An Artificial Intelligence Method for Energy Efficient Operation of Crude Distillation Units under Uncertain Feed Composition

Abstract

:1. Introduction

2. Process Description and Methodology

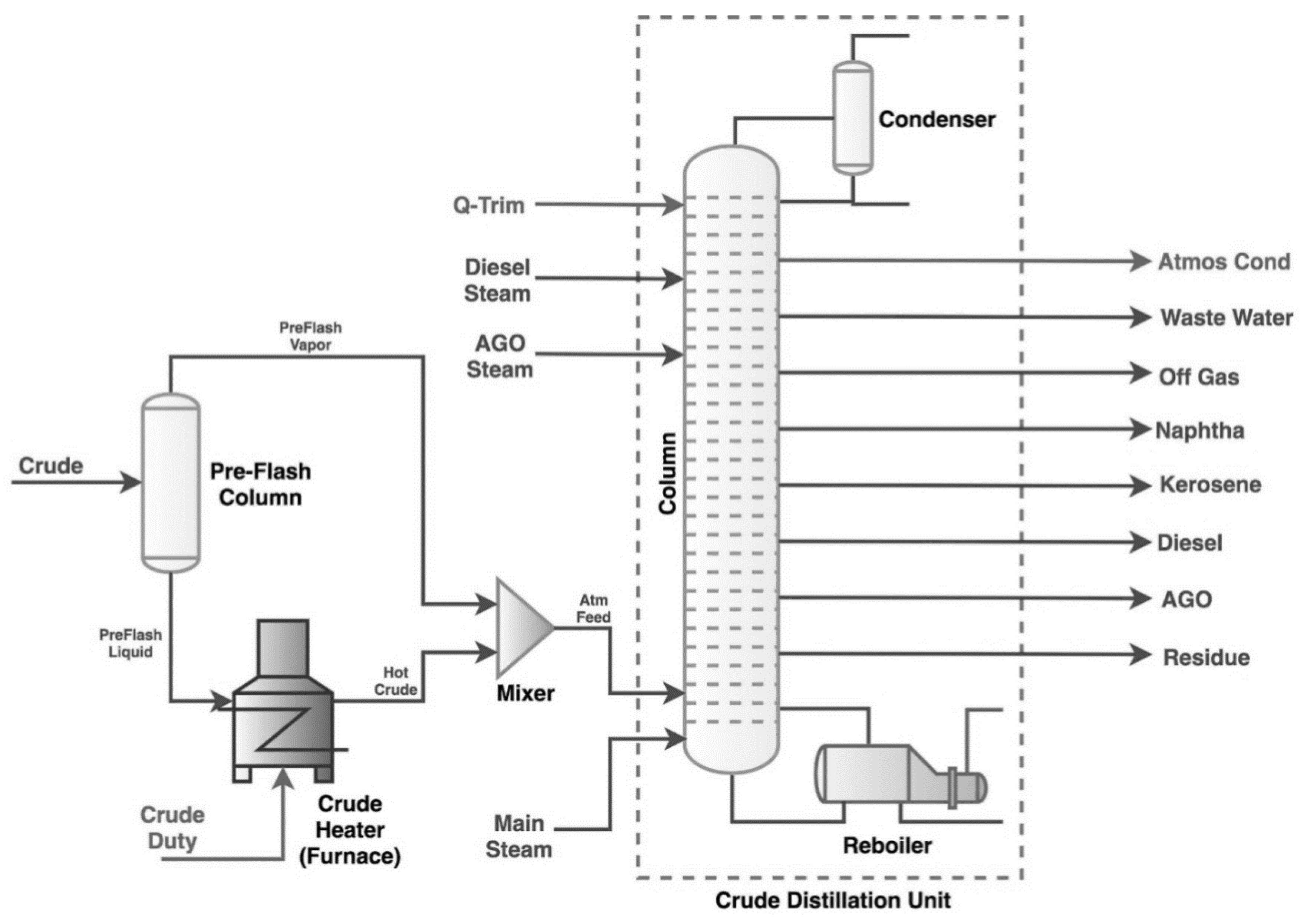

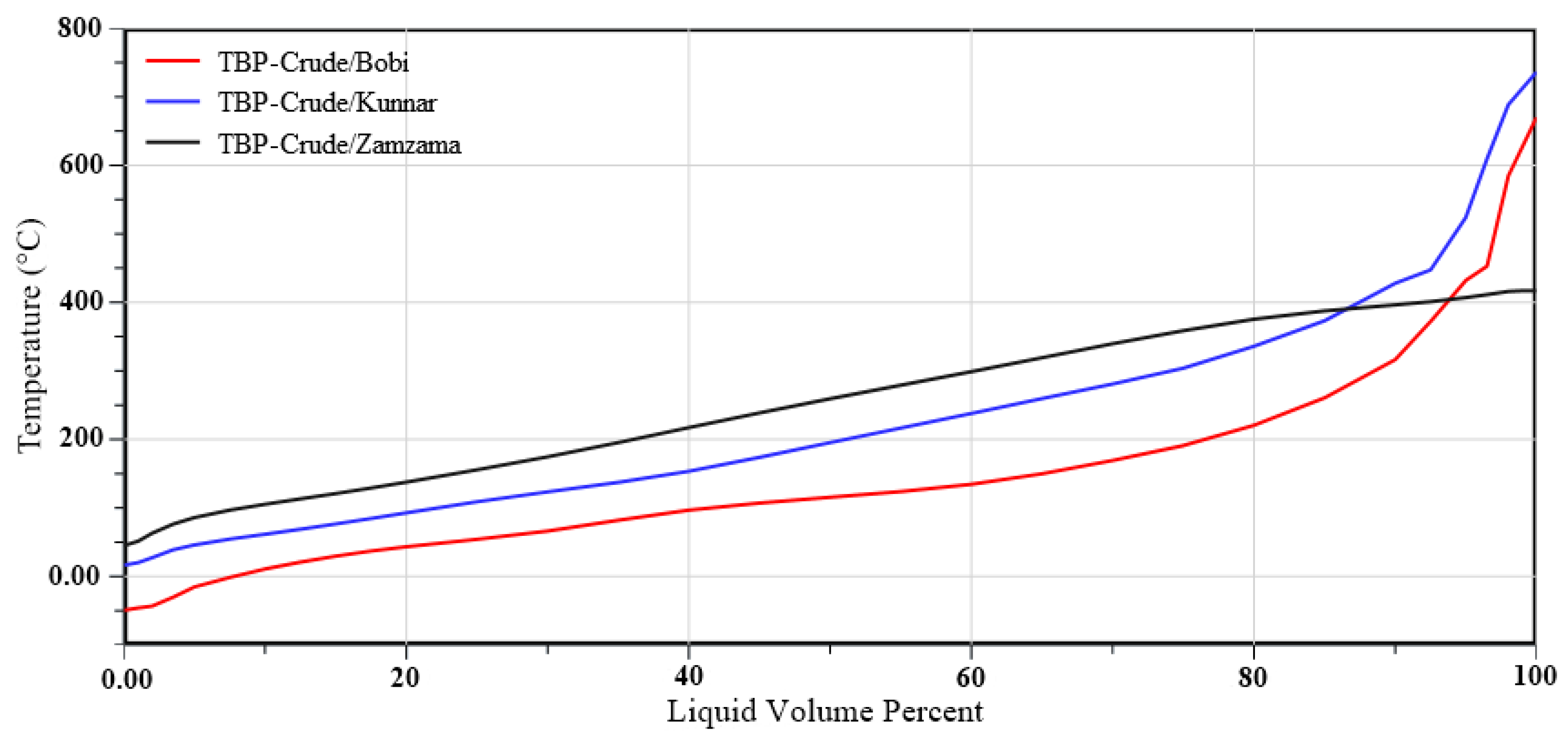

2.1. Process Description

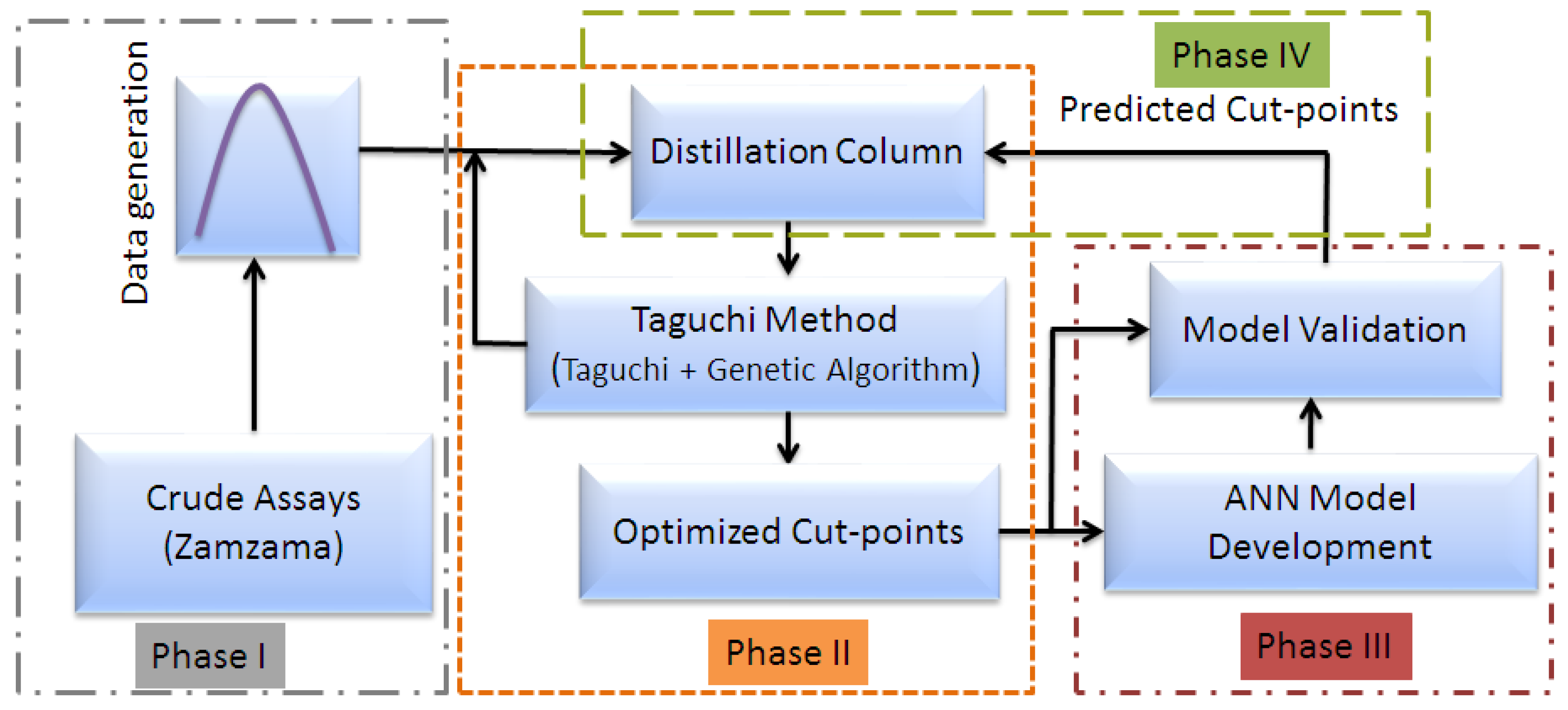

2.2. Modeling Method

- (a)

- Specify the number of controlling factors and levels for the Taguchi method.

- (b)

- Develop a standard orthogonal array for the specified factors and levels.

- (c)

- Draw response plots and select cut point temperatures with minimum E/V values.

- (d)

- Generate an initial population of the cut point temperatures for GA application.

- (e)

- Specify the upper and the lower limits of the cut point temperature and fitness function.

- (f)

- Derive E/V values against the generated cut point temperatures. If the fitness function and/or stopping criteria are satisfied, optimization is achieved otherwise the generation of population and fitness test procedure is repeated.

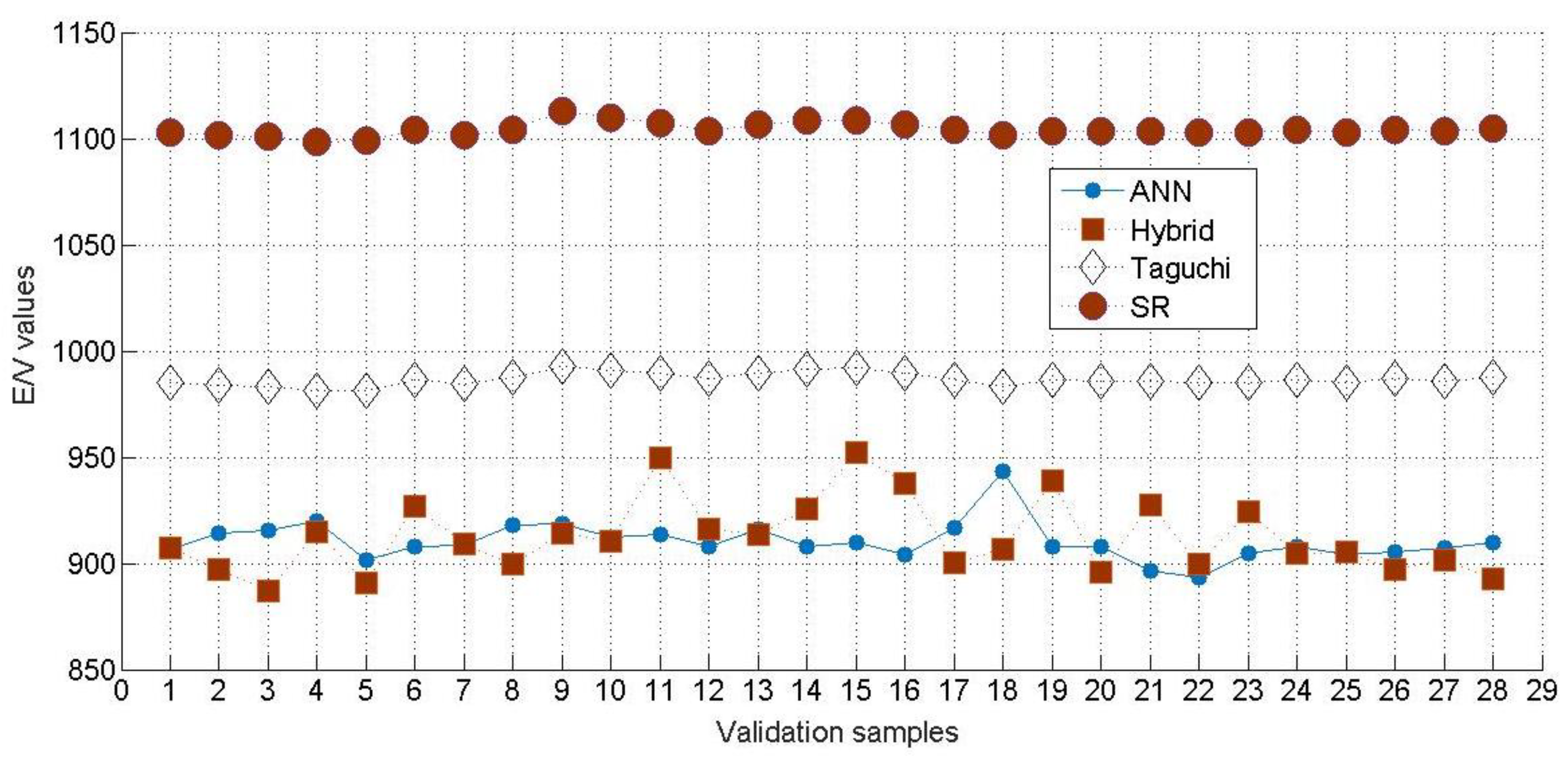

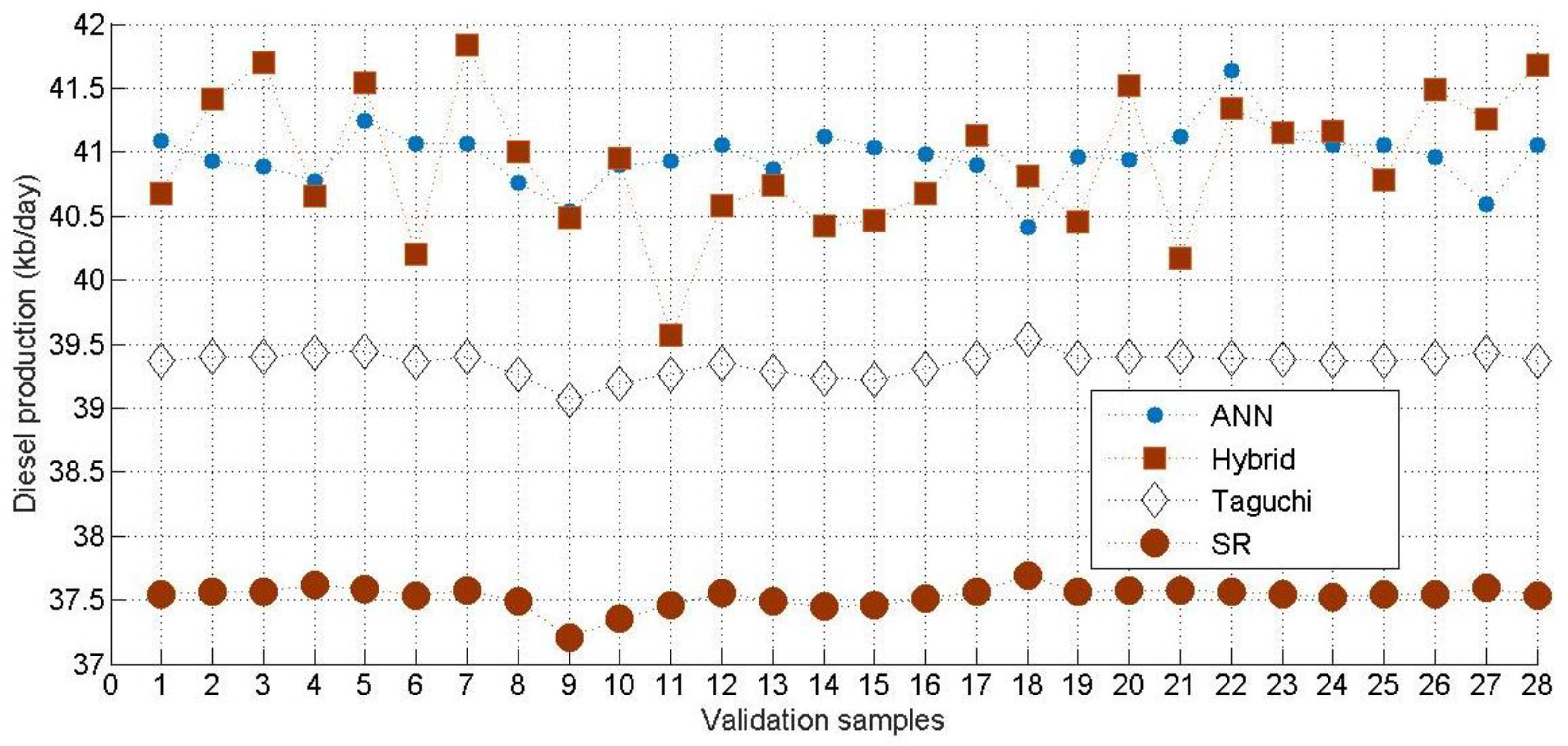

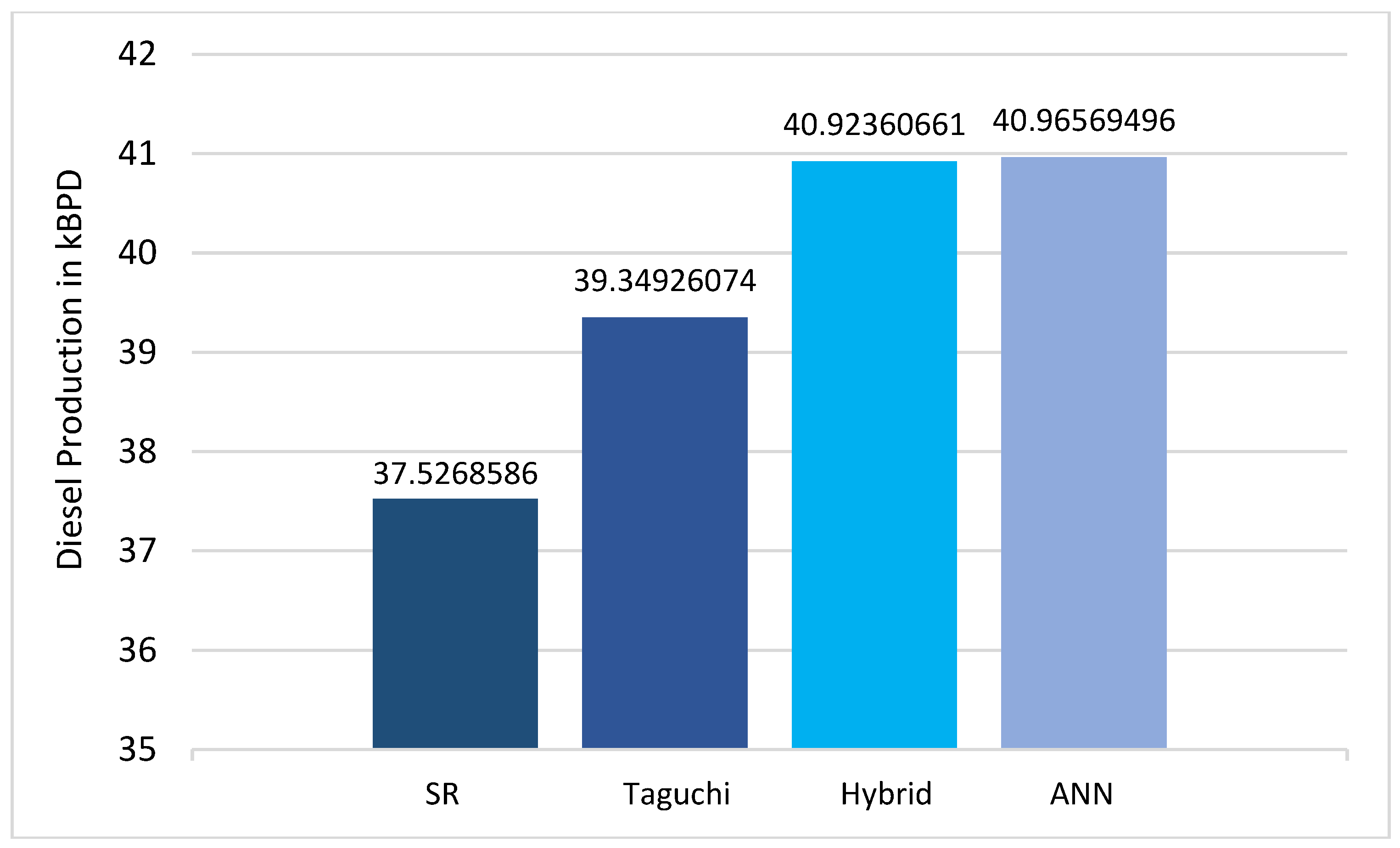

3. Results and Discussion

3.1. Results of Hybrid Optimization Framework

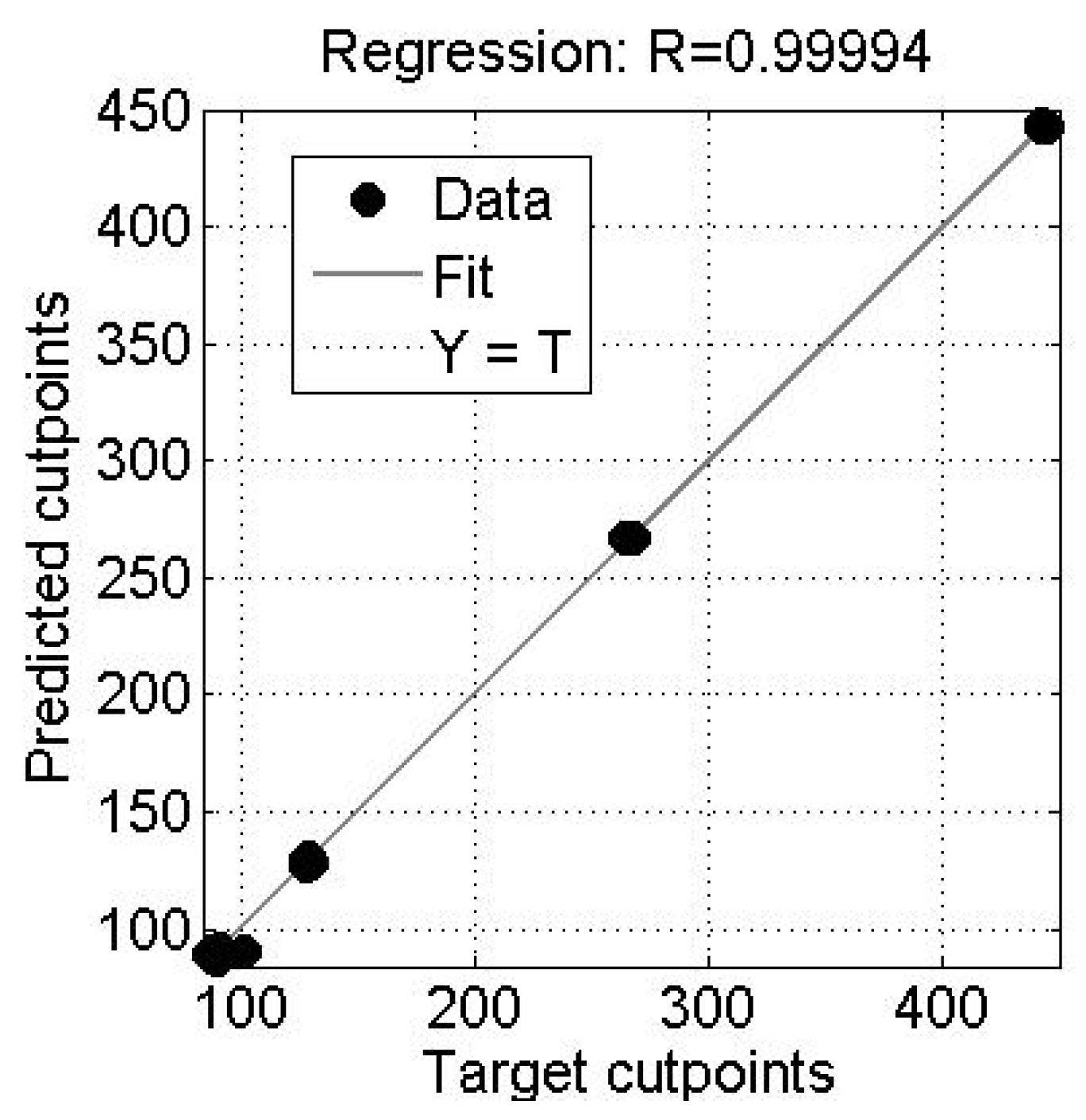

3.2. Results of Data-Driven Approach Based on ANN

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AGO | Atmospheric Gas Oil |

| ANN | Artificial Neural Network |

| ASTM | American Society for Testing and Materials |

| BPD | Barrels Per Day |

| BTU | British Thermal Unit |

| CDU | Crude Distillation Unit |

| DOE | Design of Experiments |

| E | Energy |

| EFV | Equilibrium Flash Evaporation |

| GA | Genetic Algorithm |

| MC | Monte Carlo’s Method |

| PA | Pump Around |

| PCE | Polynomial Chaos Expansion |

| SRT | Straight Run Temperature |

| SS | Side Stripper |

| TBP | True Boiling Point |

| V | Volumetric Flow Rate |

References

- Brueske, S.; Kramer, C.; Fisher, A. Bandwidth Study on Energy Use and Potential Energy Saving Opportunities in U.S. Petroleum Refining; Energy Efficiency and Renewable Energy (EERE): Washington, DC, USA, 2015. [Google Scholar]

- Saharidis, G.K.; Minoux, M.; Dallery, Y. Scheduling of Loading and Unloading of Crude Oil in a Refinery Using Event-Based Discrete Time Formulation. Comput. Chem. Eng. 2009, 33, 1413–1426. [Google Scholar] [CrossRef]

- Chryssolouris, G.; Papakostas, N.; Mourtzis, D. Refinery Short-Term Scheduling with Tank Farm, Inventory and Distillation Management: An Integrated Simulation-Based Approach. Eur. J. Oper. Res. 2005, 166, 812–827. [Google Scholar] [CrossRef]

- Qu, H.; Xu, J.; Wang, S.; Xu, Q. A Novel Minlp Model of Front-End Crude Scheduling for Refinery with Consideration of Inherent Upset Minimization. Comput. Chem. Eng. 2018, 117, 42–62. [Google Scholar] [CrossRef]

- Qu, H.; Xu, J.; Wang, S.; Xu, Q. Optimal Front-End Crude Schedule for Refineries under Consideration of Inherent Upset Reduction. In Computer Aided Chemical Engineering; Elsevier: San Diego, CA, USA, 2018; pp. 1315–1320. [Google Scholar]

- Rogina, A.; Šiško, I.; Mohler, I.; Ujević, Ž.; Bolf, N. Soft Sensor for Continuous Product Quality Estimation (in Crude Distillation Unit). Chem. Eng. Res. Des. 2011, 89, 2070–2077. [Google Scholar] [CrossRef]

- Chatterjee, T.; Saraf, D.N. On-Line Estimation of Product Properties for Crude Distillation Units. J. Process Control 2004, 14, 61–77. [Google Scholar] [CrossRef]

- Dam, M.; Saraf, D.N. Design of Neural Networks Using Genetic Algorithm for on-Line Property Estimation of Crude Fractionator Products. Comput. Chem. Eng. 2006, 30, 722–729. [Google Scholar] [CrossRef]

- Torgashov, A.; Goncharov, A.; Zhuravlev, E. Evaluation of Steady-State and Dynamic Soft Sensors for Industrial Crude Distillation Unit under Parametric Constraints. IFAC-PapersOnLine 2018, 51, 566–571. [Google Scholar] [CrossRef]

- Bolf, N.; Ivandic, M.; Galinec, G. Soft Sensors for Crude Distillation Unit Product Properties Estimation and Control. In Proceedings of the 2008 16th Mediterranean Conference on Control and Automation, Ajaccio, France, 25–27 June 2008. [Google Scholar]

- Pannocchia, G.; Gallinelli, L.; Brambilla, A.; Marchetti, G.; Trivella, F. Rigorous Simulation and Model Predictive Control of a Crude Distillation Unit. IFAC Proc. 2006, 39, 635–640. [Google Scholar] [CrossRef]

- Skogestad, S. Dynamics and Control of Distillation Columns—A Critical Survey. In Dynamics and Control of Chemical Reactors, Distillation Columns and Batch Processes; Elsevier: Maryland, MD, USA, 1992; pp. 11–35. [Google Scholar]

- Luyben, W.L. Distillation Design and Control Using Aspen Simulation; John Wiley & Sons: Jersey City, NJ, USA, 2013. [Google Scholar]

- Brooks, R.W.; Van Walsem, F.D.; Drury, J. Choosing Cut-Points to Optimize Product Yields. Hydrocarbon Process. 1999, 78, 53–60. [Google Scholar]

- Trierwiler, D.; Tan, R.L. Advances in Crude Oil LP Modelling; National Petrochemical & Refiners Association: Singapore, 2001; pp. 52–58. [Google Scholar]

- Zhang, J.; Zhu, X.X.; Towler, G.P. A Level-by-Level Debottlenecking Approach in Refinery Operation. Ind. Eng. Chem. Res. 2001, 40, 1528–1540. [Google Scholar] [CrossRef]

- Li, W.; Hui, C.W.; Karimi, I.A.; Srinivasan, R. A Novel CDU Model for Refinery Planning. Asia-Pac. J. Chem. Eng. 2007, 2, 282–293. [Google Scholar] [CrossRef]

- Alattas, A.M.; Grossmann, I.E.; Palou-Rivera, I. Integration of Nonlinear Crude Distillation Unit Models in Refinery Planning Optimization. Ind. Eng. Chem. Res. 2011, 50, 6860–6870. [Google Scholar] [CrossRef]

- Ali, S.F.; Yusoff, N. Determination of Optimal Cut Point Temperatures at Crude Distillation Unit Using the Taguchi Method. Int. J. Eng. Technol. 2012, 12, 36–46. [Google Scholar]

- Kelly, J.D.; Menezes, B.C.; Grossmann, I.E. Distillation Blending and Cutpoint Temperature Optimization Using Monotonic Interpolation. Ind. Eng. Chem. Res. 2014, 53, 15146–15156. [Google Scholar] [CrossRef]

- Durrani, M.A.; Avila, A.; Rafael, J.; Ahmad, I. An Integrated Mechanism of Genetic Algorithm and Taguchi Method for Cut-Point Temperatures Optimization of Crude Distillation Unit. In Proceedings of the 2018 International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Sukkur, Pakistan, 3–4 March 2018. [Google Scholar]

- Janak, S.L.; Lin, X.; Floudas, C.A. A New Robust Optimization Approach for Scheduling under Uncertainty—II. Uncertainty with Known Probability Distribution. Comput. Chem. Eng. 2007, 31, 171–195. [Google Scholar] [CrossRef]

- Li, Z.; Ierapetritou, M. Process Scheduling under Uncertainty: Review and Challenges. Comput. Chem. Eng. 2008, 32, 715–727. [Google Scholar] [CrossRef]

- Lin, X.; Janak, S.L.; Floudas, C.A. A New Robust Optimization Approach for Scheduling under Uncertainty: I. Bounded Uncertainty. Comput. Chem. Eng. 2004, 28, 1069–1085. [Google Scholar] [CrossRef]

- Sahinidis, N.V. Optimization under Uncertainty: State-of-the-Art and Opportunities. Comput. Chem. Eng. 2004, 28, 971–983. [Google Scholar] [CrossRef]

- Ahmad, I.; Kano, M.; Hasebe, S. Dimensions and Analysis of Uncertainty in Industrial Modeling Process. J. Chem. Eng. Jpn. 2018, 51, 533–543. [Google Scholar] [CrossRef]

- Panda, D.; Ramteke, M. Reactive Scheduling of Crude Oil Using Structure Adapted Genetic Algorithm under Multiple Uncertainties. Comput. Chem. Eng. 2018, 116, 333–351. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Artificial Neural Networks in Renewable Energy Systems Applications: A Review. Renew. Sustain. Energy Rev. 2001, 5, 373–401. [Google Scholar] [CrossRef]

- Yaïci, W.; Entchev, E. Adaptive Neuro-Fuzzy Inference System Modelling for Performance Prediction of Solar Thermal Energy System. Renew. Energy 2016, 86, 302–315. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Optimization of Solar Systems Using Artificial Neural-Networks and Genetic Algorithms. Appl. Energy 2004, 77, 383–405. [Google Scholar] [CrossRef]

- Cabello, J.J.; Sagastume, A.; Sousa, V.; Herrera, H.; Balbis, M.; Silva, J. Soft Sensors to Assess the Energy Consumption in the Formation of Lead-Acid Batteries. In Proceedings of the 6th International Workshop on Advances in Cleaner Production, São Paulo, Brazil, 24–26 May 2017. [Google Scholar]

- Jha, S.K.; Bilalovic, J.; Jha, A.; Patel, N.; Zhang, H. Renewable Energy: Present Research and Future Scope of Artificial Intelligence. Renew. Sustain. Energy Rev. 2017, 77, 297–317. [Google Scholar] [CrossRef]

| Test Description | Bobi | Kunnar | Zamzama |

|---|---|---|---|

| Specific Gravity 60/60 F | 0.7513 | 0.7934 | 0.7588 |

| Total Sulphur Content (Wt.%) | 0.05 | 0.0376 | 0.0083 |

| Basic Sediment (Vol %) | 0.05 | <0.05 | <0.05 |

| Water Content (Vol %) | 0.02 | <0.05 | <0.05 |

| Salt Content Lb/1000 bbl | <1 | 4.5 | Nil |

| Kinematic Viscosity 40 C (cSt) | 0.8 | 1.27 | 0.78 |

| Parameters | Values |

|---|---|

| Total Number of Trays | 29 |

| Column Temperature | 70.99 °C (top tray) 338.57 °C (bottom tray) |

| Column Pressure | 135.82 kPa (top tray) 225.45 kPa (bottom tray) |

| Number of pump arounds | 3 |

| Number of side strippers | 3 |

| Crude Feed Rate | 100.00 kBPD |

| Crude Feed Location | Tray–28 |

| Crude Feed Temperature | 328.60 °C |

| Crude Feed Pressure | 448.20 kPa |

| Type of Condenser | Partial Condenser |

| Fluid Package | Peng-Robinson |

| Side Strippers | Draw Line | Return Line | Stripping Through | Flow/Duty |

|---|---|---|---|---|

| SS–1 | Tray–9 | Tray–8 | Reboiler | 2198.03 kW |

| SS–2 | Tray–17 | Tray–16 | Steam | 1362.00 kg/h |

| SS–3 | Tray–22 | Tray–21 | Steam | 1135.00 kg/h |

| Pump Arounds | Draw Line | Return Line | Duty (kW) | Flow (kBPD) |

|---|---|---|---|---|

| PA–1 | Tray–2 | Tray–1 | −16,118.91 | 50.00 |

| PA–2 | Tray–17 | Tray–16 | −10,257.48 | 29.99 |

| PA–3 | Tray–22 | Tray–21 | −10,257.48 | 30.00 |

| Factors | Level A | Level B | Level C | |

|---|---|---|---|---|

| 1 | Cutpoint Temperature (Naphtha) | −5 °C | SR Temp | +5 °C |

| 2 | Cutpoint Temperature (Kerosene) | −5 °C | SR Temp | +5 °C |

| 3 | Cutpoint Temperature (Diesel) | −5 °C | SR Temp | +5 °C |

| 4 | Cutpoint Temperature (AGO) | −5 °C | SR Temp | +5 °C |

| Crude Blends | Factors | |||

|---|---|---|---|---|

| 1 (Naphtha) | 2 (Kerosene) | 3 (Diesel) | 4 (AGO) | |

| Blend A: Bobi Oil | B | A | B | A |

| Blend B: Kunnar | B | A | C | A |

| Blend C: Zamzama | C | A | C | A |

| Blend D: Bobi + Kunnar Blend | C | A | C | A |

| Blend E: Bobi + Zamzama Blend | A | A | C | A |

| Blend F: Kunnar + Zamzama Blend | A | A | C | A |

| Blend G: Bobi + Kunnar + Zamzama Blend | B | A | C | C |

| Method | Objective Functions | Unit | Blend C (Zamzama) |

|---|---|---|---|

| Straight Run Results | E/V | kW/kBPD | 1104.12 |

| Diesel Output | kBPD | 37.52 | |

| Taguchi Optimized Results | E/V | kW/kBPD | 979.30 |

| Diesel Output | kBPD | 40.09 | |

| Hybrid Framework Results | E/V | kW/kBPD | 895.41 |

| Diesel Output | kBPD | 41.59 |

| Component No. | Dataset 1 | Dataset 2 | Dataset 3 | Dataset 4 | Dataset 5 | Dataset 6 |

|---|---|---|---|---|---|---|

| 1 | 0.023626351 | 0.023665842 | 0.0236852 | 0.023666 | 0.0236273 | 0.02356837 |

| 2 | 0.027626334 | 0.027672511 | 0.0276952 | 0.0276727 | 0.0276275 | 0.02755854 |

| 3 | 0.036053581 | 0.036113844 | 0.0361434 | 0.0361141 | 0.0360551 | 0.0359651 |

| 4 | 0.061877081 | 0.061980508 | 0.0620313 | 0.061981 | 0.0618797 | 0.06172523 |

| 5 | 0.082073145 | 0.082210329 | 0.0822777 | 0.082211 | 0.0820766 | 0.08187173 |

| 6 | 0.08343473 | 0.081902706 | 0.0811501 | 0.0818952 | 0.0833965 | 0.08568402 |

| 7 | 0.091063729 | 0.091215941 | 0.0912907 | 0.0912167 | 0.0910675 | 0.09084026 |

| 8 | 0.071834448 | 0.071954518 | 0.0720135 | 0.0719551 | 0.0718374 | 0.07165816 |

| 9 | 0.056970183 | 0.057065407 | 0.0571122 | 0.0570659 | 0.0569726 | 0.05683038 |

| 10 | 0.052350227 | 0.05243773 | 0.0524807 | 0.0524382 | 0.0523524 | 0.05222176 |

| 11 | 0.047732605 | 0.047812389 | 0.0478516 | 0.0478128 | 0.0477346 | 0.04761547 |

| 12 | 0.041477561 | 0.04154689 | 0.0415809 | 0.0415472 | 0.0414793 | 0.04137577 |

| 13 | 0.035915059 | 0.035975091 | 0.0360046 | 0.0359754 | 0.0359166 | 0.03582692 |

| 14 | 0.032084289 | 0.032137918 | 0.0321643 | 0.0321382 | 0.0320856 | 0.03200555 |

| 15 | 0.028328743 | 0.028376094 | 0.0283994 | 0.0283763 | 0.0283299 | 0.02825922 |

| 16 | 0.025733674 | 0.025776688 | 0.0257978 | 0.0257769 | 0.0257347 | 0.02567052 |

| 17 | 0.024027203 | 0.024067365 | 0.0240871 | 0.0240676 | 0.0240282 | 0.02396824 |

| 18 | 0.024935002 | 0.024976681 | 0.0249972 | 0.0249769 | 0.024936 | 0.02487381 |

| 19 | 0.024652781 | 0.024693987 | 0.0247142 | 0.0246942 | 0.0246538 | 0.02459228 |

| 20 | 0.021172035 | 0.021207423 | 0.0212248 | 0.0212076 | 0.0211729 | 0.02112008 |

| 21 | 0.017883244 | 0.017913135 | 0.0179278 | 0.0179133 | 0.017884 | 0.01783936 |

| 22 | 0.01491413 | 0.014939059 | 0.0149513 | 0.0149392 | 0.0149148 | 0.01487753 |

| 23 | 0.012335549 | 0.012356168 | 0.0123663 | 0.0123563 | 0.0123361 | 0.01230528 |

| 24 | 0.010290474 | 0.010307675 | 0.0103161 | 0.0103078 | 0.0102909 | 0.01026522 |

| 25 | 0.008847667 | 0.008862455 | 0.0088697 | 0.0088625 | 0.008848 | 0.00882595 |

| 26 | 0.007717981 | 0.007730881 | 0.0077372 | 0.0077309 | 0.0077183 | 0.00769904 |

| 27 | 0.006733757 | 0.006745012 | 0.0067505 | 0.0067451 | 0.006734 | 0.00671723 |

| 28 | 0.005805959 | 0.005815663 | 0.0058204 | 0.0058157 | 0.0058062 | 0.00579171 |

| 29 | 0.005260808 | 0.005269601 | 0.0052739 | 0.0052696 | 0.005261 | 0.0052479 |

| 30 | 0.004453308 | 0.004460752 | 0.0044644 | 0.0044608 | 0.0044535 | 0.00444238 |

| 31 | 0.00623265 | 0.006243067 | 0.0062482 | 0.0062431 | 0.0062329 | 0.00621735 |

| 32 | 0.003340658 | 0.003346242 | 0.003349 | 0.0033463 | 0.0033408 | 0.00333246 |

| 33 | 0.003215055 | 0.003220429 | 0.0032231 | 0.0032205 | 0.0032152 | 0.00320716 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durrani, M.A.; Ahmad, I.; Kano, M.; Hasebe, S. An Artificial Intelligence Method for Energy Efficient Operation of Crude Distillation Units under Uncertain Feed Composition. Energies 2018, 11, 2993. https://doi.org/10.3390/en11112993

Durrani MA, Ahmad I, Kano M, Hasebe S. An Artificial Intelligence Method for Energy Efficient Operation of Crude Distillation Units under Uncertain Feed Composition. Energies. 2018; 11(11):2993. https://doi.org/10.3390/en11112993

Chicago/Turabian StyleDurrani, Muhammad Amin, Iftikhar Ahmad, Manabu Kano, and Shinji Hasebe. 2018. "An Artificial Intelligence Method for Energy Efficient Operation of Crude Distillation Units under Uncertain Feed Composition" Energies 11, no. 11: 2993. https://doi.org/10.3390/en11112993

APA StyleDurrani, M. A., Ahmad, I., Kano, M., & Hasebe, S. (2018). An Artificial Intelligence Method for Energy Efficient Operation of Crude Distillation Units under Uncertain Feed Composition. Energies, 11(11), 2993. https://doi.org/10.3390/en11112993