Abstract

The energy demand of vehicles is influenced, not only by the drive systems, but also by a number of add-on systems. Electric vehicles must satisfy this energy demand completely from the battery. Hence, the use of power steering systems directly result in a range reduction. The “e2-Lenk” joint project funded by the German Federal Ministry of Education and Research (BMBF) involves a novel steering concept for electric vehicles to integrate the function of steering assistance into the drive-train. Specific distribution of driving torque at the steered axle allows the steering wheel torque to be influenced to support the steering force. This provides a potential for complete substitution of conventional power steering systems and reduces the vehicle’s energy demand. This paper shows the potential of wheel-individual drives influencing the driver’s steering torque using a control technique based on classical EPS control plans. Compared to conventional power-assisted steering systems, a reduced energy demand becomes evident over a wide range of operating conditions.

Keywords:

torque vectoring; power steering; electric vehicles; energy demand; powertrain; simulation 1. Introduction

Drive-trains of electric vehicles operate more efficiently compared to those of conventionally motorized vehicles. Therefore electric vehicles are a promising opportunity to reduce local carbon dioxide emissions and to increase the vehicle’s overall energy efficiency. Furthermore, modern electric drive-trains provide a variety of new features besides propulsion. Consequently, both the power train and the wheel suspension systems can be rethought for integration of these functions. Especially the development and use of wheel-individual drives offer a considerable potential in this regard. For instance, a power-assisted steering effect can be achieved by wheel-individual drives. Different torques applied to the left and right front wheels can significantly influence the driver’s steering torque. Compared to conventional power-assisted steering systems, less actuators fulfil the same functions and offer potential for energy saving.

This contribution serves to analyse and evaluate the energy demand of a vehicle equipped with a power steering system using wheel-individual drives compared to vehicles equipped with conventional power steering systems. In Section 2 and Section 3, the state of research and the concept of power steering using wheel-individual drives are introduced. In Section 4, we propose a vehicle model and driving manoeuvres for simulation and discuss the results. The summary and conclusion are given in Section 5 and Section 6.

2. State of Research

Modern drive-train concepts allow a wheel-individual drive torque control to influence the lateral dynamics of vehicles by longitudinal dynamics. In the following, publications are introduced that represent the state of research in assisted steering and steer-by-wire concepts by using longitudinal forces.

A steering system called “driving force power steering” (DFPS) presented by Li-Qiang et al. in [1] reduces the driver’s steering torque in a vehicle with a positive scrub radius and wheel hub drives. Polmans et al. [2] study a redundant steering system by wheel-individual driving of the front wheels by means of wheel hub motors. In this case, the front wheels are steered exclusively by the power of the drive motors. Wang et al. in [3] study a similar steering system based on wheel hub motors and a chassis also with a scrub radius of 70 mm. The presented “differential drive assisted steering” system (DDAS) is able to reduce the driver’s steering torque by up to 10 Nm. Gauger et al. [4] present a similar approach using wheel-selective braking. It is possible to effectively influence the steering torque and, with limitations, to actuate the steering system. Dominguez et al. [5] improve this system by using a customized chassis with a larger scrub radius. Wu et al. [6] present a vehicle equipped with wheel hub motors and a very large scrub radius of 240 mm of the front axle, which can reduce the driver’s steering torque to 0 Nm. As chassis parameters of this type could cause unintended steering torque on road surfaces with different friction coefficients, the use of a traction control system is recommended.

These studies clearly show that suitable chassis design and specific actuation of longitudinal forces can achieve steering power assistance and, to a limited extent, even independent steering actuation. However, the use of wheel hub motors or conventional friction brakes to generate longitudinal forces entails the considerable disadvantage of the influences of driving and braking forces on the steering system being identical and inseparable.

The authors therefore present in [7] a chassis and steering system concept based on chassis mounted wheel-individual drives. Thus, the driving forces generate a steering torque via the disturbance force lever arm instead of the scrub radius. Hence, braking and driving forces can be separated, which offers clear advantages especially with regard to other driver assistance systems, such as Anti-lock Braking System (ABS) or Electronic Stability Program (ESP).

3. Power Steering System Driven by Wheel-Individual Drives

The function of power-assisted steering can be integrated into the drive-train by using suitably controlled wheel-individual drives on the front axle and a suitable chassis geometry. The objective of development in the research project “Energy-optimized Intelligent Power Steering System for Electric Vehicles—e2-Lenk” is to completely substitute the conventional power-assisted steering system. The project is handled jointly by Schaeffler and the Karlsruhe Institute of Technology.

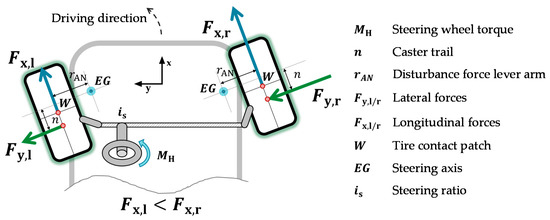

The basic idea of e2-Lenk is as follows: Different torques applied to the left and right wheels can influence the driver’s steering torque in the sense of power-assisted steering. This is achieved via the driving forces acting on the wheel contact patch W, which, together with the acting lever arms of the wheel suspension, result in a steering torque around the steering axis EG. The produced steering torque counteracts the self-centering effect caused by the lateral forces and the caster trail n (see Figure 1).

Figure 1.

Functioning principle of power steering by wheel-individual drives.

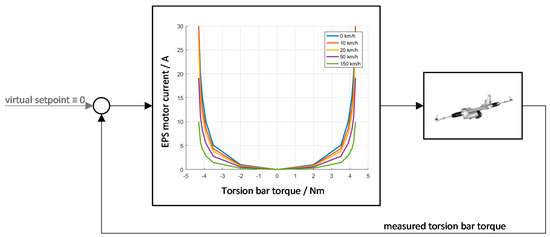

Regarding to Harrer and Pfeffer [8], all classical control plans for conventional power steering systems have in common that they emulate the functions of a hydraulic power steering system: a suitable assistance torque is applied by the power steering system as a function of the driver’s steering wheel torque respectively the torsion bar torque. This structure can be interpreted as a P control algorithm with a virtual set point of 0 Nm and variable gain (see Figure 2). The steering feel is the resulting residual deviation of the P controller that can be adjusted by the power assistance characteristic curves. Classical characteristic curves increase the P gain factor with rising deviation. Thus, a rising torsion bar torque leads to a rising assistance torque which produces a degressive steering wheel torque over lateral acceleration.

Figure 2.

Control circuit with classical Electric Power Steering (EPS) control plan (based on [8]) and power assistance characteristic curves (based on [9]).

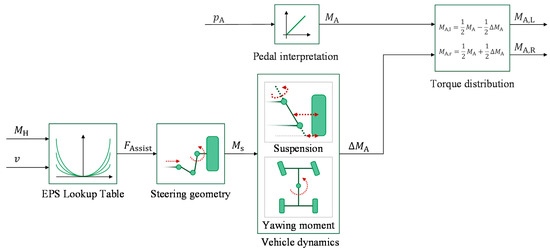

The conventional power steering system and the steering assistance by means of wheel-individual drives have to offer the same steering support, in order to make an energetic comparison meaningful. For influencing the driver’s steering torque as in a conventional power-assisted steering system, we also use the classical kind of control system to produce the assistance torque by actuating the driving motors (see Figure 3). As a function of the steering wheel torque and the vehicle speed the assistance characteristic curves based on [9] supply the required assistance force to suitably influence the steering wheel torque. The same curves of assistance characteristics are used in both systems (EPS lookup table), in order to ensure that the steering assistance of conventional systems and our novel process by using wheel-individual drives show a high level of agreement with respect to assistance. However, this requires the steering kinematics to be determined, from the conventional EPS motor to the connection of the rack up to the steering torque generated at the steering axle. The torque around the steering axle generated by the EPS motor is converted to the required differential torques at the wheels, in consideration of chassis parameters, chassis kinematics and effects of driving dynamics.

Figure 3.

Control structure of steering assistance by means of wheel-individual drives.

The driver’s desired acceleration is detected via the accelerator pedal position and is distributed equally to the drive torque of the left and right wheel. To take the steering assistance torque into account without influencing the vehicle’s acceleration, the required torque difference is equally superimposed with inverse effective direction.

4. Analysis of Energy Demand

4.1. Simulation Environment

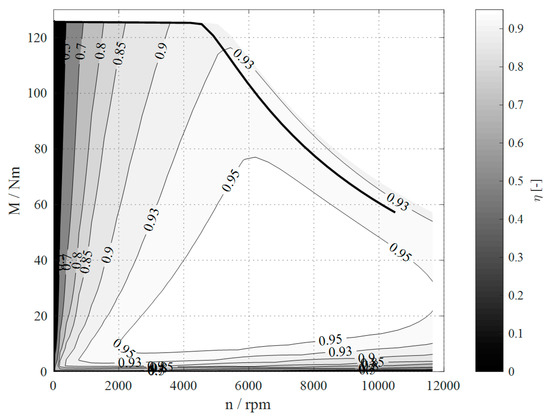

The energetic analysis performed in this study uses the vehicle simulation software CARMAKER® 5.1.3 by IPG Automotive GmbH (Karlsruhe, Germany). The standard vehicle (DemoCar) represents a compact-class car equipped with an internal combustion engine. We adapted the model to represent two wheel-individual electric drives of 65 kW, 125 Nm and a gear ratio of each at the steered front axle. The simulation of electric drives uses a map of efficiency curves obtained by electric drive simulation (see Figure 4).

Figure 4.

Map of efficiency curves of the electric drives used for simulation.

We use double wishbone suspensions with a disturbance force lever arm of , a caster trail of and a scrub radius of . The weight of a power-assisted steering system, such as BOSCH Servolectric® EPSapa [10], not including the steering output systems (tie rods, bellows, outer joints) is 12–15 kg, depending on engineering. This means a difference of approximately 7 kg (motor including control unit) in comparison to a steering system without assistance actuators [11]. This is taken into account appropriately in the total mass of the vehicle of and , respectively.

4.2. Test Procedure and Driving Manoeuvres

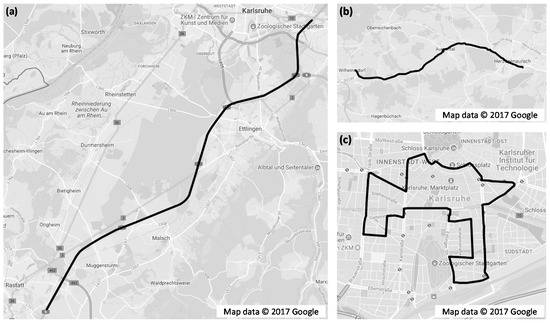

Four different types of test procedures are used to analyse the assistance function and energy demand of the steering assistance systems. We use the standardized driving manoeuvres quasi-steady-state circular driving (as per [12]), double lane change (as per [13]) and a slalom course (based on ISO 13674-1 [14] to cover driving situations encountered frequently and relevant to vehicle design and one self-designed procedure (realistic driving cycles) to obtain realistic information about the energetic effects of the novel power steering system. The procedure to obtain realistic information consists of three different realistic driving cycles on basis of city and out-of-city trips in Germany (see Figure 5). Driving cycle (a) models a motorway trip near Karlsruhe of approximately 25.5 km. Driving cycle (b) models a highway trip near Herzogenaurach of approximately 12.5 km. Driving cycle (c) finally represents a trip through the city of Karlsruhe of approximately 13 km length.

Figure 5.

Realistic driving cycles: (a) Karlsruhe motorway, (b) Herzogenaurach highway, (c) within Karlsruhe.

The maximum driving speed is 130 km/h on motorways, 100 km/h on highways, and 50 km/h in cities. The driving cycles are simulated with different parameters of the virtual driver. The maximum permissible lateral acceleration of the driver is varied in ten steps between and . Thus, a style of driving ranging between defensive and dynamic is modelled. Hence, a broad spectrum of driving situations can be covered.

4.3. Results and Discussion

4.3.1. Quasi-Steady-State Circular Operation

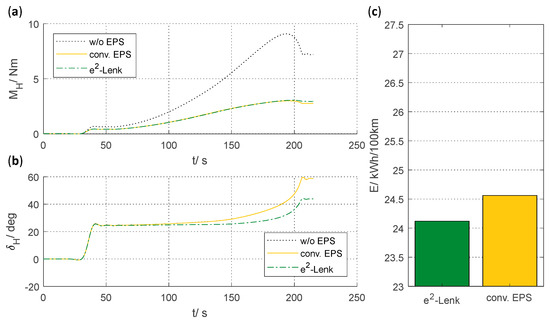

Quasi-steady-state circular operation clearly shows the function of power steering systems. The steering wheel torque required to drive through the circle is reduced (see Figure 6a). Both the conventional power-assisted steering system and the e2-Lenk system reduce the steering wheel torque, compared to the vehicle without power assisted steering, by up to a factor of three.

Figure 6.

Quasi-steady-state circular operation: (a) dynamic response of steering wheel torque, (b) dynamic response of steering wheel angle and (c) comparison of each suspension with a conventional EPS regarding energy.

Considering the steering wheel angle, the influence of the occurring torque vectoring effect becomes evident (see Figure 6b). The e2-Lenk process reduces the steering wheel angle compared to the conventional power steering system and to a vehicle without any assistance functionality by reducing the slip angle. The steering wheel angle remains almost constant despite increasing lateral acceleration.

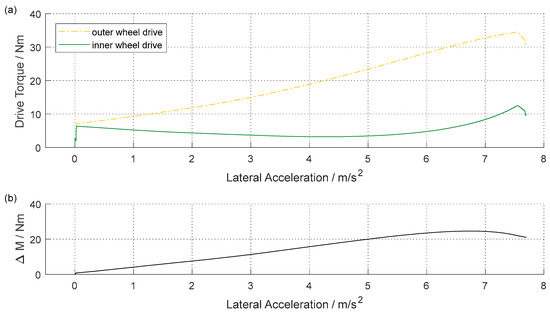

Steady-state circular operation represents a sophisticated driving manoeuvre for the e2-Lenk approach regarding energy demand. As very little longitudinal acceleration of is necessary to maintain the slight increase in lateral acceleration , the mean driving torque of the vehicle is very low. Roemer et al. [15] showed that with conventional chassis parameters the inner wheel drive has to use recuperation mode to achieve the required differential torque at lateral accelerations of .

This problem is solved by the use of the new suspension with a larger disturbance force lever arm. Thus, the inner wheel drive torque is positive all the time (see Figure 7a) and the energy demand is reduced by in comparison to a conventional vehicle with EPS (see Figure 6c).

Figure 7.

Quasi-steady-state circular operation: (a) drive torques of outer and inner wheel drives and (b) difference between the drive torques over later acceleration.

The self-aligning torque and thus the steering wheel torque initially increases linearly over lateral acceleration. However, the self-aligning torque decreases at a lateral acceleration of approximately . This effect is based on the reduction of the pneumatic trail, which reduces the lever arm, with which the lateral forces generate the self-aligning torque. At this point, the torque difference between both drive torques is reduced, in order not to get too high steering assistance (see Figure 7b). Thus, the steering assistance of both systems is equivalent. The steering wheel torque of e2-Lenk and of the conventional power steering system differ by as a root mean square value, the maximum deviation is . The largest deviation occurs towards the end of circular driving because of reaching the vehicle’s limits at a lateral acceleration of .

4.3.2. Double Lane Change

In double lane change, steering movement and high vehicle speed cause lateral accelerations of . In this case, the absence of steering assistance causes a steering wheel torque of up to (see Figure 8a). Both assistance systems clearly reduce the driver’s steering effort by decreasing steering wheel torque by up to approximately 3.5 Nm. The assistance is almost identical in both systems except for a minor deviation in the case of rapid steering to one lane and switching back to the first lane. The root mean square deviation is , with a maximum deviation of . Moreover, the e2-Lenk process reduces the required steering wheel angle by up to approximately 16% (see Figure 8b). Despite the high dynamic demands on the driving motors, the e2-Lenk process reduces the energy requirement compared to the conventional system by (see Figure 8c).

Figure 8.

Double lane change: (a) dynamic response of steering wheel torque, (b) dynamic response of steering wheel angle and (c) comparison of each suspension with a conventional EPS regarding energy.

4.3.3. Slalom-Weave Manoeuvre

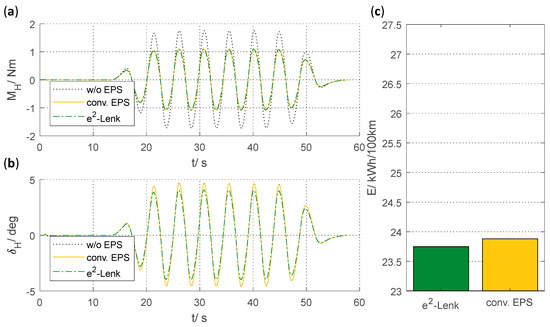

The slalom-weave manoeuvre simulates a situation with constant need of steering over a long period of time with moderate lateral accelerations. Without steering assistance, a steering wheel torque of up to (see Figure 9a) occurs, which can be reduced by both assistance systems by approximately 0.6 Nm. The steering wheel angle without steering assistance and with use of conventional EPS is identical (see Figure 9b), while the e2-Lenk system reduces the maximum steering wheel angle by approximately 12%. Furthermore, e2-Lenk reduces the energy requirements by (see Figure 9c) compared to the conventional system. The result of driving manoeuvre show, that the vehicle is stable over long steering actions with e2-Lenk.

Figure 9.

Slalom-weave manoeuvre: (a) dynamic response of steering wheel torque, (b) dynamic response of steering wheel angle and (c) comparison of each suspension with a conventional EPS regarding energy.

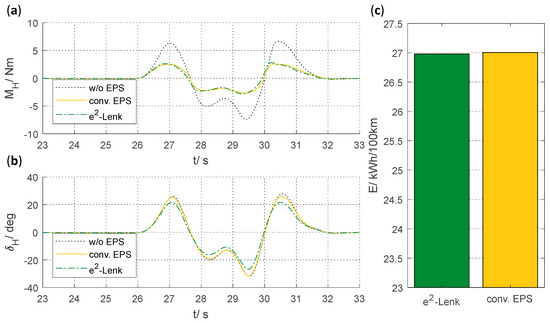

4.3.4. Realistic Driving Cycles

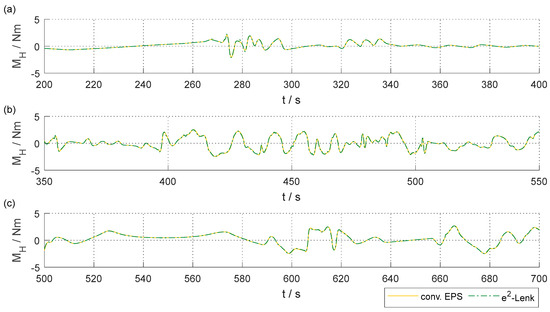

Also in realistic driving cycles, the assistance functions of conventional steering assistance and the e2-Lenk approach show a high degree of agreement. Figure 10 shows excerpts of the steering wheel torque occurring in the realistic driving cycles. The excerpts are representative of the entire course. Even with the occurring quasi-stochastic steering manoeuvers the same support as in the conventional system can be achieved. Thus, the driver’s steering torque is largely identical in both assistance variants (see Table 1).

Figure 10.

Excerpts of steering wheel torque over time: (a) Karlsruhe motorway, (b) Herzogenaurach highway and (c) within Karlsruhe.

Table 1.

Mean values of root mean square and maximum deviations of driver steering torques, MH, between conventional steering assistance systems and e2-Lenk.

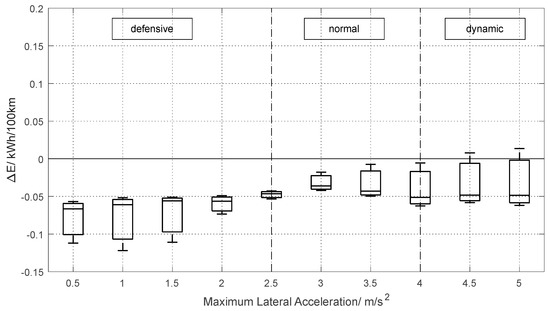

A comparison of the energy demand of the e2-Lenk process and of a conventional steering assistance system is shown in Figure 11. A box-whisker plot was drafted for the three realistic driving cycles within a defined maximum lateral acceleration of the virtual driver. This shows the potential of the e2-Lenk process especially in a defensive mode of driving (the classification of types of drivers follows [16,17]). In this way, energy demand in lateral acceleration ranges below can be reduced compared to conventional steering assistance systems by up to respectively approximately 0.95%. Even in a dynamic mode of driving, energy demand can be reduced as a function of driving manoeuvre. This results in a median energy demand reduction in a range of approximately 0.28–0.64% with a mean median value of approximately 0.43%.

Figure 11.

Comparison of energy demands between e2-Lenk and conventional steering assistance systems as a function of lateral acceleration (classification of types of drivers in accordance with [16,17]). The line in a box represents the median of the data values.

5. Summary

Various standard manoeuvres and realistic driving cycles show that operation of the e2-Lenk process for steering assistance and of conventional steering assistance systems achieve equivalent quality of driver assistance. This results in an equivalent influence on driver’s sensation with respect to the driver’s steering torque. In addition, e2-Lenk decreases the steering wheel angle by reducing the tire slip angle of the front axle. This reduces both the driver’s steering effort and tire rolling resistance.

Energetic analysis shows that steering assistance based on wheel-individual drives reduces energy demand compared to conventional power steering systems. Especially in defensive driving, the effect of reduced energy demand becomes most evident. An energy demand reduction of up to approximately 0.95% can be achieved in realistic driving cycles. The mean value is approximately 0.43%.

6. Conclusions

Our simulation-based investigations show the feasibility of a power steering system using wheel-individual drive torque at the front axle. We can establish that no dedicated actuators are needed for steering assistance, if wheel-individual drives and suspensions are properly used. This results in a slight reduction of energy demand and in gaining packaging space. To validate our data a real 1:1.5 scale model is in production.

The presented torque distribution algorithm is based on a classical EPS control plan in order to provide a meaningful energetic comparison. The use of more complex control methods will certainly provide further benefits for the e2-Lenk process and is the subject of further research. An optimized chassis design can further improve the assistance potential of the e2-Lenk process and reduce the energy demand even further. Undoubtedly, there is the potential for complete substitution of conventional power steering systems.

Acknowledgments

The authors are grateful to the Federal Ministry for Education and Research (FKZ 16EMO0073K, 16EMO0074) for funding the “Energy-optimized Intelligent Power Steering System for Electric Vehicles—e2-Lenk” joint project.

Author Contributions

Jürgen Römer designed the algorithm, performed the simulations and prepared the manuscript as the first author. Philipp Kautzmann designed the suspension for the simulated vehicle and contributed to the manuscript. Michael Frey coordinated the research as the scientific project leader. Frank Gauterin discussed the simulation results. All authors read and approved the publication.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li-Qiang, J.; Song, C.; Hu, C. Driving Force Power Steering for the Electric Vehicles with Motorized Wheels. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Dearborn, MI, USA, 7–10 September 2009; pp. 1518–1524. [Google Scholar]

- Polmans, K.; Stracke, S. Torque vectoring as redundant steering for automated driving or steer-by-wire. In 5th International Munich Chassis Symposium 2014; Pfeffer, P.E., Ed.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2014. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Q.; Jin, L.; Song, C. Independent Wheel Torque Control of 4WD Electric Vehicle for Differential Drive Assisted Steering. Mechatronics 2011, 21, 63–76. [Google Scholar] [CrossRef]

- Gauger, A.; Kern, A.; Kanngießer, S.; Greul, R. Potential of wheel individual brake interventions as a backup for steering systems failures during automated driving. In 7th International Munich Chassis Symposium 2016; Pfeffer, P.E., Ed.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2016. [Google Scholar]

- Dominguez-Garcia, A.; Kassakian, J.; Schindall, J. A backup system for automotive steer-by-wire, actuated by selective braking. In Proceedings of the IEEE 35th Annual Power Electronics Specialists Conference, Aachen, Germany, 20–25 June 2004. [Google Scholar]

- Wu, F.; Yeh, T.; Huang, C. Motor control and torque coordination of an electric vehicle actuated by two in-wheel motors. Mechatronics 2013, 23, 46–60. [Google Scholar] [CrossRef]

- Kautzmann, P.; Römer, J.; Frey, M.; Mayer, M.P. A Novel Chassis Concept for Power Steering Systems Driven by Wheel Individual Torque at the Front Axle. In Proceedings of the 25th Aachener Kolloquium Fahrzeug- und Motorentechnik, Aachen, Germany, 10–12 October 2016. [Google Scholar]

- Harrer, M.; Pfeffer, P. Steering Handbook; Springer International Publishing: Cham, Switzerland, 2017; ISBN 978-3-319-05449-0. [Google Scholar] [CrossRef]

- IPG Automotive GmbH. CarMaker Reference Manual Version 6.0.3; IPG Automotive GmbH: Karlsruhe, Germany, 2017. [Google Scholar]

- Robert Bosch Automotive Steering GmbH. Servolectric—Elektromechanisches Lenksystem für ein Dynamisches Fahrgefühl und Hochautomatisierte Funktionen; Hg. v. Robert Bosch GmbH: Schwäbisch Gmünd, Germany, 2015. [Google Scholar]

- ISA-Racing Motorsportzubehör: Motorsport-Standard-Servolenkung. Available online: http://www.isa-racing.com (accessed on 29 June 2016).

- International Standard Organization. ISO 4138. Passenger Cars—Steady-State Circular Driving Behavior—Open-Loop Test Methods; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- International Standard Organization. ISO 3888-1. Passenger Cars—Test Track for a Severe Lane-Change Manoeuvre—Part 1: Double Lane-Change; ISO: Geneva, Switzerland, 1999. [Google Scholar]

- International Standard Organization. ISO 13674-1. Road Vehicle—Test Method for the Quantification of on-Centre Handling—Part 1: Weave Test; ISO: Geneva, Switzerland, 2010. [Google Scholar]

- Römer, J.; Kautzmann, P.; Mayer, M.P.; Frey, M. Energetische Analyse einer radabhängigen Drehmomentvariation als EPS-Substitution für Elektrofahrzeuge. In Proceedings of the Tag des Fahrwerks, Aachen, Germany, 6 October 2016; Institut für Kraftfahrzeuge: Aachen, Germany, 2016. [Google Scholar]

- Schulz, A.; Fröming, R. Analyse des Fahrerverhaltens zur Darstellung adaptiver Eingriffsstrategien von Assistenzsystemen. Automobiltechnische Zeitschrift 2008, 110, 1124–1131. [Google Scholar] [CrossRef]

- Mayser, C.; Lippold, C.; Ebersbach, D.; Dietze, M. Fahrerassistenzsysteme zur Unterstützung der Längsregelung im ungebundenen Verkehr. In Proceedings of the 1. Tagung Aktive Sicherheit Durch Fahrerassistenzsysteme, Garching, Germany, 7–8 April 2004. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).