Investigation of Thermal Stress of Cement Sheath for Geothermal Wells during Fracturing

Abstract

:1. Introduction

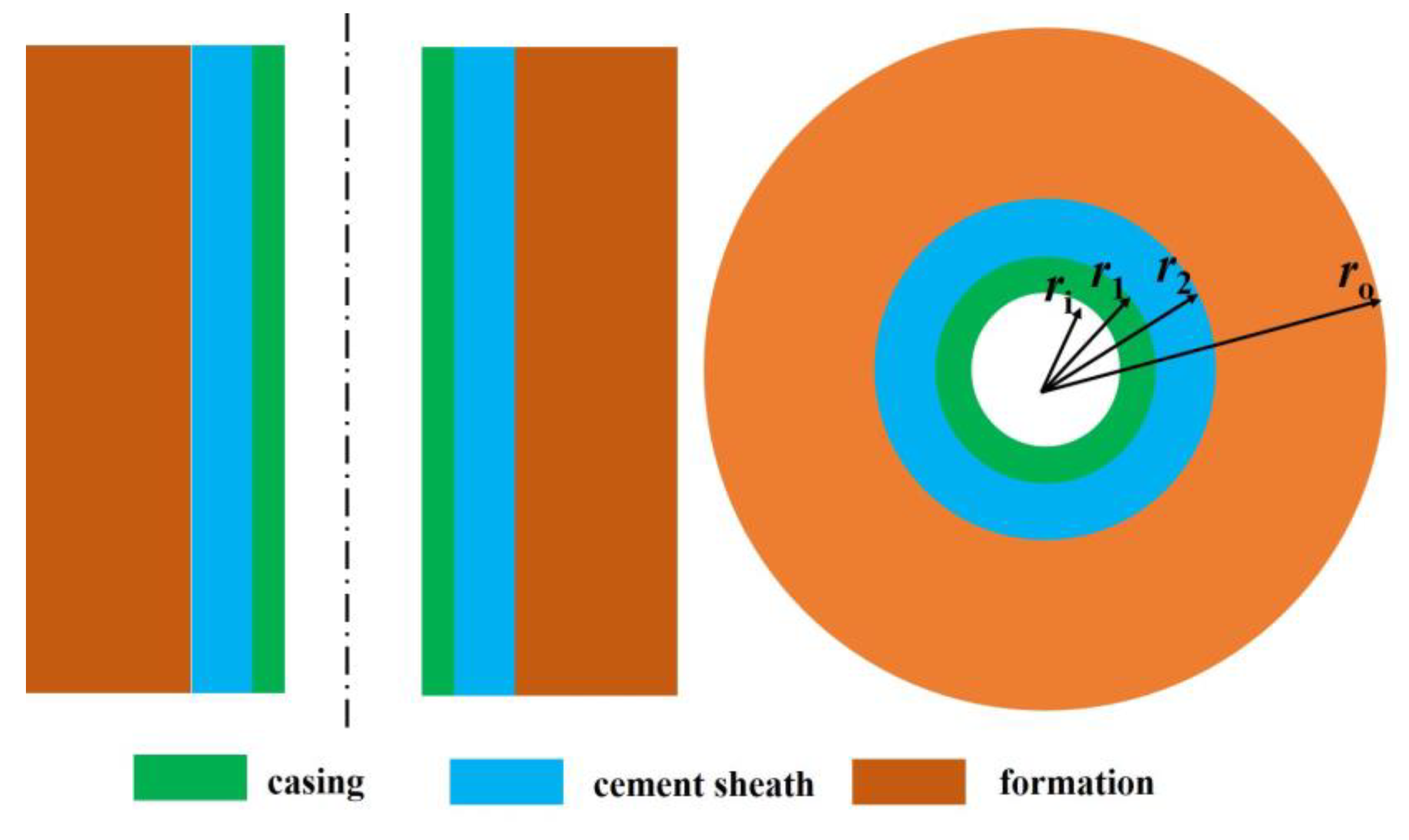

2. Thermal Stress Model Development and Solution

2.1. Basic Assumptions

- The casing, cement sheath, and formation are all considered as homogeneous isotropic materials;

- The casing-cement sheath-formation combined system is completely cemented and deemed as a composed thick-wall cylinder;

- The radial stress and radial displacement at the casing-cement sheath interface and the cement sheath-formation interface are both continuous;

- The nonuniform temperature varies along the radial direction of the combined system except for the casing in consideration of its thin wall and well heat conduction performance;

- The temperature at the inner wall of the casing is equal to wellbore temperature, and that at the outer wall of the combined system maintains at formation temperature during fracturing.

- The combined cylinder is deemed as an axisymmetric problem.

2.2. Modelling

2.3. Model Solution

3. Thermal Stress Analysis of Cement Sheath for Fracturing Geothermal Well

3.1. Basic Input Parameters

3.2. Results and Discussion

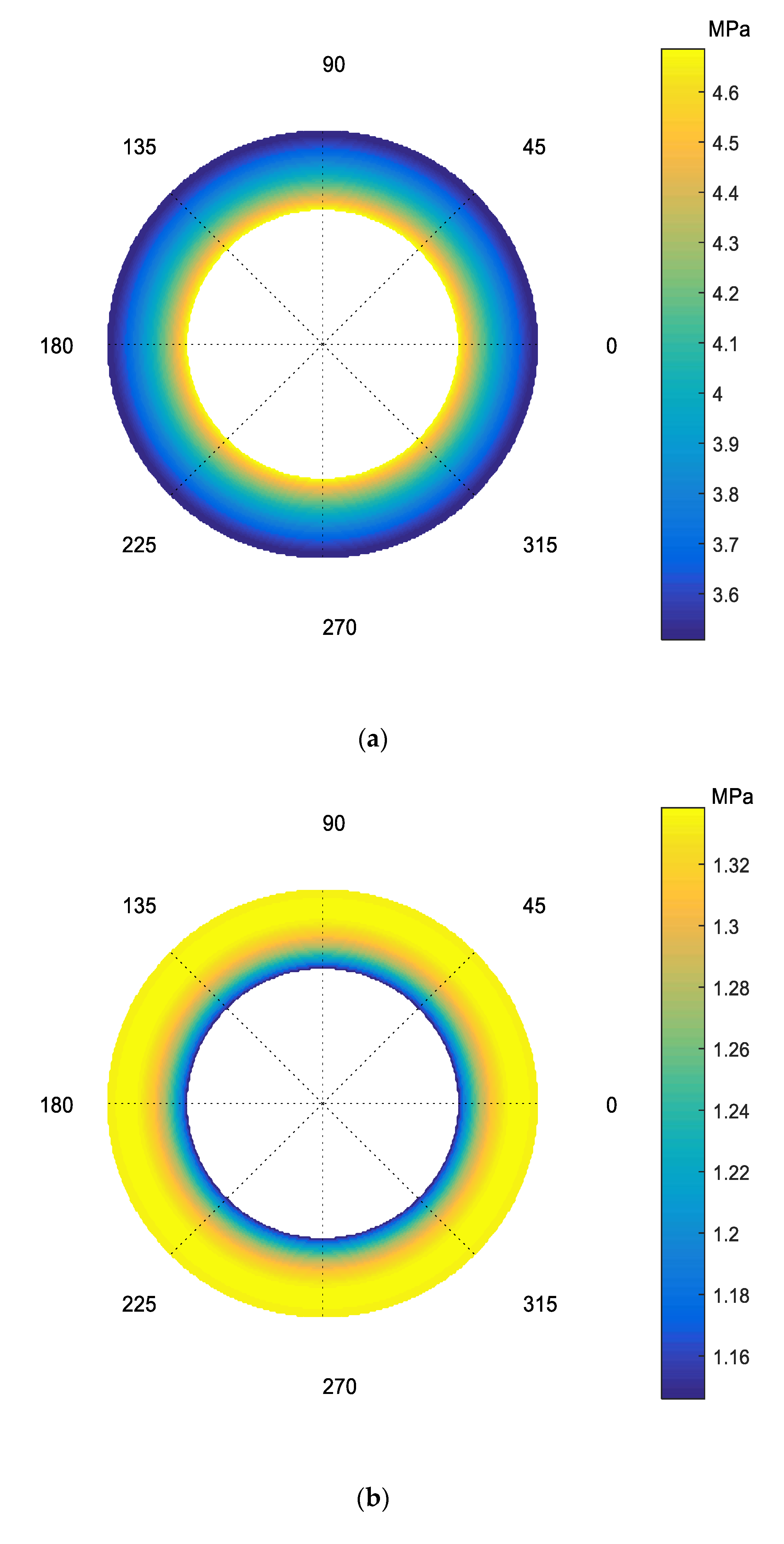

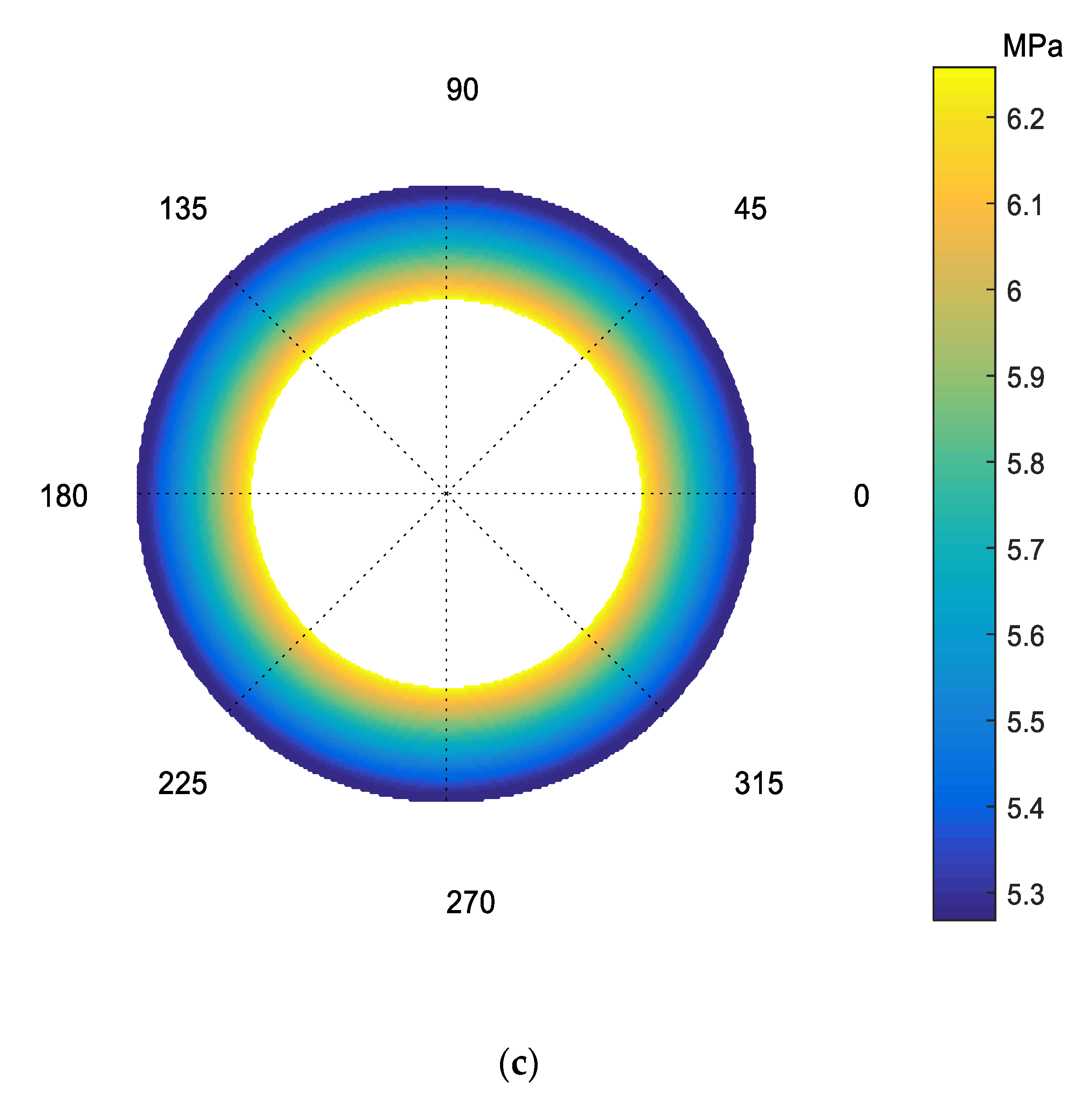

3.2.1. Thermal Stress under Basic Calculation Parameters

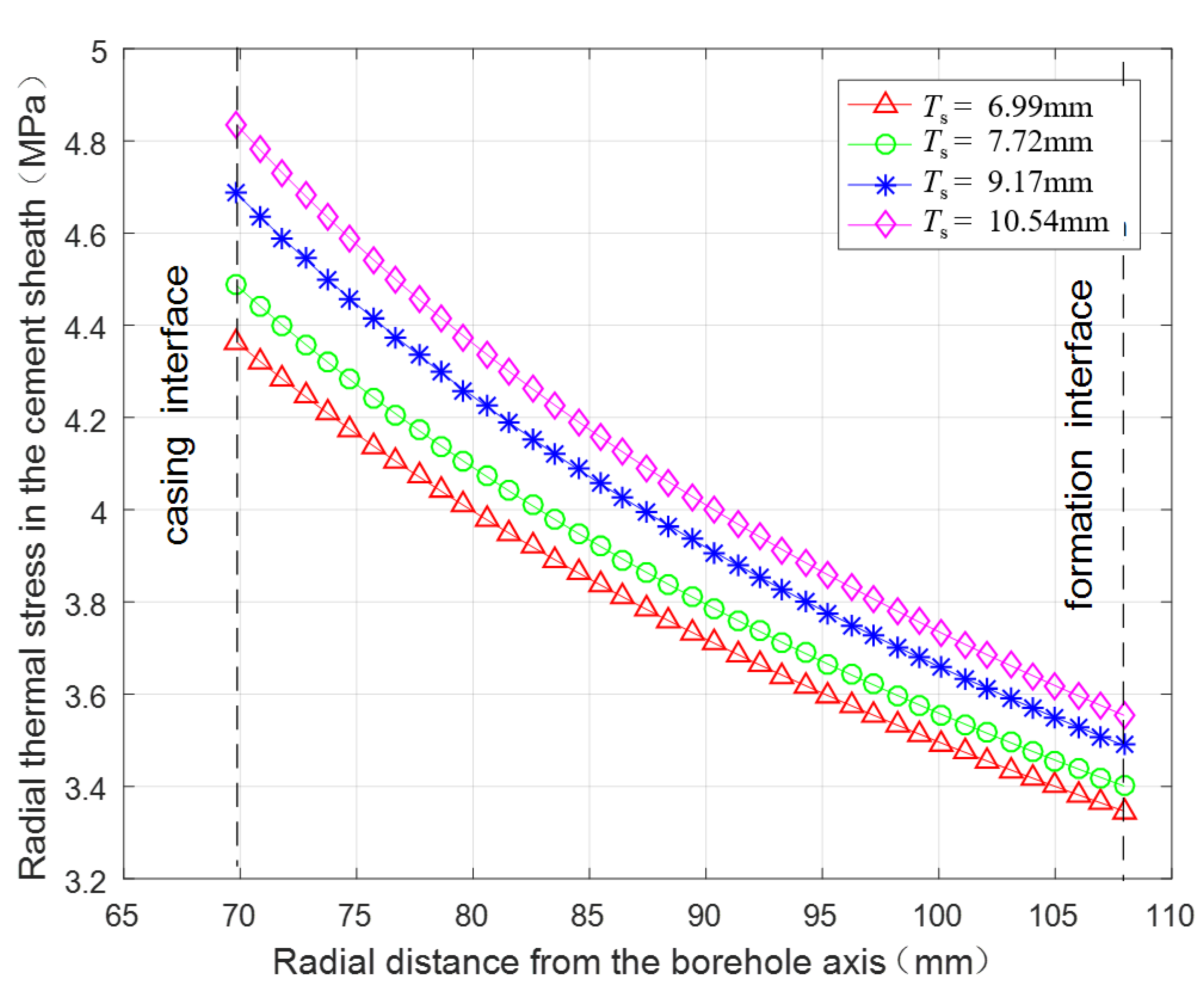

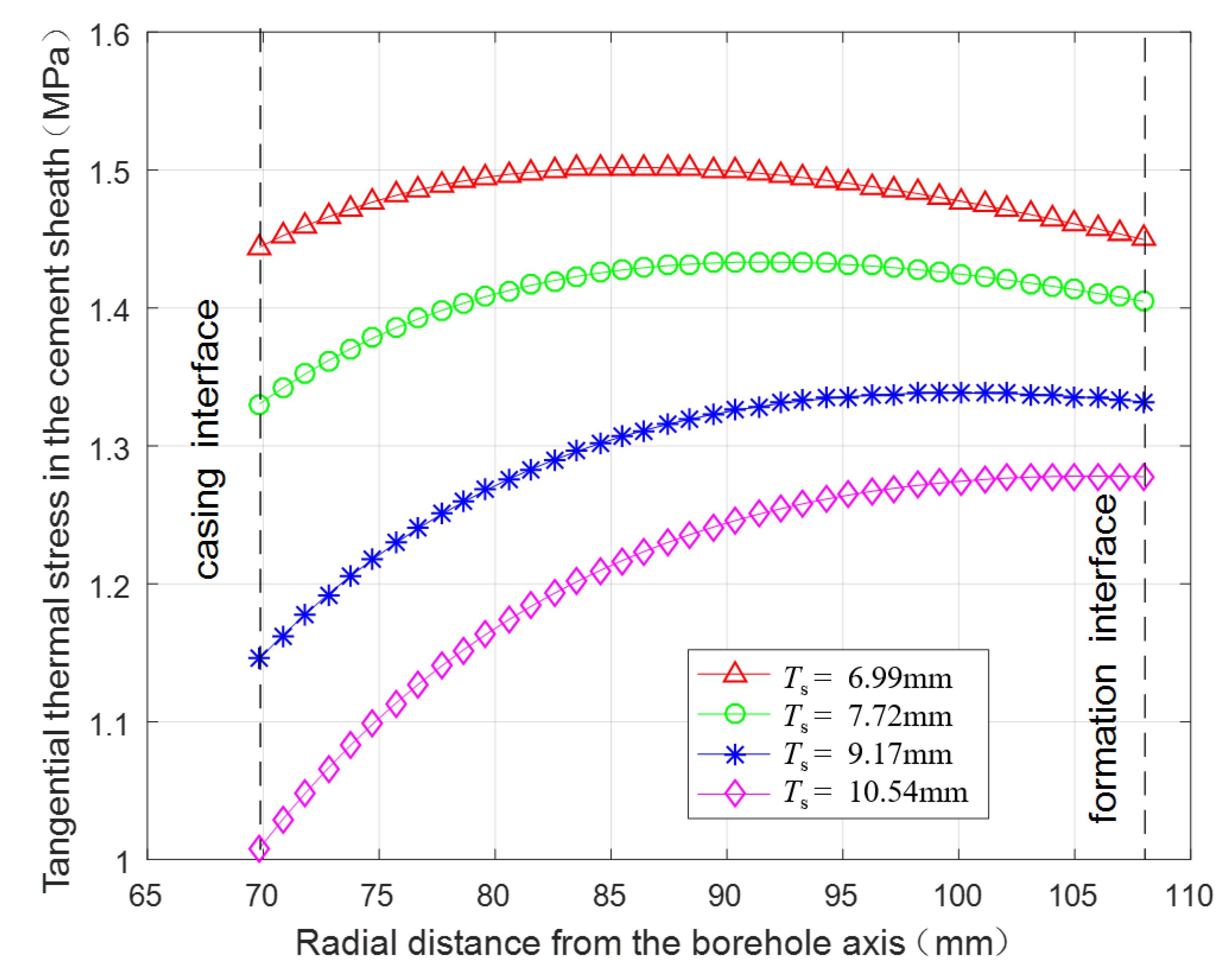

3.2.2. Thermal Stress under Different Wall Thicknesses of the Casing

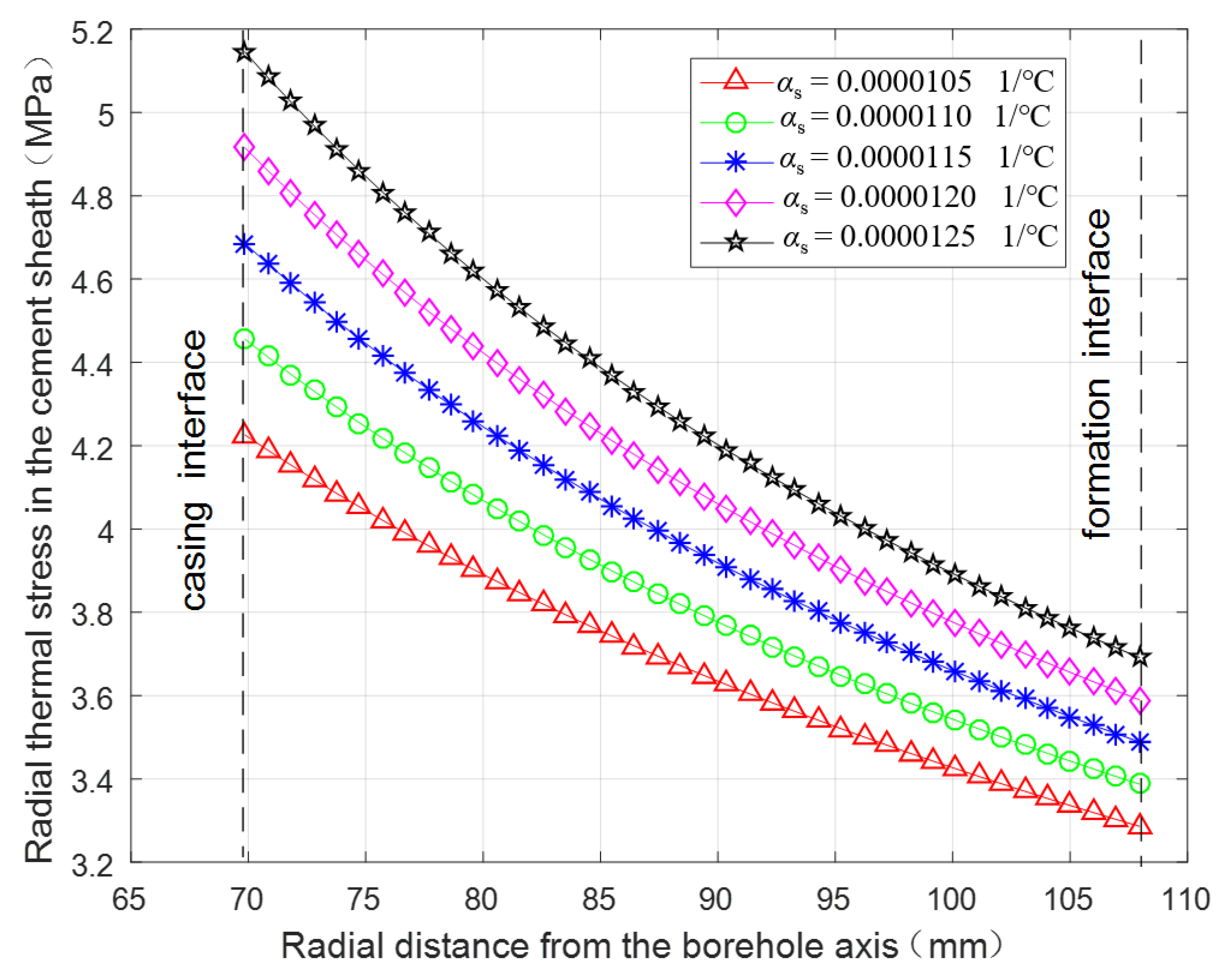

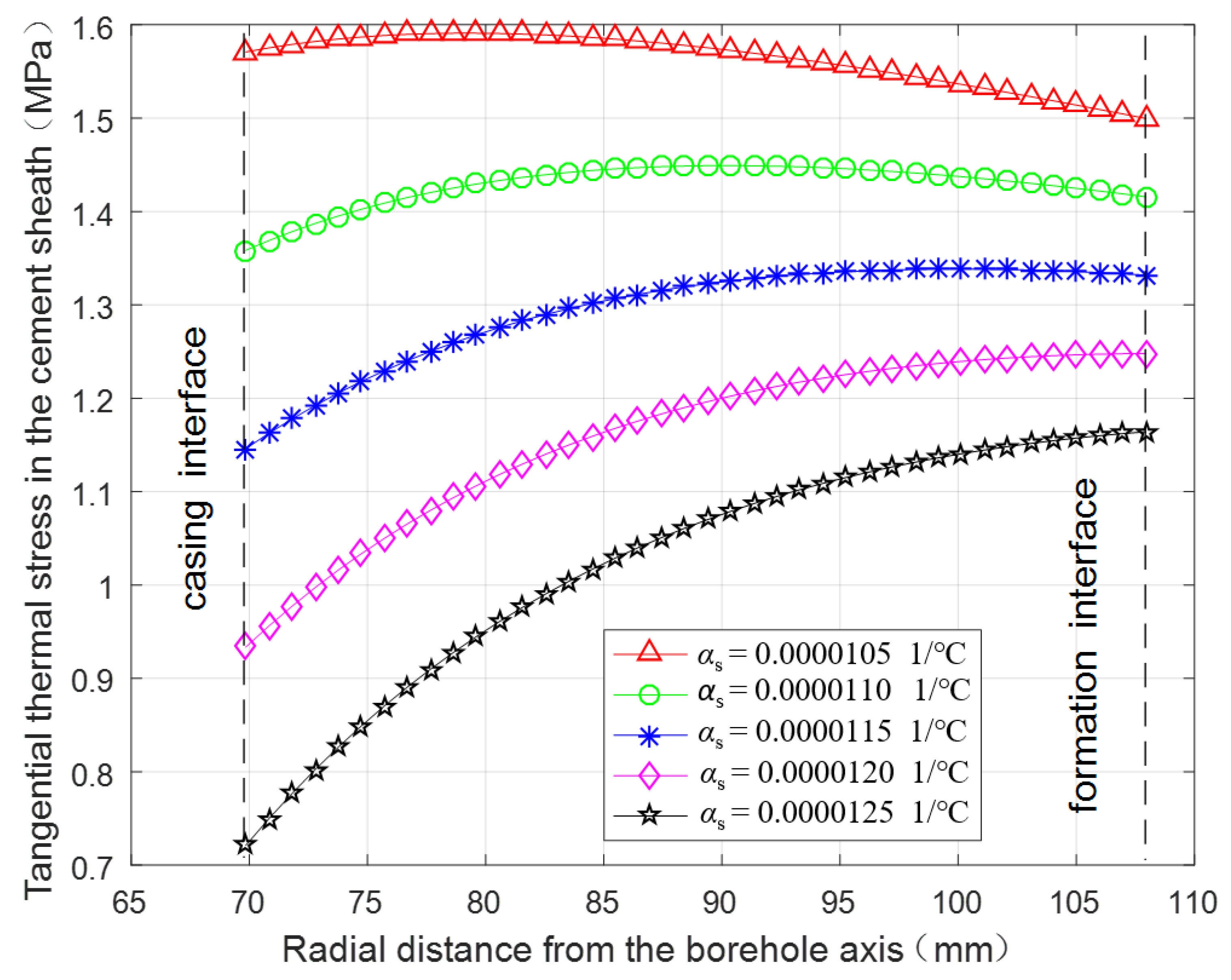

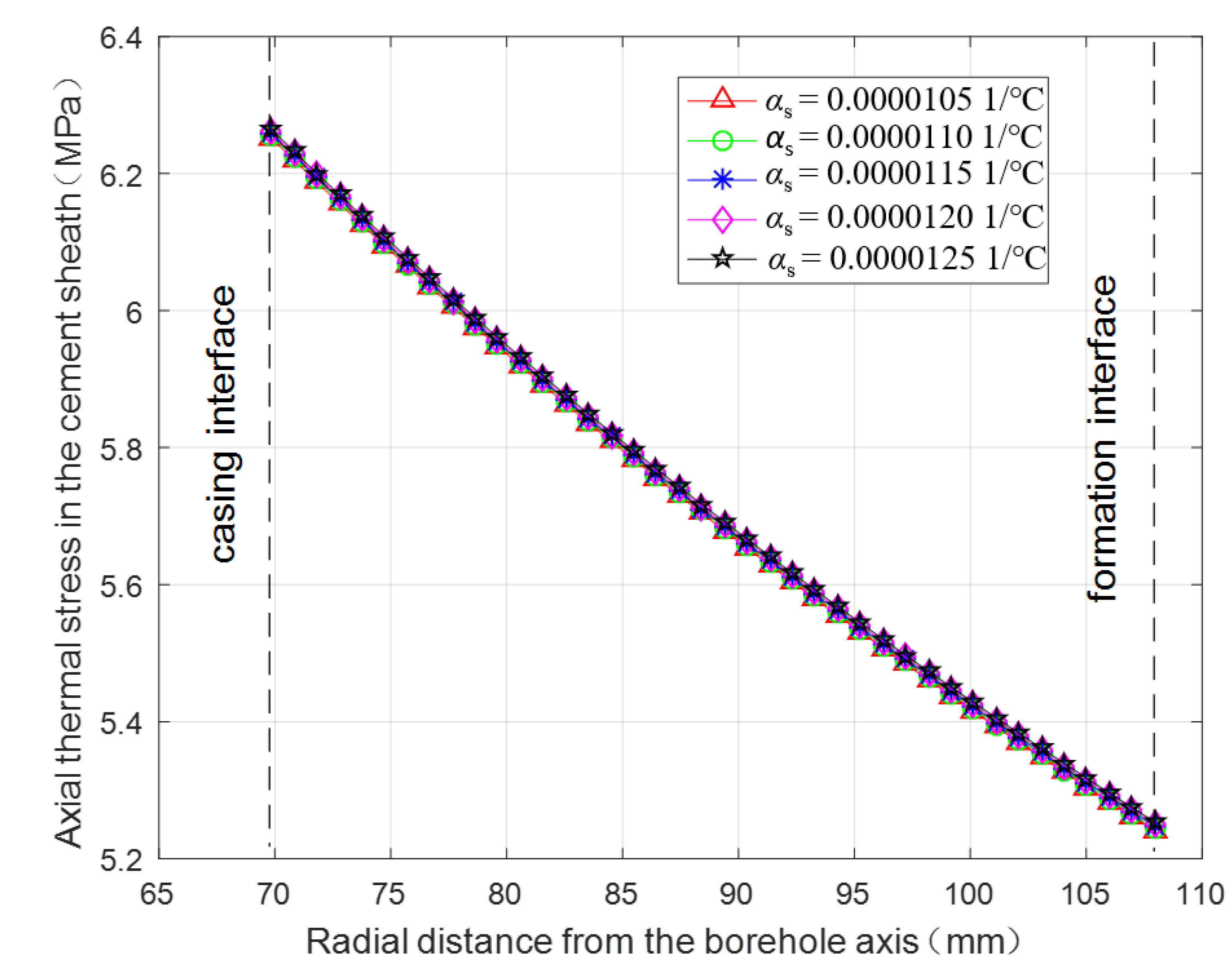

3.2.3. Thermal Stress under Different Linear Thermal Expansion Coefficients of the Casing

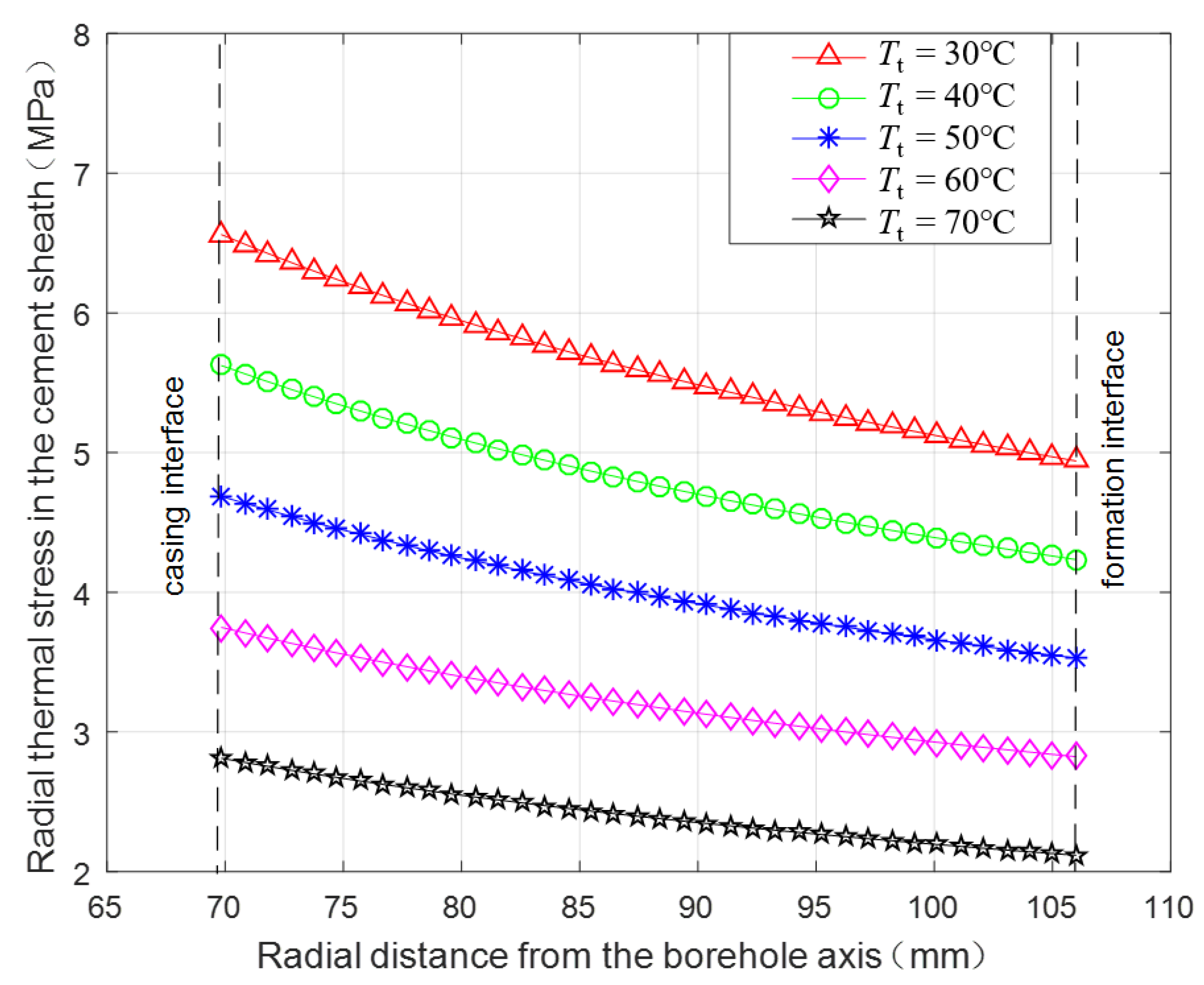

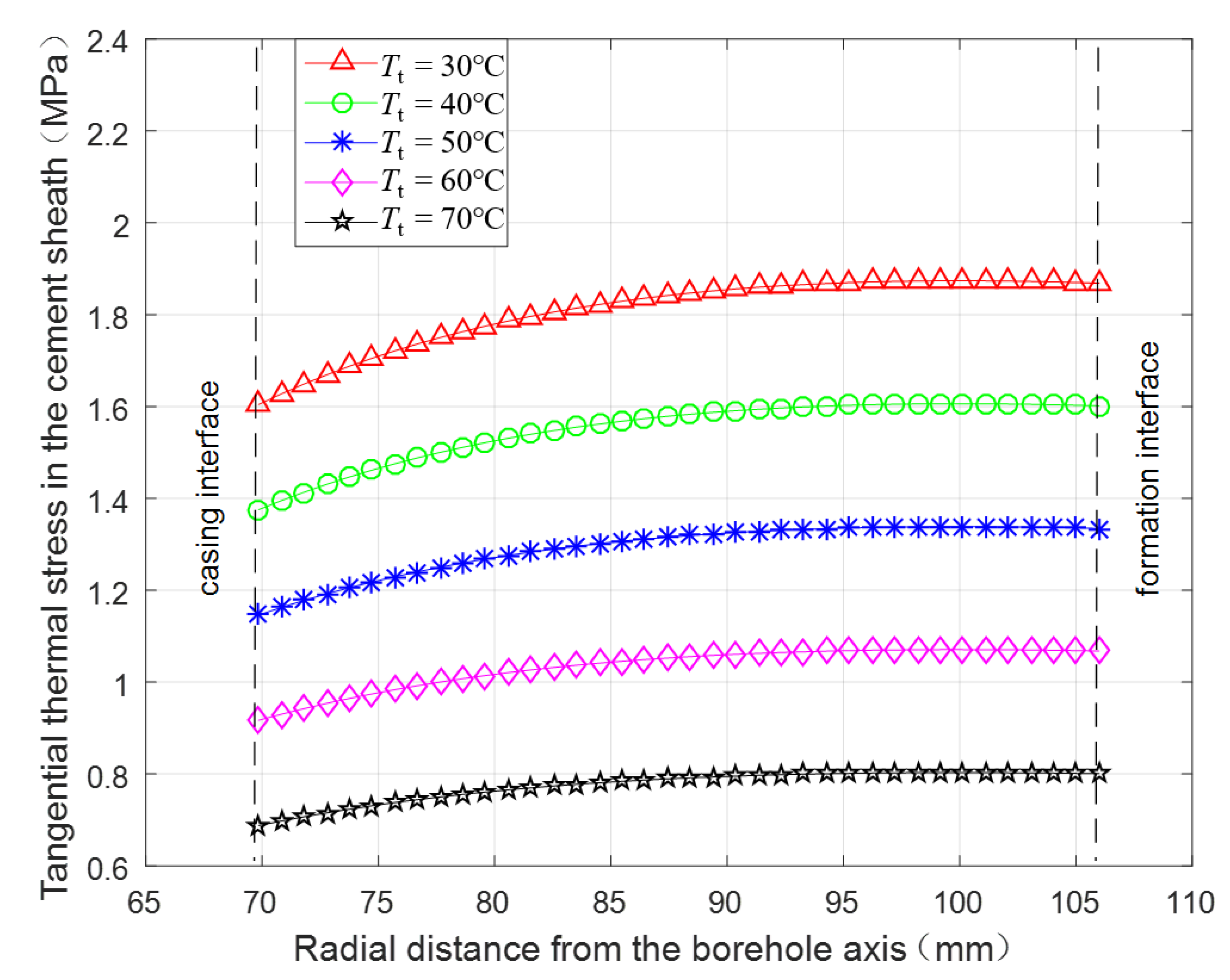

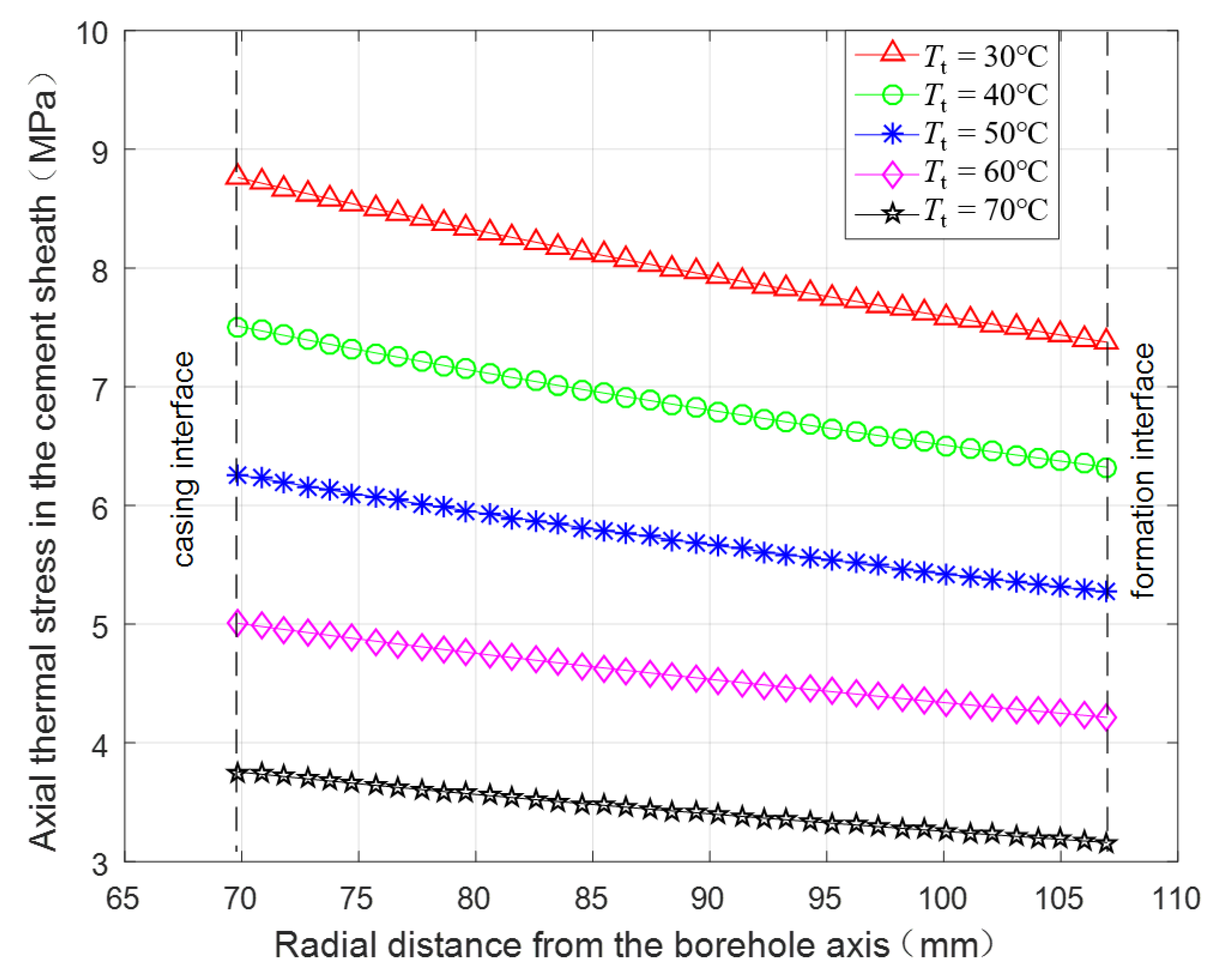

3.2.4. Thermal Stress under Different Wellbore Temperatures after Fracturing Fluid Injection

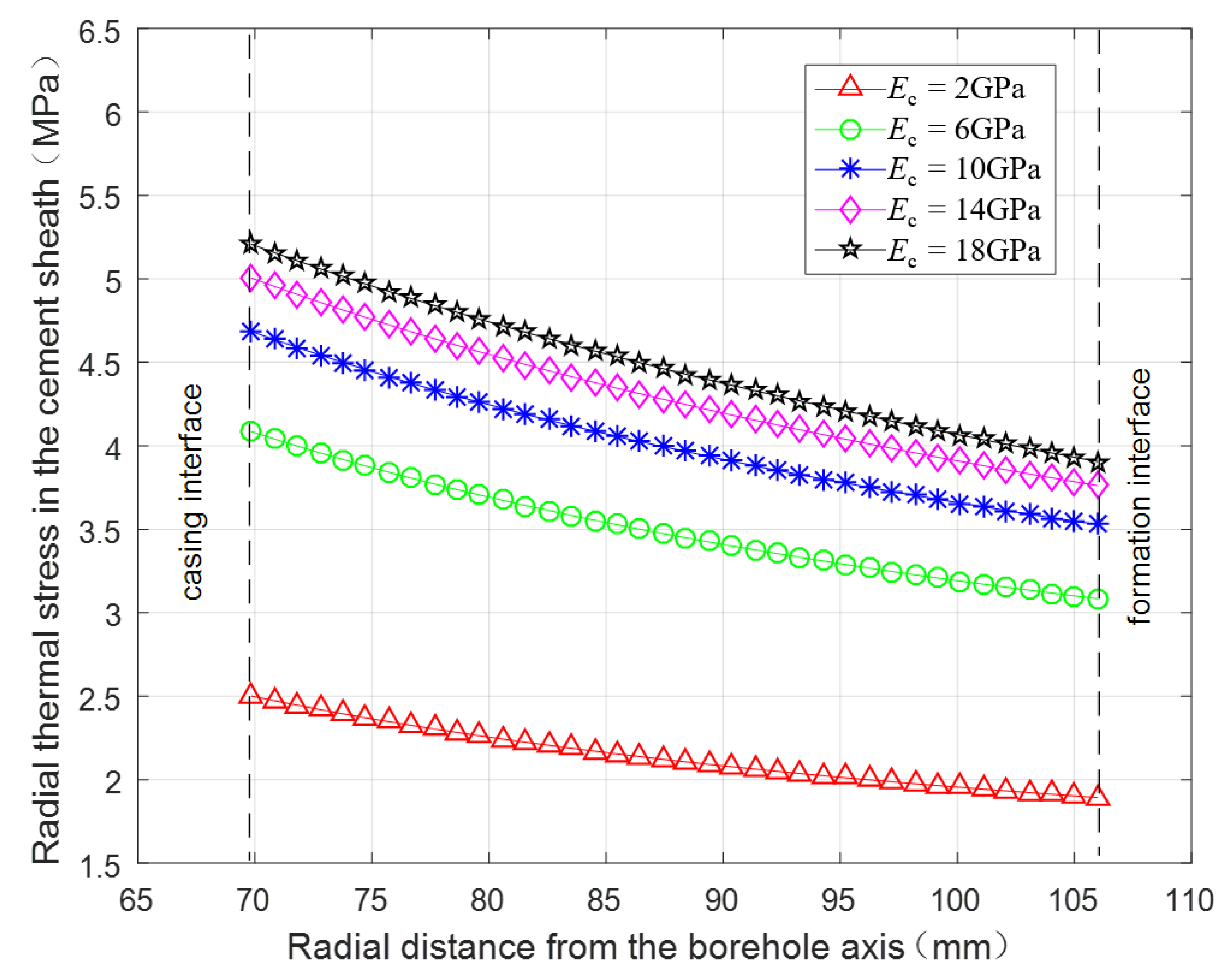

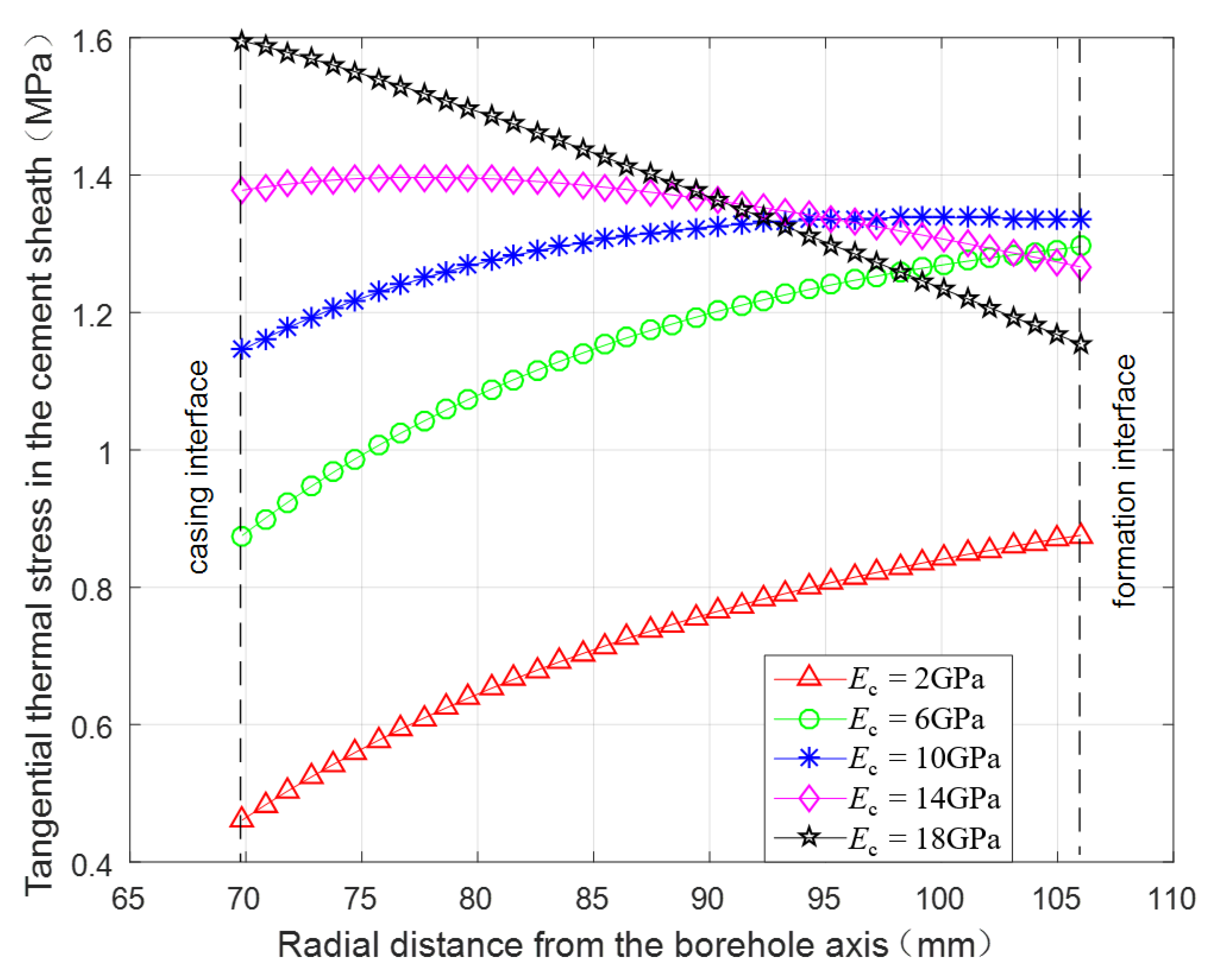

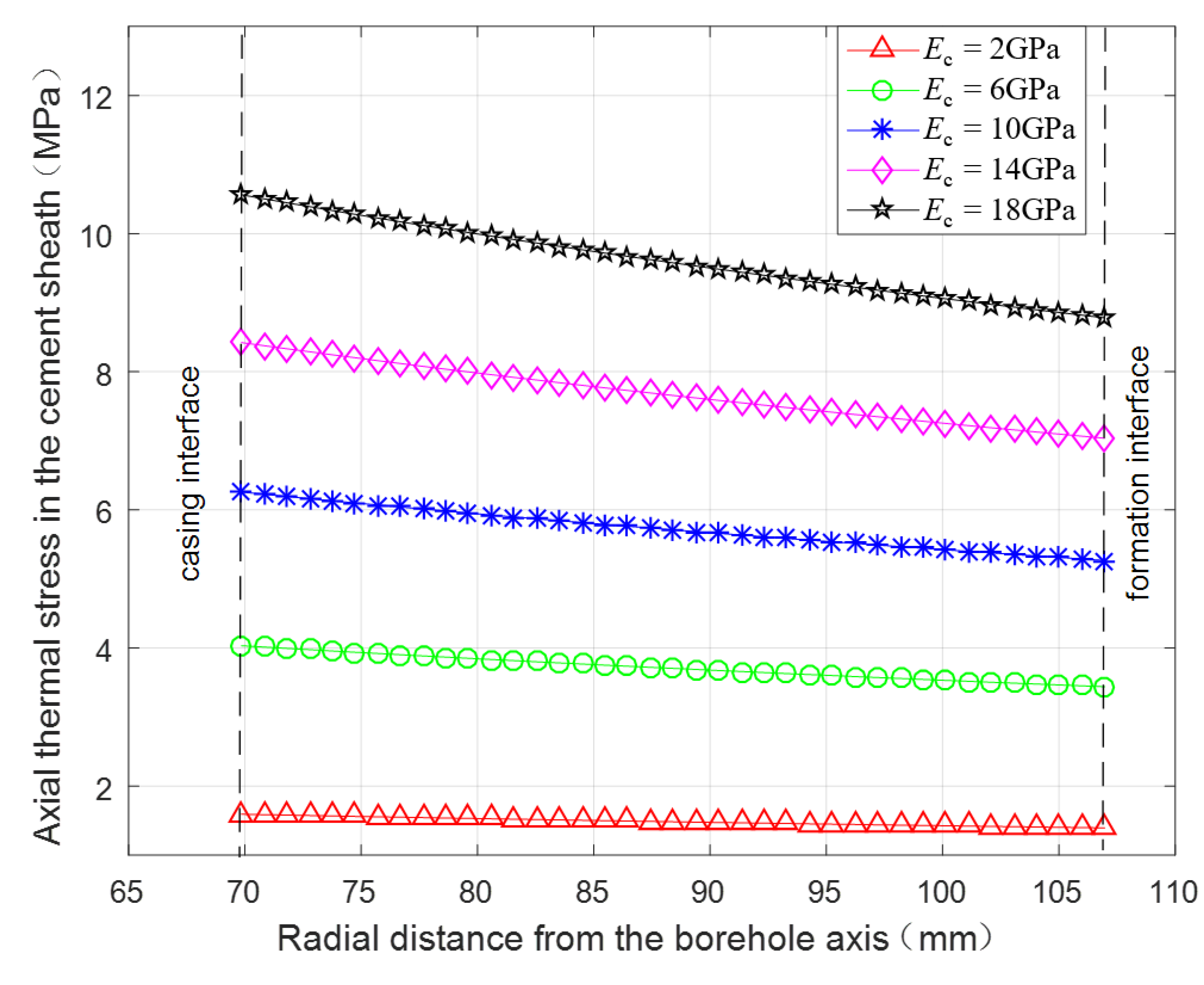

3.2.5. Thermal Stress under Different Elasticity Moduli of the Cement Sheath

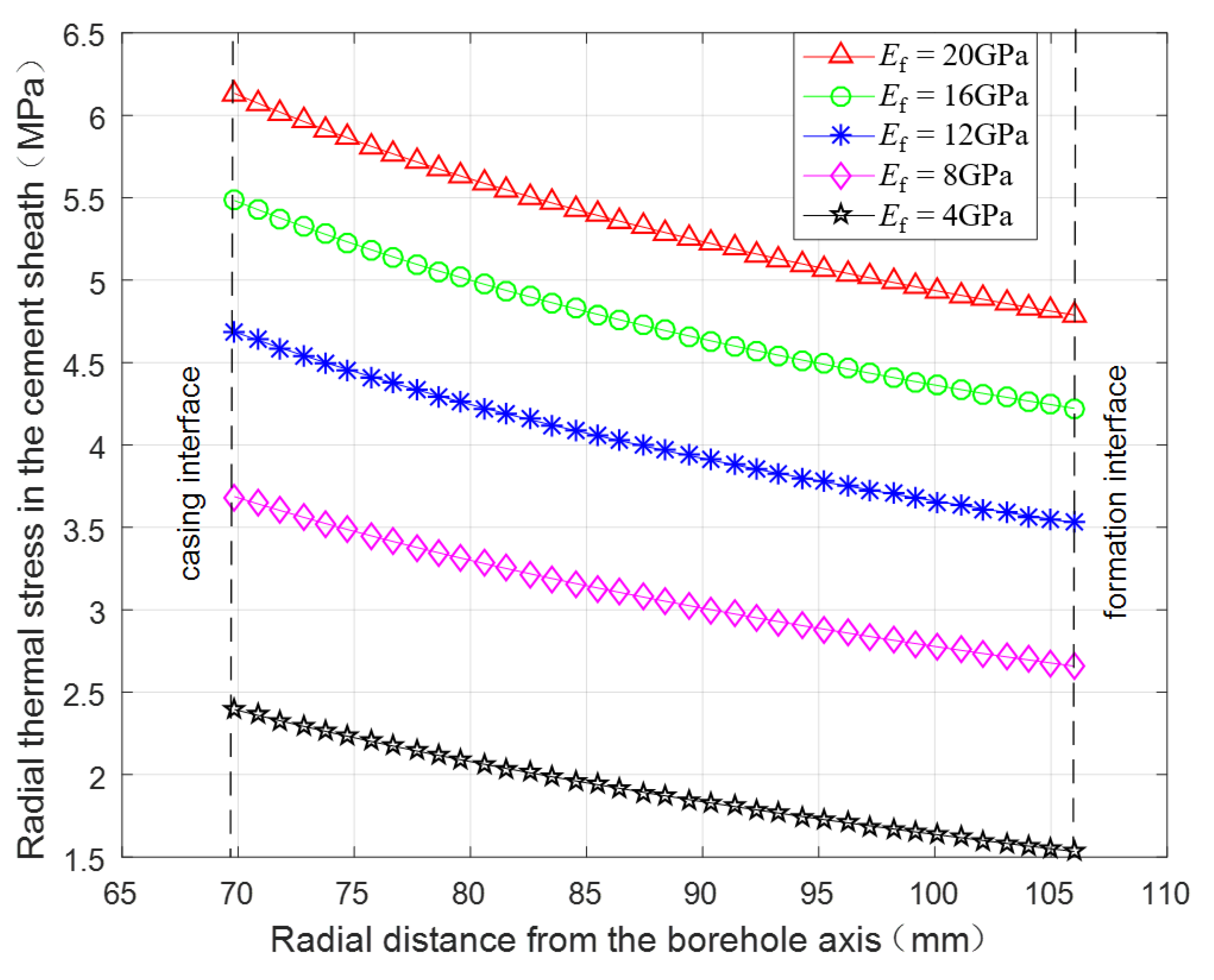

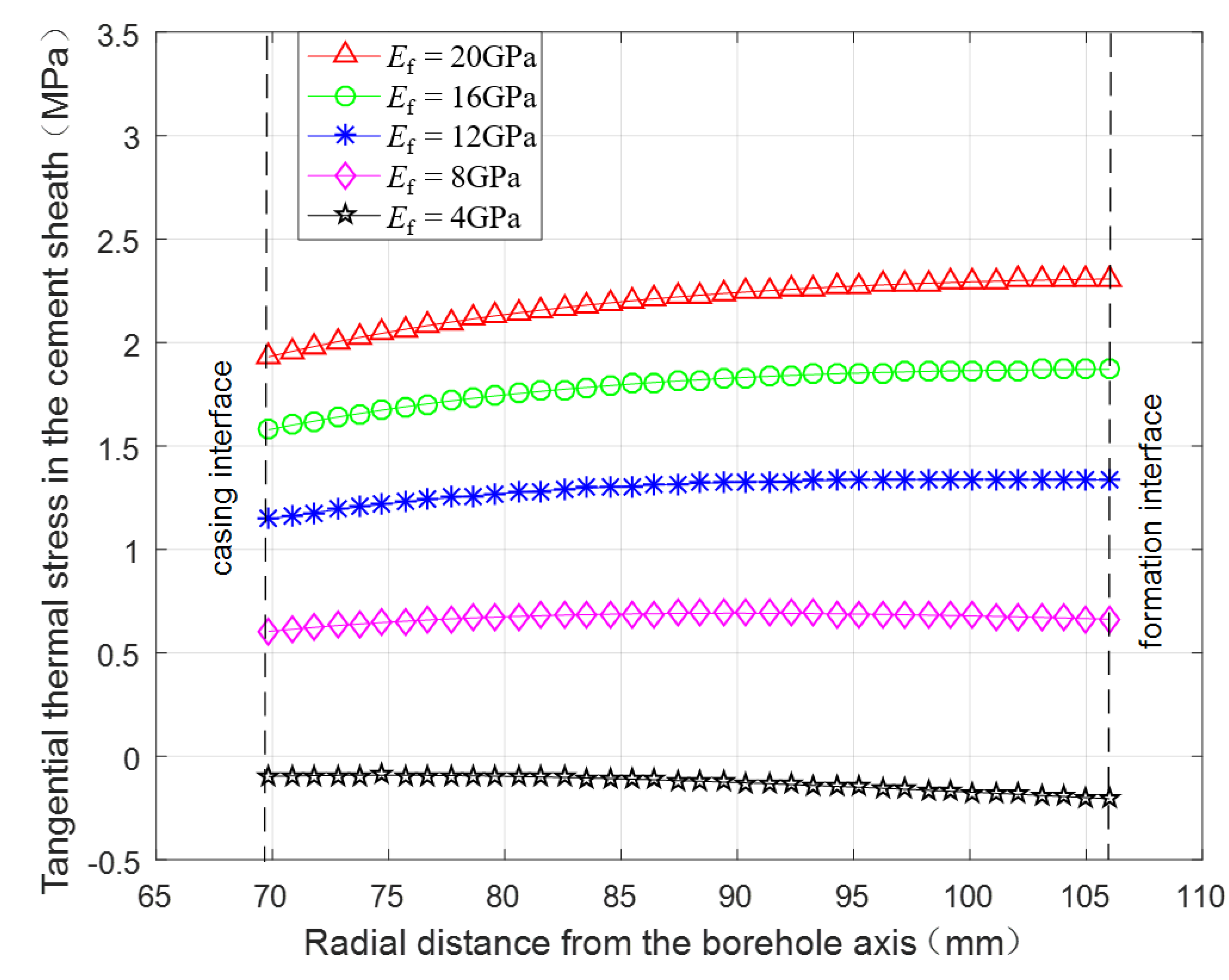

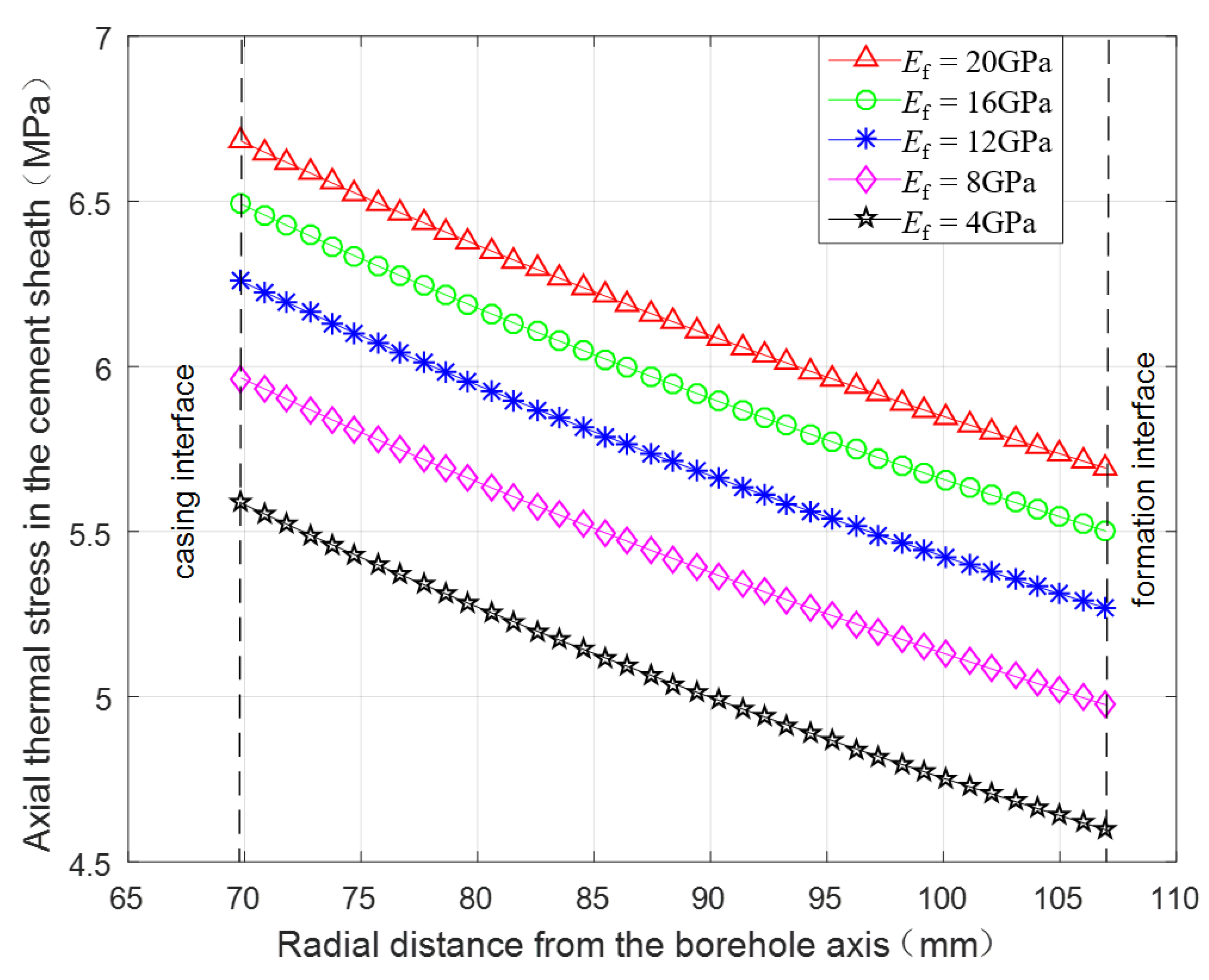

3.2.6. Thermal Stress under Different Elasticity Moduli of the Formation

4. Conclusions

- The radial and axial tensile thermal stresses are both obviously larger than tangential tensile thermal stress. The maximum radial and axial thermal stresses always occur at the casing interface while the location of the maximum tangential thermal stress is varying.

- The thermal stresses are more likely to induce radial and axial micro cracks in the cement sheath and cement sheath will fail more easily from the casing interface.

- Decreasing the casing wall thickness, casing linear thermal expansion coefficient, and cement sheath elasticity modulus, and increasing the fracturing fluid temperature can be effective for protecting cement sheath. The cement sheath will fail more easily in a formation with a higher elasticity modulus.

Author Contributions

Funding

Conflicts of Interest

List of Symbols

| εr, εθ, εz | Radial, tangential, and axial strain of cylinder, respectively, dimensionless |

| σr, σθ, σz | Radial, tangential, and axial thermal stress of cylinder, respectively, MPa |

| σrs, σθs, σzs | Radial, tangential, and axial thermal stress of casing, respectively, MPa |

| σrc, σθc, σzc | Radial, tangential, and axial thermal stress of cement sheath, respectively, MPa |

| σrf, σθf, σzf | Radial, tangential, and axial thermal stress of formation, respectively, MPa |

| u | Radial thermal displacement, mm |

| us, uc, uf | Radial thermal displacement for casing, cement sheath, and formation, respectively, mm |

| E, Es, Ec, Ef | Elasticity modulus of ordinary cylinder, casing, cement sheath, and formation respectively, MPa |

| μ, μs, μc, μf | Poisson’s ratio of ordinary cylinder, casing, cement sheath, and formation, respectively, dimensionless |

| α, αs, αc, αf | Linear thermal expansion coefficient of ordinary cylinder, casing, cement sheath, and formation, respectively, 1/°C |

| a | Internal radius of thick wall cylinder, mm |

| r | Radial distance from the axis of wellbore, mm |

| ri | Inside radius of casing, mm |

| r1 | Outside radius of casing or inside radius of cement sheath, mm |

| r2 | Outside radius of cement sheath or inside radius of formation, mm |

| ro | Outside radius of formation, mm |

| Ts | Wall thickness of the casing, mm |

| Tb(r) | Temperature value at the radius of r before fracturing fluid injection, °C |

| Ta(r) | Temperature value at the radius of r after fracturing fluid injection, °C |

| T(r) | Temperature change value at the radius of r after fracturing fluid injection, °C |

| Ti | Wellbore temperature before fracturing fluid injection, °C |

| Tt | Wellbore temperature after fracturing fluid injection, °C |

| Te | Formation temperature, °C |

| C1, C1s, C1c, C1f | Undetermined coefficients, dimensionless |

| C2, C2s, C2c, C2f | Undetermined coefficients, m2 |

| [A], {B} | Coefficient matrix and constant vector for Equation (15), respectively |

References

- Wang, K.; Yuan, B.; Ji, G.; Wu, X. A comprehensive review of geothermal energy extraction and utilization in oilfields. J. Pet. Sci. Eng. 2018, 168, 465–477. [Google Scholar] [CrossRef]

- Hou, J.; Cao, M.; Liu, P. Development and utilization of geothermal energy in China: Current practices and future strategies. Renew. Energy 2018, 125, 401–412. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, Q. Development of Geothermal Resources in China: A Review. J. Earth Sci. 2018, 29, 452–467. [Google Scholar] [CrossRef]

- Shao, S.; Ranjith, P.G.; Wasantha, P.L.P.; Chen, B.K. Experimental and numerical studies on the mechanical behaviour of Australian Strathbogie granite at high temperatures: An application to geothermal energy. Geothermics 2015, 54, 96–108. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Shao, S.; Chen, B.K.; Lashin, A.; AlArifi, N.; Rathnaweera, T.D. Mechanical behaviour of Australian Strathbogie granite under in-situ stress and temperature conditions: An application to geothermal energy extraction. Geothermics 2017, 65, 44–59. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Chen, B.K. Experimental investigation of quenching effect on mechanical, microstructural and flow characteristics of reservoir rocks: Thermal stimulation method for geothermal energy extraction. J. Pet. Sci. Eng. 2018, 162, 419–433. [Google Scholar] [CrossRef]

- Kumari, W.G.P.; Ranjith, P.G.; Perera, M.S.A.; Li, X.; Li, L.H.; Chen, B.K.; AvanthiIsaka, B.L.; De Silva, V.R.S. Hydraulic fracturing under high temperature and pressure conditions with micro CT applications: Geothermal energy from hot dry rocks. Fuel 2018, 230, 138–154. [Google Scholar] [CrossRef]

- Wu, B.; Ma, T.; Feng, G.; Chen, Z.; Zhang, X. An approximate solution for predicting the heat extraction and preventing heat loss from a closed-loop geothermal reservoir. Geofluids 2017, 2017, 2041072. [Google Scholar] [CrossRef]

- Yang, S.Q.; Ranjith, P.G.; Jing, H.W.; Tian, W.L.; Ju, Y. An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments. Geothermics 2017, 65, 180–197. [Google Scholar] [CrossRef]

- Bina, S.M.; Jalilinasrabady, S.; Fujii, H.; Pambudi, N.A. Classification of geothermal resources in Indonesia by applying exergy concept. Renew. Sustain. Energy Rev. 2018, 93, 499–506. [Google Scholar] [CrossRef]

- Moeck, I.S. Catalog of geothermal play types based on geologic controls. Renew. Sustain. Energy Rev. 2014, 37, 867–882. [Google Scholar] [CrossRef]

- Lu, S.M. A global review of enhanced geothermal system (EGS). Renew. Sustain. Energy Rev. 2018, 81, 2902–2921. [Google Scholar] [CrossRef]

- Wan, Z.; Zhao, Y.; Kang, J. Forecast and evaluation of hot dry rock geothermal resource in China. Renew. Energy 2005, 30, 1831–1846. [Google Scholar] [CrossRef]

- Hofmann, H.; Babadagli, T.; Yoon, J.S.; Blöcher, G.; Zimmermann, G. A hybrid discrete/finite element modeling study of complex hydraulic fracture developments for enhanced geothermal systems (EGS) in granitic basements. Geothermics 2016, 64, 362–381. [Google Scholar] [CrossRef]

- Hou, B.; Chen, M.; Zhimeng, L.I.; Wang, Y.; Diao, C. Propagation area evaluation of hydraulic fracture networks in shale gas reservoirs. Pet. Explor. Dev. 2014, 41, 833–838. [Google Scholar] [CrossRef]

- Shadravan, A.; Schubert, J.; Amani, M.; Teodoriu, C. HPHT cement sheath integrity evaluation method for unconventional wells. In Proceedings of the SPE International Conference on Health, Safety, and Environment, Long Beach, CA, USA, 17–19 March 2014; SPE 168321. Society of Petroleum Engineers: Richardson, TX, USA, 2014. [Google Scholar]

- Wang, W.; Taleghani, A.D. Cement sheath integrity during hydraulic fracturing: An integrated modeling approach. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 4–6 February 2014; SPE 168642. Society of Petroleum Engineers: Richardson, TX, USA, 2014. [Google Scholar]

- Vrålstad, T.; Skorpa, R.; Opedal, N.; Andrade, J.D. Effect of thermal cycling on cement sheath integrity: Realistic experimental tests and simulation of resulting leakages. In Proceedings of the SPE Thermal Well Integrity and Design Symposium, Banff, AB, Canada, 23–25 November 2015; SPE 178467. Society of Petroleum Engineers: Richardson, TX, USA, 2015. [Google Scholar]

- Tian, Z.; Shi, L.; Qiao, L. Research of and countermeasure for wellbore integrity of shale gas horizontal well. Nat. Gas Ind. 2015, 35, 70–76. [Google Scholar]

- Teodoriu, C.; Falcone, G. Comparing completion design in hydrocarbon and geothermal wells: The need to evaluate the integrity of casing connections subject to thermal stresses. Geothermics 2009, 38, 238–246. [Google Scholar] [CrossRef]

- Zhou, C.; Wan, Z.; Zhang, Y.; Gui, B. Experimental study on hydraulic fracturing of granite under thermal shock. Geothermics 2018, 71, 146–155. [Google Scholar] [CrossRef]

- Thiercelin, M.J.; Dargaud, B.; Baret, J.F.; Rodriquez, W.J. Cement design based on cement mechanical response. SPE Drill. Complet. 1998, 13, 266–273. [Google Scholar] [CrossRef]

- Jing, L.I.; Lin, C.Y.; Yang, S.C.; Zhi, Y.; Chen, S. Theoretical solution of thermal stress for casing-cement-formation coupling system. J. China Univ. Pet. 2009, 33, 63–69. [Google Scholar]

- Li, Y.; Liu, S.; Wang, Z.; Yuan, J.; Qi, F. Analysis of cement sheath coupling effects of temperature and pressure in non-uniform in-situ stress field. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 8–10 June 2010; SPE 131878. Society of Petroleum Engineers: Richardson, TX, USA, 2010. [Google Scholar]

- Teodoriu, C.; Ugwu, I.O.; Schubert, J.J. Estimation of casing-cement-formation interaction using a new analythical model. In Proceedings of the SPE EUROPEC/EAGE Annual Conference and Exhibition, Barcelona, Spain, 14–17 June 2010; SPE 131335. Society of Petroleum Engineers: Richardson, TX, USA, 2010. [Google Scholar]

- Bois, A.P.; Garnier, A.; Galdiolo, G.; Laudet, J.B. Use of a mechanistic model to forecast cement-sheath integrity. SPE Drill. Complet. 2012, 27, 303–314. [Google Scholar] [CrossRef]

- Haider, M.G.; Sanjayan, J.; Ranjith, P.G. Modeling of a wellbore composite cylinder system for cement sheath stress analysis in geological sequestration of CO2. In Proceedings of the 46th U.S. Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, 24–27 June 2012; ARMA 12-369. American Rock Mechanics Association: Alexandria, VA, USA, 2012. [Google Scholar]

- Bui, B.T.; Tutuncu, A.N. Modeling the failure of cement sheath in anisotropic stress field. In Proceedings of the SPE Unconventional Resources Conference Canada, Calgary, AB, Canada, 5–7 November 2013; SPE 167178. Society of Petroleum Engineers: Richardson, TX, USA, 2013. [Google Scholar]

- Xu, H.; Zhang, Z.; Shi, T.; Xiong, J.Y. Influence of the WHCP on cement sheath stress and integrity in HTHP gas well. J. Pet. Sci. Eng. 2015, 126, 174–180. [Google Scholar]

- Xu, B.; Wang, J. Theory of Elastic Mechanics; Tsinghua University Press: Beijing, China, 2007. [Google Scholar]

- Li, Q.; Wang, N. Numerical Analysis; Tsinghua University Press: Beijing, China, 2008. [Google Scholar]

| Number | Symbol | Value | Unit | Number | Symbol | Value | Unit |

|---|---|---|---|---|---|---|---|

| 1 | ri | 60.68 | mm | 9 | Ec | 10 | GPa |

| 2 | r1 | 69.85 | mm | 10 | Ef | 12 | GPa |

| 3 | r2 | 107.95 | mm | 11 | μs | 0.30 | dimensionless |

| 4 | ro | 1079.5 | mm | 12 | μc | 0.19 | dimensionless |

| 5 | αs | 1.15 × 10−5 | 1/°C | 13 | μf | 0.21 | dimensionless |

| 6 | αc | 1.03 × 10−5 | 1/°C | 14 | Ti | 100 | °C |

| 7 | αf | 1.03 × 10−5 | 1/°C | 15 | Tt | 50 | °C |

| 8 | Es | 206 | GPa | 16 | Te | 100 | °C |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Peng, N.; Ma, T.; Yang, B. Investigation of Thermal Stress of Cement Sheath for Geothermal Wells during Fracturing. Energies 2018, 11, 2581. https://doi.org/10.3390/en11102581

Xu H, Peng N, Ma T, Yang B. Investigation of Thermal Stress of Cement Sheath for Geothermal Wells during Fracturing. Energies. 2018; 11(10):2581. https://doi.org/10.3390/en11102581

Chicago/Turabian StyleXu, Honglin, Nian Peng, Tianshou Ma, and Bin Yang. 2018. "Investigation of Thermal Stress of Cement Sheath for Geothermal Wells during Fracturing" Energies 11, no. 10: 2581. https://doi.org/10.3390/en11102581

APA StyleXu, H., Peng, N., Ma, T., & Yang, B. (2018). Investigation of Thermal Stress of Cement Sheath for Geothermal Wells during Fracturing. Energies, 11(10), 2581. https://doi.org/10.3390/en11102581