Effectiveness Analysis and Temperature Effect Mechanism on Chemical and Electrical-Based Transformer Insulation Diagnostic Parameters Obtained from PDC Data

Abstract

1. Introduction

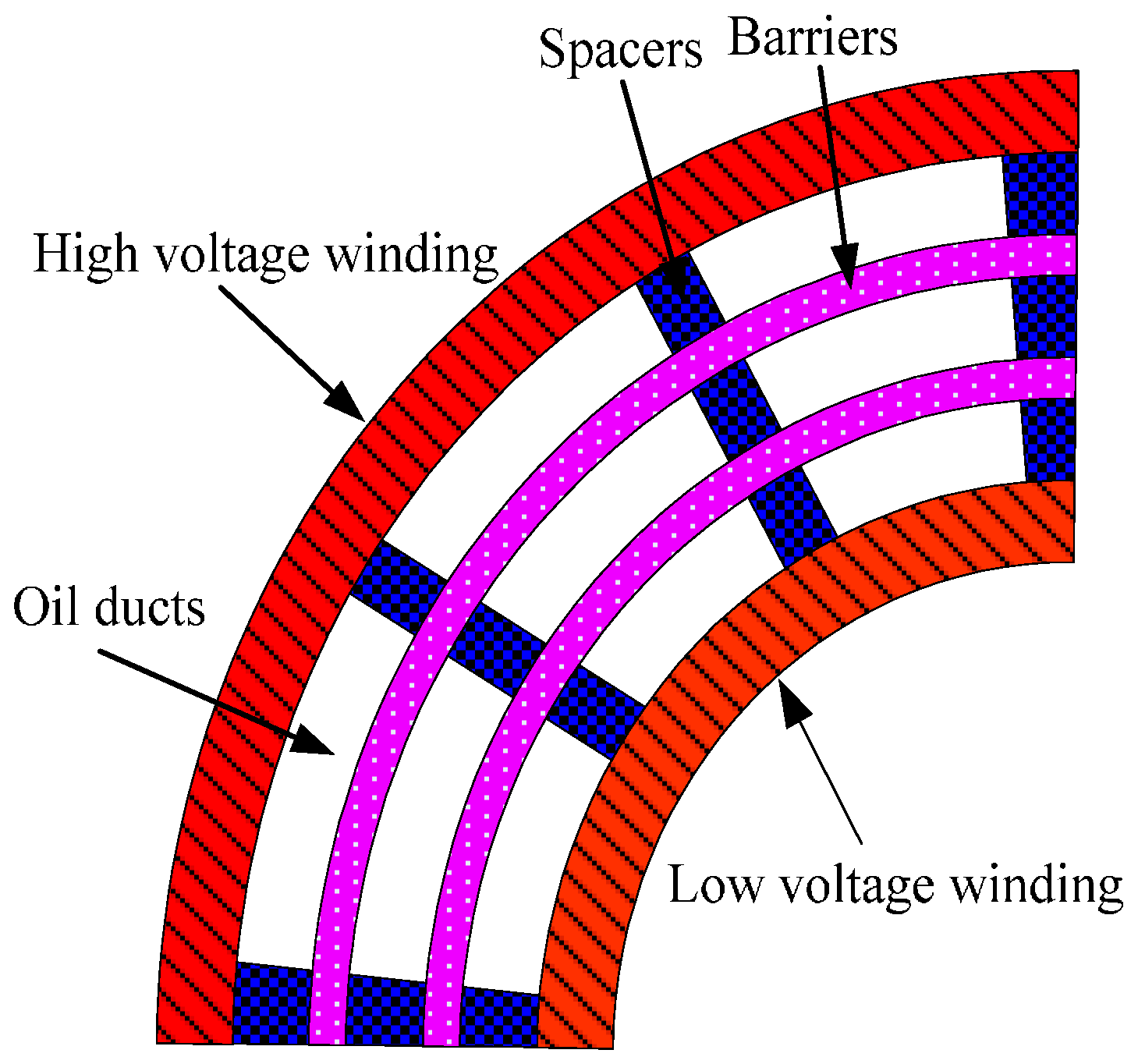

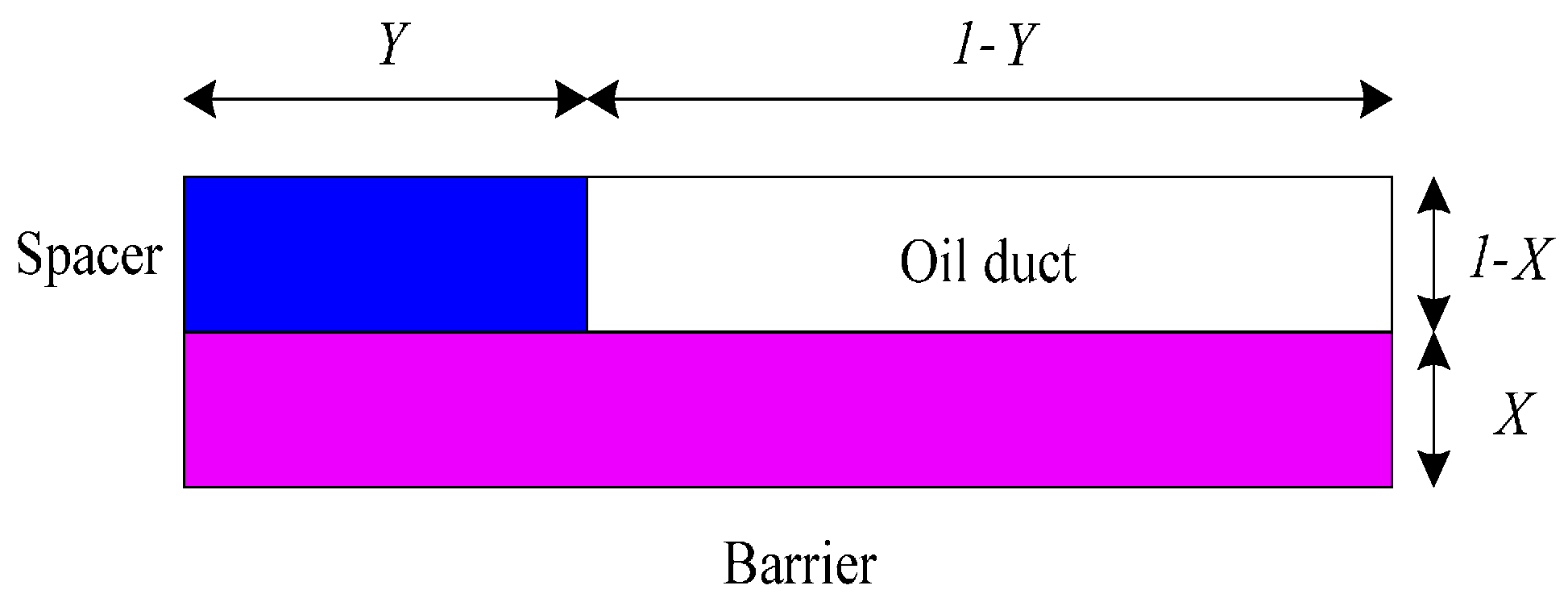

2. Experimental Specimens and PDC Measurement Platform [4,11]

2.1. Preparation of Experimental Specimens

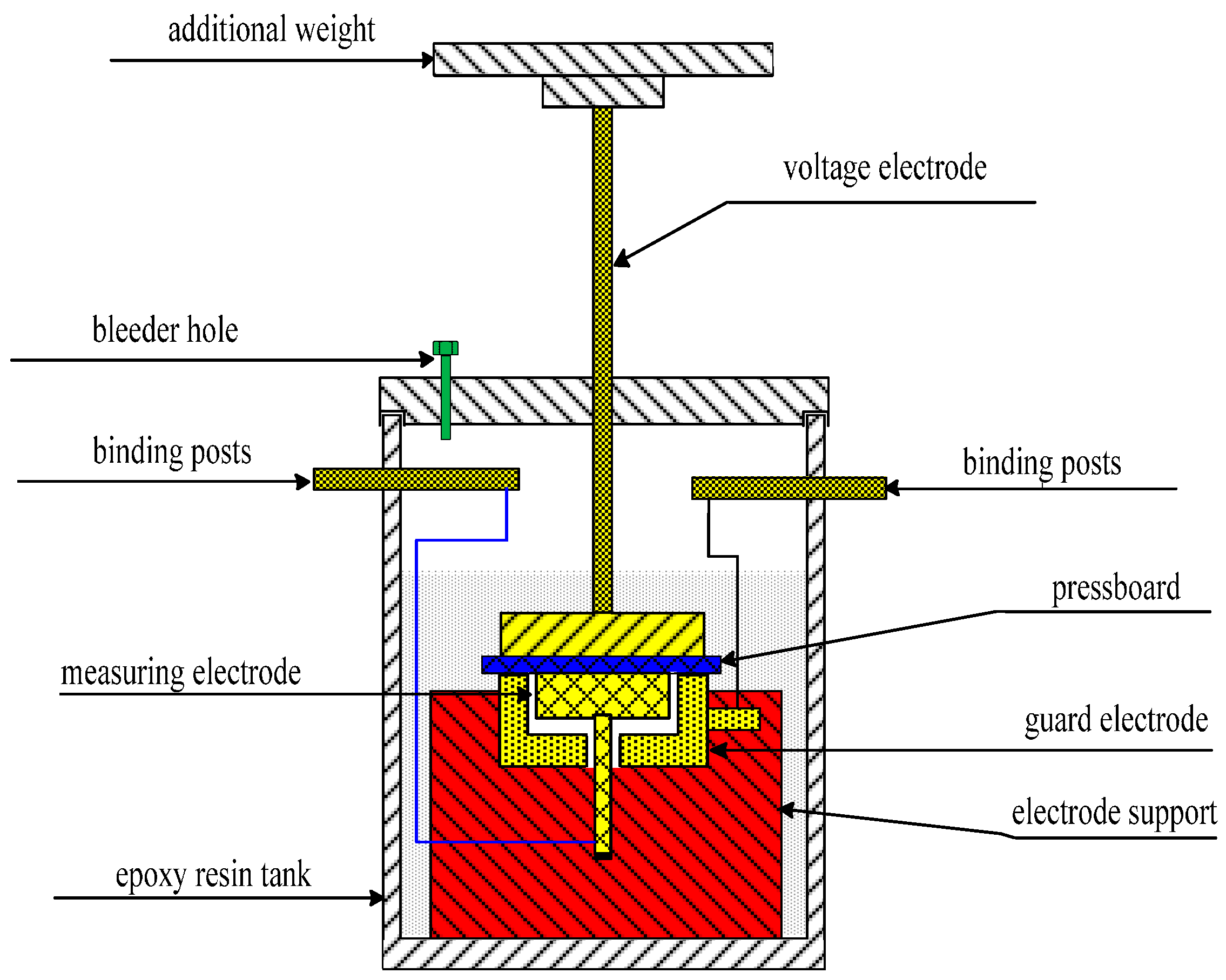

2.2. PDC Measurement Platform (Three Electrode Test Cell and DIRANA Using the PDC Measurement)

3. Measurement Results of Polarization and Depolarization Current (PDC)

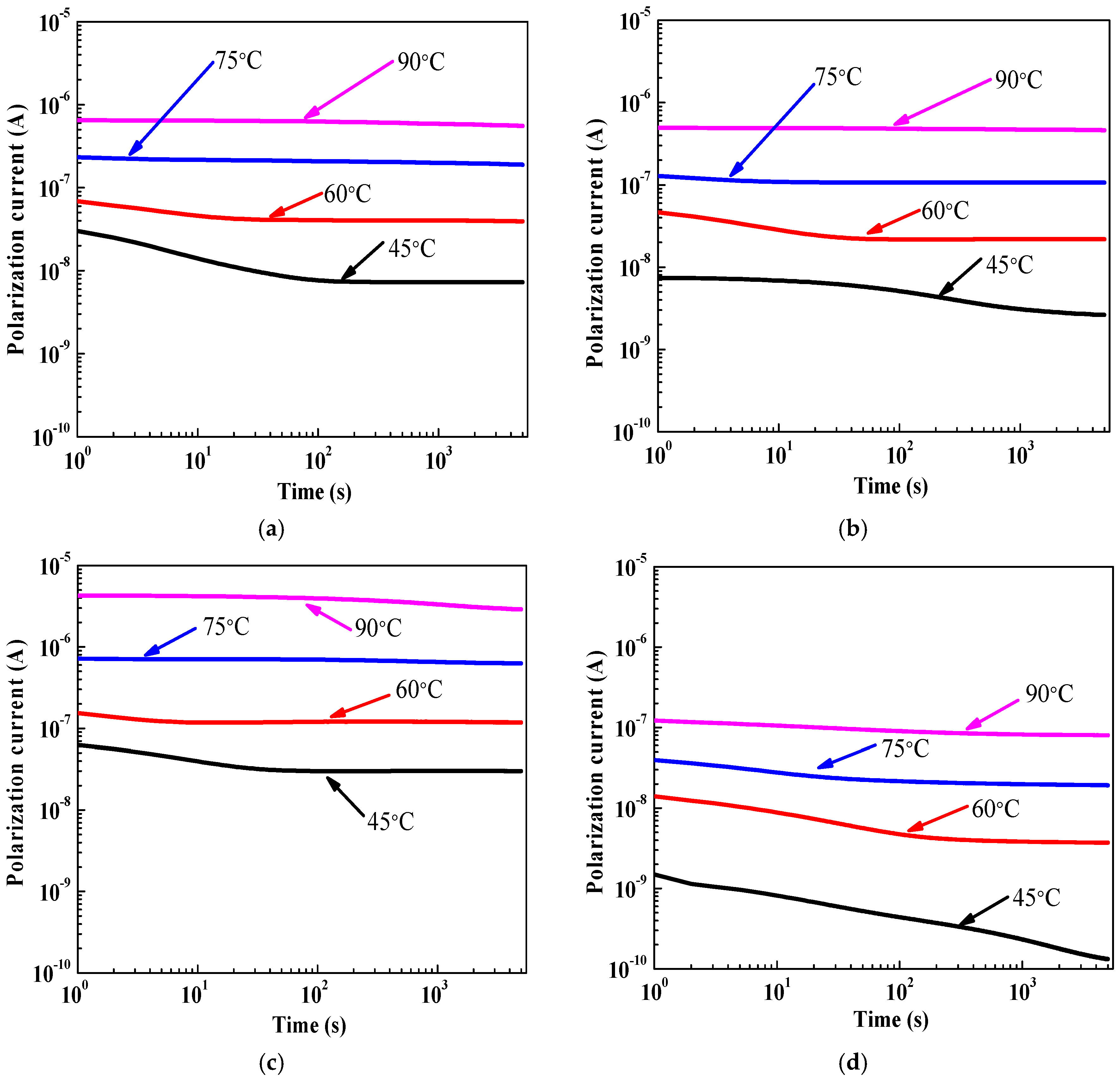

3.1. Polarization Current

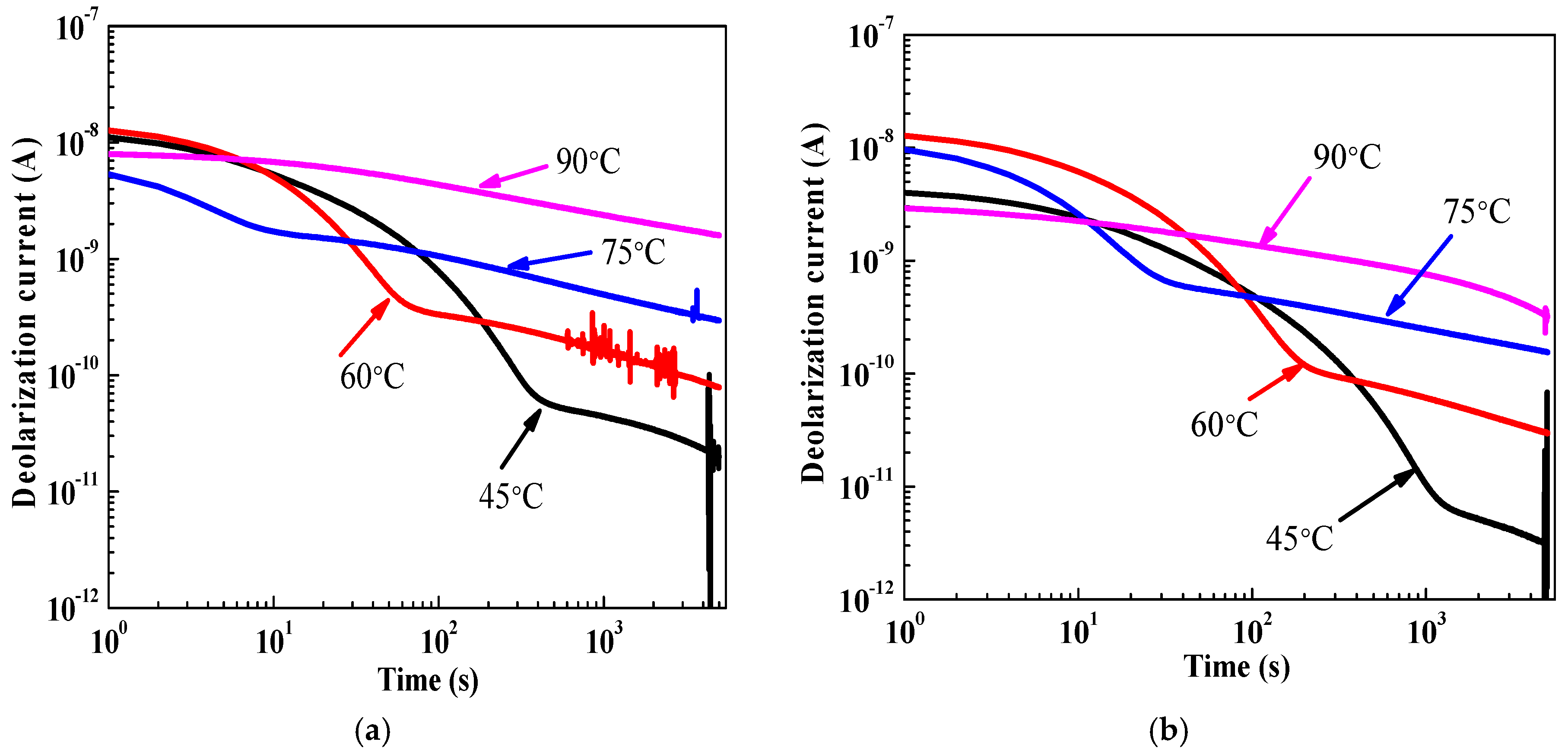

3.2. Deolarization Current

4. Chemical and Electrical-Based Transformer Insulation Diagnostic Parameters Obtained from PDC Data

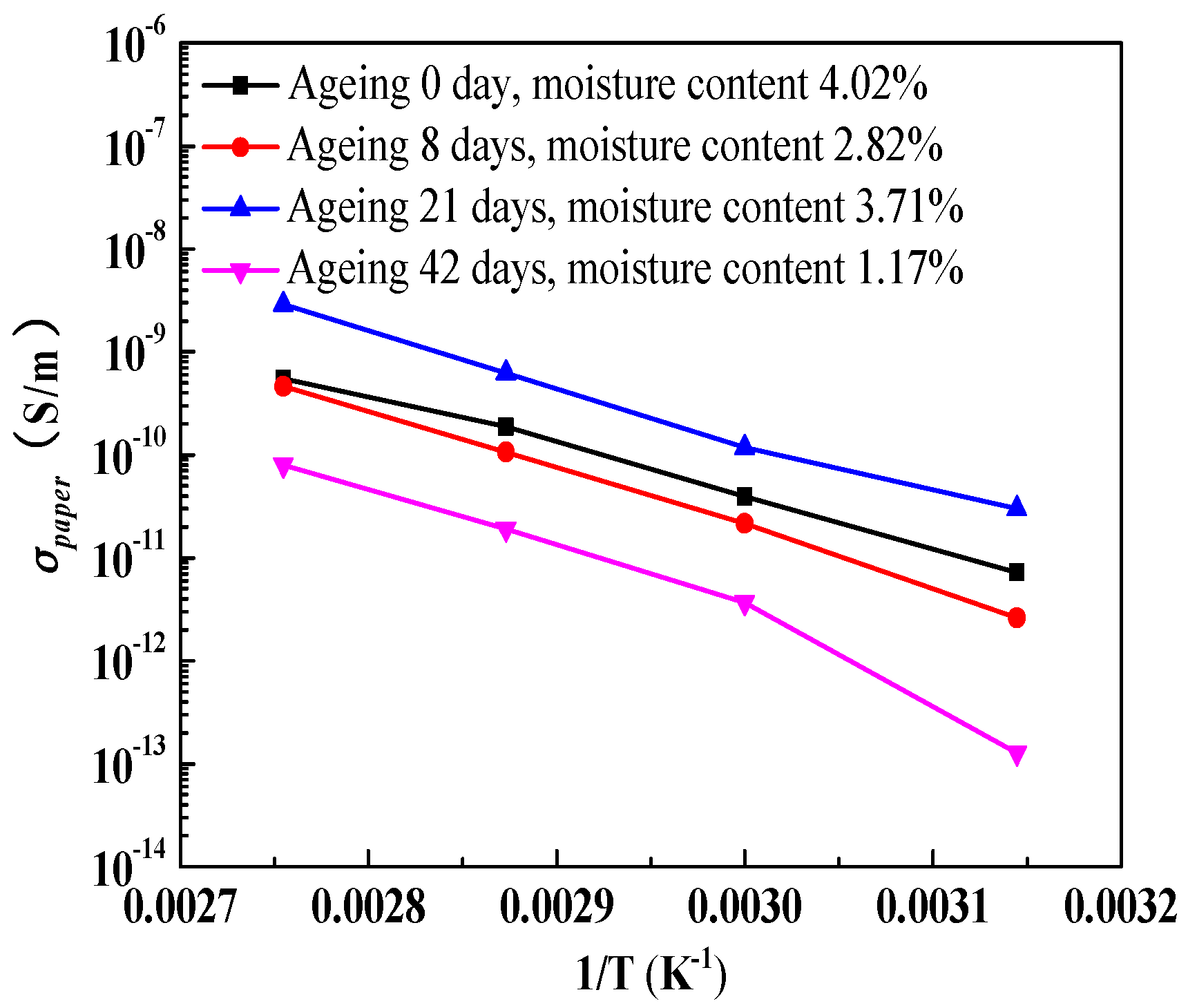

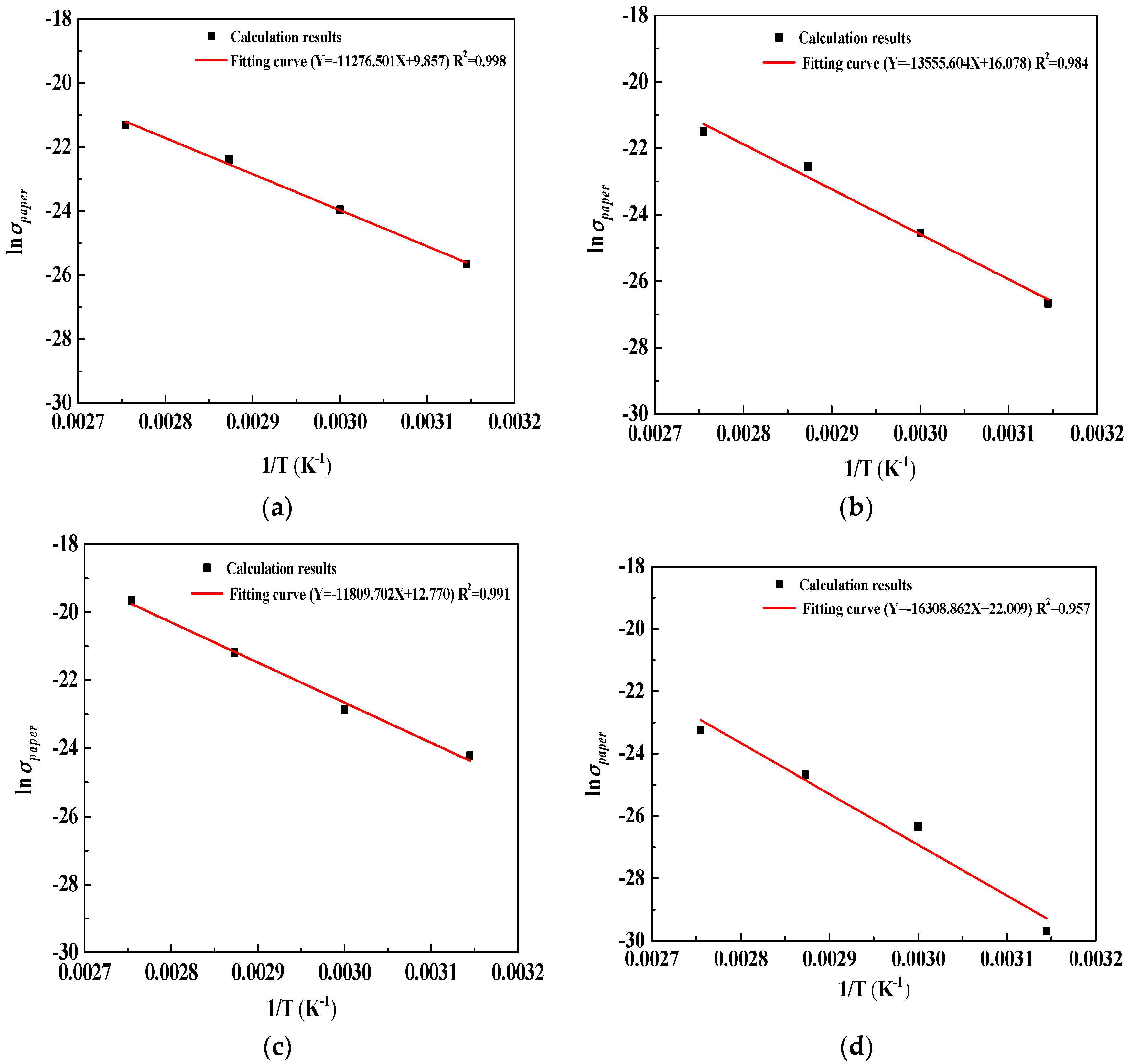

5. Temperature Effect Mechanism Together with Effectiveness Analysis on Chemical and Electrical-Based Transformer Insulation Diagnostic Parameters

6. Conclusions

- (1)

- The magnitudes of polarization/depolarization current obviously decrease with a decreasing insulation temperature. Moreover, the ‘inflection point’ of polarization/depolarization currents will occur with insulation temperature decrease. This inflection point phenomenon seems to be related to the relaxation time constant with temperature dependant. The inflection point will migrate from smaller measurement time point to larger measurement time point with an insulation temperature decrease.

- (2)

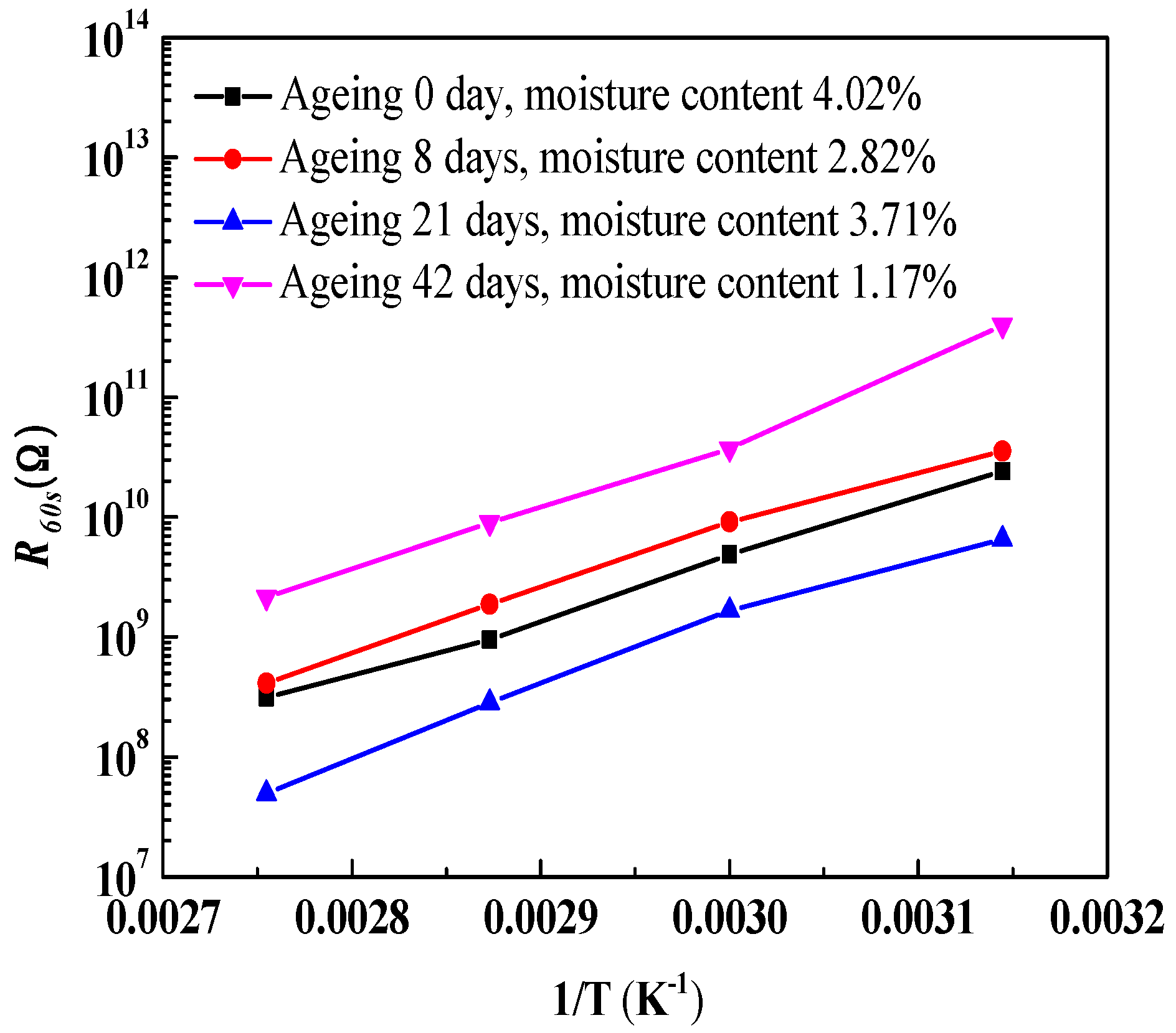

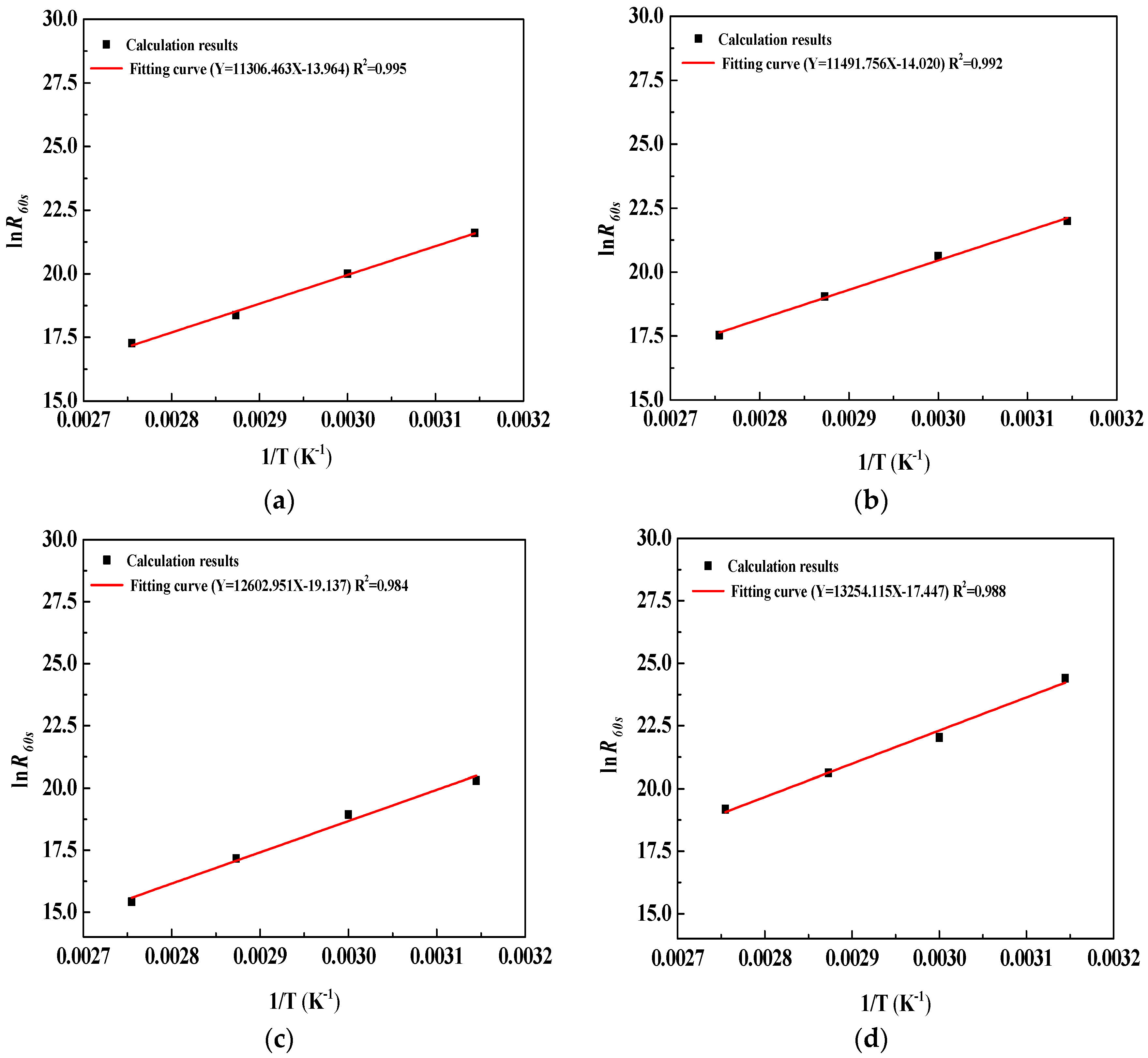

- The chemical and electric-based transformer insulation diagnostic parameters reported in this work can be calculated from PDC measurement and their effectiveness can be effectively verified by the activation energy obtained from the well-known Arrhenius relationship between paper conductivity/insulation resistance and absolute temperature. Moreover, the fluctuation range of the activation energy using the linear relation between lnR60s (T) and 1/T is smaller than using the linear relation between lnσpaper (T) and 1/T due to the better goodness of fit on fitting curves between lnR60s (T) and 1/T.

- (3)

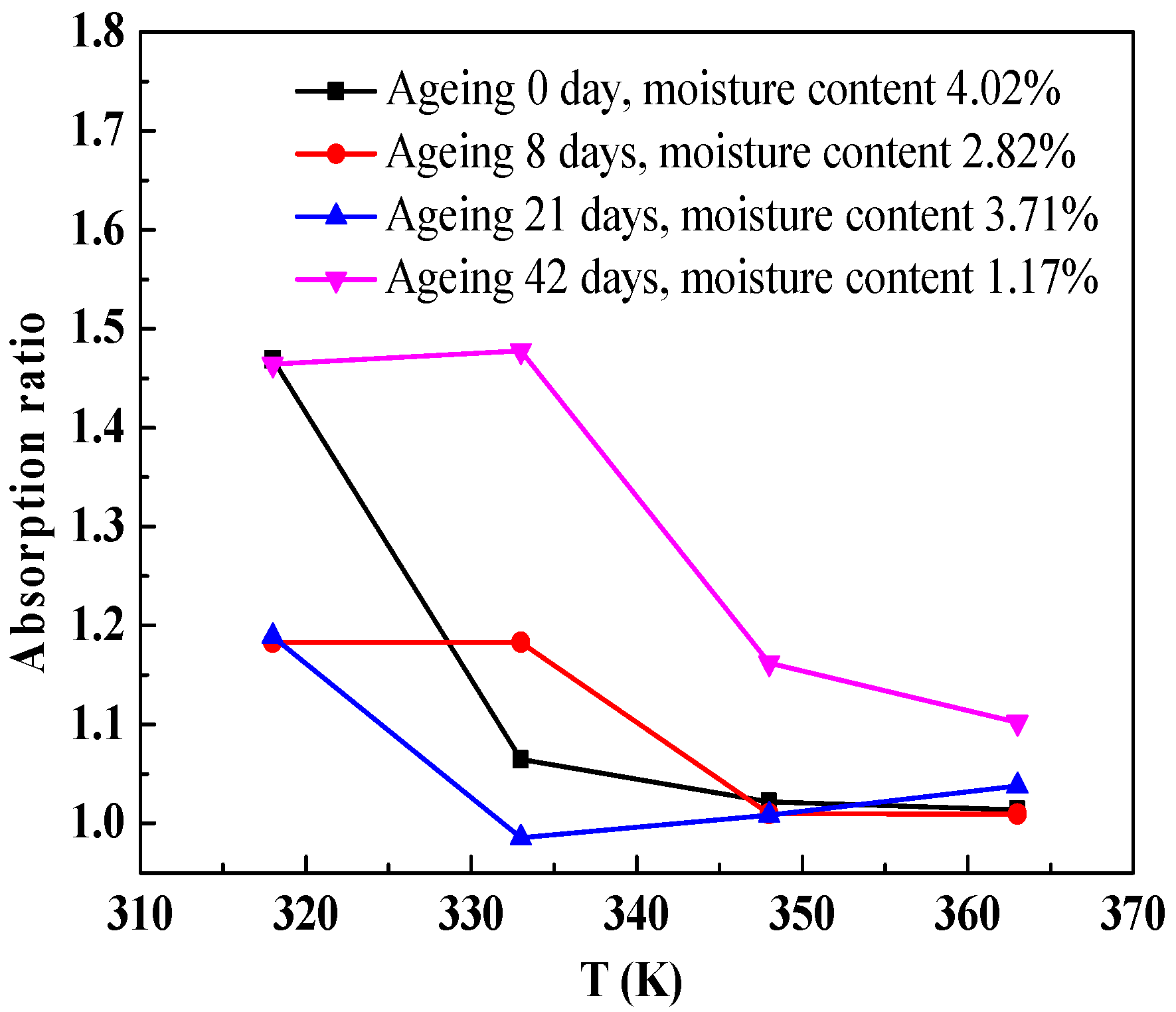

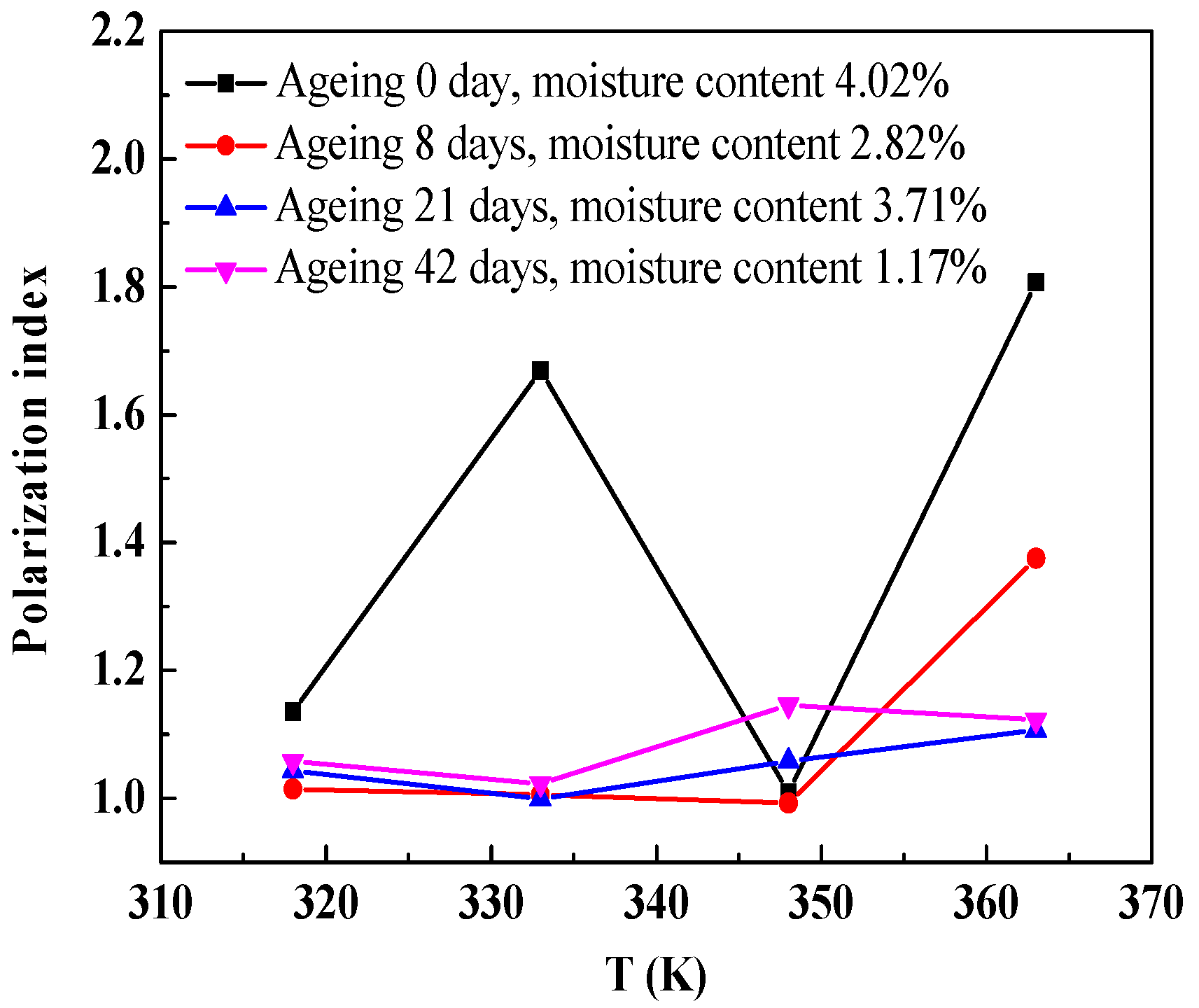

- The temperature effect on paper conductivity and insulation resistance can be effectively eliminated by using the well-known Arrhenius equation. The two parameters are suitable for field application. While the absorption ratio and polarization index obtained from polarization and depolarization current measurement are irregular and it is indicated that these parameters are not suitable for field application.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fofana, I.; Hemmatjou, H.; Meghnefi, F.; Farzaneh, M.; Setayeshmehr, A.; Borsi, H.; Gockenbach, E. On the frequency domain dielectric response of oil-paper insulation at low temperatures. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 799–807. [Google Scholar] [CrossRef]

- Fofana, I.; Hadjadj, Y. Electrical-based diagnostic techniques for assessing insulation condition in aged transformers. Energies 2016, 6, 697. [Google Scholar] [CrossRef]

- Hadjadj, Y.; Meghnefi, F.; Fofana, I.; Ezzaidi, H. On the feasibility of using poles computed from frequency domain spectroscopy to assess oil impregnated paper insulation conditions. Energies 2013, 6, 2204–2220. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.; Zheng, H.; Wei, H.; Liao, R. Study on quantitative correlations between the ageing condition of transformer cellulose insulation and the large time constant obtained from the extended Debye model. Energies 2017, 10, 1842. [Google Scholar] [CrossRef]

- Fofana, I.; Hemmatjou, H.; Farzaneh, M. Low temperature and water effects on polarization and depolarization currents of oil-paper insulation. Electr. Power Syst. Res. 2010, 80, 91–97. [Google Scholar] [CrossRef]

- Sylvestre N’cho, J.; Fofana, I.; Hadjadj, Y.; Beroual, A. Review of physicochemical-based diagnostic techniques for assessing insulation condition in aged transformers. Energies 2016, 9, 367. [Google Scholar] [CrossRef]

- Koch, M.; Prevost, T. Analysis of dielectric response measurements for condition assessment of oil-paper transformer insulation. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1908–1915. [Google Scholar] [CrossRef]

- Munajad, A.; Subroto, C.; Suwarno. Study on the effects of thermal aging on insulating paper for high voltage transformer composite with natural ester from palm oil using Fourier transform infrared spectroscopy (FTIR) and energy dispersive X-ray spectroscopy (EDS). Energies 2017, 10, 1857. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, Y.; Liu, J.; Wei, H.; Zhao, J.; Liao, R. A novel model based on wavelet LS-SVM integrated improved PSO algorithm for forecasting of dissolved gas contents in power transformers. Electr. Power Syst. Res. 2018, 40, 196–205. [Google Scholar] [CrossRef]

- Saha, T.K. Review of Modern Diagnostic Techniques for Assessing Insulation Condition in aged transformers. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 903–917. [Google Scholar] [CrossRef]

- Liu, J.; Zheng, H.; Zhang, Y.; Wei, H.; Liao, R. Grey relational analysis for insulation condition assessment of power transformers based upon conventional dielectric response measurement. Energies 2017, 10, 1526. [Google Scholar] [CrossRef]

- Saha, T.K.; Yao, Z.T. Experience with return voltage measurements for assessing insulation conditions in service-aged transformers. IEEE Trans. Power Deliv. 2003, 18, 128–135. [Google Scholar] [CrossRef]

- Saha, T.K. Review of time-domain polarization measurements for assessing insulation condition in aged transformers. IEEE Trans. Power Deliv. 2003, 18, 1293–1301. [Google Scholar] [CrossRef]

- Hao, J.; Liao, R.; Chen, G.; Ma, Z.; Yang, L. Quantitative analysis ageing condition of natural ester-paper insulation and mineral oil-paper insulation by polarization/depolarization current. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 188–199. [Google Scholar]

- Fofana, I.; Hemmatjou, H.; Meghnefi, F. Effect of thermal transient on the polarization and depolarization current measurements of oil-paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 513–520. [Google Scholar] [CrossRef]

- Liu, J.; Liao, R.; Zhang, Y.; Gong, C.; Wang, C.; Gao, J. Condition evaluation for aging state of transformer oil-paper insulation based on time-frequency domain dielectric characteristics. Electr. Power Compon. Syst. 2015, 43, 759–769. [Google Scholar] [CrossRef]

- Liao, R.; Liu, J.; Yang, L.; Gao, J.; Zhang, Y.; Lv, Y.; Zheng, H. Understanding and analysis on frequency dielectric parameter for quantitative diagnosis of water content in paper-oil insulation system. IET Electr. Power Appl. 2015, 9, 213–222. [Google Scholar] [CrossRef]

- Liao, R.; Liu, J.; Yang, L.; Wang, K.; Hao, J.; Ma, Z.; Gao, J.; Lv, Y. Quantitative analysis of insulation condition of oil-paper insulation based on frequency domain spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 322–334. [Google Scholar] [CrossRef]

- Liao, R.; Liu, J.; Yang, L.; Zhang, Y.; Gao, J.; Ma, Z.; Hao, J. Extraction of frequency domain dielectric characteristic parameter of oil-paper insulation for transformer condition assessment. Electr. Power Compon. Syst. 2015, 43, 578–587. [Google Scholar] [CrossRef]

- Saha, T.K.; Purkait, P. Investigation of polarization and depolarization current measurements for the assessment of oil-paper insulation of aged transformers. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 144–154. [Google Scholar] [CrossRef]

- We, J.; Zhang, G.; Xu, H.; Peng, H.; Wang, S.; Dong, M. Novel characteristic parameters for oil-paper insulation assessment from differential time-domain spectroscopy based on polarization and depolarization current measurement. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1918–1928. [Google Scholar] [CrossRef]

- Saha, T.K.; Purkait, P. Investigations of temperature effects on the dielectric response measurements of transformer oil-paper insulation system. IEEE Trans. Power Deliv. 2008, 23, 252–260. [Google Scholar] [CrossRef]

- Kumar, A.; Mahajan, S.M. Time domain spectroscopy measurements for the insulation diagnosis of a current transformer. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1803–1811. [Google Scholar] [CrossRef]

- Gafvert, U.; Frimpong, G.; Fuhr, J. Modelling of dielectric measurements on power transformers. In Proceedings of the International Conference on Large High Voltage Electric Systems (CIGRE), Paris, France, 15–17 September 1998; pp. 15–103. [Google Scholar]

- Ekanayake, C.; Gubanski, S.M.; Graczkowski, A.; Walczak, K. Frequency response of oil impregnated pressboard and paper samples for estimating moisture in transformer insulation. IEEE Trans. Power Deliv. 2006, 21, 1309–1317. [Google Scholar] [CrossRef]

- Liao, R.; Hao, J.; Chen, G.; Yang, L. Quantitative analysis of ageing condition of oil-Paper insulation by frequency domain spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 821–830. [Google Scholar] [CrossRef]

- Linhjell, D.; Lundgaard, L.E.; Gafvert, U. Dielectric response of mineral oil impregnated cellulose and the impact of aging. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 156–169. [Google Scholar] [CrossRef]

- Gao, J.; Yang, L.; Wang, Y.; Liu, X.; Du, Y.; Yao, R. Effect of moisture and thermal degradation on the activation energy of oil–paper insulation in frequency domain spectroscopy measurement. IET Gener. Transm. Distrib. 2016, 10, 2042–2049. [Google Scholar] [CrossRef]

| Insulation Status | Ea (kJ/mol) |

|---|---|

| Ageing 0 day (DP = 1285), water content 4.02% | 93.75 |

| Ageing 8 days (DP = 994), water content 2.82% | 112.70 |

| Ageing 21 days (DP = 841), water content 3.71% | 98.19 |

| Ageing 42 days (DP = 415), water content 1.17% | 135.59 |

| Insulation Status | Ea (kJ/mol) |

|---|---|

| Ageing 0 day (DP = 1285), water content 4.02% | 94.00 |

| Ageing 8 days (DP = 994), water content 2.82% | 95.54 |

| Ageing 21 days (DP = 841), water content 3.71% | 104.78 |

| Ageing 42 days (DP = 415), water content 1.17% | 110.19 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, H.; Liu, J.; Zhang, Y.; Ma, Y.; Shen, Y.; Zhen, X.; Chen, Z. Effectiveness Analysis and Temperature Effect Mechanism on Chemical and Electrical-Based Transformer Insulation Diagnostic Parameters Obtained from PDC Data. Energies 2018, 11, 146. https://doi.org/10.3390/en11010146

Zheng H, Liu J, Zhang Y, Ma Y, Shen Y, Zhen X, Chen Z. Effectiveness Analysis and Temperature Effect Mechanism on Chemical and Electrical-Based Transformer Insulation Diagnostic Parameters Obtained from PDC Data. Energies. 2018; 11(1):146. https://doi.org/10.3390/en11010146

Chicago/Turabian StyleZheng, Hanbo, Jiefeng Liu, Yiyi Zhang, Yijie Ma, Yang Shen, Xiaochen Zhen, and Zilai Chen. 2018. "Effectiveness Analysis and Temperature Effect Mechanism on Chemical and Electrical-Based Transformer Insulation Diagnostic Parameters Obtained from PDC Data" Energies 11, no. 1: 146. https://doi.org/10.3390/en11010146

APA StyleZheng, H., Liu, J., Zhang, Y., Ma, Y., Shen, Y., Zhen, X., & Chen, Z. (2018). Effectiveness Analysis and Temperature Effect Mechanism on Chemical and Electrical-Based Transformer Insulation Diagnostic Parameters Obtained from PDC Data. Energies, 11(1), 146. https://doi.org/10.3390/en11010146