Joint Elasticity Effect on the Failure Behaviours of Rock Masses using a Discrete Element Model

Abstract

:1. Introduction

2. Simulation Methodology and Validation

2.1. Simulation Methodology

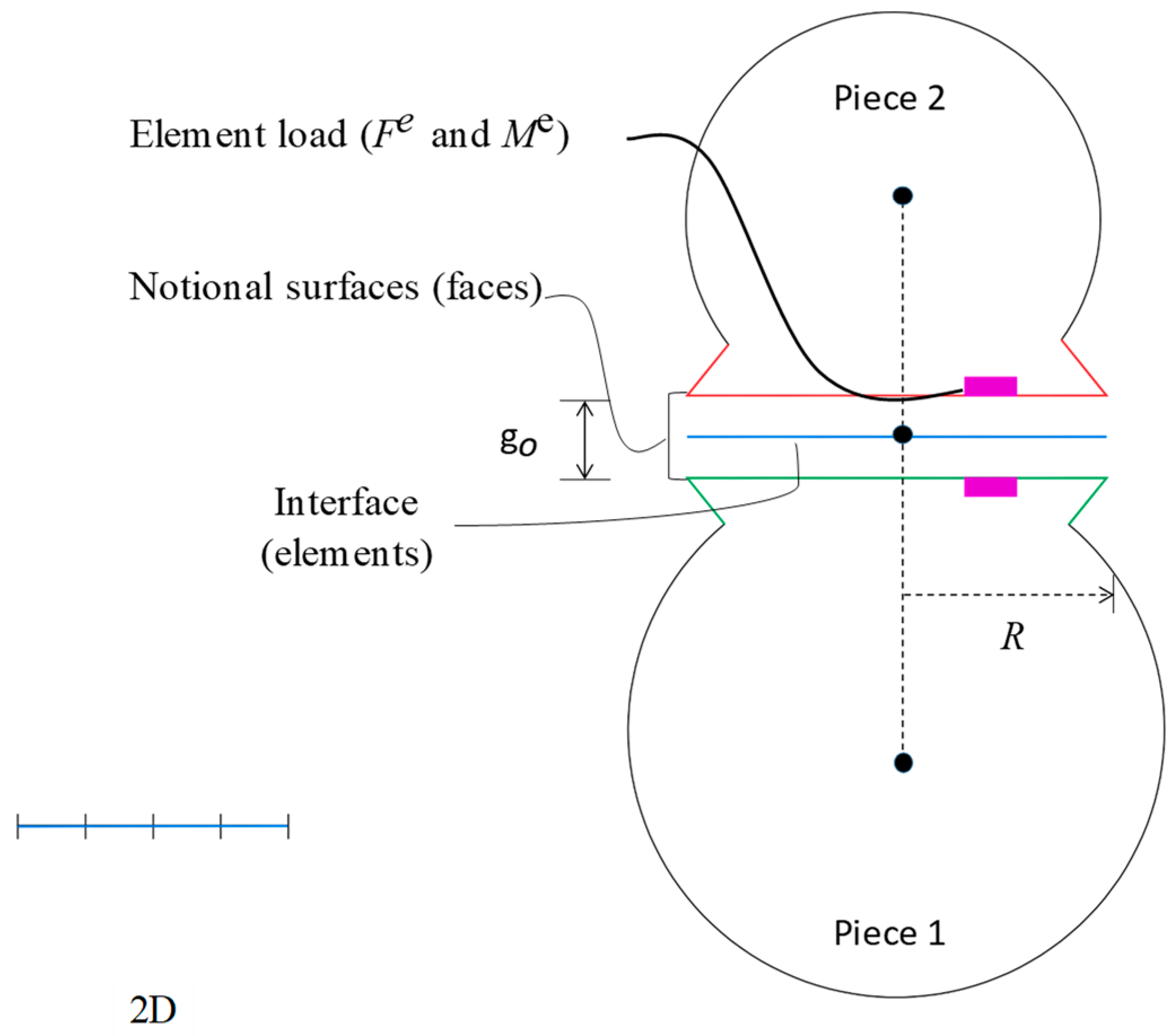

2.1.1. The Flat Joint Model (FJM)

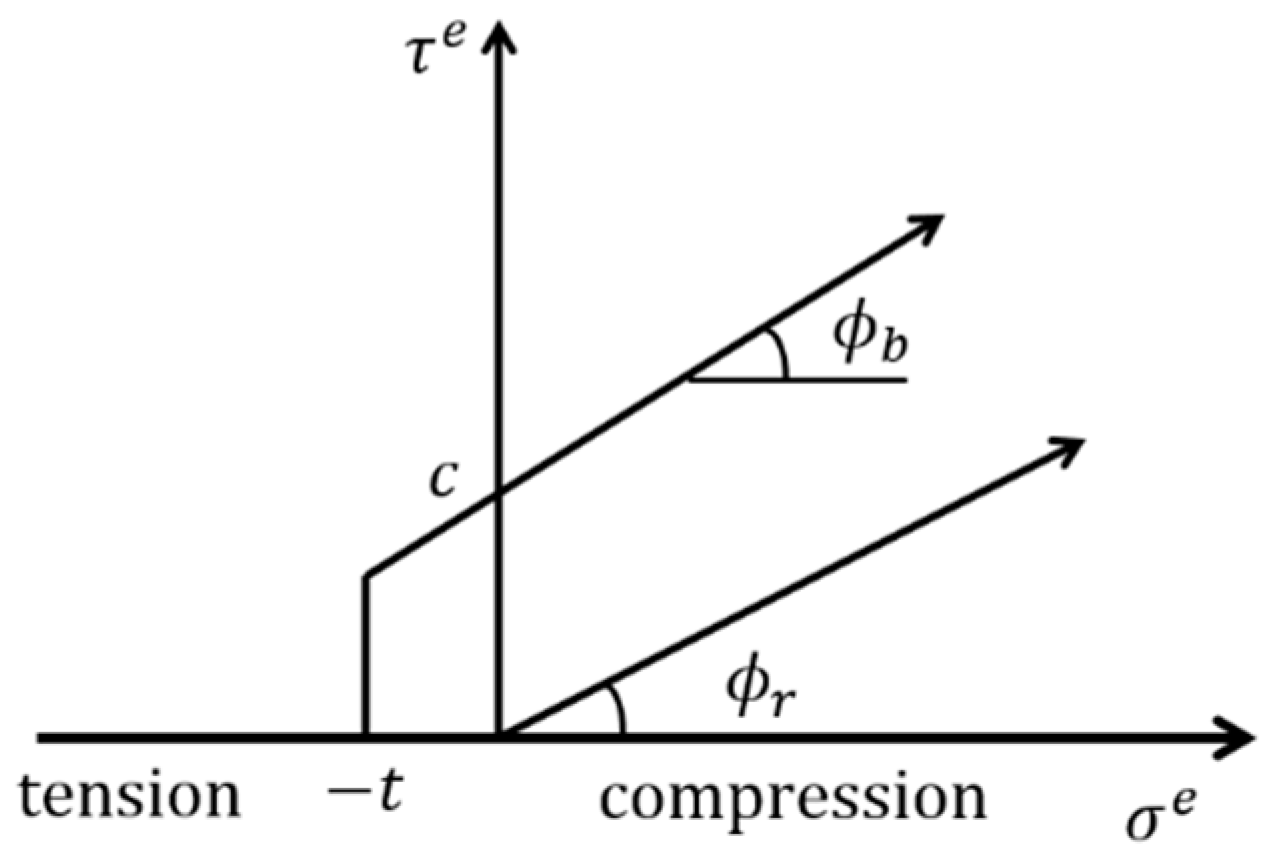

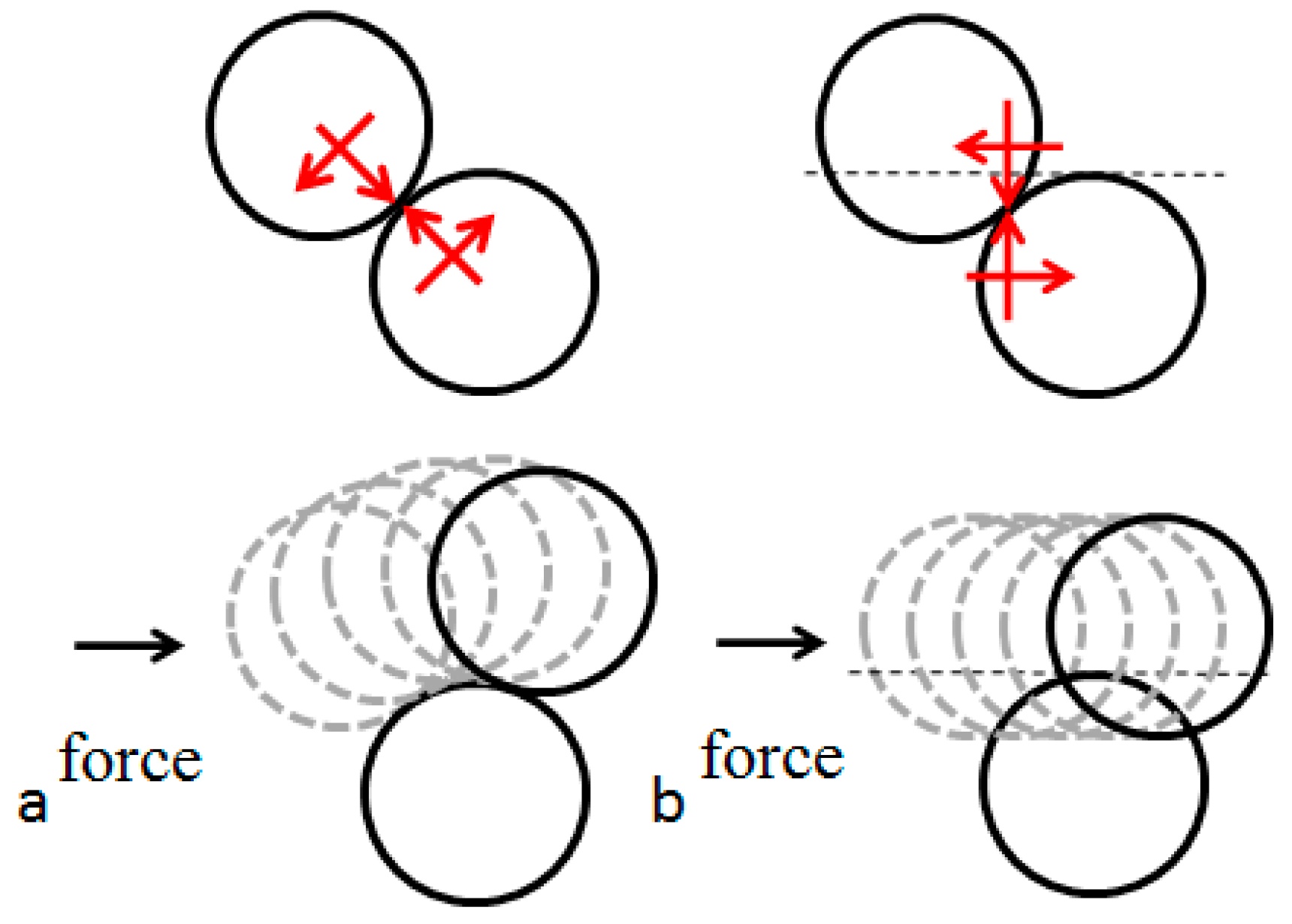

2.1.2. The Smooth Joint Model (SJM)

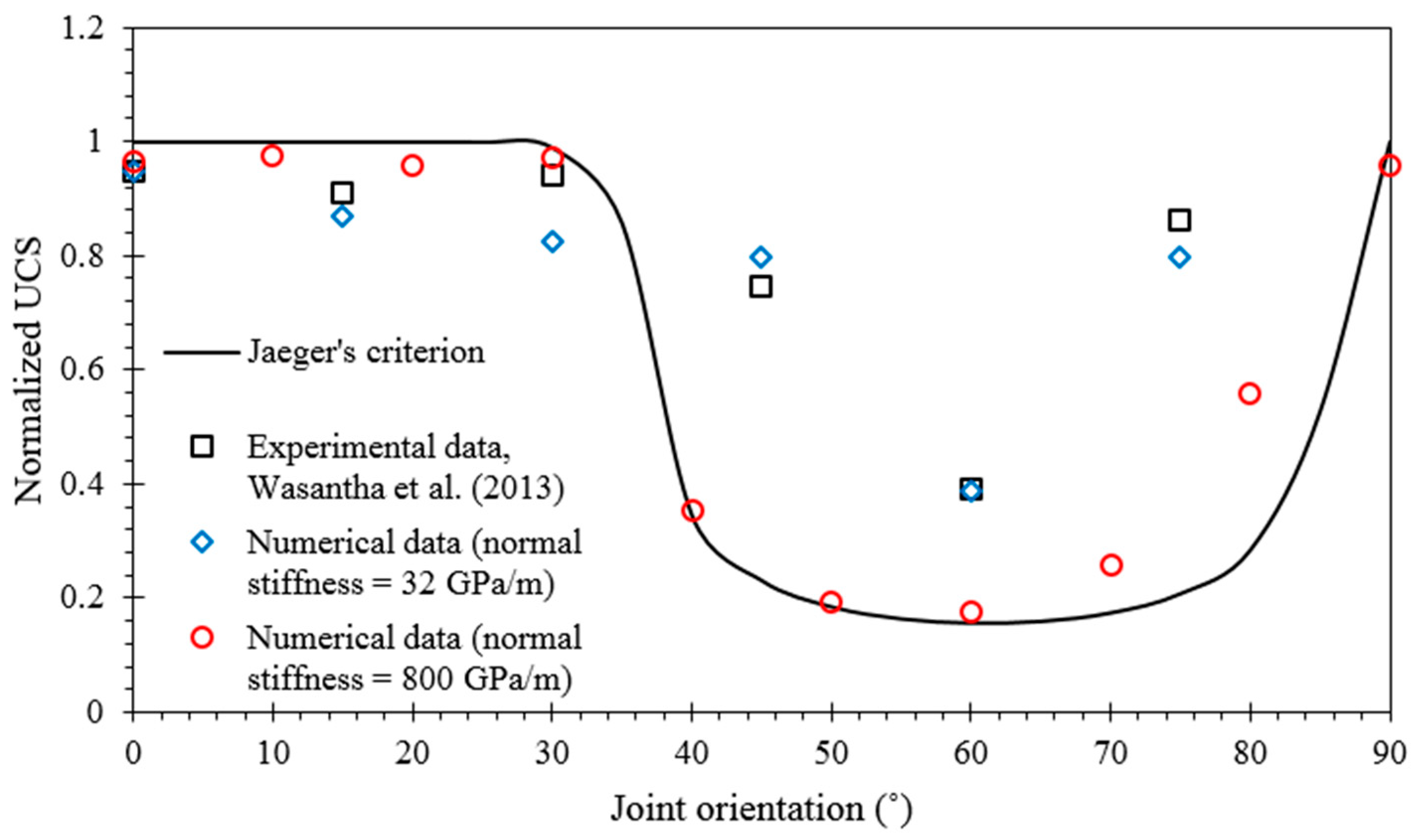

2.2. Model Calibration and Validation

2.2.1. Model Setup and Calibration

2.2.2. Model Validation

3. Simulation Results

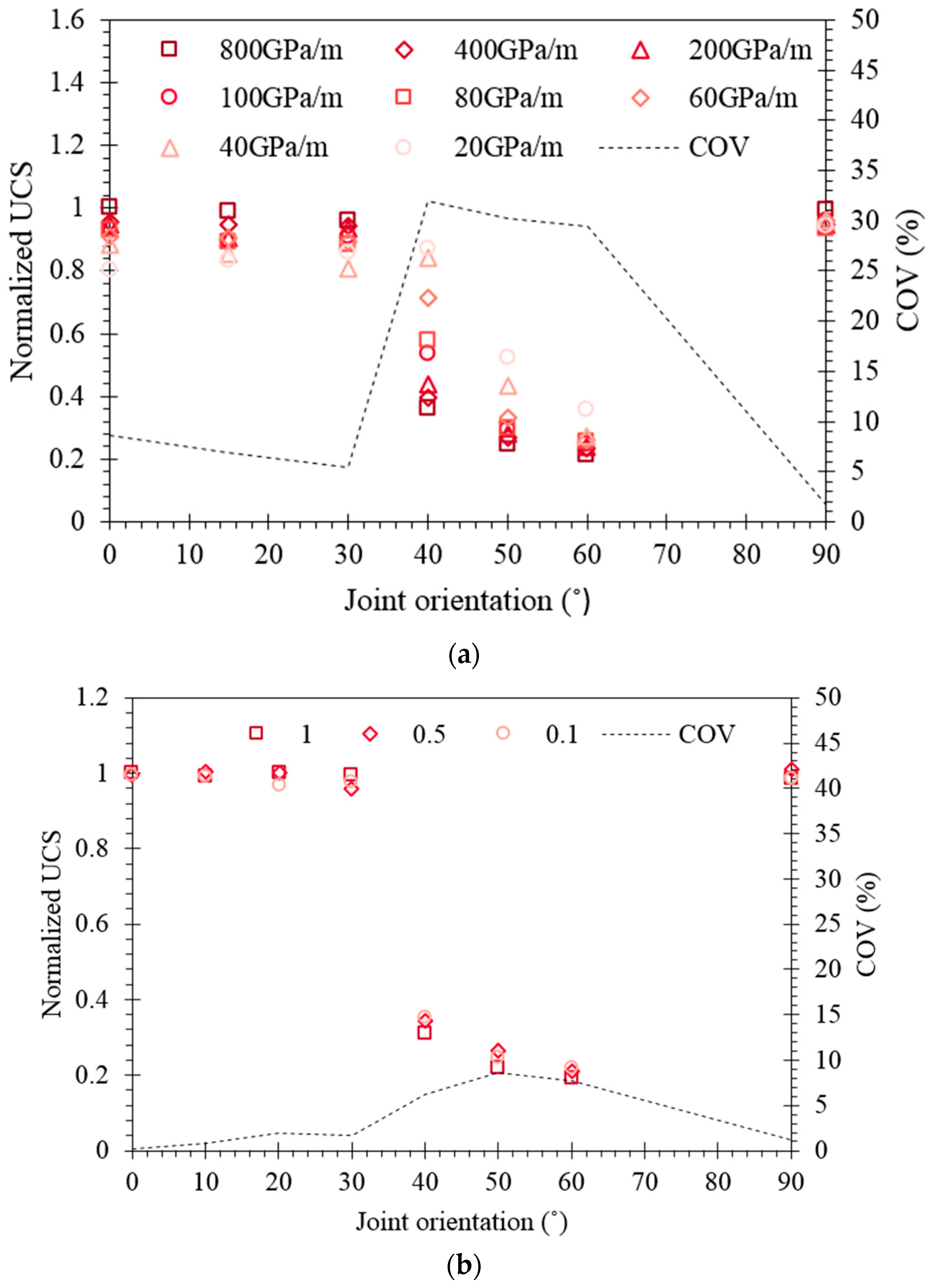

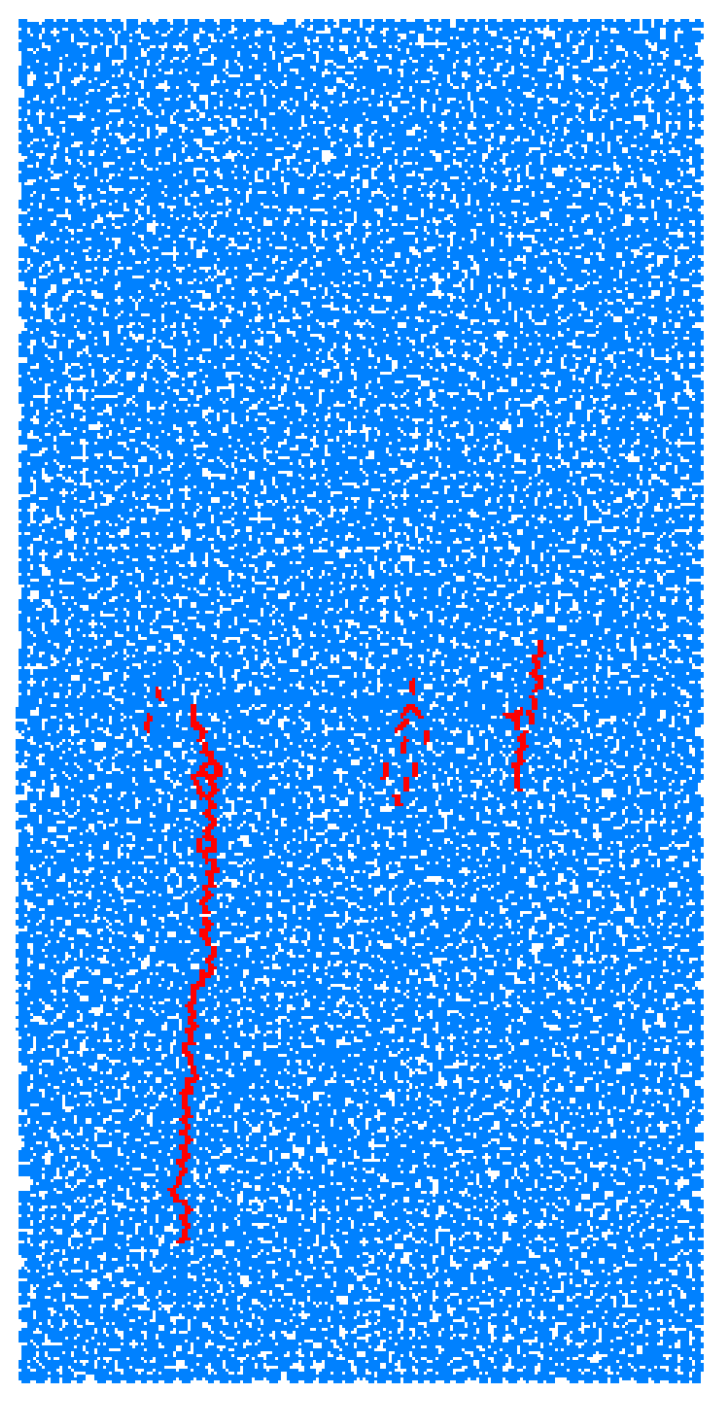

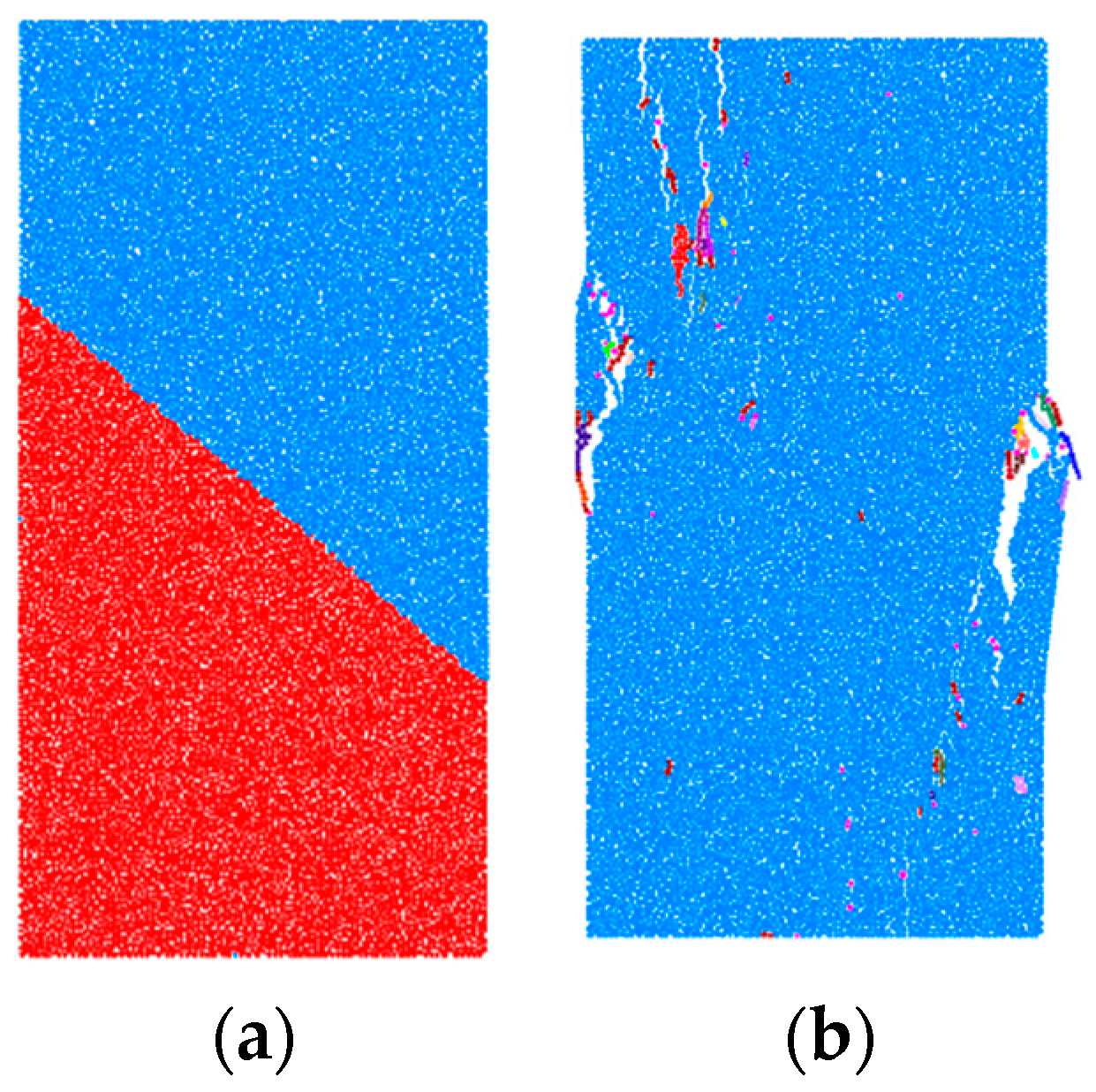

3.1. Failure Strength

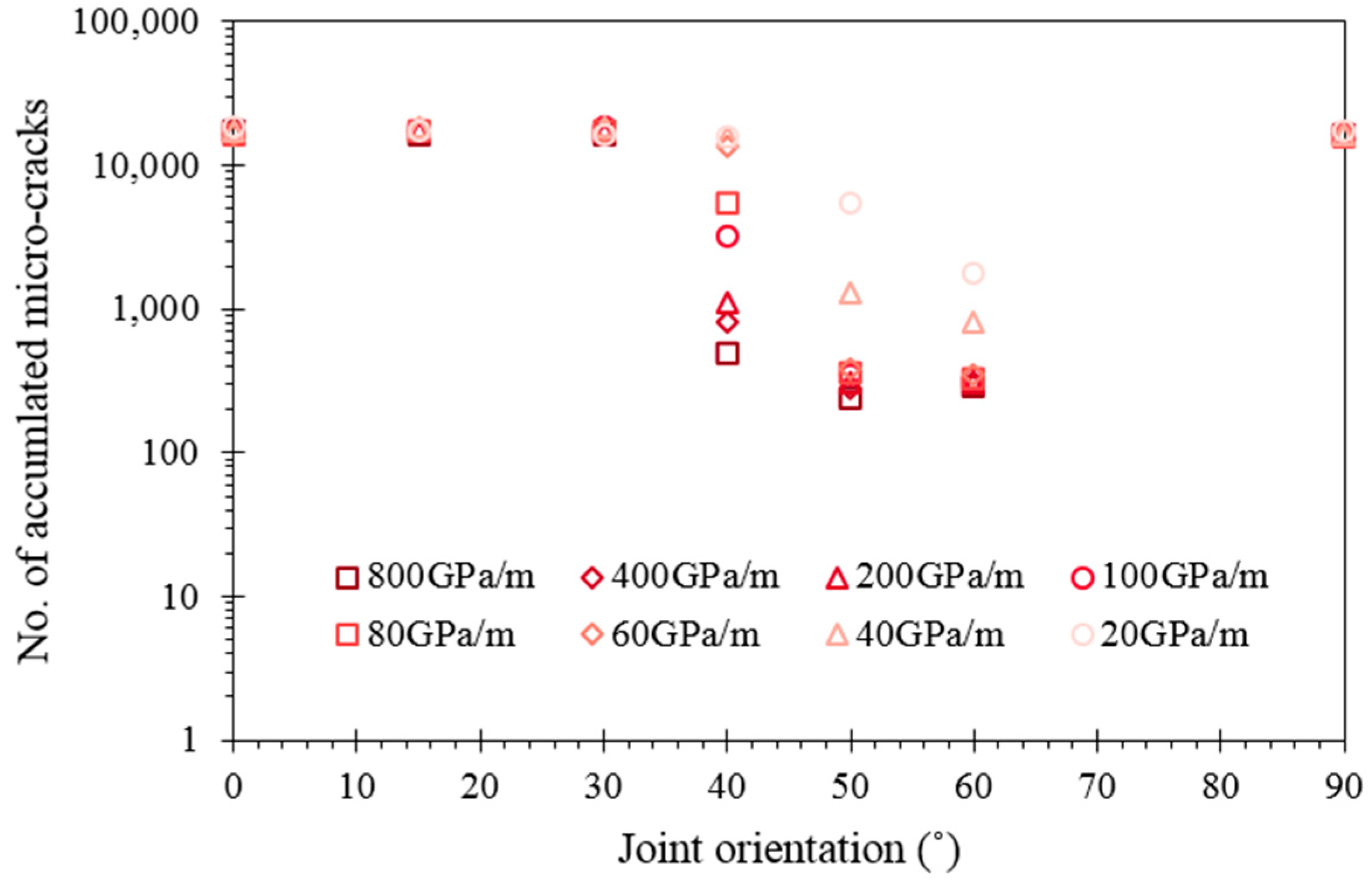

3.2. Degree of Fracturing

4. Discussion

5. Conclusions

- The failure strength of the jointed rock mass was strongly influenced by the joint elasticity. A positive relationship and a negative relationship between the joint elasticity and failure strength of the jointed rock mass were observed from the simulation results when and , respectively. However, the joint elasticity had limited effect on the failure strength when .

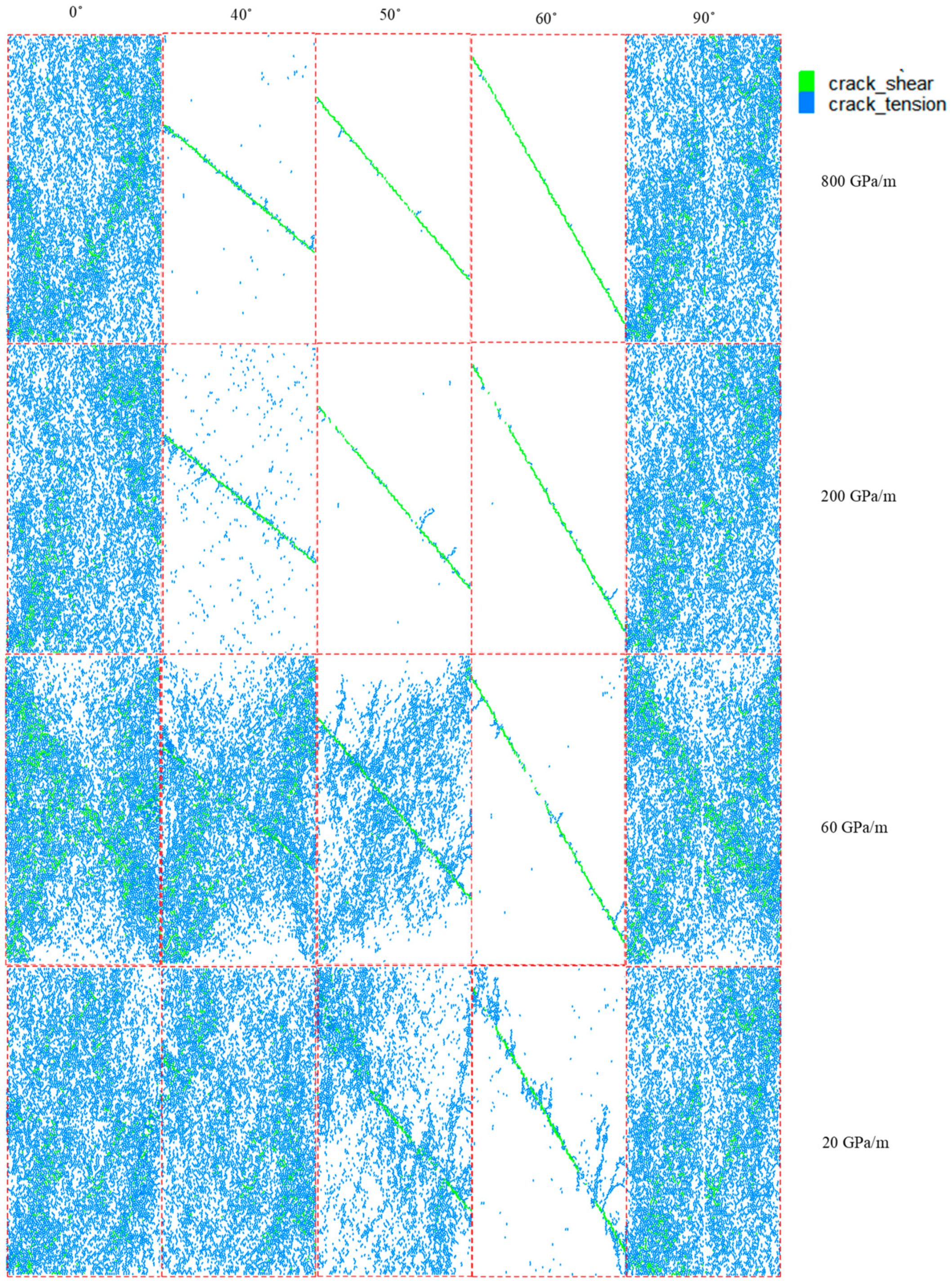

- The failure mode of the jointed rock mass was closely related to the joint elasticity. When , a failure mode transition from sliding failure to mixed failure mode was observed as joint elasticity became smaller. When , the jointed rock mass was prone to fail in a tensile failure mode with softer joint.

- A close connection between the degree of fracturing of the jointed rock mass and joint elasticity was found under uniaxial compression. When , more micro-cracks appeared in the jointed rock mass as the joint became softer. However, it had limited effect on the degree of fracturing when .

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bozorgzadeh, N.; Harrison, J.P. Heteroscedasticity of axial strength of transversely anisotropic rock. Géotech. Lett. 2014, 4, 322–329. [Google Scholar] [CrossRef]

- Shi, X.; Yang, X.; Meng, Y.; Li, G. An anisotropic strength model for layered rocks considering planes of weakness. Rock Mech. Rock Eng. 2016, 49, 3783–3792. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Hu, Y.; Mao, T. Brazilian test for tensile failure of anisotropic shale under different strain rates at quasi-static loading. Energies 2017, 10, 1324. [Google Scholar] [CrossRef]

- Saeidi, O.; Rasouli, V.; Vaneghi, R.G.; Gholami, R.; Torabi, S.R. A modified failure criterion for transversely isotropic rocks. Geosci. Front. 2014, 5, 215–225. [Google Scholar] [CrossRef]

- Mclamore, R.; Gray, K.E. The mechanical behavior of anisotropic sedimentary rocks. J. Eng. Ind. 1967, 89, 62–73. [Google Scholar] [CrossRef]

- Li, W.; Rezakhani, R.; Jin, C.; Zhou, X.; Cusatis, G. A multiscale framework for the simulation of the anisotropic mechanical behavior of shale. Int. J. Numer. Anal. Methods Geomech. 2017, 41, 1494–1522. [Google Scholar] [CrossRef] [Green Version]

- Hu, W.; Kwok, C.Y.; Duan, K.; Wang, T. Parametric study of the smooth-joint contact model on the mechanical behavior of jointed rock. Int. J. Numer. Anal. Methods Geomech. 2017, 1–19. [Google Scholar] [CrossRef]

- Wasantha, P.L.P.; Ranjith, P.G.; Viete, D.R. Specimen slenderness and the influence of joint orientation on the uniaxial compressive strength of singly jointed rock. J. Mater. Civ. Eng. 2013, 26, 06014002. [Google Scholar] [CrossRef]

- Wasantha, P.L.P.; Ranjith, P.G.; Viete, D.R. Effect of joint orientation on the hydromechanical behavior of singly jointed sandstone experiencing undrained loading. J. Geophys. Res. Solid Earth 2014, 119, 1701–1717. [Google Scholar] [CrossRef] [Green Version]

- Jaeger, J.C. The frictional properties of joints in rock. Pure Appl. Geophys. 1959, 43, 148–158. [Google Scholar] [CrossRef]

- Nova, R. The failure of transversely isotropic rocks in triaxial compression. Int. J. Rock Mech. Min. Sci. 1980, 17, 325–332. [Google Scholar] [CrossRef]

- Fjær, E.; Nes, O.M. The impact of heterogeneity on the anisotropic strength of an outcrop shale. Rock Mech. Rock Eng. 2014, 47, 1603–1611. [Google Scholar] [CrossRef]

- Duveau, G.; Shao, J.F.; Henry, J.P. Assessment of some failure criteria for strongly anisotropic geomaterials. Mech. Cohes.-Frict. Mater. 1998, 3, 1–26. [Google Scholar] [CrossRef]

- Tsai, S.W.; Wu, E.M. A general theory of strength for anisotropic materials. J. Compos. Mater. 1971, 5, 58–80. [Google Scholar] [CrossRef]

- Boon, C.W.; Houlsby, G.T.; Utili, S. DEM modelling of a jointed rock beam with emphasis on interface properties. Géotech. Lett. 2015, 5, 49–55. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Zhou, K.; Wu, M.S. Interface cracks with surface elasticity in anisotropic bimaterials. Int. J. Solids Struct. 2015, 59, 110–120. [Google Scholar] [CrossRef]

- Walker, P.E. The Shearing Behaviour of Jointed Rock Model; Queen’s University of Belfast: Belfast, UK, 1971. [Google Scholar]

- Lama, R.C.; Vutukuri, V.S.; Saluja, S.S. Handbook on Mechanical Properties of Rocks; Testing Techniques and Results; Trans Tech Publications: Stafa-Zurich, Switzerland, 1978; Volume IV. [Google Scholar]

- Barton, N.; Choubey, V. The shear strength of rock joints in theory and practice. Rock Mech. 1977, 10, 1–54. [Google Scholar] [CrossRef]

- Barton, N. Review of a new shear-strength criterion for rock joints. Eng. Geol. 1973, 7, 287–332. [Google Scholar] [CrossRef]

- Gupta, A.S.; Seshagiri Rao, K. Weathering effects on the strength and deformational behaviour of crystalline rocks under uniaxial compression state. Eng. Geol. 2000, 56, 257–274. [Google Scholar] [CrossRef]

- Bai, T.; Pollard, D.; Gao, H. Explanation for fracture spacing in layered materials. Nature 2000, 403, 753–756. [Google Scholar] [CrossRef] [PubMed]

- Bourne, S.J. Contrast of elastic properties between rock layers as a mechanism for the initiation and orientation of tensile failure under uniform remote compression. J. Geophys. Res. 2003, 108, 2395. [Google Scholar] [CrossRef]

- Verma, A.K.; Singh, T.N. Modeling of a jointed rock mass under triaxial conditions. Arab. J. Geosci. 2010, 3, 91–103. [Google Scholar] [CrossRef]

- Wasantha, P.L.P.; Ranjith, P.G.; Viete, D.R. Specimen slenderness and the influence of joint orientation on the uniaxial compressive strength of jointed rock: A numerical study. In Proceedings of the ISRM Regional Symposium-7th Asian Rock Mechanics Symposium, Seoul, Korea, 15–19 October 2012; International Society for Rock Mechanics: Lisboa, Portugal, 2012; pp. 174–180. [Google Scholar]

- Mas Ivars, D.; Pierce, M.E.; Darcel, C.; Reyes-Montes, J.; Potyondy, D.O.; Paul Young, R.; Cundall, P.A. The synthetic rock mass approach for jointed rock mass modelling. Int. J. Rock Mech. Min. Sci. 2011, 48, 219–244. [Google Scholar] [CrossRef]

- Huang, D.; Wang, J.; Liu, S. A comprehensive study on the smooth joint model in DEM simulation of jointed rock masses. Granul. Matter. 2015, 17, 775–791. [Google Scholar] [CrossRef]

- Bahaaddini, M.; Hagan, P.C.; Mitra, R.; Hebblewhite, B.K. Parametric Study of Smooth Joint Parameters on the Shear Behaviour of Rock Joints. Rock Mech. Rock Eng. 2015, 48, 923–940. [Google Scholar] [CrossRef]

- Lambert, C.; Coll, C. Discrete modeling of rock joints with a smooth-joint contact model. J. Rock Mech. Geotech. Eng. 2014, 6, 1–12. [Google Scholar] [CrossRef]

- Zhao, W.; Huang, R.; Yan, M. Mechanical and fracture behavior of rock mass with parallel concentrated joints with different dip angle and number based on PFC simulation. Geomech. Eng. 2015, 8, 757–767. [Google Scholar] [CrossRef]

- Cheng, C.; Chen, X.; Zhang, S. Multi-peak deformation behavior of jointed rock mass under uniaxial compression: Insight from particle flow modeling. Eng. Geol. 2016, 213, 25–45. [Google Scholar] [CrossRef]

- Park, B.; Min, K.-B. Bonded-particle discrete element modeling of mechanical behavior of transversely isotropic rock. Int. J. Rock Mech. Min. Sci. 2015, 76, 243–255. [Google Scholar] [CrossRef]

- Duan, K.; Kwok, C.Y. Discrete element modeling of anisotropic rock under Brazilian test conditions. Int. J. Rock Mech. Min. Sci. 2015, 78, 46–56. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhu, H.; Zhang, L.; Ding, X. Study of scale effect on intact rock strength using particle flow modeling. Int. J. Rock Mech. Min. Sci. 2011, 48, 1320–1328. [Google Scholar] [CrossRef]

- Zhao, W.; Huang, R.; Yan, M. Study on the deformation and failure modes of rock mass containing concentrated parallel joints with different spacing and number based on smooth joint model in PFC. Arab. J. Geosci. 2015, 8, 7887–7897. [Google Scholar] [CrossRef]

- Duan, K.; Kwok, C.Y.; Pierce, M. Discrete element method modeling of inherently anisotropic rocks under uniaxial compression loading. Int. J. Numer. Anal. Methods Geomech. 2015, 32, 189–213. [Google Scholar] [CrossRef]

- Potyondy, D.O.; Cundall, P.A. A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar] [CrossRef]

- Potyondy, D.O. A flat-jointed bonded-particle material for hard rock. In Proceedings of the 46th US Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, 24–27 June 2012; American Rock Mechanics Association: New York, NY, USA, 2012. [Google Scholar]

- Wu, S.; Xu, X. A study of three intrinsic problems of the classic discrete element method using flat-joint model. Rock Mech. Rock Eng. 2016, 49, 1813–1830. [Google Scholar] [CrossRef]

- Mas Ivars, D.; Potyondy, D.; Pierce, M.; Cundall, P. The smooth-joint contact model. In Proceedings of the 2008 8th WCCM8-ECCOMAS, Venice, Italy, 30 June–4 July 2008. [Google Scholar]

- Zhang, X.P.; Wong, L.N.Y. Choosing a proper loading rate for bonded-particle model of intact rock. Int. J. Fract. 2014, 189, 163–179. [Google Scholar] [CrossRef]

- Zhou, C.; Xu, C.; Karakus, M.; Shen, J.A. Systematic approach to calibrate micro-parameters for macro-rock properties of a flat joint bonded particle model (BPM). Geomech. Eng. 2018, 16, 471–482. [Google Scholar] [CrossRef]

- Bahaaddini, M.; Sharrock, G.; Hebblewhite, B.K. Numerical investigation of the effect of joint geometrical parameters on the mechanical properties of a non-persistent jointed rock mass under uniaxial compression. Comput. Geotech. 2013, 49, 206–225. [Google Scholar] [CrossRef]

- Griffith, A.A. The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. Lond. Ser. A Contain. Pap. Math. Phys. Character 1921, 221, 163–198. [Google Scholar] [CrossRef]

- Mandl, G. Rock Joints; Springer: Berlin, Germany, 2005. [Google Scholar]

- Kemeny, J.M.; Cook, N.G.W. Micromechanics of deformation in rocks. In Toughening Mechanisms in Quasi-Brittle Materials; Springer: Berlin, Germany, 1991; pp. 155–188. [Google Scholar]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Hobbs, D.W. The Formation of Tension Joints in Sedimentary Rocks: An Explanation. Geol. Mag. 1967, 104, 550–556. [Google Scholar] [CrossRef]

- Amann, F.; Button, E.A.; Evans, K.F.; Gischig, V.; Blümel, M. Experimental Study of the Brittle Behavior of Clay shale in Rapid Unconfined Compression. Rock Mech. Rock Eng. 2011, 415–430. [Google Scholar] [CrossRef]

- Lama, R.D. The Uniaxial Compressive Strength of Jointed Rock; Institute of Soil Mechanics and Rock Mechanics: Karlsruhe, Germany, 1974; pp. 67–77. [Google Scholar]

| Reference | Joint Type | Test | Research Scope |

|---|---|---|---|

| [27] | A single non-persistent joint | UC | Compressive study on the SJM. |

| [7] | A single persistent joint | UC and TC | Parametric study on the SJM. |

| [28] | A single roughness joint | DS | Explore the SJM parameters effect on the shear behaviour of the jointed rock mass. |

| [29] | A single roughness joint | DS | Joint roughness effect on shear behaviours. |

| [35] | A set of persistent parallel joints | UC | Spacing and number of parallel joints effect on failure behaviours of the jointed rock mass. |

| [31] | A set of non-persistent joints | UC | Joint orientations and continuity factors effect on the deformation behaviour of the jointed rock mass. |

| [32] | A set of persistent parallel joints | UC | Modeling of mechanical behaviour of transversely isotropic rock. |

| [36] | A set of non-persistent joints | UC | Modeling of inherently anisotropic rocks. |

| [34] | Random joints | UC | Study of scale effect on intact rock strength. |

| This study | A single persistent joint | UC | Investigation of joint elasticity effect on the failure behaviours of rock masses |

| Intact Rock Properties | Joint Properties | |||||

|---|---|---|---|---|---|---|

| Type of Test | UCS (MPa) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Poisson’s Ratio | Friction Angle (°) | Cohesion (MPa) |

| Experimental | 50.80 | 4.00 | 11.00 | 0.20 | 32.00 | 2.20 |

| Numerical | 50.17 | 4.08 | 11.02 | 0.20 | 31.79 | 2.19 |

| COV (%) | 0.51 | 1.40 | 0.13 | 0.00 | 0.46 | 0.32 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Y.; Zhou, C.; Wang, Z.; Du, J. Joint Elasticity Effect on the Failure Behaviours of Rock Masses using a Discrete Element Model. Energies 2018, 11, 2968. https://doi.org/10.3390/en11112968

Yuan Y, Zhou C, Wang Z, Du J. Joint Elasticity Effect on the Failure Behaviours of Rock Masses using a Discrete Element Model. Energies. 2018; 11(11):2968. https://doi.org/10.3390/en11112968

Chicago/Turabian StyleYuan, Yong, Changtai Zhou, Zhihe Wang, and Jifang Du. 2018. "Joint Elasticity Effect on the Failure Behaviours of Rock Masses using a Discrete Element Model" Energies 11, no. 11: 2968. https://doi.org/10.3390/en11112968

APA StyleYuan, Y., Zhou, C., Wang, Z., & Du, J. (2018). Joint Elasticity Effect on the Failure Behaviours of Rock Masses using a Discrete Element Model. Energies, 11(11), 2968. https://doi.org/10.3390/en11112968