Investigation of Sectional-Stage Loading Strategies on a Two-Stage Turbocharged Heavy-Duty Diesel Engine under Transient Operation with EGR

Abstract

:1. Introduction

2. Experimental Work

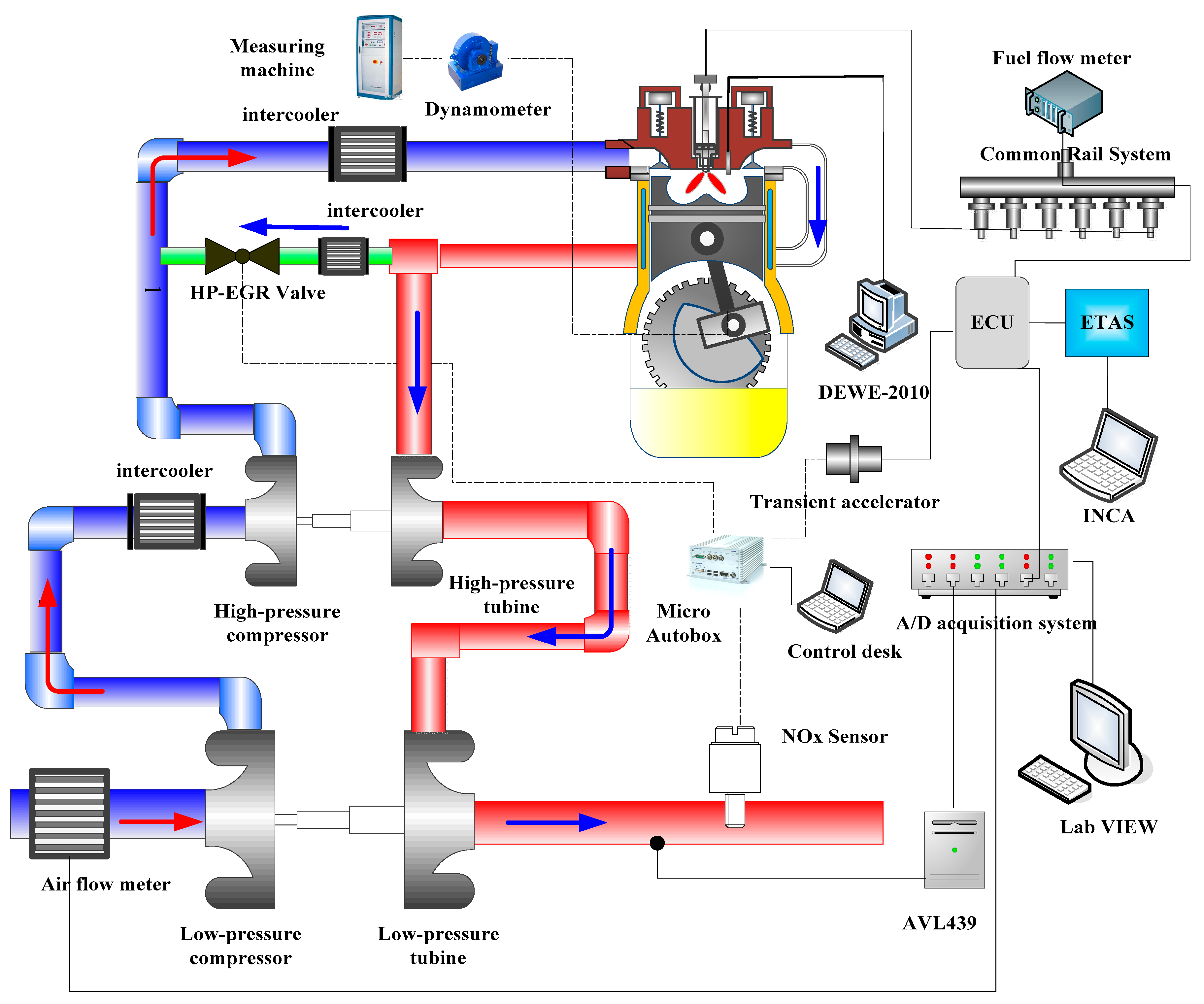

2.1. Experimental Setup and Procedure

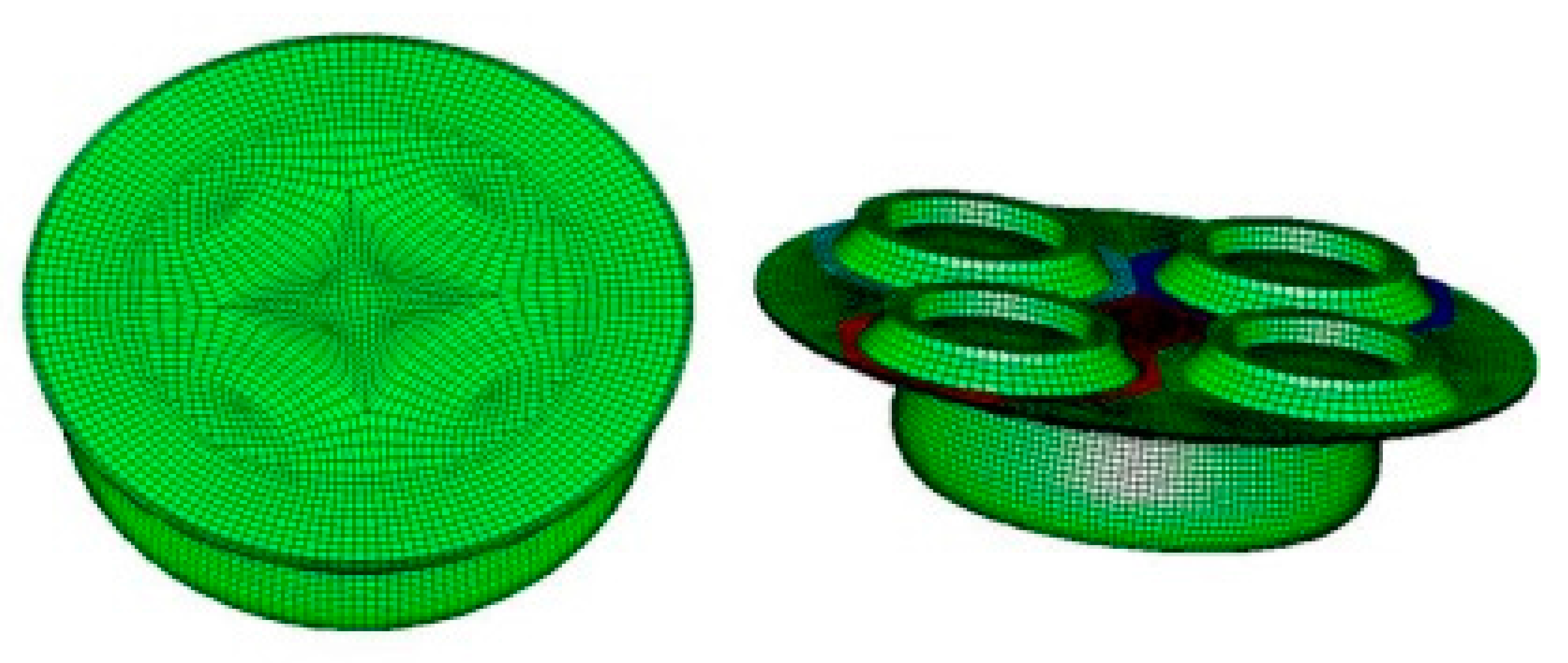

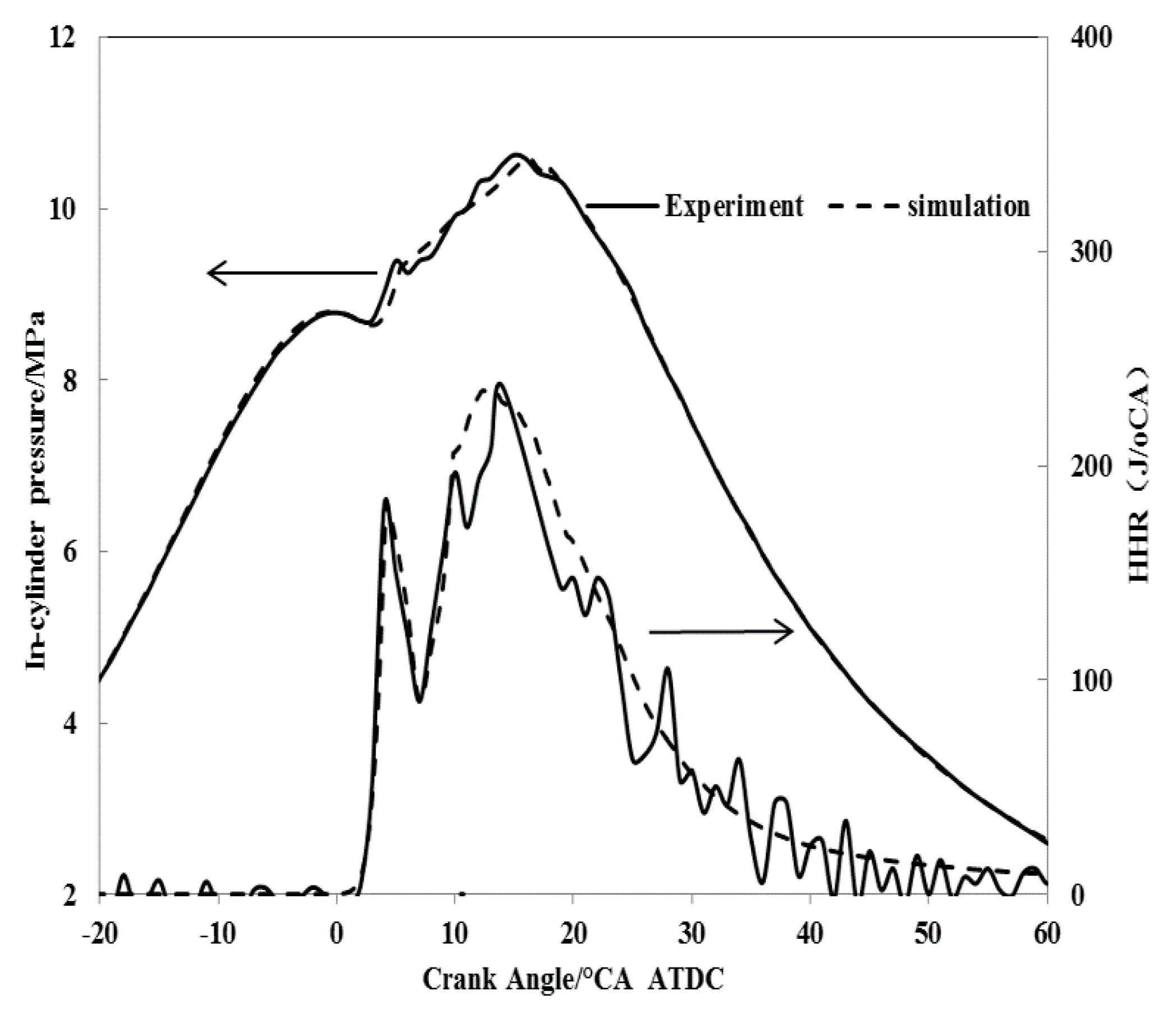

2.2. Simulation Model

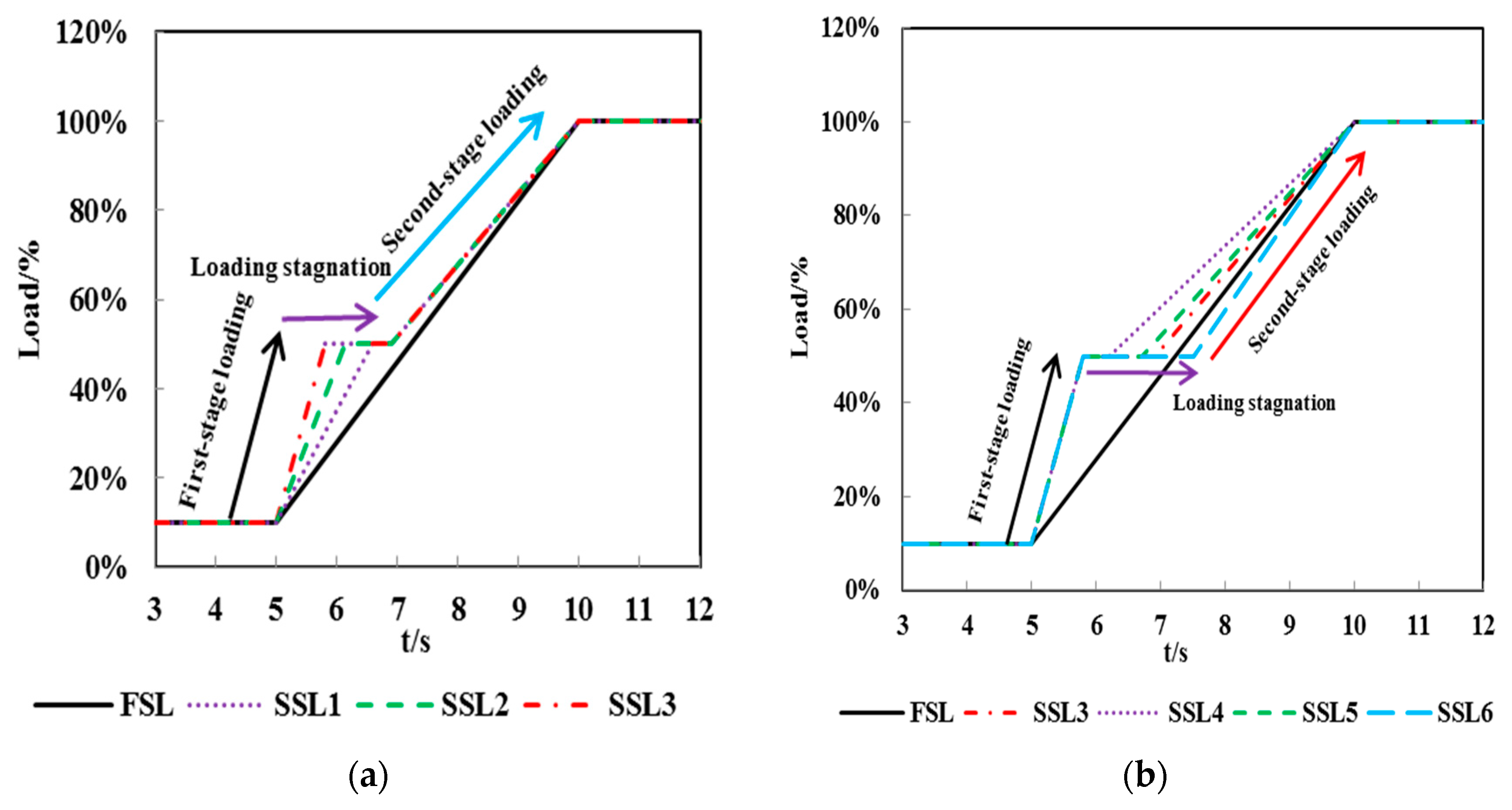

2.3. Test Conditions

3. Results and Discussion

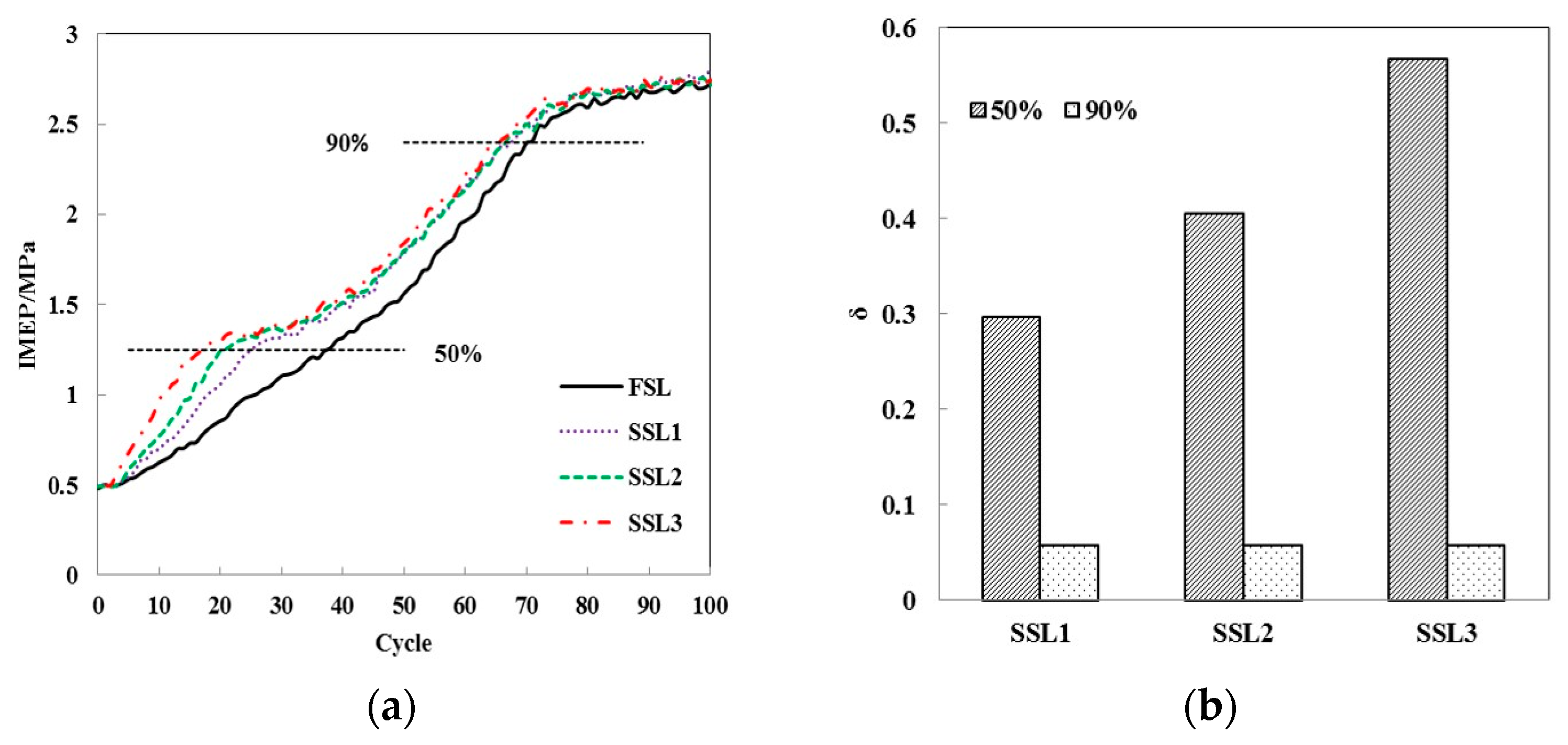

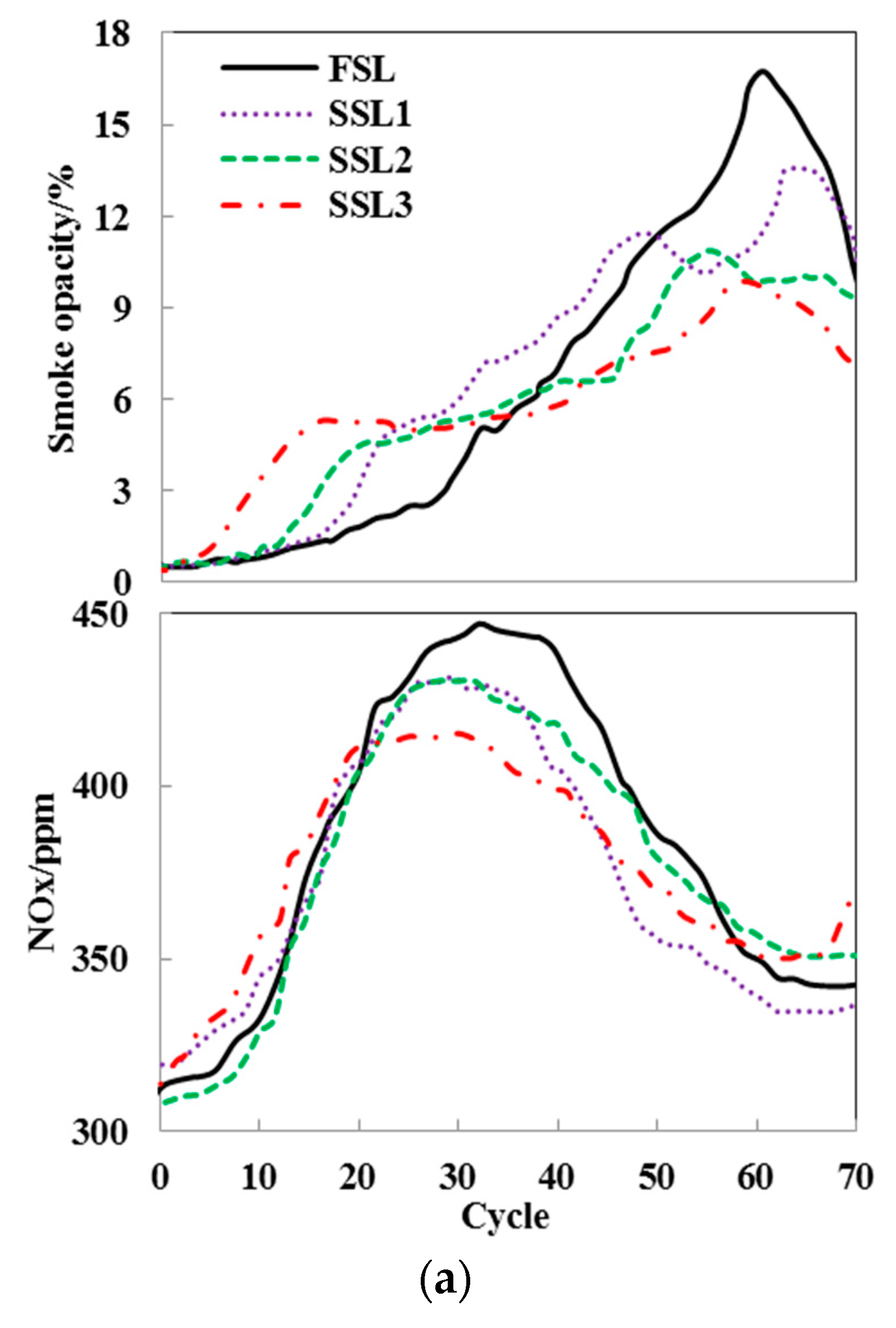

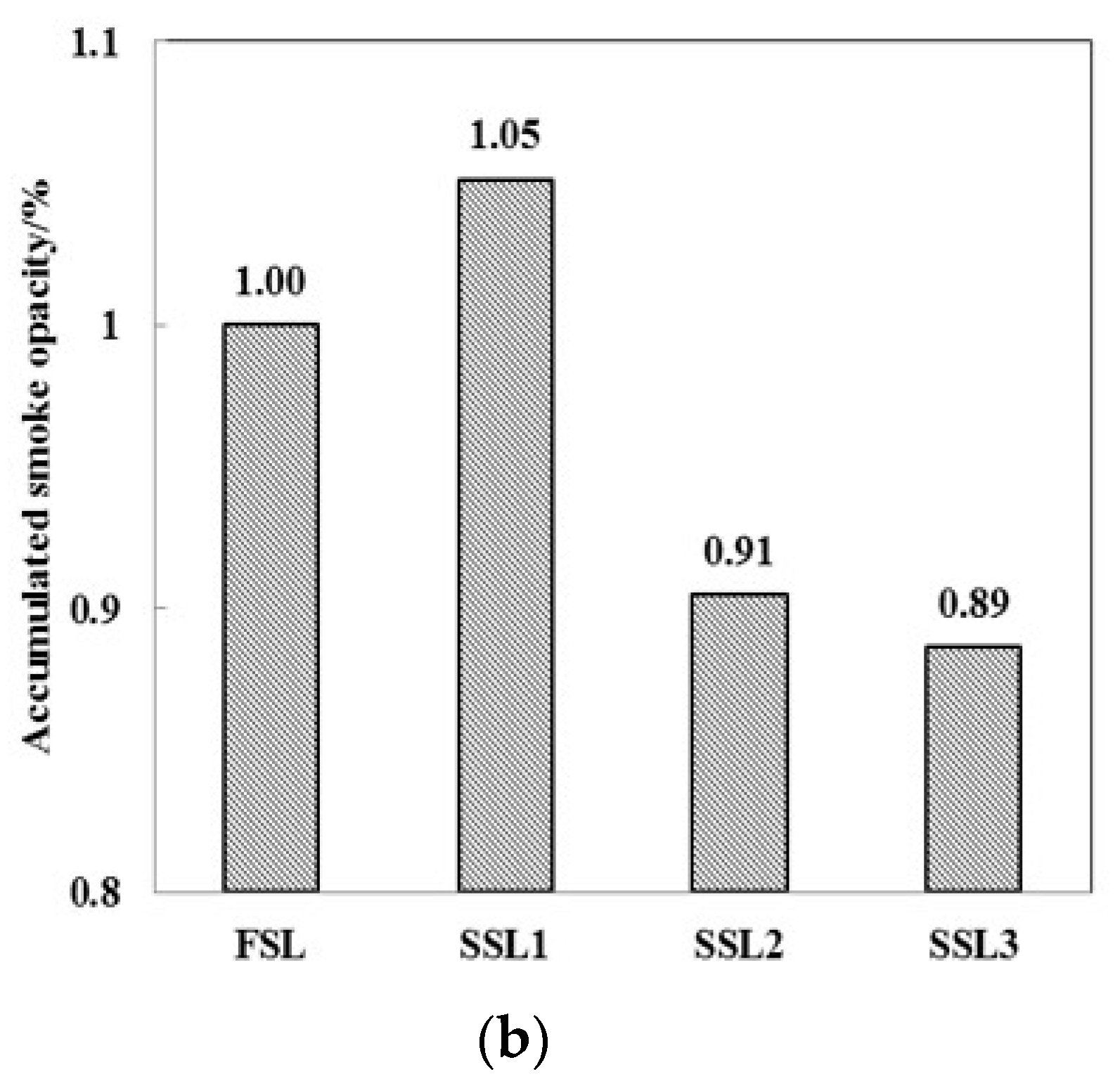

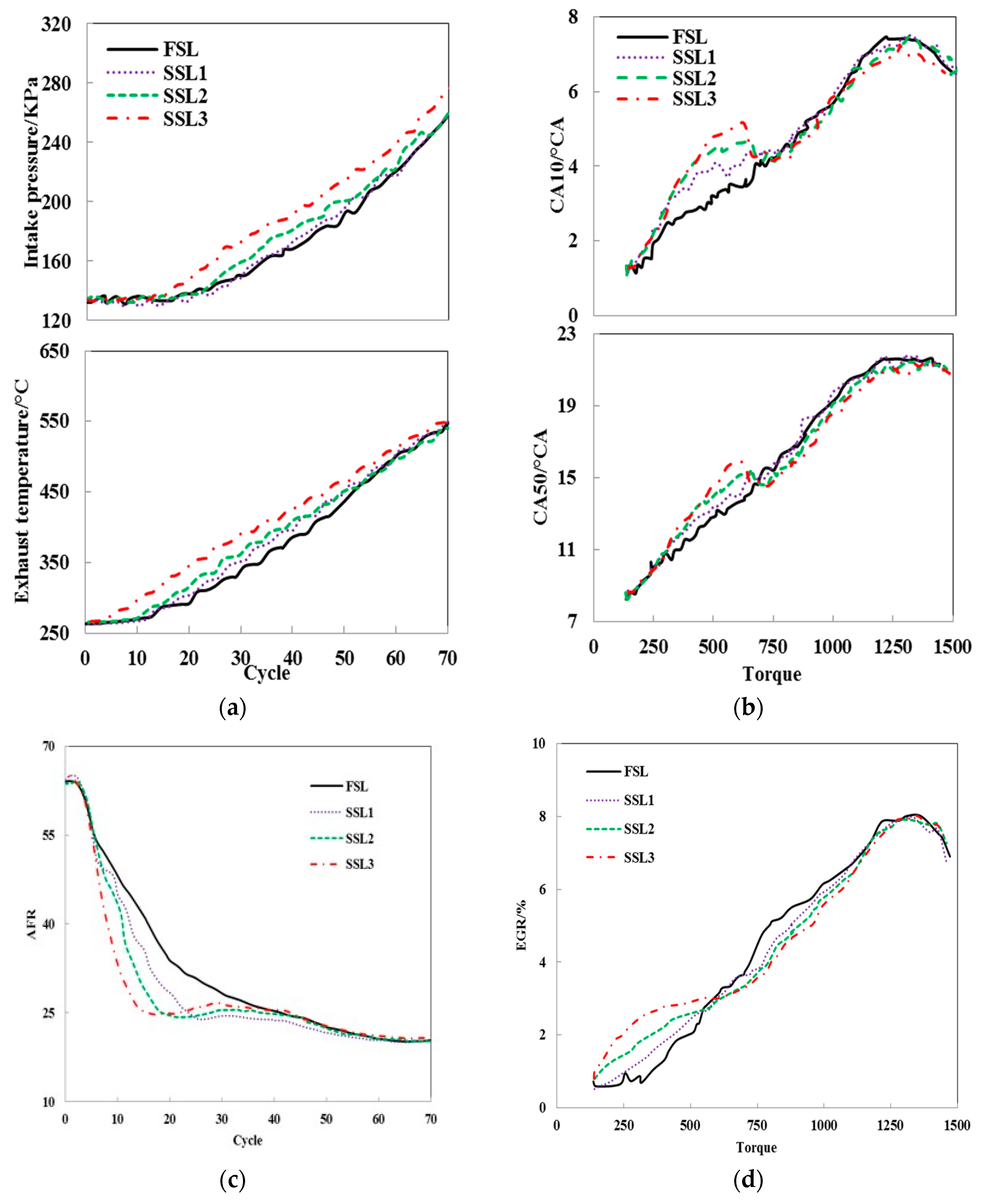

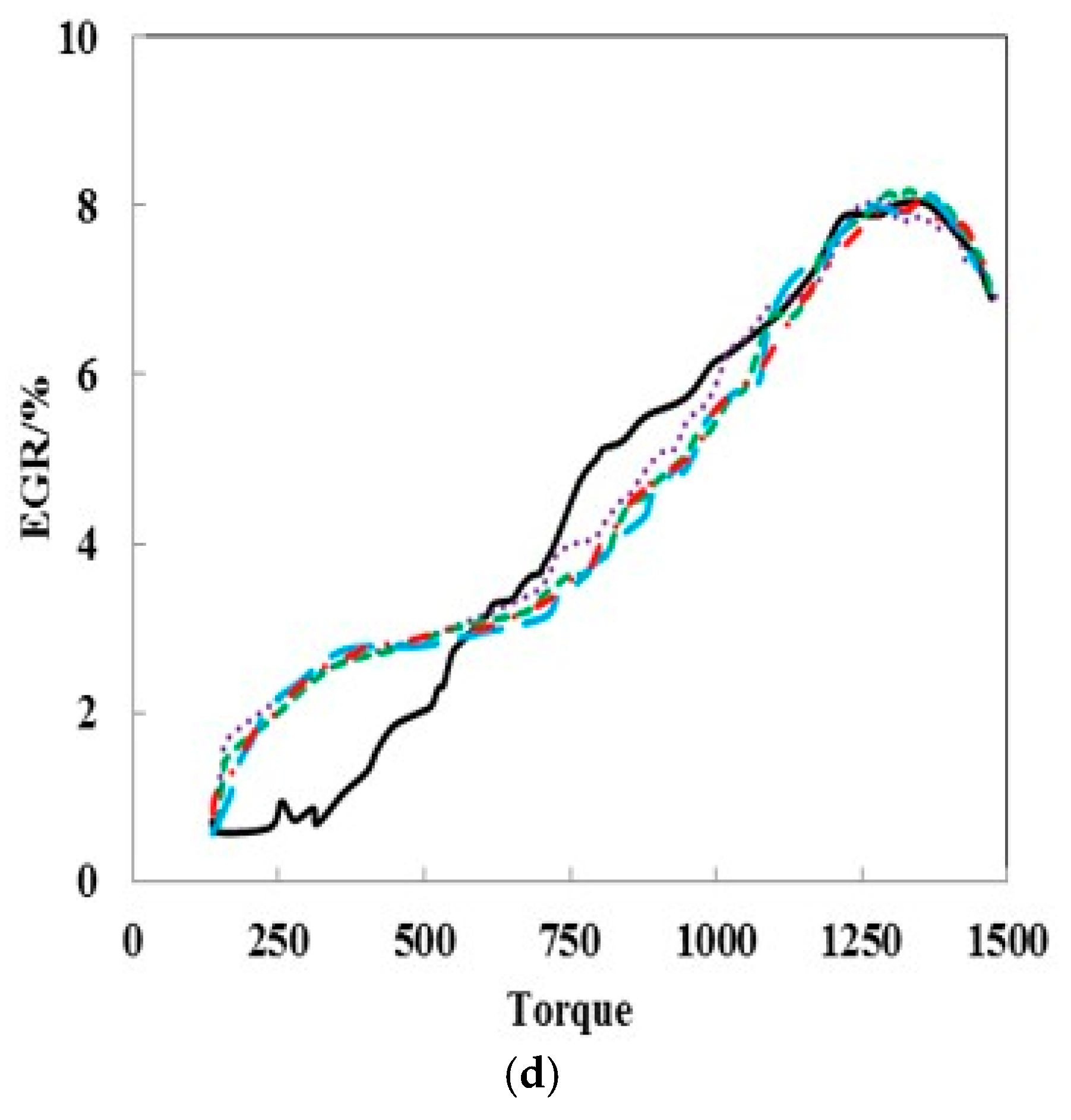

3.1. Influence of Different First-Stage Loading Rates and Loading Hold Times on Transient Performance

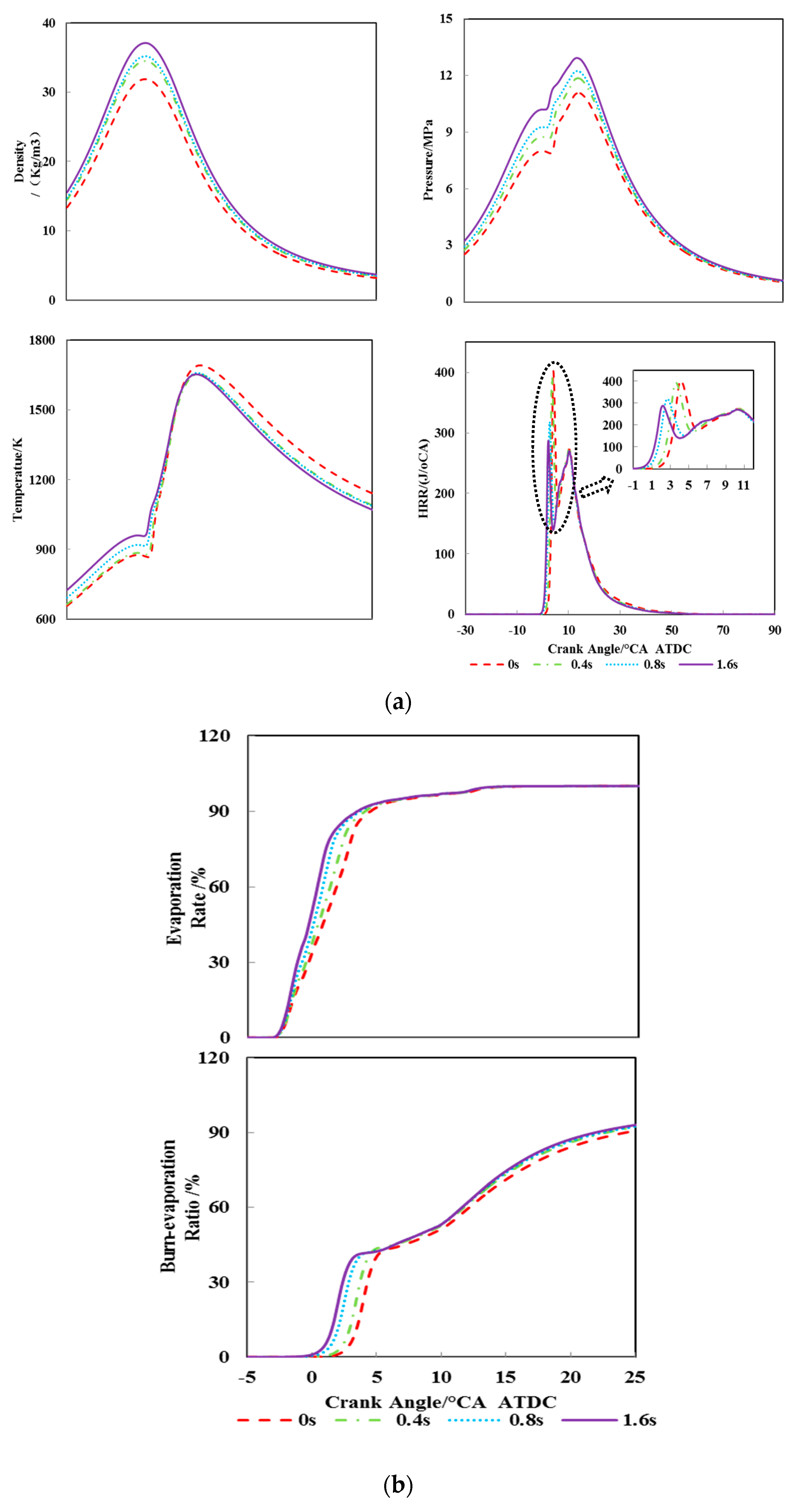

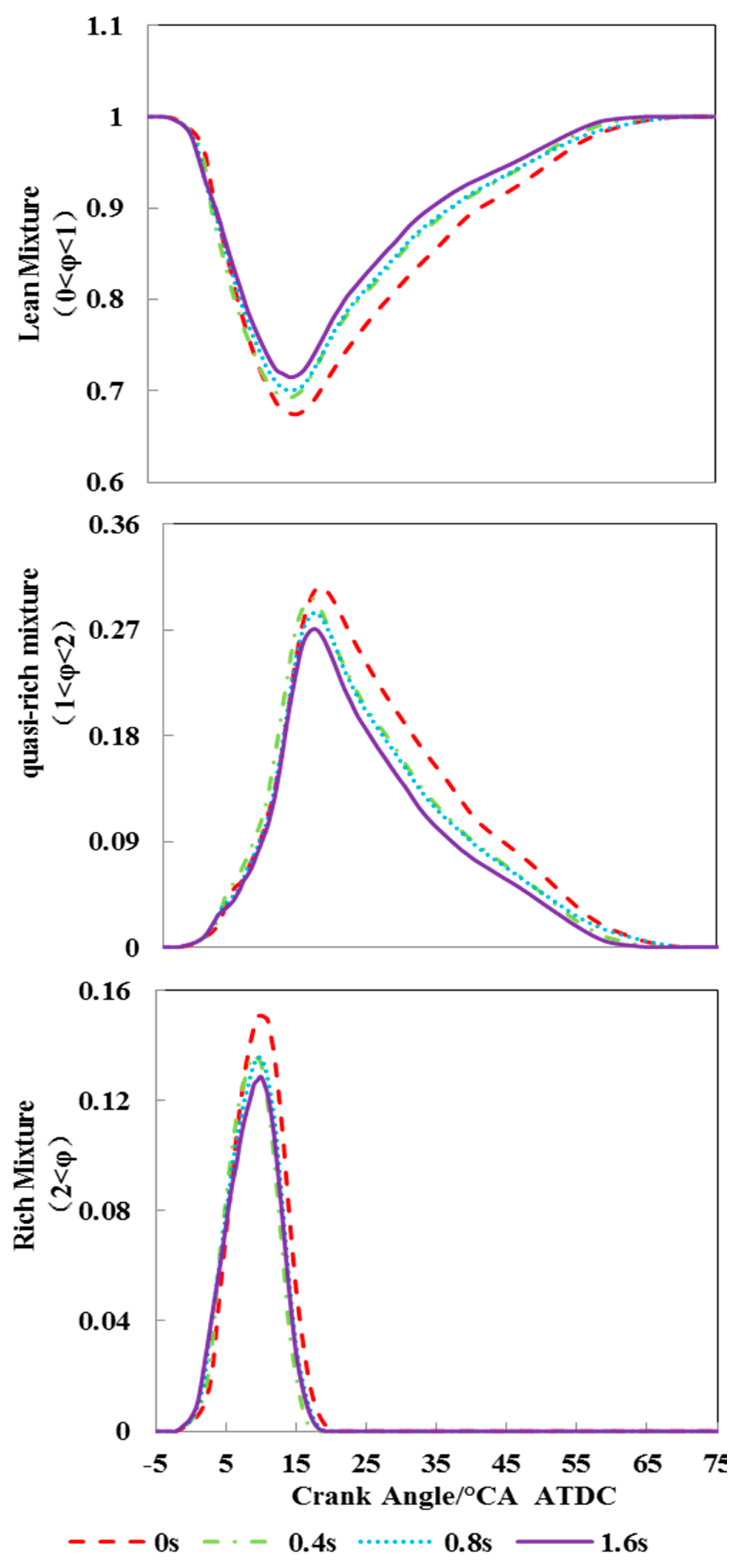

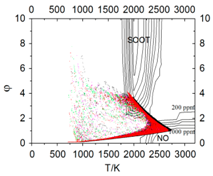

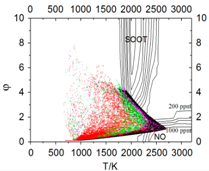

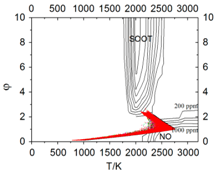

3.2. Simulation Analysis of Loading Hold Time on Transient Performance

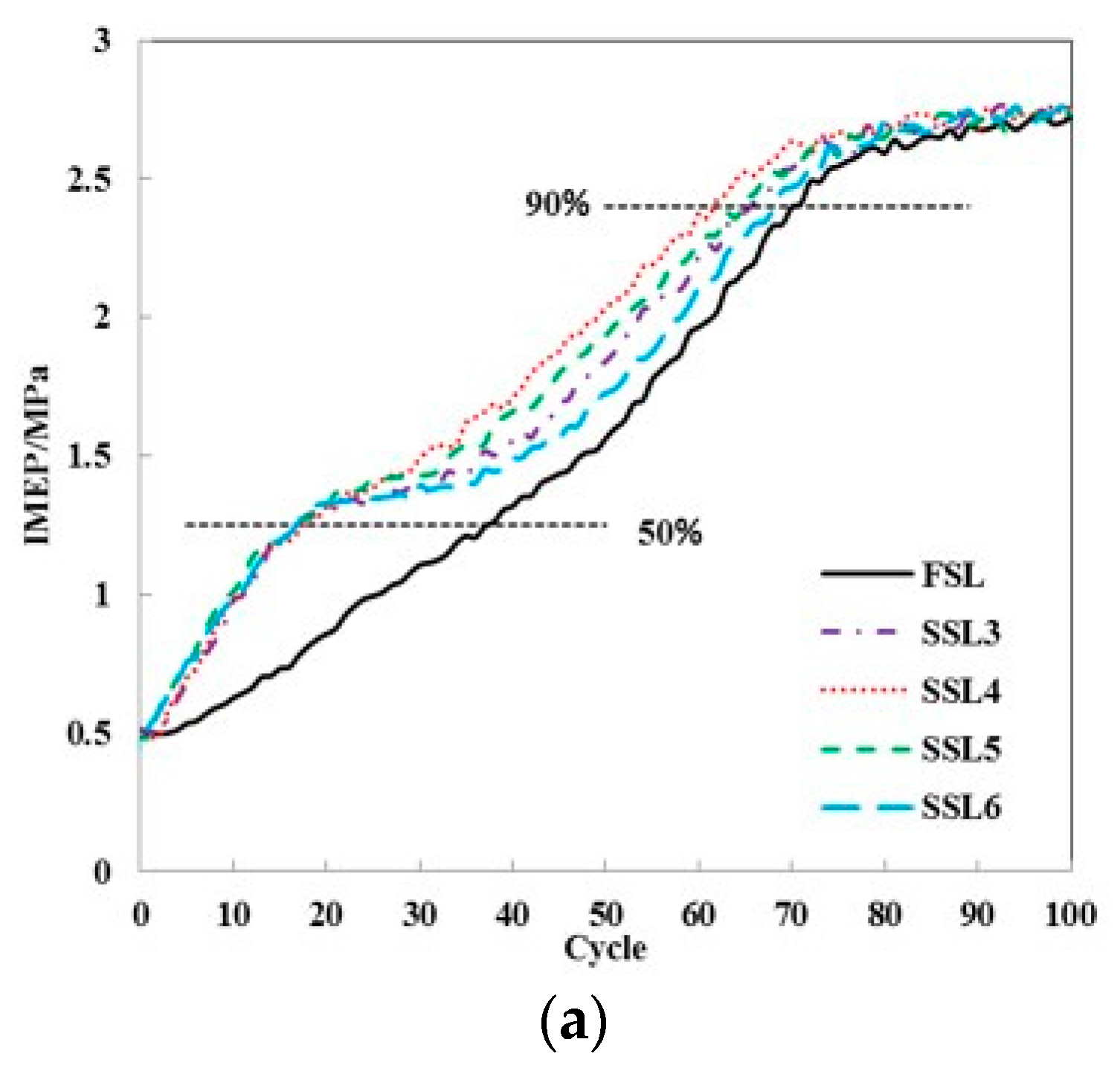

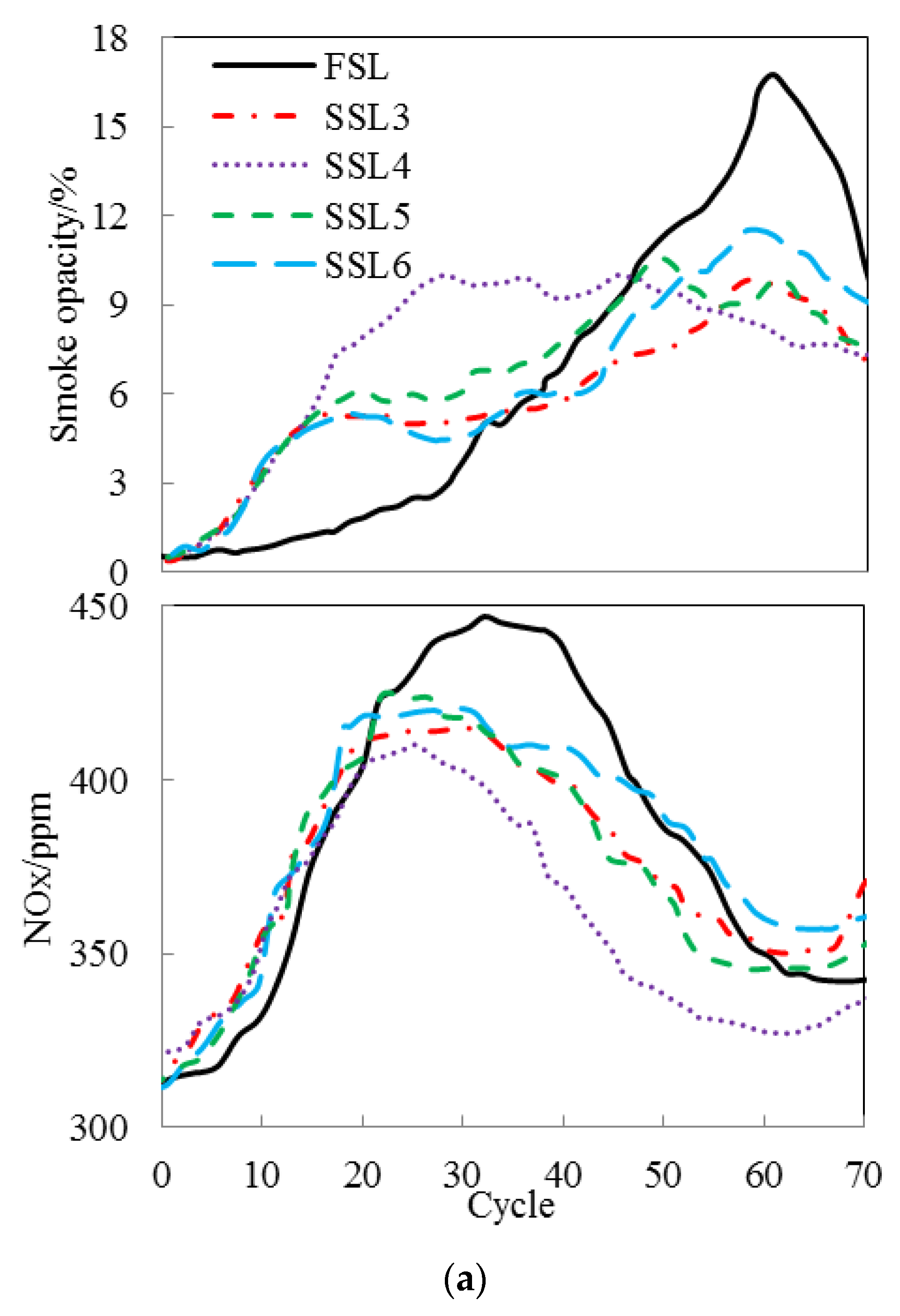

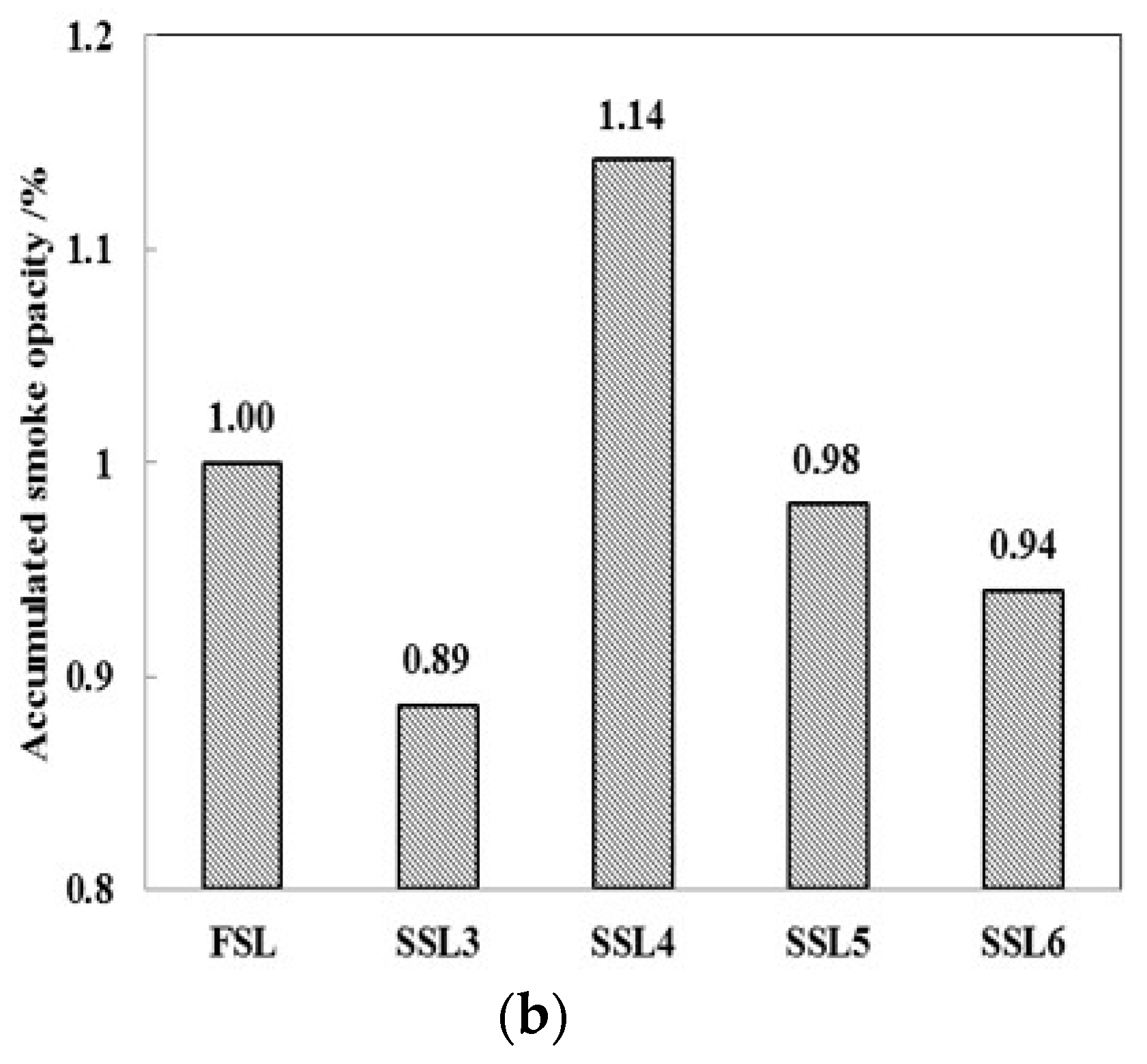

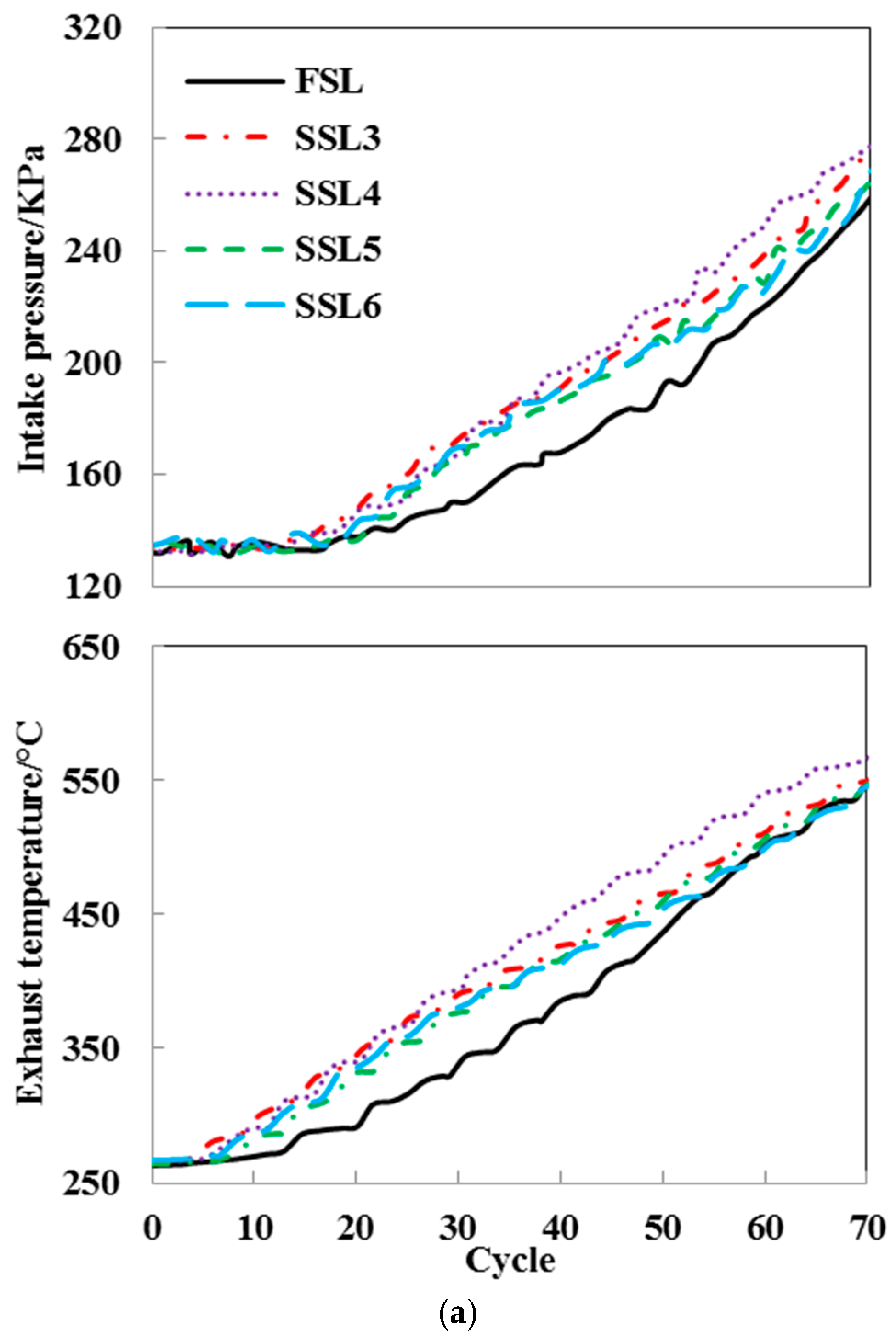

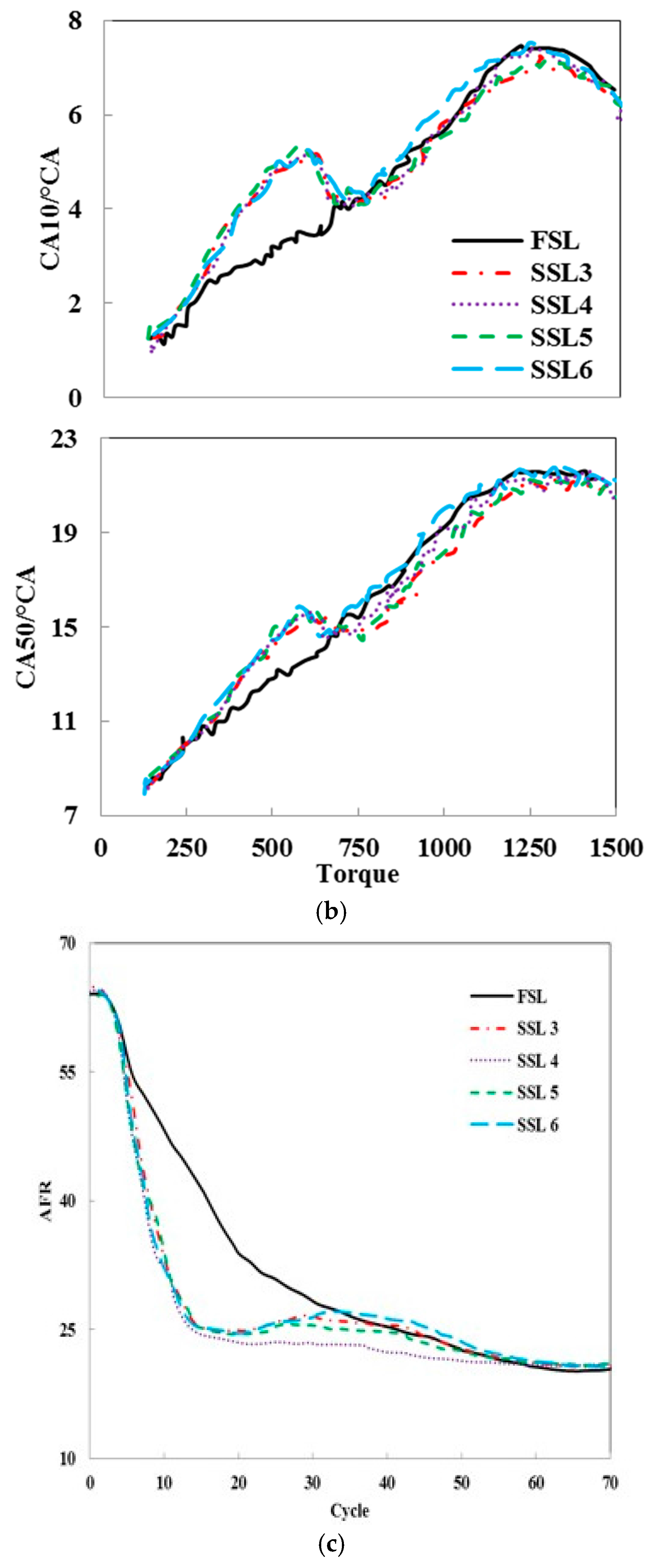

3.3. Influence of Different the Second-Stage Loading Rate and Loading Hold Time on Transient Performance

4. Conclusions

- The SSL strategies can enhance the intake air energy during the early stage of transient conditions. Hence, it raises the combustion rate and advances the combustion phase significantly under medium and large loads.

- Compared with the FSL strategy, the SSL strategies maximally increase the torque response performance by 56.7%. Meanwhile, the maximum decreases of smoke opacity and NOX peak are 41.3 % and 7.3 %, respectively.

- Thanks to extending the loading hold time, an evident reduction of rich mixture is an essential reason for the soot emission improvement.

- The application of the SSL 3 strategy obviously restrains the deterioration of thermal conditions caused by larger second-stage loading rate, then achieves an outstanding trade-off between torque response and emissions performance.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| FSL | full-stage loading |

| SSL | sectional-stage loading |

| ATDC | after top dead center |

| °CA | degrees of crank angle |

| CA10 | crank angle where 10% total heat released |

| CA50 | crank angle where 50% total heat released |

| EGR | exhaust gas recirculation |

| TDC | top dead center |

| ECU | electronic control unit |

| DAC | digital to analog converter |

| ADC | analog to digital converter |

| rpm | revolutions per minute |

| AFR | air-fuel ratio |

| BSFC | brake specific fuel consumption |

| ppm | parts per million |

| φ | equivalence ratio |

References

- Glewen, W.; Heuwetter, D.; Foster, D.E.; Andrie, M.; Krieger, R. Analysis of deviations from steady state performance during transient operation of a light duty diesel engine. Cryogenics 2012, 5, 909–922. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Lioutas, S.C. Diesel-engined vehicle nitric oxide and soot emissions during the European light-duty driving cycle using a transient mapping approach. Trans. Res. Part D Trans. Environ. 2010, 15, 134–143. [Google Scholar] [CrossRef]

- Serrano, J.; Climent, H.; Guardiola, C.; Piqueras, P. Methodology for characterization and simulation of turbocharged diesel engines combustion during transient operation. Appl. Therm. Eng. 2009, 29, 142–149. [Google Scholar] [CrossRef]

- Xia, M.; Zhao, C.L.; Zhang, F.J.; Huang, Y. Modeling the performance of a new speed adjustable compound supercharging diesel engine working under plateau conditions. Energies 2017, 10, 689. [Google Scholar] [CrossRef]

- Han, Y.; Liu, Z.; Zhu, J.; Xu, Y.; Li, J.; Li, K. EGR response in a turbo-charged and after-cooled DI diesel engine and its effects on smoke opacity. SAE Tech. Pap. 2012. [Google Scholar] [CrossRef]

- Nilsson, T.; Froberg, A.; Aslund, J. Optimal operation of a turbocharged diesel engine during transients. SAE Tech. Pap. 2012. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Dimaratos, A.M.; Giakoumis, E.G.; Rakopoulos, D.C. Evaluation of the effect of engine, load and turbocharger parameters on transient emissions of diesel engine. Energy Convers. Manag. 2009, 50, 2381–2393. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, C.D.; Dimaratos, A.M.; Rakopoulos, D.C. Exhaust emissions with ethanol or n-butanol diesel fuel blends during transient operation: A review. Renew. Sustain. Energy Rev. 2013, 17, 170–190. [Google Scholar] [CrossRef]

- Watel, E.; Pagot, A.; Pacaud, P.; Schmitt, J. Matching and evaluating methods for euro 6 and efficient two-stage turbocharging diesel engine. SAE Tech. Pap. 2010. [Google Scholar] [CrossRef]

- Gautier, P.; Albrecht, A.; Chasse, A.; Moulin, P.; Pagot, A.; Fontvieille, L.; Issartel, D. A simulation study of the impact of LP EGR on a two-stage turbocharged diesel engine. Oil Gas Sci. Technol. 2009, 64, 361–379. [Google Scholar] [CrossRef]

- Albin, T.; Ritter, D.; Liberda, N.; Abel, D. Boost pressure control strategy to account for transient behavior and pumping losses in a two-stage turbocharged air path concept. Energies 2016, 9, 530. [Google Scholar] [CrossRef]

- Shi, L.; Li, H.L.; Zhang, H.Y.; Mao, X.J.; Deng, K.Y.; Liu, B.; Hua, L. The effect of bypass valve control on the steady-state and transient performance of diesel engines with regulated two-stage turbocharging system. SAE Tech. Pap. 2015. [Google Scholar] [CrossRef]

- Wu, B.Y.; Zhan, Q.; Yu, X.Y.; Lv, G.J.; Nie, X.K.; Liu, S. Effects of miller cycle and variable geometry turbocharger on combustion and emissions in steady and transient cold process. Appl. Therm. Eng. 2017, 118, 621–629. [Google Scholar] [CrossRef]

- Grönman, A.; Sallinen, P.; Honkatukia, J.; Backman, J.; Uusitalo, A. Design and experiments of two-stage intercooled electrically assisted turbocharger. Energy Convers. Manag. 2016, 111, 115–124. [Google Scholar] [CrossRef]

- Jeong, K.; Lee, D.G.; Park, S.W.; Lee, C.S. Effect of two-stage fuel injection parameters on NOX reduction characteristics in a DI diesel engine. Energies 2011, 411, 2049–2060. [Google Scholar] [CrossRef]

- Li, G.; Zhang, C.H.; Li, Y.Y. Effects of diesel injection parameters on the rapid combustion and emissions of an HD common-rail diesel engine fueled with diesel-methanol dual-fuel. Appl. Therm. Eng. 2016, 108, 1214–1225. [Google Scholar] [CrossRef]

- Xie, H.Z.; Song, L.B.; Xie, Y.Z.; Pi, D.; Shao, C.Y.; Lin, Q.Z. An experimental study on the macroscopic spray characteristics of biodiesel and diesel in a constant volume chamber. Energies 2015, 8, 5952–5972. [Google Scholar] [CrossRef]

- Zhang, L.P.; Liu, Z.C.; Tian, J.; Sun, S.J. Investigation of the combustion deterioration of an automotive diesel engine under transient operation. Sci. China Technol. Sci. 2014, 57, 480–488. [Google Scholar] [CrossRef]

- Liu, Z.C.; Yu, K.B.; Tian, J.; Han, Y.Q.; Qi, S.L.; Teng, P.K. Influence of rail pressure on a two-stage turbocharged Heavy-duty diesel engine under transient operation. Int. J. Automot. Technol. 2017, 18, 19–29. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Dhar, A.; Gupta, J.G.; Kim, W.I.; Choi, K.; Lee, C.S.; Park, S. Effect of fuel injection pressure and injection timing of Karanja biodiesel blends on fuel spray, engine performance, emissions and combustion characteristics. Energy Convers. Manag. 2015, 91, 302–314. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Srivastava, D.K.; Dhar, A.; Maurya, R.K.; Shukla, P.C.; Singh, A.P. Effect of fuel injection timing and pressure on combustion, emissions and performance characteristics of a single cylinder diesel engine. Fuel 2013, 111, 374–383. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Dhar, A.; Gupta, J.G.; Kim, W.I.; Lee, C.S.; Park, S.W. Effect of fuel injection pressure and injection timing on spray characteristics and particulate size-number distribution in a biodiesel fuelled common rail direct injection diesel engine. Appl. Energy 2014, 130, 212–221. [Google Scholar] [CrossRef]

- Han, Y.Q.; Zhang, L.P.; Liu, Z.C.; Tian, J. Investigation of transient deterioration mechanism and improved method for turbocharged diesel engine. Energy 2016, 116, 250–264. [Google Scholar] [CrossRef]

- Darlington, A.; Glover, K.; Collings, N. A simple diesel engine air-path model to predict the cylinder charge during transients Strategies for reducing transient emissions spikes. SAE Tech. Pap. 2006. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Dimaratos, A.M.; Giakoumis, E.G. Experimental assessment of turbocharged diesel engine transient emissions during acceleration, load change and starting. SAE Tech. Pap. 2010. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Alafouzos, A.I. Study of diesel engine performance and emissions during a transient cycle applying an engine mapping-based methodology. Appl. Energy 2010, 87, 1358–1365. [Google Scholar] [CrossRef]

- Shen, Z.J.; Liu, Z.C.; Tian, J.; Liu, J.W. Investigation of in-cylinder gas stratification of diesel engine during intake and compression stroke. Energy 2014, 72, 671–679. [Google Scholar] [CrossRef]

| Engine Parameters | Specifications |

|---|---|

| Bore × Stroke | 112 × 145 mm |

| Number of cylinders | 6 |

| Volume | 8.6 L |

| Rated power/speed | 260 kW/2100 rpm |

| Compression ratio | 17.0:1 |

| Piston bowl | ω |

| Number of injector nozzle holes | 8 |

| Injection System | The 2nd generation of Common-rail (Bosch) |

| Turbocharged | HOLSET400 |

| EGR cooling | Intercooling |

| Equipment | Manufacturer | Type | Accuracy |

|---|---|---|---|

| Eddy current dynamometer | CAMA | CW440 | Speed: ±1 rpm Torque: ±0.2~0.3% FS |

| Electrically operated EGR valve | Mitsubishi | SBZB1N-0013 | ±1.0% FS |

| NOX sensor | Continental | 5WK9-6614H | ±0.2% FS |

| In-cylinder pressure sensor | Kistler | 6125C | ±0.4% FS |

| Air flow meter | AVL | AVL1000 | ±1.0% FS |

| Opacimeter | AVL | AVL439 | ±0.1% FS |

| Fuel mass flow meter | ToCeiL-Shanghai | CMFD/G | ±0.4% FS |

| Combustion analyzer | DEWETRON | DEWE-2010 | Resolution: 0.2 °CA |

| dSPACE | dSPACE | MicroAutoBoxII 1401 | ADC: 12-bit DAC: 12-bit |

| Item | Model |

|---|---|

| Turbulence model | k-Epsilon/RNG |

| Cavitation model | MPI-2 |

| Atomization model | Reitz/Diwakar |

| Droplet-wall interaction model | Bai |

| Spray model | Huh |

| Droplet breakup | Reitz |

| Ignition | Shell auto-ignition |

| Reaction model | EBU LATCT |

| Algorithm | PISO |

| Exp No. | The First-Stage Loading Rate (N·m/s) | The Loading Stagnation Time (s) | The Second-Stage Loading Rate (N·m/s) |

|---|---|---|---|

| FSL | 252 | 0 | 252 |

| SSL 1 | 350 | 0.4 | 233.3 |

| SSL 2 | 490 | 0.8 | 233.3 |

| SSL 3 | 700 | 1.2 | 233.3 |

| SSL 4 | 700 | 0.4 | 184.2 |

| SSL 5 | 700 | 0.8 | 212.1 |

| SSL 6 | 700 | 1.6 | 269.2 |

| Exp No. | Operating Point 1 | Operating Point 2 | Operating Point 3 | Operating Point 4 |

|---|---|---|---|---|

| Loading hold time/s | 0 | 0.4 | 0.8 | 1.6 |

| Stagnation load | 50% | 50% | 50% | 50% |

| 4 °CA ATDC | 8 °CA ATDC | 16 °CA ATDC |

|---|---|---|

|  |  |

| ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Yuan, X.; Tian, J.; Han, Y.; Li, R.; Gao, G. Investigation of Sectional-Stage Loading Strategies on a Two-Stage Turbocharged Heavy-Duty Diesel Engine under Transient Operation with EGR. Energies 2018, 11, 69. https://doi.org/10.3390/en11010069

Liu Z, Yuan X, Tian J, Han Y, Li R, Gao G. Investigation of Sectional-Stage Loading Strategies on a Two-Stage Turbocharged Heavy-Duty Diesel Engine under Transient Operation with EGR. Energies. 2018; 11(1):69. https://doi.org/10.3390/en11010069

Chicago/Turabian StyleLiu, Zhongchang, Xing Yuan, Jing Tian, Yongqiang Han, Runzhao Li, and Guanlong Gao. 2018. "Investigation of Sectional-Stage Loading Strategies on a Two-Stage Turbocharged Heavy-Duty Diesel Engine under Transient Operation with EGR" Energies 11, no. 1: 69. https://doi.org/10.3390/en11010069

APA StyleLiu, Z., Yuan, X., Tian, J., Han, Y., Li, R., & Gao, G. (2018). Investigation of Sectional-Stage Loading Strategies on a Two-Stage Turbocharged Heavy-Duty Diesel Engine under Transient Operation with EGR. Energies, 11(1), 69. https://doi.org/10.3390/en11010069