A Micro Swing Rotor Engine and the Preliminary Study of Its Thermodynamic Characteristics

Abstract

1. Introduction

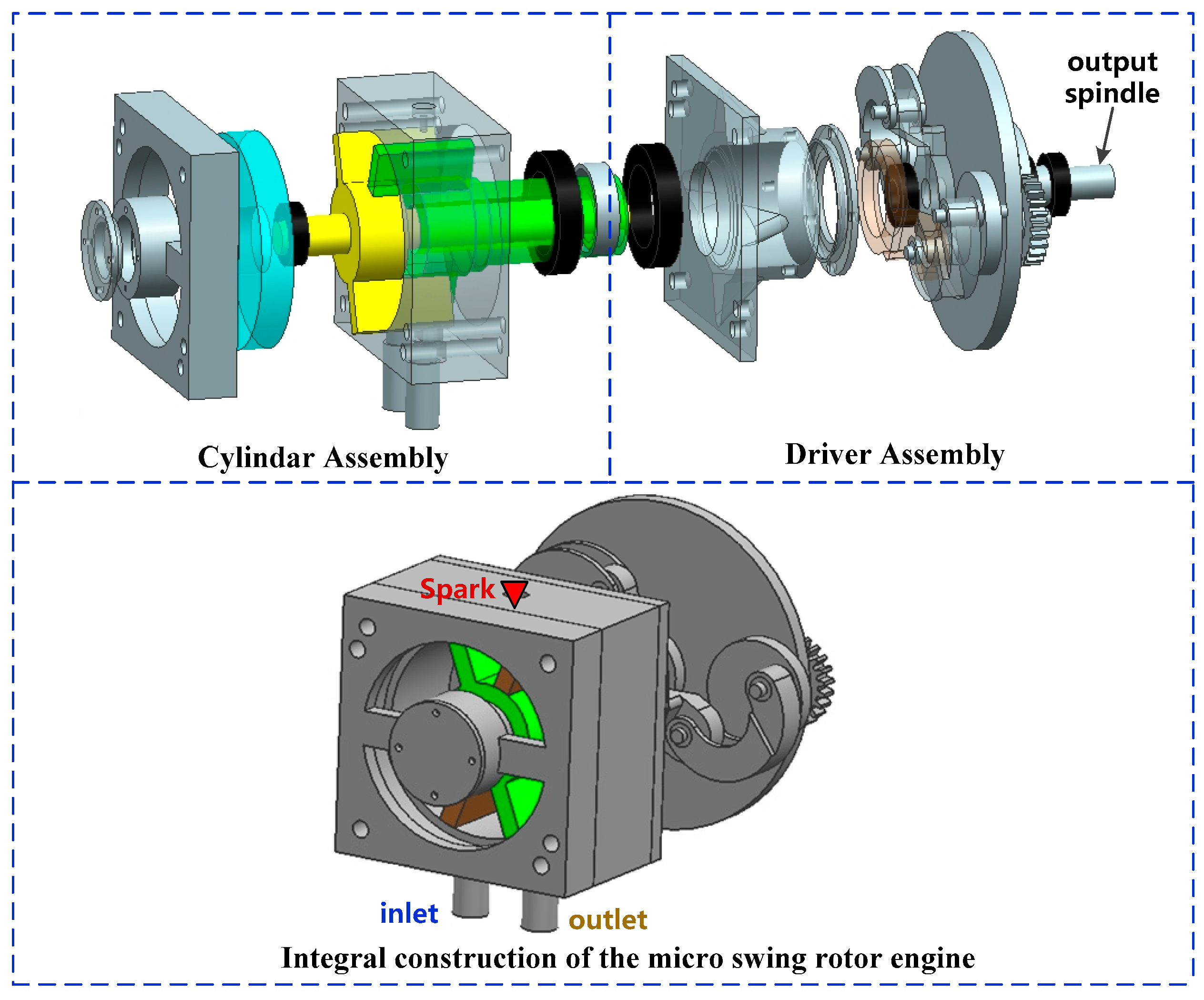

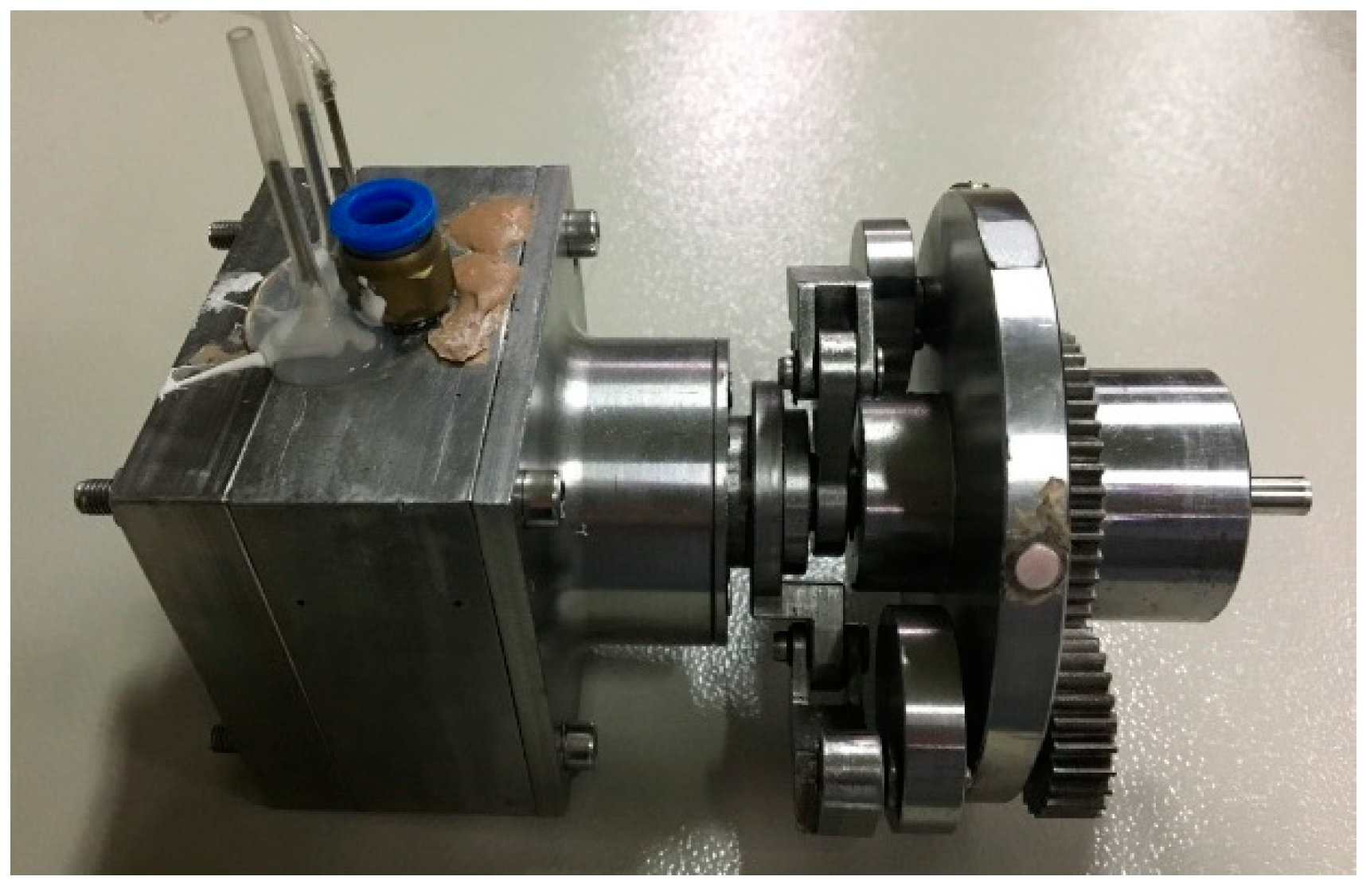

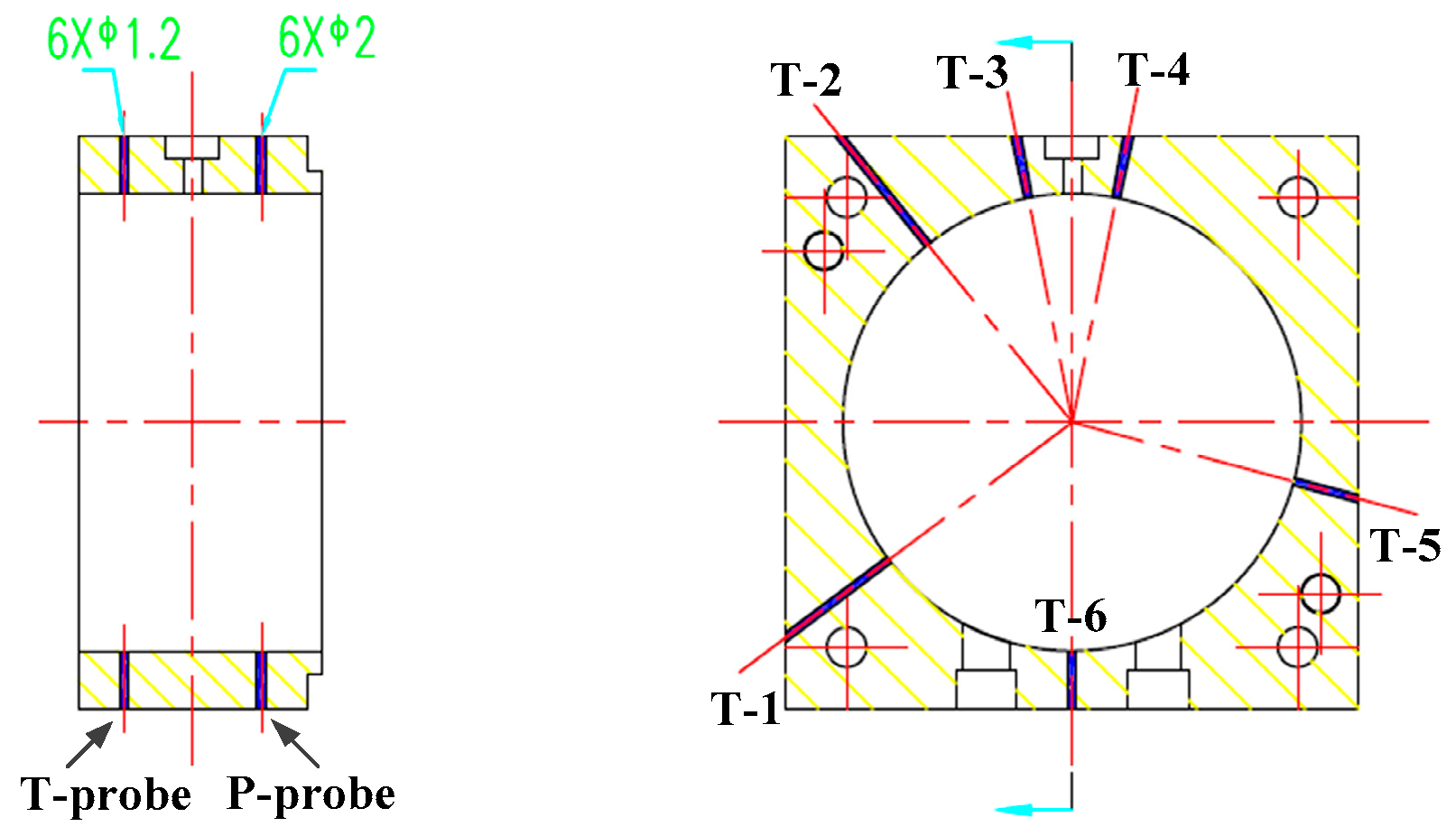

2. Operation Principle and Mechanical Design of the Micro Swing Rotor Engine

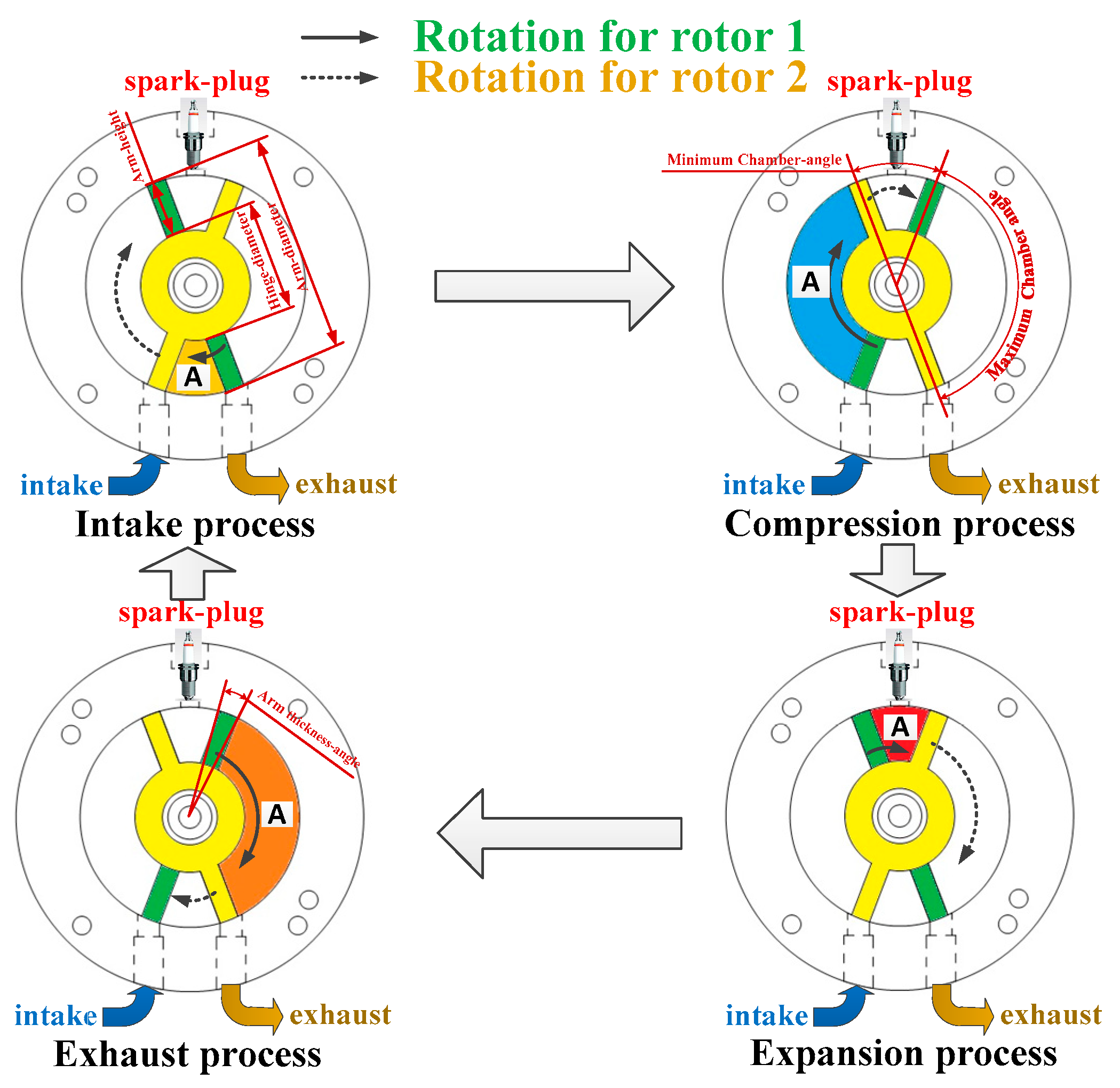

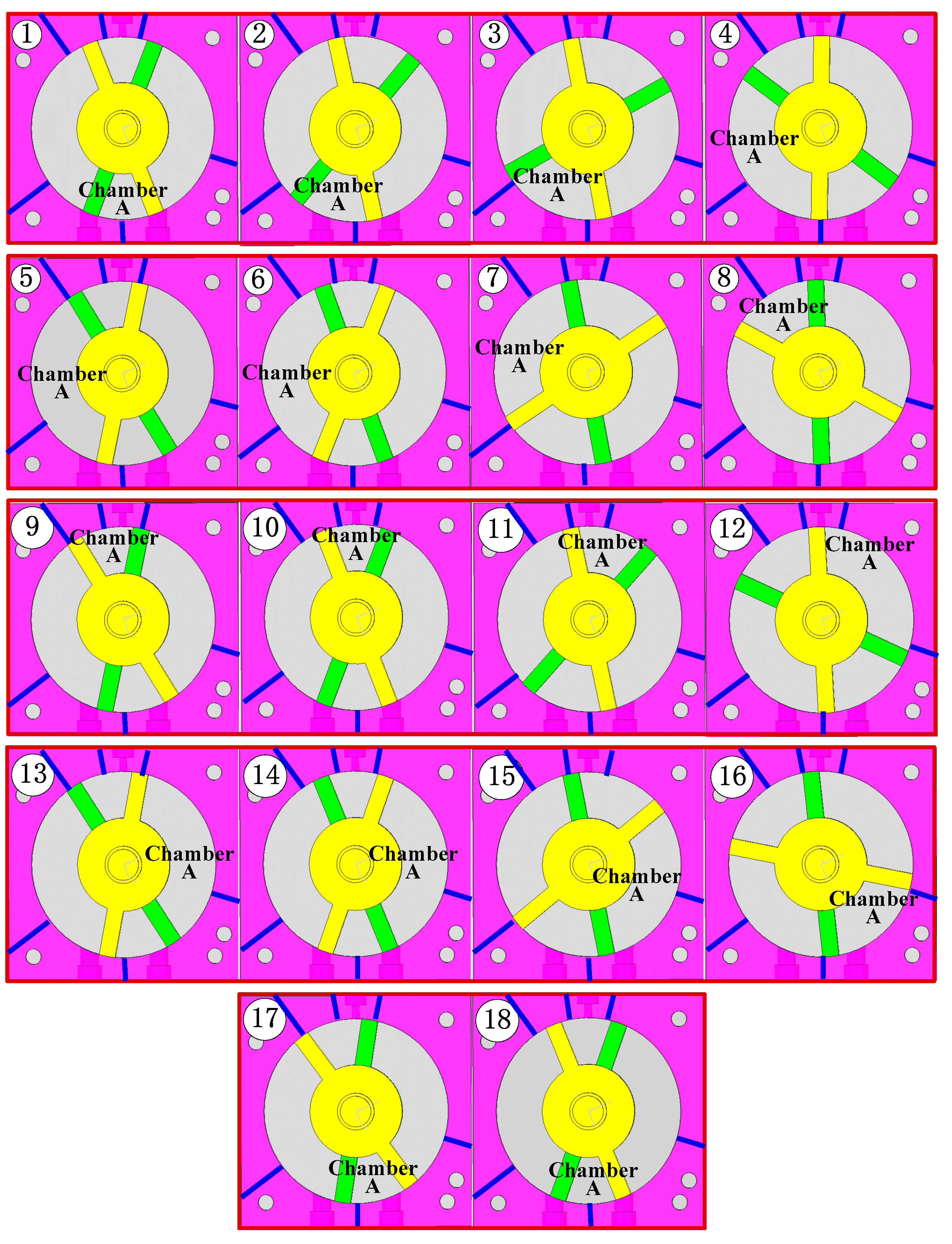

2.1. Working Principle for this Novel Engine

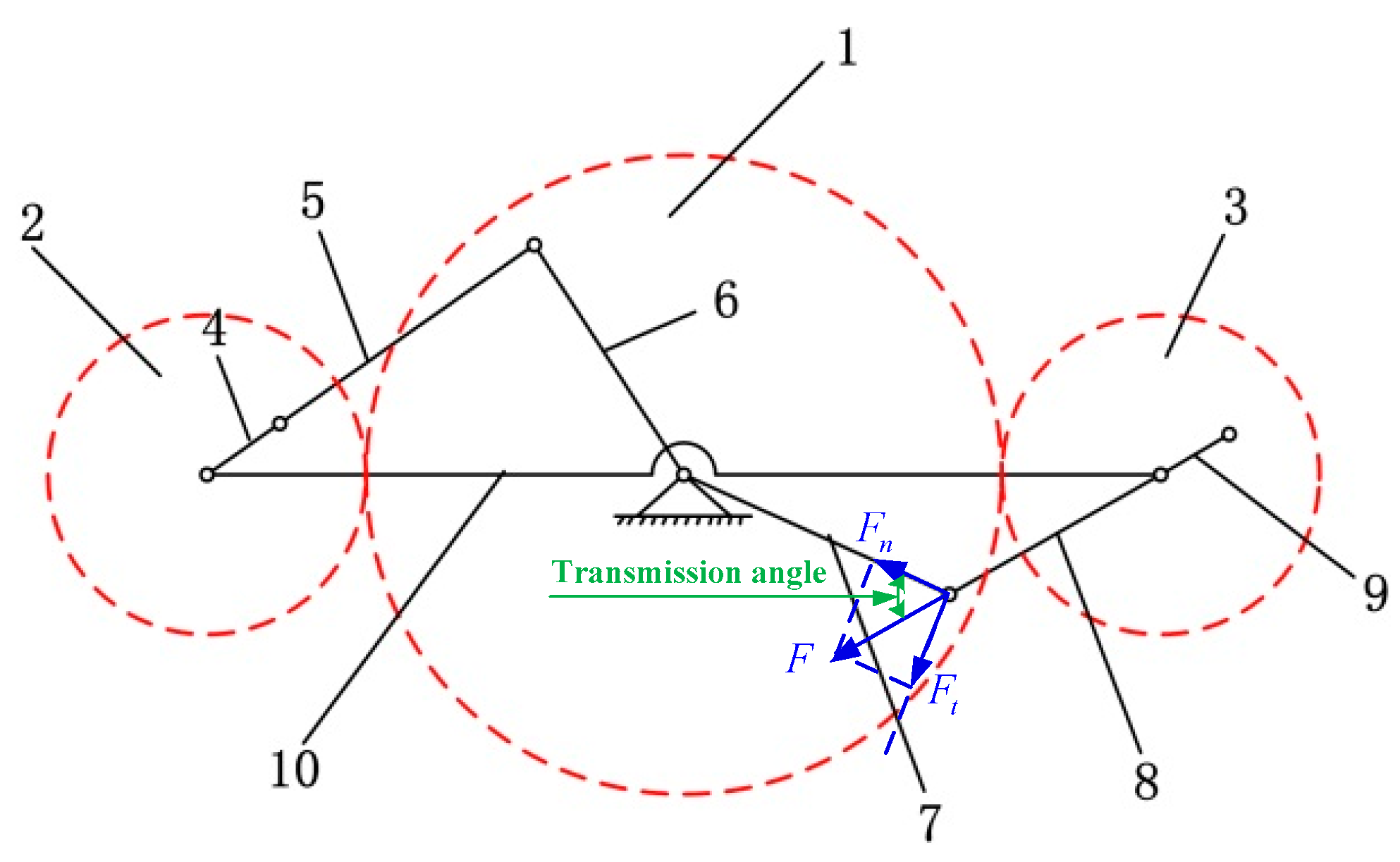

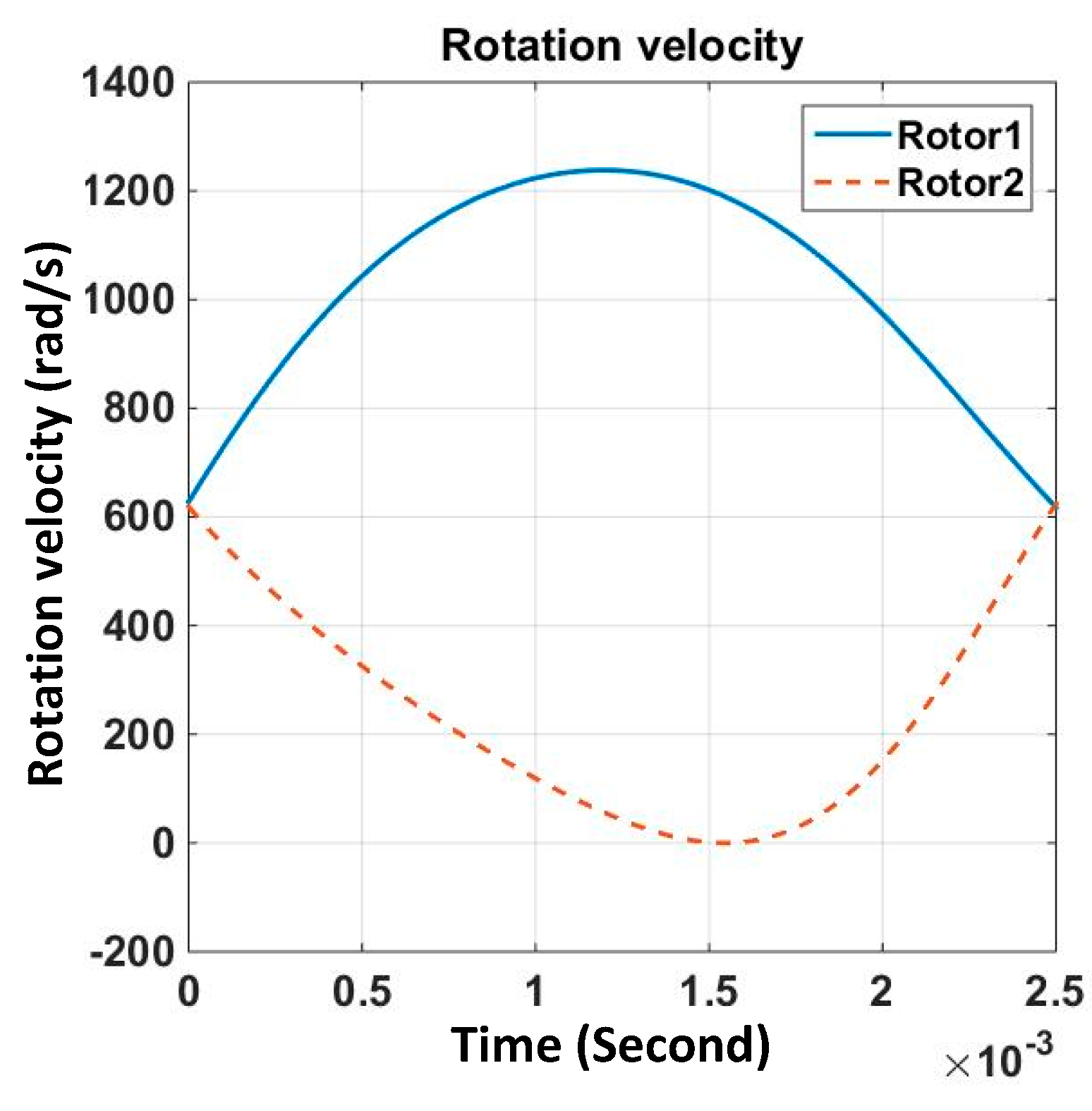

2.2. Design of the Driving Mechanism and Kinematic Analysis

3. Thermodynamic Characteristics of the Micro Swing Rotor Engine

3.1. Thermodynamic Model for the MSRE in Steady Operation State and the Solution Method

3.1.1. Establishment of the Thermodynamic Model

3.1.2. Solution Method for the Thermodynamic Model

3.2. Results of Thermodynamic Simulation for MSRE and Discussion

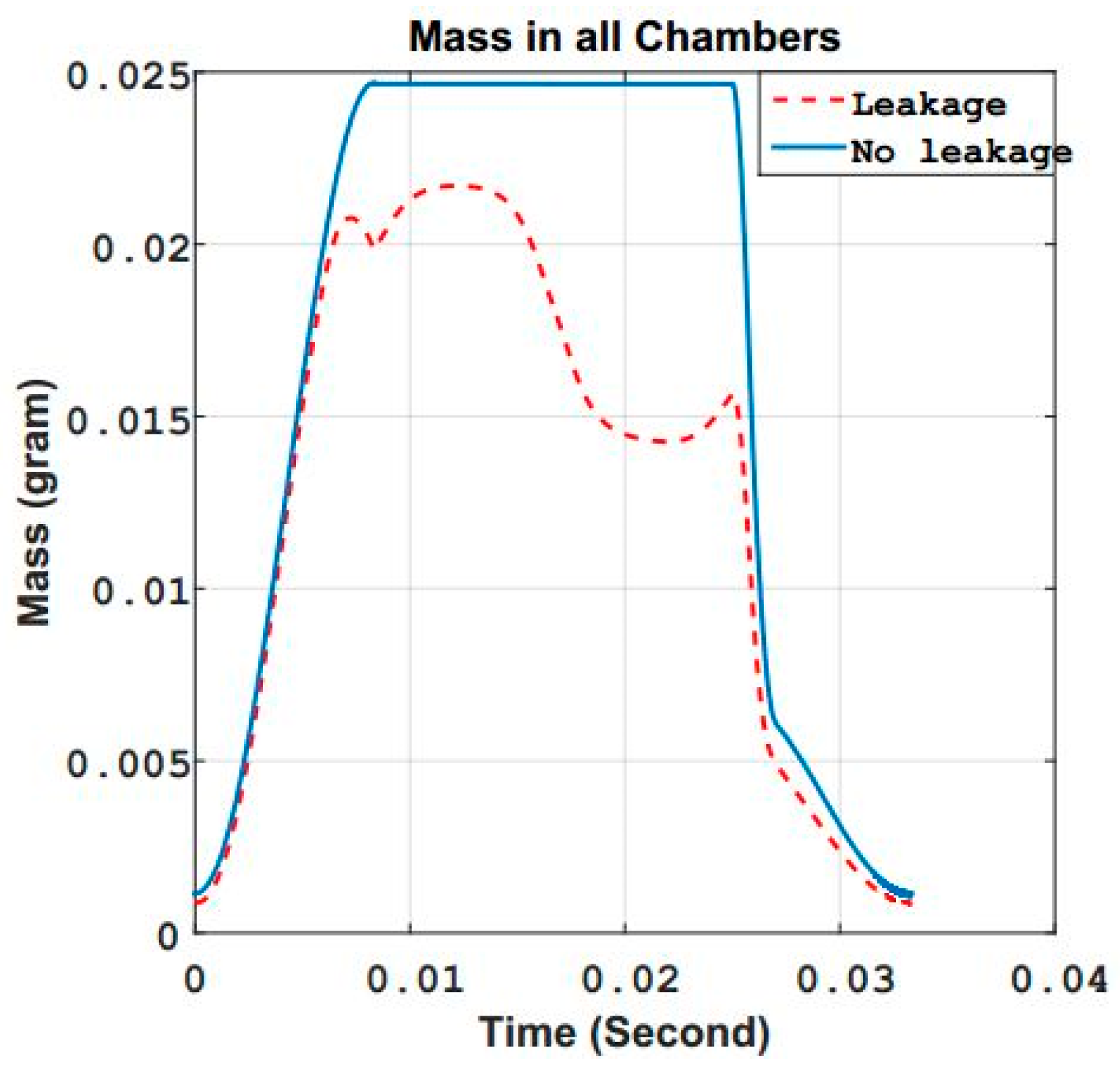

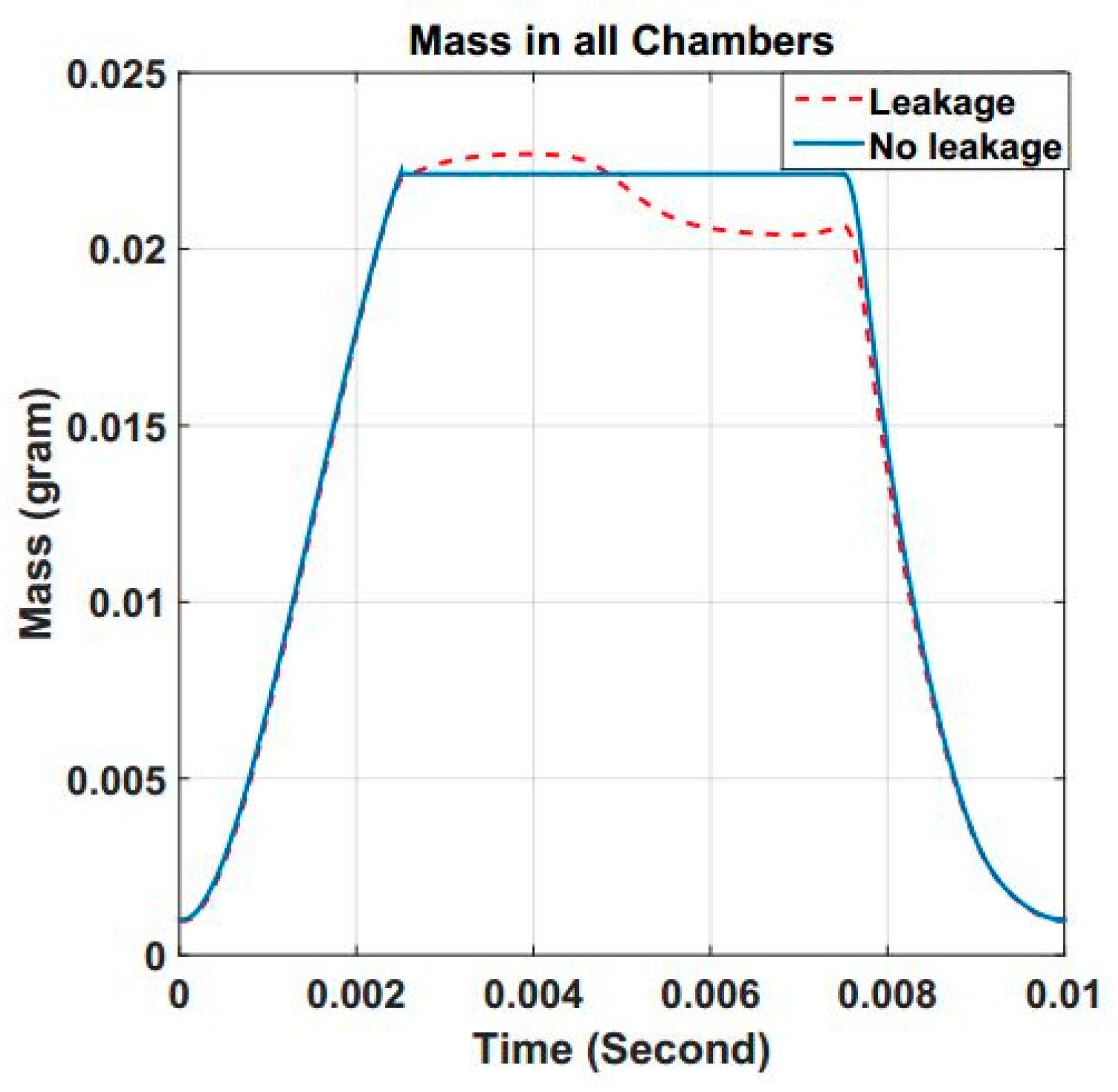

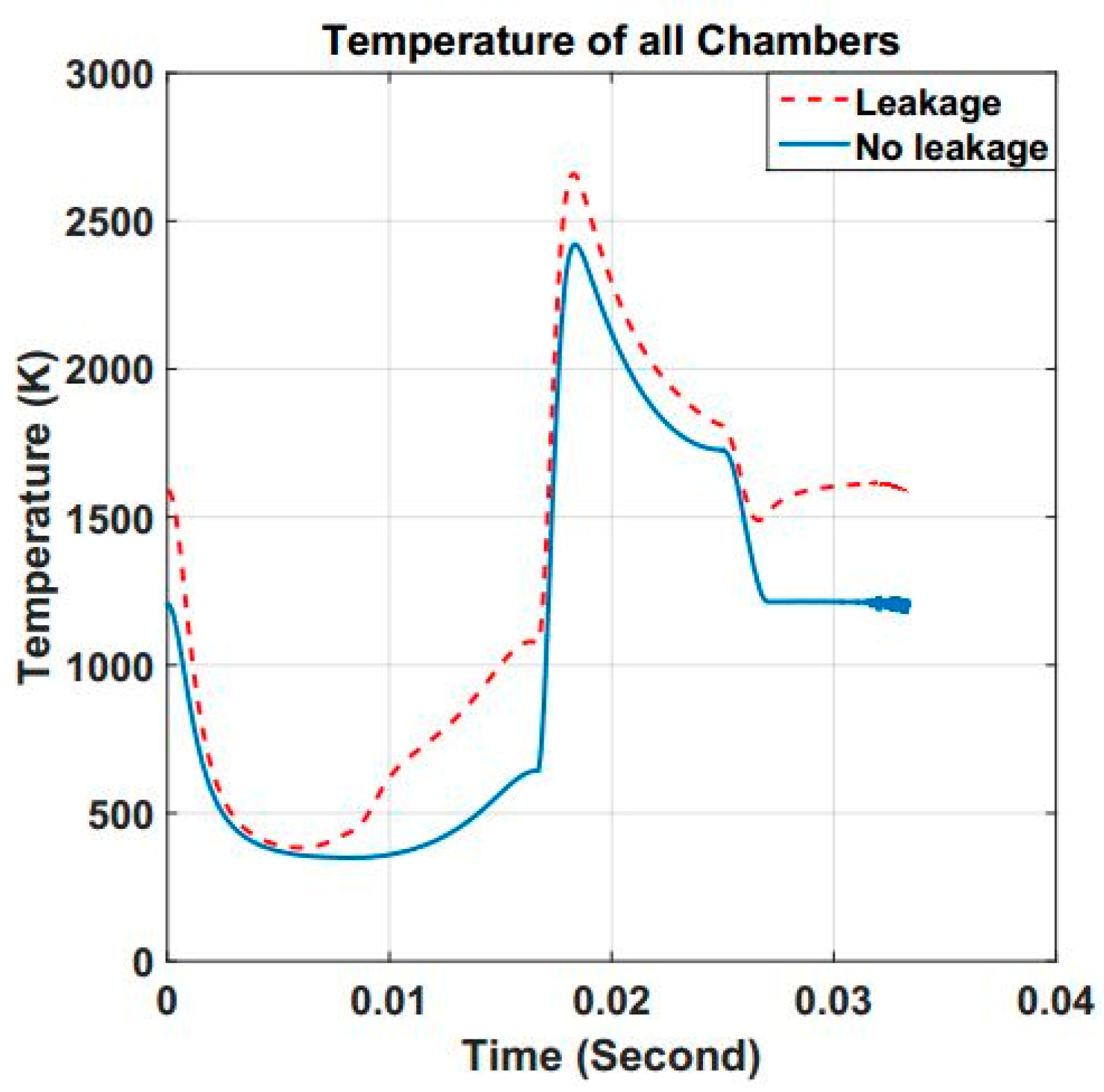

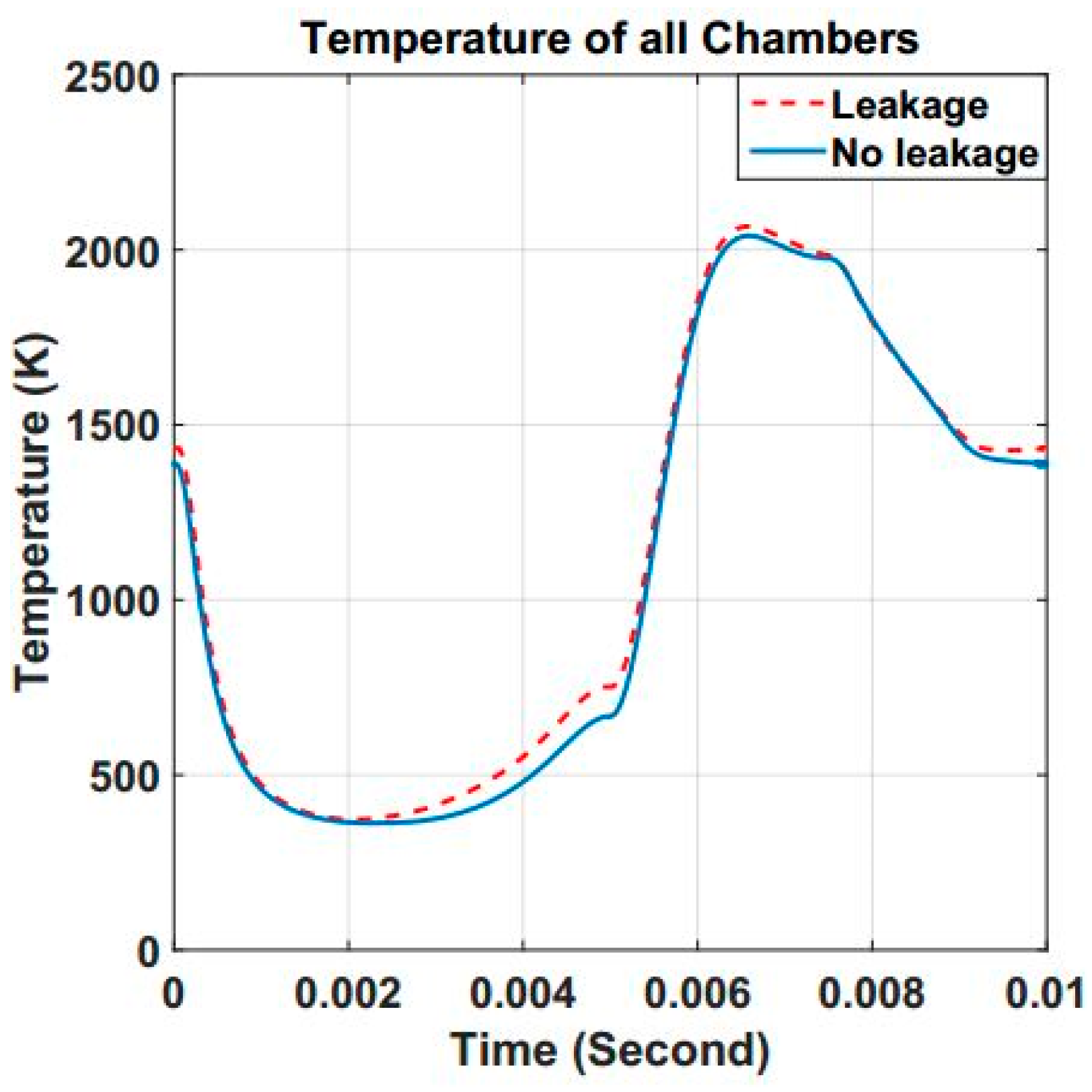

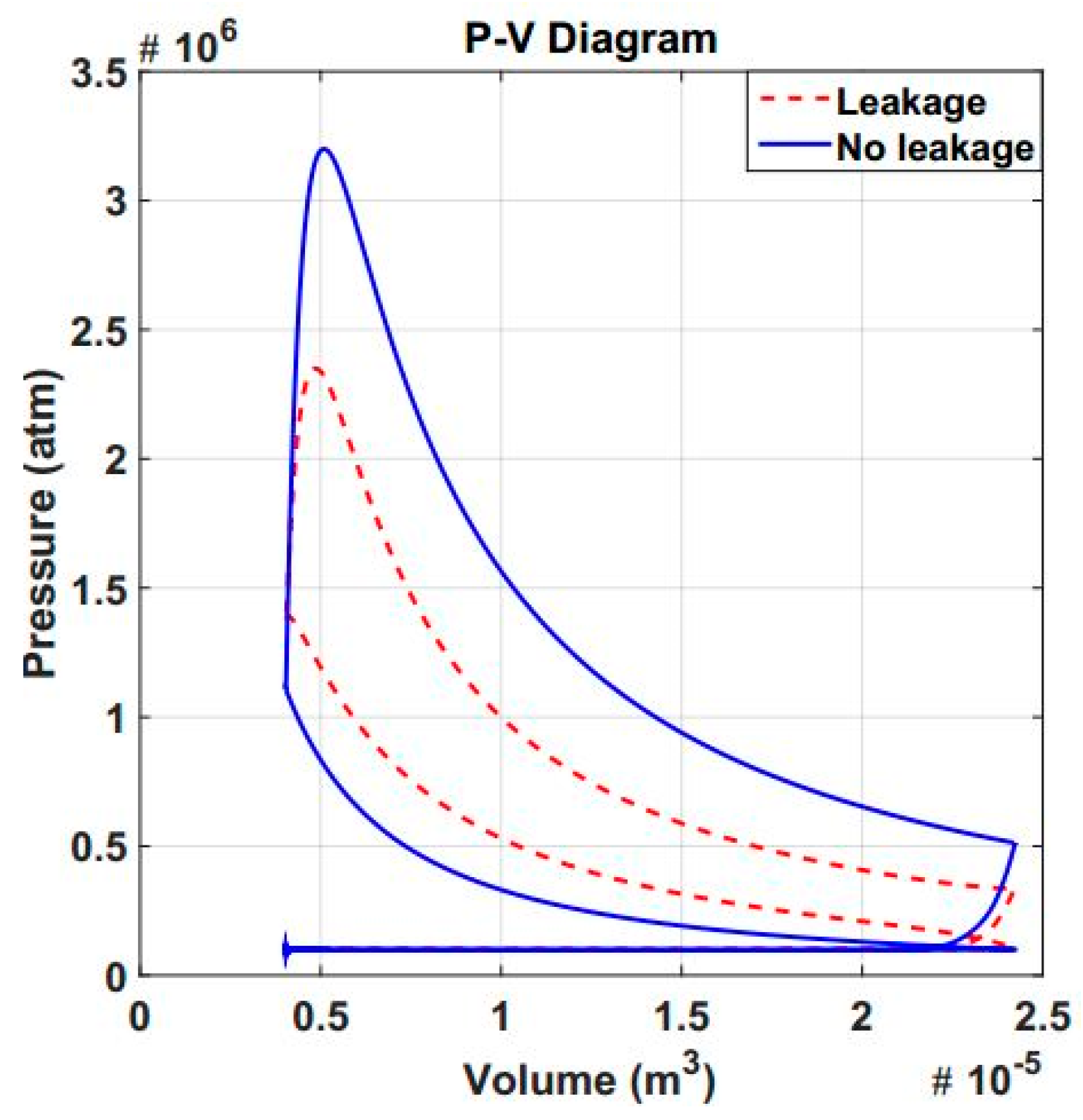

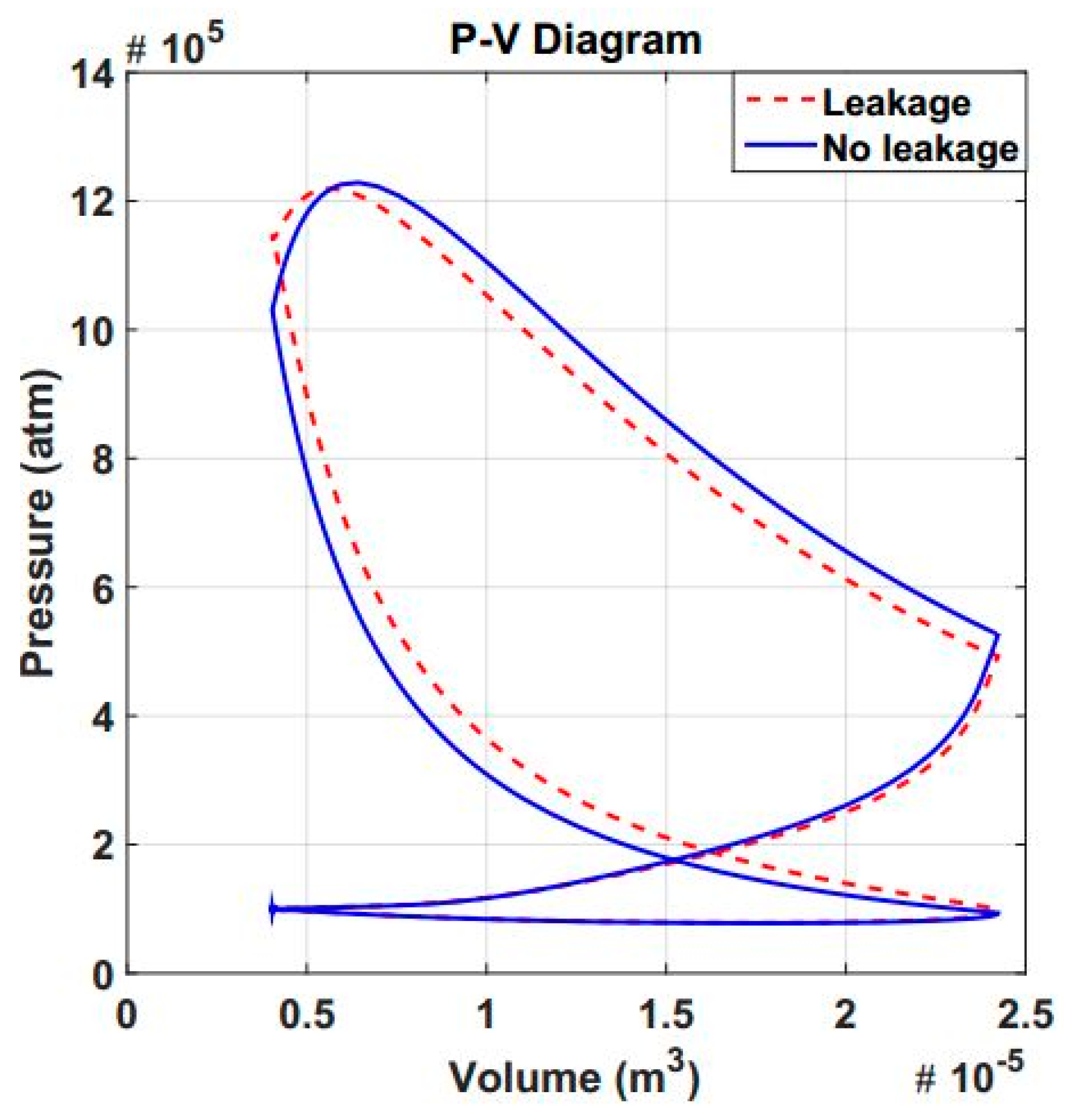

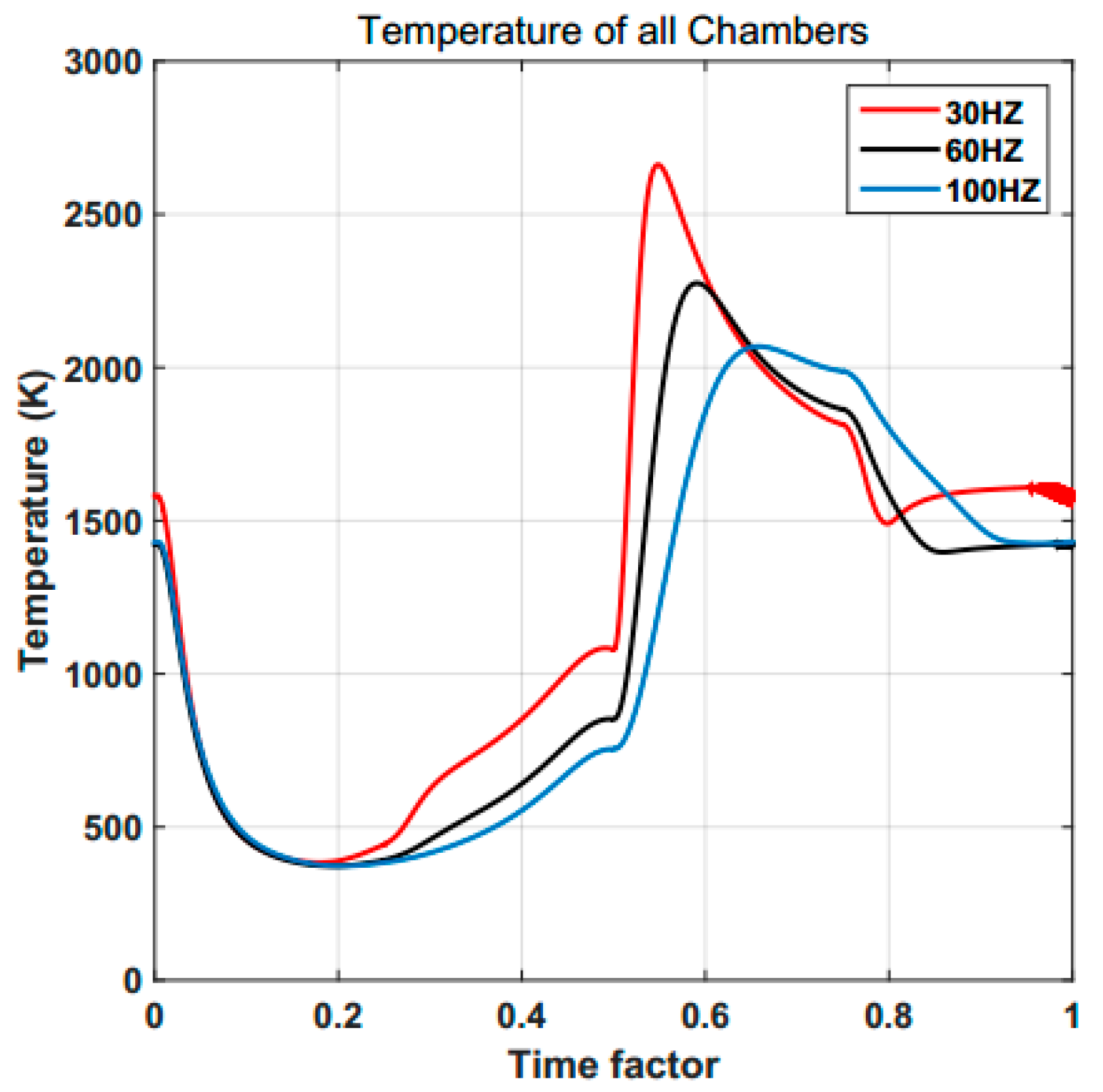

3.2.1. Basic Thermodynamic Characteristics of the MSRE

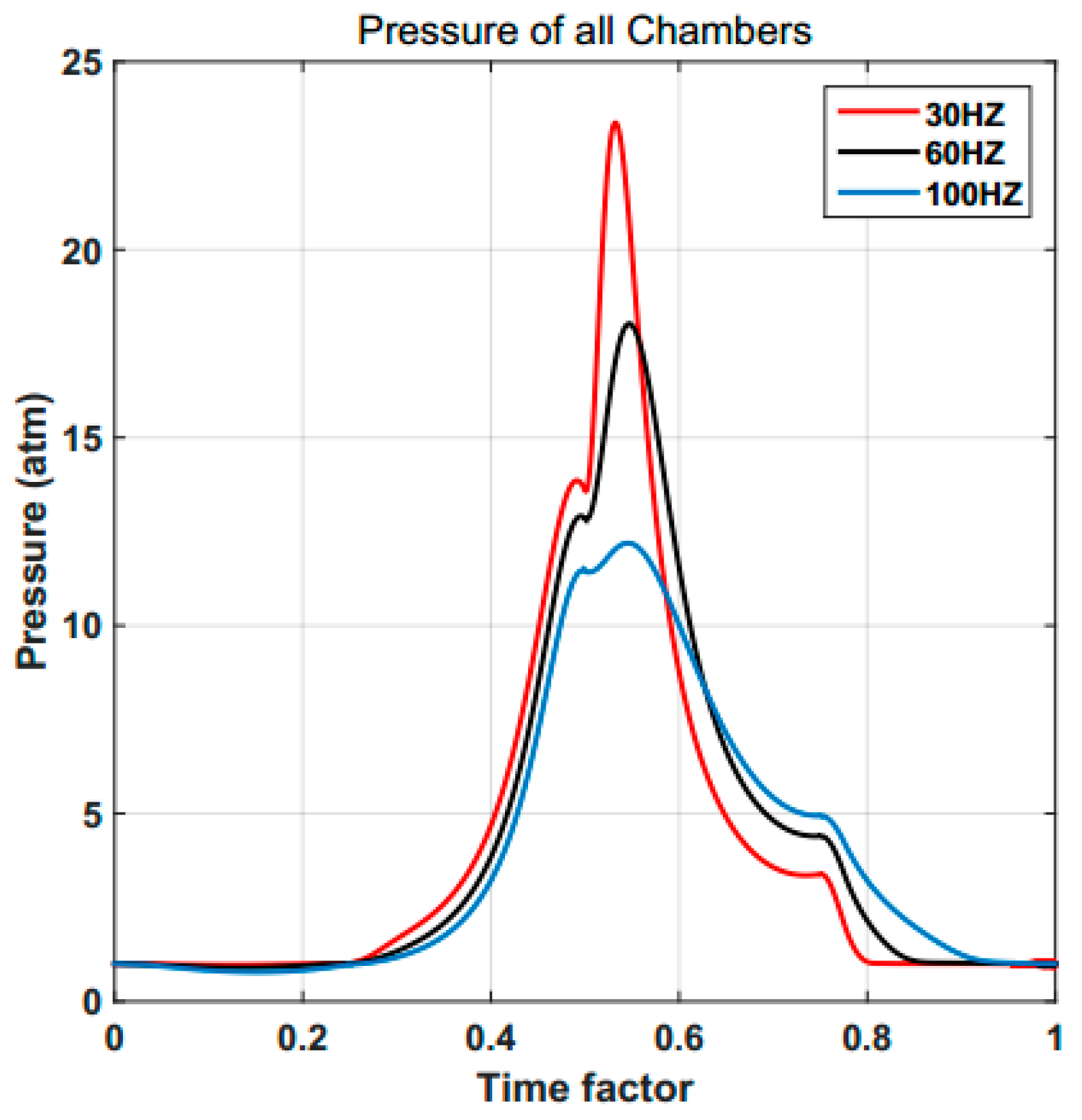

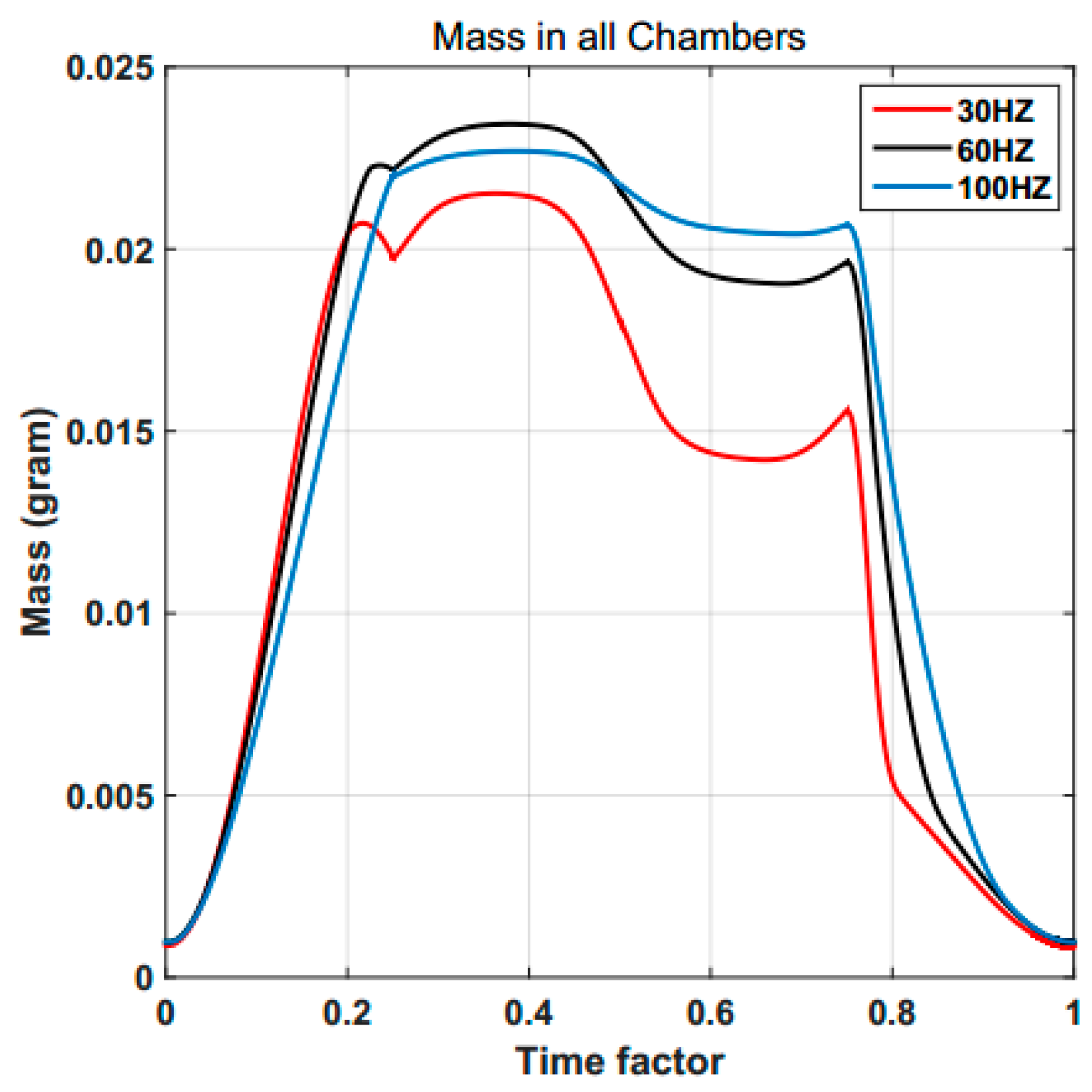

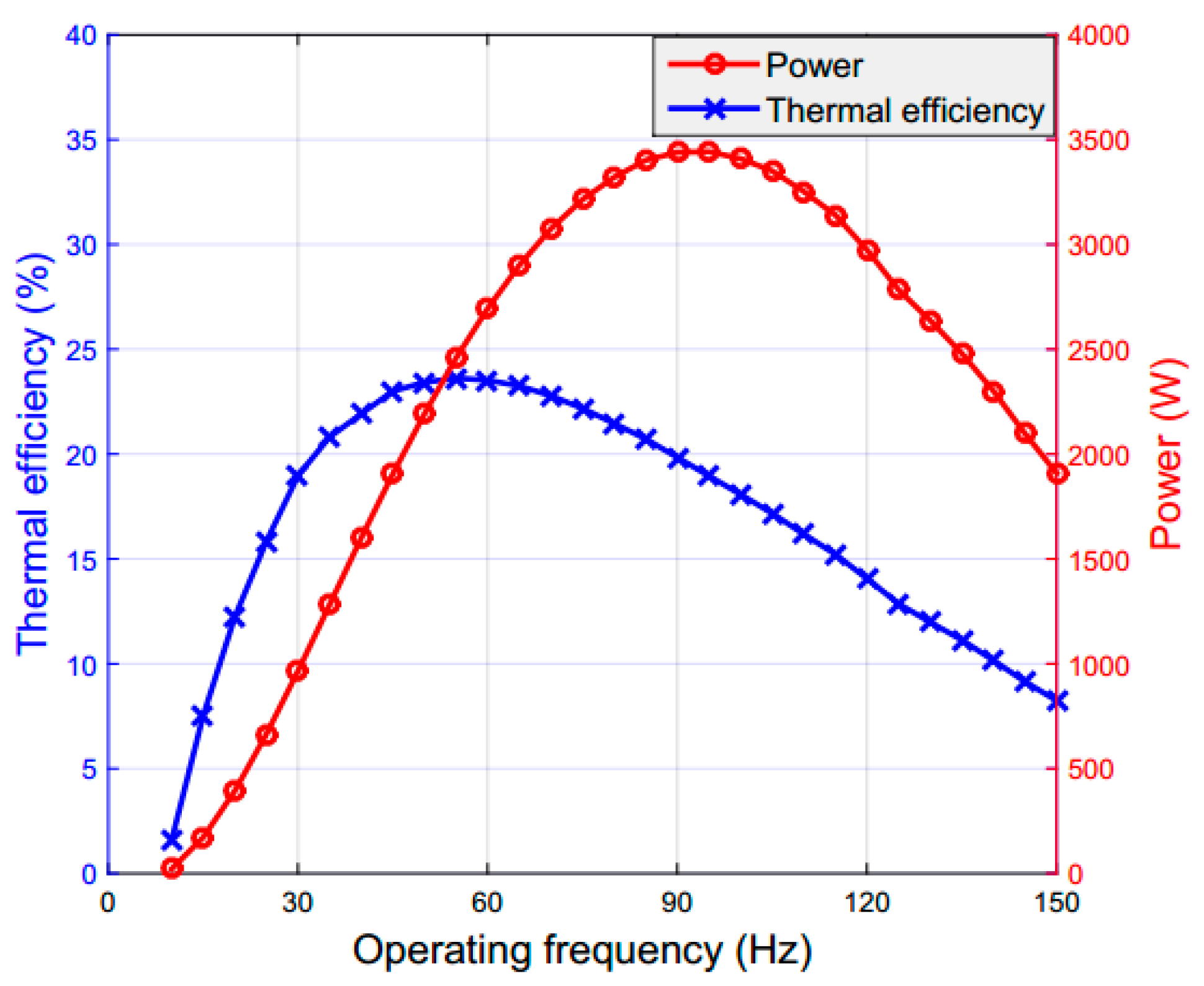

3.2.2. Influence of Operation Frequency on the Engine Thermodynamic Characteristics

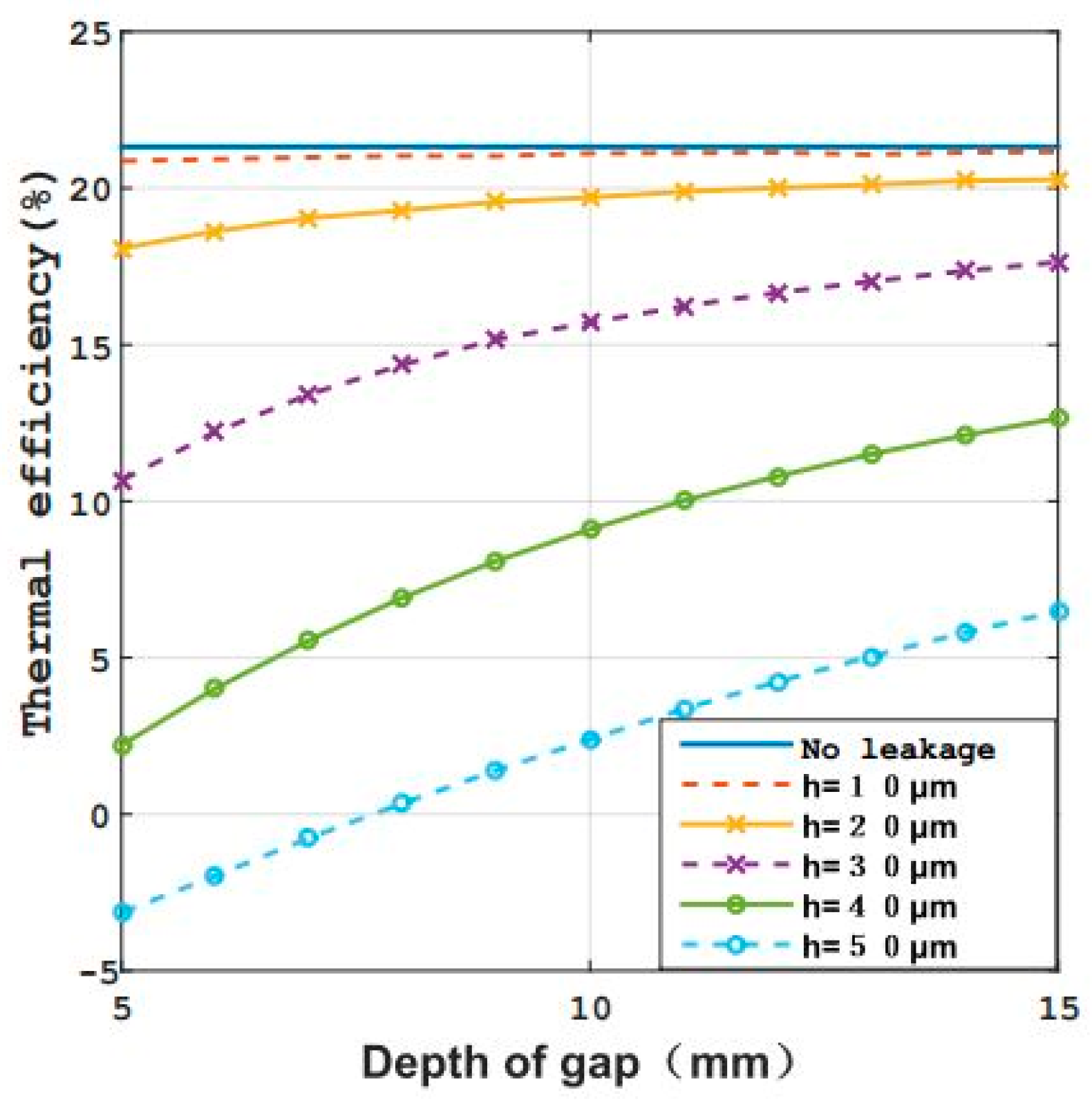

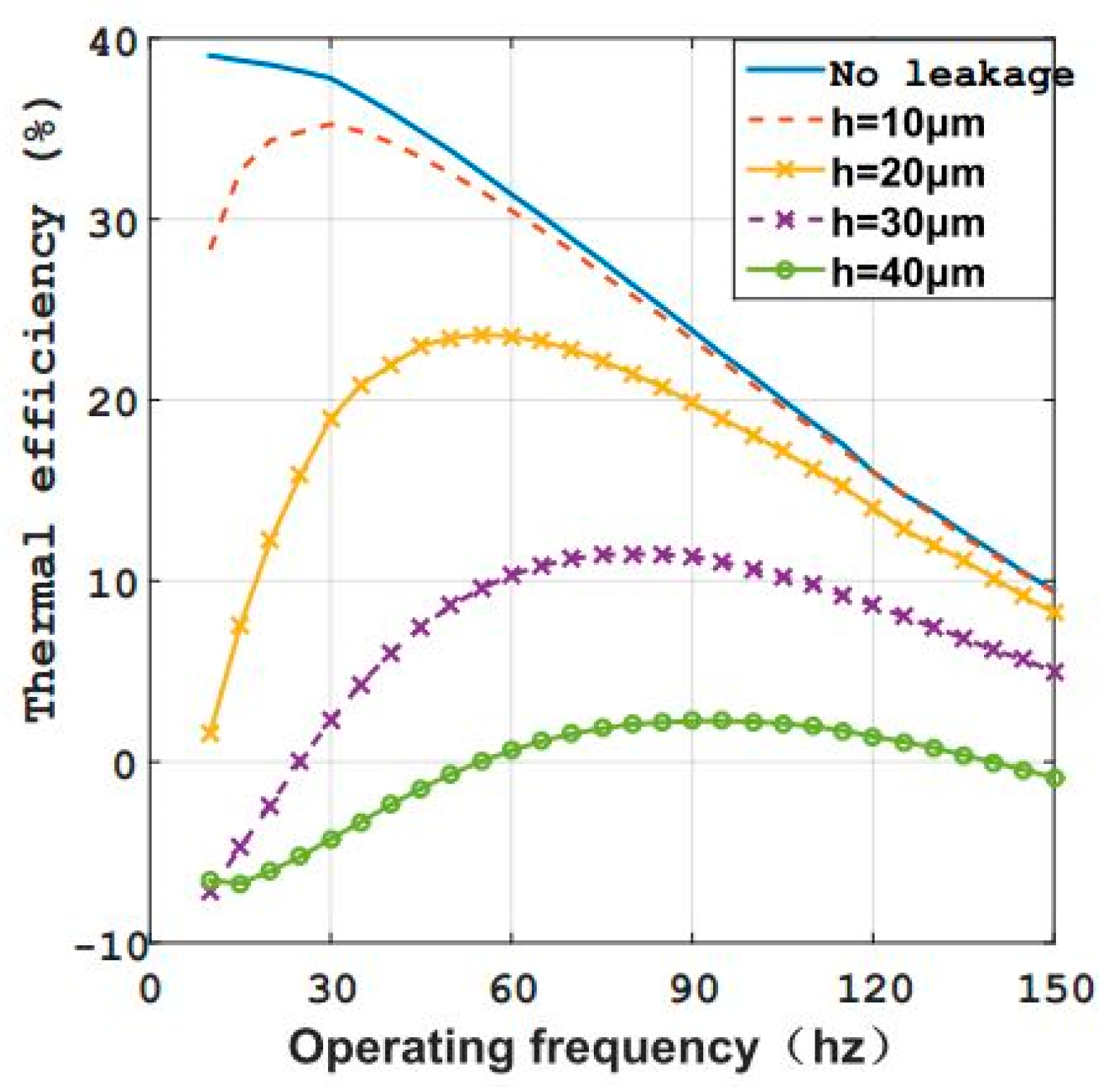

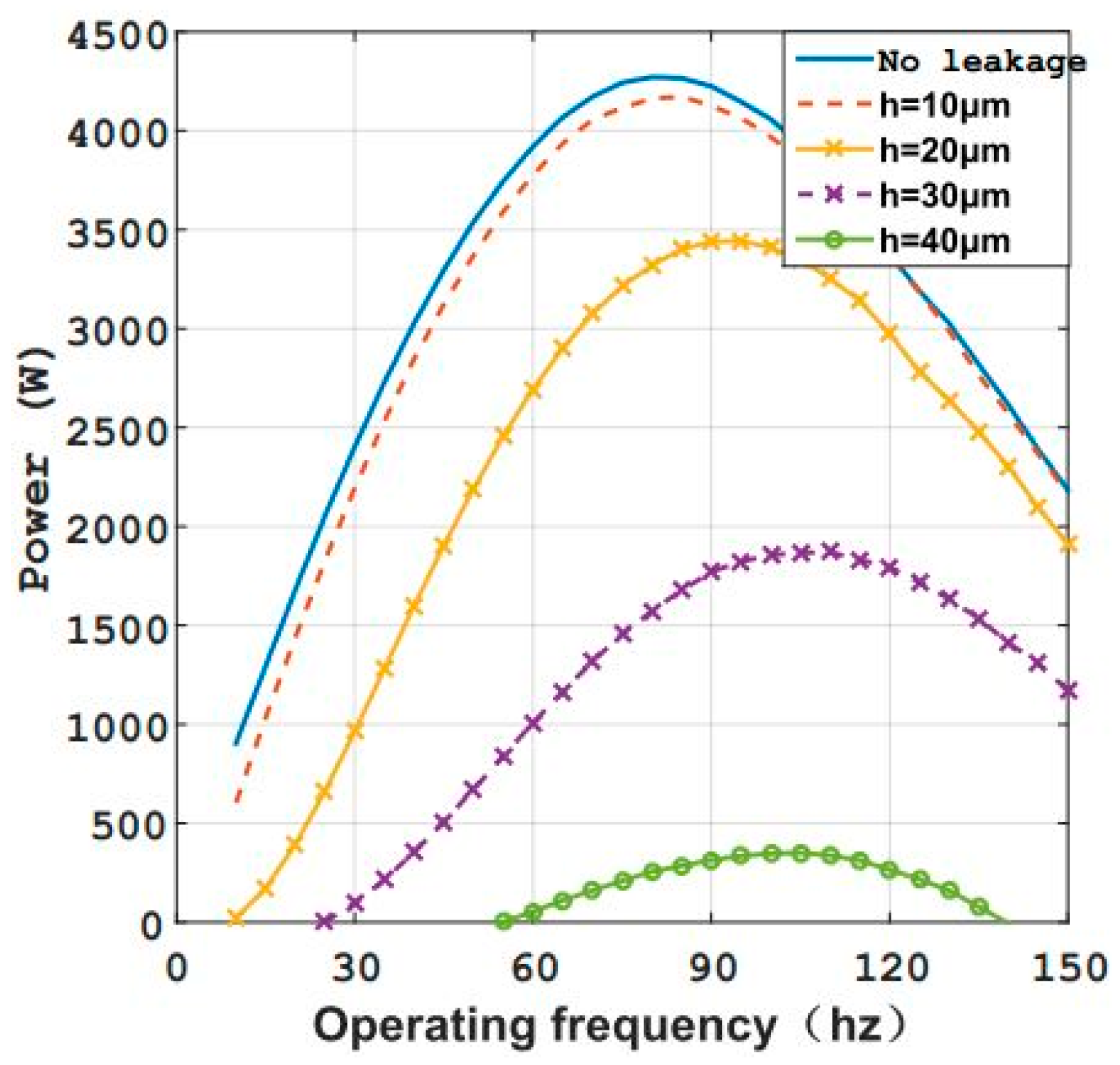

3.2.3. Combined Effect of Gap Height and Operating Frequency

4. Preliminary Experiments on the Micro Swing Rotor Engine

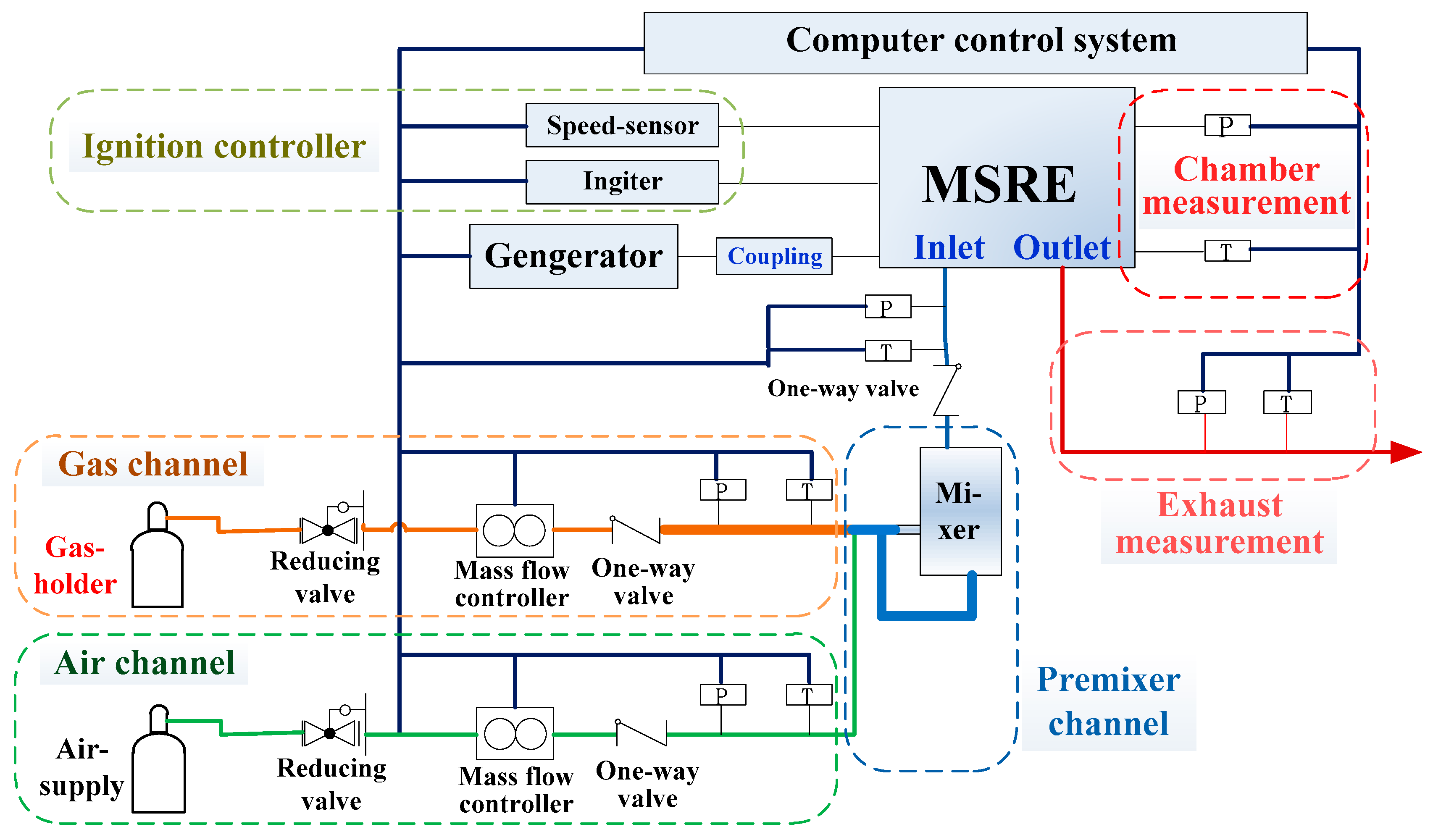

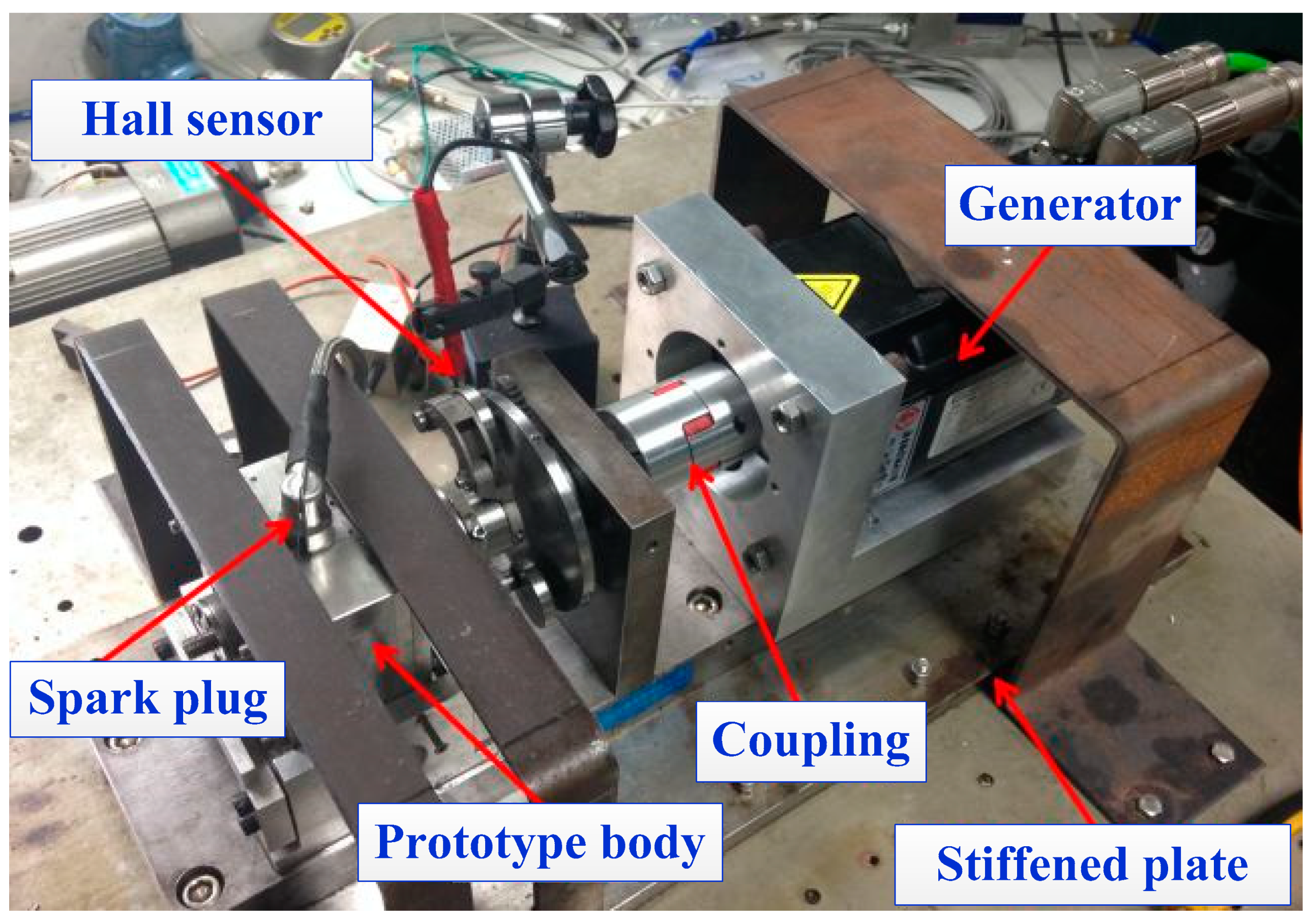

4.1. Establishment of the Experimental Platform

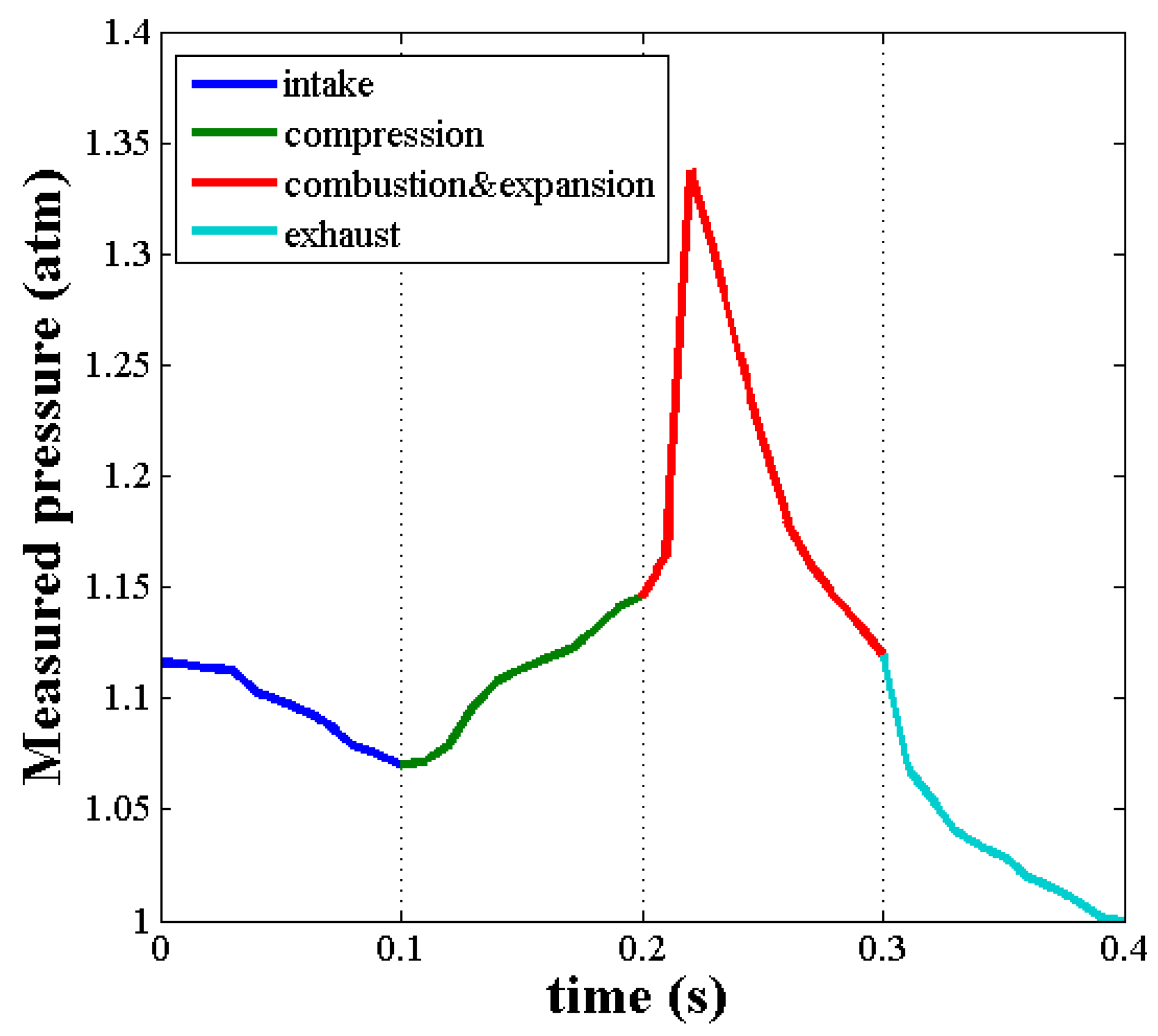

4.2. Cold State Test with Pressure-Air Blow

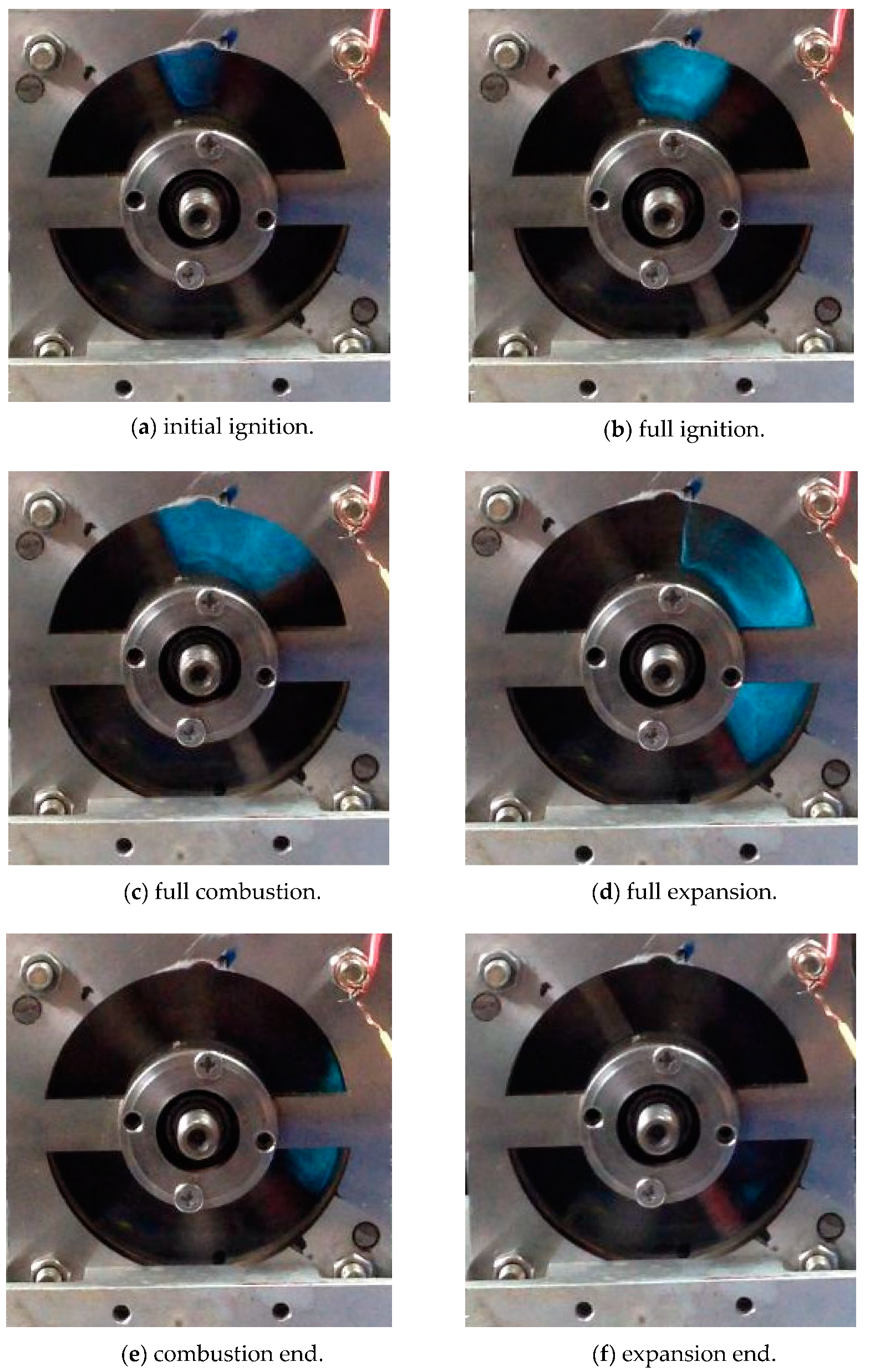

4.3. Combustion Test for Engine Operation at Thermal State

5. Conclusions

- (1)

- The proposed MSRE in four-stroke is composed of cylinder assembly and driver assembly, which can make the best of advantages for the micro swing engine and other IC engines. Without any complex components, surface sealing is applicable and the working frequency of this engine is relatively low at approximately 100 Hz order. Since available volume in cylinder assembly is high, the power to weight ratio is remarkable.

- (2)

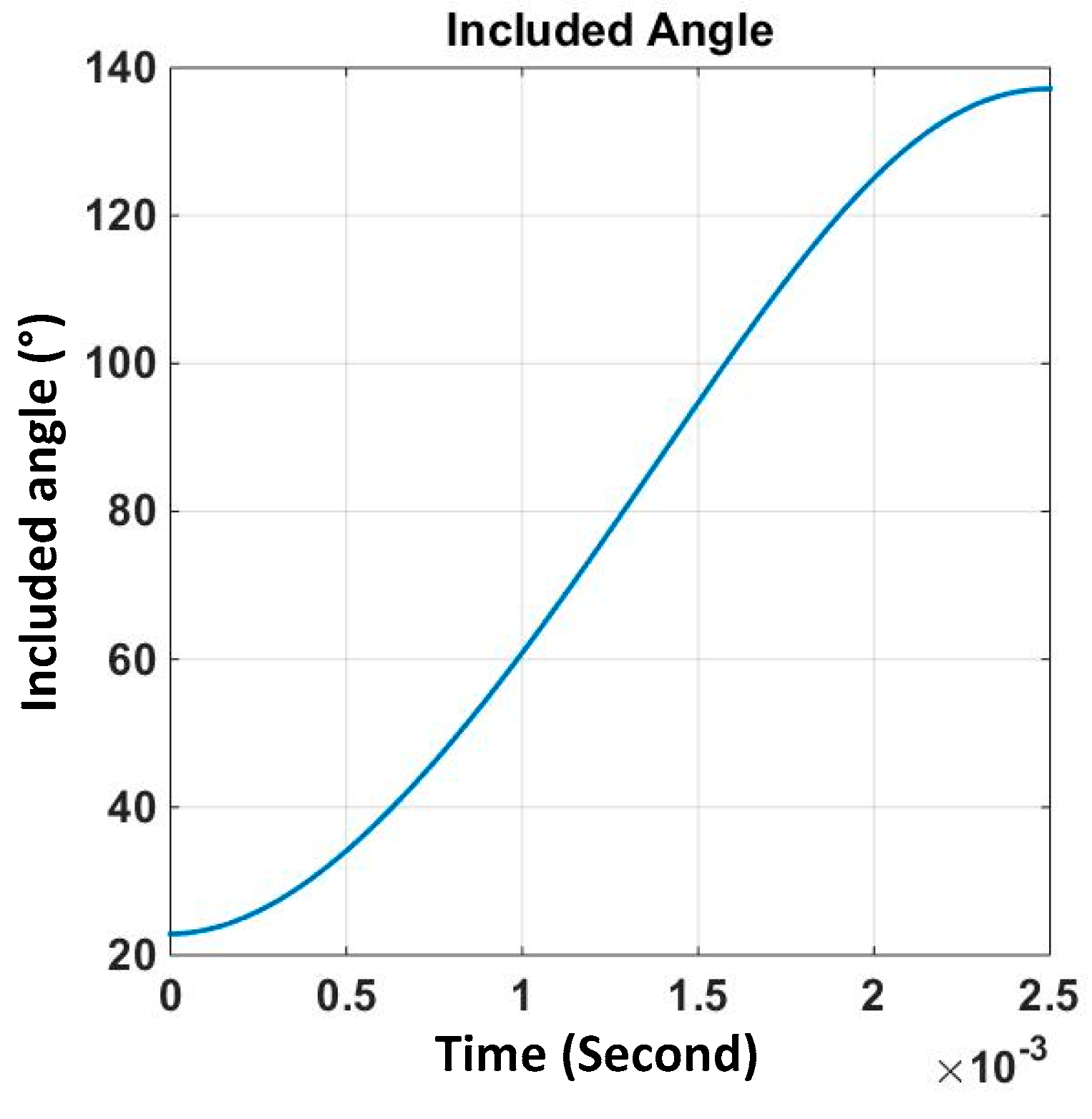

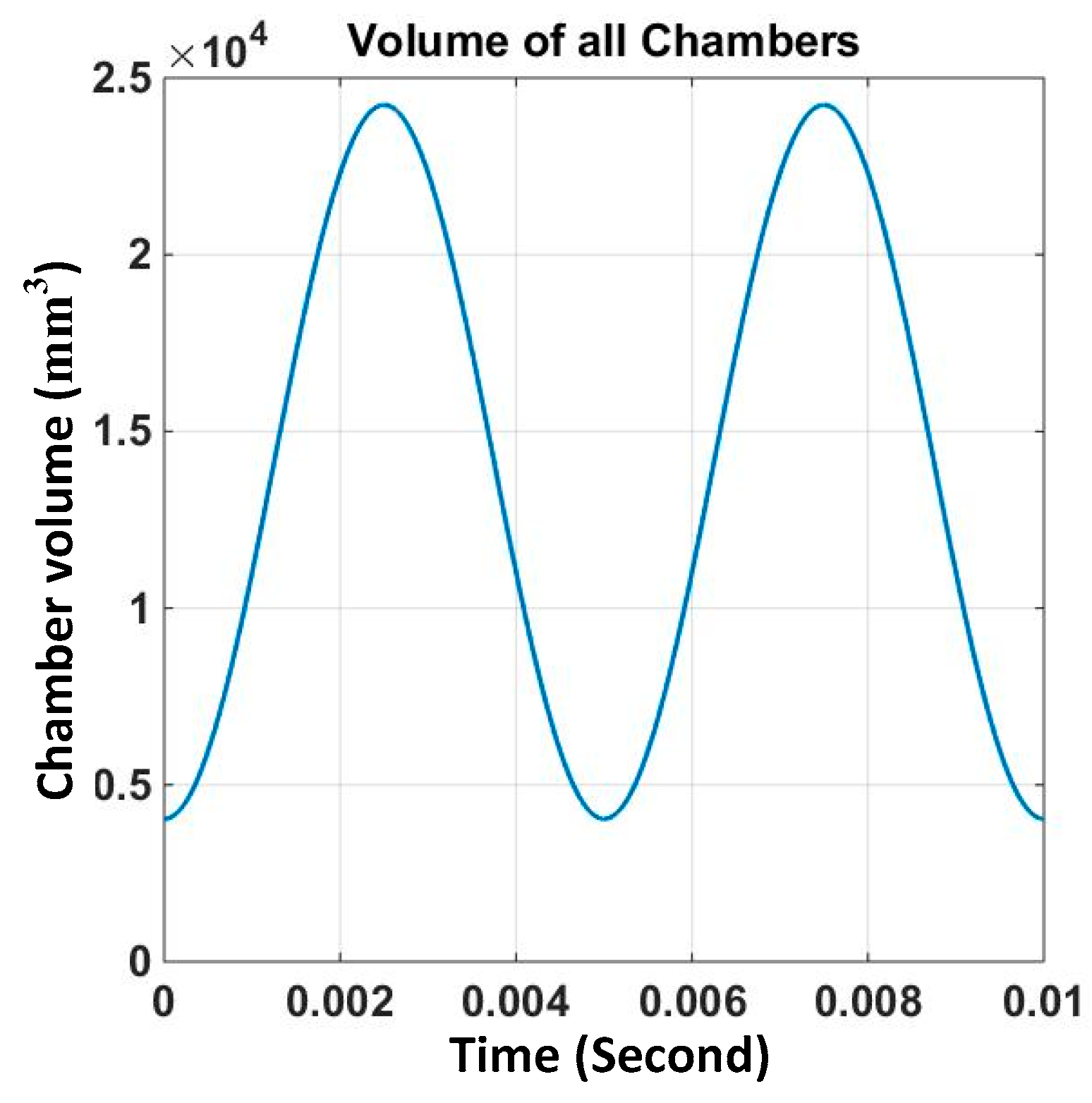

- In accordance with the operating characteristics of the MSRE, the design principle of the driver assembly was proven, so that the required periodical pursue motion of the two rotors was accomplished. In the prototype, the bar-length ratio of the crank-rocker mechanism was designed to be 3:0.5973:2.7402:1.2503; the rotor-thickness angle was 10°. With a compression ratio of 6, the volume of each chamber in the MSRE varied in a sine-like waveform, meeting well the design requirements.

- (3)

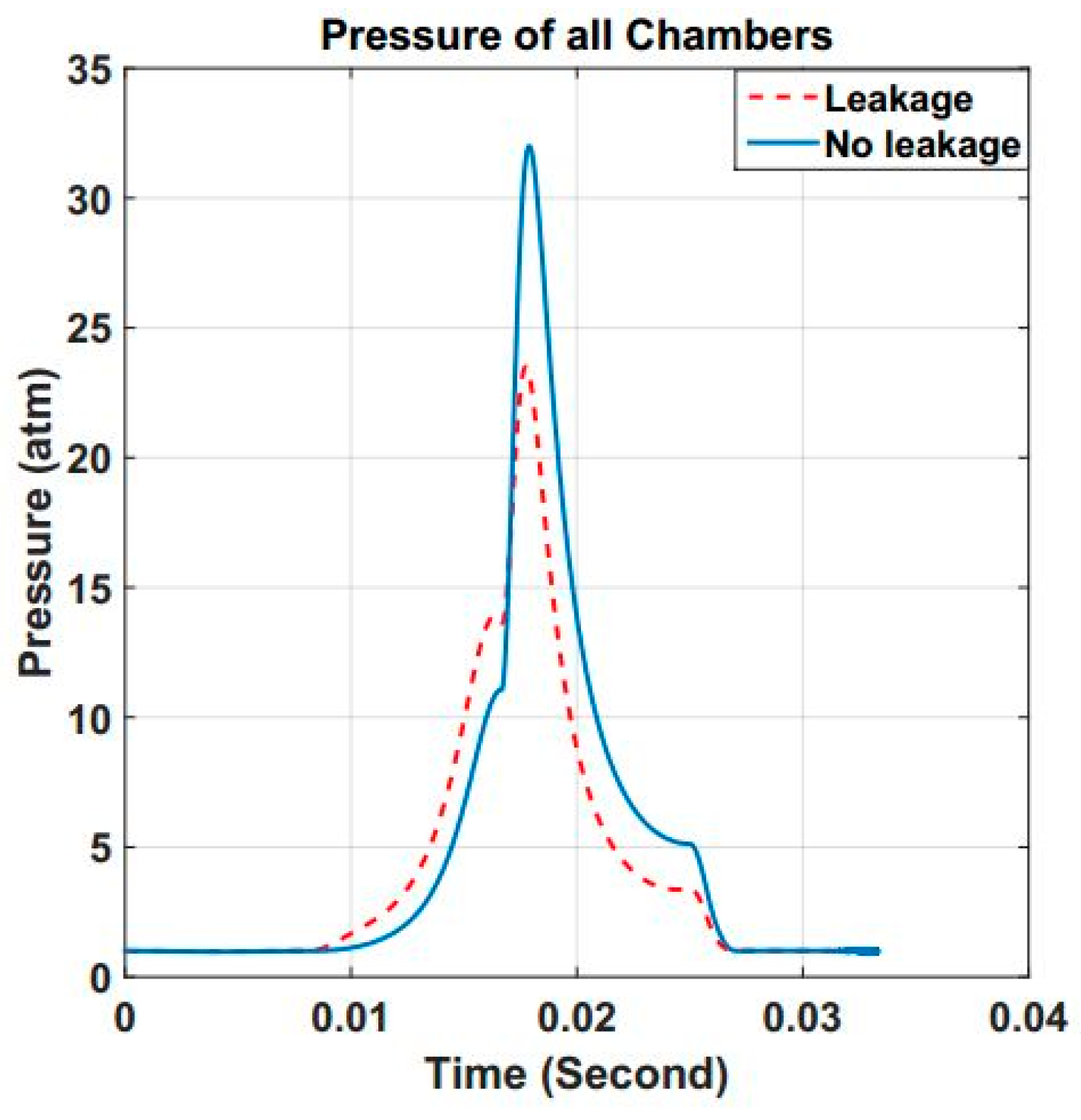

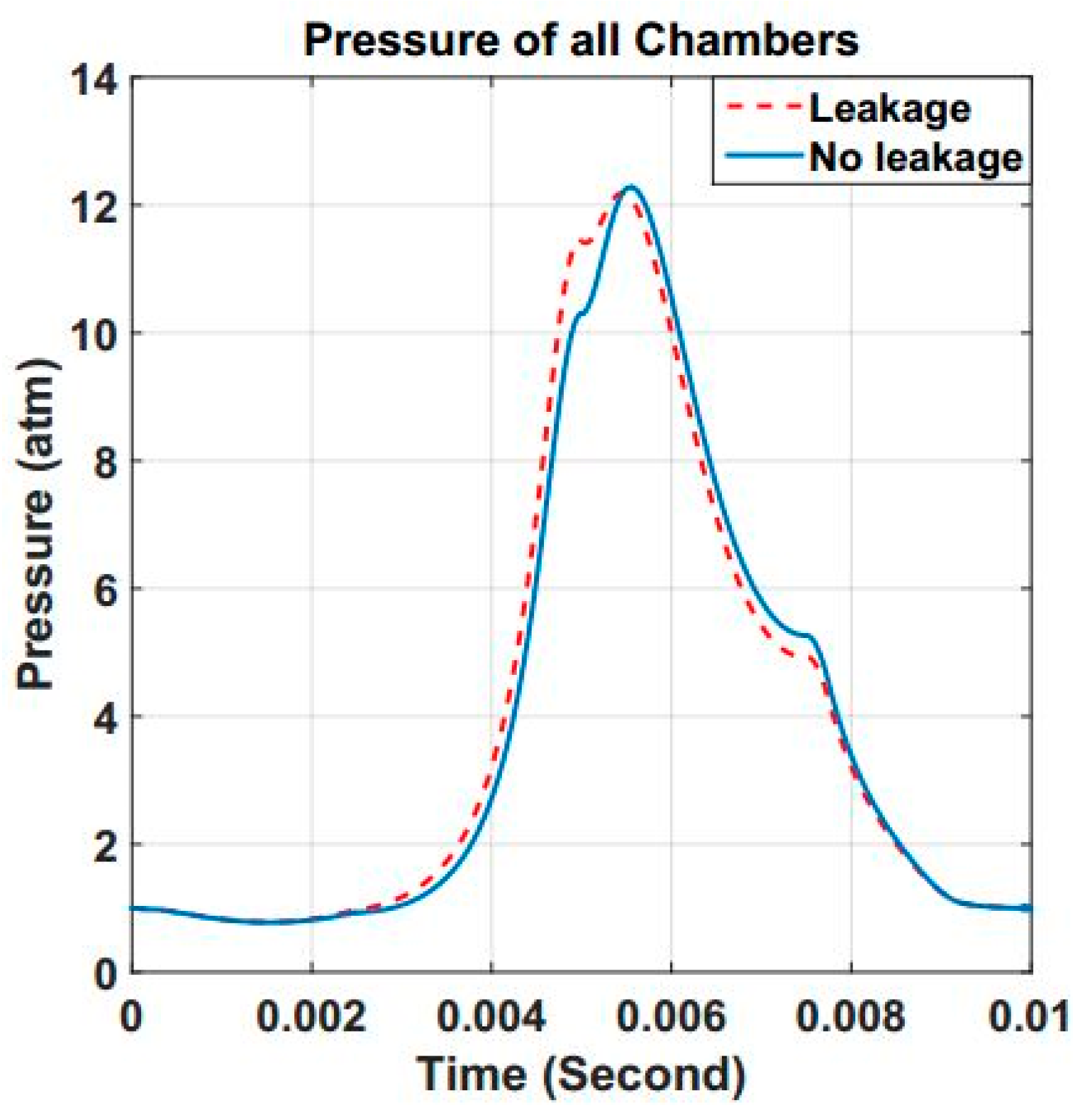

- Considering leakage effect, the thermodynamic model for the engine in steady working cycle was established. Simulation results indicated that the engine performance suffers poorly due to the leakage influence, especially when working at low frequencies. Thus, the effect of leakage size was analyzed. As the gap height increased, the engine efficiency diminishes sharply.

- (4)

- Gap height and the operation frequency were demonstrated as the two dominant factors that affect the engine performance. Analyses show that, under certain gap height, the MSRE must work at a specific frequency range, and the corresponding optical values exist for engine efficiency and power. With a gap height of 20 μm, the MSRE will reach the maximum efficiency of 23.62% at 55 Hz and achieve its maximum power of 3442 W at 95 Hz. Compared to the Micro-turbine by IHI or MICSE, the MSRE has remarkable advantages in power weight ratio and efficiency.

- (5)

- An experimental platform has been established and a preliminary test on the engine operation characteristics was conducted. In the cold state test with pressure-air blow, the experimental pressure changing trend was similar to the numerical result. Moreover, the research on combustion for the MSRE at thermal state showed that a full combustion process of butane was realized when the engine worked at 150 rpm.

- (6)

- Theoretical feasibility and creativity of MSRE were validated primitively by simulation analysis, together with the experimental test in this study. This work contributes a lot to the development of micro power systems.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fernandez-Pello, A.C. Micropower generation using combustion: Issues and approaches. Proc. Combust. Inst. 2002, 29, 883–899. [Google Scholar] [CrossRef]

- Sher, E.; Sher, I. Theoretical limits of scaling-down internal combustion engines. Chem. Eng. Sci. 2011, 66, 260–267. [Google Scholar] [CrossRef]

- Ju, Y.; Maruta, K. Microscale combustion: Technology development and fundamental research. Prog. Energy Combust. Sci. 2011, 37, 669–715. [Google Scholar] [CrossRef]

- Taywade, U.W.; Deshpande, A.A.; Kumar, S. Thermal performance of a micro combustor with heat recirculation. Fuel Process. Technol. 2013, 109, 179–188. [Google Scholar] [CrossRef]

- Walther, D.C.; Ahn, J. Advances and challenges in the development of power-generation systems at small scales. Prog. Energy Combust. Sci. 2011, 37, 583–610. [Google Scholar] [CrossRef]

- Chou, S.K.; Yang, W.M.; Chua, K.J.; Li, J.; Zhang, K.L. Development of micro power generators—A review. Appl. Energy 2011, 88, 1–16. [Google Scholar] [CrossRef]

- Epstein, A.; Senturia, S.; Al-Midani, O.; Anathasuresh, G.; Epstein, A.; Senturia, S.; Al-Midani, O.; Anathasuresh, G.; Ayon, A.; Breuer, K.; et al. Micro-heat engines, gas turbines and rocket engines—The MIT Microengine project. In Proceedings of the 28th AIAA Fluid Dynamics Conference, Snowmass Village, CO, USA, 29 June–2 July 1997. [Google Scholar]

- Epstein, A.H. Millimeter-Scale, MEMS Gas Turbine Engines. In Proceedings of the ASME Turbo Expo 2003, Atlanta, GA, USA, 16–19 June 2003. [Google Scholar]

- Isomura, K.; Tanaka, S.; Togo, S.; Esashi, M. Development of high-speed micro-gas bearings for three-dimensional micro-turbo machines. J. Micromech. Microeng. 2005, 15, S222. [Google Scholar] [CrossRef]

- Isomura, K.; Murayama, M.; Teramoto, S.; Hikichi, K.; Endo, Y.; Togo, S.; Tanaka, S. Experimental verification of the feasibility of a 100 W class micro-scale gas turbine at an impeller diameter of 10 mm. J. Micromech. Microeng. 2006, 16, S254–S261. [Google Scholar] [CrossRef]

- Tanaka, S.; Hikichi, K.; Togo, S.; Murayama, M.; Hirose, Y.; Sakurai, T.; Yuasa, S.; Teramoto, S.; Niino, T.; Mori, T.; et al. World’s smallest gas turbine establishing Brayton cycle. In Proceedings of the 7th International Workshop on Micro and Nanotechnology for Power Generation and Energy Conversion Applications, Freiburg, Germany, 27–29 November 2007; pp. 359–362. [Google Scholar]

- Lee, C.; Arslan, S.; Frechette, L.G. Design principles and measured performance of multistage radial flow microturbomachinery at low Reynolds numbers. J. Fluids Eng. Trans. ASME 2008, 130, 1349–1357. [Google Scholar] [CrossRef]

- Savoulides, N.; Jacobson, S.A.; Li, H.; Ho, L.; Khanna, R.; Teo, C.J.; Protz, J.M.; Wang, L.; Ward, D.; Schmidt, M.A.; et al. Fabrication and Testing of a High-Speed Microscale Turbocharger. J. Microelectromech. Syst. 2008, 17, 1270–1282. [Google Scholar] [CrossRef]

- Peck, J.; Jacobson, S.A.; Waitz, I.A. Design and Characterization of a Liquid-Fueled Microcombustor. J. Eng. Gas Turbines Power 2011, 133, 573–586. [Google Scholar] [CrossRef]

- Fu, K.; Knobloch, A.; Cooley, B.; Miyasaka, K. Micro-scale combustion research for applications to MEMS Rotary IC Engines. In Proceedings of the 35th ASME National Heat Transfer Conference, Anaheim, CA, USA, 10–12 June 2001. [Google Scholar]

- Fu, K.; Knobloch, A.; Martinez, F.; Walther, D.; Fernandez-Pello, C.; Pisano, A.P.; Liepmann, D. Design and fabrication of a silicon-based MEMS rotary engine. In Proceedings of the International Mechanical Engineering Congress and Exposition (IMECE), New York, NY, USA, 11–16 November 2001. [Google Scholar]

- Lee, C.H.; Jiang, K.C.; Jin, P.; Prewett, P.D. Design and fabrication of a micro Wankel engine using MEMS technology. Microelectron. Eng. 2004, 73, 529–534. [Google Scholar] [CrossRef]

- Sprague, S.B.; Park, S.W.; Walther, D.C.; Pisano, A.P.; Fernandez-Pello, A.C. Development and characterization of small-scale rotary engines. Int. J. Altern. Propuls. 2007, 1, 275–293. [Google Scholar] [CrossRef]

- Liu, Y.; Li, W.; Yang, C.; Song, R. Design and Test of Small-Scale Rotary Engine Power System. In Proceedings of the 2007 First International Conference on Integration and Commercialization of Micro and Nanosystems, Sanya, China, 10–13 January 2007; pp. 47–51. [Google Scholar]

- Wang, W.; Zuo, Z.; Liu, J. Miniaturization limitations of rotary internal combustion engines. Energy Convers. Manag. 2016, 112, 101–114. [Google Scholar] [CrossRef]

- Deng, H.; Pan, C.Y.; Wang, X.C.; Zhang, L.; Deng, L. Comparison of two types of twin-rotor piston engine mechanisms. J. Cent. South Univ. 2013, 20, 363–371. [Google Scholar] [CrossRef]

- Deng, H.; Pan, C.Y.; Xu, X.J.; Zhang, X. Mathematical modeling and analysis of gas torque in twin-rotor piston engine. J. Cent. South Univ. 2013, 20, 3536–3544. [Google Scholar] [CrossRef]

- Xu, H.; Zhang, L.; Pan, C.; Zhang, X. Design and dynamic characteristic prediction of air-powered twin-rotor piston engine. J. Cent. South Univ. 2015, 22, 4585–4596. [Google Scholar] [CrossRef]

- Yang, W. MEMS free-piston knock engine. Poster presentation. In Proceedings of the 28th International Symposium on Combustion, Edinburgh, UK, 30 July–4 August 2000. [Google Scholar]

- Aichlmayr, H.T.; Kittelson, D.B.; Zachariah, M.R. Miniature free-piston homogeneous charge compression ignition engine-compressor concept—Part I: Performance estimation and design considerations unique to small dimensions. Chem. Eng. Sci. 2002, 57, 4161–4171. [Google Scholar] [CrossRef]

- Aichlmayr, H.T. Design Considerations, Modeling, and Analysis of Micro-Homogeneous Charge Compression Ignition Combustion Free-piston Engines. Ph.D. Thesis, University of Minnesota, Minneapolis, MN, USA, 2002. [Google Scholar]

- Aichlmayr, H.T.; Kittelson, D.B.; Zachariah, M.R. Micro-HCCI combustion: Experimental characterization and development of a detailed chemical kinetic model with coupled piston motion. Combust. Flame 2003, 135, 227–248. [Google Scholar] [CrossRef]

- Sher, I.; Levinzon-Sher, D.; Sher, E. Miniaturization limitations of HCCI internal combustion engines. Appl. Therm. Eng. 2009, 29, 400–411. [Google Scholar] [CrossRef]

- Bai, J.; Wang, Q.; He, Z.; Li, C.; Pan, J. Study on methane HCCI combustion process of micro free-piston power device. Appl. Therm. Eng. 2014, 73, 1066–1075. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, D.; Bai, J.; He, Z. Numerical simulation of catalysis combustion inside micro free-piston engine. Energy Convers. Manag. 2016, 113, 243–251. [Google Scholar] [CrossRef]

- Mijit, K. Design, Analysis, and Experimentation of a Micro Internal Combustion Swing Engine. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2000. [Google Scholar]

- Dahm, W.; Mijit, J.; Mayor, R.; Qiao, G.; Benajmin, A.; Gu, Y.; Lei, Y.; Papke, M.; Wu, S. Micro internal combustion swing engine (MICSE) for portable power generation systems. In Proceedings of the 40th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 14–17 January 2002. [Google Scholar]

- Gu, Y.; Dahm, W. Turbulence-augmented minimization of combustion time in mesoscale internal combustion engines. In Proceedings of the 44th AIAA Aerospace Sciences Meeting & Exhibit, Reno, NV, USA, 9–12 January 2006. [Google Scholar]

- Zhang, S.; Wang, J.; Guo, Z. Novel Micro Free-Piston Swing Engine and Its Feasibility Validation. Tsinghua Sci. Technol. 2005, 10, 381–386. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, Z.; Wang, J. Performance analysis of a 2-stroke micro free-piston swing engine. Pet. Sci. 2009, 6, 313–318. [Google Scholar] [CrossRef]

- Gao, D.; Lei, Y.; Zhu, H.; Ni, J. Constant Speed Control of Four-stroke Micro Internal Combustion Swing Engine. Chin. J. Mech. Eng. 2015, 28, 971–982. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, Z.; Kong, W.; Du, N. Investigations of leakage mechanisms and its influences on a micro swing engine considering rarefaction effects. Appl. Therm. Eng. 2016, 106, 674–680. [Google Scholar] [CrossRef]

- Xia, C.; Zhang, Z.; Huang, G.; Xu, Y. Study on the new hybrid thermodynamic cycle for a developed MICSE with heat recovery process. Appl. Therm. Eng. 2018, 129C, 1135–1149. [Google Scholar] [CrossRef]

- Samanta, A.; Vinuesa, R.; Lashgari, I.; Schlatter, P.; Brandt, L. Enhanced secondary motion of the turbulent flow through a porous square duct. J. Fluid Mech. 2015, 784, 681–693. [Google Scholar] [CrossRef]

- Samanta, A.; Freund, J.B. A model supersonic buried-nozzle jet: Instability and acoustic wave scattering and the far field sound. J. Fluid Mech. 2015, 778, 189–215. [Google Scholar] [CrossRef]

- Vinuesa, R.; Schlatter, P.; Nagib, H.M. Role of data uncertainties in identifying the logarithmic region of turbulent boundary layers. Exp. Fluids 2014, 55, 1751. [Google Scholar] [CrossRef]

- Rezaeiravesh, S.; Vinuesa, R.; Liefvendahl, M.; Schlatter, P. Assessment of uncertainties in hot-wire anemometry and oil-film interferometry measurements for wall-bounded turbulent flows. Eur. J. Mech. B Fluids 2018, 72, 57–73. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Compression ratio | 6 |

| Minimum transmission angle for crank-rocker mechanism/° | 60 |

| Arm thickness-angle/° | 10 |

| Relative lengths of four-bar linkage | 3:0.5973:2.7402:1.2503 |

| Arm-diameter/mm | 60 |

| Hinge-diameter/mm | 30 |

| Arm-height/mm | 15 |

| Initial Parameters | Value | Initial Parameters | Value |

|---|---|---|---|

| Equivalence ratio | 0.8 | Exhaust port diameter/mm | 10 |

| Reactants | C4H10, air | Intake discharge coefficient | 0.7 |

| Intake pressure/MPa | 0.1 | Exhaust discharge coefficient | 0.7 |

| Intake temperature/K | 300 | Compression ratio | 6 |

| Ambient pressure/MPa | 0.1 | Burn duration /ms | 2 |

| Ambient temperature/K | 300 | Weibe function parameters [31] | a = 5, m = 1 |

| Intake port diameter/mm | 10 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, C.; Zhang, Z.; Huang, G.; Zhou, T.; Xu, J. A Micro Swing Rotor Engine and the Preliminary Study of Its Thermodynamic Characteristics. Energies 2018, 11, 2684. https://doi.org/10.3390/en11102684

Xia C, Zhang Z, Huang G, Zhou T, Xu J. A Micro Swing Rotor Engine and the Preliminary Study of Its Thermodynamic Characteristics. Energies. 2018; 11(10):2684. https://doi.org/10.3390/en11102684

Chicago/Turabian StyleXia, Chen, Zhiguang Zhang, Guoping Huang, Tong Zhou, and Jianhua Xu. 2018. "A Micro Swing Rotor Engine and the Preliminary Study of Its Thermodynamic Characteristics" Energies 11, no. 10: 2684. https://doi.org/10.3390/en11102684

APA StyleXia, C., Zhang, Z., Huang, G., Zhou, T., & Xu, J. (2018). A Micro Swing Rotor Engine and the Preliminary Study of Its Thermodynamic Characteristics. Energies, 11(10), 2684. https://doi.org/10.3390/en11102684