A Bi-Level Optimization Approach to Charging Load Regulation of Electric Vehicle Fast Charging Stations Based on a Battery Energy Storage System

Abstract

1. Introduction

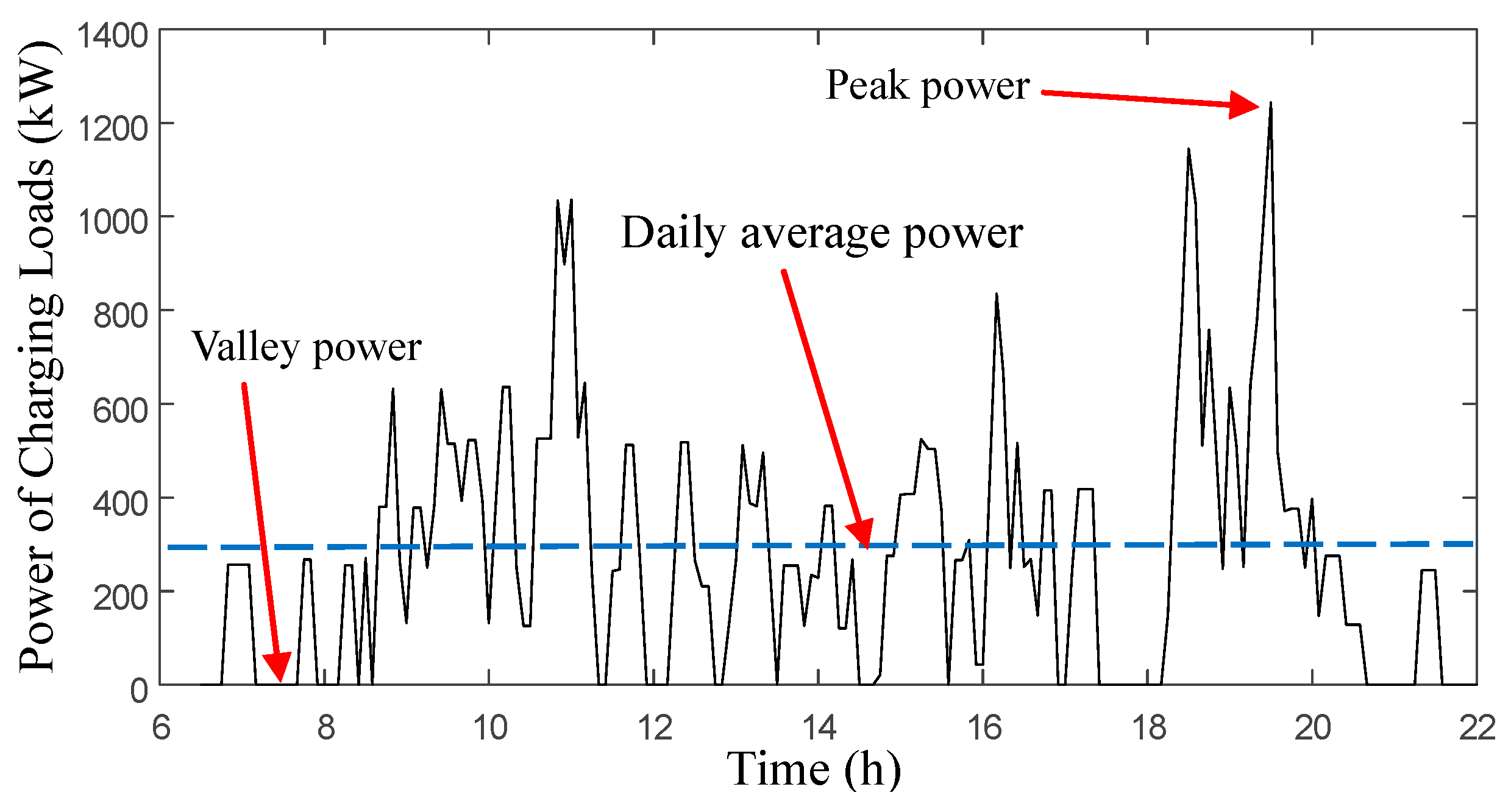

2. Problems and Motivating Scenarios

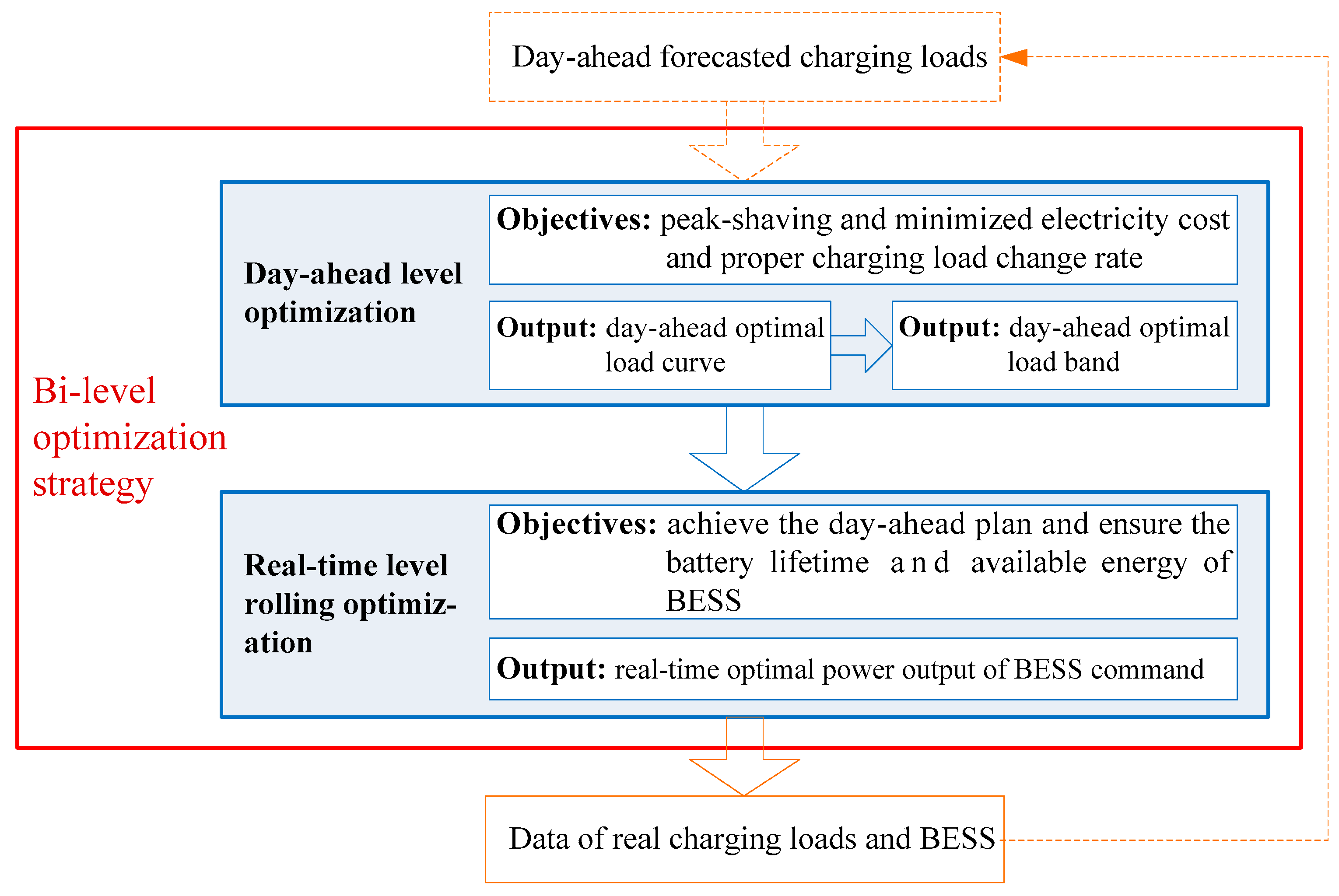

3. Control Model and Bi-Level Optimization Strategy

3.1. The BESS-Based Fast Charging Station Control Model

3.2. Day-Ahead Level Optimization Strategy

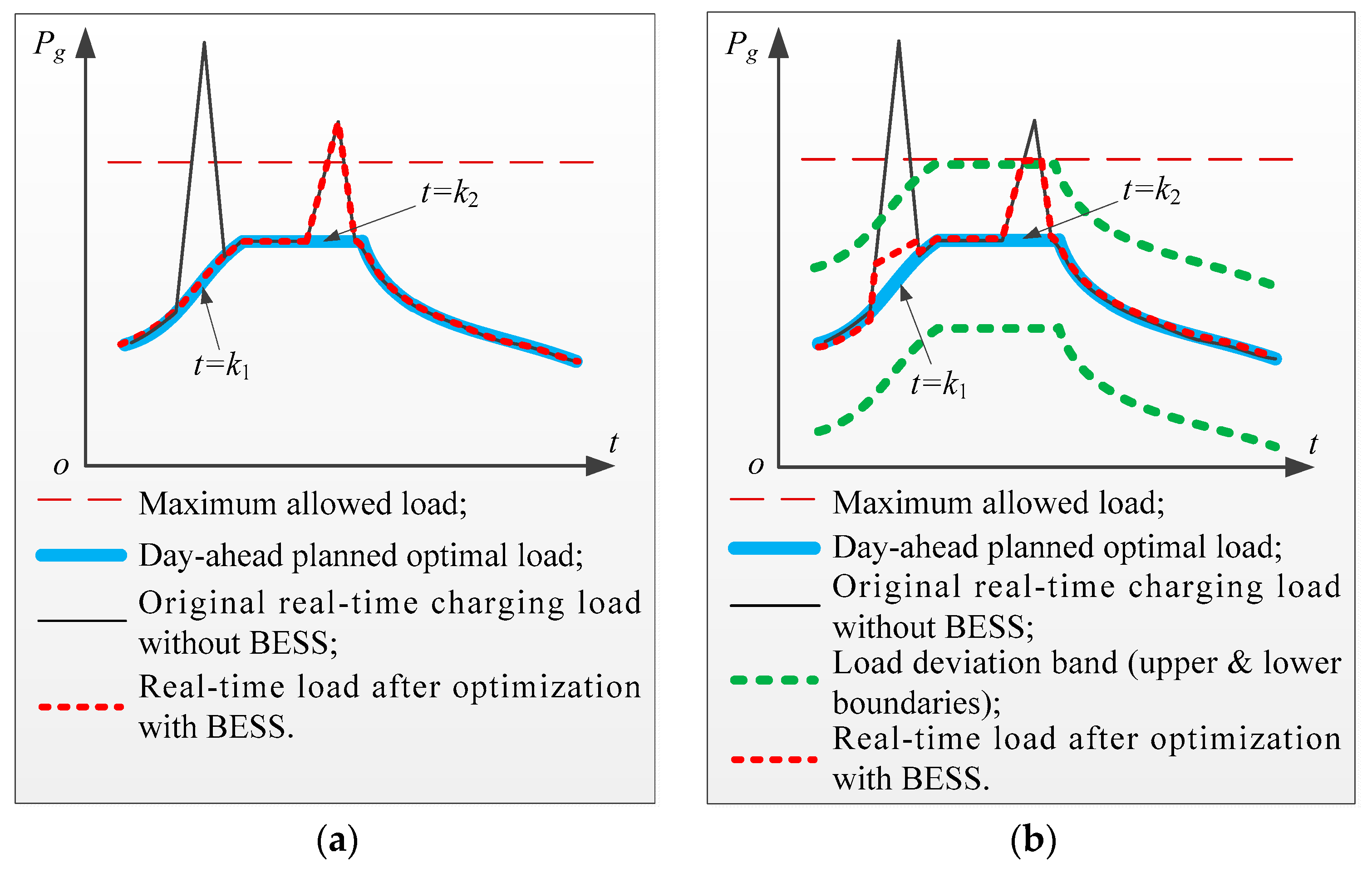

3.3. Day-Ahead Optimal Planned Load Deviation Band

3.4. Real-Time Rolling Optimization

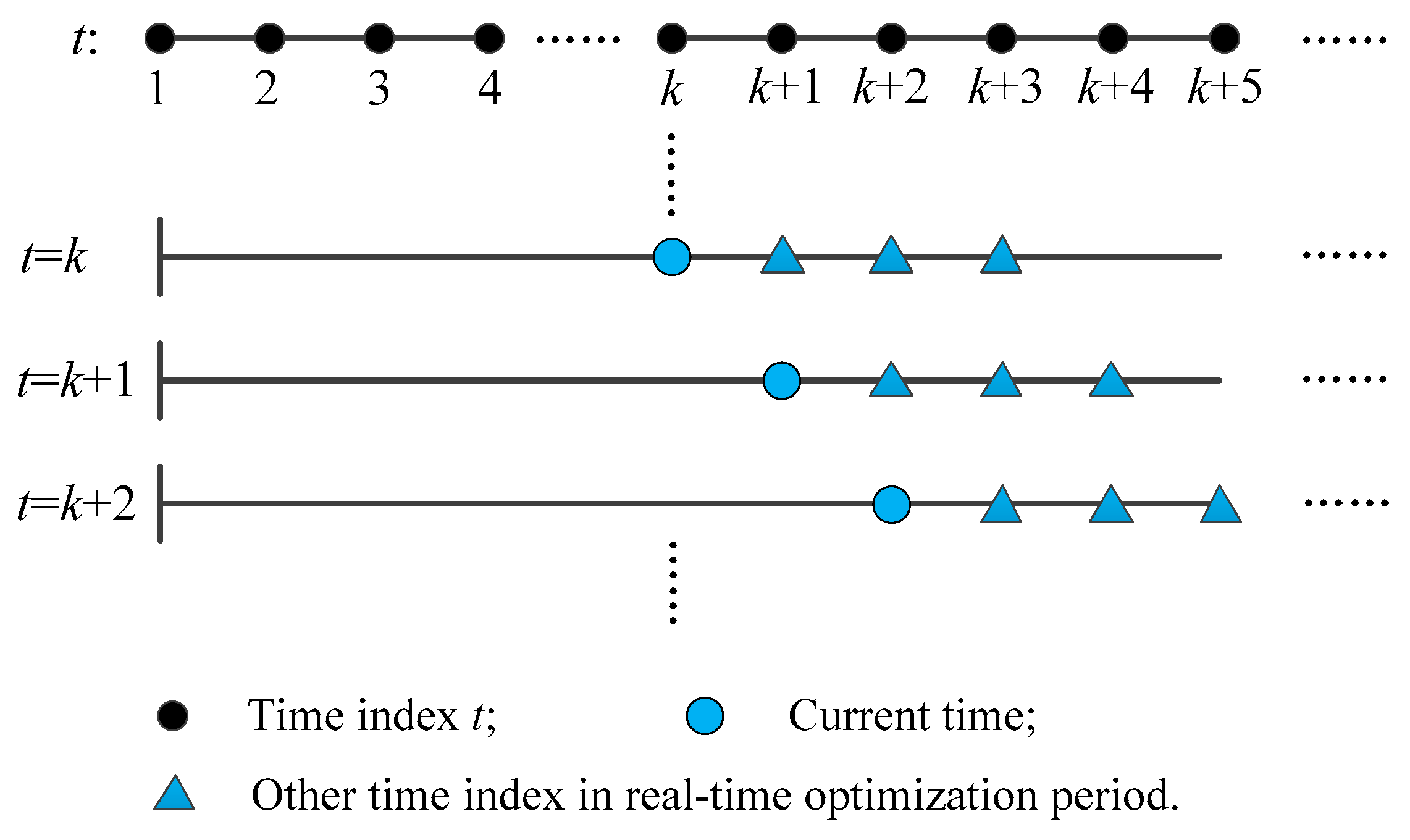

4. MPC-Based Real-Time Rolling Optimization Model

5. Case Studies and Validation

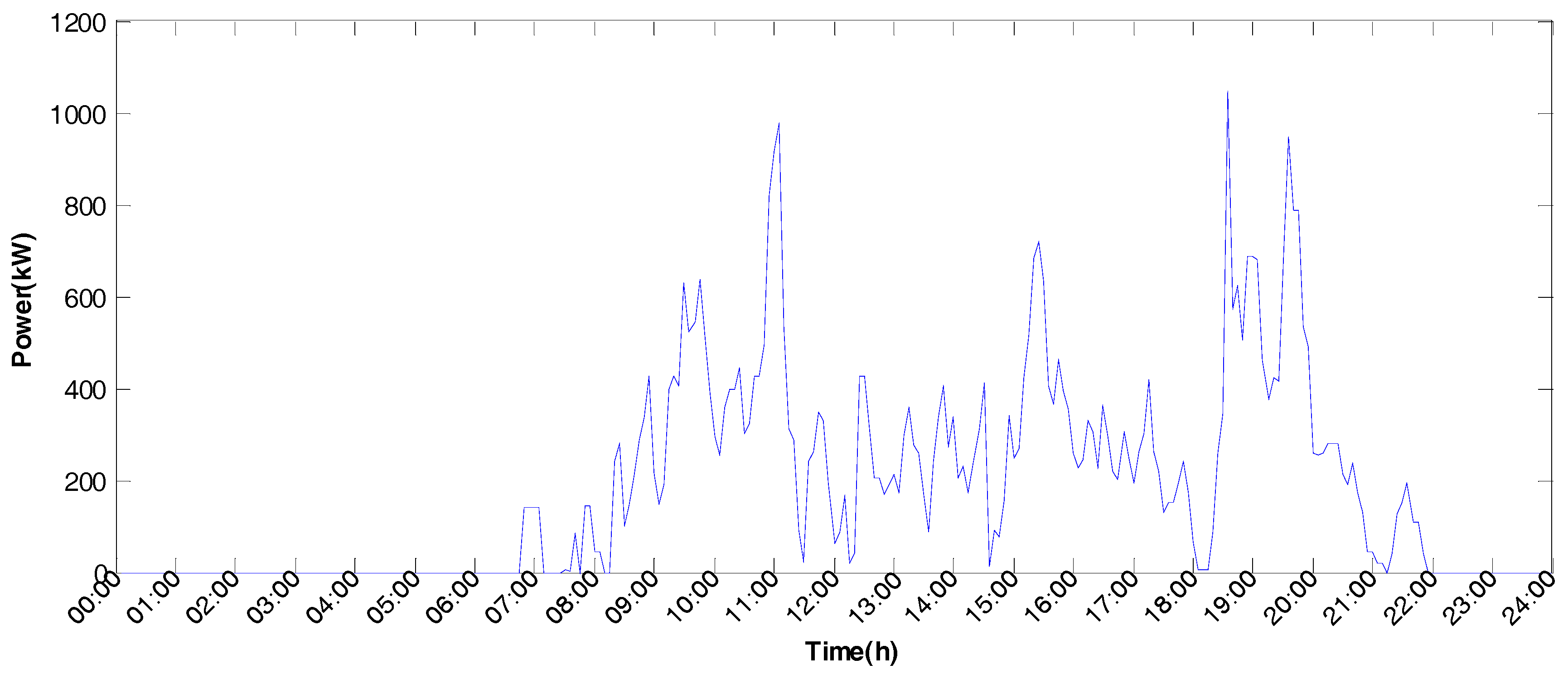

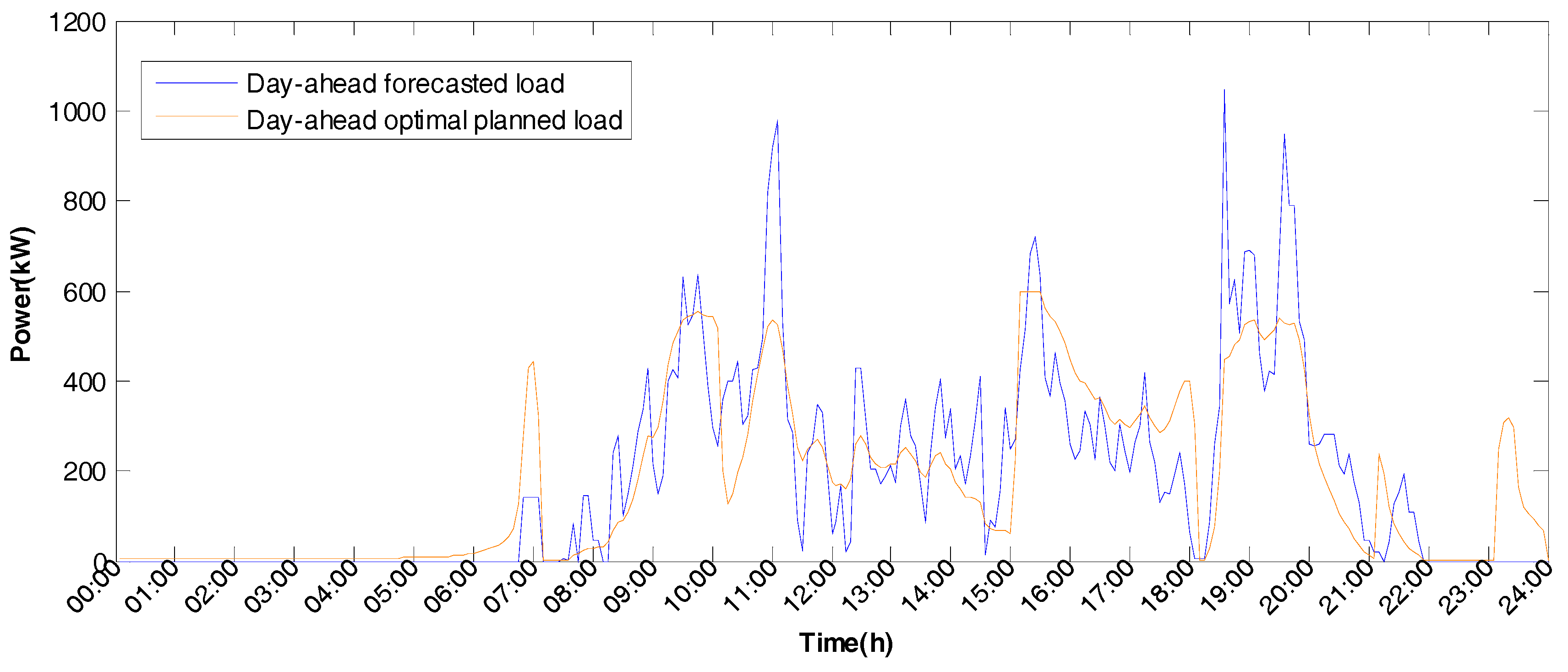

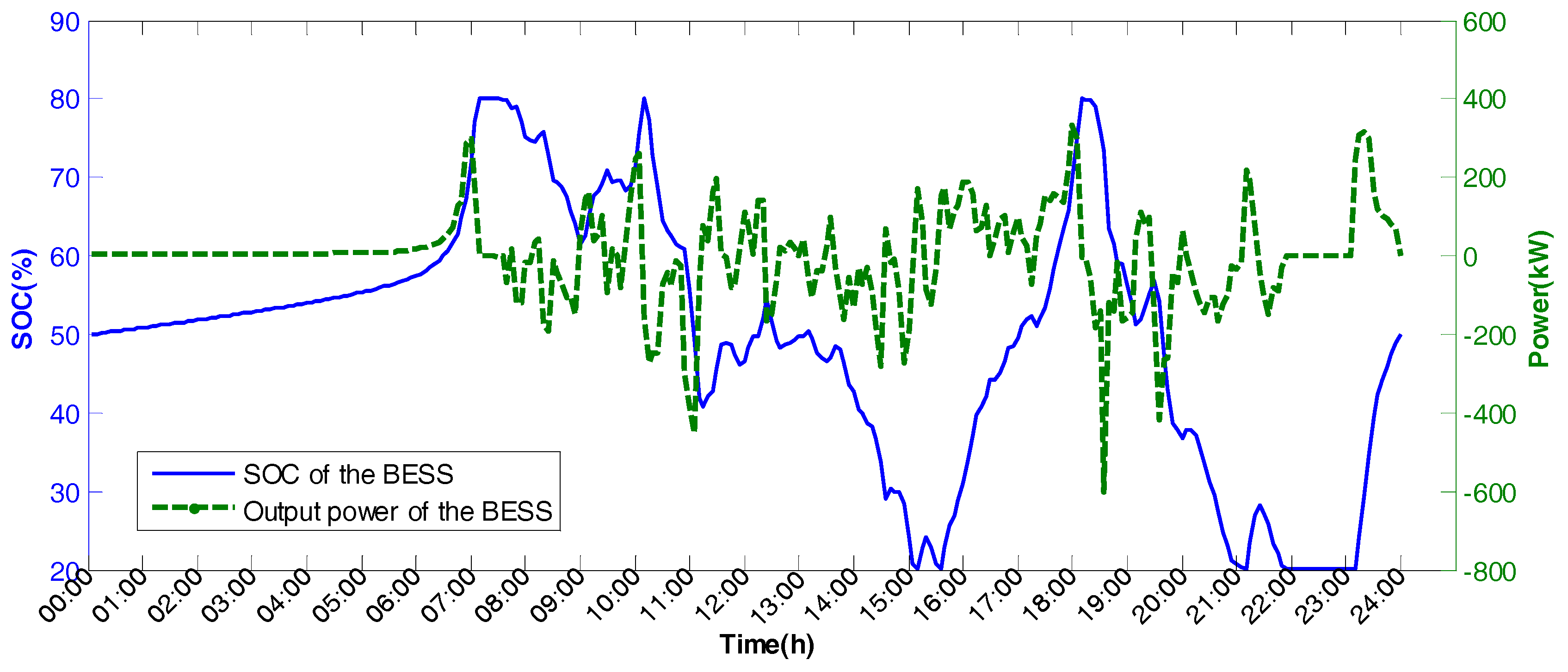

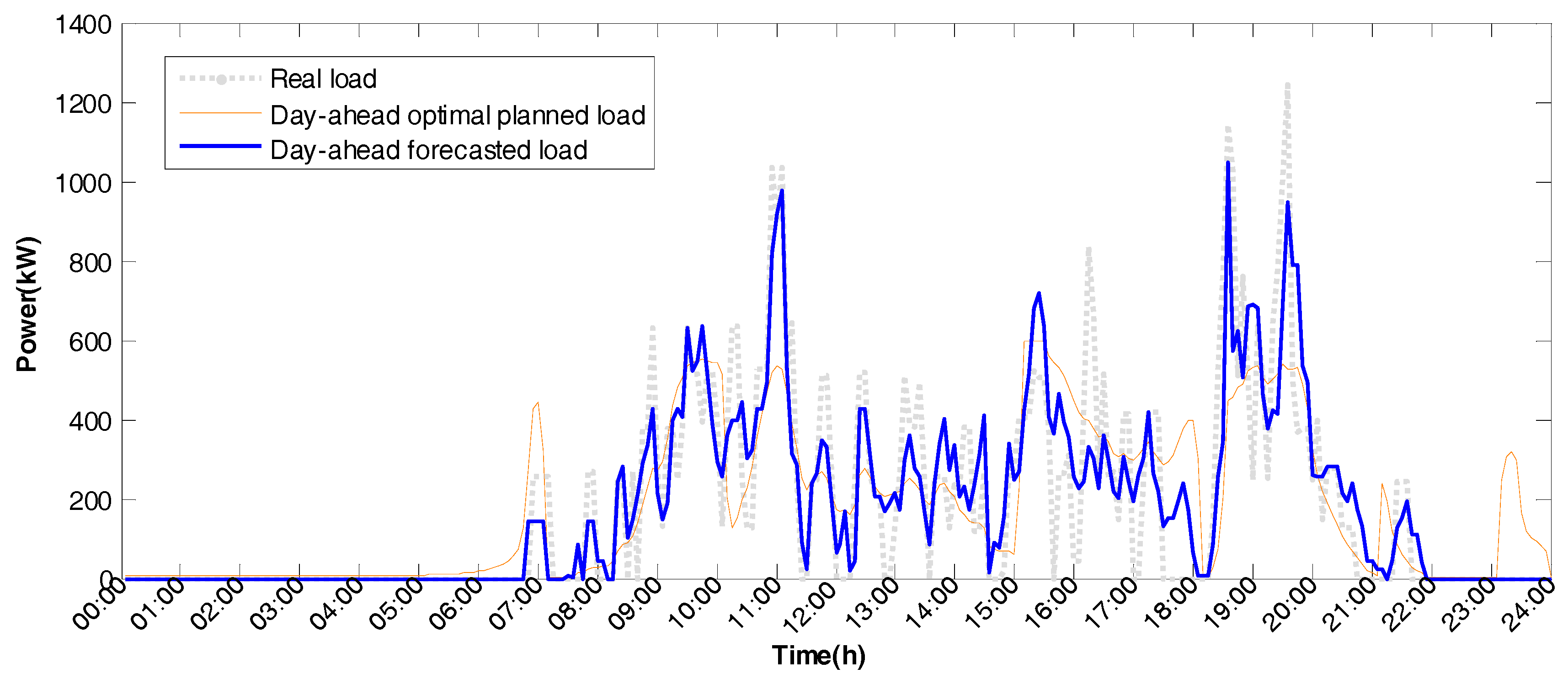

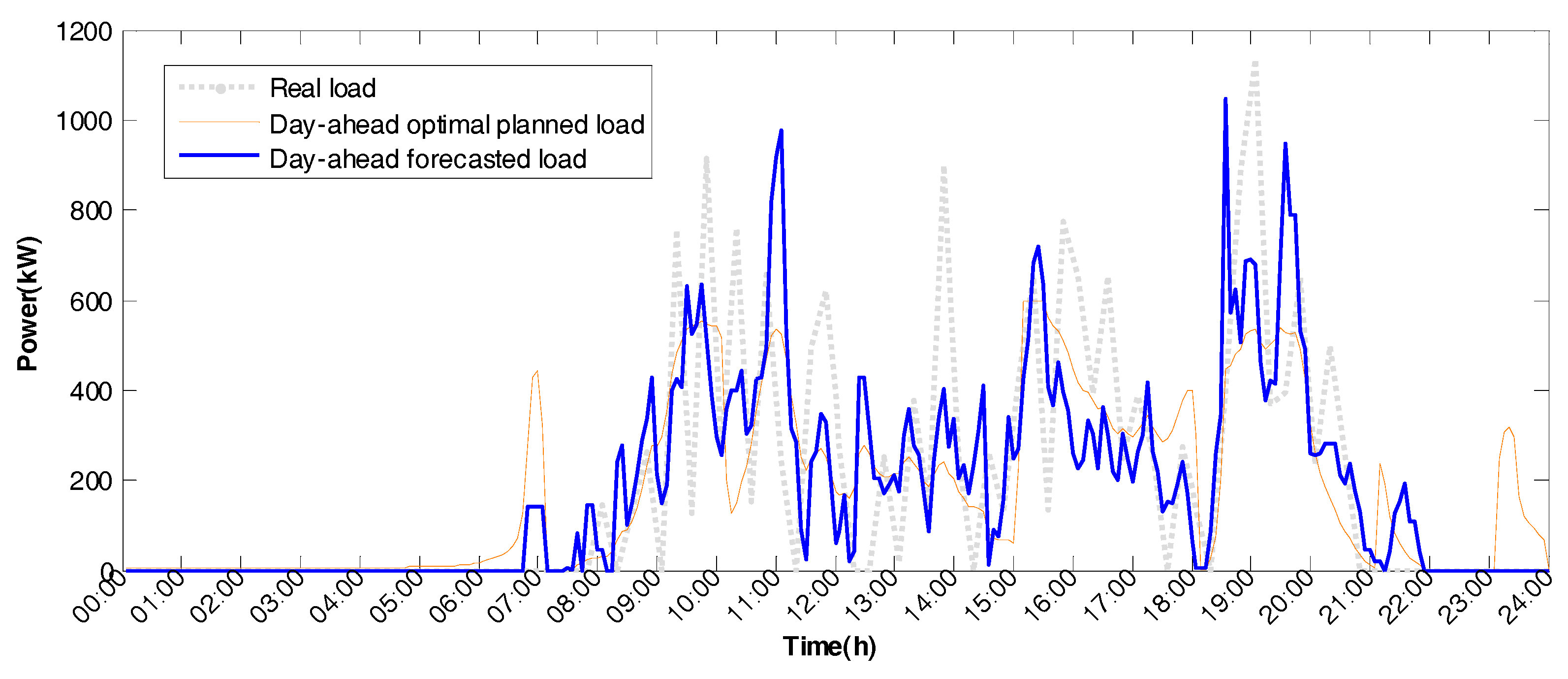

5.1. Day-Ahead Level Optimization Case Study

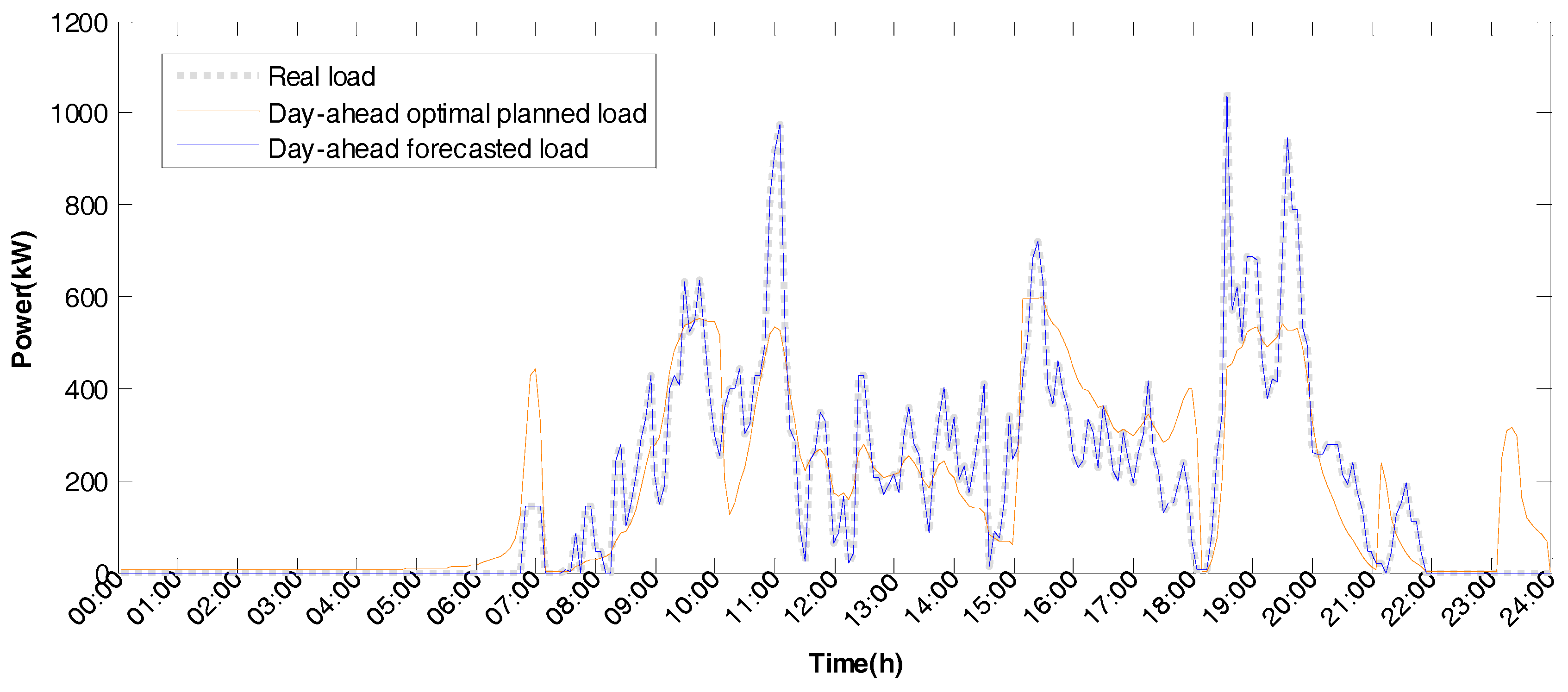

5.2. Real-Time Level Rolling Optimization Case Study

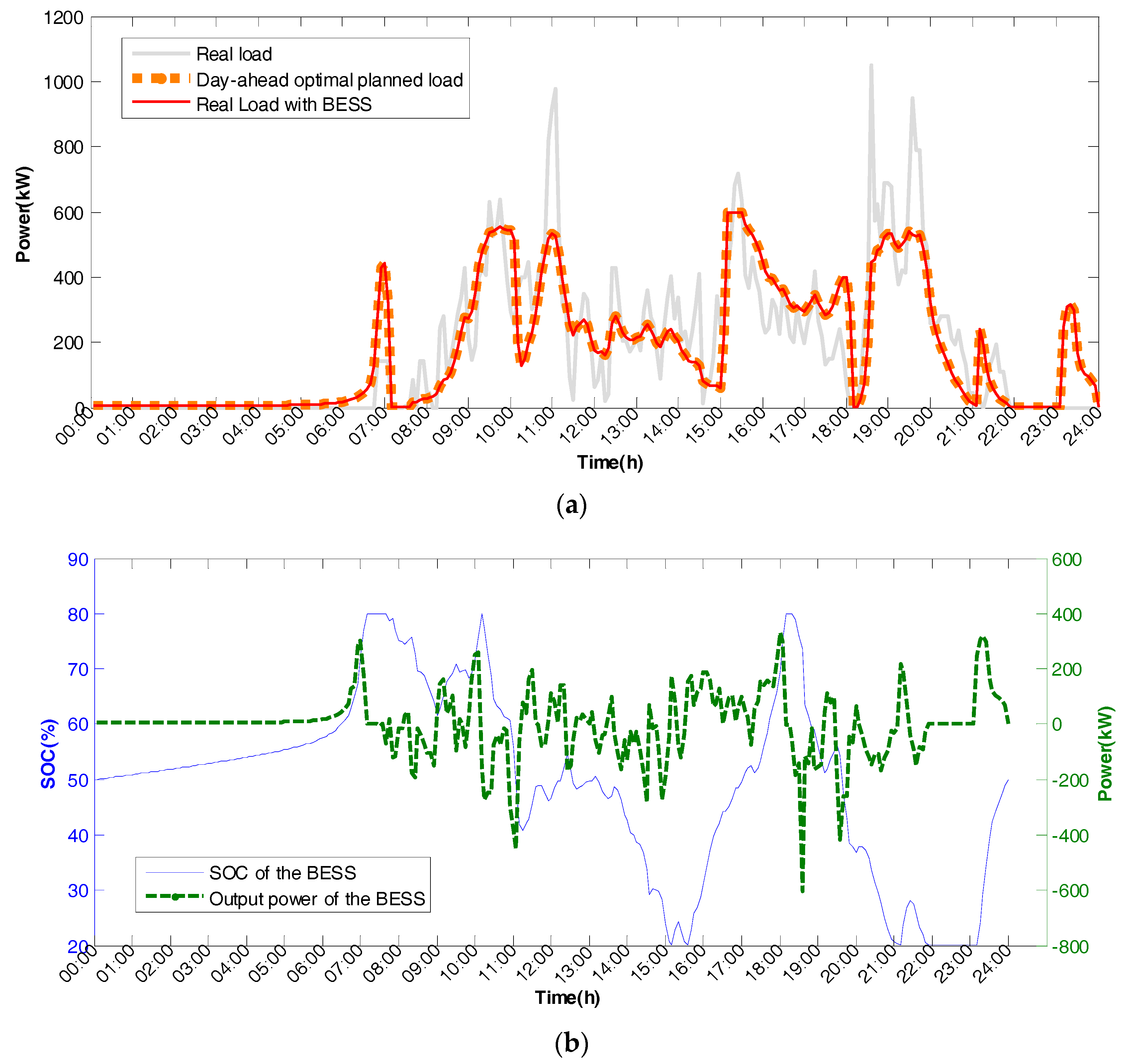

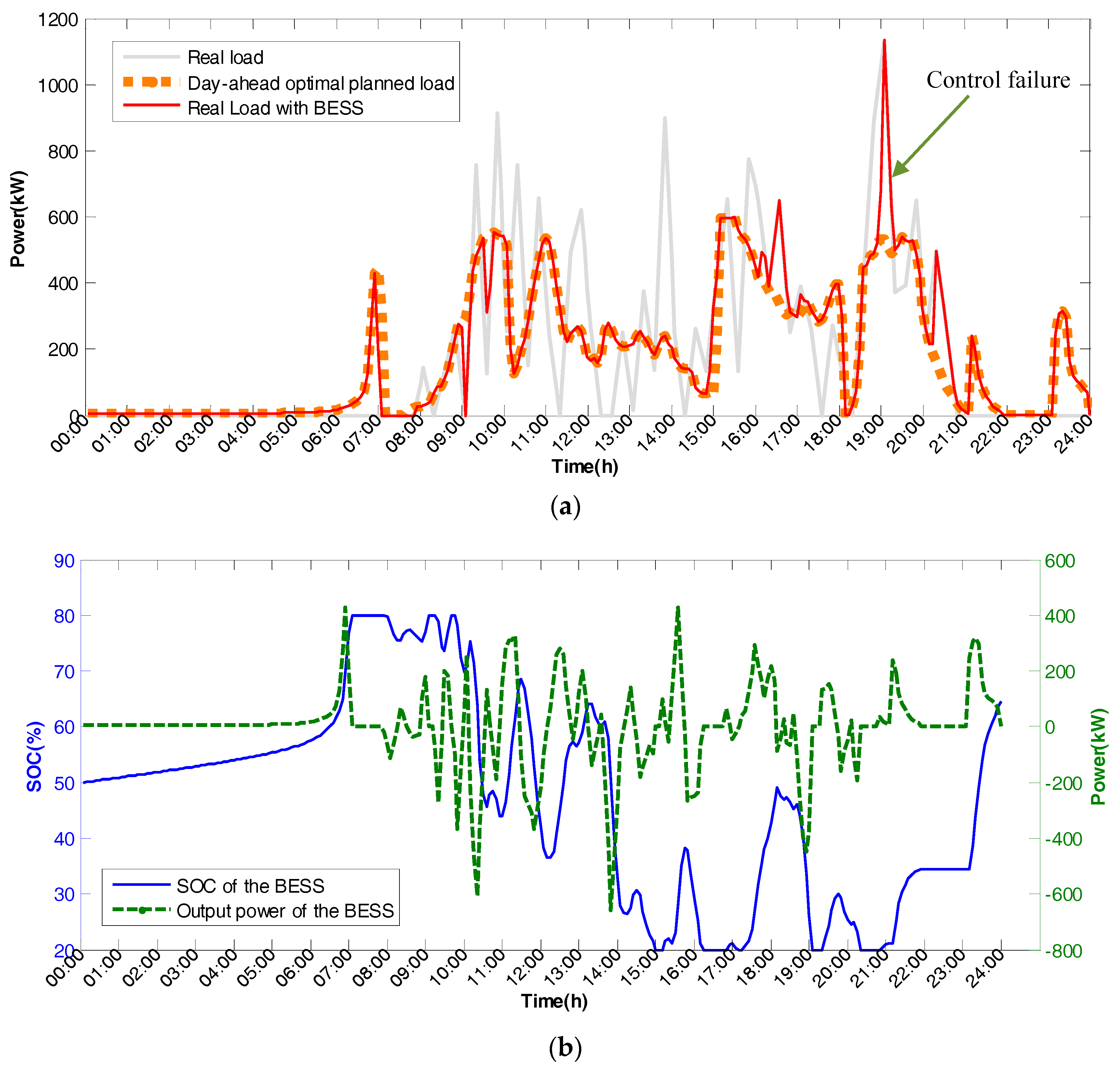

5.2.1. Real-Time Optimization Case I

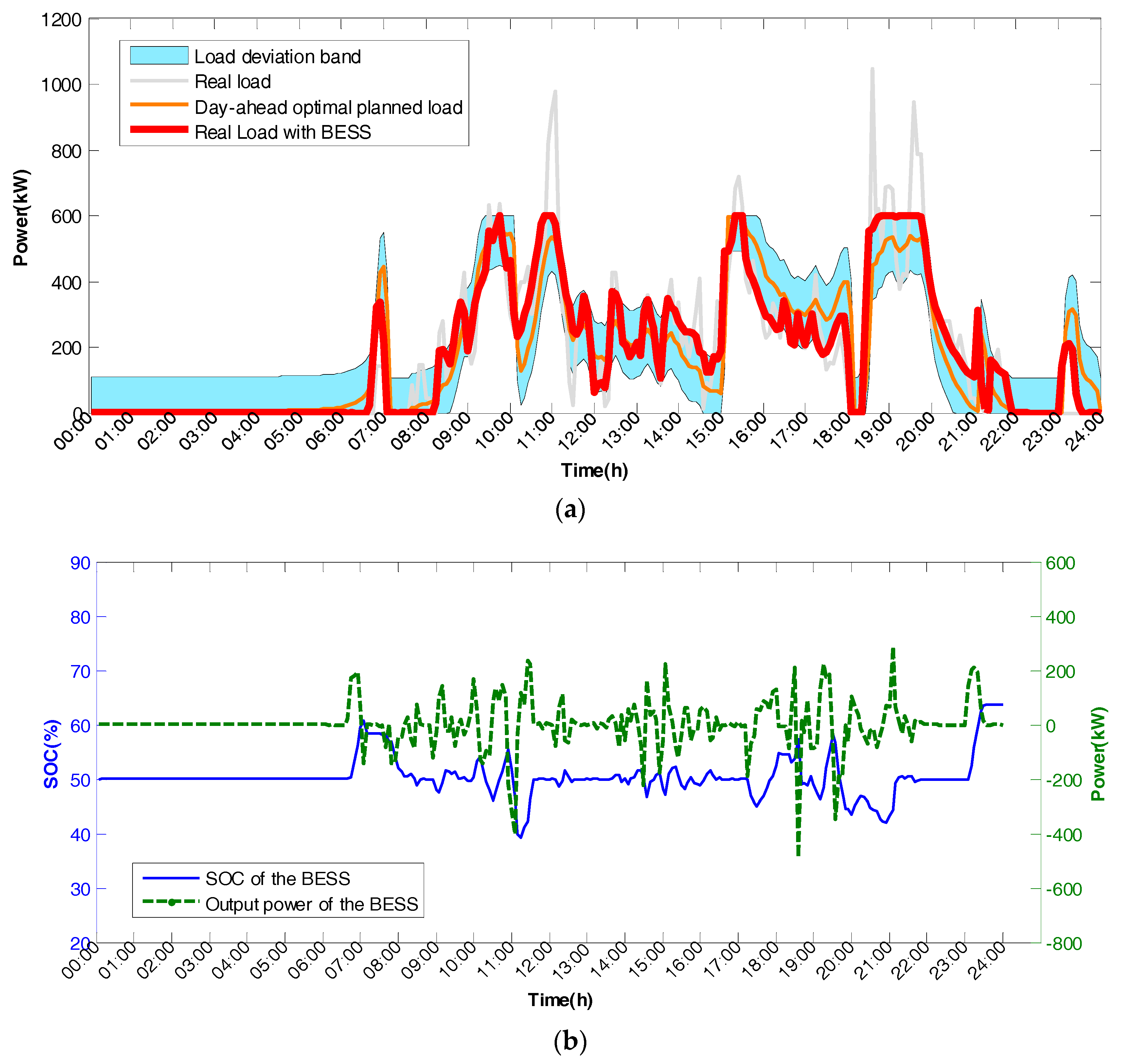

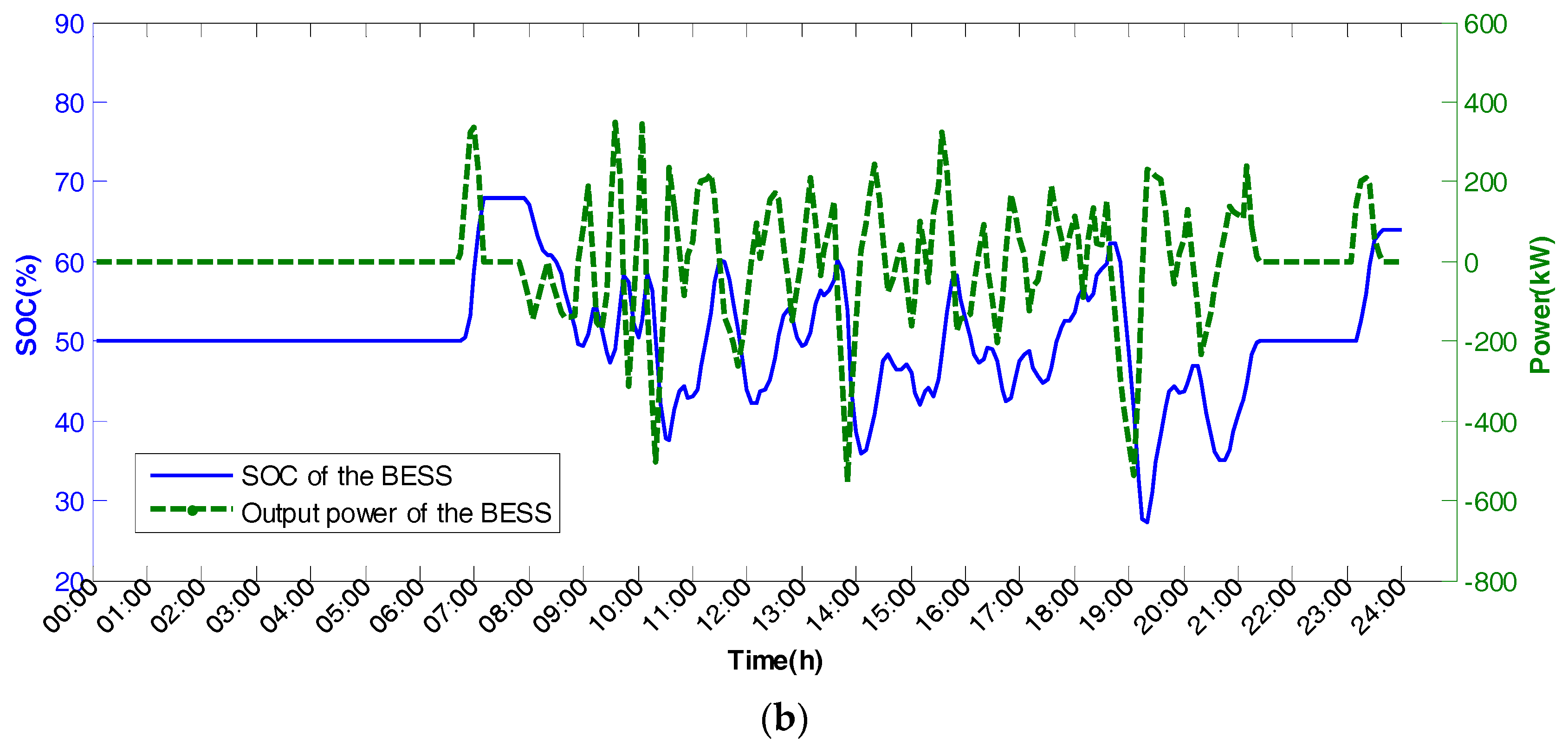

5.2.2. Real-Time Optimization Case II

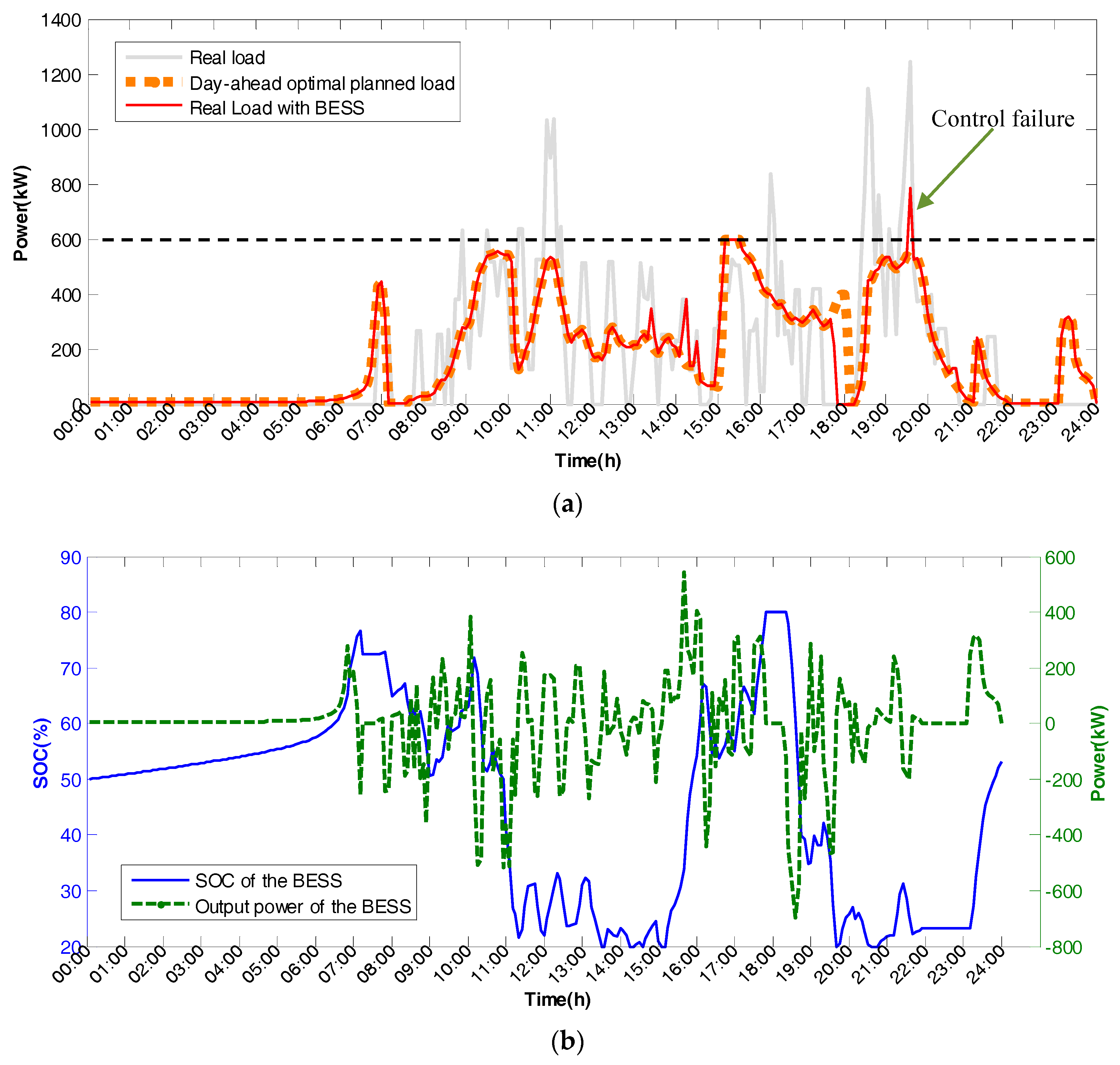

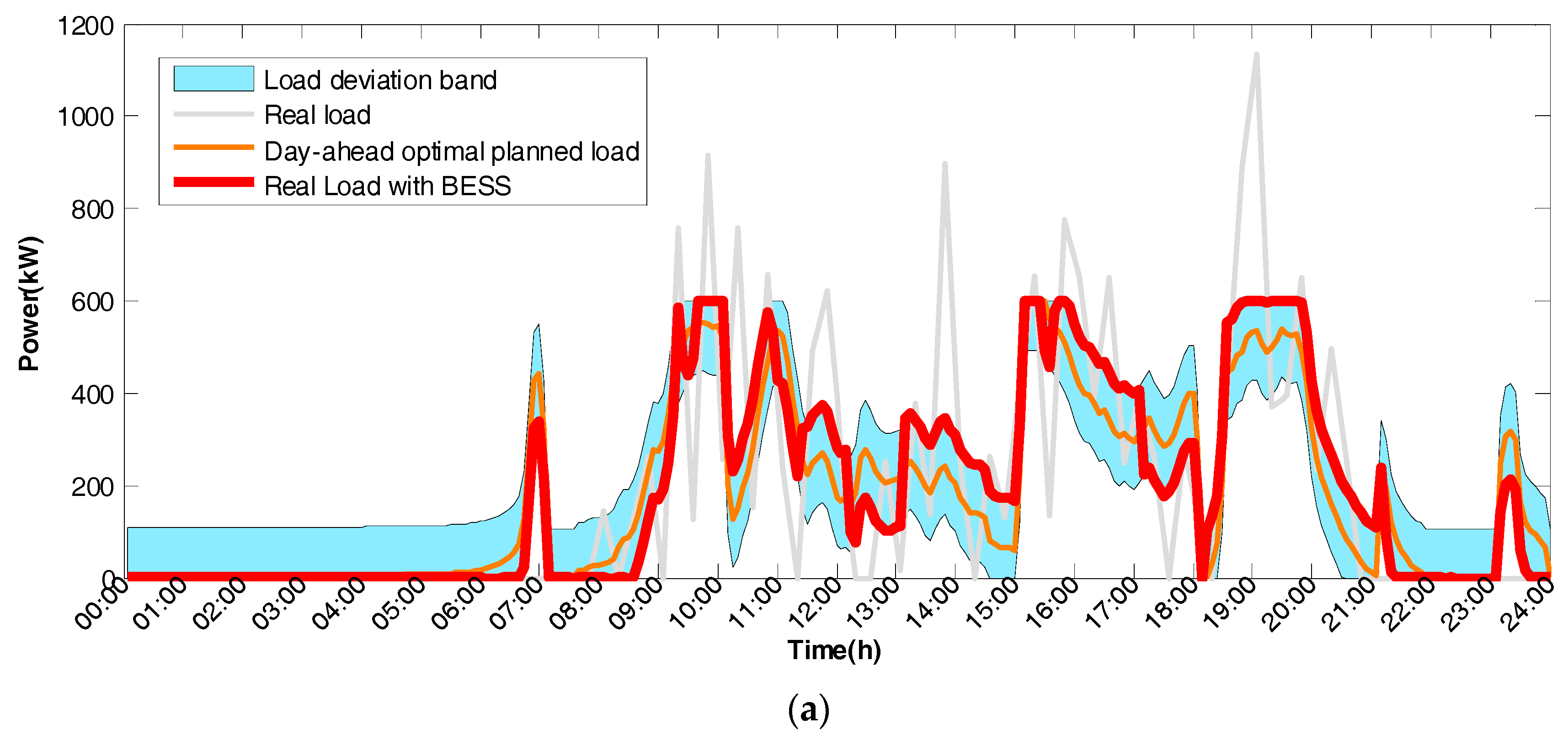

5.2.3. Real-Time Optimization Case III

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Madina, C.; Zamora, I.; Zabala, E. Methodology for assessing electric vehicle charging infrastructure business models. Energy Policy 2016, 89, 284–293. [Google Scholar] [CrossRef]

- Morrissey, P.; Weldon, P.; O’Mahony, M. Future standard and fast charging infrastructure planning: An analysis of electric vehicle charging behavior. Energy Policy 2016, 89, 257–270. [Google Scholar] [CrossRef]

- Chan, C.C. The state of the art of electric, hybrid, and fuel cell vehicles. Proc. IEEE 2007, 95, 704–718. [Google Scholar] [CrossRef]

- Serradilla, J.; Wardle, J.; Blythe, P.; Gibbon, J. An evidence-based approach for investment in rapid-charging infrastructure. Energy Policy 2017, 106, 514–524. [Google Scholar] [CrossRef]

- Xylia, M.; Leduc, S.; Patrizio, P.; Kraxner, F.; Silveira, S. Locating charging infrastructure for electric buses in Stockholm. Transp. Res. Part C Emerg. Technol. 2017, 78, 183–200. [Google Scholar] [CrossRef]

- Xiong, R.; He, H.; Sun, F.; Zhao, K. Online estimation of peak power capability of Li-ion batteries in electric vehicles by a hardware-in-Loop approach. Energies 2012, 5, 1455–1469. [Google Scholar] [CrossRef]

- Lee, J.; Madanat, S. Optimal design of electric vehicle public charging system in an urban network for Greenhouse Gas Emission and cost minimization. Transp. Res. Part C Emerg. Technol. 2017, 85, 494–508. [Google Scholar] [CrossRef]

- Marra, F.; Yang, G.Y.; Fawzy, Y.T.; Traeholt, C. Improvement of local voltage in feeders with photovoltaic using electric vehicles. IEEE Trans. Power Syst. 2013, 28, 3515–3516. [Google Scholar] [CrossRef]

- Sortomme, E.; Hindi, M.M.; Macpherson, S.D.J.; Venkata, S.S. Coordinated charging of plug-in hybrid electric vehicles to minimize distribution system losses. IEEE Trans. Smart Grid 2011, 2, 198–205. [Google Scholar] [CrossRef]

- Clement-Nyns, K.; Haesen, E.; Driesen, J. The impact of charging plug-in hybrid electric vehicles on a residential distribution grid. IEEE Trans. Power Syst. 2010, 25, 371–380. [Google Scholar] [CrossRef]

- Xu, Z.; Hu, Z.; Song, Y.; Zhao, W.; Zhang, Y. Coordination of PEVs charging across multiple aggregators. Appl. Energy 2014, 136, 582–589. [Google Scholar] [CrossRef]

- Han, J.; Park, J.; Lee, K. Optimal scheduling for electric vehicle charging under variable maximum charging power. Energies 2017, 10, 933. [Google Scholar] [CrossRef]

- Masoum, A.S.; Deilami, S.; Moses, P.S.; Masoum, M.A.S.; Abu-Siada, A. Smart load management of plug-in electric vehicles in distribution and residential networks with charging stations for peak shaving and loss minimization considering voltage regulation. IET Gener. Transm. Distrib. 2011, 5, 877–888. [Google Scholar] [CrossRef]

- Deilami, S.; Masoum, A.S.; Moses, P.S.; Masoum, M.A.S. Real-time coordination of plug-in electric vehicle charging in smart grids to minimize power losses and improve voltage profile. IEEE Trans. Smart Grid 2011, 2, 456–467. [Google Scholar] [CrossRef]

- He, L.; Yang, J.; Yan, J.; Tang, Y.; He, H. A bi-layer optimization based temporal and spatial scheduling for large-scale electric vehicles. Appl. Energy 2016, 168, 179–192. [Google Scholar] [CrossRef]

- D’Hulst, R.; Ridder, F.D.; Claessens, B. Decentralized coordinated charging of electric vehicles considering locational and temporal flexibility. Int. Trans. Electr. Energy Syst. 2014, 25, 2562–2575. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, D.; Mu, B.; Wang, L.Y.; Bao, Y.; Jiang, J.C.; Morais, H. Decentralized electric vehicle charging strategies for reduced load variation and guaranteed charge completion in regional distribution grids. Energies 2017, 10, 147. [Google Scholar] [CrossRef]

- Silvestre, M.L.D.; Sanseverino, E.R.; Zizzo, G.; Graditi, G. An optimization approach for efficient management of EV parking lots with batteries recharging facilities. J. Ambient Intell. Humaniz. Comput. 2013, 4, 641–649. [Google Scholar] [CrossRef]

- Tikader, R.; Ganguly, S. Energy management at municipal parking deck for charging of Plug-in hybrid electric vehicles. In Proceedings of the IEEE Students’ Conference on Electrical, Electronics and Computer Science, Bhopal, India, 1–2 March 2014; pp. 1–5. [Google Scholar]

- Zheng, Y.; Dong, Z.Y.; Xu, Y.; Meng, K.; Zhao, J.H.; Qiu, J. Electric vehicle battery charging/swap stations in distribution systems: Comparison study and optimal planning. IEEE Trans. Power Syst. 2014, 29, 221–229. [Google Scholar] [CrossRef]

- Yang, Z.; Sun, L.; Chen, J.; Yang, Q.; Chen, X.; Xing, K. Profit maximization for plug-in electric taxi with uncertain future electricity prices. IEEE Trans. Power Syst. 2014, 29, 3058–3068. [Google Scholar] [CrossRef]

- Yang, P.; Tang, G.; Nehorai, A. A game-theoretic approach for optimal time-of-use electricity pricing. IEEE Trans. Power Syst. 2013, 28, 884–892. [Google Scholar] [CrossRef]

- Awad, A.; Shaaban, M.; El-Fouly, T.; El-Saadany, E.; Salama, M. Optimal resource allocation and charging prices for benefit maximization in smart PEV-parking lots. IEEE Trans. Sustain. Energy 2017, 3, 906–915. [Google Scholar] [CrossRef]

- Yang, H.; Yang, S.; Xu, Y.; Cao, E.; Lai, M.; Dong, Z. Electric vehicle route optimization considering time-of-use electricity price by learnable partheno-genetic algorithm. IEEE Trans. Smart Grid 2015, 6, 657–666. [Google Scholar] [CrossRef]

- Liu, P.; Yu, J.; Fan, K.; Eissa, M. PEV charging coordination to absorb excess wind energy via group differentiated dual-tariff schemes. Electr. Power Syst. Res. 2017, 151, 208–217. [Google Scholar] [CrossRef]

- Islam, S.; Mithulananthan, N.; Lee, K.Y. Suitability of PV and battery storage in EV charging at business premises. IEEE Trans. Power Syst. 2017. [Google Scholar] [CrossRef]

- Graber, G.; Galdi, V.; Calderaro, V.; Mancarella, P. A stochastic approach to size EV charging stations with support of second life battery storage systems. In Proceedings of the IEEE PES PowerTech Conference, Manchester, UK, 18–22 June 2017; pp. 1–6. [Google Scholar]

- Makohin, D.; Jordan, F.V.; Zeni, V.S.; Lemos, K.H.M.; Pica, C.; Gianesini, M.A. Use of lithium iron phosphate energy storage system for EV charging station demand side management. In Proceedings of the IEEE International Symposium on Power Electronics for Distributed Generation Systems, Florianópolis, Brazil, 17–20 April 2017; pp. 1–6. [Google Scholar]

- Xiong, R.; Yu, Q.Q.; Wang, L.Y.; Lin, C. A novel method to obtain the open circuit voltage for the state of charge of lithium ion batteries in electric vehicles by using h infinity filter. Appl. Energy 2017, 207, 346–353. [Google Scholar] [CrossRef]

- Yu, Q.; Xiong, R.; Lin, C.; Shen, W.; Deng, J. Lithium-ion battery parameters and state-of-charge joint estimation based on h infinity and unscented kalman filters. IEEE Trans. Veh. Technol. 2017, 66, 8693–8701. [Google Scholar] [CrossRef]

- Xiong, R.; Cao, J.; Yu, Q.; He, H.; Sun, F. Critical review on the battery state of charge estimation methods for electric vehicles. IEEE Access 2017. [Google Scholar] [CrossRef]

- Ecker, M.; Nieto, N.; Käbitz, S.; Schmalstieg, J.; Blanke, H.; Warnecke, A. Calendar and cycle life study of Li(NiMnCo)O2-based 18650 lithium-ion batteries. J. Power Sources 2014, 248, 839–851. [Google Scholar] [CrossRef]

- Saxena, S.; Hendricks, C.; Pecht, M. Cycle life testing and modeling of graphite/LiCoO2, cells under different state of charge ranges. J. Power Sources 2016, 327, 394–400. [Google Scholar] [CrossRef]

- Xiong, R.; Tian, J.; Mu, H.; Wang, C. A systematic model-based degradation behavior recognition and health monitoring method for lithium-ion batteries. Appl. Energy 2017, 207, 372–383. [Google Scholar] [CrossRef]

- Mattingley, J.; Wang, Y.; Boyd, S. Receding horizon control: Automatic generation of high-speed solvers. IEEE Control Syst. Mag. 2011, 31, 52–65. [Google Scholar] [CrossRef]

- Maciejowski, J.M. Predictive Control with Constraints; Prentice Hall: London, UK, 2002; pp. 154–331. ISBN 0-201-39823-0. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| Maximum grid-side power | 600 | kW |

| Minimum grid-side power | 0 | kW |

| Maximum charging load change rate | 10% | - |

| Minimum charging load change rate | −10% | - |

| Maximum permitted percentage of BESS energy | 80% | - |

| Minimum permitted percentage of BESS energy | 20% | - |

| BESS original SOC | 50% | - |

| Maximum output power of BESS | 800 | kW |

| Minimum output power of BESS | −800 | kW |

| Time | Price Grade | Price (CNY/kWh) |

|---|---|---|

| 0:00–7:00 | Valley | 0.3946 |

| 7:00–10:00 | Flat | 0.6950 |

| 10:00–15:00 | Peak | 1.0044 |

| 15:00–18:00 | Flat | 0.6950 |

| 18:00–21:00 | Peak | 1.0044 |

| 21:00–23:00 | Flat | 0.6950 |

| 23:00–24:00 | Valley | 0.3946 |

| Item | Without BESS-Based Control | Direct Control | MPC |

|---|---|---|---|

| Peak load (kW) | 1048.64 | 598.4 | 600 |

| Load factor | 17.19% | 30.13% | 30.53% |

| Peak-valley difference (kW) | 1048.64 | 598.4 | 600 |

| Maximum SOC | - | 80% | 63.74% |

| Minimum SOC | - | 20% | 39.17% |

| Variation range of SOC | - | 60% | 24.56% |

| TOU electricity cost (CNY/Day) | 3805.84 | 3530.08 | 3584.73 |

| Basic electricity cost (CNY/Day) | 1597.93 | 911.85 | 914.29 |

| Item | Without BESS-Based Control | Direct Control | MPC |

|---|---|---|---|

| Peak load (kW) | 1244.37 | 783.45 | 600 |

| Load factor | 14.35% | 22.88% | 30.24% |

| Peak-valley difference (kW) | 1244.37 | 783.45 | 600 |

| Maximum SOC | - | 80% | 73.36% |

| Minimum SOC | - | 20% | 31.3% |

| Variation range of SOC | - | 60% | 42.06% |

| TOU electricity cost (CNY/Day) | 3790.28 | 3546.27 | 3747.06 |

| Basic electricity cost (CNY/Day) | 1896.18 | 1193.83 | 914.29 |

| Item | Without BESS Based Control | Direct Control | MPC |

|---|---|---|---|

| Peak load (kW) | 1134.84 | 1134.84 | 600 |

| Load factor | 16.45% | 16.72% | 31.59% |

| Peak-valley difference (kW) | 1134.84 | 1134.84 | 600 |

| Maximum SOC | - | 80% | 67.9% |

| Minimum SOC | - | 20% | 27.25% |

| Variation range of SOC | - | 60% | 40.65% |

| TOU electricity cost (CNY/Day) | 3946.15 | 3777.82 | 3902.7 |

| Basic electricity cost (CNY/Day) | 1729.28 | 1729.28 | 914.29 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, Y.; Luo, Y.; Zhang, W.; Huang, M.; Wang, L.Y.; Jiang, J. A Bi-Level Optimization Approach to Charging Load Regulation of Electric Vehicle Fast Charging Stations Based on a Battery Energy Storage System. Energies 2018, 11, 229. https://doi.org/10.3390/en11010229

Bao Y, Luo Y, Zhang W, Huang M, Wang LY, Jiang J. A Bi-Level Optimization Approach to Charging Load Regulation of Electric Vehicle Fast Charging Stations Based on a Battery Energy Storage System. Energies. 2018; 11(1):229. https://doi.org/10.3390/en11010229

Chicago/Turabian StyleBao, Yan, Yu Luo, Weige Zhang, Mei Huang, Le Yi Wang, and Jiuchun Jiang. 2018. "A Bi-Level Optimization Approach to Charging Load Regulation of Electric Vehicle Fast Charging Stations Based on a Battery Energy Storage System" Energies 11, no. 1: 229. https://doi.org/10.3390/en11010229

APA StyleBao, Y., Luo, Y., Zhang, W., Huang, M., Wang, L. Y., & Jiang, J. (2018). A Bi-Level Optimization Approach to Charging Load Regulation of Electric Vehicle Fast Charging Stations Based on a Battery Energy Storage System. Energies, 11(1), 229. https://doi.org/10.3390/en11010229