Optimization of Control Variables and Design of Management Strategy for Hybrid Hydraulic Vehicle

Abstract

1. Introduction

2. Mathematical Model of Delivery Truck Drivetrain

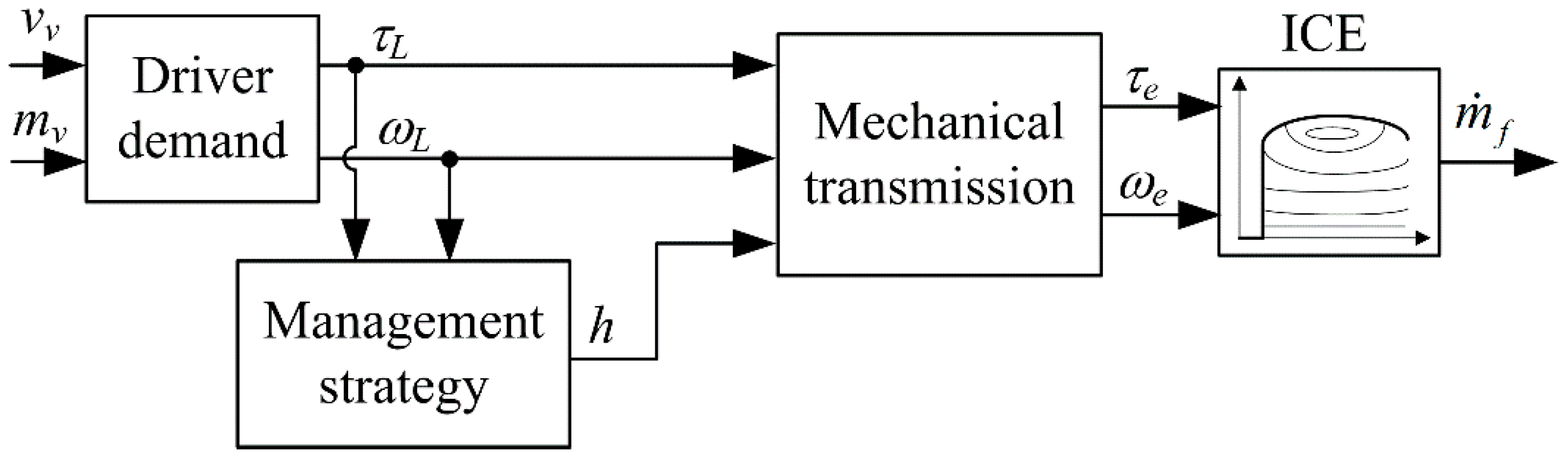

2.1. Mathematical Model of Conventional Vehicle Driveline

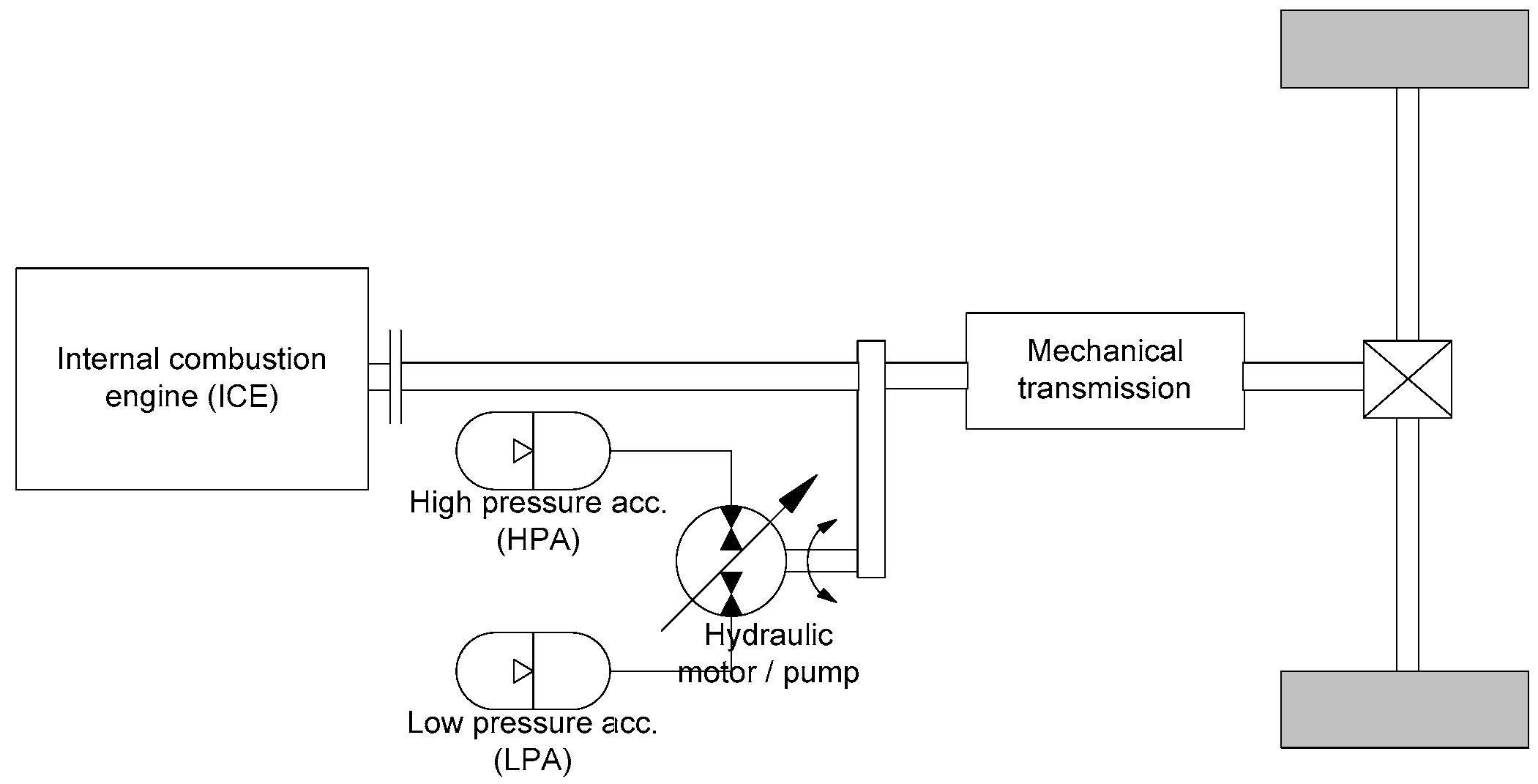

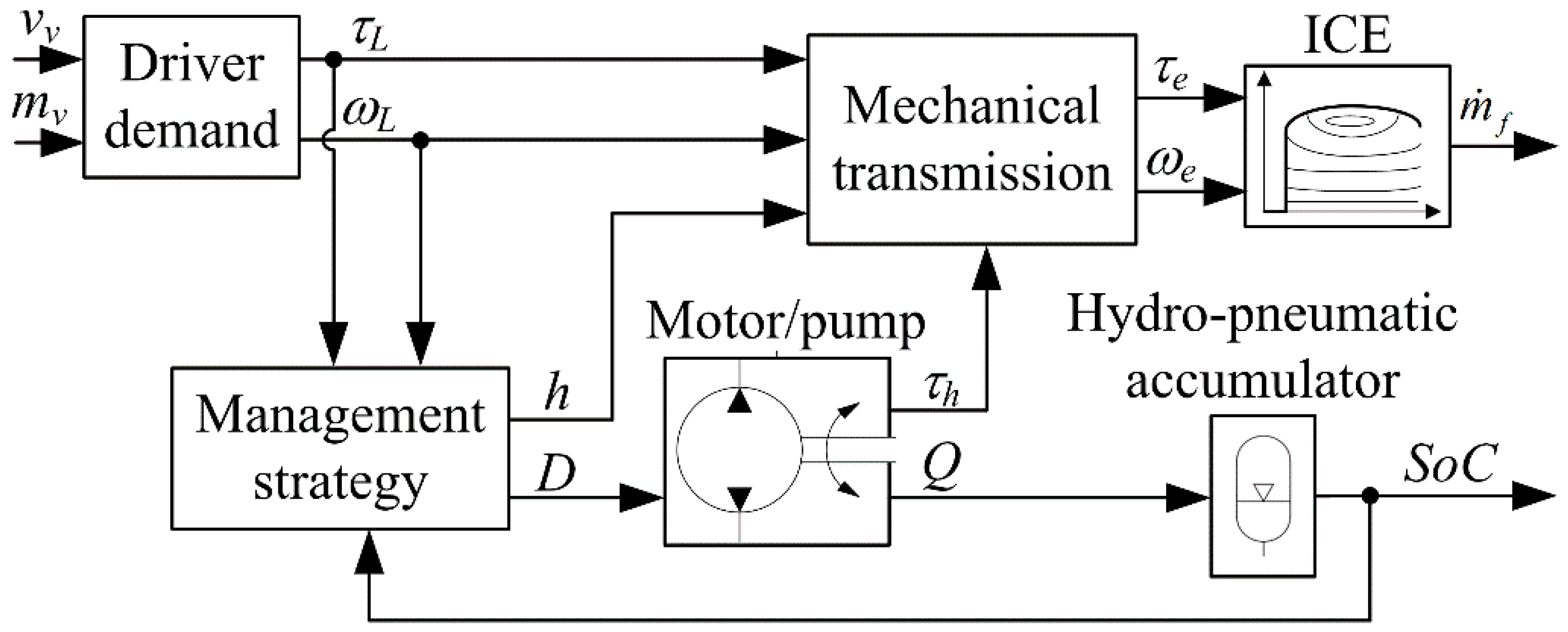

2.2. Mathematical Model of Parallel Hybrid Hydraulic Vehicle Driveline

3. Optimization of Control Variables

3.1. General Formulation of Optimization Problem

3.2. Optimization of Control Variables of HHV

4. Management Strategy for HHV Drivetrain

4.1. Analysis of Optimization Results

4.2. Gear Ratio Selector

4.3. Basic Management Strategy

4.4. Improved Management Strategy

5. Simulation Results and Analysis of Management Strategies

6. Discussion

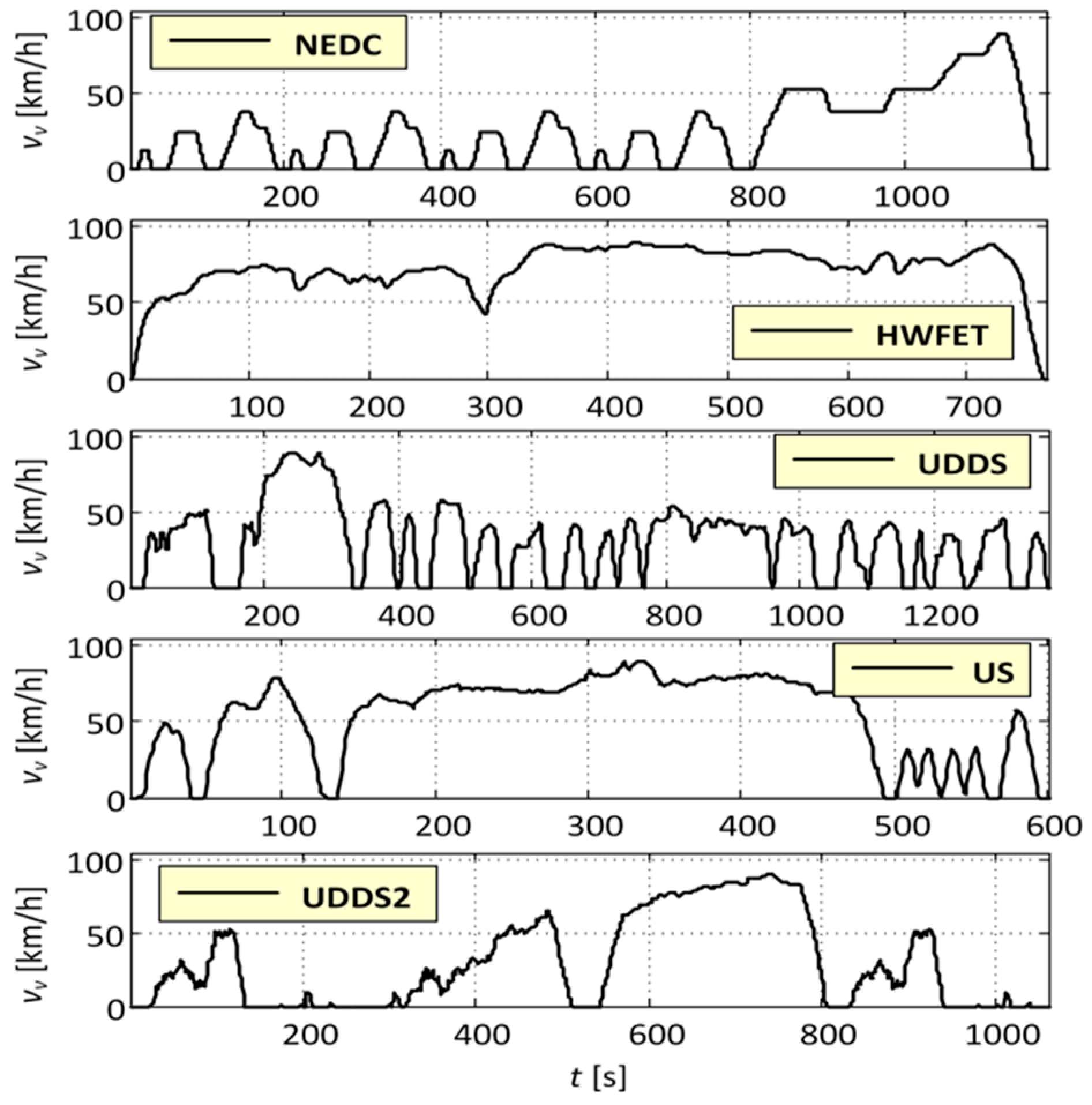

- Expanding the conventional drive with a hydraulic part that includes a hydraulic motor/pump unit and a hydro-pneumatic accumulator in a parallel configuration can reduce fuel consumption by 5% to 30% depending on the driving cycle characteristics (Table 4). More dynamic cycles that have a larger number of “stop-and-go” events score greater reduction (HWFET 4.6%, US 15.8%, UDDS2 18.3%, NEDC 19.6%, UDDS 29.8 %).

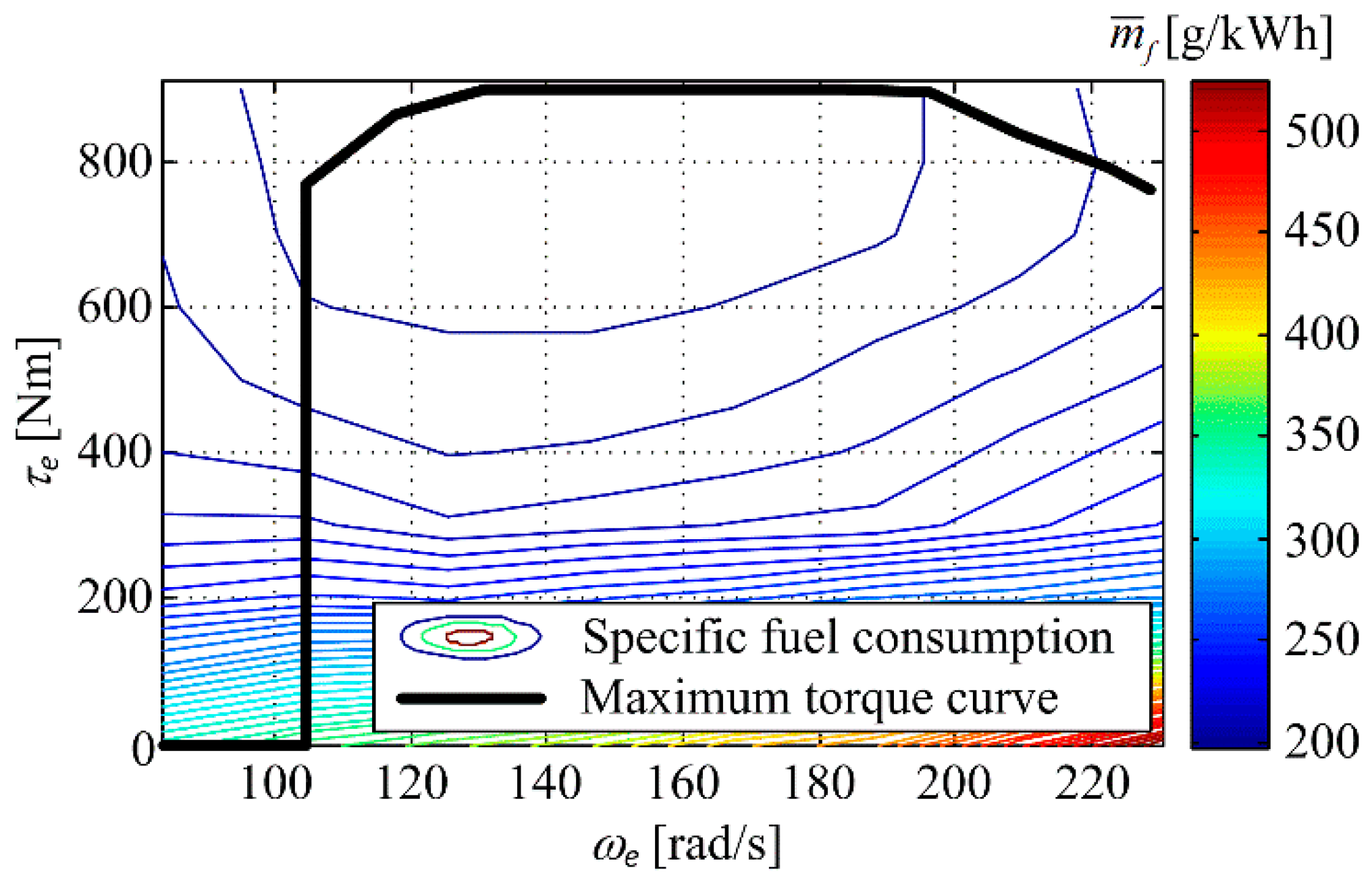

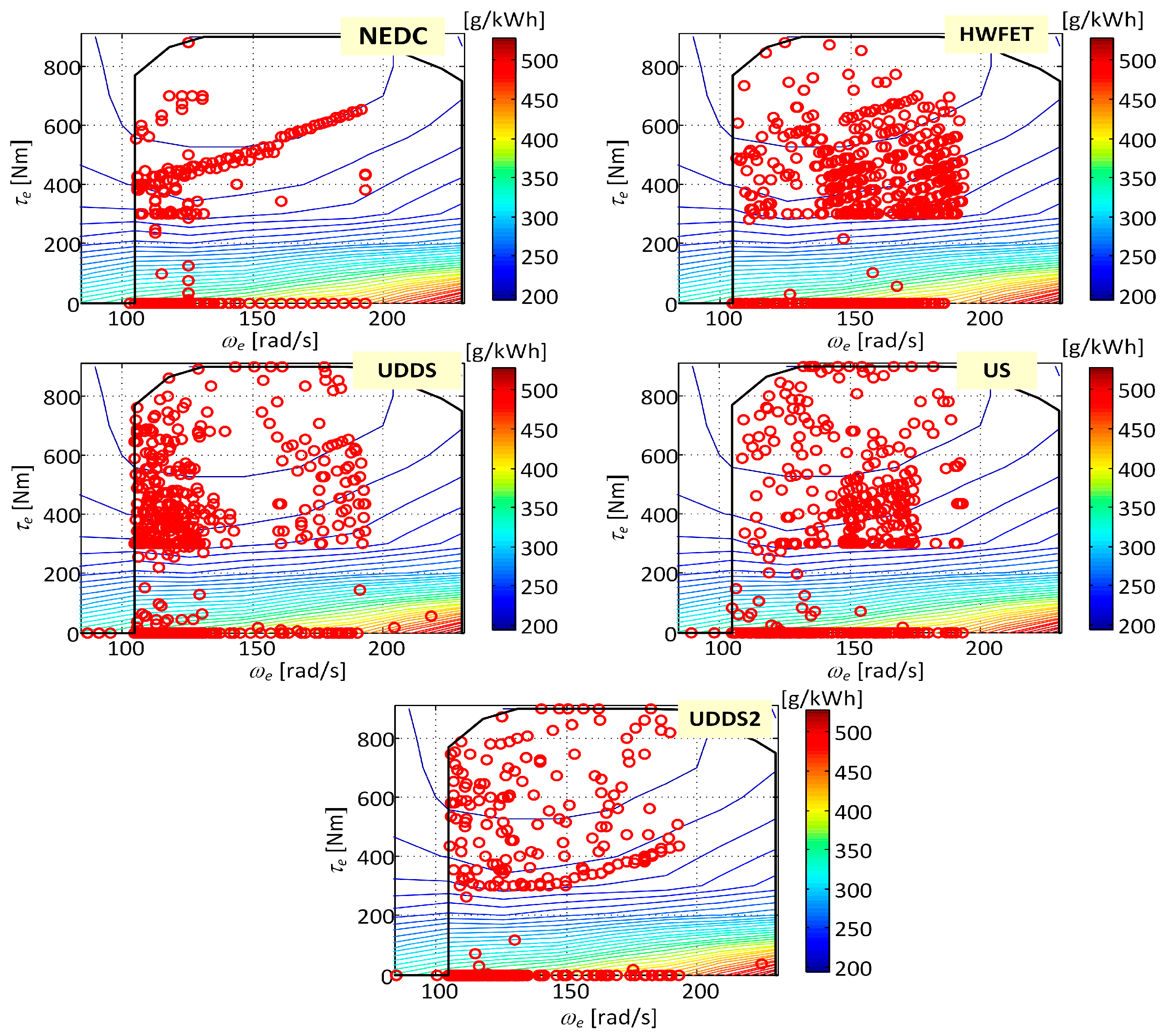

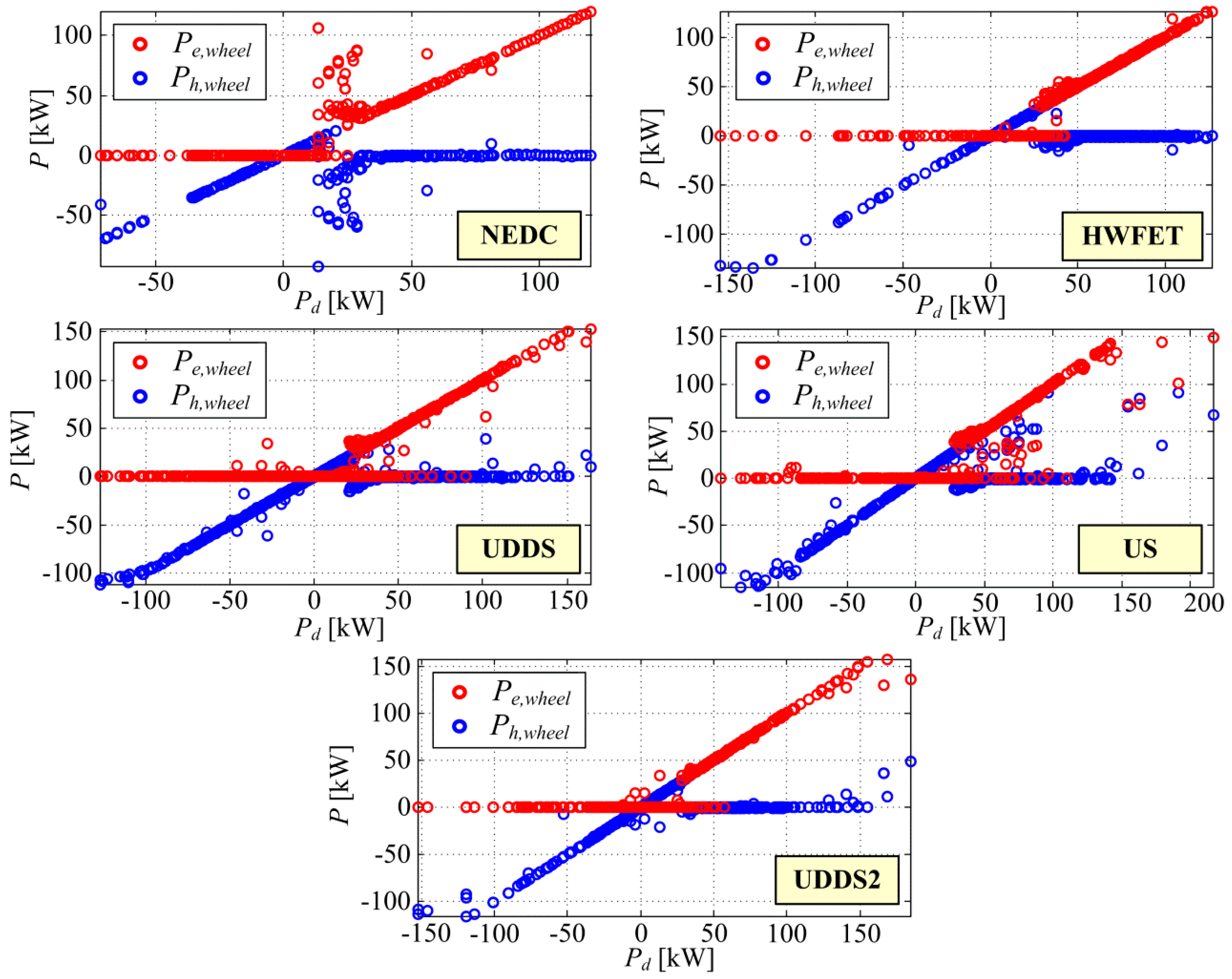

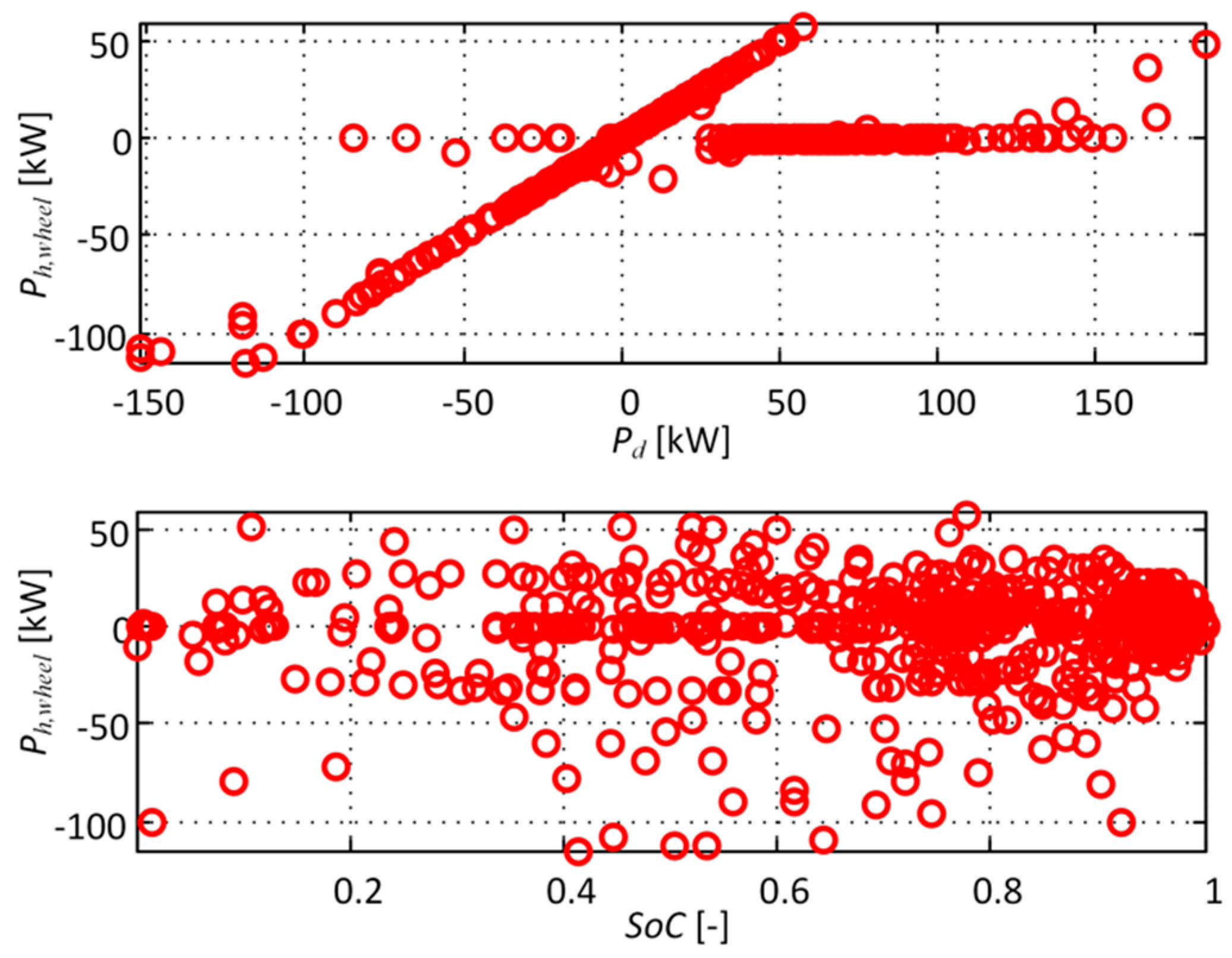

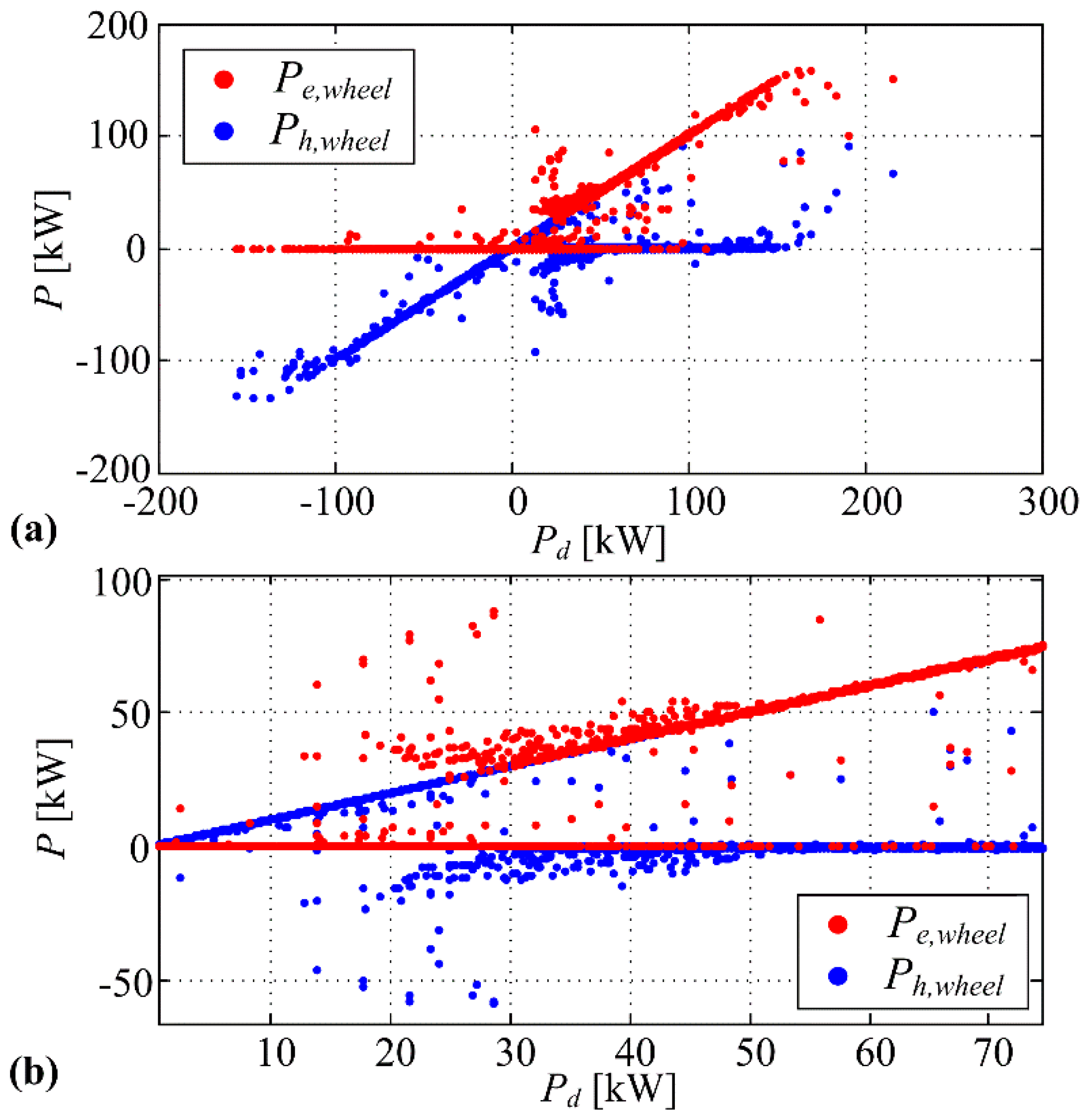

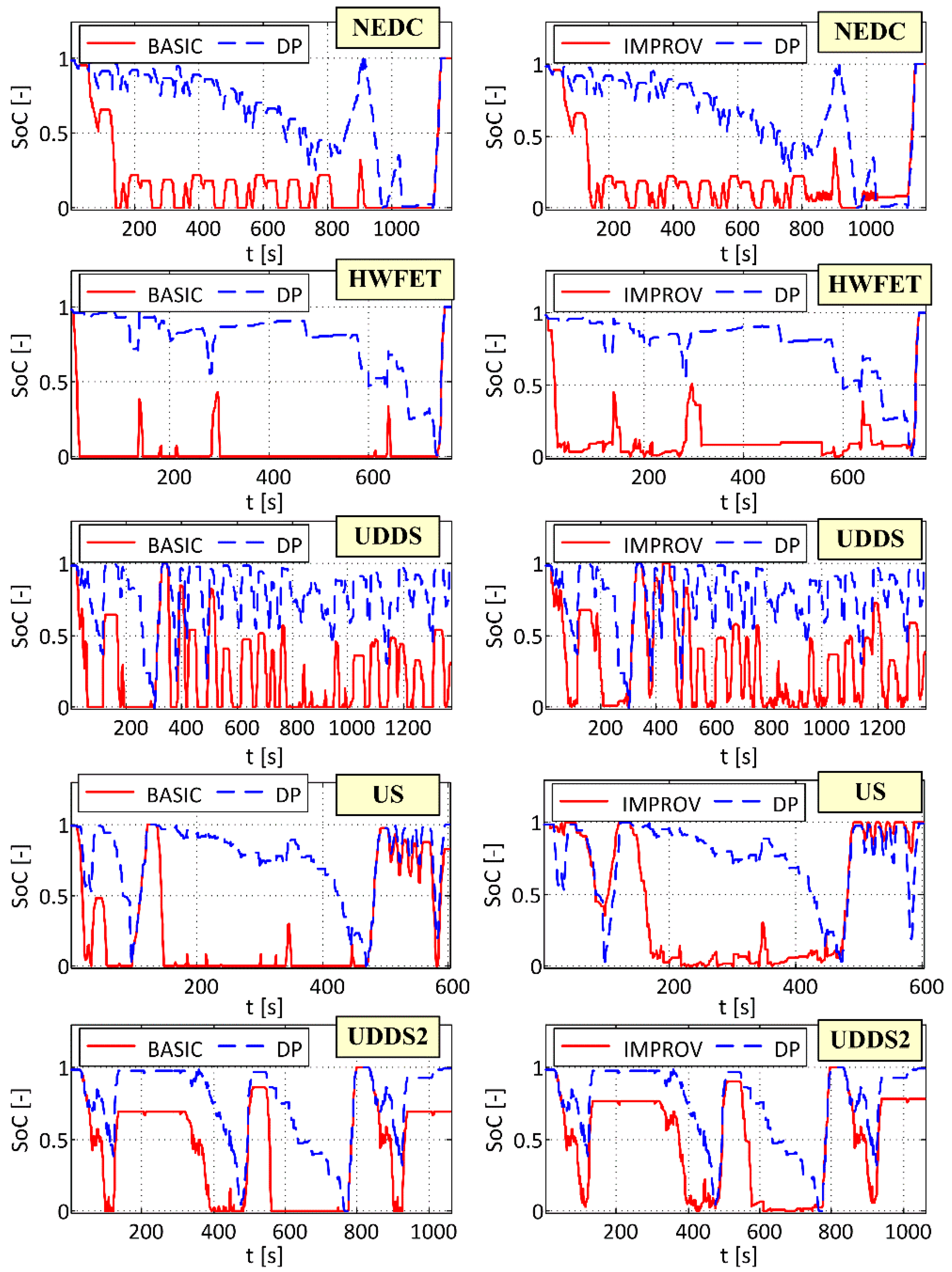

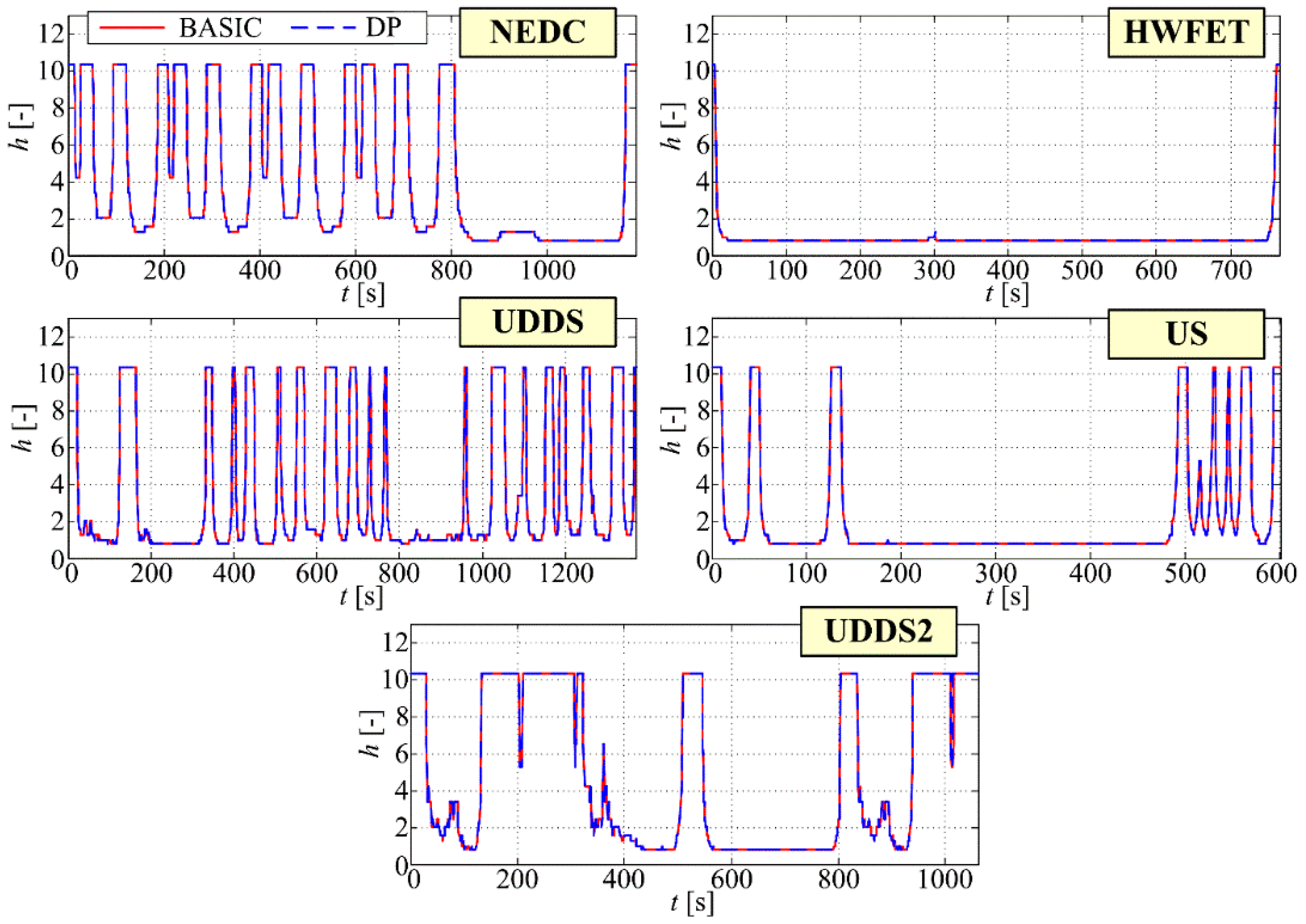

- The main characteristics that can be observed in the optimum DP results are: (i) consistent avoidance of ICE operating range between 0 and 300 Nm where the specific fuel consumption is quite large (Figure 7); (ii) SoC is trying to keep at a relatively high values to reduce losses in fluid flow (Figure 12 and Equations (7), (8) and (10)); (iii) For driver requirements for power Pd < 20 kW hydraulic motor delivers power and ICE is off; for power Pd > 50 kW ICE delivers power and hydraulic motor is off; and in the range between (20 kW < Pd < 50 kW) sometimes the driver’s demand meets the hydraulic motor and sometimes ICE which in that case gives a little more power than required in order to supplement the accumulator (Figure 10b).

- The Basic (BASIC) and Improved (IMPROV) causal management strategies approach DP fuel consumption to 1–9% (NEDC + 4.6%, HWFET + 1.2%, UDDS + 8.6%, US 2.5%, UDDS2 + 0.9%) or to 1–7% (NEDC + 4.3%, HWFET +0.9%, UDDS + 6.5%, US + 7.0%, UDDS2 + 1.1%), respectively. That can be considered to be rather favourable respected that causal management strategies lack of “knowledge” of the whole cycle as opposed to DP optimization (Table 4).

- IMPROV management strategy has achieved a more similar distribution of ICE operating points as DP optimization. However, this did not result in a consistent reduction of fuel consumption compared to BASIC strategy for all cycles. The deviation from the minimum fuel consumption for both strategies (BASIC and IMPROV) can be explained essentially with the difference of BASIC and IMPROV SoC trajectories from the optimal DP SoC trajectories. If the SoC is “compulsory” held at higher values with lower losses, the potential for recovery of regenerative braking energy would be significantly reduced. Therefore, for further fuel consumption reduction using the causal management strategy, it is necessary to predict the driving cycle from which the optimal trajectory of SoC will be further estimated.

- Predicting the driving cycle future based on the past cycle, calculating the optimal SoC trajectories for the anticipated driving cycle profile and applying the model predictive control (MPC),

- Considering Equivalent Consumption Management Strategy (ECMS) for HHV,

- Extending the existing management strategy with additional rules for example introducing different ICE deployment /exclusion thresholds and optimizing the same for different driving cycles,

- An analysis of DP optimization algorithm robustness to different changes in the model parameters values,

- The use of stochastic dynamic programming (SDP) for control which is possible, unlike the DP, to be implemented in a causal form, which has the advantage to “catch” trends in driving cycles in optimal way,

- Optimizing the HHV drive components dimensions using Willans descriptions of drive components,

- Identification and analysis of the statistical parameters of the driving cycles which are most dependent on the reduction of fuel consumption of HHV compared to CV. In this way, it is possible to examine what kind of driving cycles or applications it is profitable to apply hybridization.

7. Conclusions

Author Contributions

Funding

Conflicts of interest

Appendix A

| Symbol | Value | Description |

|---|---|---|

| Af | 9.63 [m2] | Forehead area of vehicle |

| Cd | 0.63 [-] | Drag coefficient |

| Dmin | −2.38 × 10−5 [m3] | Minimal volume of hydraulic motor/pump |

| Dmax | 2.38 × 10−5 [m3] | Maximal volume of hydraulic motor/pump |

| g | 9.81 [m/s2] | Gravity acceleration |

| h | 10.33, 8.40, 6.49, 5.27, 4.18, 3.40, 2.47, 2.01, 1.55, 1.26, 1, 0.81 | Gear ratios |

| io | 3.7 [-] | Output reduction ratio |

| Kf | 105 [-] | Penalization factor in criterion in (23) |

| Kg | 106 [-] | Penalization factor in criterion in (19) |

| m | 14.2 [kg] | Mass of gas in hydro-pneumatic accumulator |

| mv | 7860 [kg] | Vehicle mass |

| pa | 101,300 [Pa] | Ambient pressure |

| r | 0.388 [m] | Effective radius of tire |

| R | 296.8 [J/kg·K] | Specific gas constant |

| Ro | 0.012 [-] | Rolling resistance factor |

| T | 300 [K] | Gas temperature |

| Vmin | 0.05 [m3] | Min. volume of gas in hydro-pneumatic acc. |

| Vmax | 0.1 [m3] | Max. volume of gas in hydro-pneumatic acc. |

| ηf | 0.96 [-] | Mechanical transmission efficiency |

| ηh-m | 0.91 [-] | Hydraulic-mechanical efficiency |

| ηv | 0.95 [-] | Volumetric efficiency |

| ρair | 1.225 [kg/m3] | Air density |

| Af | 9.63 [m2] | Forehead area of vehicle |

| Cd | 0.63 [-] | Drag coefficient |

| Dmin | −2.38 × 10−5 [m3] | Minimal volume of hydraulic motor/pump |

| Dmax | 2.38 × 10−5 [m3] | Maximal volume of hydraulic motor/pump |

| g | 9.81 [m/s2] | Gravity acceleration |

| h | 10.33, 8.40, 6.49, 5.27, 4.18, 3.40, 2.47, 2.01, 1.55, 1.26, 1, 0.81 | Gear ratios |

| ih | 2 [-] | Reduction ratio of joint between hydraulics and mechanical transmission |

| io | 3.7 [-] | Output reduction ratio |

| Kf | 105 [-] | Penalization factor in criterion in (23) |

| Kg | 106 [-] | Penalization factor in criterion in (19) |

| m | 14.2 [kg] | Mass of gas in hydro-pneumatic accumulator |

| mv | 7860 [kg] | Vehicle mass |

| pa | 101,300 [Pa] | Ambient pressure |

| r | 0.388 [m] | Effective radius of tire |

| R | 296.8 [J/kg·K] | Specific gas constant |

| Ro | 0.012 [-] | Rolling resistance factor |

| T | 300 [K] | Gas temperature |

| Vmin | 0.05 [m3] | Min. volume of gas in hydro-pneumatic acc. |

| Vmax | 0.1 [m3] | Max. volume of gas in hydro-pneumatic acc. |

| ηf | 0.96 [-] | Mechanical transmission efficiency |

| ηh-m | 0.91 [-] | Hydraulic-mechanical efficiency |

| ηv | 0.95 [-] | Volumetric efficiency |

| ρair | 1.225 [kg/m3] | Air density |

| Abbreviation | Description |

|---|---|

| CV | Conventional vehicle |

| DP | Dynamic programming |

| HEV | Hybrid electric vehicle |

| HHV | Hybrid hydraulic vehicle |

| HPA | High-pressure accumulator |

| ICE | Internal combustion engine |

| LPA | Low-pressure accumulator |

| Symbol | Unit | Description |

|---|---|---|

| D | [m3] | Displacement, volume of motor/pump |

| E | [kWh] | Energy |

| m | [kg] | Mass |

| p | [Pa] | Pressure |

| P | [kW] | Power |

| Q | [m3/s] | Volume flow |

| SoC | [-] | State of charge |

| t | [s] | Time |

| T | [s], [K] | Duration, temperature |

| ∆T | [s] | Sampling period |

| v | [m/s] | Speed |

| V | [m3] | Volume |

| α | [rad] | Angle (of inclination) |

| η | [-] | Efficiency |

| ρ | [kg/m3] | Density |

| τ | [N/m] | Torque |

| ω | [1/s] | Rotational speed |

| Index | Description | |

| d | Desired, required | |

| e | Engine, ICE | |

| h | Hydraulic motor/pump | |

| h-m | Hydraulic-mechanic | |

| L | Load (wheel load) | |

| v | Vehicle or volumetric | |

| wheel | On wheel (load) | |

Appendix B

Explanation of Matrix Variables

Initialization

- Initialize vectors which contain discrete values of the state and control variables: SoCvec = [0 0.01 … 0.99 1], τe,vec = [0 1∙∆τe,vec 2∙∆τe,vec … 900] where ∆τe,vec = 900/99 (the maximum value of 900 Nm corresponds to the maximum ICE torque) and hvec = [10.33 8.4 6.49 5.27 4.18 3.4 2.47 2.01 1.55 1.26 1.00 0.81]

- Initialize each element of matrix Jopt to relatively large value (e.g., Jopt(i1, i0) = 1010 for each i1, i1 ∈ {1, 2, ..., NSoC}; and for each i0, i0 ∈ {0, 1, ..., Nt − 1})

Final State Variable Penalization (According to Equation (23))

- Set i0 = Nt − 1 (i.e., the final discrete time step of the optimization horizon; i0∈{0, 1, ..., Nt − 1})for i1 ← 1 to NSoCfor i2 ← 1 to Nτefor i3 ← 1 to Nh

- Calculate SoC(Nt) as a function of SoCvec(i1), τe,vec(i2), hvec(i3) and ωL and τL for the particular time step i0 (i.e., by using Equations (3) → (20) → (13) → (7) → (9) → (8) → (18a) → (18b))

- Calculate the cumulative cost function J(i1, i0) = Jf based on the Equation (23)

- If J(i1, i0) < Jopt (i1, i0), then store new optimal solution as Jopt(i1, i0) = J(i1, i0), τe,opt(i1, i0) = τe,vec(i2), hopt(i1, i0) = hvec(i3)

Optimization—Backward-in-Time Phase

- Set i0 = Nt − k (iterations backward-in-time; the outermost loop corresponds to the time loop)

- Calculate SoC (i0 + 1) as a function of SoCvec(i1), τe,vec(i2), hvec(i3) and ωL and τL for the particular time step i0 (i.e., by using Equations (3) → (20) → (13) → (7) → (9) → (8) → (18a) → (18b))

- Calculate F(i0) as a function of control variables τe,vec(i2), hvec(i2); and SoC(i0 + 1) and D(i0) calculated in the previous algorithm step (based on the Equation (19))

- Extract the optimal cumulative cost function J* from the matrix Jopt for the discrete time step i0 + 1 and for the calculated SoC (i0 + 1) (linear interpolation is used if SoC (i0 + 1) falls between two discrete values of vector SoCvec).

- Calculate the cumulative cost function as J(i1, i0) = F(i0) + J* for the current discrete time step i0 and SoCvec(i1) (candidate for new optimal value)

- If J(i1, i0) < Jopt (i1, i0), then store new optimal solution as Jopt(i1, i0) = J(i1, i0), τe,opt(i1, i0) = τe,vec(i2), hopt(i1, i0) = hvec(i3)

Reconstruction of Optimal State and Control Trajectories—Forward-in-Time Phase

- Set i0 = 0 and set the initial value of optimal state variable SoC, SoC*(i0) = SoCinit (initial SoC is set to be equal to one of the values from the vector SoCvec)

- Find the index i1 such that the vector element SoCvec(i1) is equal to SoC*(i0)

- Extract the optimal control variables τe*(i0) and h*(i0), for the discrete time step i0 and the index i1 (representing SoC*(i0)), from the matrices τe,opt and hopt (τe*(i0) = τe,opt(i1, i0), h*(i0) = hopt(i1, i0))for i0 ← 0 to Nt −1

- Calculate SoC*(i0 + 1) as a function of SoC*(i0), τe*(i0), h*(i0); and ωL and τL for the particular time step i0 (i.e., by using Equations (3) → (20) → (13) → (7) → (9) → (8) → (18a) → (18b))

- Find the indices i1,l and i1,u of adjacent values of discretised SoC such as SoCvec(i1,l) ≤ SoC*(i0 + 1) ≤ SoCvec(i1,u)

- Reconstruct the optimal control variables for the discrete time step i0 + 1, τe*(i0 + 1), h*(i0 + 1); from the previously stored backward-in-time optimization results τe,opt(i1,l, i0 + 1) and τe,opt (i1,u, i0 + 1); and hopt(i1,l, i0 + 1) and hopt(i1,u, i0 + 1) (see the discussion related to Equation (22))

Algorithm Output

References

- Hu, H.; Smaling, R.; Baseley, S.J. Advanced Hybrid Powertrains for Commercial Vehicles; SAE International: Warrendale, PA, USA, 2012; ISBN 978-0-7680-3359-5. [Google Scholar]

- Guzella, L.; Sciarretta, A. Control of hybrid electric vehicles. IEEE Control Syst. 2007, 27, 60–70. [Google Scholar]

- Guzella, L.; Sciarretta, A. Vehicle Propulsion Systems: Introduction to Modeling and Optimization; Springer: Berlin, Germany, 2013; ISBN 978-3-642-35913-2. [Google Scholar]

- Zhao, K.; Liang, Z.; Huang, Y.; Wang, H.; Khajepour, A.; Zhen, Y. Research on a Novel Hydraulic/Electric Synergy Bus. Energies 2018, 11, 34. [Google Scholar] [CrossRef]

- Filipi, Z. Hydraulic and pneumatic hybrid powertrains for improved fuel economy in vehicles. In Alternative Fuels and Advanced Vehicle Technologies for Improved Environmental Performance: Towards Zero Carbon Transportation; Woodhead Publishing Limited: Sawston, UK, 2014; pp. 505–540. [Google Scholar]

- Škugor, B.; Cipek, M.; Deur, J. Control Variables Optimization and Feedback Control Strategy Design for the Blended Operating Mode of an Extended Range Electric Vehicle. SAE Int. J. Altern. Powertrain. SAE Pap. 2014, 3, 152–162. [Google Scholar] [CrossRef]

- Škugor, B.; Deur, J.; Cipek, M.; Pavković, D. Design of a Power-split Hybrid Electric Vehicle Control System Utilizing a Rule-based Controller and an Equivalent Consumption Minimization Strategy. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 228, 631–648. [Google Scholar] [CrossRef]

- Mustardo, C.; Rizzoni, G.; Guezennec, Y.; Staccia, B. A-ECMS: An adaptive algorithm for hybrid electric vehicle energy management. Eur. J. Control 2005, 11, 509–524. [Google Scholar] [CrossRef]

- Onori, S.; Serrao, L. On adaptive-ECMS strategies for hybrid electric vehicles. In Proceedings of the International Scientific Conference on Hybrid and Electric Vehicles, Rueil-Malmaison, France, 6–7 December 2011. [Google Scholar]

- Qin, F.; Xu, G.; Hu, Y.; Xu, K.; Li, W. Stochastic Optimal Control of Parallel Hybrid Electric Vehicles. Energies 2017, 10, 214. [Google Scholar] [CrossRef]

- Xu, G.; Li, W.; Xu, K.; Song, Z. An Intelligent Regenerative Braking Strategy for Electric Vehicles. Energies 2011, 4, 1461–1477. [Google Scholar] [CrossRef]

- Samadani, E.; Farhad, S.; Panchal, S.; Fraser, R.; Fowler, M. Modeling and Evaluation of Li-Ion Battery Performance Based on the Electric Vehicle Field Tests; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Karbaschian, M.A.; Söffker, D. Review and Comparison of Power Management Approaches for Hybrid Vehicles with Focus on Hydraulic Drives. Energies 2014, 7, 3512–3536. [Google Scholar] [CrossRef]

- Kim, H.; Wi, J.; Yoo, J.; Son, H.; Park, C.; Kim, H. A Study on the Fuel Economy Potential of Parallel and Power Split Type Hybrid Electric Vehicles. Energies 2018, 11, 2103. [Google Scholar] [CrossRef]

- Cipek, M.; Škugor, B.; Deur, J. Comparative Analysis of Conventional and Electric Delivery Vehicles Based on Realistic Driving Cycles. In Proceedings of the EEVC European Electric Vehicle Congress (EEVC-2014), Brussels, Belgium, 2–5 December 2014. [Google Scholar]

- Mance, M. Mathematical Modelling of Hybrid Hydraulic Vehicle. Bachelor’s Thesis, University of Zagreb, Zagreb, Croatia, 4 March 2014. (In Croatian). [Google Scholar]

- How Parallel Hydraulic Hybrid Vehicles Work. Available online: https://archive.epa.gov/otaq/technology/web/html/how-it-works-parallel.html (accessed on 12 October 2018).

- Pfeffer, A.; Glück, T.; Kemmetmüller, W.; Kugi, A. State of Charge Estimator Design for a Gas Charged Hydraulic Accumulator. J. Dyn. Syst. Meas. Control 2015, 137. [Google Scholar] [CrossRef]

- Lemofouet, S. Investigation and Optimization of Hybrid Electricity Storage Systems Based on Compressed Air and Supercapacitors. Ph.D. Thesis, Ecole Polytechnique Federale de Lausanne, Lausanne, Switzerland, 20 October 2006. [Google Scholar]

- Perković, V. Short-time energy storage using hydro-pneumatic accumulators. Master’s Thesis, University of Zagreb, Zagreb, Croatia, 15 December 2011. (In Croatian). [Google Scholar]

- Petrić, J. Modeling of hydro-pneumatic energy storage system. In Proceedings of the 8th EUROSIM Congress on Modelling and Simulation, Cardiff, UK, 10–13 September 2013. [Google Scholar]

- Pfeffer, A.; Glück, T.; Kemmetmüller, W.; Kugi, A. Mathematical modelling of a hydraulic accumulator for hydraulic hybrid drives. Math. Comput. Model. Dyn. Syst. 2016, 22, 397–411. [Google Scholar] [CrossRef]

- Bellman, R.E.; Dreyfus, S.E. Applied Dynamic Programming; Princeton University Press: Princeton, NJ, USA, 1962; ISBN 978-0691625423. [Google Scholar]

- Giakoumis, E.G. Driving and Engine Cycles; Springer International Publishing AG: Cham, Switzerland, 2017; ISBN 978-3-319-49033-5. [Google Scholar]

- 2016 Chevrolet Volt Battery System. Available online: https://media.gm.com/content/dam/Media/microsites/product/Volt_2016/doc/VOLT_BATTERY.pdf (accessed on 12 October 2018).

| Cumulative Energies | NEDC | HWFET | UDDS | US | UDDS2 |

| Ed,p | 4.7185 | 11.7260 | 8.1824 | 7.0316 | 6.5585 |

| Ed,n | −1.0127 | −0.6569 | −3.1100 | −1.5745 | −1.5939 |

| DP | NEDC | HWFET | UDDS | US | UDDS2 |

| Ee,p + Eh,p | 4.7185 | 11.7259 | 8.1797 | 7.0274 | 6.5585 |

| Ee,p | 4.2628 | 11.3606 | 6.0142 | 5.9687 | 5.5322 |

| Eh,p | 0.4557 | 0.3653 | 2.1656 | 1.0587 | 1.0264 |

| Eh,n | −0.9120 | −0.5796 | −3.0062 | −1.4041 | −1.4441 |

| BASIC | NEDC | HWFET | UDDS | US | UDDS2 |

| Ee,p + Eh,p | 4.7187 | 11.7234 | 8.1203 | 6.9964 | 6.5073 |

| Ee,p | 4.0803 | 11.3027 | 6.0162 | 5.9129 | 5.4329 |

| Eh,p | 0.6385 | 0.4207 | 2.1042 | 1.0835 | 1.0744 |

| Eh,n | −0.9120 | −0.5818 | −2.7221 | −1.4315 | −1.4004 |

| IMPROV | NEDC | HWFET | UDDS | US | UDDS2 |

| Ee,p + Eh,p | 4.7187 | 11.7260 | 8.1853 | 7.0108 | 6.5542 |

| Ee,p | 4.2081 | 11.3652 | 6.2023 | 6.3394 | 5.5196 |

| Eh,p | 0.5106 | 0.3608 | 1.9829 | 0.6714 | 1.0345 |

| Eh,n | −0.8952 | −0.5727 | −2.7311 | −0.9868 | −1.4116 |

| Driving Cycle | DP | BASIC | IMPROV |

|---|---|---|---|

| Eh,n vs. Ed,n [%] | Eh,n vs. Ed,n [%] | Eh,n vs. Ed,n [%] | |

| NEDC | 90.0563 | 90.0563 | 88.3974 |

| HWFET | 88.2326 | 88.5675 | 87.1822 |

| UDDS | 96.6624 | 87.5273 | 87.8167 |

| US | 89.1775 | 90.9178 | 62.6739 |

| UDDS2 | 90.6017 | 87.8600 | 88.5626 |

| Driving Cycle | CV | HHV | ||

|---|---|---|---|---|

| DP | BASIC | IMPROV | ||

| Vf,tot [L] ([L/100 km]) | Vf,tot [L] ([L/100 km]) | Vf,tot [L] ([L/100 km]) | Vf,tot [L] ([L/100 km]) | |

| NEDC | 1.35 (16.5) | 1.08 (13.2) | 1.13 (13.8) | 1.13 (13.8) |

| HWFET | 3.02 (19.6) | 2.88 (18.7) | 2.92 (18.9) | 2.91 (18.9) |

| UDDS | 2.15 (18.2) | 1.51 (12.8) | 1.64 (13.9) | 1.61 (13.6) |

| US | 1.77 (19.7) | 1.49 (16.6) | 1.53 (17.0) | 1.59 (17.7) |

| UDDS2 | 1.69 (19.7) | 1.38 (16.1) | 1.40 (16.2) | 1.40 (16.2) |

| *AVG | (18.7) | (15.5) | (15.7) | (16.0) |

| vs. CV | CV | DP | BASIC | IMPROV |

|---|---|---|---|---|

| NEDC | 0.0% | −19.6% | −16.1% | −16.2% |

| HWFET | 0.0% | −4.6% | −3.4% | −3.7% |

| UDDS | 0.0% | −29.8% | −23.8% | −25.3% |

| US | 0.0% | −15.8% | −13.7% | −9.9% |

| UDDS2 | 0.0% | −18.3% | −17.6% | −17.4% |

| vs. DP | CV | DP | BASIC | IMPROV |

| NEDC | +24.4% | 0.0% | +4.6% | +4.3% |

| HWFET | +4.79% | 0.0% | +1.2% | +0.9% |

| UDDS | +42.6% | 0.0% | +8.6% | +6.5% |

| US | +18.8% | 0.0% | +2.5% | +7.0% |

| UDDS2 | +22.4% | 0.0% | +0.9% | +1.1% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Škugor, B.; Petrić, J. Optimization of Control Variables and Design of Management Strategy for Hybrid Hydraulic Vehicle. Energies 2018, 11, 2838. https://doi.org/10.3390/en11102838

Škugor B, Petrić J. Optimization of Control Variables and Design of Management Strategy for Hybrid Hydraulic Vehicle. Energies. 2018; 11(10):2838. https://doi.org/10.3390/en11102838

Chicago/Turabian StyleŠkugor, Branimir, and Joško Petrić. 2018. "Optimization of Control Variables and Design of Management Strategy for Hybrid Hydraulic Vehicle" Energies 11, no. 10: 2838. https://doi.org/10.3390/en11102838

APA StyleŠkugor, B., & Petrić, J. (2018). Optimization of Control Variables and Design of Management Strategy for Hybrid Hydraulic Vehicle. Energies, 11(10), 2838. https://doi.org/10.3390/en11102838