Optimization of Hybrid Energy Storage Systems for Vehicles with Dynamic On-Off Power Loads Using a Nested Formulation

Abstract

1. Introduction

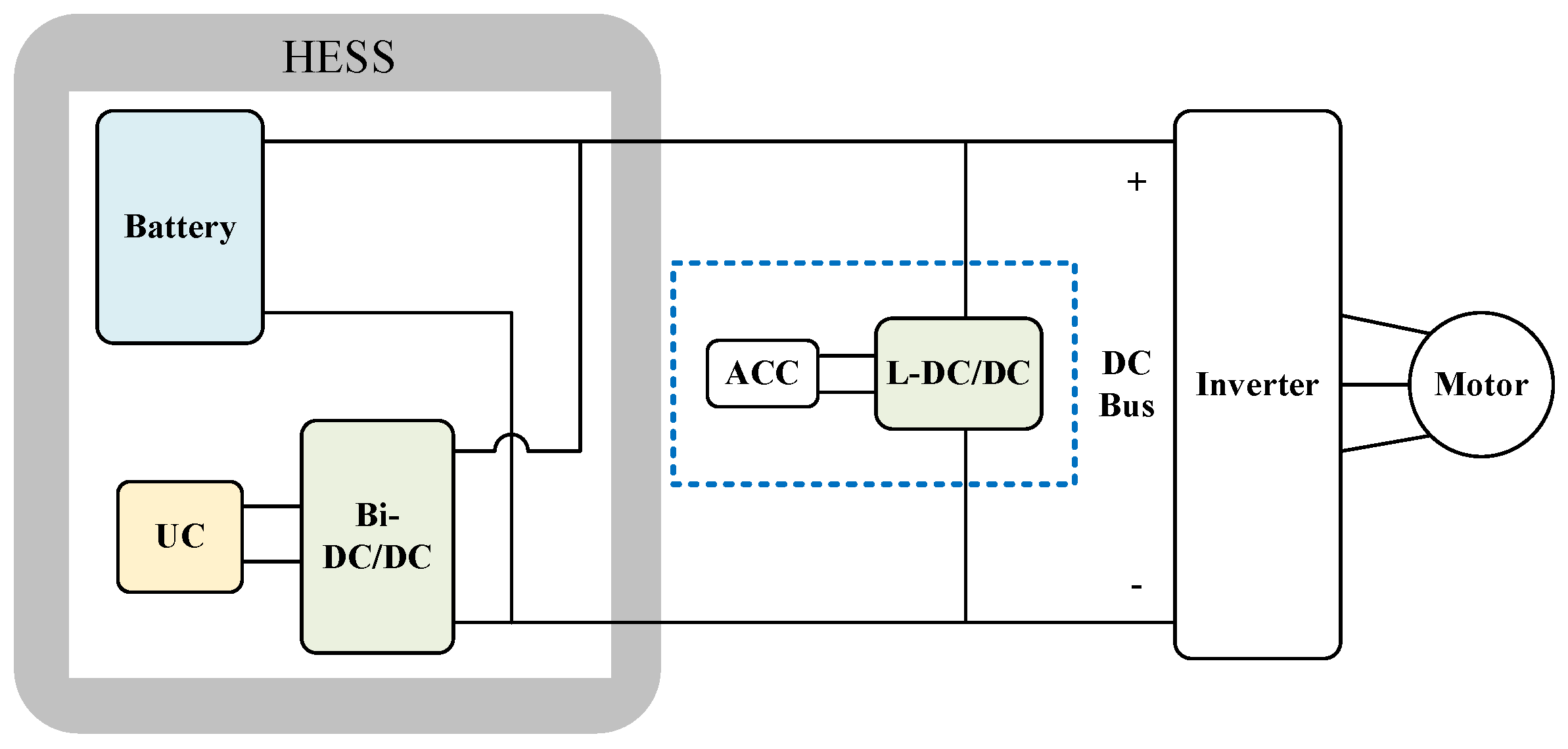

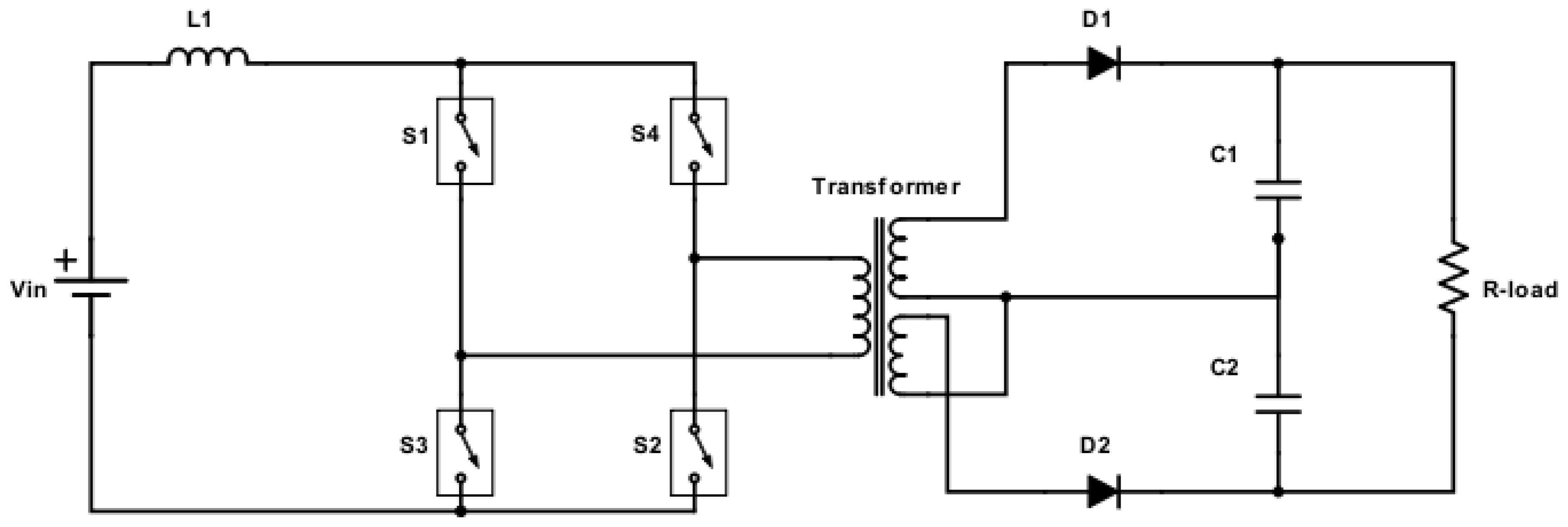

2. HESS Architecture and Performance/Power-Loss Model

2.1. Topology

2.2. HESS Performance and Power-Loss Model

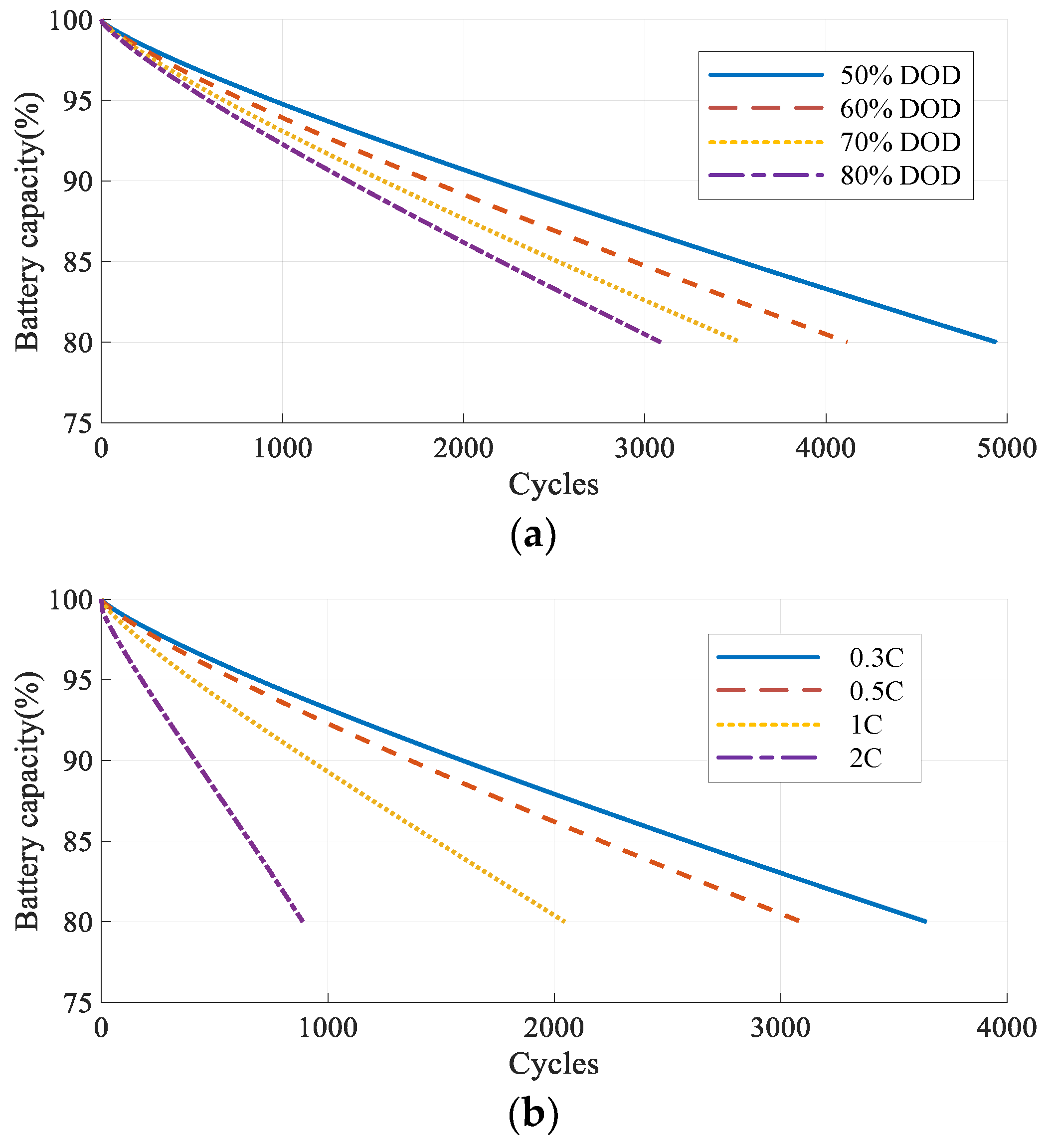

2.2.1. Battery Performance Degradation Model

2.2.2. Battery Equivalent Circuit Model

2.2.3. UC Equivalent Circuit Model

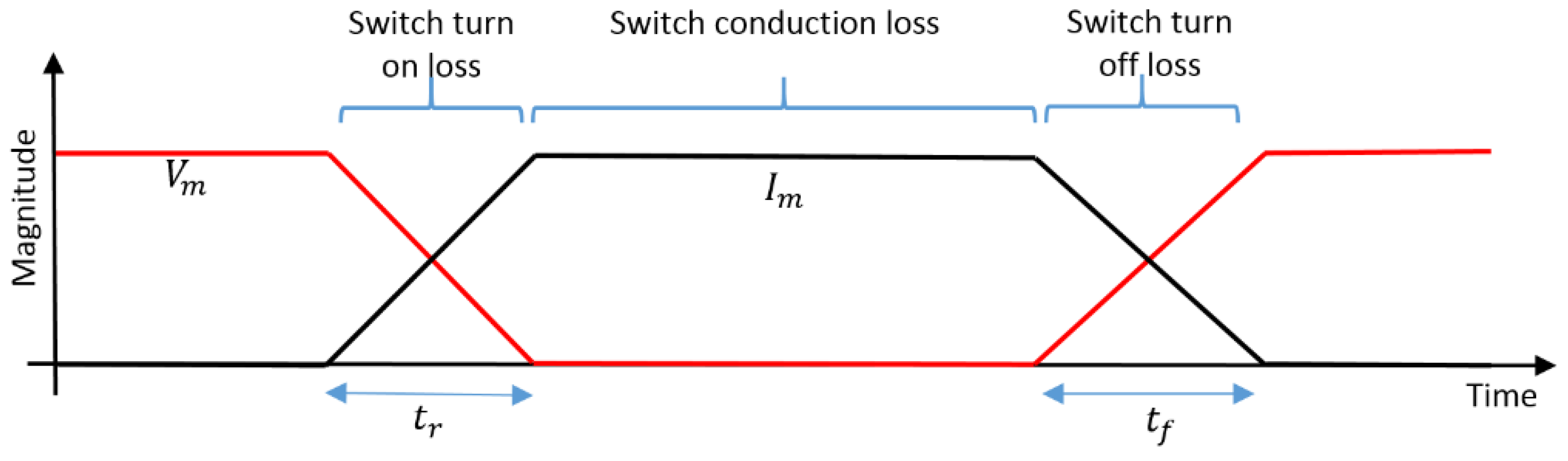

2.2.4. DC/DC Converter Power Loss Model

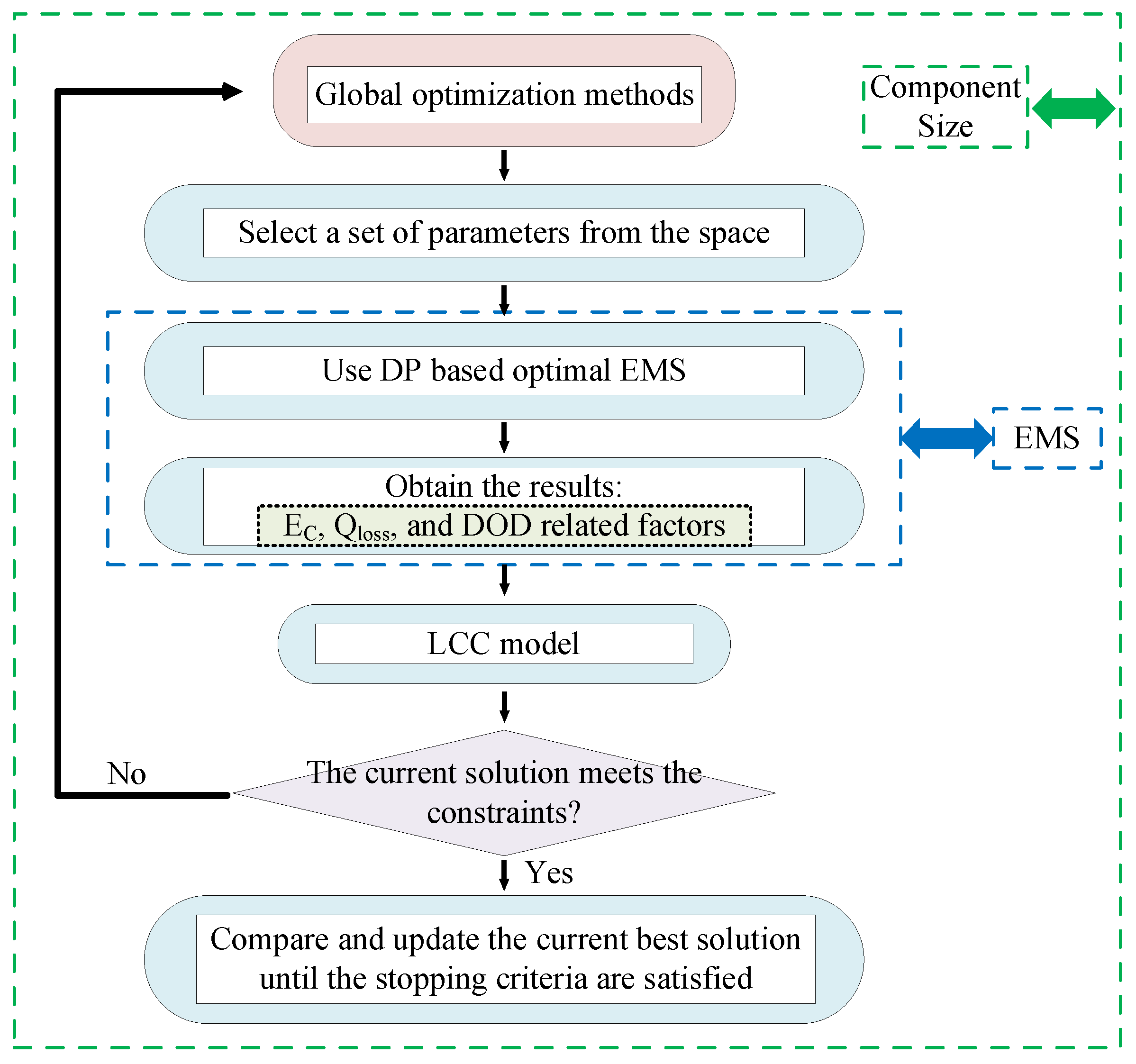

3. Nested Optimization of HESS

3.1. Problem Formulation

- (1)

- Select a set of parameters as the input from the design space based on the search method of the optimization algorithm.

- (2)

- DP-based optimal EMS is used to evaluate the corresponding EC, Qloss, and DOD-related factors.

- (3)

- The results obtained by DP are utilized to achieve the objective function via the LCC model.

- (4)

- If the current solution meets the constraints, compare and update the best solution and then terminate until the stopping criteria are satisfied. Otherwise, repeat the steps (1) to (3) until the global stopping conditions are met.

3.2. DP-Based EMS

3.3. LCC Model

4. Global Optimization Algorithms

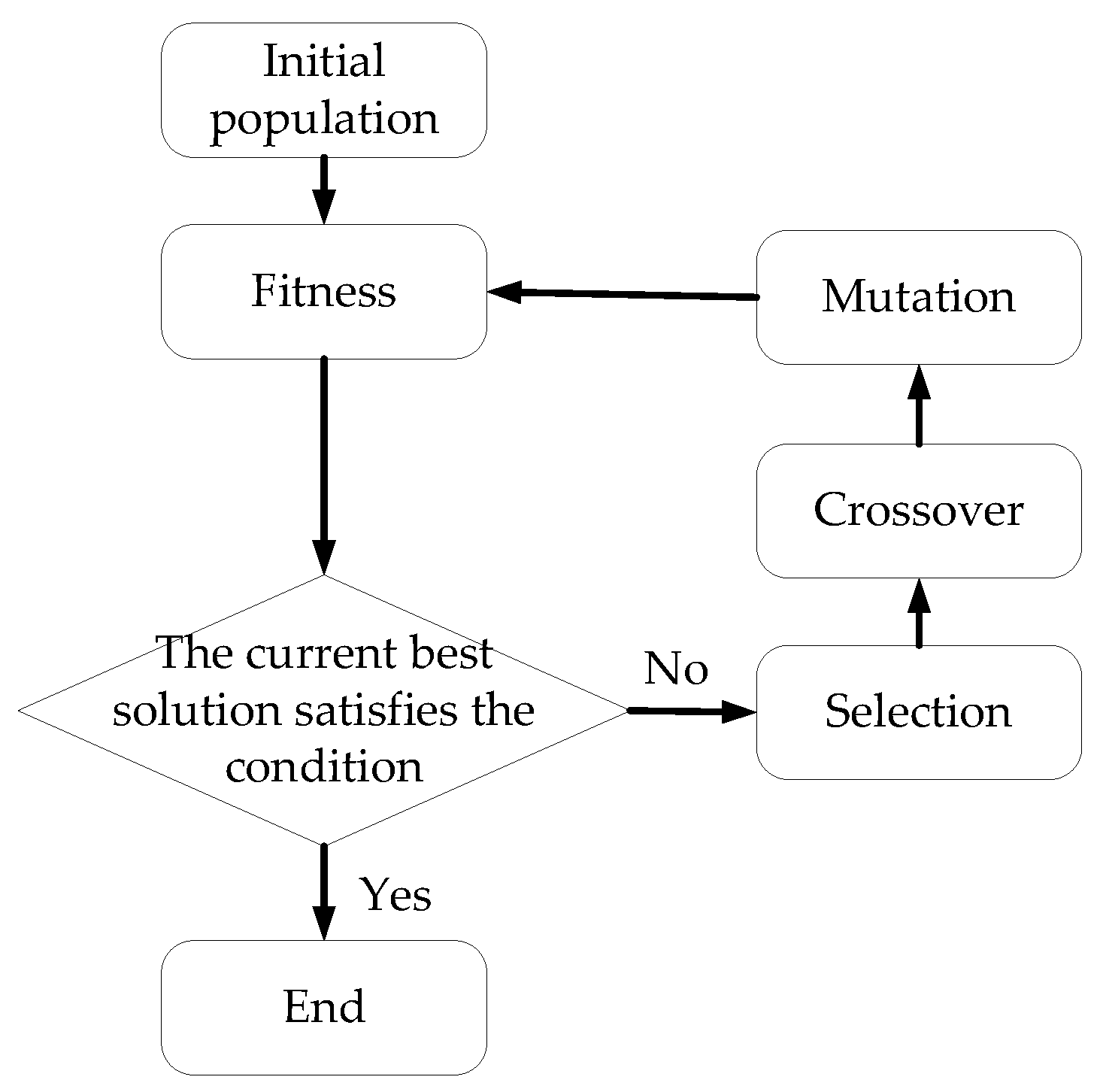

4.1. GA

- (1)

- Produce an initial population.

- (2)

- Evaluate the fitness function of each individual of the population.

- (3)

- Select individuals from the current population to be parents.

- (4)

- Generate the next population via crossover and mutation.

- (5)

- Iterate steps (2) to (4) until the stopping criteria are fulfilled.

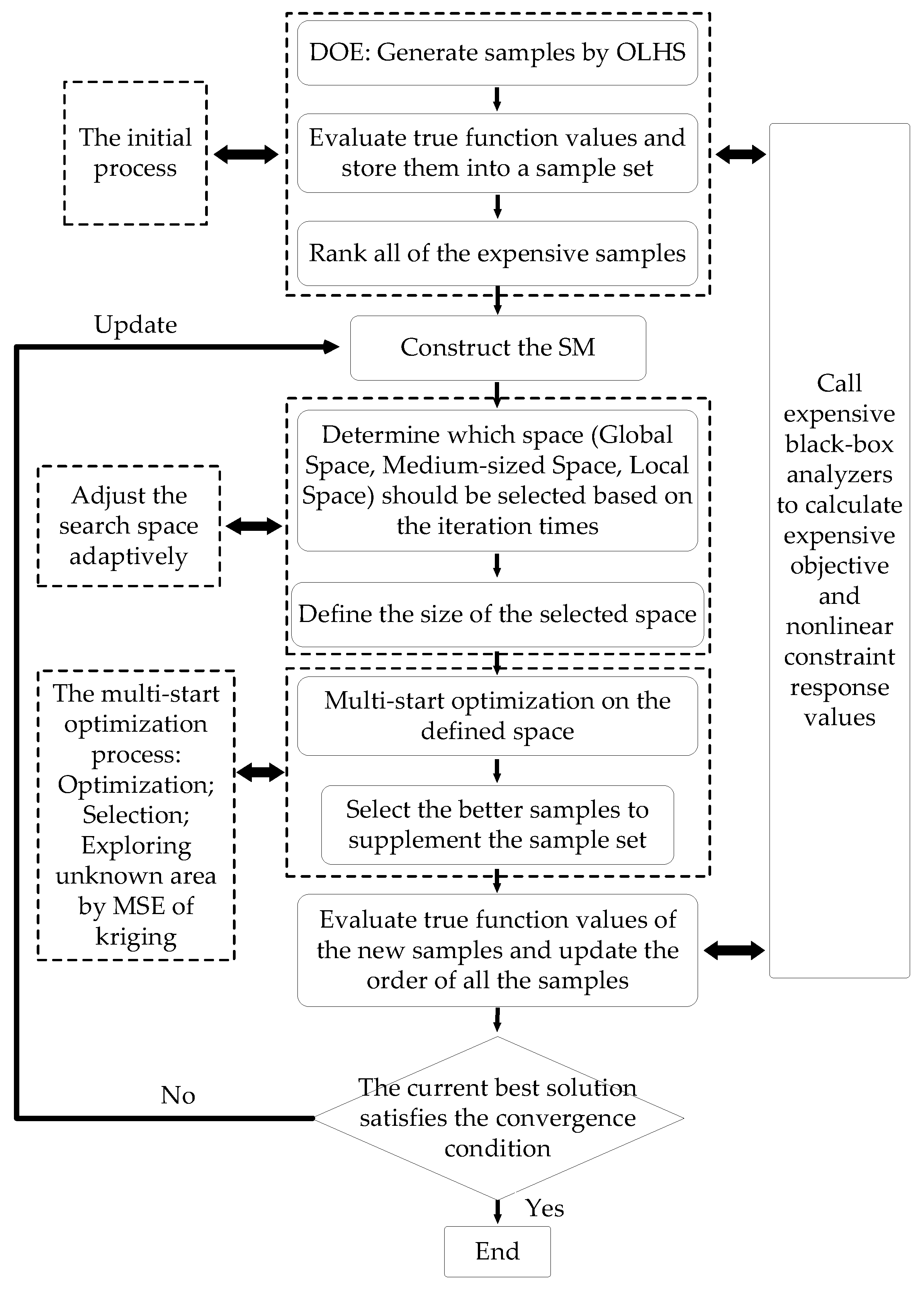

4.2. MSSR

- (1)

- Design of experiment: using optimized Latin hypercube sampling to generate sample points in the entire design space.

- (2)

- Evaluate the expensive function with these sample points and store the results in the sample set.

- (3)

- Rank all expensive samples based on their function values (add a large penalty factor of 106 to the value if the point does not meet the constraints).

- (4)

- Build the kriging-based SM.

- (5)

- Determine which space should be explored based on the present number of iterations. The global search, medium-sized search, and local search will be implemented in the process.

- (6)

- Define the size of the search space according to the expensive sample set.

- (7)

- Utilize the multi-start local optimization method to optimize the kriging-based SM in the defined space.

- (8)

- Store the local optimal solutions obtained from the database “potential sample points” and select better samples. If there is no better sample, two new samples from the unknown area will be selected.

- (9)

- Evaluate the expensive function with the selected sample points and update the order of the expensive samples in step (3).

- (10)

- Terminate the loop if the current best sample value satisfies the stopping criteria. Otherwise, update the SM and repeat the steps (4) to (9) until the stopping criteria are satisfied.

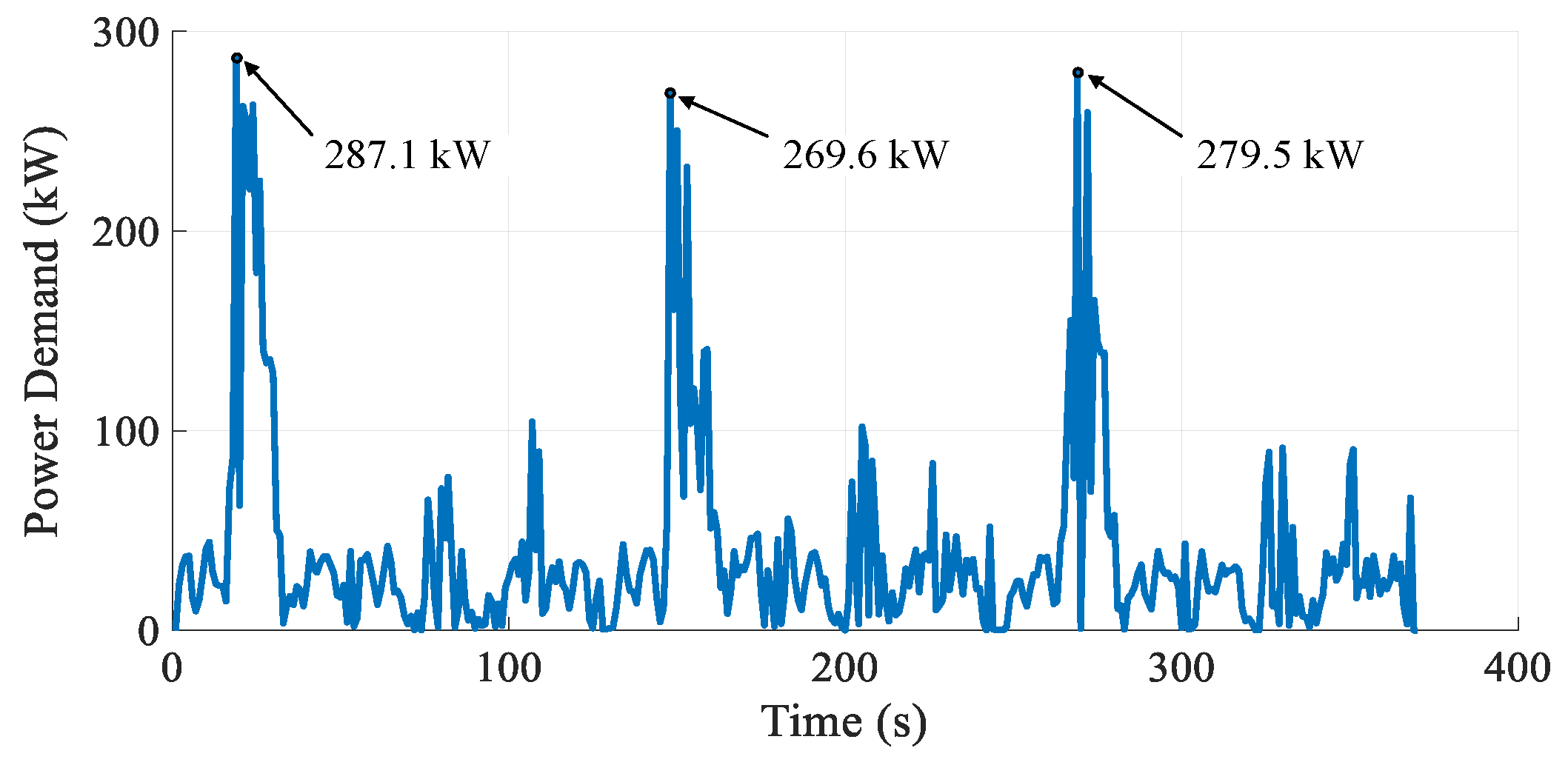

5. Dynamic On-Off Power Loads Example: LHD

5.1. LHD Data Description

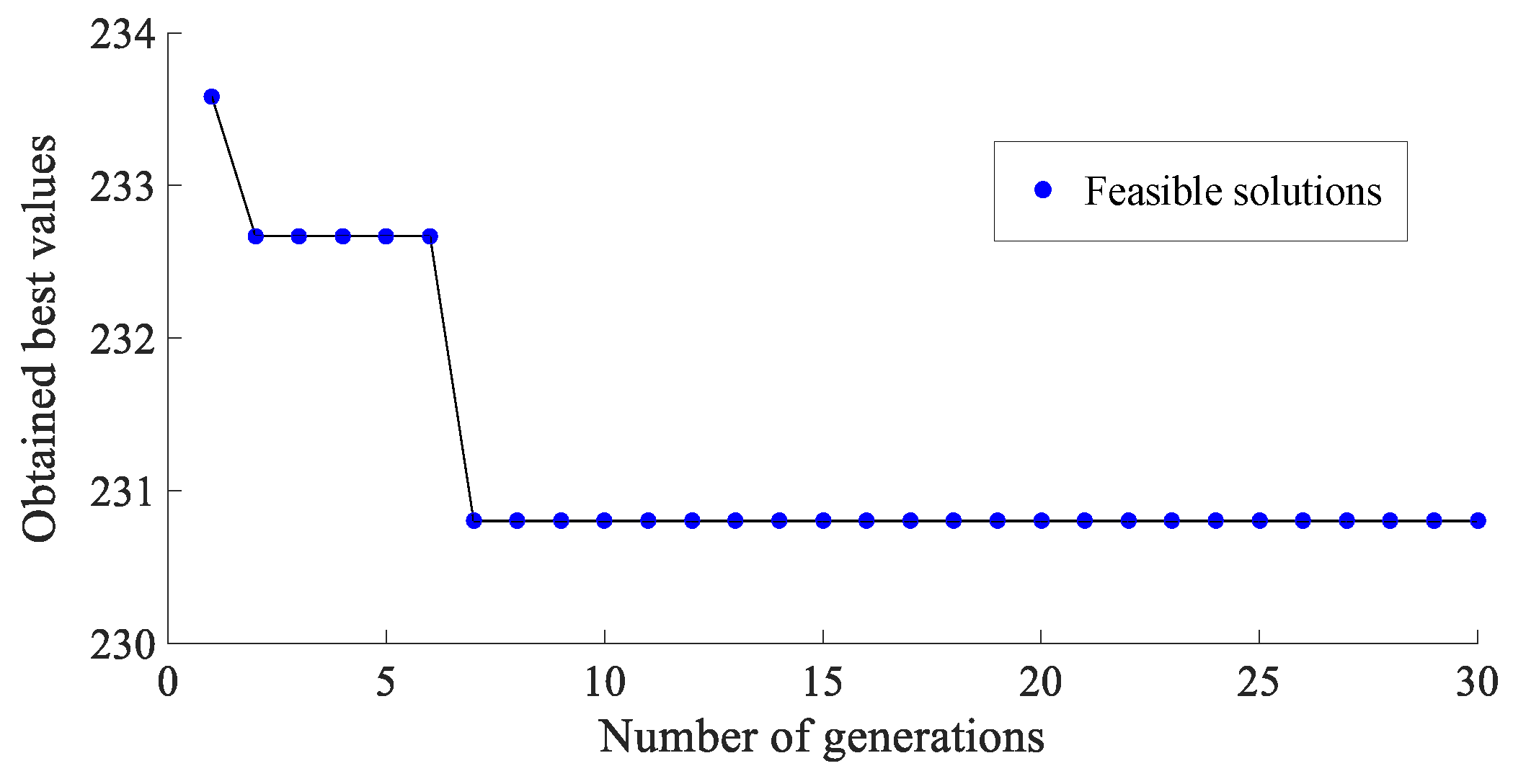

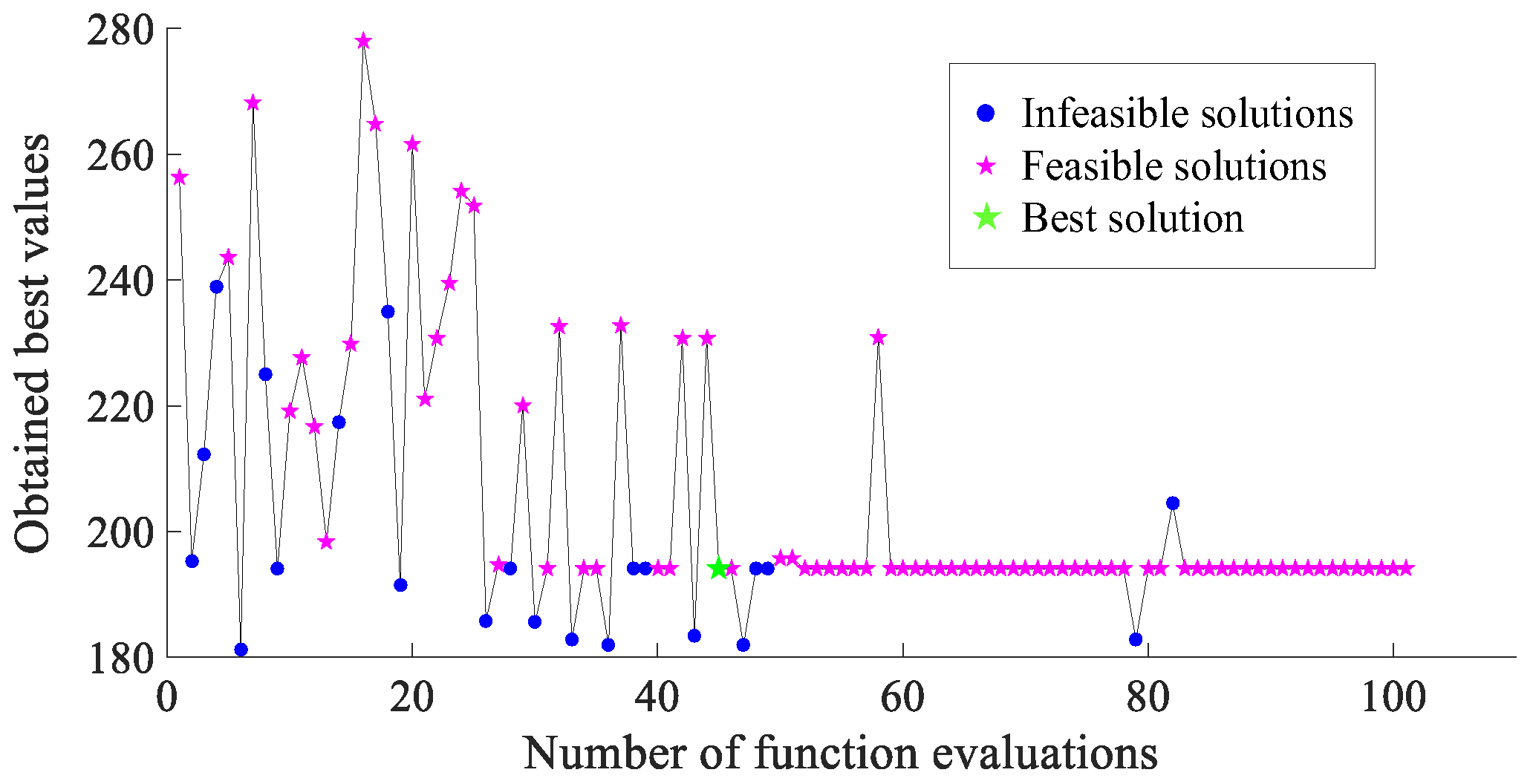

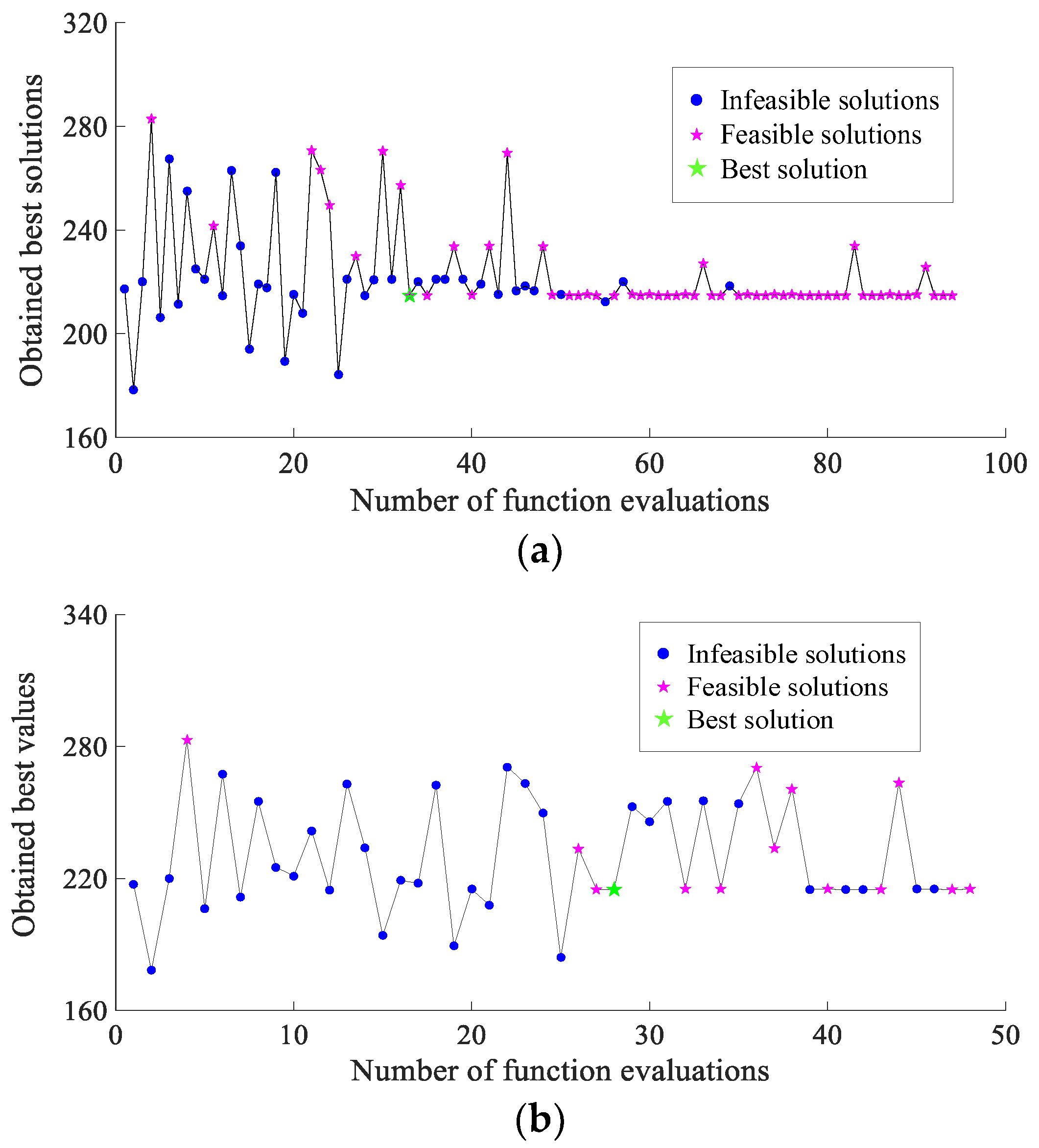

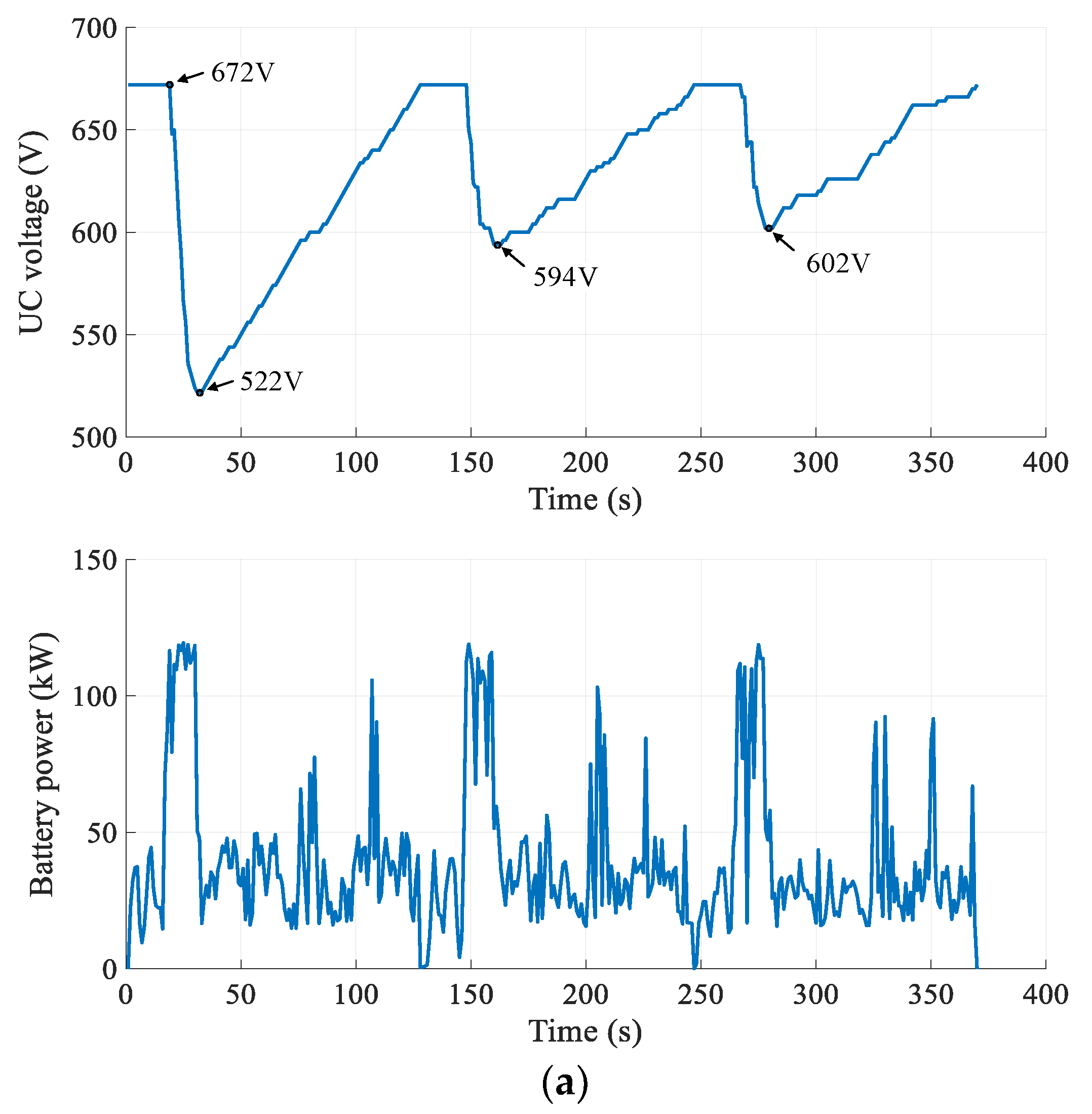

5.2. Optimization Results

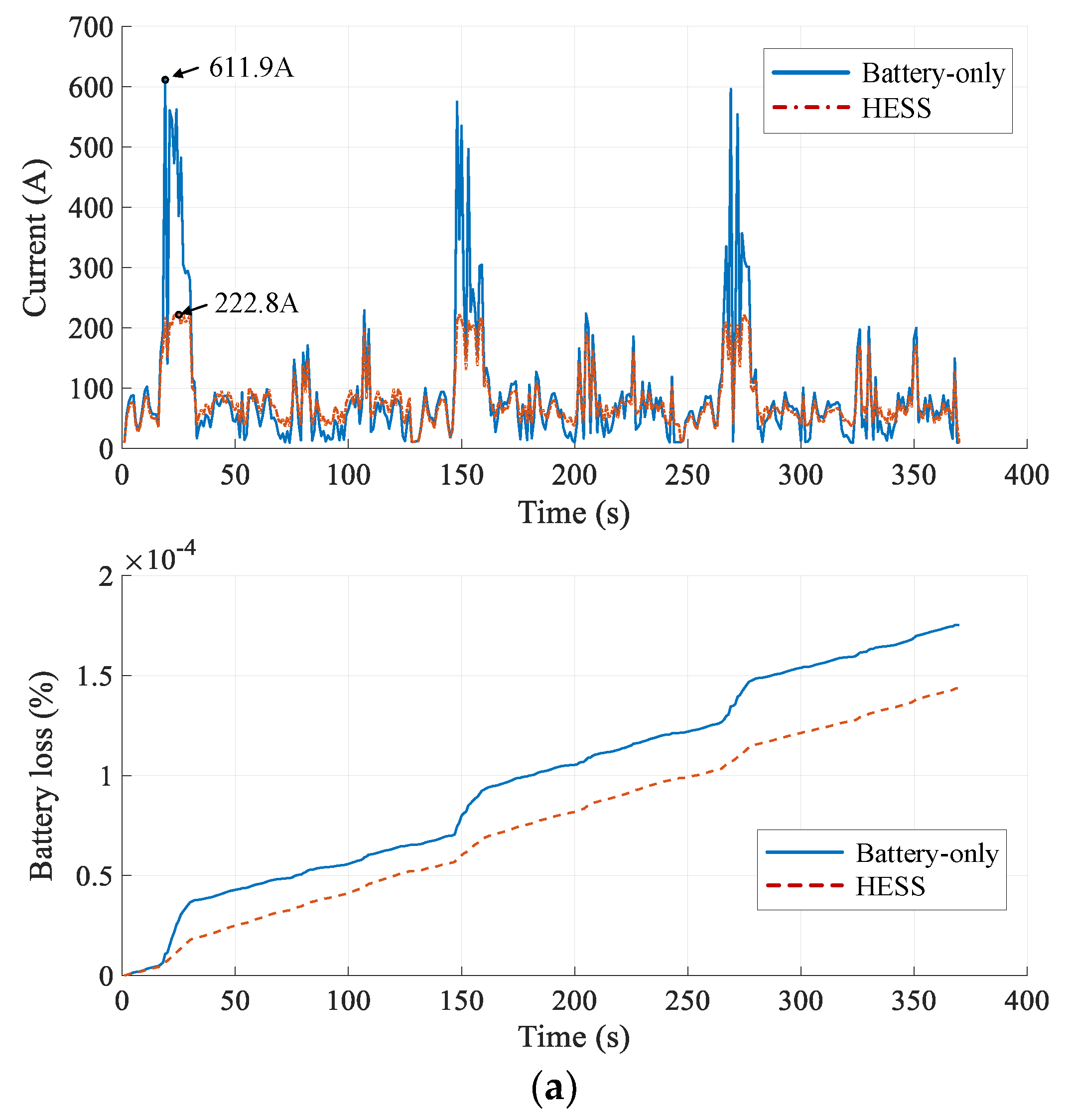

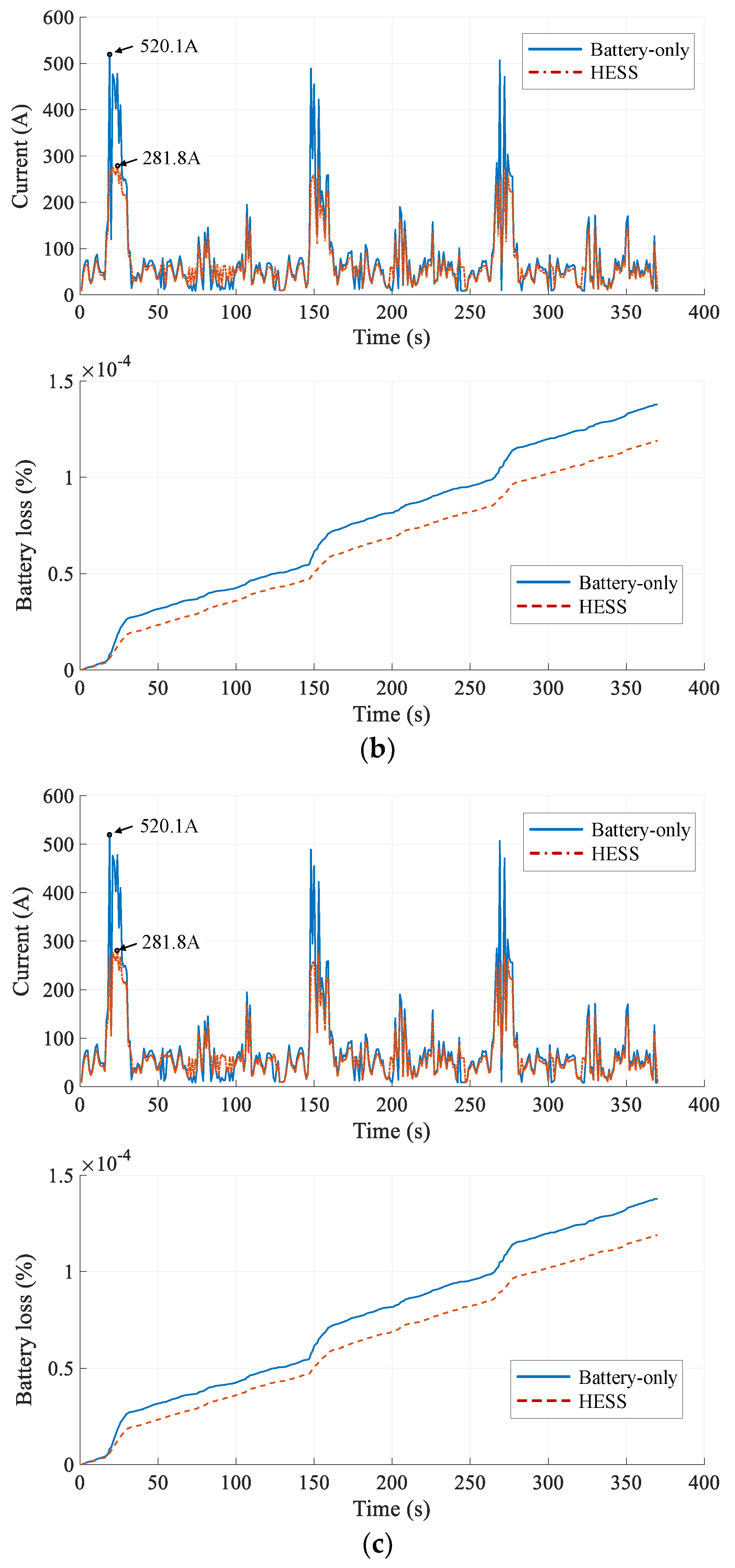

5.3. HESS vs. Battery-Only Options

5.4. Comparison with Previous Work

6. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| Acronyms | IM | Maximum current across the switch | |

| ACC | Electric accessories | MBT | Battery parallel number |

| DOD | Depth of discharge | MUC | UC parallel number |

| DP | Dynamic programming | n_BT | Number of battery replacements during the reference time |

| EMS | Energy management strategy | NBT | Battery series number |

| EREV | Extended range electric vehicle | NUC | UC series number |

| ESS | Energy storage system | Pacc | Nominal power of the accessories |

| EV | Electrified vehicle | PBT | Actual output power of the battery pack |

| GA | Genetic algorithm | PBT_cell | Power of the battery cell |

| GO | Global optimization | Pcycle | Total power of the driving cycle |

| GS | Global space | Pdem | Power demand |

| HESS | Hybrid energy storage system | PUC | Actual output power of the UC pack |

| HEV | Hybrid electric vehicle | PUC_max | Maximal power of the UC pack |

| ICE | Internal combustion engine | PUC_min | Minimal power of the UC pack |

| LCC | Life-cycle cost | Q(k) | Battery cell capacity at the discrete step k |

| LHD | Load haul dump | QBT | Nominal capacity of the battery pack |

| LS | Local space | QBT_cell | Nominal capacity of the battery cell |

| MS | Medium space | Qloss | Percentage of capacity loss |

| MSSR | Multi-Start Space Reduction | Qloss_y | Battery capacity loss within the reference time |

| NFE | Number of function evaluations | R | Gas constant |

| PEV | Pure electric vehicle | RT | Reference time |

| PHEV | Plug-in hybrid electric vehicle | RBT | Internal resistance of the battery pack |

| SBGO | Surrogate-based global optimization | RBT_cell | Internal resistance of the battery cell |

| SM | Surrogate model | RdsON | Transistor resistance |

| SOC | State of charge | RF | Diode resistance |

| UC | Ultracapacitor | RUC | Internal resistance of the UC pack |

| RUC_module | Internal resistance of the UC module | ||

| Variables | SoCBT_cell(k) | Battery cell SOC at the discrete step k | |

| Ah | Ah-throughput | SoCUC 0 | Initial value of the UC SOC |

| B | Pre-exponential factor | SoCUC end | End value of the UC SOC |

| BTcap | Capital cost of battery | SoCUC H | Upper limit of the UC SOC |

| CkWh_BT | Referential cost of battery | SoCUC L | Lower limit of the UC SOC |

| CkWh_DC | Referential cost of DC/DC converters | SoCUC | SOC of the UC pack |

| CkWh_e | Referential cost of electricity | SoCUC min | Lower limit of the UC pack SOC |

| CkWh_UC | Referential cost of UC | t | Discrete time |

| CUC | Capacity of the UC pack | Fall time | |

| CUC_module | Capacity of the UC module | tf | Rise time |

| Costcap | Capital cost | T | Number of sample points |

| Costope | Operating cost of electricity | Ten | Absolute temperature |

| Costrep | Replacement cost | Top | Operating time |

| CRF | Capital recovery factor | U | Mean utilization of vehicles |

| C_Rate | Discharge rate | UOCV_cell | Open circuit voltage of the battery cell |

| DCcap | Capital cost of DC/DC converter | UCcap | Capital cost of UC |

| DODBT | Battery DOD | VBT | Voltage of the battery pack |

| ΔEBT | Energy consumption of the battery pack | VBT_cell | Voltage of the battery cell |

| ΔEC | Energy consumption of the UC pack | VF | Diode forward voltage |

| EUC | Stored energy of the UC pack | Vm | Maximum voltage across the switch |

| EffDC | Efficiency of the low-voltage DC/DC converter | ΔVUC | UC voltage change |

| f | Frequency of the switch | ΔVUC(k,k − 1) | Voltage change of UC from k − 1 step to k step |

| i | Interest rate | VUC | Voltage of the UC pack |

| IBT_cell | Battery cell current | VUC_max | UC pack voltage in a fully charged condition |

| IBT_max | Maximal discharge current of the battery pack | VUC_min | Lower limit of the UC pack voltage |

| IF(AV) | Diode average current | VUC_mobile | Voltage of the UC module |

| IT(rms) | Transistor RMS current | Whrs | LHD’s working hours |

Appendix A

References

- Burke, A. Batteries and Ultracapacitors for Electric, Hybrid, and Fuel Cell Vehicles. Proc. IEEE 2007, 95, 806–820. [Google Scholar] [CrossRef]

- Salisa, A.; Zhang, N.; Zhu, J. A comparative analysis of fuel economy and emissions between a conventional HEV and the UTS PHEV. IEEE Trans. Veh. Technol. 2011, 60, 44–54. [Google Scholar] [CrossRef]

- Bilgin, B.; Magne, P.; Malysz, P.; Yang, Y.; Pantelic, V.; Preindl, M.; Korobkine, A.; Jiang, W.; Lawford, M.; Emadi, A. Making the case for electrified transportation. IEEE Trans. Transp. Electrif. 2015, 1, 4–17. [Google Scholar] [CrossRef]

- Evans, A.; Strezov, V.; Evans, T. Assessment of utility energy storage options for increased renewable energy penetration. Renew. Sustain. Energy Rev. 2012, 16, 4141–4147. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, Q.; Hu, S.; Xu, H.; Rasmussen, C. Review of energy storage system for wind power integration support. Appl. Energy 2015, 137, 545–553. [Google Scholar] [CrossRef]

- Lukic, S.; Jian, C.; Bansal, R.; Rodriguez, F.; Emadi, A. Energy Storage Systems for Automotive Applications. IEEE Trans. Ind. Electron. 2008, 55, 2258–2267. [Google Scholar] [CrossRef]

- Hu, X.; Johannesson, L.; Murgovski, N.; Egardt, B. Longevity-conscious dimensioning and power management of the hybrid energy storage system in a fuel cell hybrid electric bus. Appl. Energy 2015, 137, 913–924. [Google Scholar] [CrossRef]

- Liu, J.; Jin, T.; Liu, L.; Chen, Y.; Yuan, K. Multi-Objective Optimization of a Hybrid ESS Based on Optimal Energy Management Strategy for LHDs. Sustainability 2017, 9, 1874. [Google Scholar] [CrossRef]

- Cao, J.; Emadi, A. A new battery/ultracapacitor hybrid energy storage system for electric, hybrid, and plug-in hybrid electric vehicles. IEEE Trans. Power Electron. 2012, 27, 122–132. [Google Scholar] [CrossRef]

- Trovão, J.; Pereirinha, P.; Jorge, H.; Antunes, C. A multi-level energy management system for multi-source electric vehicles-An integrated rule-based meta-heuristic approach. Appl. Energy 2013, 105, 304–318. [Google Scholar] [CrossRef]

- Masih-Tehrani, M.; Ha’iri-Yazdi, M.; Esfahanian, V.; Safaei, A. Optimum sizing and optimum energy management of a hybrid energy storage system for lithium battery life improvement. J. Power Sources 2013, 244, 2–10. [Google Scholar] [CrossRef]

- Song, Z.; Li, J.; Han, X.; Xu, L.; Lu, L.; Ouyang, M.; Hofmann, H. Multi-objective optimization of a semi-active battery/supercapacitor energy storage system for electric vehicles. Appl. Energy 2014, 135, 212–224. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, X.; Wang, Z.; Sun, F.; Deng, J.; Dorrell, D. Multi-Objective Optimal Sizing of Hybrid Energy Storage System for Electric Vehicles. IEEE Trans. Veh. Technol. 2018, 67, 1027–1035. [Google Scholar] [CrossRef]

- Hu, X.; Moura, S.; Murgovski, N.; Egardt, B.; Cao, D. Integrated Optimization of Battery Sizing, Charging, and Power Management in Plug-In Hybrid Electric Vehicles. IEEE Trans. Control Syst. Technol. 2016, 24, 1036–1043. [Google Scholar] [CrossRef]

- Li, T.; Liu, H.; Zhao, D.; Wang, L. Design and analysis of a fuel cell supercapacitor hybrid construction vehicle. Int. J. Hydrogen Energy 2016, 41, 12307–12319. [Google Scholar] [CrossRef]

- Cai, Q.; Brett, D.; Browning, D.; Brandon, N. A sizing-design methodology for hybrid fuel cell power systems and its application to an unmanned underwater vehicle. J. Power Sources 2010, 195, 6559–6569. [Google Scholar] [CrossRef]

- Wu, X.; Cao, B.; Li, X.; Xu, J.; Ren, X. Component sizing optimization of plug-in hybrid electric vehicles. Appl. Energy 2011, 88, 799–804. [Google Scholar] [CrossRef]

- Tani, A.; Camara, M.; Dakyo, B. Energy management based on frequency approach for hybrid electric vehicle applications: Fuel-cell/lithium-battery and ultracapacitors. IEEE Trans. Veh. Technol. 2012, 61, 3375–3386. [Google Scholar] [CrossRef]

- Shen, J.; Dusmez, S.; Khaligh, A. Optimization of sizing and battery cycle life in battery/ultracapacitor hybrid energy storage systems for electric vehicle applications. IEEE Trans. Ind. Inform. 2014, 10, 2112–2121. [Google Scholar] [CrossRef]

- Kim, M.; Peng, H. Power management and design optimization of fuel cell/battery hybrid vehicles. J. Power Sources 2007, 165, 819–832. [Google Scholar] [CrossRef]

- Xu, L.; Mueller, C.; Li, J.; Ouyang, M.; Hu, Z. Multi-objective component sizing based on optimal energy management strategy of fuel cell electric vehicles. Appl. Energy 2015, 157, 664–674. [Google Scholar] [CrossRef]

- Herrera, V.; Milo, A.; Gaztañaga, H.; Otadui, I.; Villarreal, I.; Camblong, H. Adaptive energy management strategy and optimal sizing applied on a battery-supercapacitor based tramway. Appl. Energy 2016, 169, 831–845. [Google Scholar] [CrossRef]

- Hung, Y.; Wu, C. An integrated optimization approach for a hybrid energy system in electric vehicles. Appl. Energy 2012, 98, 479–490. [Google Scholar] [CrossRef]

- Hung, Y.; Wu, C. A combined optimal sizing and energy management approach for hybrid in-wheel motors of EVs. Appl. Energy 2015, 139, 260–271. [Google Scholar] [CrossRef]

- Murgovski, N.; Johannesson, L.; Sjöberg, J.; Egardt, B. Component sizing of a plug-in hybrid electric powertrain via convex optimization. Mechatronics 2012, 22, 106–120. [Google Scholar] [CrossRef]

- Murgovski, N.; Johannesson, L.; Sjöberg, J. Engine On/Off Control for Dimensioning Hybrid Electric Powertrains via Convex Optimization. IEEE Trans. Veh. Technol. 2013, 62, 2949–2962. [Google Scholar] [CrossRef]

- Murgovski, N.; Johannesson, L.; Egardt, B. Optimal Battery Dimensioning and Control of a CVT PHEV Powertrain. IEEE Trans. Veh. Technol. 2014, 63, 2151–2161. [Google Scholar] [CrossRef]

- Hu, X.; Jiang, J.; Egardt, B.; Cao, D. Advanced power-source integration in hybrid electric vehicles: Multicriteria optimization approach. IEEE Trans. Ind. Electron. 2015, 62, 7847–7858. [Google Scholar] [CrossRef]

- Holland, J. Adaptation in Natural and Artificial Systems; University of Michigan Press: Ann Arbor, MI, USA, 1975. [Google Scholar]

- Ong, Y.; Nair, P.; Keane, A. Evolutionary optimization of computationally expensive problems via surrogate modeling. Am. Inst. Aeronaut. Astronaut. J. 2003, 41, 687–696. [Google Scholar] [CrossRef]

- Zhou, Z.; Ong, Y.; Lim, M.; Lee, B. Memetic algorithm using multi-surrogates for computationally expensive optimization problems. Soft Comput. 2007, 11, 957–971. [Google Scholar] [CrossRef]

- Dong, H.; Song, B.; Dong, Z.; Wang, P. Multi-start Space Reduction (MSSR) surrogate-based global optimization method. Struct. Multidiscip. Optim. 2016, 54, 907–926. [Google Scholar] [CrossRef]

- Zheng, J.; Jow, T.; Ding, M. Hybrid power sources for pulsed current applications. IEEE Trans. Aerosp. Electron. Syst. 2001, 37, 288–292. [Google Scholar] [CrossRef]

- Napoli, A.; Crescimbini, F.; Capponi, F.; Solero, L. Control strategy for multiple input DC-DC power converters devoted to hybrid vehicle propulsion systems. Proc. IEEE Int. Symp. Ind. Electron. 2002, 3, 1036–1041. [Google Scholar]

- Ortúzar, M.; Moreno, J.; Dixon, J. Ultracapacitor-based auxiliary energy system for an electric vehicle: Implementation and evaluation. IEEE Trans. Ind. Electron. 2007, 54, 2147–2156. [Google Scholar] [CrossRef]

- Spotnitz, R. Simulation of capacity fade in lithium-ion batteries. J. Power Sources 2003, 113, 72–80. [Google Scholar] [CrossRef]

- Ramadass, P.; Haran, B.; Gomadam, P.; White, R.; Popov, B. Development of first principles capacity fade model for Li-ion cells. J. Electrochem. Soc. 2004, 151, A196–A203. [Google Scholar] [CrossRef]

- Wang, J.; Liu, P.; Garner, J.; Sherman, E.; Soukiazian, S.; Verbrugge, M.; Tataria, H.; Musser, J.; Finamore, P. Cycle-life model for graphite-LiFePO4 cells. J. Power Sources 2011, 196, 3942–3948. [Google Scholar] [CrossRef]

- Bloom, I.; Cole, B.; Sohn, J.; Jones, S.; Polzin, E.; Battaglia, V.; Henriksen, G.; Motloch, C.; Richardson, R.; Unkelhaeuser, T.; et al. An accelerated calendar and cycle life study of Li-ion cells. J. Power Sources 2001, 101, 238–247. [Google Scholar] [CrossRef]

- Plett, G. Extended Kalman filtering for battery management systems of LiPB-based HEV battery packs Part 2. Modeling and identification. J. Power Sources 2004, 134, 262–276. [Google Scholar] [CrossRef]

- Kong, X.; Choi, L.; Khambadkone, A. Analysis and control of isolated current-fed full bridge converter in fuel cell system. In Proceedings of the 30th Annual Conference of IEEE Industrial Electronics Society (IECON 2004), Busan, Korea, 2–6 November 2004. [Google Scholar]

- Ansarey, M.; Panahi, M.; Ziarati, H.; Mahjoob, M. Optimal energy management in a dual-storage fuel-cell hybrid vehicle using multi-dimensional dynamic programming. J. Power Sources 2014, 250, 359–371. [Google Scholar] [CrossRef]

- Santucci, A.; Sorniotti, A.; Lekakou, C. Power split strategies for hybrid energy storage systems for vehicular applications. J. Power Sources 2014, 258, 395–407. [Google Scholar] [CrossRef]

- Song, Z.; Hofmann, H.; Li, J.; Han, X.; Ouyang, M. Optimization for a hybrid energy storage system in electric vehicles using dynamic programing approach. Appl. Energy 2015, 139, 151–162. [Google Scholar] [CrossRef]

- Zakeri, B.; Syri, S. Electrical energy storage systems: A comparative life cycle cost analysis. Renew. Sustain. Energy Rev. 2015, 42, 569–596. [Google Scholar] [CrossRef]

- Man, K.; Tang, K.; Kwong, S. Genetic algorithms: Concepts and applications [in engineering design]. IEEE Trans. Ind. Electron. 1996, 43, 519–534. [Google Scholar] [CrossRef]

- Montazeri-Gh, M.; Poursamad, A.; Ghalichi, B. Application of genetic algorithm for optimization of control strategy in parallel hybrid electric vehicles. J. Frankl. Inst. 2006, 343, 420–435. [Google Scholar] [CrossRef]

- Jacobs, W.; Hodkiewicz, M.; Bräunl, T. A Cost-Benefit Analysis of Electric Loaders to Reduce Diesel Emissions in Underground Hard Rock Mines. IEEE Trans. Ind. Electron. 2015, 51, 2565–2573. [Google Scholar] [CrossRef]

| Variable | Definition | Unit |

|---|---|---|

| Costcap | Capital costs of battery, UC, and DC/DC converters | €/year |

| BTcap | Capital cost of battery | € |

| UCcap | Capital cost of UC | € |

| DCcap | Capital costs of battery, UC, and DC/DC converters | € |

| CRF [45] | capital recovery factor | 1/year |

| i | interest rate | % |

| RT | reference time | years |

| CkWh_BT | referential cost of battery | €/kWh |

| CkWh_UC | referential cost of UC | €/kWh |

| CkW_DC | referential cost of DC/DC converters | €/kW |

| Costope | operating cost of electricity | €/day |

| CkWh_e | referential cost of electricity | €/kWh |

| T | number of sample points for the driving cycle | / |

| Top | Vehicles operating time | hours/day |

| U | mean utilization of vehicles | % |

| Qloss_y | battery capacity loss within the reference time | % |

| n_BT | number of battery replacements during the reference time | / |

| Costrep | replacement cost of the battery | €/year |

| Battery Cell | UC Module | ||

|---|---|---|---|

| Nominal voltage (V) | 3.3 | Nominal voltage (V) | 48 |

| Nominal capacity (Ah) | 60 | Nominal capacity (F) | 165 |

| Stored energy (kWh) | 0.198 | Stored energy (kWh) | 0.053 |

| Internal resistance (mΩ) | 1.5 | Internal resistance (mΩ) | 6.3 |

| Name | Coefficient | Value | Unit |

|---|---|---|---|

| DP algorithm | 370 | s | |

| 50 | % | ||

| 100 | % | ||

| () | 100 | % | |

| −250 | kW | ||

| 250 | kW | ||

| 0.5C | A | ||

| LCC model | 2.5 [45] | % | |

| 10 [48] | Years | ||

| 500 [22] | €/kWh | ||

| 4000 [22] | €/kWh | ||

| 150 [22] | €/kW | ||

| 0.05 [45] | €/kWh | ||

| 60 [48] | % | ||

| 303.15 | K | ||

| 5 | kW |

| Coefficient | Value |

|---|---|

| Population size | 10 |

| Number of generations | 30 |

| Crossover rate | 1.0 |

| Mutation rate | 0.01 |

| Algorithm | LCC (€/day) | Computation Time (h) | NFE | |||||

|---|---|---|---|---|---|---|---|---|

| GA | 230.81 | 126.23 | 300 | 198 | 10 | 12 | 2 | 0.5534 |

| MSSR | 194.07 | 49.13 | 101 | 170 | 7 | 14 | 1 | 0.7793 |

| Constraint | LCC (€/day) | Computation Time (h) | NFE | |||||

|---|---|---|---|---|---|---|---|---|

| 214.79 | 45.41 | 94 | 200 | 9 | 12 | 2 | 0.6474 | |

| 214.89 | 23.04 | 48 | 200 | 9 | 13 | 2 | 0.7623 |

| Constraint | LCC (€/day) | Costcap (€/day) | Costope (€/day) | Costrep (€/day) | Whrs (h) |

|---|---|---|---|---|---|

| 194.0652 | 50.4694 | 32.5236 | 111.0722 | 4.0649 | |

| 214.7879 | 70.3076 | 32.1997 | 112.2806 | 5.1594 | |

| 214.8893 | 70.4418 | 32.1669 | 112.2806 | 6.0812 |

| Constraint | Option | LCC (€/day) | (€/day) | (€/day) | (€/day) | (104 KJ) | (10−4 %) | (h) |

|---|---|---|---|---|---|---|---|---|

| HESS | 194.07 | 50.47 | 32.52 | 111.07 | 1.6714 | 1.4371 | 4.07 | |

| Battery-only | 227.66 | 43.24 | 36.69 | 147.73 | 1.8855 | 1.7538 | 3.61 | |

| HESS | 214.79 | 70.31 | 32.20 | 112.28 | 1.6547 | 1.1889 | 5.16 | |

| Battery-only | 269.97 | 65.28 | 36.68 | 168.01 | 1.8850 | 1.3784 | 4.53 | |

| HESS | 214.89 | 70.44 | 32.17 | 112.28 | 1.6530 | 1.1874 | 6.08 | |

| Battery-only | 269.97 | 65.28 | 36.68 | 168.01 | 1.8850 | 1.3784 | 5.33 |

| Solution | LCC (€/day) | Capital Cost (€/day) | Replacement Cost (€/day) | DODBT (%) | Whrs (h) |

|---|---|---|---|---|---|

| [8] | 232.28 | 50.85 | 148.98 | 100 | 5.27 |

| 214.89 | 70.44 | 112.28 | 76.23 | 6.08 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Dong, H.; Jin, T.; Liu, L.; Manouchehrinia, B.; Dong, Z. Optimization of Hybrid Energy Storage Systems for Vehicles with Dynamic On-Off Power Loads Using a Nested Formulation. Energies 2018, 11, 2699. https://doi.org/10.3390/en11102699

Liu J, Dong H, Jin T, Liu L, Manouchehrinia B, Dong Z. Optimization of Hybrid Energy Storage Systems for Vehicles with Dynamic On-Off Power Loads Using a Nested Formulation. Energies. 2018; 11(10):2699. https://doi.org/10.3390/en11102699

Chicago/Turabian StyleLiu, Jiajun, Huachao Dong, Tianxu Jin, Li Liu, Babak Manouchehrinia, and Zuomin Dong. 2018. "Optimization of Hybrid Energy Storage Systems for Vehicles with Dynamic On-Off Power Loads Using a Nested Formulation" Energies 11, no. 10: 2699. https://doi.org/10.3390/en11102699

APA StyleLiu, J., Dong, H., Jin, T., Liu, L., Manouchehrinia, B., & Dong, Z. (2018). Optimization of Hybrid Energy Storage Systems for Vehicles with Dynamic On-Off Power Loads Using a Nested Formulation. Energies, 11(10), 2699. https://doi.org/10.3390/en11102699