fat is that it is perfectly achievable with current technologies up to a mass percentage of 10–15% fats in diesel, both by combustion in the engine and in an outbreak. The main advantage of using a blend of fats and classic fuel is that they combine to reduce fume emissions, mainly smoke and NOx emissions. In particular, for the diesel engine, if the setup parameters of the engine remain unchanged, the indicated mean effective pressure increases and the maximum pressure during animal fat-diesel fuel blend combustion is reduced compared to diesel fuel combustion. Increasing the animal fat concentration to more than 10–15% has undesirable effects because it leads to an increased self-ignition delay and reduction of the combustion efficiency, reflected in indicated mean effective pressure values. Therefore, it increases the specific energy consumption and the concentration of CO and HC in combustion gases.

From the experimental data obtained it was concluded that by correlating the fuel injection time with the fat concentration, the negative effects on engine operation are reduced. The direct combustion of the blend of fats with classic fuel is perfectly achievable and can be an economical solution to remove this waste from the leather industry through an environmentally-friendly and energy-efficient process. Fats of animal origin from the leather industry are present in significant quantities and are an important environmental issue for the leather industry.

The characteristics of the miscibility of animal fat in the classic fuel allow the use of regular nozzles. The preheat temperature of the fats and, therefore, their blend with classic fuel is 45–50 °C, which is perfectly feasible. It should be noted that this preheat temperature depends on the quality of the animal fats and the characteristics of the burner.

3.2. Crude Vegetable Oils

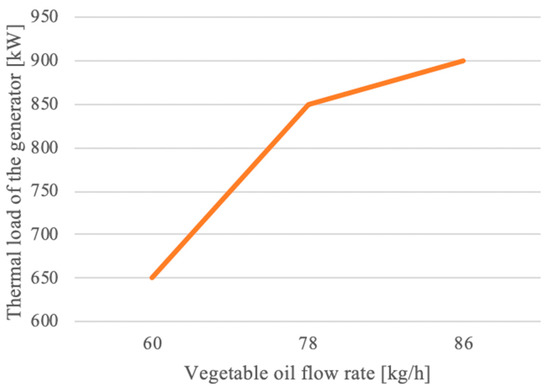

Figure 15 shows the results obtained for the combustion of crude vegetable oil, using a burner with a rotating cup specially manufactured for the purposes of this research as illustrated in Figure 6. The burner was mounted on the 2 MW pilot boiler as previously described, and allowed to reach 900 kW thermal power for a vegetable oil flow rate of 86 kg/h.

Figure 15.

Thermal load variation with vegetable oil flow rate.

It can be seen that up to a flow rate of around 78 kg/h, the thermal loading of the generator increases linearly, by 11.11 kW/(kg/h). Exceeding this value, the slope at which the heat output increases halves.

Based on the experimental results, the following observations can also be made:

- The air excess decreased with the thermal loading of the generator, stabilizing at 1.6 close to the nominal load;

- Exhaust gas temperatures were only slightly influenced by variation in both thermal loading of the generator and vegetable oil flow rate;

- Pollutant emissions were also only slightly influenced by the thermal loading of the generator and vegetable oil flow rate, with the following limits: 240–250 mg/m3 carbon oxide, 140–150 mg/m3 nitrogen oxides. The sulfur dioxide emission was constant, at 6 mg/m3. These low recorded values indicate that the burning of vegetable oils has a reduced impact on the environment;

- Analysis of the composition of the combustion gases showed that the percentage of carbon dioxide did not exceed 11.5%.

3.3. Hydrogen-Solid Biomass

Experimental determinations of HRG co-burning with solid biomass were carried out in a furnace with the installed thermal power of 400 kW. For comparison, each type of bioassay was tested in the firing process alone and then mixed with HRG. The amount of HRG injected for biomass co-burning was 15 L for 1 dm3 of biomass. The flame, with HRG thermal support, resulting from grate combustion for various categories of biomass is illustrated in Figure 16. The image was acquired through a visualization aperture placed 1.5 m above the boiler grate. Figure 16a illustrates the results obtained for combustion chopped wood, while Figure 16b shows the results for string vines. Figure 16c illustrates the results obtained by burning corn cobs (the characteristics data are reported in Table 2).

Figure 16.

Flame shape: (a) obtained flame by burning chopped wood; (b) obtained flame by burning string vine; (c) obtained flame by burning corn cobs.

Combustion gases at the end of the furnace were analyzed with the HORIBA gas analyzer, type PG250. This analyzer is reliable, versatile and allows simultaneous measurement of five components: NOx, SO2, CO, CO2 and O2. These can be measured both continuously and intermittently.

At the same time, combustion gases were analyzed with the NG MAXILYZER equipped with a double filtration system (humidity and dust). This analyzer has measurement cells for O2, CO, NO, NO2, and SO2.

Based on measured data, the analyzer calculates the excess air, CO2, and CO in the air, along with the efficiency and heat loss in the combustion gases.

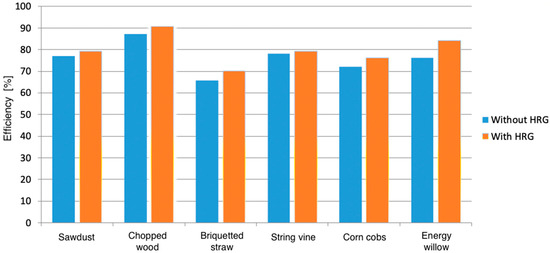

As shown in Figure 17, combustion efficiency increased by up to 5% when HRG was used, but this percentage depended on the type of solid biomass. The lowest efficiency was recorded for the burning of briquetted straw and the highest for chopped wood combustion; an explanation of this would be the difference in porosity of the materials.

Figure 17.

Combustion efficiency with/without HRG.

As shown in Figure 18, by using HRG the pollutant concentration reduced by almost 50%. The lowest pollutant concentration was recorded for chopped wood combustion, representing less than 30% of the highest concentration value which was for string vine. The greatest influence was observed regarding the burning of sawdust and corn cobs. Regarding the ratio of each pollutant emission in the total amount, it can be observed that the highest contribution belonged to carbon monoxide, followed by the nitrogen oxides and sulfur dioxide for which the ratio never exceeded 10%.

Figure 18.

Concentration of pollutants.

The combustion of solid biomass in the presence of HRG leads to positive synergistic effects, thus reducing not only the overall level of pollutants produced (NOx, CO, CO2, dust), but also the SO2 concentration by injection of hydrogen or HRG.

4. Conclusions

This paper presented the experimental results of combustion a large range of biomass types. The combustion technology adopted was burning chopped solid biomass, with or without HRG support, and also biomass represented by animal fats blended with liquid fuel in mechanical spray pumping technology. The combustion of solid biomass in the presence of HRG leads to positive synergistic effects, thus reducing not only the overall level of pollutants produced (NOx, CO, CO2, dust), but also the SO2 concentration by injection of hydrogen or HRG.

The direct combustion of the blend of fats with classic fuel is perfectly achievable and can be an economical solution to remove this waste from the leather industry through an environmentally- friendly and energy-efficient process. Fats of animal origin from the leather industry are present in significant quantities and are an important environmental issue for the leather industry. Experimental investigations revealed high-quality burning in the sense of a continuous, clear and bright flame, and good combustion efficiency. In all cases tested, the CO concentration and general level of NOx were reduced.

Author Contributions

Conceptualization, G.L., L.M. and C.P.; Methodology, G.L., L.M. and C.P.; Data curation, G.N. and I.P.; Writing— review and editing, G.L., L.M., A.C. and D.A.C.

Funding

This work was supported by a grant from the Romanian Ministry of Research and Innovation, CCCDI—UEFISCDI, project number PN-III-P1-1.2-PCCDI-2017-0404/31PCCD/2018, within PNCDI.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Future Transport Fuels. Report of the European Expert Group on Future Transport Fuels; ALBA-Fachverlag: Dusseldorf, Germany, 2011. [Google Scholar]

- United Nations Industrial Development Organization. Wastes generated in the leather products industry. In Proceedings of the Fourteenth Session of the Leather and Leather Products Industry Panel, Zlin, Czech Republic, 13–15 December 2000. [Google Scholar]

- Lazaroiu, G.; Pana, C.; Mihaescu, L.; Cernat, A.; Negurescu, N.; Mocanu, R.; Negreanu, G. Solutions for energy recovery of animal waste from leather industry. Energy Convers. Manag. 2017, 149, 1085–1095. [Google Scholar] [CrossRef]

- Kumar, A.; Kerihuel, J.; Bellettre, J.; Tazerout, M.; Senthyl, M. The use of the preheated animal fat as fuel in a compression ignition engine. Renew. Energy 2005, 30, 1443–1456. [Google Scholar] [CrossRef]

- Kumar, M.S.; Kerihuel, J.; Bellettre, J.; Tazerout, M. A comparative study of a different methods of using animal fat as a fuel in a compression ignition engine. J. Eng. Gas Turbines Power 2006, 128, 907–914. [Google Scholar] [CrossRef]

- Pham, P.X.; Bodisco, T.A.; Stevanovic, S.; Rahman, M.D.; Wang, H.; Ristovski, Z.D.; Brown, R.J.; Masri, A.R. Engine performance characteristics for biodiesels of different degrees of saturation and carbon chain lengths. SAE Int. J. Fuel Lubr. 2013, 6, 188–198. [Google Scholar] [CrossRef]

- Stengel, B.; Vium, J.H. Synthesis, Characterization and Use of Hydro-Treated Oils and Fats for Engine Operation. In A Report from IEA Advanced Motor Fuels Implementing Agreement; Alberta Innovates Technology Futures-Fuels and Lubricants: Edmonton, AB, Canada, 2015; pp. 1–51. [Google Scholar]

- Lazaroiu, G.; Pop, E.; Negreanu, G.; Pisa, I.; Mihaescu, L.; Bondrea, A.; Berbece, V. Biomass combustion with hydrogen injection for energy applications. Energy 2017, 127, 351–357. [Google Scholar] [CrossRef]

- Pisa, I.; Lazaroiu, G.; Mihaescu, L.; Prisecaru, T.; Negreanu, G.P. Mathematical model and experimental tests of hydrogen diffusion in the porous system of biomass. Int. J. Green Energy 2016, 13, 774–780. [Google Scholar] [CrossRef]

- Pisa, I.; Lazaroiu, G.; Prisecaru, T. Influence of hydrogen enriched gas injection upon polluting emissions from pulverized coal combustion. Int. J. Hydrog. Energy 2014, 39, 17702–17709. [Google Scholar] [CrossRef]

- Neri, E.; Cespi, D.; Setti, L.; Gombi, E.; Bernardi, E.; Vassura, I.; Passarini, F. Biomass residues to renewable energy: a life cycle perspective applied at a local scale. Energies 2016, 9, 922. [Google Scholar] [CrossRef]

- Maj, G. Emission factors and energy properties of Agro and forest biomass in aspect of sustainability of energy sector. Energies 2018, 11, 1516. [Google Scholar] [CrossRef]

- Adam, I.K.; Abdul Aziz, A.R.; Heikal, M.R.; Yusup, S.; Firmansyah; Ahmad, A.S.; Zainal Abidin, E.Z. Performance and emission analysis of rubber seed, palm, and their combined blend in a multi-cylinder diesel engine. Energies 2018, 11, 1522. [Google Scholar] [CrossRef]

- Prochazka, P.; Honig, V. Economic Analysis of diesel-fuel replacement by crude palm oil in indonesian power plants. Energies 2018, 11, 504. [Google Scholar] [CrossRef]

- Bartocci, P.; Zampilli, M.; Bidini, G.; Fantozzi, F. Hydrogen rich gas production through gasification of charcoal pellet. Appl. Therm. Eng. 2018, 132, 817–823. [Google Scholar] [CrossRef]

- Molino, A.; Larocca, V.; Chianese, S.; Musmarra, D. Biofuels production by biomass gasification: A review. Energies 2018, 11, 811. [Google Scholar] [CrossRef]

- Cancela, A.; Pérez, L.; Febrero, A.; Sánchez, A.; Salgueiro, J.L.; Ortiz, L. Exploitation of Nannochloropsis gaditana biomass for biodiesel and pellet production. Renew. Energy 2019, 133, 725–730. [Google Scholar] [CrossRef]

- Bartels, J.R.; Pate, M.B.; Norman, K.; Olson, N.K. An economic survey of hydrogen production from conventional and alternative energy sources. Int. J. Hydrog. Energy 2010, 35, 8371–8384. [Google Scholar] [CrossRef]

- Ge, J.G.; Kim, M.S.; Yoon, S.K.; Choi, N.J. Effects of the pilot injection timing and egr on combustion, performance and exhaust emissions in a common rail diesel engine fueled with canola oil biodiesel-diesel blend. Energies 2015, 8, 7312–7325. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).