Investigation into the Classification of Tight Sandstone Reservoirs via Imbibition Characteristics

Abstract

:1. Introduction

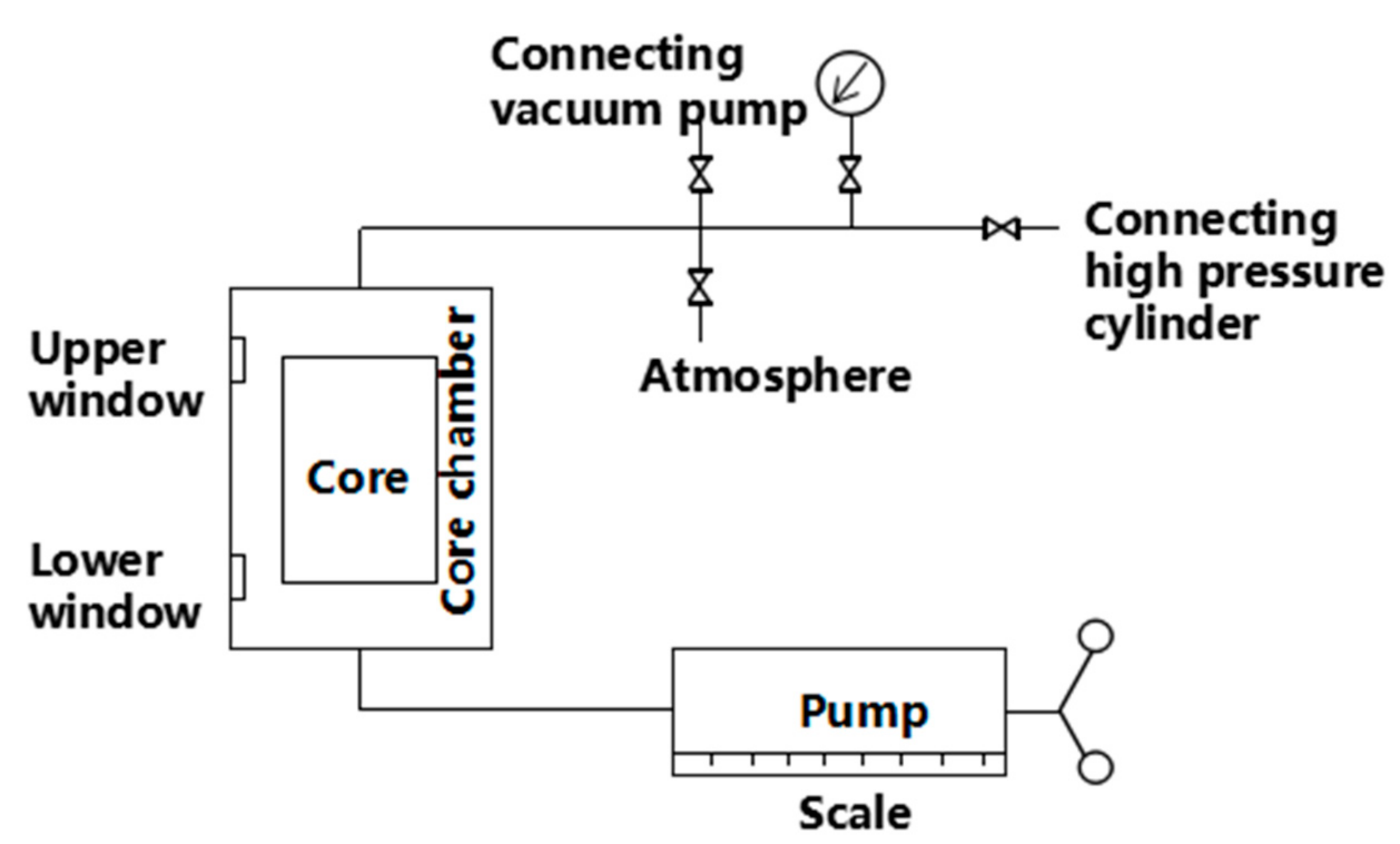

2. Experimental Setup

2.1. Spontaneous Imbibition Tests

2.2. Mercury Intrusion Porosimetry Tests

3. Results and Discussions

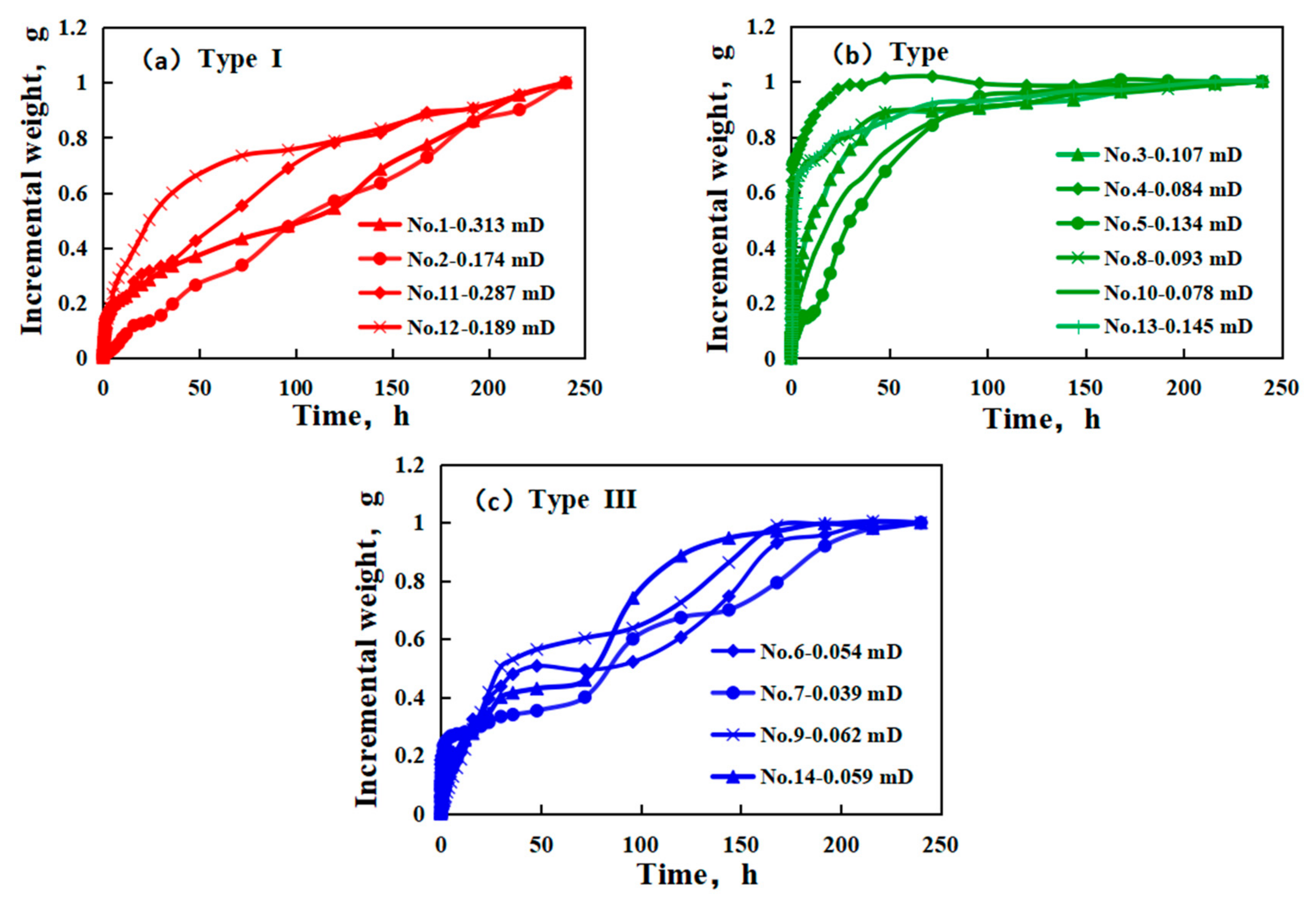

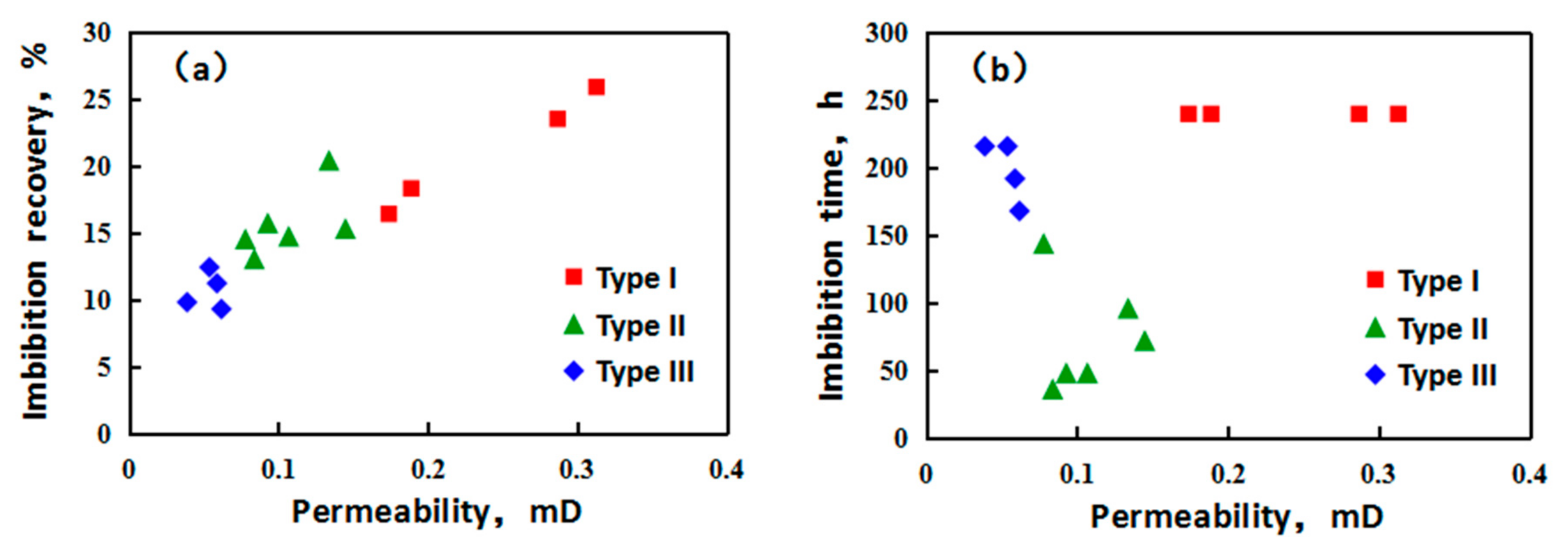

3.1. Imbibition Tests

3.2. Mercury Intrusion Porosimetry Tests

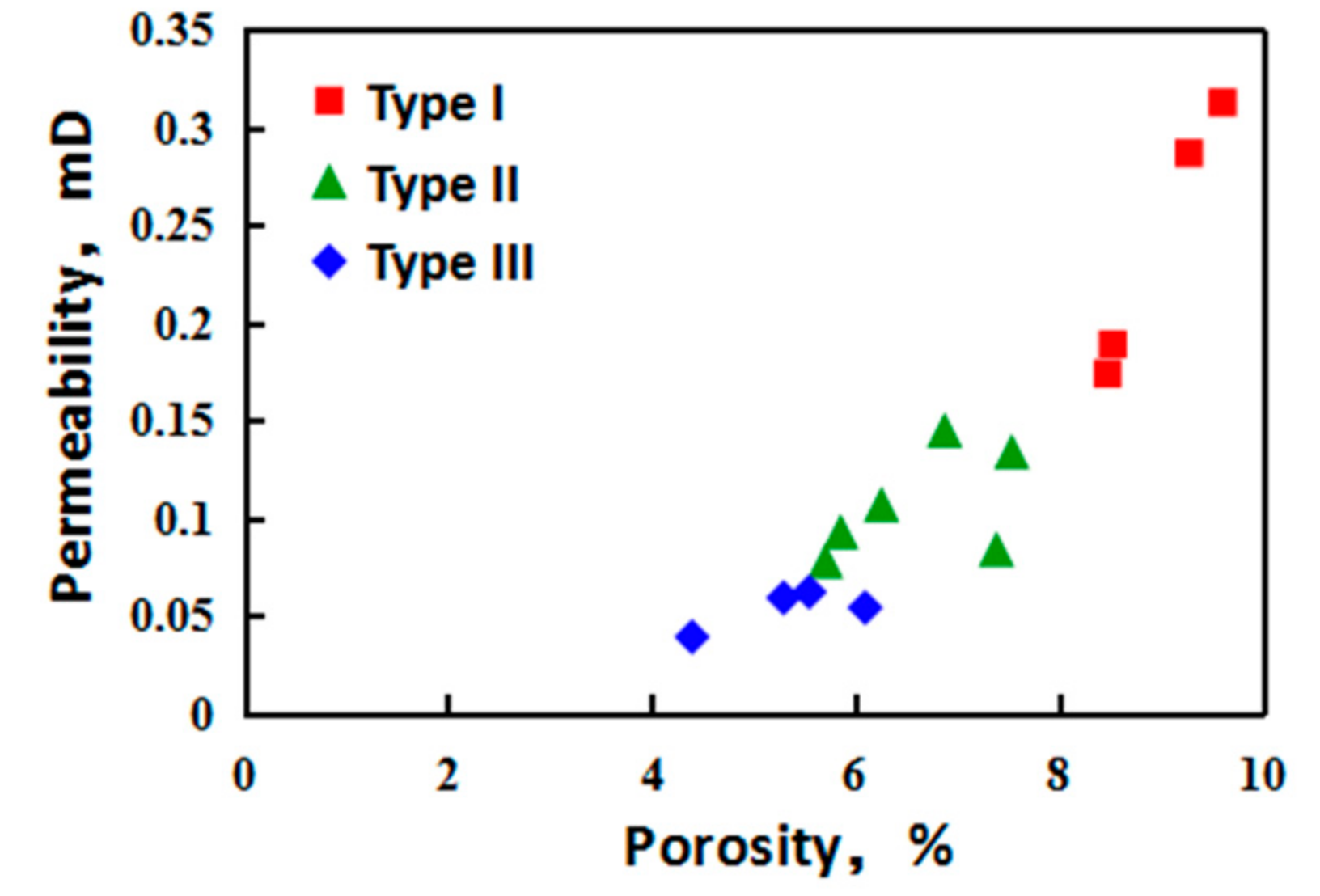

3.3. Classification Standard

4. Conclusions

- (1)

- Three types of formation were identified. For the first type, reservoir permeability was above 0.15 mD and its porosity ranged from 8 to 10%. The capillary effect was less intense, and imbibition and drainage occurred continuously without ever reaching a plateau within the experiment duration. A longer time was required to reach a steady state of imbibition, and therefore a longer shut-in time will yield a higher oil recovery. For the practical reservoir development, the optimal shut-in time should be determined while also considering the cost.

- (2)

- For the second category, reservoir permeability ranged from 0.08 to 0.15 mD, and the porosity was between 5% and 8%. This type of core displayed a strong imbibition effect. The aqueous phase quickly entered the matrix and displaced the oil, requiring less time to reach the plateau. This type of reservoir is most suitable for adopting imbibition as the recovery method, owing to a relatively shorter shut-in time and a greater oil recovery efficiency. The average shut-in time was experimentally determined as three days under laboratory conditions.

- (3)

- For the third category, reservoir permeability was mainly below 0.08 mD, and the porosity ranged from 4% to 7%. The capillary effect was prominent, leading to vigorous imbibition activity. Water was readily imbibed into the matrix, yet oil was difficult to expel due to a large resistance within small pores. It is highly likely that “water block” will occur. However, when the displacement pressure surpasses the flow resistance, “water block” can be eliminated and imbibition continues. This type of reservoir therefore demonstrates two stages of an increase in oil production and demands a longer imbibition time, resulting in a relatively low oil recovery efficiency. The average shut-in time was eight days under laboratory conditions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Boudet, H.S.; Zanocco, C.M.; Howe, P.D.; Clarke, C.E. The effect of geographic proximity to unconventional oil and gas development on public support for hydraulic fracturing. Risk Anal. 2018, 38. [Google Scholar] [CrossRef] [PubMed]

- Jia, C.; Zheng, M.; Zhang, Y. Unconventional hydrocarbon resources in China and the prospect of exploration and development. Pet. Explor. Dev. 2012, 39, 129–136. [Google Scholar] [CrossRef]

- Leimkuhler, J.; Leveille, G. Unconventional Resources; Society of Petroleum Engineers: Richardson, TX, USA, 2012; Volume 8, pp. 27–28. [Google Scholar]

- Kazempour, M.; Kiani, M.; Nguyen, D.; Salehi, M.; Moradi, M.; Lantz, M. Boosting Oil Recovery in Unconventional Resources Utilizing Wettability Altering Agents: Successful Translation from Laboratory to Field. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2018. [Google Scholar]

- Zhang, D.; Zhang, J.; Wang, Y.; Tang, Y.; Yu, W. China’s unconventional oil and gas exploration and development: Progress and prospects. Resour. Sci. 2015, 37, 106–112. [Google Scholar]

- Wheaton, R. Unconventional Resources. In Fundamentals of Applied Reservoir Engineering; Elsevier Science: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Wang, X.; Ren, L.; He, Y. Definition of tight oil in Ordos Basin. Pet. Geol. Recover. Effic. 2016, 23, 1–7. [Google Scholar]

- Zou, C.; Zhang, G.; Yang, Z.; Tao, S.; Hou, L.; Zhu, R.; Yuan, X.; Ran, Q.; Li, D.; Wang, Z. Geological concepts, characteristics, resource potential and key techniques of unconventional hydrocarbon: On unconventional petroleum geology. Pet. Explor. Dev. 2013, 40, 385–399. [Google Scholar] [CrossRef]

- Zhou, Q.; Yang, G. Definition and application of tight oil and shale oil terms. Oil Gas Geol. 2012, 33, 541–544. [Google Scholar]

- Li, M.; Li, J. “Dynamic trap”: A main action of hydrocarbon charging to form accumulations in low permeability-tight reservoir. Acta Pet. Sin. 2010, 31, 718–722. [Google Scholar]

- Ghanizadeh, A.; Clarkson, C.R.; Aquino, S.; Ardakani, O.H.; Sanei, H. Petrophysical and geomechanical characteristics of Canadian tight oil and liquid-rich gas reservoirs: I. Pore network and permeability characterization. Fuel 2015, 153, 682–691. [Google Scholar] [CrossRef]

- Wang, H.; Liao, X.; Lu, N.; Cai, Z.; Liao, C.; Dou, X. A study on development effect of horizontal well with SRV in unconventional tight oil reservoir. J. Energy Inst. 2014, 87, 114–120. [Google Scholar] [CrossRef]

- Khan, R.; Al-Nakhli, A.R. An Overview of Emerging Technologies and Innovations for Tight Gas Reservoir Development. In Proceedings of the SPE International Production and Operations Conference & Exhibition, Doha, Qatar, 14–16 May 2012; p. 387. [Google Scholar]

- Truong, N.H.; Bae, W. Optimal Fracturing Parameters Condition of Integrated Model Development for Tight Oil Sands Reservoir with 2D Fracture Geometry Using Response Surface Methodology. Res. J. Appl. Sci. Eng. Technol. 2016, 12, 994–1006. [Google Scholar] [CrossRef]

- Schmitt, M.; Halisch, M.; Müller, C.; Fernandes, C.P. Classification and quantification of pore shapes in sandstone reservoir rocks with 3-D X-ray micro-computed tomography. Solid Earth 2016, 7, 3441–3479. [Google Scholar] [CrossRef]

- Claes, S.; Soete, J.; Cnudde, V.; Swennen, R. A three-dimensional classification for mathematical pore shape description in complex carbonate reservoir rocks. Math. Geosci. 2016, 48, 619–639. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Xie, Q.; Zhou, J. Micro Pore Throat Structural Classification of Chang 7 Tight Oil Reservoir of Jiyuan Oilfi eld in Ordos Basin. China Pet. Explor. 2014, 19, 73–79. [Google Scholar]

- Chen, S.-B.; Xia, X.-G.; Fu, C.-Q. Classification of pore structures in shale gas reservoir at the Longmaxi Formation in the south of Sichuan Basin. J. Coal Sci. Eng. 2013, 38, 760–765. [Google Scholar]

- Zhao, C.; Qu, H.; Zhang, Z. The characteristics and classification evaluation of Chang-6 reservoir in south Huaziping Area of Xingzichuan oilfield. Unconv. Oil Gas 2017, 4, 44–50. [Google Scholar]

- Jiang, R.; Qian, J.; Sun, H.; Fu, J.; Peng, G.; Qiao, X. Reservoir classification method for low-permeability glutenite reservoirs. Pet. Geol. Recover. Effic. 2018, 1, 90–93. [Google Scholar]

- Dai, J.; Xie, J.; Li, Z.; Ren, Q.; Zhang, H. Reservoir classification and evaluation in the east of Sulige gasfield. Pet. Geol. Recover. Effic. 2017, 31, 57–60. [Google Scholar]

- Ghosh, A.; Vasudevan, K. Bipartite Carbonate Reservoir classification methodology to address data inadequacy and capture pore level heterogeneity: A Case Study. In Proceedings of the Spwla India Symposium, Mumbai, India, 11–12 February 2017. [Google Scholar]

- Cao, J. Reservoir identification: Parameter characterization or feature classification. In Proceedings of the AGU Fall Meeting, New Orleans, LA, USA, 11–15 December 2017. [Google Scholar]

- Xu, X.; Wang, H.; Zhang, Z. Classification and evaluation of low permeability reservoir of Chang 8 formation in Jiyuan oilfield. Coal Technol. 2017, 36, 118–120. [Google Scholar]

- Oen, P.M.; Engell-Jensen, M.; Barendregt, A.A. Skjold field, Danish North Sea: Early evaluations of oil recovery through water imbibition in a fractured reservoir. SPE Reservoir Eng. 1988, 3, 17–22. [Google Scholar] [CrossRef]

- Babadagli, T.; Ershaghi, I. Imbibition assisted two-phase flow in natural fractures. In Proceedings of the Western Regional Meeting, Bakersfield, CA, USA, 30 March–1 April 1992. [Google Scholar]

- Al-Lawati, S.; Oman, P.D.O.; Saleh, S. Oil recovery in fractured Oil Reservoirs by low IFT imbibition process. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 6–9 October 1996. [Google Scholar]

- Bertoncello, A.; Wallace, J.; Blyton, C.; Honarpour, M.; Kabir, C.S. Imbibition and water blockage in unconventional reservoirs: Well management implications during flowback and early production. In Proceedings of the SPE/EAGE European Unconventional Conference and Exhibition, Vienna, Austria, 25–27 February 2014. [Google Scholar]

- Mirzaei, M.; Dicarlo, D.A.; Pope, G.A. Visualization and analysis of surfactant imbibition into oil-wet fractured core. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar]

- Kathel, P.; Mohanty, K.K. EOR in tight oil reservoirs through wettability alteration. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar]

- Alvarez, J.O.; Schechter, D.S. Wettability Alteration and Spontaneous Imbibition in Unconventional Liquid Reservoirs by Surfactant Additives. SPE Reserv. Eval. Eng. 2017. [Google Scholar] [CrossRef]

- Gao, Z.; Hu, Q. Initial water saturation and imbibition fluid affect spontaneous imbibition into Barnett shale samples. J. Nat. Gas Sci. Eng. 2016, 34, 541–551. [Google Scholar] [CrossRef]

- Mehana, M.; Alsalman, M.; Fahes, M. The Impact of Salinity and Mineralogy on Slick Water Spontaneous Imbibition and Formation Strength in Shale. Energy Fuels 2018, 32, 5725–5735. [Google Scholar] [CrossRef]

- Habibi, A.; Binazadeh, M.; Dehghanpour, H.; Binazadeh, M.; Bryan, D.; Uswak, G. Advances in understanding wettability of tight oil formations. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015. [Google Scholar]

- Chahardowli, M.; Farajzadeh, R.; Masalmeh, S.K.; Mahani, H.; Bruining, H. A novel enhanced oil recovery technology using dimethyl ether/brine: Spontaneous imbibition in sandstone and carbonate rocks. In Proceedings of the SPE annual technical conference and exhibition, Dubai, UAE, 26–28 September 2016. [Google Scholar]

- Valluri, M.K.; Alvarez, J.O.; Schechter, D.S. Study of the rock/fluid interactions of sodium and calcium brines with ultra-tight rock surfaces and their impact on improving oil recovery by spontaneous imbibition. In Proceedings of the SPE Low Perm Symposium, Denver, CO, USA, 5–6 May 2016. [Google Scholar]

- Lan, Q.; Ghanbari, E.; Dehghanpour, H.; Hawkes, R. Water loss versus soaking time: Spontaneous imbibition in tight rocks. In Proceedings of the SPE/EAGE European Unconventional Conference and Exhibition, Vienna, Austria, 25–27 February 2014. [Google Scholar]

- Gu, X.; Pu, C.; Huang, H.; Huang, F.; Li, Y.; Liu, Y.; Liu, H. Micro-influencing mechanism of permeability recovery for tight sandston on spontaneous imbibition reservoirs. Pet. Explor. Dev. 2017, 44, 948–954. [Google Scholar] [CrossRef]

- Wei, Q.; Li, Z.; Wang, X.; Wang, C.; Bai, R.; Wang, C.; Li, H. Mechanism and influence factors of imbibition in fractured tight sandstone reservoir: An example from Chang 8 reservoir of Wuqi area in Ordos Basin. Pet. Geol. Recover. Effic. 2016, 23, 102–107. [Google Scholar]

- Santanna, V.C.; Castro, T.A.; Borges, T.A.; Bezerril, A.R.; Nascimento, A.E.G. The Influence of Surfactant Solution Injection in Oil Recovery by Spontaneous Imbibition. Pet. Sci. Technol. 2014, 32, 2896–2902. [Google Scholar] [CrossRef]

- Towler, B.F.; Lehr, H.L.; Austin, S.W.; Bowthorpe, B.; Feldman, J.H.; Forbis, S.K.; Germack, D.; Firouzi, M. Spontaneous Imbibition Experiments of Enhanced Oil Recovery with Surfactants and Complex Nano-Fluids. J. Surfactants Deterg. 2017, 20, 1–11. [Google Scholar] [CrossRef]

- Li, X.; Teklu, T.W.; Abass, H.; Cui, Q. The Impact of Water Salinity/Surfactant on Spontaneous Imbibition through Capillarity and Osmosis for Unconventional IOR. In Proceedings of the Unconventional Resources Technology Conference, San Antonio, TX, USA, 1–3 August 2016. [Google Scholar]

| No. | Depth, m | Length, cm | Diameter, cm | Porosity, % | Permeability, mD |

|---|---|---|---|---|---|

| 1 | 1671.8 | 4.380 | 2.532 | 9.61 | 0.313 |

| 2 | 1674.25 | 4.392 | 2.530 | 8.48 | 0.174 |

| 3 | 1680.5 | 4.340 | 2.532 | 6.26 | 0.107 |

| 4 | 1737.24 | 4.364 | 2.516 | 7.39 | 0.084 |

| 5 | 1837.8 | 4.378 | 2.500 | 7.54 | 0.134 |

| 6 | 2149.76 | 4.386 | 2.500 | 6.10 | 0.054 |

| 7 | 2136.75 | 4.510 | 2.516 | 4.40 | 0.039 |

| 8 | 2424 | 4.342 | 2.514 | 5.86 | 0.093 |

| 9 | 2458.7 | 4.260 | 2.514 | 5.55 | 0.062 |

| 10 | 2035.18 | 4.406 | 2.520 | 5.71 | 0.078 |

| 11 | 2043.81 | 4.306 | 2.520 | 9.28 | 0.287 |

| 12 | 2074.4 | 4.330 | 2.522 | 8.53 | 0.189 |

| 13 | 2083 | 4.386 | 2.518 | 6.88 | 0.145 |

| 14 | 2207 | 4.394 | 2.518 | 5.30 | 0.059 |

| No. | Porosity, % | Permeability, mD | Oil Recovery, % | Time Required to Reach Plateau, h |

|---|---|---|---|---|

| 1 | 9.61 | 0.313 | 25.94 | 240 |

| 2 | 8.48 | 0.174 | 16.43 | 240 |

| 3 | 6.26 | 0.107 | 14.76 | 48 |

| 4 | 7.39 | 0.084 | 13.07 | 36 |

| 5 | 7.54 | 0.134 | 20.45 | 96 |

| 6 | 6.10 | 0.054 | 12.43 | 216 |

| 7 | 4.40 | 0.039 | 9.81 | 216 |

| 8 | 5.86 | 0.093 | 15.76 | 48 |

| 9 | 5.55 | 0.062 | 9.3 | 168 |

| 10 | 5.71 | 0.078 | 14.56 | 144 |

| 11 | 9.28 | 0.287 | 23.55 | 240 |

| 12 | 8.53 | 0.189 | 18.34 | 240 |

| 13 | 6.88 | 0.145 | 15.34 | 72 |

| 14 | 5.30 | 0.059 | 11.23 | 192 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Yang, H.; Lu, H.; Wu, T.; Zhou, D.; Liu, Y. Investigation into the Classification of Tight Sandstone Reservoirs via Imbibition Characteristics. Energies 2018, 11, 2619. https://doi.org/10.3390/en11102619

Li M, Yang H, Lu H, Wu T, Zhou D, Liu Y. Investigation into the Classification of Tight Sandstone Reservoirs via Imbibition Characteristics. Energies. 2018; 11(10):2619. https://doi.org/10.3390/en11102619

Chicago/Turabian StyleLi, Ming, Hai’en Yang, Hongjun Lu, Tianjiang Wu, Desheng Zhou, and Yafei Liu. 2018. "Investigation into the Classification of Tight Sandstone Reservoirs via Imbibition Characteristics" Energies 11, no. 10: 2619. https://doi.org/10.3390/en11102619

APA StyleLi, M., Yang, H., Lu, H., Wu, T., Zhou, D., & Liu, Y. (2018). Investigation into the Classification of Tight Sandstone Reservoirs via Imbibition Characteristics. Energies, 11(10), 2619. https://doi.org/10.3390/en11102619