Relationship between Torrefaction Parameters and Physicochemical Properties of Torrefied Products Obtained from Selected Plant Biomass

Abstract

:1. Introduction

2. Material and Methods

2.1. Parameters of The Torrefaction Process

2.2. Evaluation of Energy Parameters

2.3. Mineralization and Determination of Elements in the Analyzed Biomass

2.4. Determination of Organic Compounds in Biomass

2.5. Statistical Methods

3. Results and Discussion

3.1. Content of Lignin, Cellulose, and Hemicellulose in the Analyzed Biomass.

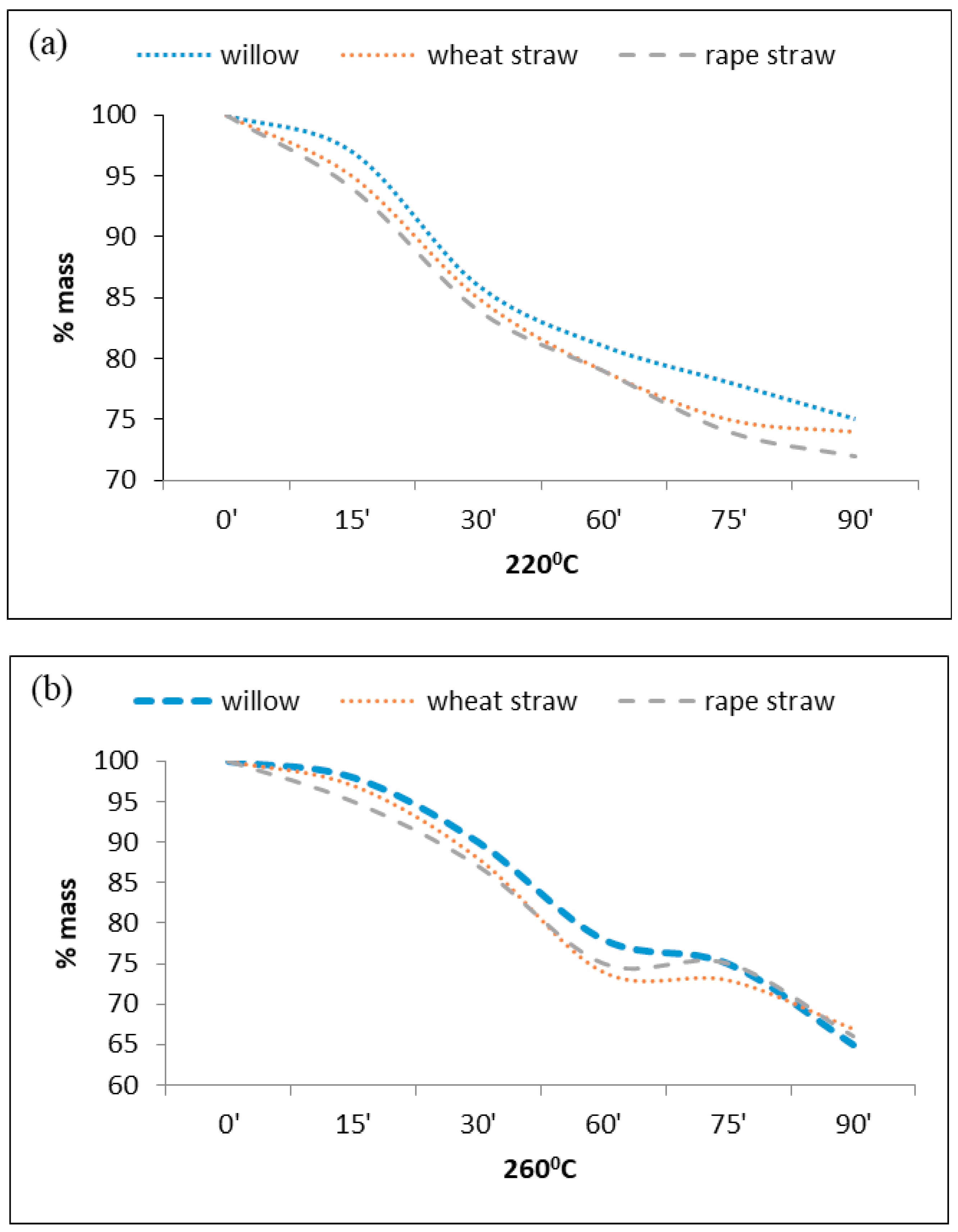

3.2. Assessment of the Impact of Torrefaction Temperature on Mass and Energy Efficiency

3.3. Mineralization and Determination of Elements in the Analyzed Biomass

3.4. Assessment of the Granulometric Composition Depending on the Parameters of the Torrefaction Process

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Phanphanich, M.; Mani, S. Impact of torrefaction on the grindability and fuel characteristics of forest biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef] [PubMed]

- Williams, A.; Jones, J.A.; Ma, L.; Pourkashanian, M. Pollutants from the combustion of solid biomass fuels. Prog. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- Pröll, T.; Hofbauer, H. H2 rich syngas by selective CO2 removal from biomass gasification in a dual fluidized bed system—Process modelling approach. Fuel Process. Technol. 2008, 89, 1207–1217. [Google Scholar] [CrossRef]

- Elliott, D.C. Historical developments in hydroprocessing bio-oils. Energy Fuel 2007, 21, 1792–1815. [Google Scholar] [CrossRef]

- Chen, W.H.; Wu, J.S. An evaluation on rice husk and pulverized coal blends using a drop tube furnace and a thermogravimetric analyzer for application to a blast furnace. Energy 2009, 34, 1458–1466. [Google Scholar] [CrossRef]

- Yan, W.; Acharjee, T.C.; Coronella, C.J.; Vaquez, R.V. Thermal pretreatment of lignocellulosic biomass. Environ. Prog. Sustain. 2009, 28, 435–440. [Google Scholar] [CrossRef]

- Ratte, J.; Fardet, E.; Mateos, D.; Hery, J.S. Mathematical modelling of a continuous biomass torrefaction reactor: TORSPYD (TM) column. Biomass Bioenergy 2011, 35, 3481–3495. [Google Scholar] [CrossRef]

- Uslu, A.; Faaij, A.P.C.; Bergman, P.C.A. Pre-treatment technologies, and their effect on international bioenergy supply chain logistics. Techno-economic evaluation of torrefaction, fast pyrolysis and pelletisation. Energy 2008, 33, 1206–1223. [Google Scholar] [CrossRef]

- Bergman, P.C.A.; Kiel, J.H.A. Torrefaction for biomass upgrading. In Proceedings of the 14th European Biomass Conference & Exhibition, Paris, France, 17–21 October 2005. [Google Scholar]

- Chen, W.; Kuo, P. A study on torrefaction of various biomass materials and its impact on lignocellulosic structure simulated by a thermogravimetry. Energy 2010, 35, 2580–2586. [Google Scholar] [CrossRef]

- Arcate, J. New Process for Torrefied Wood Manufacturing. Available online: http://www.techtp.com/Bioenergy%20Update%20.pdf (accessed on 15 July 2018).

- Bridgeman, T.G.; Jones, J.M.; Shield, I.; Williams, P.T. Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties. Fuel 2008, 87, 844–856. [Google Scholar] [CrossRef]

- Arias, B.; Pevida, C.; Fermoso, J.; Plaza, M.G.; Rubeira, F.; Pis, J.J. Influence of torrefaction on the grindability and reactivity of woody biomass. Fuel Process. Technol. 2008, 89, 169–175. [Google Scholar] [CrossRef] [Green Version]

- Brachi, P.; Miccio, F.; Miccio, M.; Ruoppolo, G. Torrefaction of Tomato Peel Residues in a Fluidized Bed of Inert Particles and a Fixed-Bed Reactor. Energy Fuel 2016, 30, 4858–4868. [Google Scholar] [CrossRef]

- Brachi, P.; Miccio, F.; Ruoppolo, G.; Stanzione, F.; Miccio, M. Pressurized steam torrefaction of wet agroindustrial residues. Chem. Eng. Trans. 2018, 65, 49–54. [Google Scholar]

- Bergman, P.C.A.; Boersma, A.R.; Zwart, R.W.R.; Kiel, J.H.A. Torrefaction for Biomass Existing Coal-Fired Power Stations. ECN Publication. ECN-C.-05-013. 2005. Available online: https://www.ecn.nl/publicaties/PdfFetch.aspx?nr=ECN-C--05-013 (accessed on 15 July 2018).

- Prins, M.J.; Ptasinski, K.; Janssen, F. Torrefaction of wood. Part 2: Analysis of products. J. Anal. Appl. Pyrol. 2006, 77, 35–40. [Google Scholar] [CrossRef]

- Kasparbauer, R.D. The Effects of Biomass Pretreatments on the Products of Fast Pyrolysis. Master’s Thesis, Iowa State University, Ames, IA, USA, 2009. [Google Scholar]

- Medic, D.; Darr, M.; Shah, A.; Potter, B.; Zimmerman, J. Effects of torrefaction process parameters on biomass feedstock upgrading. Fuel 2012, 91, 147–154. [Google Scholar] [CrossRef]

- PN-EN 14774-3: 2010. Solid Biofuels—Determination of Moisture Content—Drying Method—Part 3: Moisture in the General Test Sample. Available online: http://sklep.pkn.pl/pn-en-14774-3-2010e.html (accessed on 10 June 2015).

- PN-EN 14775: 2010. Solid Biofuels—Determination of Ash Content. Available online: http://sklep.pkn.pl/pn-en-14775-2010e.html (accessed on 10 June 2015).

- PN-EN 15104: 2011. Solid Biofuels—Determination of Total Carbon, Hydrogen and Nitrogen Content—Instrumental Methods. Available online: http://sklep.pkn.pl/pn-en-15104-2011e.html (accessed on 10 June 2015).

- PN-EN 15289: 2011. Solid Biofuels—Determination of Total Sulfur Content. Available online: http://sklep.pkn.pl/pn-en-15289-2011e.html (accessed on 10 June 2015).

- PN-EN 14918: 2010. Solid Biofuels—Determination of Calorific Value. Available online: http://sklep.pkn.pl/pn-en-14918-2010e.html (accessed on 10 June 2015).

- Lima, I.M.; Marshall, W.E. Granular Activated Carbons from Broiler Manure: Physical, Chemical and Adsorptive Properties. Bioresour. Technol. 2005, 96, 699–706. [Google Scholar] [CrossRef] [PubMed]

- Dence, C.W.; Lin, S.Y. The determination of lignin. In Methods in Lignin Chemistry; Lin, S.Y., Dence, C.W., Eds.; Springer: Berlin/Heidelberg, Germany, 1992; pp. 33–61. [Google Scholar]

- PN-92/P-50092. Raw Materials for the Paper Industry. Wood-Chemical Analysis. Available online: http://sklep.pkn.pl/pn-p-50092-1992p.html (accessed on 10 June 2015).

- Binti-Saleh, S.; Brun-Hansen, B.; Arendt-Jensen, P.; Dam-Johansen, K. Influence of Biomass Chemical Properties on Torrefaction Characteristics. Energy Fuel 2013, 27, 7541–7548. [Google Scholar] [CrossRef]

- Kumar, P.; Barrett, D.M.; Delwiche, M.J.; Stroeve, P. Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind. Eng. Chem. Res. 2009, 48, 3713–3729. [Google Scholar] [CrossRef]

- Alizadeh, H.; Teymouri, F.; Gilbert, T.I.; Dale, B.E. Pretreatment of switchgrass by ammonia fiber explosion. Appl. Biochem. Biotechnol. 2005, 124, 1133–1141. [Google Scholar] [CrossRef]

- Hill, S.J.; Grigsby, W.J.; Hall, P.W. Chemical and cellulose crystallite changes in Pinus radiata during torrefaction. Biomass Bioenergy 2013, 56, 92–98. [Google Scholar] [CrossRef]

- Chin, K.; H’ng, P.; Go, W.; Wong, W.; Lim, T.; Maminski, M.; Paridah, M.; Luqman, A. Optimization of torrefaction conditions for high energy density solid biofuel from oil palm biomass and fast growing species available in Malaysia. Ind. Crops Prod. 2013, 49, 768–774. [Google Scholar] [CrossRef]

- Poudel, J.; Karki, S.; Oh, S.C. Valorization of Waste Wood as a Solid Fuel by Torrefaction. Energies 2018, 11, 1641. [Google Scholar] [CrossRef]

- Werkelin, J.; Skrifvars, B.J.; Hupa, M. Ash-forming elements in four Scandinavian wood species. Part 1: Summer harvest. Biomass Bioenergy 2005, 29, 451–466. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J. More efficient biomass gasification via torrefaction. Energy 2006, 31, 3458–3470. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Sokhansanj, S.; Hess, R.J.; Wright, C.T.; Boardman, R.D. A review on biomass torrefaction process and product properties for energy applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef]

- Bridgeman, T.; Jones, J.; Williams, A.; Waldron, D. An investigation of the grindability of two torrefied energy crops. Fuel 2010, 89, 3911–3918. [Google Scholar] [CrossRef] [Green Version]

- Sadaka, S.; Negi, S. Improvements of biomass physical and thermochemical characteristics via torrefaction process. Environ. Prog. Sustain. 2009, 28, 427–434. [Google Scholar] [CrossRef]

| Biomass | Lignin | Cellulose % | Hemicellulose |

|---|---|---|---|

| Willow | 14.5 | 44.6 | 32.1 |

| Rapeseed straw | 18.6 | 41.1 | 29.8 |

| Wheat straw | 21.3 | 38.1 | 30.6 |

| Biomass | Temperature °C | Yield Mass | Yield Energy |

|---|---|---|---|

| % | |||

| Willow | 220 | 83.1 | 91.3 |

| 260 | 78.4 | 95.8 | |

| 300 | 65.3 | 80.1 | |

| Rapeseed straw | 220 | 81.4 | 87.1 |

| 260 | 76.7 | 88.5 | |

| 300 | 67.2 | 79.5 | |

| Wheat straw | 220 | 81.4 | 83.2 |

| 260 | 74.1 | 86.9 | |

| 300 | 69.3 | 82.6 | |

| Parameters | Raw | Torrefaction Temperature (°C) | ||

|---|---|---|---|---|

| 220 | 260 | 300 | ||

| x ± SD | ||||

| WILLOW | ||||

| C % | 48.1 c ± 0.1 | 48.2 c ± 0.35 | 52.1 b ± 0.31 | 55.5 a ± 0.14 |

| H % | 5.55 ab ± 0.03 | 5.87 a ± 0.03 | 4.42 c ± 0.12 | 3.64 d ± 0.02 |

| N % | 0.55 d ± 0.02 | 1.48 a ± 0.06 | 1.15 c ± 0.02 | 1.30 b ± 0.06 |

| O % | 53.1 a ± 0.14 | 44.9 b ± 0.12 | 43.6 b ± 0.14 | 42.2 b ± 0.25 |

| LHV MJ kg−1 | 17.5 c ± 0.25 | 19.2 b ± 0.06 | 21.4 a ± 0.22 | 21.5 a ± 0.09 |

| Moisture content % | 10.3 a ± 0.1 | 9.12 b ± 0.07 | 8.42 bc ± 0.1 | 7.96 c ± 0.1 |

| Ash content % | 3.15 ab ± 0.1 | 3.17 ab ± 0.1 | 3.52 a ± 0.1 | 3.72 a ± 0.13 |

| Volatile matter % | 25.5 c ± 0.34 | 23.1 d ± 0.25 | 31.6 b ± 0.41 | 44.9 a ± 0.31 |

| RAPESEED STRAW | ||||

| C % | 46.9 c ± 0.09 | 47.2 c ± 0.2 | 55.0 b ± 0.4 | 58.5 a ± 0.24 |

| H % | 7.92 a ± 0.01 | 5.26 b ± 0.08 | 5.28 b ± 0.07 | 4.24 c ± 0.06 |

| N % | 0.17 d ± 0.01 | 1.03 c ± 0.13 | 1.59 b ± 0.09 | 1.74 a ± 0.13 |

| O % | 51.1 a ± 0.16 | 43.0 c ± 0.21 | 50.1 a ± 0.17 | 45.5 b ± 0.12 |

| LHV MJ kg−1 | 16.8 d ± 0.24 | 18.3 c ± 0.1 | 19.1 b ± 0.08 | 19.9 a ± 0.09 |

| Moisture content % | 8.91 a ± 0.08 | 8.74 a ± 0.10 | 6.02 b ± 0.13 | 5.40 c ± 0.01 |

| Ash content % | 3.80 c ± 0.07 | 3.02 d ± 0.11 | 5.48 b ± 0.12 | 6.37 a ± 0.08 |

| Volatile matter % | 20.6 d ± 0.24 | 23.9 c ± 0.26 | 41.4 b ± 0.23 | 52.2 a ± 0.16 |

| WHEAT STRAW | ||||

| C % | 45.3 d ± 0.07 | 48.2 c ± 0.15 | 52.1 b ± 0.21 | 55.5 a ± 0.04 |

| H % | 7.10 a ± 0.05 | 5.87 b ± 0.04 | 4.42 c ± 0.12 | 3.64 d ± 0.02 |

| N % | 0.15 d ± 0.01 | 1.05 c ± 0.06 | 1.15 b ± 0.02 | 1.30 a ± 0.06 |

| O % | 54.6 a ± 0.22 | 44.1 b ± 0.1 | 44.0 b ± 0.14 | 44.7 b ± 0.14 |

| LHV MJ kg−1 | 17.6 d ± 0.1 | 18.8 c ± 0.09 | 19.8 b ± 0.31 | 21.0 a ± 0.31 |

| Moisture content % | 9.18 a ± 0.12 | 8.50 b ± 0.14 | 6.32 c ± 0.11 | 4.52 d ± 0.1 |

| Ash content % | 4.56 d ± 0.12 | 6.27 c ± 0.13 | 8.66 b ± 0.1 | 9.25 a ± 0.1 |

| Volatile matter % | 17.7 d ± 0.19 | 20.5 c ± 0.3 | 36.4 b ± 0.26 | 47.9 a ± 0.25 |

| Parameters | Ca | K | Mg | P | S | Fe | Mn | Zn | |

|---|---|---|---|---|---|---|---|---|---|

| x ± SD | |||||||||

| mg g−1 | |||||||||

| Wheat straw | 12.7 g ± 0.09 | 8.34 h ± 0.13 | 1.42 ef ± 0.10 | 0.97 f ± 0.07 | 0.97 a ± 0.08 | 0.10 a ± 0.01 | 0.03 b ± 0.01 | 0.01 b ± 0.004 | |

| TORREFACTION | 220°/60′ | 13.1 f ± 0.12 | 9.68 fg ± 0.22 | 1.64 e ± 0.08 | 0.99 f ± 0.10 | 0.12 bc ± 0.01 | 0.04 d ± 0.01 | 0.02 b ± 0.01 | 0.02 b ± 0.01 |

| 220°/75′ | 12.8 fg ± 0.07 | 9.42 fg ± 0.11 | 1.62 e ± 0.09 | 1.04 f ± 0.07 | 0.09 c ± 0.01 | 0.04 d ± 0.01 | 0.04 a ± 0.01 | 0.04 a ± 0.01 | |

| 220°/90′ | 13.1 f ± 0.12 | 10.4 f ± 0.22 | 1.54 e ± 0.08 | 1.00 f ± 0.08 | 0.10 c ± 0.01 | 0.04 d ± 0.01 | 0.02 b ± 0.01 | 0.02 b ± 0.01 | |

| 260°/60′ | 14.4 e ± 0.20 | 13.9 e ± 0.14 | 2.43 cd ± 0.11 | 1.02 f ± 0.02 | 0.11 c ± 0.02 | 0.05 d ± 0.01 | 0.02 b ± 0.004 | 0.02 b ± 0.004 | |

| 260°/75′ | 15.1 d ± 0.22 | 15.8 d ± 0.18 | 2.82 c ± 0.21 | 1.42 de ± 0.05 | 0.10 c ± 0.02 | 0.07 c ± 0.004 | 0.03 b ± 0.01 | 0.03 a ± 0.01 | |

| 260°/90′ | 15.5 d ± 0.26 | 17.5 c ± 0.34 | 2.88 c ± 0.12 | 1.52 d ± 0.06 | 0.09 c ± 0.01 | 0.07 c ± 0.01 | 0.04 a ± 0.01 | 0.04 a ± 0.01 | |

| 300°/60′ | 16.3 c ± 0.22 | 20.2 b ± 0.21 | 3.75 b ± 0.22 | 1.70 c ± 0.07 | 0.13 b ± 0.04 | 0.09 ab ± 0.01 | 0.05 a ± 0.01 | 0.05 a ± 0.01 | |

| 300°/75′ | 17.6 b ± 0.25 | 24.4 a ± 0.33 | 4.09 a ± 0.21 | 1.83 ab ± 0.07 | 0.14 b ± 0.06 | 0.10 a ± 0.01 | 0.04 a ± 0.01 | 0.04 a ± 0.01 | |

| 300°/90′ | 18.6 a ± 0.21 | 24.4 a ± 0.46 | 4.14 a ± 0.01 | 1.98 a ± 0.69 | 0.16 b ± 0.07 | 0.10 a ± 0.02 | 0.04 a ± 0.04 | 0.04 a ± 0.04 | |

| Parameters | Ca | K | Mg | P | S | Fe | Mn | Zn | |

|---|---|---|---|---|---|---|---|---|---|

| x ± SD | |||||||||

| mg g−1 | |||||||||

| Rape straw | 17.4 c ± 0.11 | 6.92 e ± 0.10 | 1.03 f ± 0.13 | 1.77 e ± 0.05 | 0.98 e ± 0.08 | 0.24 c ± 0.02 | 0.02 a ± 0.01 | 0.01 a ± 0.003 | |

| TORREFACTION | 220°/60′ | 15.3 c ± 0.12 | 6.21 e ± 0.10 | 1.33 de ± 0.15 | 1.73 e ± 0.10 | 1.00 e ± 0.10 | 0.22 c ± 0.06 | 0.02 a ± 0.07 | 0.01 a ± 0.003 |

| 220°/75′ | 17.7 c ± 0.30 | 6.44 e ± 0.10 | 1.49 d ± 0.08 | 1.86 e ± 0.07 | 1.13 d ± 0.06 | 0.17 c ± 0.03 | 0.02 a ± 0.004 | 0.01 a ± 0.001 | |

| 220°/90′ | 17.9 c ± 0.21 | 6.54 e ± 0.14 | 1.51 d ± 0.10 | 1.88 e ± 0.21 | 1.37 c ± 0.06 | 0.19 c ± 0.06 | 0.02 a ± 0.004 | 0.01 a ± 0.002 | |

| 260°/60′ | 26.3 b ± 0.27 | 10.7 d ± 0.13 | 2.01 c ± 0.10 | 2.46 cd ± 0.18 | 1.02 e ± 0.08 | 0.10 d ± 0.05 | 0.02 a ± 0.01 | 0.01 a ± 0.004 | |

| 260°/75′ | 27.8 b ± 0.17 | 12.0 c ± 0.28 | 1.95 c ± 0.14 | 2.89 c ± 0.12 | 1.44 c ± 0.06 | 0.24 b ± 0.08 | 0.02 a ± 0.004 | 0.01 a ± 0.002 | |

| 260°/90′ | 28.5 b ± 0.27 | 12.7 c ± 0.25 | 2.01 c ± 0.09 | 2.91 c ± 0.12 | 1.73 b ± 0.07 | 0.24 b ± 0.09 | 0.02 a ± 0.01 | 0.01 a ± 0.004 | |

| 300°/60′ | 37.3 a ± 0.43 | 15.8 b ± 0.32 | 3.35 a ± 0.20 | 4.13 a ± 0.11 | 1.32 c ± 0.06 | 0.31 a ± 0.06 | 0.03 a ± 0.01 | 0.02 a ± 0.01 | |

| 300°/75′ | 36.1 a ± 0.17 | 17.3 a ± 0.22 | 3.01 ab ± 0.11 | 3.66 b ± 0.18 | 1.61 b ± 0.05 | 0.31 a ± 0.09 | 0.02 a ± 0.01 | 0.02 a ± 0.01 | |

| 300°/90′ | 36.9 a ± 1.01 | 17.8 a ± 0.21 | 3.21 a ± 0.11 | 3.89 ab ± 0.27 | 2.01 a ± 0.70 | 0.34 a ± 0.10 | 0.02 a ± 0.003 | 0.02 a ± 0.01 | |

| Parameters | Ca | K | Mg | P | S | Fe | Mn | Zn | |

|---|---|---|---|---|---|---|---|---|---|

| X ± SD | |||||||||

| mg g−1 | |||||||||

| Willow | 14.8 c ± 0.09 | 5.88 d ± 0.09 | 0.88 e ± 0.11 | 1.50 e ± 0.04 | 0.20 c ± 0.01 | 0.02 d ± 0.01 | 0.02 a ± 0.01 | 0.01 a ± 0.003 | |

| TORREFACTION | 220°/60′ | 13.0 d ± 0.10 | 5.28 d ± 0.09 | 1.13 d ± 0.13 | 1.47 e ± 0.09 | 0.22 bc ± 0.01 | 0.06 d ± 0.01 | 0.02 a ± 0.01 | 0.01 a ± 0.003 |

| 220°/75′ | 15.1 c ± 0.26 | 5.47 d ± 0.09 | 1.27 d ± 0.07 | 1.58 e ± 0.06 | 0.22 bc ± 0.004 | 0.14 c ± 0.03 | 0.02 a ± 0.003 | 0.01 a ± 0.001 | |

| 220°/90′ | 15.2 c ± 0.18 | 5.56 d ± 0.12 | 1.28 d ± 0.09 | 1.60 e ± 0.18 | 0.23 b ± 0.004 | 0.16 c ± 0.03 | 0.02 a ± 0.003 | 0.01 a ± 0.002 | |

| 260°/60′ | 22.4 b ± 0.23 | 9.09 c ± 0.11 | 1.71 c ± 0.09 | 2.09 d ± 0.15 | 0.25 b ± 0.01 | 0.15 c ± 0.04 | 0.02 a ± 0.01 | 0.01 a ± 0.003 | |

| 260°/75′ | 23.7 b ± 0.14 | 10.2 c ± 0.24 | 1.66 c ± 0.12 | 2.46 c ± 0.10 | 0.26 ab ± 0.004 | 0.20 b ± 0.03 | 0.02 a ± 0.003 | 0.01 a ± 0.002 | |

| 260°/90′ | 24.3 b ± 0.23 | 10.8 c ± 0.21 | 1.71 c ± 0.08 | 2.47 c ± 0.10 | 0.27 ab ± 0.01 | 0.20 b ± 0.02 | 0.02 a ± 0.01 | 0.01 a ± 0.003 | |

| 300°/60′ | 31.7 a ± 0.37 | 13.4 b ± 0.27 | 2.85 a ± 0.17 | 3.51 a ± 0.09 | 0.30 a ± 0.01 | 0.26 a ± 0.05 | 0.03 a ± 0.01 | 0.02 a ± 0.01 | |

| 300°/75′ | 30.7 a ± 0.14 | 14.7 a ± 0.19 | 2.56 ab ± 0.09 | 3.11 ab ± 0.15 | 0.31 a ± 0.01 | 0.26 a ± 0.03 | 0.02 a ± 0.004 | 0.02 a ± 0.01 | |

| 300°/90′ | 31.4 a ± 0.86 | 15.2 a ± 0.18 | 2.73 a ± 0.09 | 3.31 a ± 0.23 | 0.33 a ± 0.003 | 0.29 a ± 0.04 | 0.02 a ± 0.003 | 0.02 a ± 0.01 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bajcar, M.; Zaguła, G.; Saletnik, B.; Tarapatskyy, M.; Puchalski, C. Relationship between Torrefaction Parameters and Physicochemical Properties of Torrefied Products Obtained from Selected Plant Biomass. Energies 2018, 11, 2919. https://doi.org/10.3390/en11112919

Bajcar M, Zaguła G, Saletnik B, Tarapatskyy M, Puchalski C. Relationship between Torrefaction Parameters and Physicochemical Properties of Torrefied Products Obtained from Selected Plant Biomass. Energies. 2018; 11(11):2919. https://doi.org/10.3390/en11112919

Chicago/Turabian StyleBajcar, Marcin, Grzegorz Zaguła, Bogdan Saletnik, Maria Tarapatskyy, and Czesław Puchalski. 2018. "Relationship between Torrefaction Parameters and Physicochemical Properties of Torrefied Products Obtained from Selected Plant Biomass" Energies 11, no. 11: 2919. https://doi.org/10.3390/en11112919

APA StyleBajcar, M., Zaguła, G., Saletnik, B., Tarapatskyy, M., & Puchalski, C. (2018). Relationship between Torrefaction Parameters and Physicochemical Properties of Torrefied Products Obtained from Selected Plant Biomass. Energies, 11(11), 2919. https://doi.org/10.3390/en11112919