Method for the Energy Storage Configuration of Wind Power Plants with Energy Storage Systems used for Black-Start

Abstract

1. Introduction

2. WPP with ESS in Black-Start

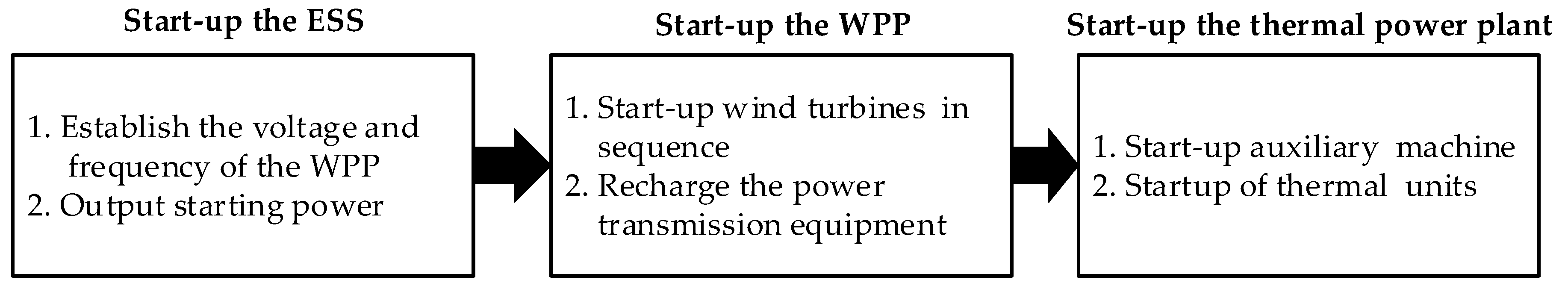

2.1. The Process of Black-Start

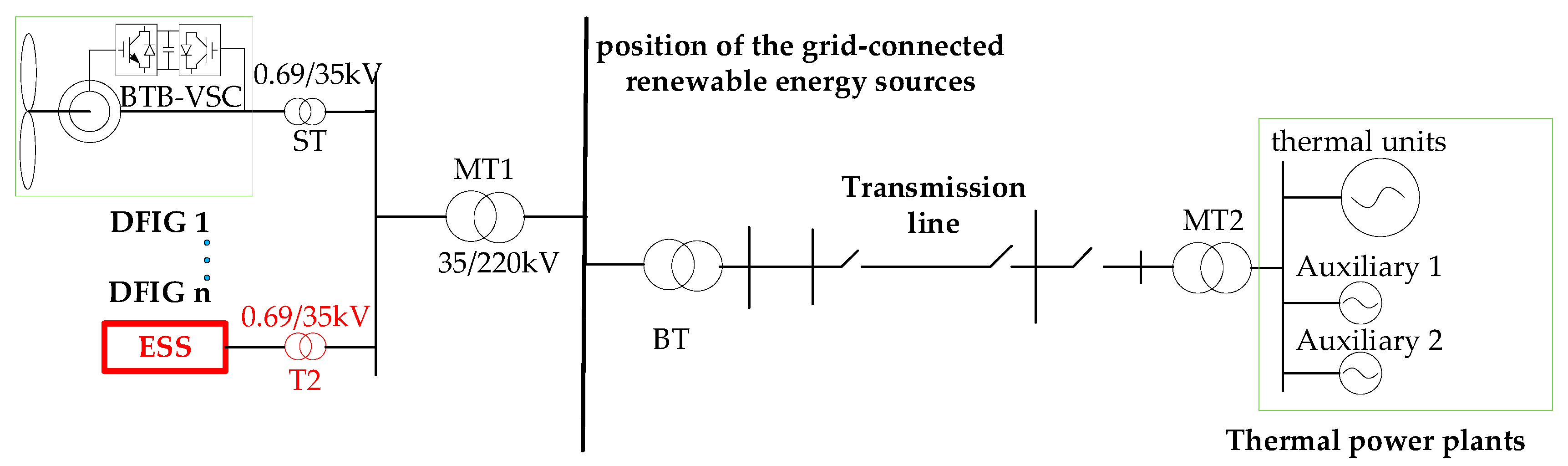

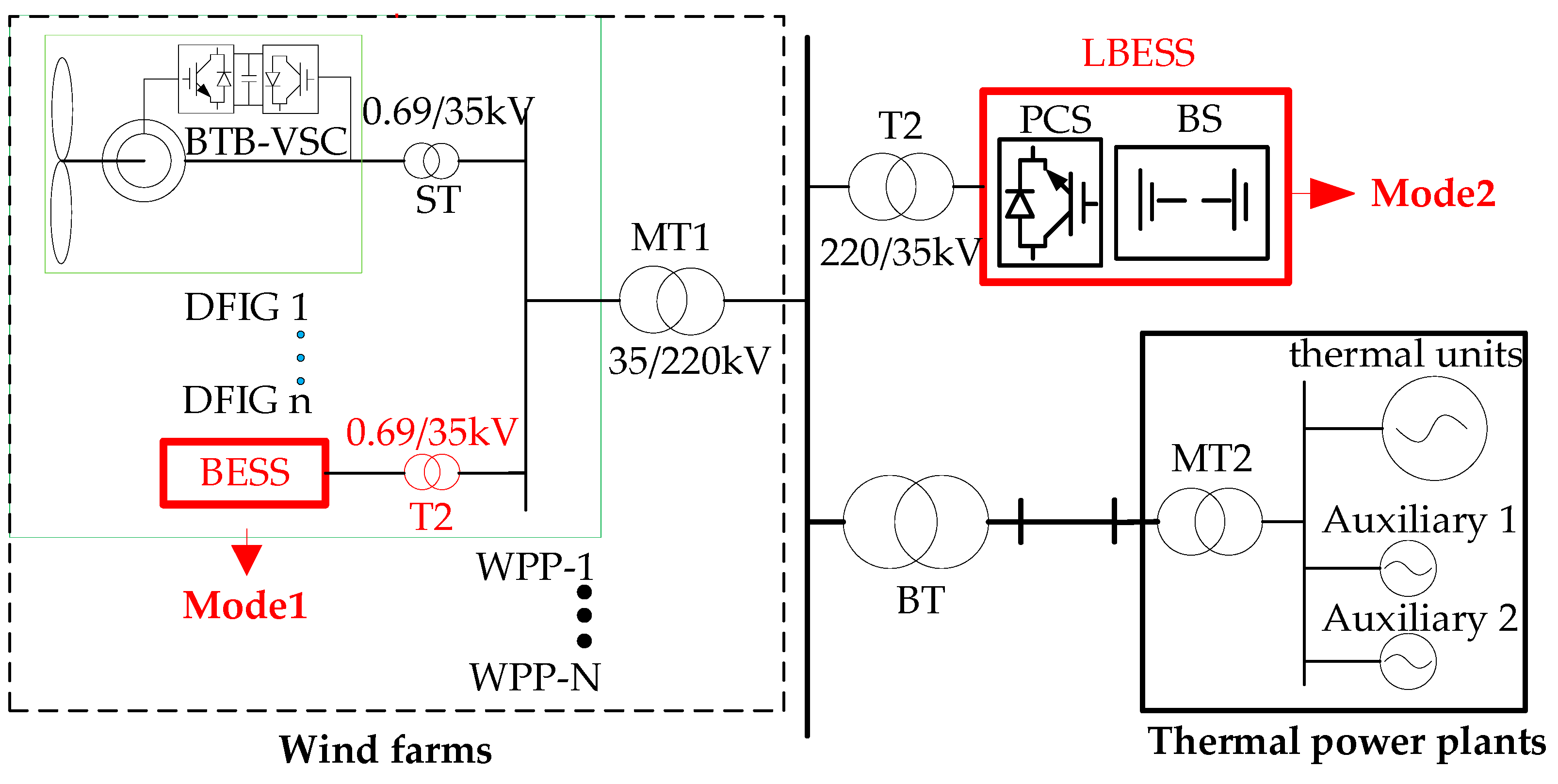

2.2. The Configuration Mode of Energy Storage

- When starting the wind turbine, multiple voltage conversions are needed. Three voltage conversions are required simultaneously in mode 2, which causes operational problems.

- The energy storage power station is multi-tasked and cannot ensure the reliability of the black-start. For example, the residual energy of the system that is involved in peak shaving cannot meet the demand from the wind turbines.

- In the black start, the energy storage capacity has not been determined. Each wind farm has its own energy storage demand in the black start, and there is no clear demand for energy storage. However, it is relatively easy to build energy storage power stations at the position of the grid-connected renewable energy sources, which are mainly used to stabilize renewable energy sources fluctuations. Moreover, considering the high cost of energy storage power station construction, it will create a situation, which is a demonstration project that has already been built in mode 2, but it is still being researched in mode 1.

3. Method for the Energy Storage Configuration Based on the Hierarchical Planning Model

3.1. Energy Storage Capacity and Configuration, and the Starting Efficiency Analysis of the WPP

3.2. Configuration and Layout of the Energy Storage

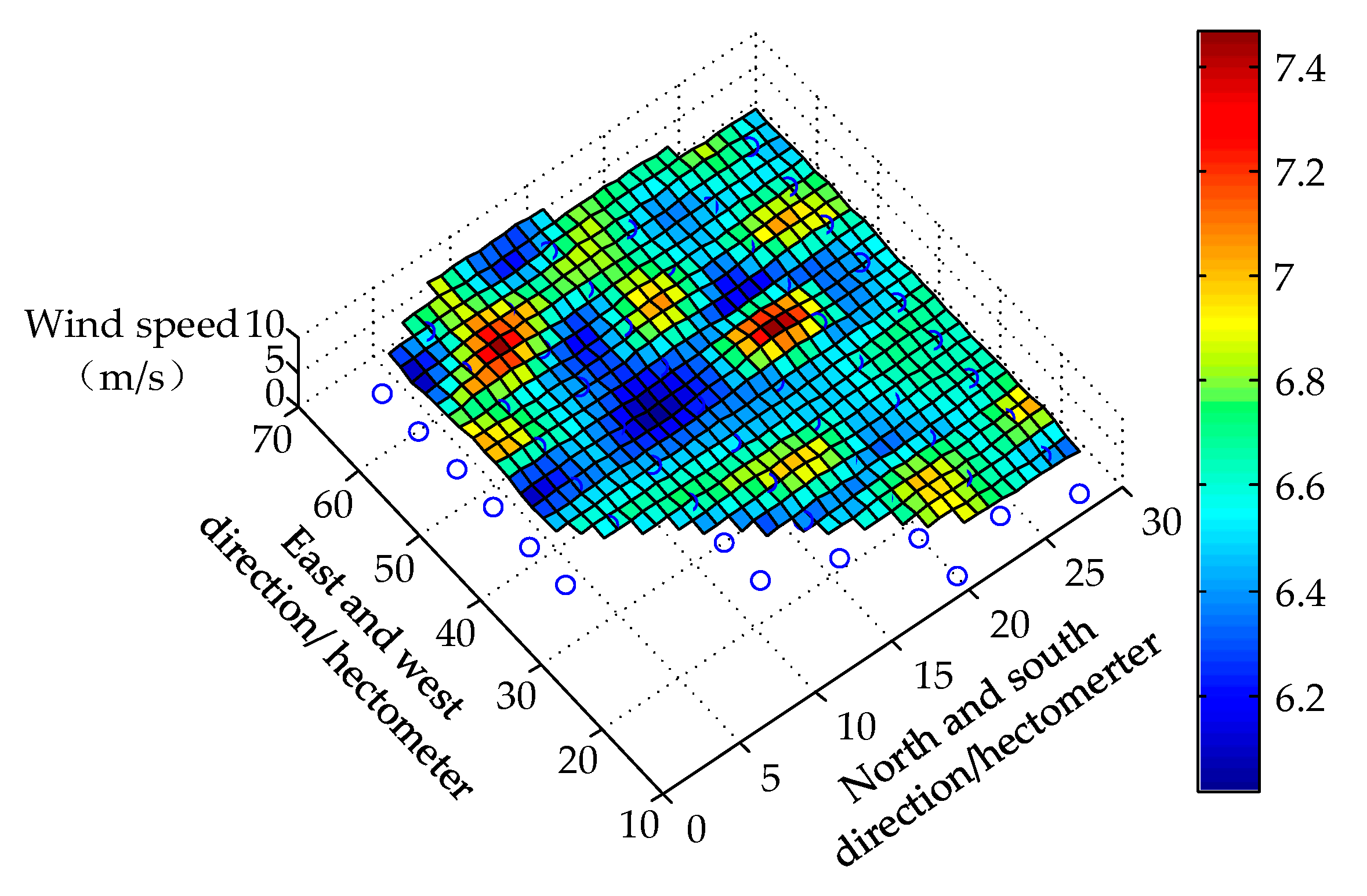

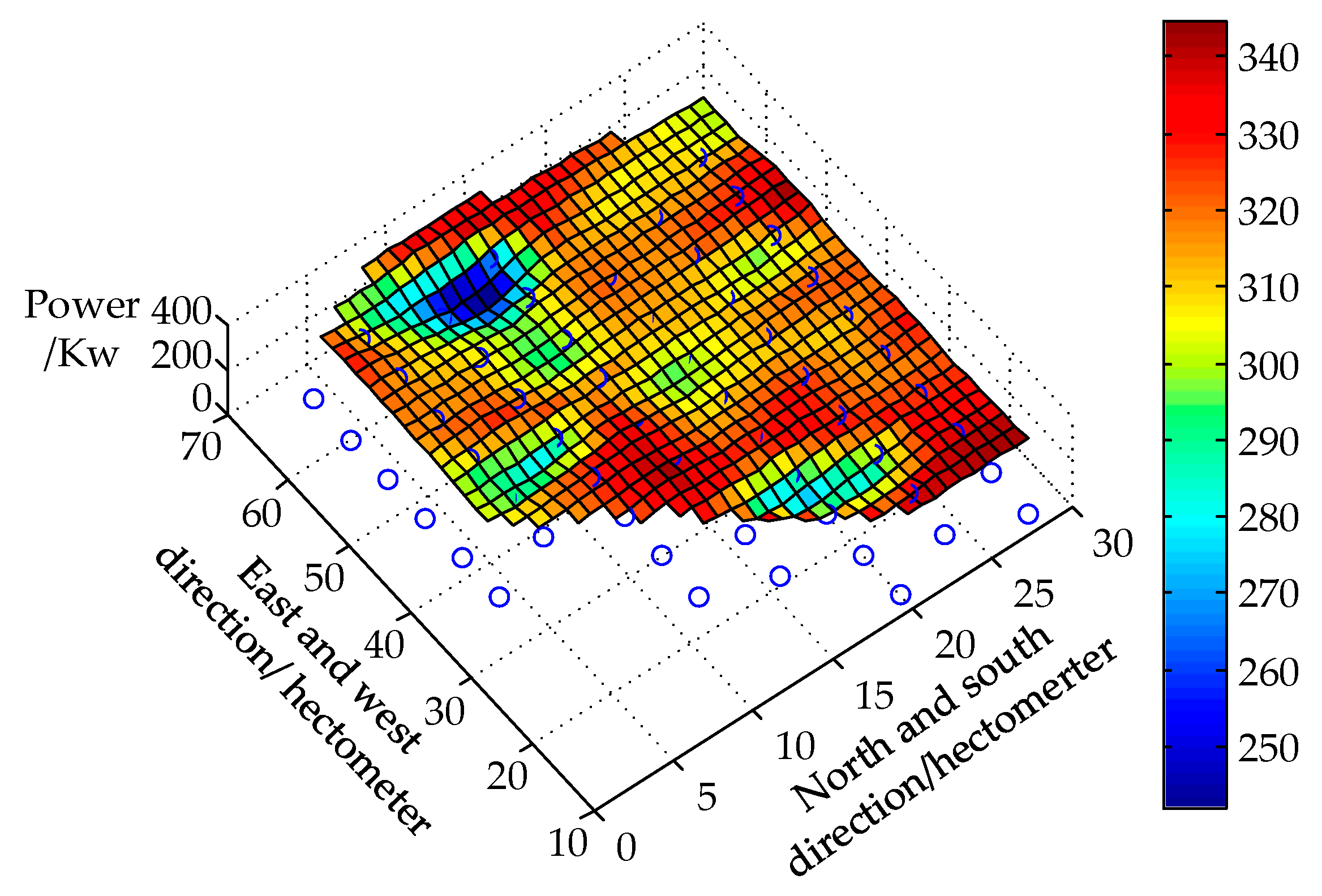

- Considering the position of the turbine in the WPP, the wake effect leads to a difference in the wind energy distribution.

- Excluding dispatching, the historical output duration of the turbine reflects the “health” situation of the turbines.

- The matching degree between the historical wind speed and the historical output of the turbine reflects the comprehensive utilization efficiency of the wind speed for the turbines.

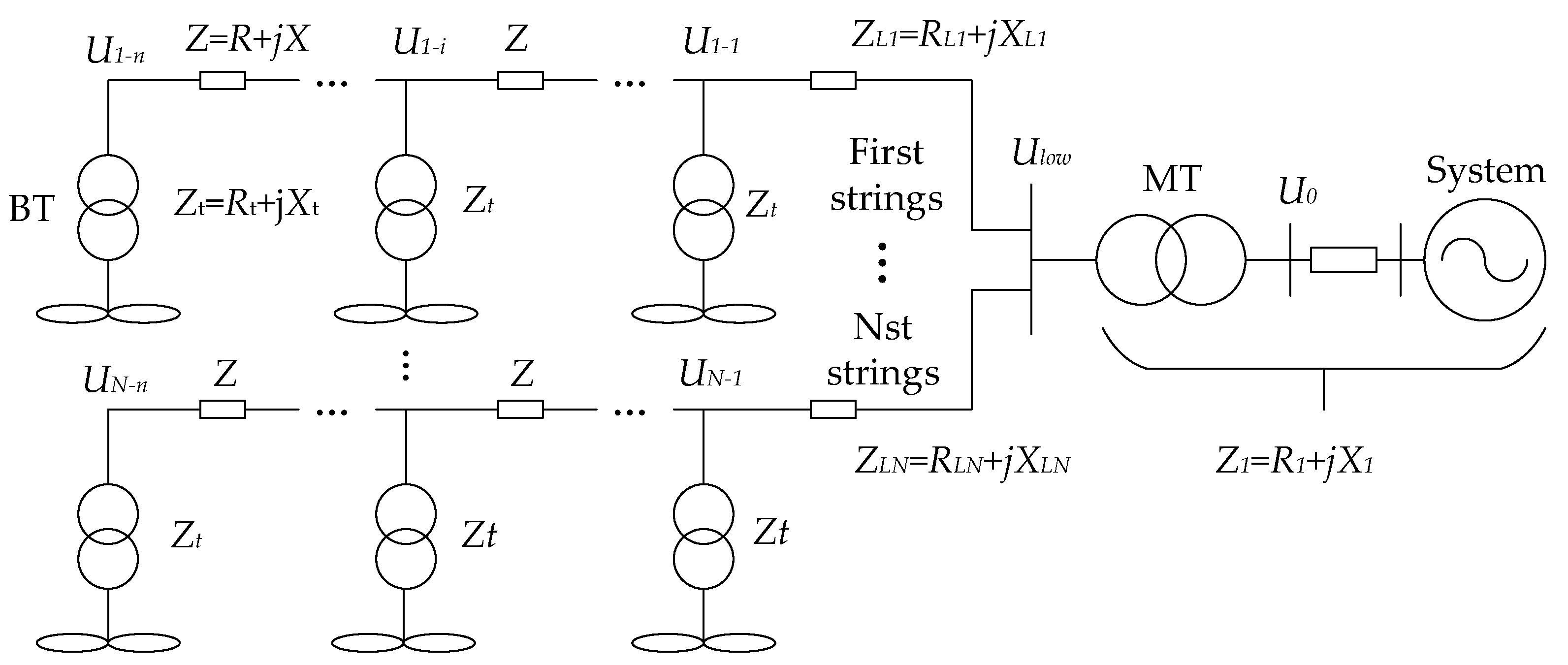

3.3. Reactive Power of the Collector System in the WPP—Voltage Characteristics

4. Hierarchical Planning Model of the Energy Storage Configuration

4.1. Constructing the Capacity Optimization Layer

4.2. Energy Storage Capacity and Configuration, and the Starting Efficiency Analysis of the WPP

- The yaw system can capture the wind energy of the wind turbine most of the time.

- The power of each turbine can reflect the overall operation of the turbine.

- The wind speed can reflect the basic external conditions of the generating turbine to embody the power loss caused by the dispatch and breakdown.

4.3. The Starting Order Constraint Conditions of the Turbine

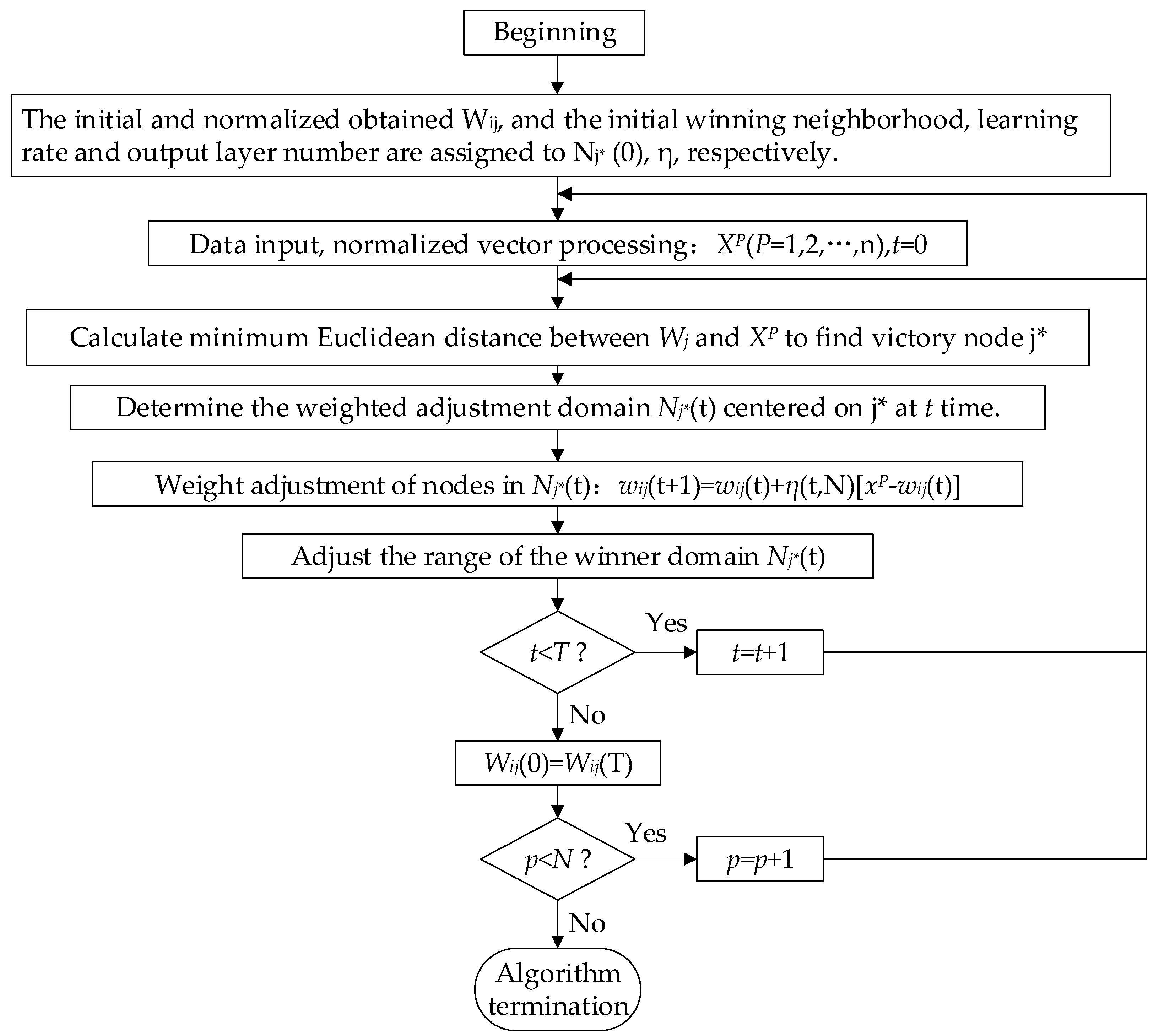

4.4. The Solving Method for the Entire Model

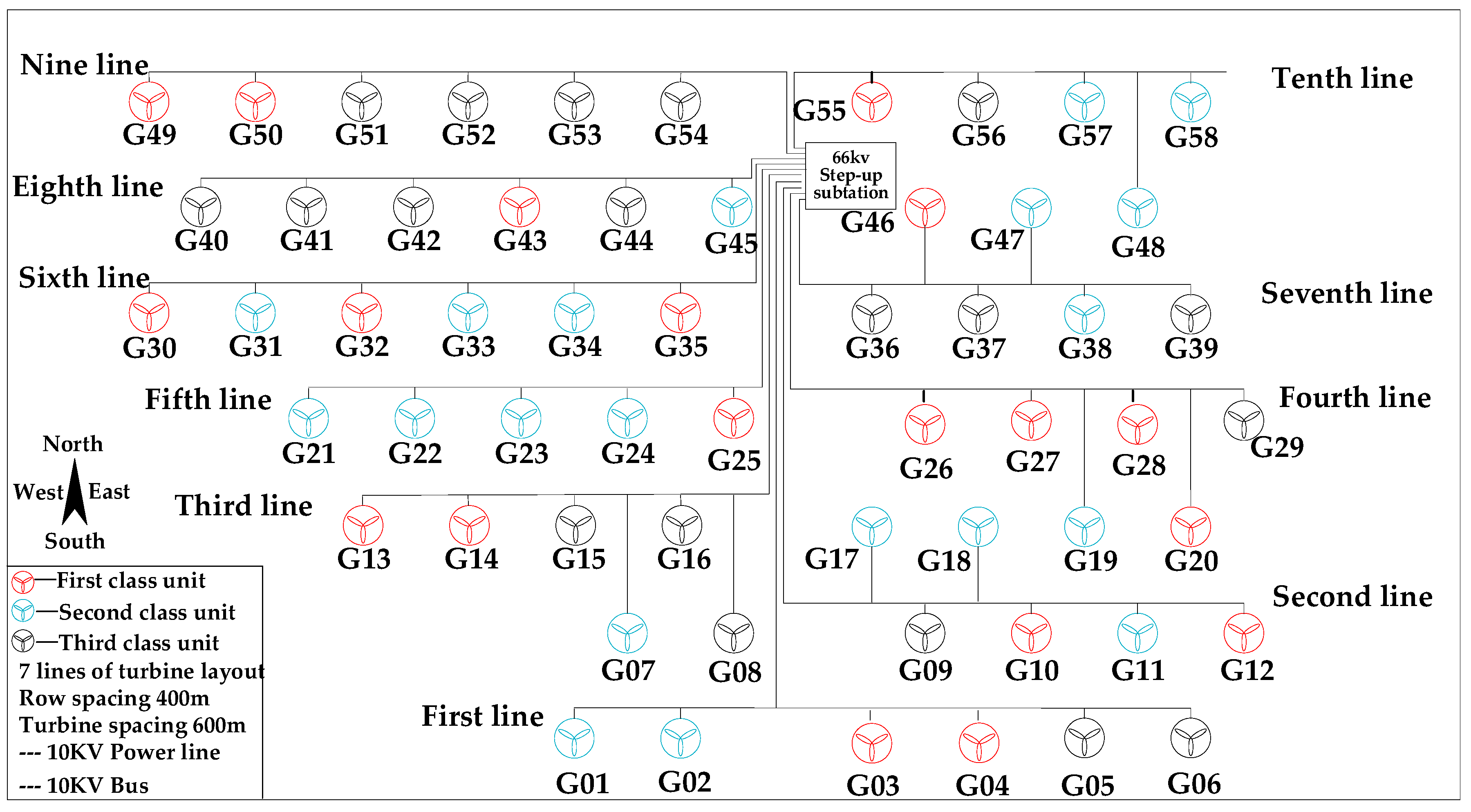

5. Case Study

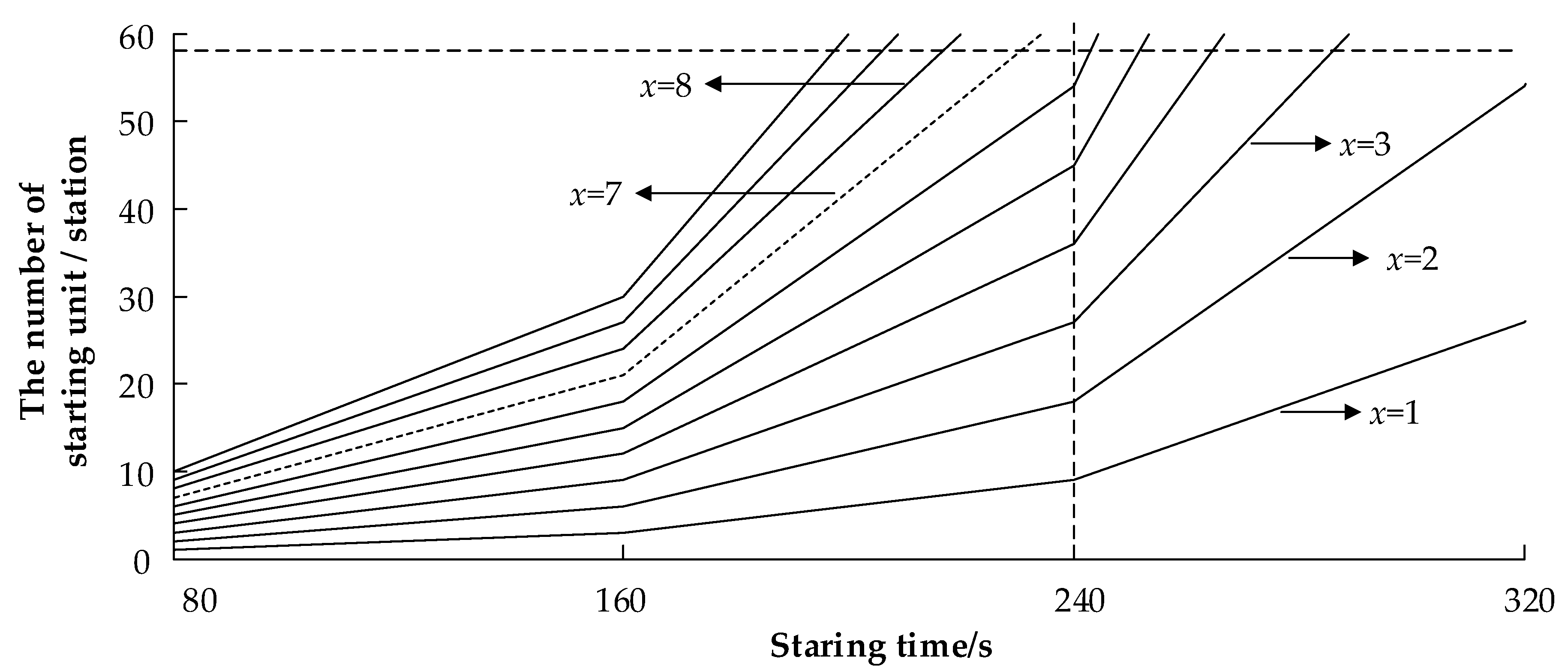

5.1. Energy Storage Configuration and Capacity

5.2. Turbines with Energy Storage

- Between the correlation coefficients of turbine 4 and turbine 3, 35 is slightly lower, and the correlation coefficient between turbine 4 and the other turbines is greater than 0.9.

- The average correlation coefficient between turbine 28 and the other turbines is 0.87. The average correlation coefficient between turbine 28 and the other turbines is 0.78.

- Therefore, we select a turbine whose the correlation coefficient is greater than 0.7. The priority turbines are then 3, 4, 25, 26, 28, 46, and 55.

5.3. Plan for the Starting Sequence of the Turbines

- For the condition of i < 3 from Equations (5) and (9), the following steps are the plan for the starting sequence of the turbine.

- For turbines on the same collector line: When a turbine with energy storage is preferentially started, the other turbines are started in sequence from near to far, according to the distance of the bus-bar.

- For turbines on different collector lines: Other collector lines that are unequipped with stored energy are started in sequence from near to far, according to the distance of the bus-bar.

6. Conclusions

- With respect to the energy storage configuration and capacity, a single turbine with the energy storage to drive other turbines is adopted. In 240 s, seven wind turbines with ESSs (a power rating of 2.24 MW and energy capacity of 1.68 MWh) are available in a 49.5 MW WPP.

- In terms of the distribution of the energy storage, according to the historical operation state of the turbine, the turbines are optimized and classified by the SOFM algorithm under the boundary conditions of the wind speed (Vm-i), the output power (Pw-i), and the matching degree between the wind speed and the output power (η). Next, a turbine with a correlation coefficient of greater than 0.7 is selected. This is accomplished in order to complete the energy storage layout and utilization maximization of the initial power.

- In order to solve the starting sequence of the turbines caused by the configuration and layout of the energy storage, the following conditions are required, in order to complete the self-starting of the WPP. First, a turbine with energy storage is used as the initial power source. Second, other turbines on the same collector line are started using the starting sequence of ‘n + 1’. The maximum reactive power variation of the turbine is 0.22 MW, and terminal voltage fluctuation is 0.06 p.u.

- In order to reduce the capacity of the frequency converter of the battery energy storage system, the reactive power compensation device in the WPP can be constructed or fully utilized.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Variables | |

| R | Radius of the wind wheel |

| ρ | Air density |

| Vm | Average wind speed of the initially starting turbine |

| PZ | Power of the plant demand for the starting turbine demand |

| PZ-Im | Power of the synchronous motor |

| PZ-R | Power of the other equipment |

| PZ | Self-starting power of wind turbine |

| Cp | Wind energy utilization coefficient |

| α | Capacity margin |

| x | Number of turbines initially starting |

| n | Number of starting turbines initially equipped energy storage |

| k | Starting batch |

| N | Turbine number |

| tf | Total time length of the wind turbine from starting turbine to stable output |

| Tall | Starting constraint time of the wpp |

| Inductance of the first turbine of collector line to the converging bus | |

| Impedance of the first turbine of collector line to the converging bus | |

| j | Line j |

| s | Line s |

| X | Inductance between the adjacent turbines on the same collector line |

| ULow | Converging bus voltage |

| ∂ | Terminal voltage variation of turbine k on the collector line j |

| ∂ | Reactive variation of turbine i on the collector line j |

| ∂ | Terminal voltage variation of turbine k on the collector line s |

| ∂ | Reactive variation of turbine on the collector line j |

| i | Number of the wind turbine |

| k | Number of the wind turbine |

| PS | Maximum power |

| Pi | Starting power of turbine i |

| Cs | Capacity of the energy storage |

| Vm-i | Wind speed |

| Pw-i | Output power |

| η | Matching degree |

| ∆ | Reactive power variation |

| PW | Active power |

| S | Apparent power |

| Abbreviation | |

| WPP | Wind power plant |

| ESS | Energy storage system |

| DFIG | Doubly fed induction generator |

References

- Leng, Y.J.; Lu, Q.; Liang, C.Y. Black-start decision making based on collaborative filtering for power system restoration. Int. J. Electr. Power Energy Syst. 2018, 100, 279–286. [Google Scholar] [CrossRef]

- Sun, P.; Liu, Y.; Qiu, X.; Wang, L. Hybrid multiple attribute group decision-making for power system restoration. Expert Syst. Appl. 2015, 42, 6795–6805. [Google Scholar] [CrossRef]

- Qu, H.; Liu, Y. Maximizing restorable load amount for specific substation during system restoration. Int. J. Electr. Power Energy Syst. 2012, 43, 1213–1220. [Google Scholar] [CrossRef]

- Liu, Y.; Gu, X. Skeleton-network reconfiguration based on topological characteristics of scale-free networks and discrete particle swarm optimization. IEEE Trans. Power Syst. 2007, 22, 1267–1274. [Google Scholar] [CrossRef]

- Chou, Y.T.; Liu, C.W.; Wang, Y.J. Development of a black-start decision supporting system for isolated power systems. IEEE Trans. Power Syst. 2013, 28, 2202–2210. [Google Scholar] [CrossRef]

- Liu, Y.T.; Wang, H.T.; Hua, Y.E. Power System Restoration Theory and Technology, 1st ed.; Science Press: Beijing, China, 2014; pp. 15–16. [Google Scholar]

- Li, J.H.; Kong, M.; Mu, G. Overview of re-searches on key technologies of power system black-start. South. Power Syst. Technol. 2017, 11, 68–77. [Google Scholar] [CrossRef]

- Liang, H.; Gu, X.P. Black-start network partitioning based on spectral clustering. Power Syst. Technol. 2013, 37, 372–377. [Google Scholar]

- Jiao, J.; Liu, Y. Optimization of units’ restoration sequence during network reconfiguration process based on robust optimization. Trans. China Electrotech. Soc. 2017, 32, 77. [Google Scholar] [CrossRef]

- Jerry, J.A. A framework for power system restoration following amajor power failure. IEEE Trans. Power Syst. 1995, 9, 1480–1485. [Google Scholar] [CrossRef]

- Liu, J.; Wen, J.Y.; Yao, W.Y.; Long, Y. Solution to short-term frequency response of wind farms by using energy storage systems. IET Renew. Power Gener. 2016, 10, 669–678. [Google Scholar] [CrossRef]

- Mehrasa, M.; Pouresmaeil, E.; Sepehr, A.; Pournazarian, B.; Marzband, M.; Catalão, J.P. Control Technique for the Operation of Grid-Tied Converters with High Penetration of Renewable Energy Resources. Electr. Power Syst. Res. 2019, 166, 18–28. [Google Scholar] [CrossRef]

- Liao, S.W.; Yao, W.; Han, X.N.; Wen, J.Y.; Cheng, S.J. Chronological operation simulation framework for regional power system under high penetration of renewable energy using meteorological data. Appl. Energy 2017, 203, 816–828. [Google Scholar] [CrossRef]

- Mehrasa, M.; Pouresmaeil, E.; Pournazarian, B.; Sepehr, A.; Marzband, M.; Catalão, J. Synchronous Resonant Control Technique to Address Power Grid Instability Problems Due to High Renewables Penetration. Energies 2018, 11, 2469. [Google Scholar] [CrossRef]

- Mehrasa, M.; Adabi, M.E.; Pouresmaeil, E.; Adabi, J.; Jørgensen, B.N. Direct Lyapunov control (DLC) technique for distributed generation (DG) technology. Electr. Eng. 2014, 96, 309–321. [Google Scholar] [CrossRef]

- Mehrasa, M.; Rezanejhad, M.; Pouresmaeil, E.; Catalão, J.P.; Zabihi, S. Analysis and control of single-phase converters for integration of small-scaled renewable energy sources into the power grid. In Proceedings of the 2016 7th Power Electronics and Drive Systems Technologies Conference, Tehran, Iran, 16–18 February 2016; pp. 384–389. [Google Scholar] [CrossRef]

- Zareifard, M.T.; Savkin, A.V. Model predictive control for output smoothing and maximizing the income of a wind power plant integrated with a battery energy storage system. In Proceedings of the 2016 35th Chinese Control Conference (CCC), Chengdu, China, 27–29 July 2016. [Google Scholar] [CrossRef]

- Yan, G.G.; Sun, Z.J.; Mu, G. Collector system voltage regulation oriented reactive power control strategy for WPP. Trans. China Electrotech. Soc. 2015, 30, 140–146. [Google Scholar] [CrossRef]

- Zhu, Y.; Zang, H.; Cheng, L. Output power smoothing control for a wind farm based on the allocation of wind turbines. Appl. Sci. 2018, 8, 980. [Google Scholar] [CrossRef]

- Dai, J.F.; Tang, Y.; Wang, Q. Black-start technology for local power grid via PMSG-based wind power generation. In Proceedings of the 2016 Future Energy Electronics Conference & ECCE Asia, Kaohsiung, Taiwan, 1–6 June 2016. [Google Scholar] [CrossRef]

- Liu, L.; Wu, J.; Mi, Z. A feasibility study of applying storage-based wind farm as black-start power source in local power grid. In Proceedings of the 6th International Conference on Smart Grid and Clean Energy Technologies, Chengdu, China, 19–22 October 2016. [Google Scholar] [CrossRef]

- Lin, W.X.; Jovcic, D. Power balancing and dc fault ride through in DC grids with dc hubs and WPPs. IET Renew. Power Gener. 2015, 9, 847–856. [Google Scholar] [CrossRef]

- Mohammad, B.D.; Sajjad, S.M.; Amirnaser, Y. Fractional-order Sliding-Mode Control of Islanded Distributed Energy Resource Systems. IEEE Trans. Sustain. Energy 2016, 4, 1482–1491. [Google Scholar] [CrossRef]

- Du, K.; Liu, Y.; Ye, M. Capacity configuration strategy of energy storage power station when assisting the WPP in integrating into the preliminary black-start. Power Syst. Protect. Control 2017, 45, 62–68. [Google Scholar] [CrossRef]

- Yuan, H.; Mi, Z.; Du, P. Research of the transformer energization control strategy applied for storage-based wind farm self-start. In Proceedings of the 2016 IEEE Information Technology, Networking, Electronic and Automation Control Conference, Chongqing, China, 20–22 May 2016; pp. 543–547. [Google Scholar] [CrossRef]

- Sun, F.; Zhao, Y.; Wang, G. Study on charging and discharging characteristics of ESS in wind storage power plant under the condition of black-start. Adv. Mater. Res. 2015, 70, 443–448. [Google Scholar] [CrossRef]

- Tang, Y.; Dai, J.F.; Feng, Y.X. Cooperative frequency control strategy for WPP black-start based on virtual inertia. Autom. Electr. Power Syst. 2017, 41, 19–24. [Google Scholar] [CrossRef]

- Li, J.H.; Fan, X.K.; Mu, G. Economic Analysis of Energy Storage Applied to Grid Frequency Regulation. J. Glob. Energy Interconnect. 2018, 1, 355–360. [Google Scholar] [CrossRef]

- Li, J.H.; Ma, Y.B.; Mu, G.; Feng, X.C.; Yan, G.G.; Guo, G.; Zhang, T.Y. Optimal Configuration of Energy Storage System Coordinating Wind Turbine to Participate Power System Primary Frequency Regulation. Energies 2018, 11, 1396. [Google Scholar] [CrossRef]

- Li, C.P.; Cao, P.J.; Li, J.H.; Zhao, B. Review on reactive voltage control methods for large-scale distributed PV integrated grid. J. Northeast Dianli Univ. 2017, 37, 82–88. [Google Scholar] [CrossRef]

- Li, J.H.; Zhang, T.Y.; Qi, L.; Yan, G.G. A Method for the Realization of an Interruption Generator Based on Voltage Source Converters. Energies 2017, 10, 1642. [Google Scholar] [CrossRef]

- Wang, Y.B.; Ye, R.L.; Zhang, S. Study on the optimal allocation of output transission capacity and energy storage capacity of WPP based on CVaR. Electr. Eng. 2017, 18, 69–74. [Google Scholar]

- Ai, X.M.; Li, JM.; Fang, J.K.; Yao, W.; Xie, H.L.; Cai, R.; Wen, J.Y. Multi-Time-Scale Ramp-Rate Control for Photovoltaic Plants Equipped with Battery Energy Storage. IET Renew. Power Gener. 2018, 12, 1390–1397. [Google Scholar] [CrossRef]

- Li, J.H.; Gao, F.J.; Yan, G.G.; Zhang, T.Y.; Li, J.L. Modeling and SOC estimation of lithium iron phosphate battery considering capacity loss. Protect. Control Mod. Power Syst. 2018, 3, 61–69. [Google Scholar] [CrossRef]

- Wu, T.; Li, H.W. Investigation of black-start for north China power system by shisanling hydroelectric generating sets. Power Syst. Technol. 2001, 25, 56–58. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| Installed capacity | 49.5 | MW |

| Space between turbine | 400 | m |

| Voltage | 10.5 | kV |

| Installed sets | 58 | - |

| Type of turbine | G58-850 | - |

| Row number of turbine | 7 | - |

| Collector line | 10 | - |

| Line model | LGJ-125/20 | - |

| Parameter | Value | Unit |

|---|---|---|

| Ventilator | 2 | kW |

| Heating cabinet | 1 | kW |

| Lighting cabinet | 0.2 | kW |

| Converter | 0.4 | kW |

| Radiator transfer | 2.8 | kW |

| Pressure transfer | 1.5 | kW |

| Circulating pump | 1.2 | kW |

| Heater | 2 | kW |

| Yaw motor | 6 | kW |

| Heating engine room | 0.8 | kW |

| Lubricating oil pump | 0.6 | kW |

| Fluid pump | 1.1 | kW |

| (a) | (b) | ||

|---|---|---|---|

| First class | 2, 5, 13, 15, 16, 18, 20, 25, 32, 38, 41, 44, 49 | First class | 3, 4, 10, 12, 13, 14, 20, 25, 26, 27, 28, 30, 32, 35, 43, 46, 49, 50, 55 |

| Second class | 1, 6, 8, 9, 17, 23, 24, 33, 34, 36, 37, 39, 40, 45, 47, 52, 55, 56, 57, 58 | Second class | 1, 2, 7, 11, 17, 18, 19, 21, 22, 23, 24, 31, 33, 34, 38, 45, 47, 48, 57, 58 |

| Third class | 3, 4, 7, 10, 11, 12, 14, 19, 21, 22, 26, 27, 28, 29, 30, 31, 35, 42, 43, 46, 48, 50, 51, 53, 54 | Third class | 5, 6, 8, 9, 15, 16, 29, 36, 37, 39, 40, 41, 42, 42, 44, 51, 52, 53, 54, 56 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Zhang, S.; Zhang, J.; Qi, J.; Li, J.; Guo, Q.; You, H. Method for the Energy Storage Configuration of Wind Power Plants with Energy Storage Systems used for Black-Start. Energies 2018, 11, 3394. https://doi.org/10.3390/en11123394

Li C, Zhang S, Zhang J, Qi J, Li J, Guo Q, You H. Method for the Energy Storage Configuration of Wind Power Plants with Energy Storage Systems used for Black-Start. Energies. 2018; 11(12):3394. https://doi.org/10.3390/en11123394

Chicago/Turabian StyleLi, Cuiping, Shining Zhang, Jiaxing Zhang, Jun Qi, Junhui Li, Qi Guo, and Hongfei You. 2018. "Method for the Energy Storage Configuration of Wind Power Plants with Energy Storage Systems used for Black-Start" Energies 11, no. 12: 3394. https://doi.org/10.3390/en11123394

APA StyleLi, C., Zhang, S., Zhang, J., Qi, J., Li, J., Guo, Q., & You, H. (2018). Method for the Energy Storage Configuration of Wind Power Plants with Energy Storage Systems used for Black-Start. Energies, 11(12), 3394. https://doi.org/10.3390/en11123394