Energy Consumption Prediction of a Greenhouse and Optimization of Daily Average Temperature

Abstract

:1. Introduction

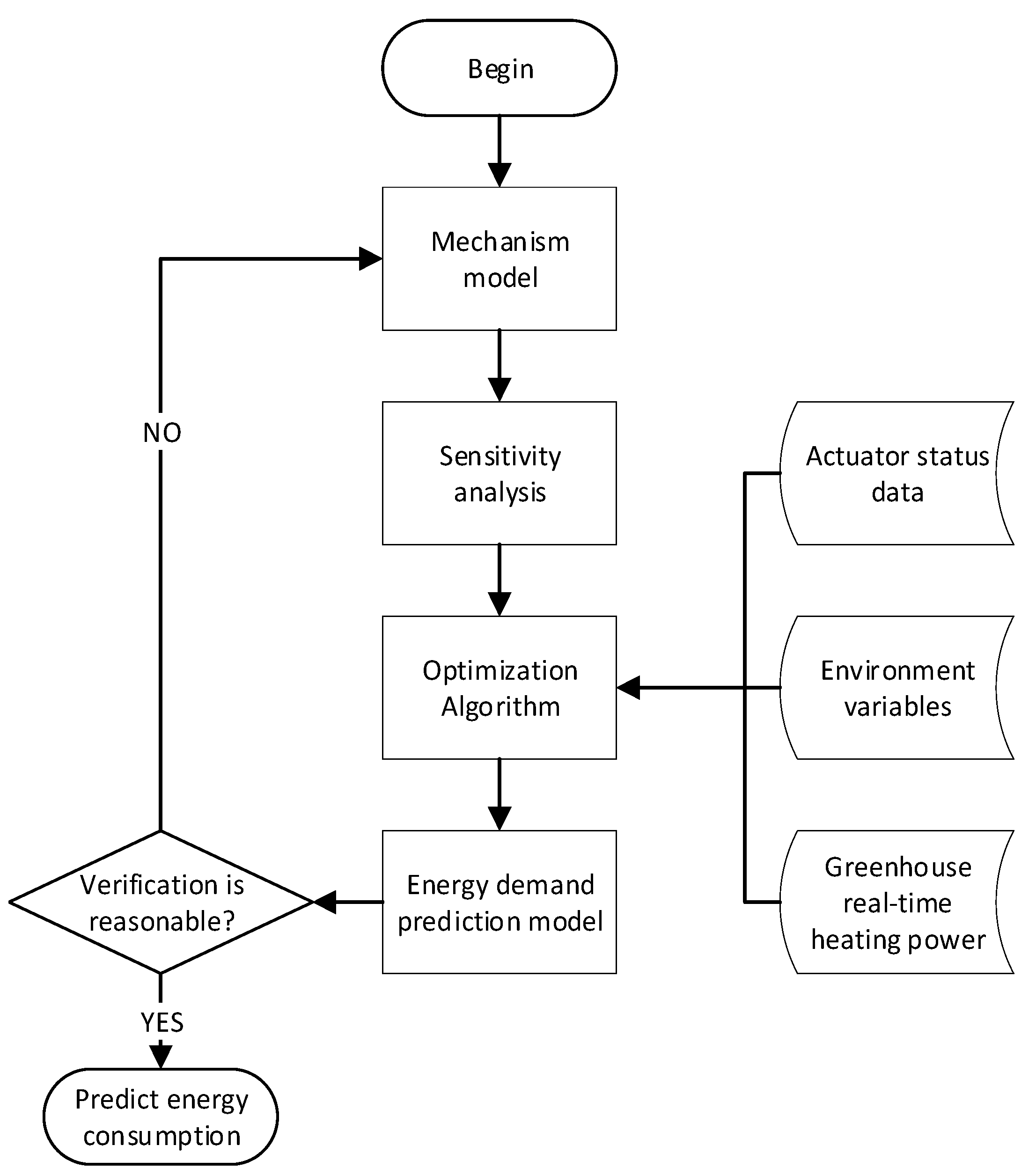

2. Methodology

2.1. Experimental Materials

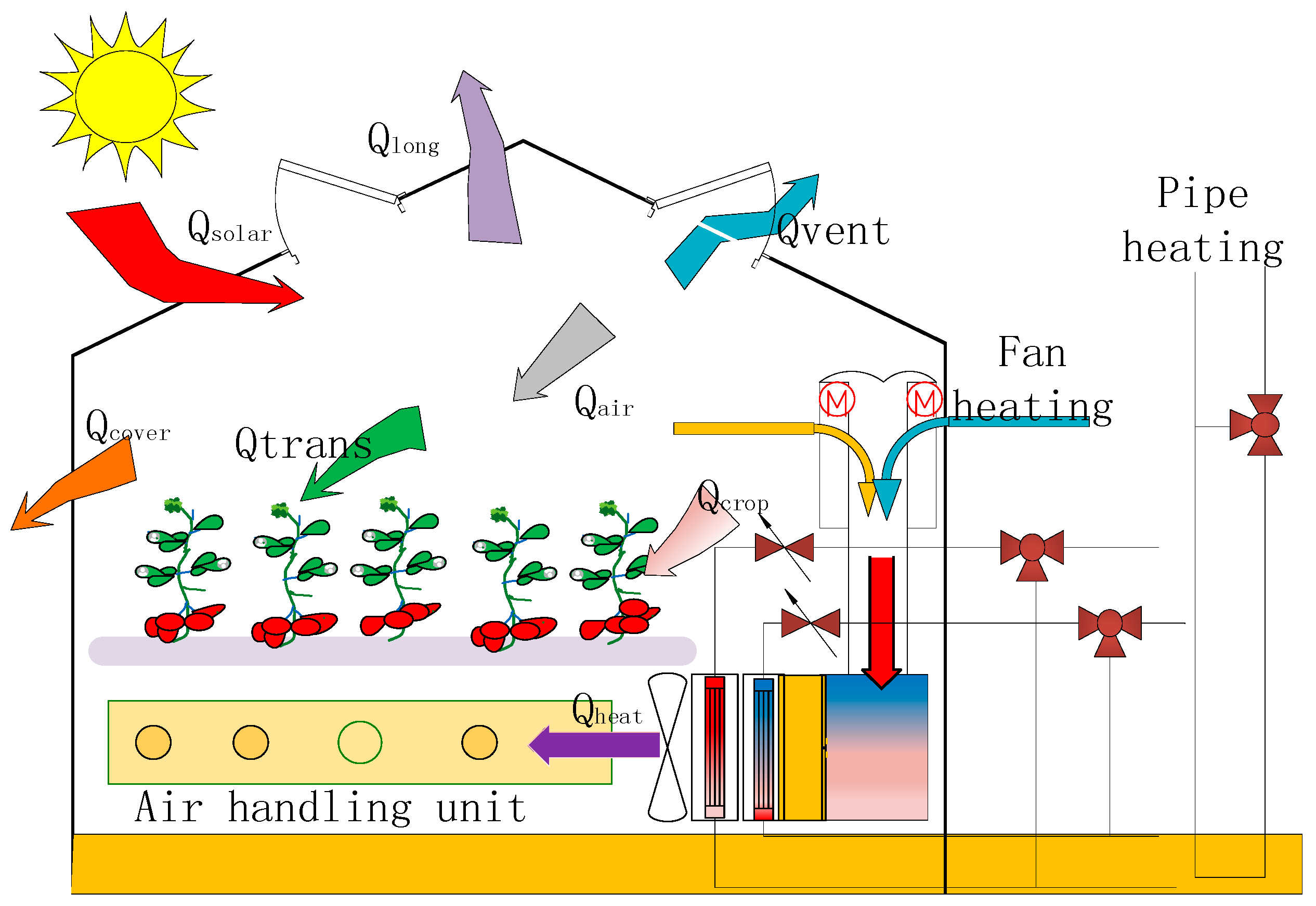

2.2. Greenhouse Mathematical Model

2.3. Method of Optimizing Parameters

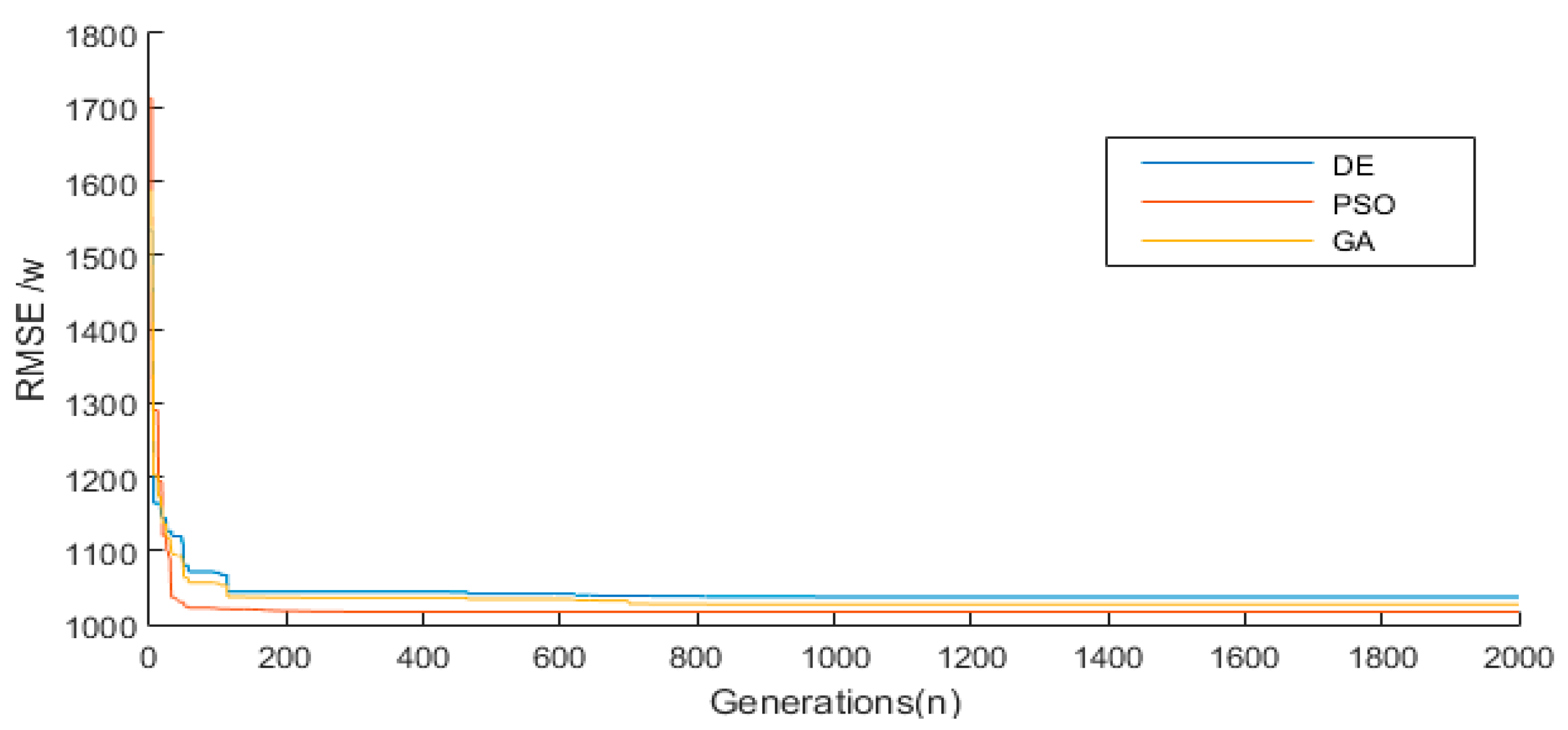

2.4. Optimization Algorithms

- PSO has a real valued representation that allows avoiding the conversion to binary field and backwards, which is common in many heuristic algorithms.

- PSO presents a swarm behavior, which is a sufficient approach in search spaces of considerable extension, due to the capability of exploration in steps of different lengths and the communication between particles, which share the information of the best results.

- PSO is well known, therefore, there exists many publications about it, and numerous variations have already been proposed, in order to tackle problems of considerable complexity. In addition, there are already a lot of references about PSO calibration and stability.

- DE is recognized as a greedy search algorithm. This marks the difference between the PSO and the DE, and allows to check whether the group behavior is better than the greedy search in the questions raised in this study.

- DE requires only two calibration factors, and the definition of these factors is quite small. This defines DE as a simple calibration algorithm.

- Genetic algorithms are often used to generate high-quality solutions to optimize and search for problems, relying on bio-inspired operators such as crossover, mutation and selection.

- Genetic algorithm simultaneously treats multiple individuals in a group, that is, evaluates multiple solutions in the search space, reduces the risk of falling into the local optimal solution, and simultaneously the algorithm itself is easy to realize parallelization.

| Algorithm 1: Outline. Steps of three algorithms in optimization. |

| Input: The environmental data: |

Output: The best vector (solution):

|

3. Results and Discussion

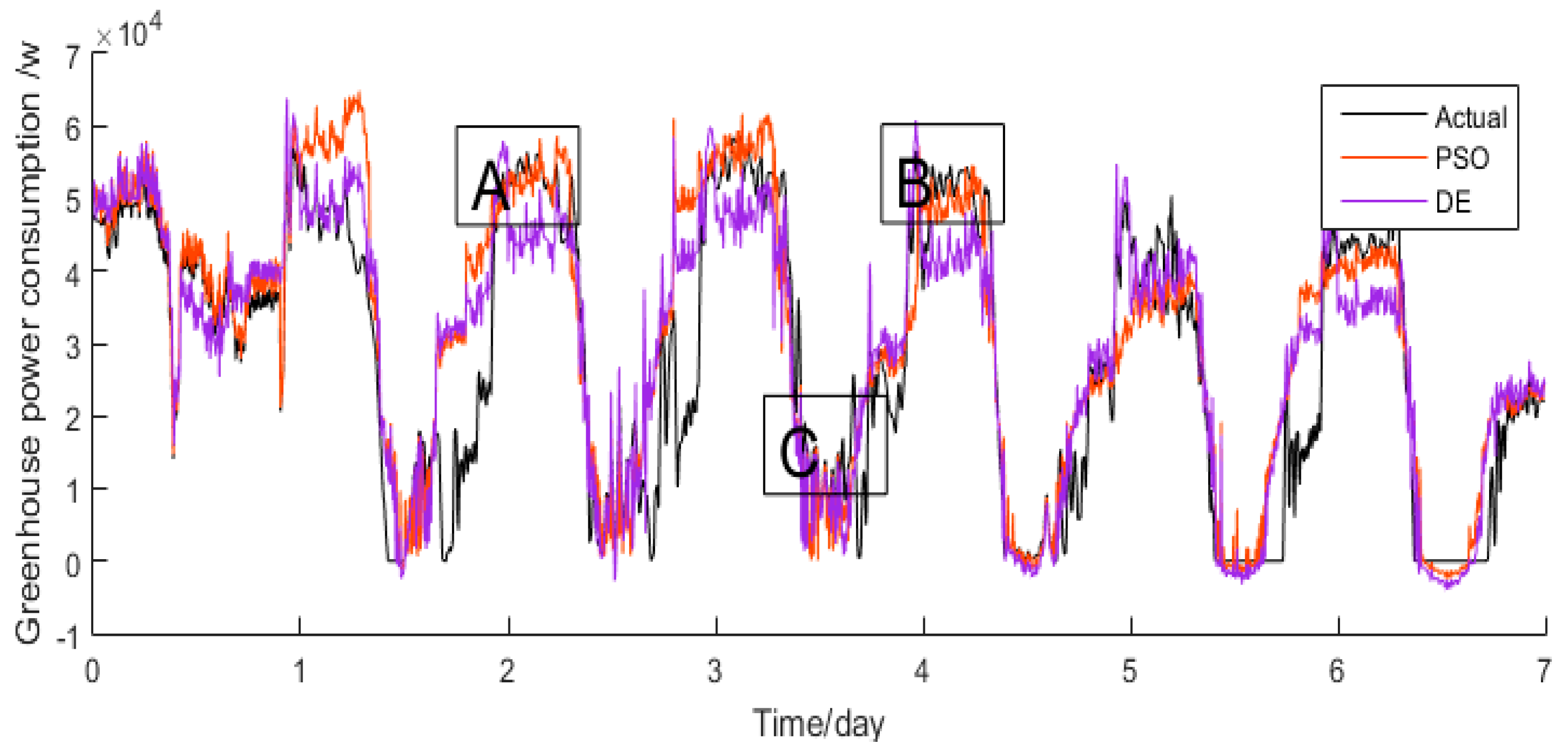

3.1. Optimization and Validation

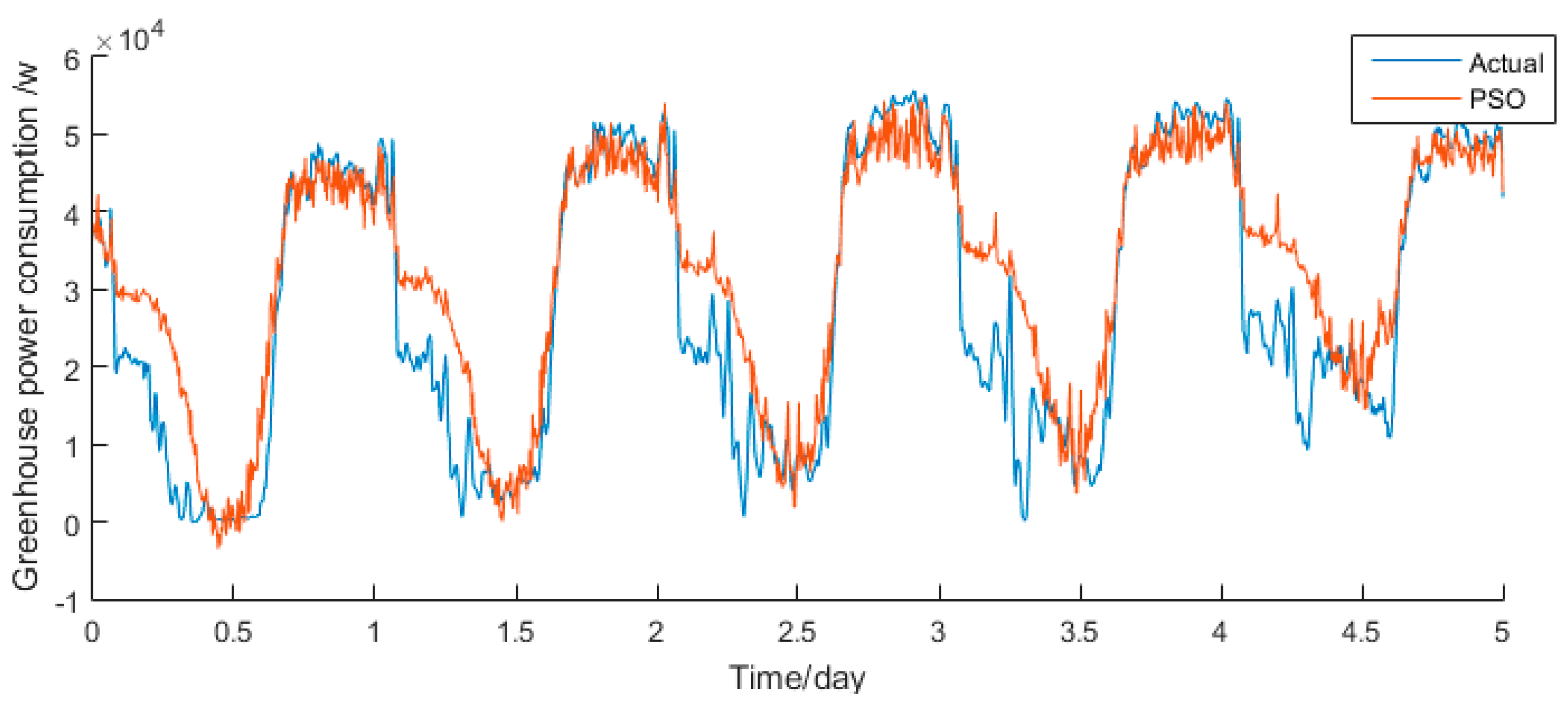

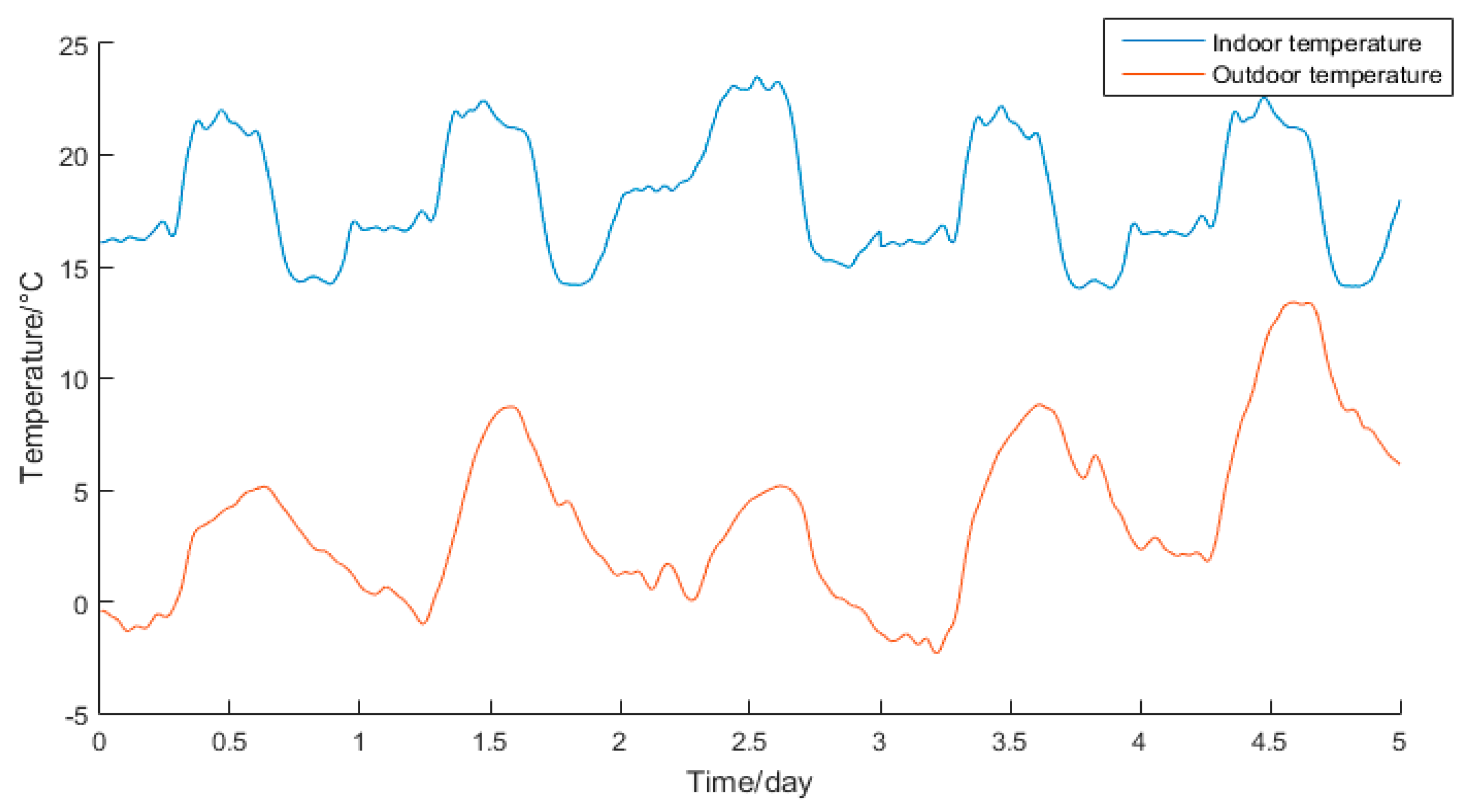

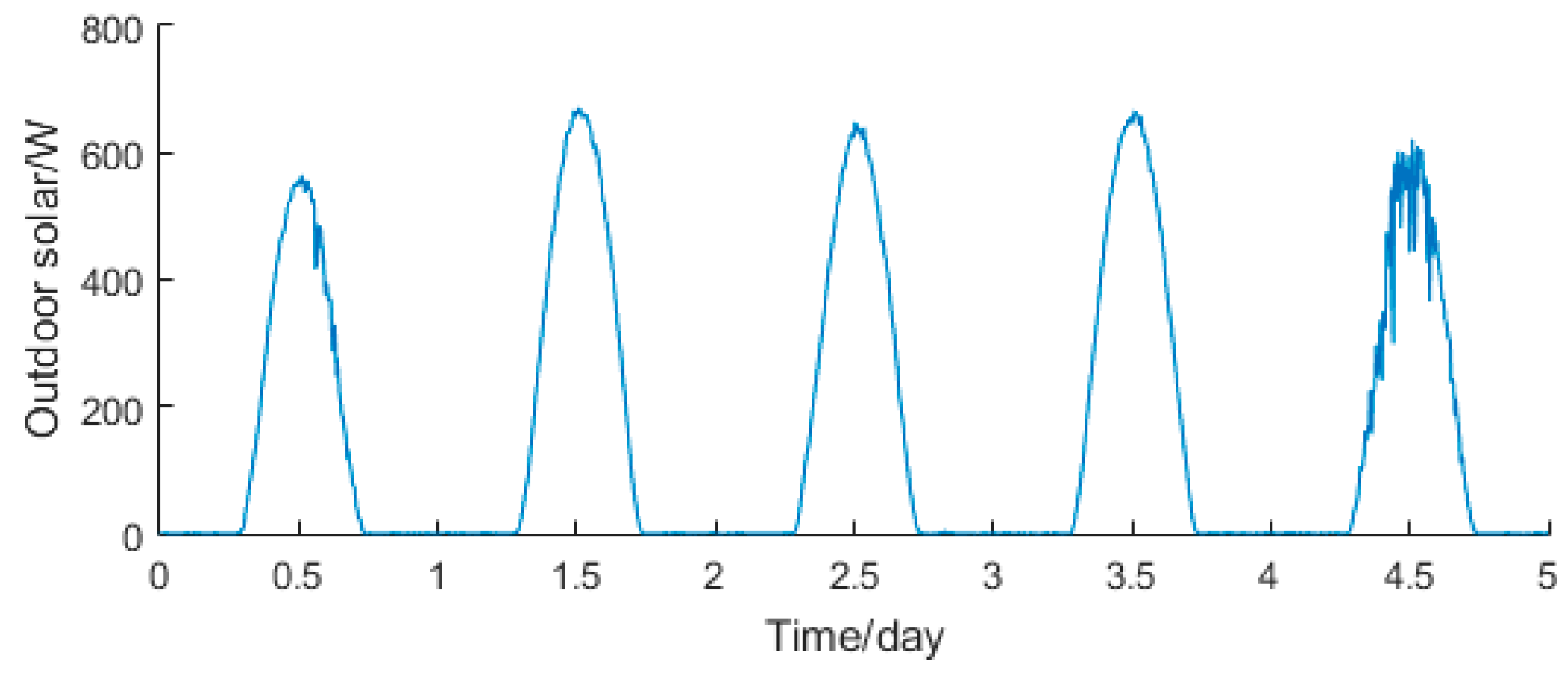

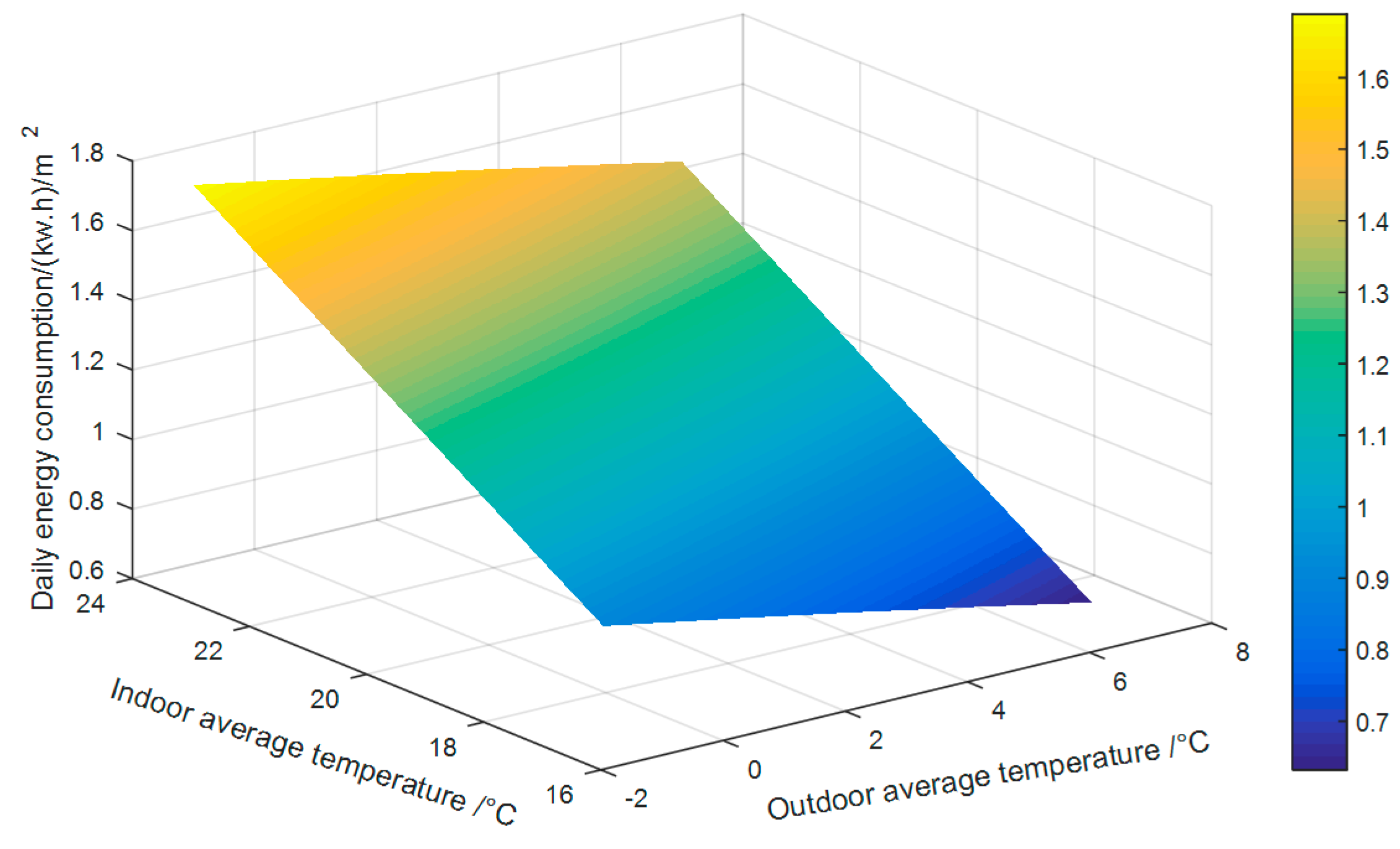

3.2. Predict Energy Consumption Based on Model

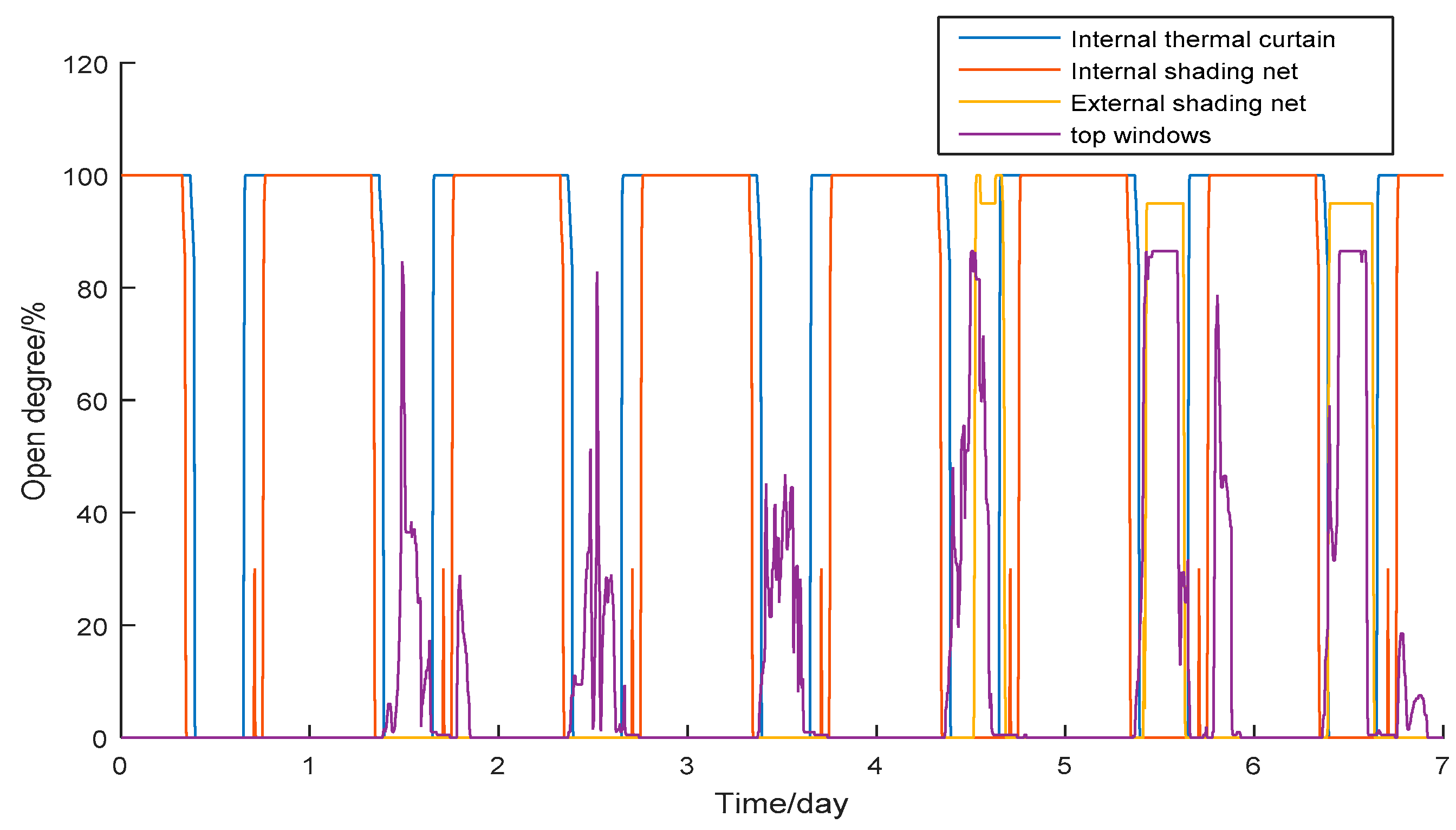

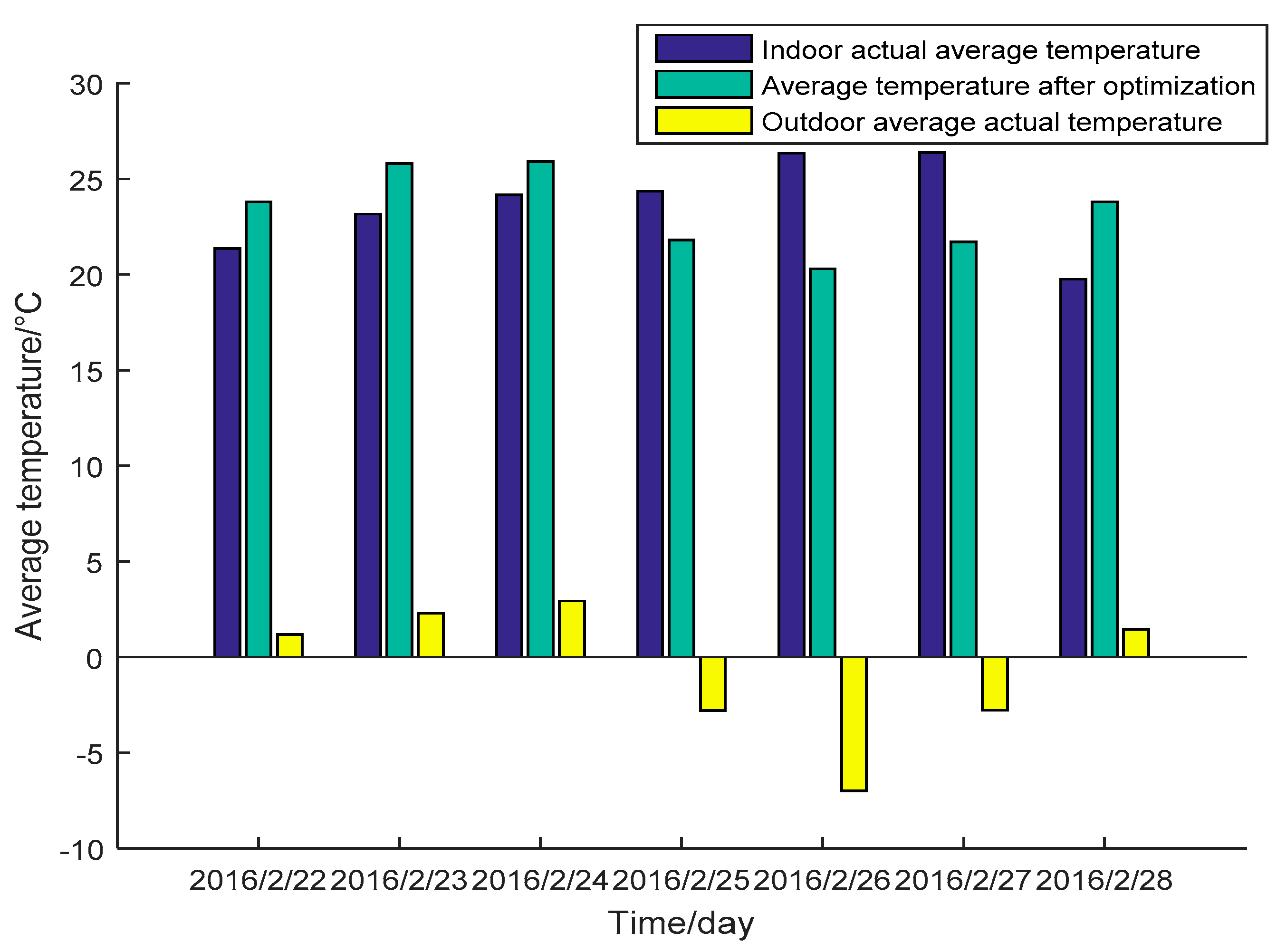

3.3. Optimization of Daily Average Temperature

3.3.1. Energy Optimization Algorithm Objective Function

3.3.2. Optimization Process of Daily Average Temperature

3.4. Discussion

4. Conclusions

- (1)

- The essence of temperature change is the result of various heat and mass transfer processes in greenhouse. Therefore, based on the dynamic equations of these processes and thermodynamic theory, greenhouse energy consumption model is established.

- (2)

- According to the analysis of the various parameters involved in the energy consumption model, we determine the parameters to be identified and the energy consumption model of the parameters to be calibrated. The measured data of greenhouse environment and the states information of devices are input into the model. Also, three optimization algorithms are used to identify the uncertain parameters in the prediction model. Finally, five days after of the greenhouse environmental data is used to verify the effectiveness of energy consumption prediction model.

- (3)

- At present, the accuracy of the weather forecast in one week has been guaranteed. Based on crops’ requirements on accumulated temperature theory, the energy consumption prediction model, the optimized economy is obtained under the constraints of weekly average temperature and daily average temperature. Optimizing the daily average temperature for one week can reasonably guide the greenhouse heating production under the extreme weather conditions. As a result, the energy consumption is reduced, and the normal crop growth is ensured. At the same time, the economic benefits of the greenhouse are improved.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hemming, S.; Balendonck, J.; Dieleman, J.A.; de Gelder, A.; Kempkes, F.L.K.; Swinkels, G.L.A.M.; de Visser, P.H.B.; de Zwart, H.F. Innovations in greenhouse systems—Energy conservation by system design, sensors and decision support systems. In Proceedings of the ISHS Acta Horticulturae 1170: International Symposium on New Technologies and Management for Greenhouses—GreenSys 2015, Evora, Portugal, 19–23 July 2015. [Google Scholar]

- De Zwart, H.F. Analyzing Energy-Saving Options in Greenhouse Cultivation Using a Simulation Model; DOL Institute of Agricultural and Environment: Wageningen, The Netherlands, 1996.

- Gupta, M.J.; Chandra, P. Effect of greenhouse design parameters on conservation of energy for greenhouse environmental control. Energy 2002, 27, 777–794. [Google Scholar] [CrossRef]

- Su, Y.; Xu, L.; Li, D. Adaptive fuzzy control of a class of MIMO nonlinear system with actuator saturation for greenhouse climate control problem. IEEE Trans. Autom. Sci. Eng. 2016, 13, 772–788. [Google Scholar] [CrossRef]

- Spanomitsios, G.K. SE—Structure and Environment: Temperature Control and Energy Conservation in a Plastic Greenhouse. J. Agric. Eng. Res. 2001, 80, 251–259. [Google Scholar] [CrossRef]

- Dai, J.; Luo, W.; Li, Y. A microclimate model-based energy consumption prediction system for greenhouse heating. Sci. Agric. Sin. 2006, 11, 21. [Google Scholar]

- Xu, F.; Zhang, L.; Chen, J.; Zhan, H. Modeling and simulation of subtropical greenhouse microclimate in China. Trans. Chin. Soc. Agric. Mach. 2005, 36, 102–105. [Google Scholar]

- Ren, S.; Yang, W.; Wang, H.; Xue, W.; Xu, H.; Xiong, Y. Prediction model on temporal and spatial variation of air temperature in greenhouse and ventilation control measures based on CFD. Trans. Chin. Soc. Agric. Eng. 2015, 31, 207–214. [Google Scholar]

- Patil, S.L.; Tantau, H.J.; Salokhe, V.M. Modelling of tropical greenhouse temperature by auto regressive and neural network models. Biosyst. Eng. 2008, 99, 423–431. [Google Scholar] [CrossRef]

- Ferreira, P.M.; Faria, E.A.; Ruano, A.E. Neural network models in greenhouse air temperature prediction. Neurocomputing 2002, 43, 51–75. [Google Scholar] [CrossRef]

- Nabavi-Pelesaraei, A.; Abdi, R.; Rafiee, S. Neural network modeling of energy use and greenhouse gas emissions of watermelon production systems. J. Saudi Soc. Agric. Sci. 2016, 15, 38–47. [Google Scholar] [CrossRef]

- Kavga, A.; Kappatos, V. Estimation of the Temperatures in an Experimental Infrared Heated Greenhouse Using Neural Network Models. Int. J. Agric. Environ. Inf. Syst. 2017, 4, 14–22. [Google Scholar] [CrossRef]

- Fourati, F. Multiple neural control of a greenhouse. Neurocomputing 2014, 139, 138–144. [Google Scholar] [CrossRef]

- Frausto, H.U.; Pieters, J.G. Modelling greenhouse temperature using system identification by means of neural networks. Neurocomputing 2004, 56, 423–428. [Google Scholar] [CrossRef]

- Trejoperea, M.; Herreraruiz, G.; Riosmoreno, J.; Miranda, R.C. Greenhouse energy consumption prediction using neural networks models. Int. J. Agric. Biol. 2009, 11, 1–6. [Google Scholar]

- Coelho, J.P.; Pbde, M.O.; Boaventura, C.J. Greenhouse air temperature predictive control using the particle swarm optimisation algorithm. Comput. Electron. Agric. 2005, 49, 330–344. [Google Scholar] [CrossRef]

- Pérez-González, A.; Begovich, O.; Ruiz-León, J. Modeling of a greenhouse prototype using PSO algorithm based on a LabViewTM application. In Proceedings of the 2014 11th International Conference on Electrical Engineering, Computing Science and Automatic Control, Campeche, Mexico, 29 September–3 October 2014; pp. 1–6. [Google Scholar]

- Hasni, A.; Taibi, R.; Draoui, B.; Boulard, T. Optimization of Greenhouse Climate Model Parameters Using Particle Swarm Optimization and Genetic Algorithms. Energy Procedia 2011, 6, 371–380. [Google Scholar] [CrossRef]

- Avila-Miranda, R.; Begovich, O.; Ruiz-León, J. An optimal and intelligent control strategy to ventilate a greenhouse. In Proceedings of the 2013 IEEE Congress on Evolutionary Computation, Cancun, Mexico, 20–23 June 2013; pp. 779–782. [Google Scholar]

- Chen, J.; Chen, J.; Yang, J.; Xu, F.; Zhen, S. Prediction on energy consumption of semi-closed greenhouses based on self-accelerating PSO-GA. Trans. Chin. Soc. Agric. Eng. 2015, 31, 186–198. [Google Scholar]

- Chen, J.; Yang, J.; Zhao, J.; Xu, F.; Zhen, S.; Zhang, L. Energy demand forecasting of the greenhouses using nonlinear models based on model optimized prediction method. Neurocomputing 2016, 174, 1087–1100. [Google Scholar] [CrossRef]

- Pérez-González, A.; Begovich-Mendoza, O.; Ruiz-León, J. Modeling of a greenhouse prototype using PSO and differential evolution algorithms based on a real-time LabView™ application. Appl. Soft Comput. 2018, 62, 86–100. [Google Scholar] [CrossRef]

- Eckel, D. Heat and Mass Transfer; Science Press: Beijing, China, 1963. [Google Scholar]

- Kittas, C.; Boulard, T.; Papadakis, G. Natural ventilation of a greenhouse with ridge and side openings: Sensitivity to temperature and wind effects. Am. Soc. Agric. Biol. Eng. 1997, 40, 415–425. [Google Scholar] [CrossRef]

- Stanghellini, C.; Jong, T.D. A model of humidity and its applications in a greenhouse. Agric. For. Meteorol. 1995, 76, 129–148. [Google Scholar] [CrossRef]

- Juang, C.F.; Liou, Y.C. On the hybrid of genetic algorithm and particle swarm optimization for evolving recurrent neural network. In Proceedings of the 2014 IEEE International Joint Conference on Neural Networks, Budapest, Hungary, 25–29 July 2004; Volume 3, pp. 2285–2289. [Google Scholar]

- Qin, A.K.; Huang, V.L.; Suganthan, P.N. Differential Evolution Algorithm with Strategy Adaptation for Global Numerical Optimization. IEEE Trans. Evol. Comput. 2009, 13, 398–417. [Google Scholar] [CrossRef]

- Qin, A.K.; Suganthan, P.N. Self-adaptive differential evolution algorithm for numerical optimization. In Proceedings of the 2005 IEEE Congress on Evolutionary Computation, Edinburgh, UK, 2–5 September 2005; Volume 2, pp. 1785–1791. [Google Scholar]

- Goldberg, D.E. Genetic Algorithm in Search, Optimization, and Machine Learning; Addison-Wesley Longman Publishing Co., Inc.: Boston, MA, USA, 1989. [Google Scholar]

- Zwickl, D.J. Genetic Algorithm Approaches for the Phylogenetic Analysis of Large Biological Sequence Datasets under the Maximum Likelihood Criterion. Ph.D. Thesis, University of Texas at Austin, Austin, TX, USA, May 2006. [Google Scholar]

- Wang, X.C.; Ding, W.M.; Luo, W.H.; Dai, J.F. An energy prediction model for modern greenhouse in the south of China. J. Nanjing Agric. Univ. 2006, 29, 116–120. [Google Scholar]

- He, C.; Zhang, Z. Modeling the relationship between tomato fruit growth and the effective accumulated temperature in solar greenhouse. In Proceedings of the ISHS Acta Horticulturae 718: III International Symposium on Models for Plant Growth, Environmental Control and Farm Management in Protected Cultivation (HortiModel 2006), Wageningen, The Netherlands, 29 October–2 November 2006. [Google Scholar]

- Guo, Z.H. Application of Accumulated Temperature Theory in Sunlight Greenhouse. J. Anhui Agric. Sci. 2011, 34, 225. [Google Scholar]

- Chen, Q.; Sun, Z. Energy-saving control strategy for greenhouse production based on crop temperature integration. Trans. Chin. Soc. Agric. Eng. 2005, 65, 93–108. [Google Scholar]

| Parameters | Physical Meaning | Value | Unit |

|---|---|---|---|

| LAI | Leaf area index | 2 | m2·m−2 |

| Sg | Greenhouse cover surface area | 1842 | m2 |

| K | Stefan–Boltzmann constant | W·m−2·K−4 | |

| g | Gravity acceleration | 9.8 | m·s−2 |

| AN,side | Maximum area of side windows | 0.10 | m2·m−2 |

| AN,roof | Maximum area of top windows | 0.18 | m2·m−2 |

| ρair | Air density | 1.2 | kg·m−3 |

| cair | Specific heat capacity of air | 1008 | J·kg−1·K−1 |

| ΔH | Water evaporation latent heat constant | J·kg−1 | |

| γ | Psychometric constant | 65.8 | Pa·K |

| Sgw | Greenhouse ground surface area | 912 | m2 |

| rsmin | Minimum somatic resistances of the leaves | 82 | s·m−1 |

| Lwater | Latent heat of evaporation for the leaf surface | J·kg−1 | |

| Molar mass of water | 18 | kg·kmol−1 | |

| R | Molar gas constant | 8314 | J·kmol−1·K−1 |

| νg | Greenhouse volume | 6840 | m−3 |

| rb | Aerodynamic resistances of the leaves | 275 | s·m−1 |

| ρwater | Water density | 1000 | kg·m−3 |

| cwater | Specific heat capacity of water | 4200 | J·kg−1·°C−1 |

| Parameters | Range | GA | DE | PSO |

|---|---|---|---|---|

| ε | [0.5, 0.8] | 0.55 | 0.61 | 0.65 |

| Xcover | [0.1, 0.9] | 0.43 | 0.27 | 0.33 |

| Cd | [0.6, 0.8] | 0.71 | 0.74 | 0.77 |

| Cw | [0.05, 0.2] | 0.15 | 0.11 | 0.12 |

| Xscreen | [0.3, 0.9] | 0.49 | 0.52 | 0.55 |

| Xglass | [1, 10] | 5.79 | 6.23 | 5.19 |

| τcov | [0.6, 1] | 0.63 | 0.77 | 0.83 |

| τscr | [0.3, 0.9] | 0.72 | 0.87 | 0.71 |

| Date (yy-mm-dd) | Outdoor Average Light () | Outdoor Average Temperature (°C) | Average Power (kW) | Relative Error (%) |

|---|---|---|---|---|

| 2016-02-06 | 167.1354 | 3.30 | 31.32 | 9.12 |

| 2016-02-07 | 210.3487 | 3.73 | 33.45 | 8.34 |

| 2016-02-08 | 223.9821 | 3.90 | 32.83 | 7.71 |

| 2016-02-09 | 218.6615 | 3.88 | 33.21 | 6.21 |

| 2016-02-10 | 228.4269 | 4.03 | 31.58 | 5.19 |

| 2016-02-11 | 245.5491 | 4.56 | 27.48 | 10.13 |

| 2016-02-12 | 230.4658 | 4.13 | 30.44 | 9.33 |

| 2016-02-13 | 248.5611 | 4.63 | 26.55 | 10.42 |

| 2016-02-14 | 270.4660 | 5.01 | 21.12 | 10.57 |

| 2016-02-15 | 297.4558 | 5.95 | 17.43 | 10.85 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Y.; Wei, R.; Xu, L. Energy Consumption Prediction of a Greenhouse and Optimization of Daily Average Temperature. Energies 2018, 11, 65. https://doi.org/10.3390/en11010065

Shen Y, Wei R, Xu L. Energy Consumption Prediction of a Greenhouse and Optimization of Daily Average Temperature. Energies. 2018; 11(1):65. https://doi.org/10.3390/en11010065

Chicago/Turabian StyleShen, Yongtao, Ruihua Wei, and Lihong Xu. 2018. "Energy Consumption Prediction of a Greenhouse and Optimization of Daily Average Temperature" Energies 11, no. 1: 65. https://doi.org/10.3390/en11010065

APA StyleShen, Y., Wei, R., & Xu, L. (2018). Energy Consumption Prediction of a Greenhouse and Optimization of Daily Average Temperature. Energies, 11(1), 65. https://doi.org/10.3390/en11010065