3.1. Numerical Simulation

Because the pipeline of a reciprocating pump is more complex, the pipe beam model is usually used. Compared with ANSYS, ABAQUS (SIMULIA, Johnston, RI, USA) and other finite element analysis software, the CAESAR II (Intergraph, Huntsville, AL, USA) software is simpler to operate and quicker in calculation speed, and the accuracy can meet engineering requirements, making it especially suitable for mechanical calculations of complex piping systems. The following assumptions are made for the calculation of the vibrations of the reciprocating pump pipelines using the CAESAR II software:

- (1)

The small deformation assumption is that the local deformation of the cross-section of the element under load is negligible;

- (2)

The pipe material is in the elastic range without considering the plastic deformation and large deformation, that is, the nonlinear nature of the pipe structure is not considered;

- (3)

The plane stays flat during loading;

- (4)

We only consider the elastic changes of the pipe and the load, i.e., Hooke’s law applies to the full load range of the tubular section;

- (5)

The forces and moments acting on the structure are assumed to be the points acting on their central axes;

- (6)

The amount of rotational deformation of the system is assumed to be small;

- (7)

The force is not affected by structural deformation;

- (8)

We ignore the friction between the liquid and the pipe wall;

- (9)

There is no vacuolization in the liquid filled pipeline [

5].

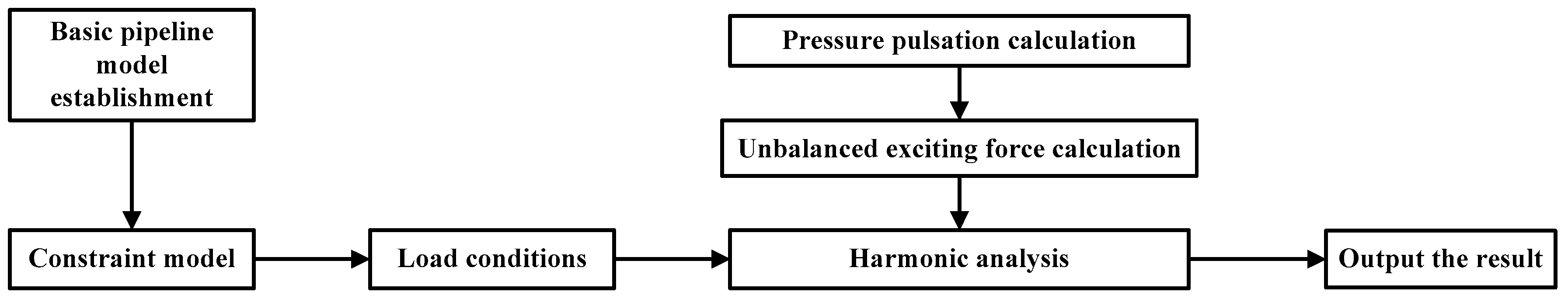

The vibration analysis of pipes is usually done according to the process shown in

Figure 1, and the corresponding numerical simulation steps are as follows: (1) establish a pipeline foundation model: input the basic parameters of the pipeline such as inner pressure, thickness, pipe material, not including pipeline constraints; (2) establish the constraint model according to the actual engineering loads or constraints; (3) set the load condition: combine the load according to the actual pipe load, such as pressure, temperature; (4) harmonic analysis: call harmonic analysis module in CAESAR II software and enter the unbalanced exciting force calculated from Equation (4).

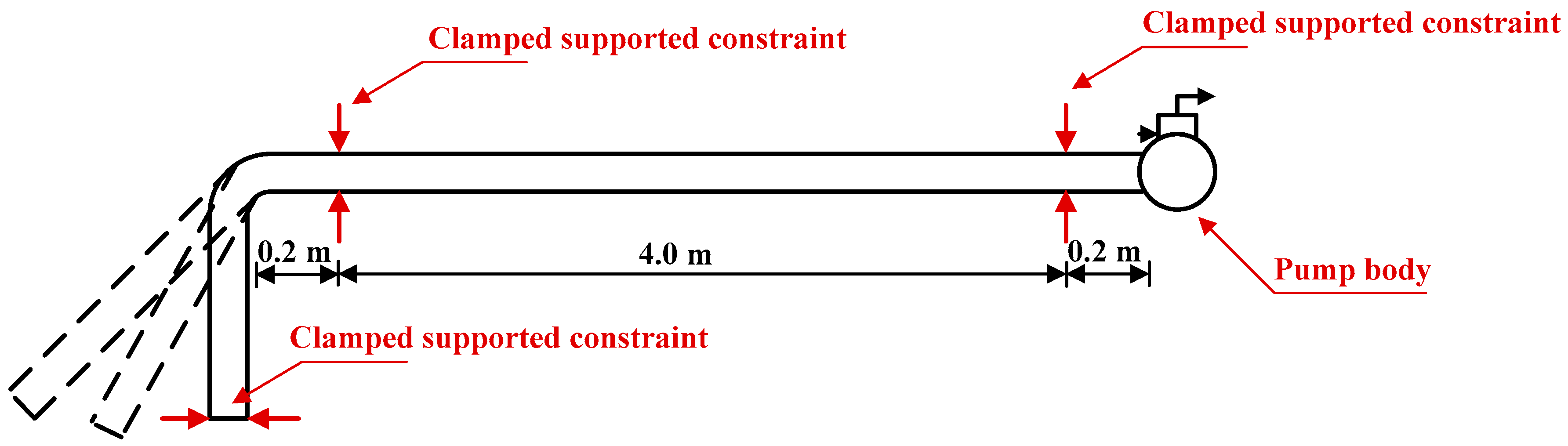

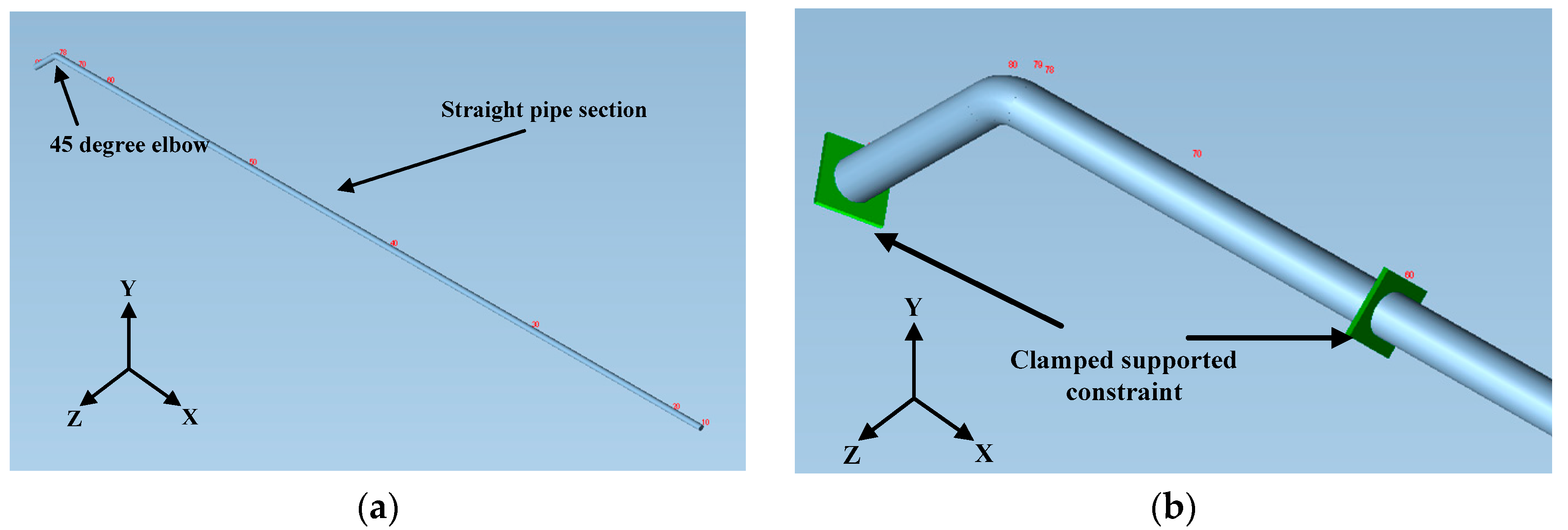

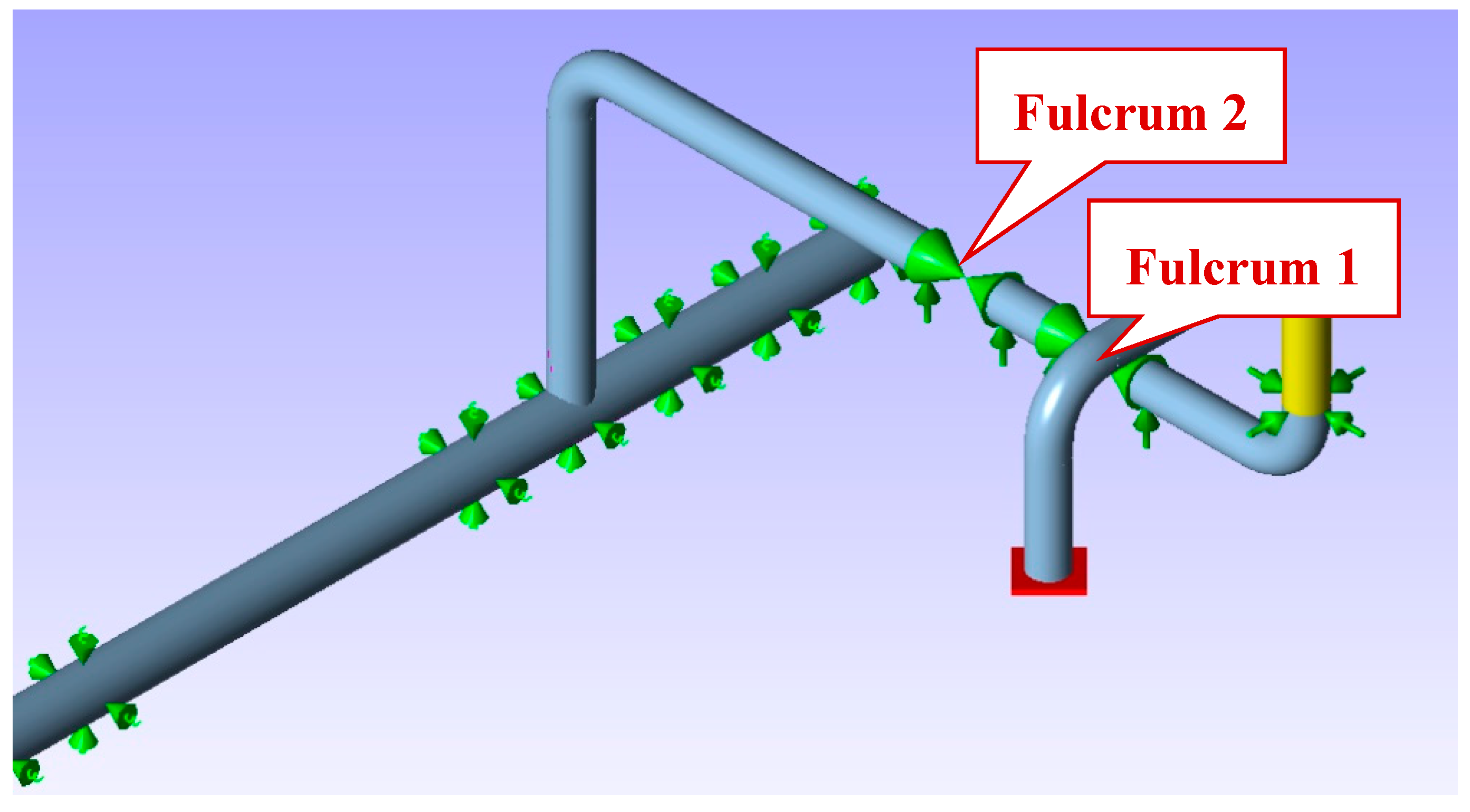

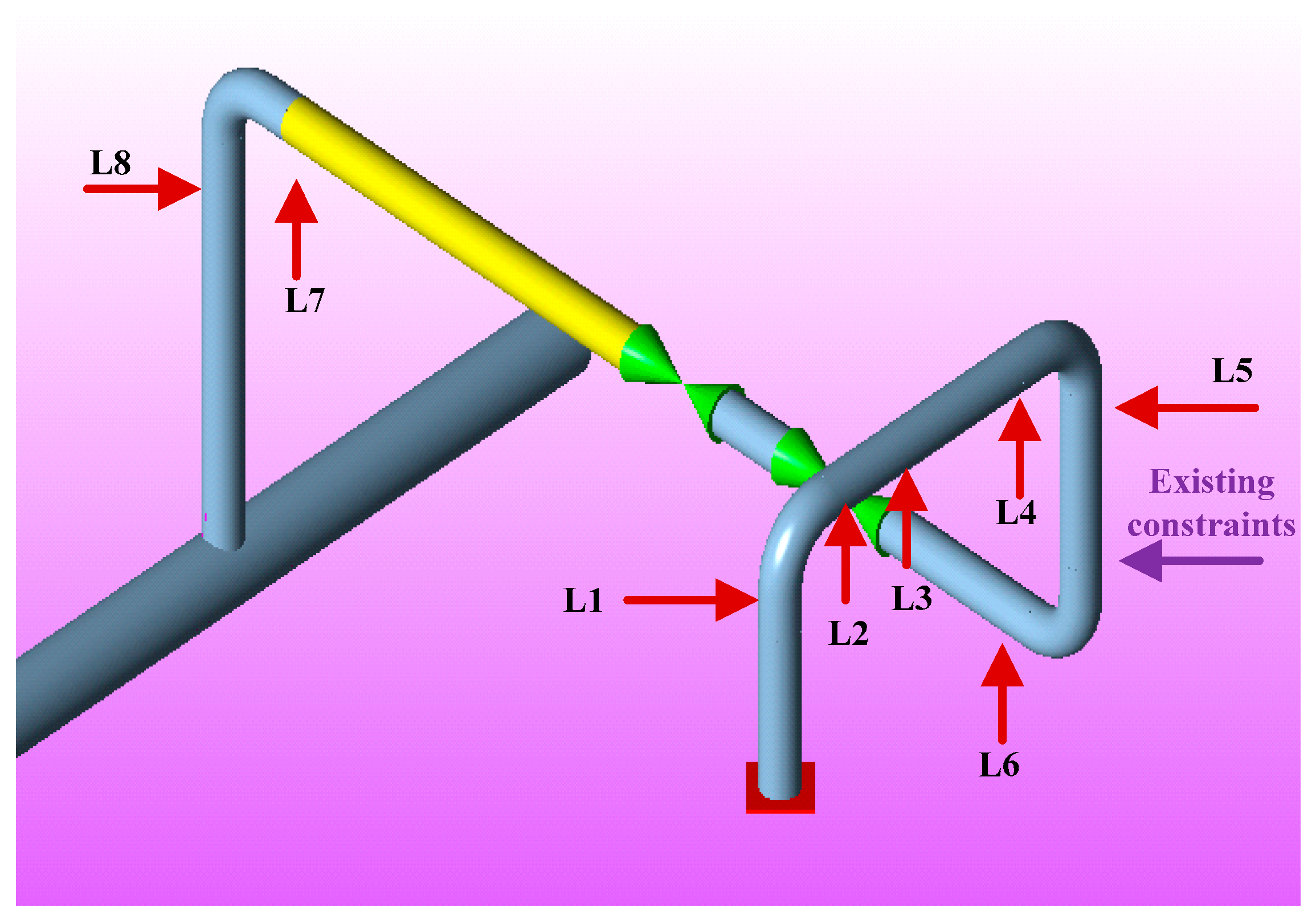

In order to verify the correctness of the numerical simulation method, this method is used to simulate a simple pipeline and is verified by indoor experiments. As shown in

Figure 3, the simple pipe model is divided into a straight pipe section and an elbow section, wherein the straight pipe section is 4.4 m long, and the angle of the elbow is set at 90 60 and 45 degrees. The direction of fluid flow in the pipeline is from right to left. There are three clamped supported constraints in the pipeline, and the specific parameters of the pipeline are listed in

Table 1. The pump delivery pressure is 0.9 MPa, the transmission medium is water, the temperature is 15 °C, and the inlet flow rate is 1283 L/h. Pipeline foundation model and constraint model can be seen in

Figure 4.

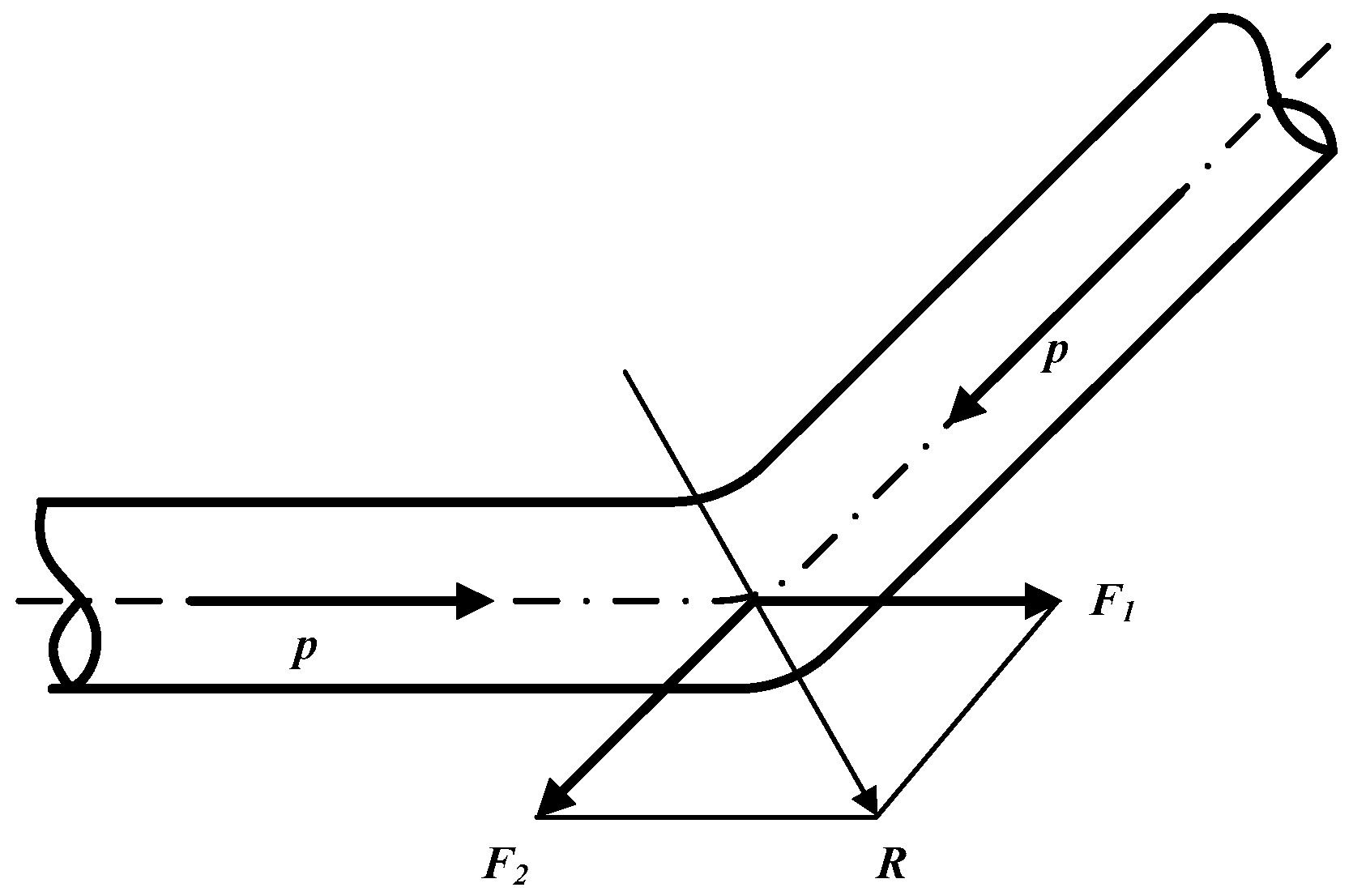

The unbalanced exciting force of the elbow is calculated as follows:

The pump revolution speed is 170 r/min, it belongs to single cylinder single-action equipment, and then the excited frequency is:

Circular frequency is:

Sound velocity is:

The distance from the starting point to the elbow is 4.4 m, and the total length of the pipe is 5 m. The pressure pulsation at different times of the elbow can be calculated based on Equation (3):

Make

x = 4.4 m,

,

n = 1, then Equation (3) can be written as:

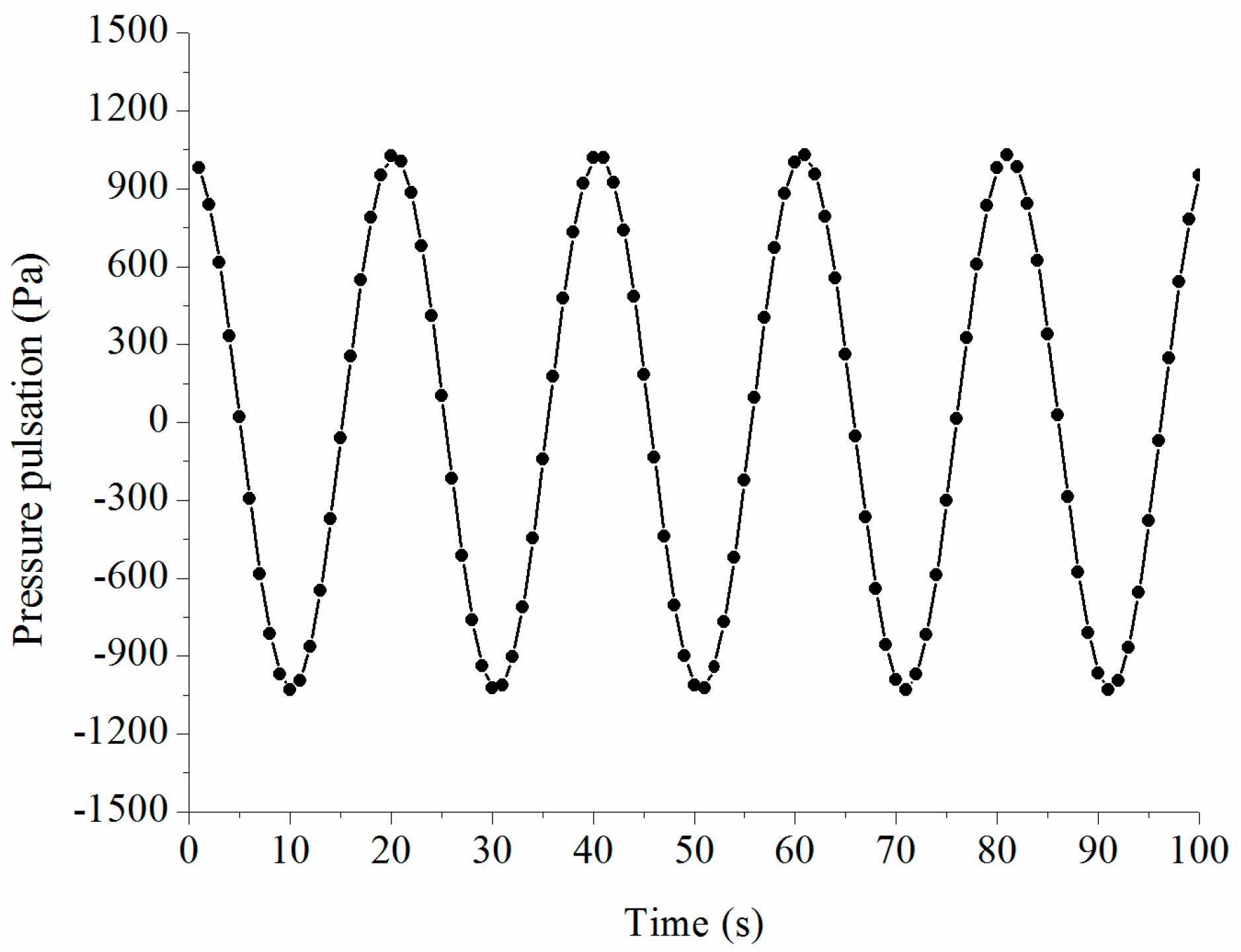

The calculated pressure pulsation of the first 100 s can be seen in

Figure 5, it can be obtained that the maximum value of the pressure pulsation is 1031.00 Pa, and the minimum value of the pressure pulsation is −1030.71 Pa.

Then ΔP is: ΔP = 0.5(Pmax − Pmin) = 0.5 × (1031.00 + 1037.71) = 1031.36.

According to Equation (4), unbalanced exciting forces of 45 degree elbow, 60 degree elbow and 90 degree elbow are calculated:

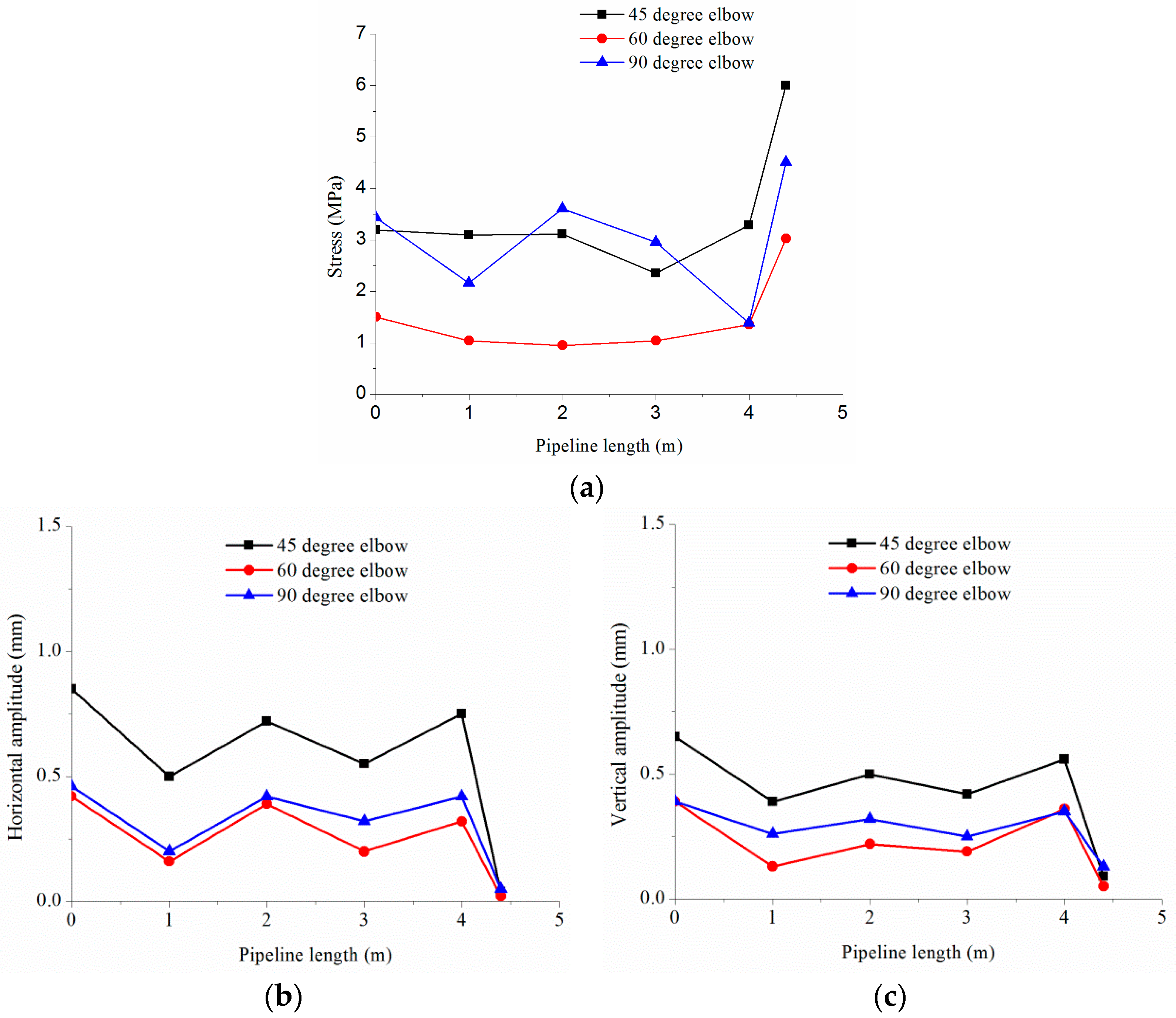

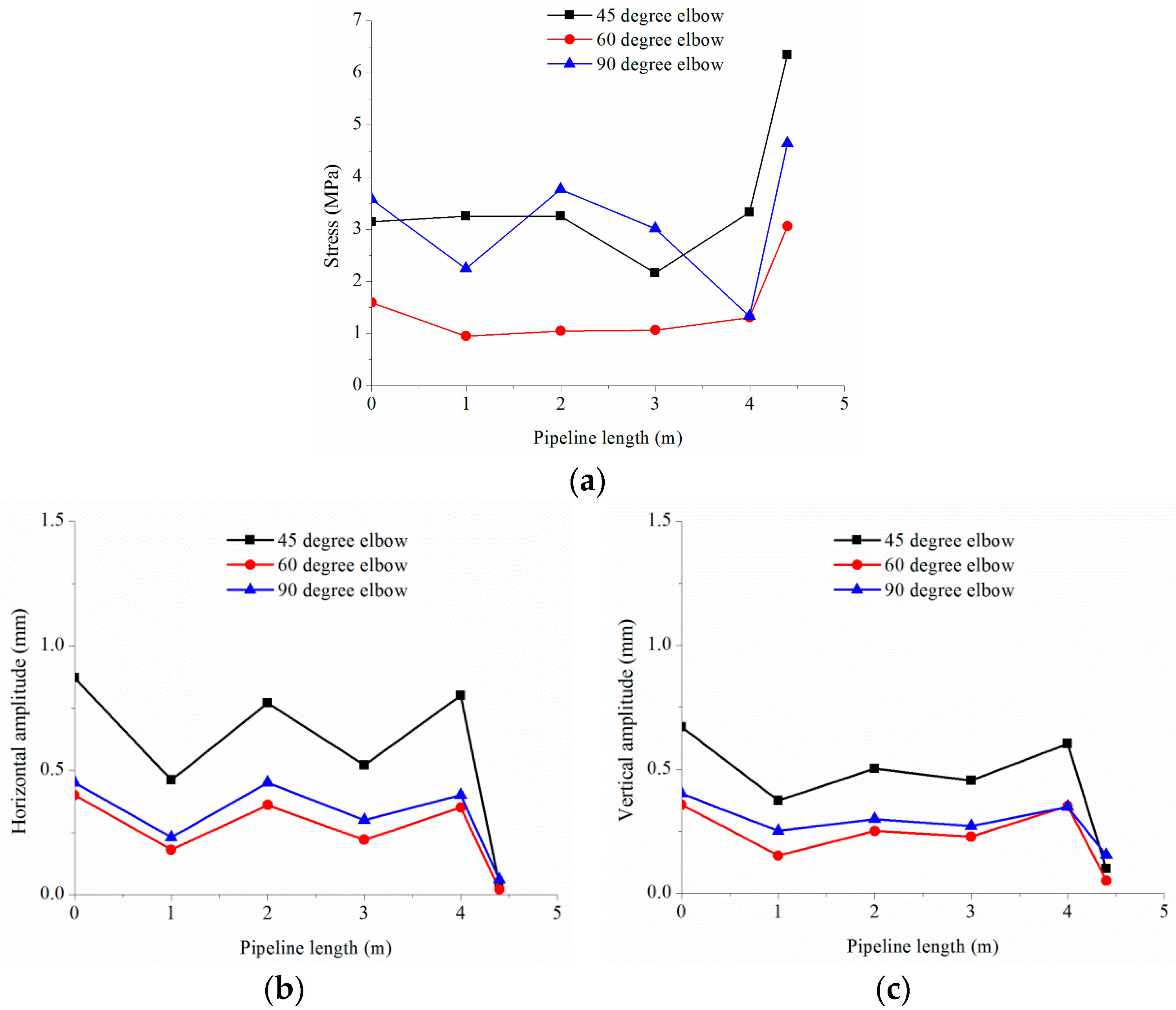

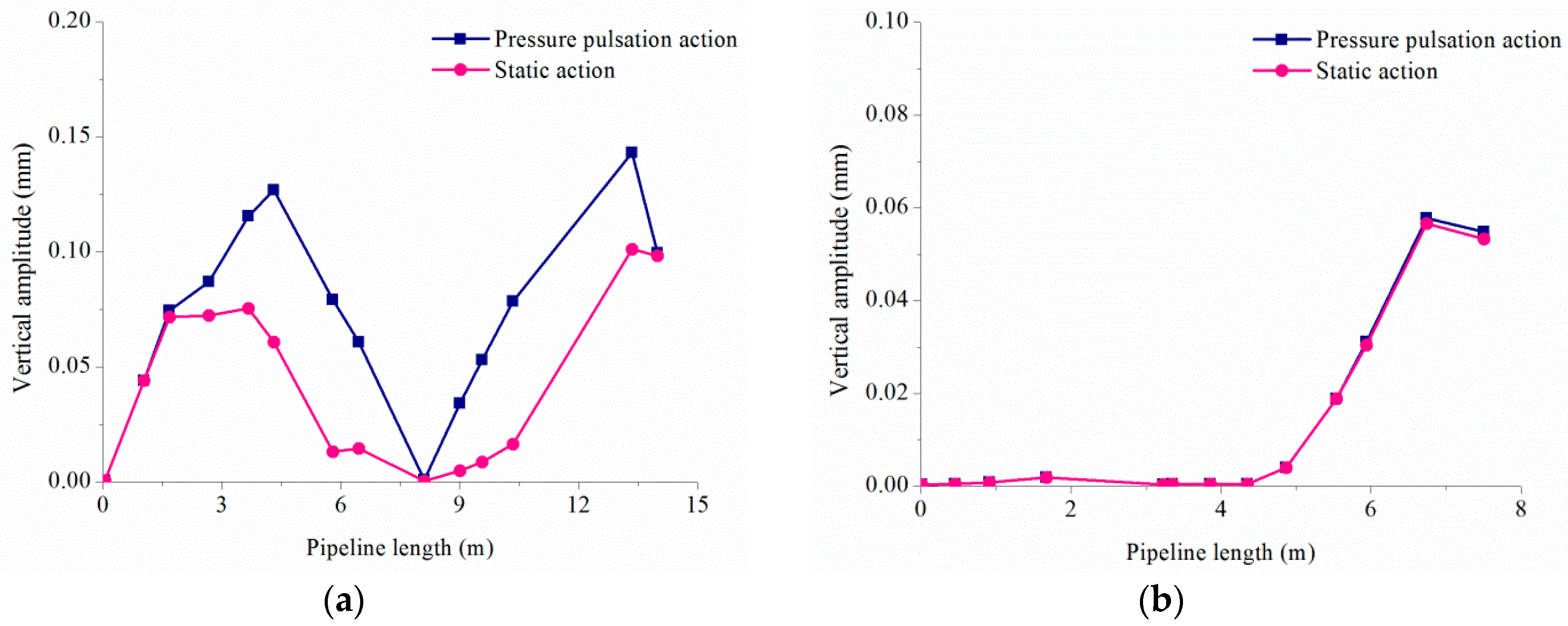

The calculated unbalanced exciting force is loaded onto the pipe, and the stress, horizontal and vertical amplitudes are computed by CAESAR II software. The results are shown in

Figure 6.

3.2. Experimental Verification of Numerical Simulation Method

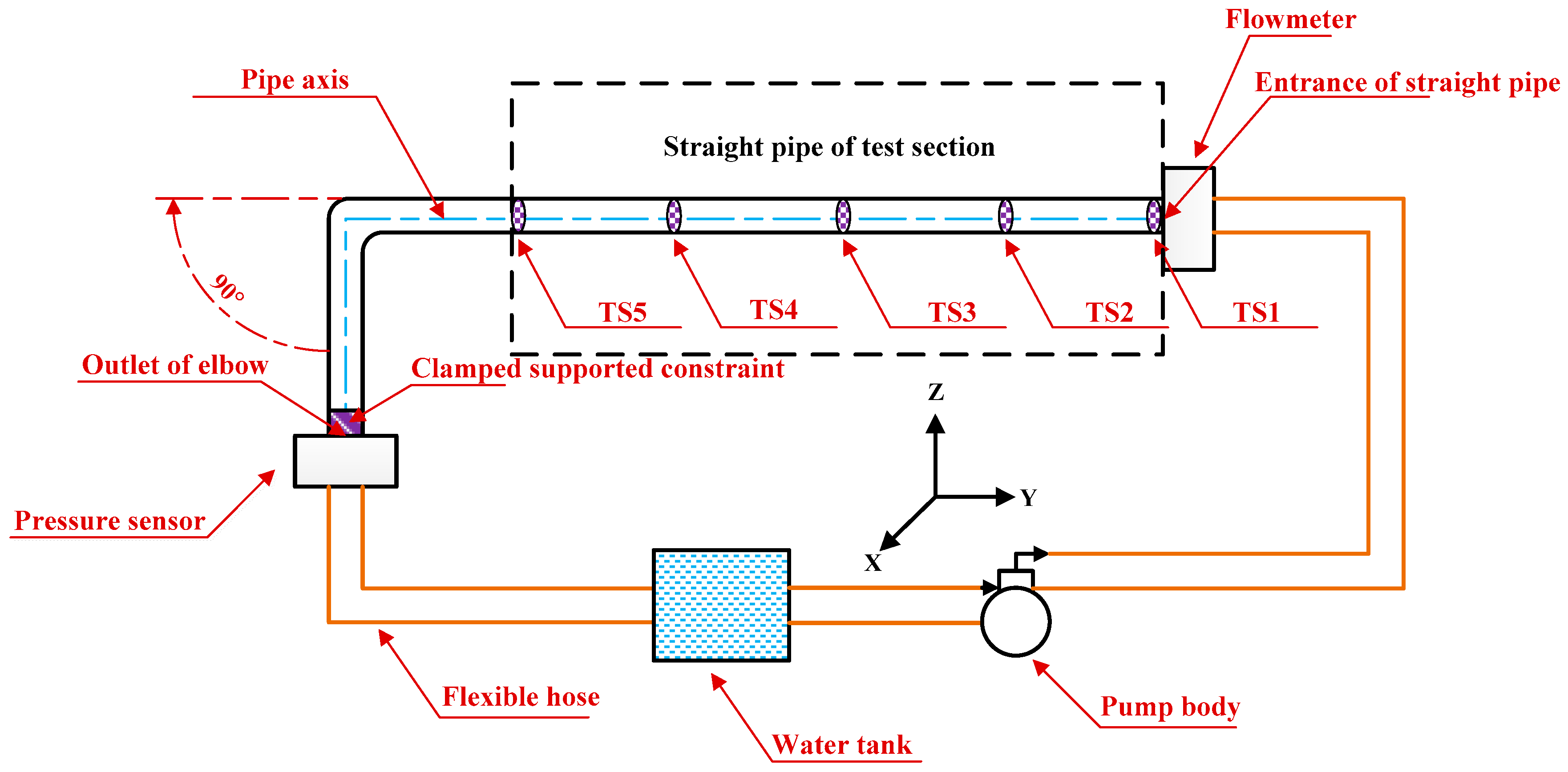

In order to verify the correctness of the numerical simulation method, an indoor experimental system is established according to the simple pipeline model used in numerical simulation. The experimental system is mainly composed of four subsystems, such as power unit, loop circuit, experimental platform and signal acquisition and analysis system. The main structure and composition are shown in

Figure 7.

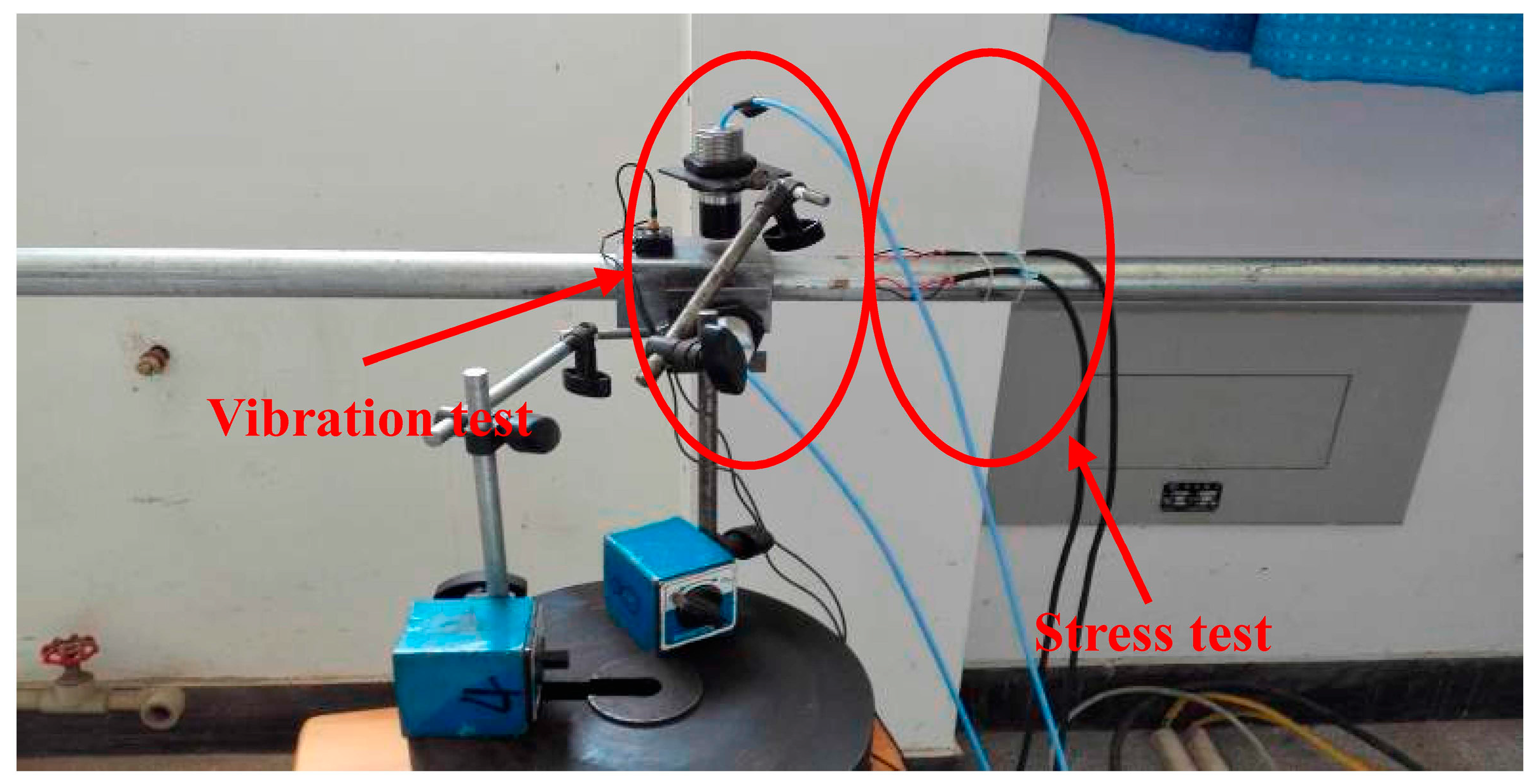

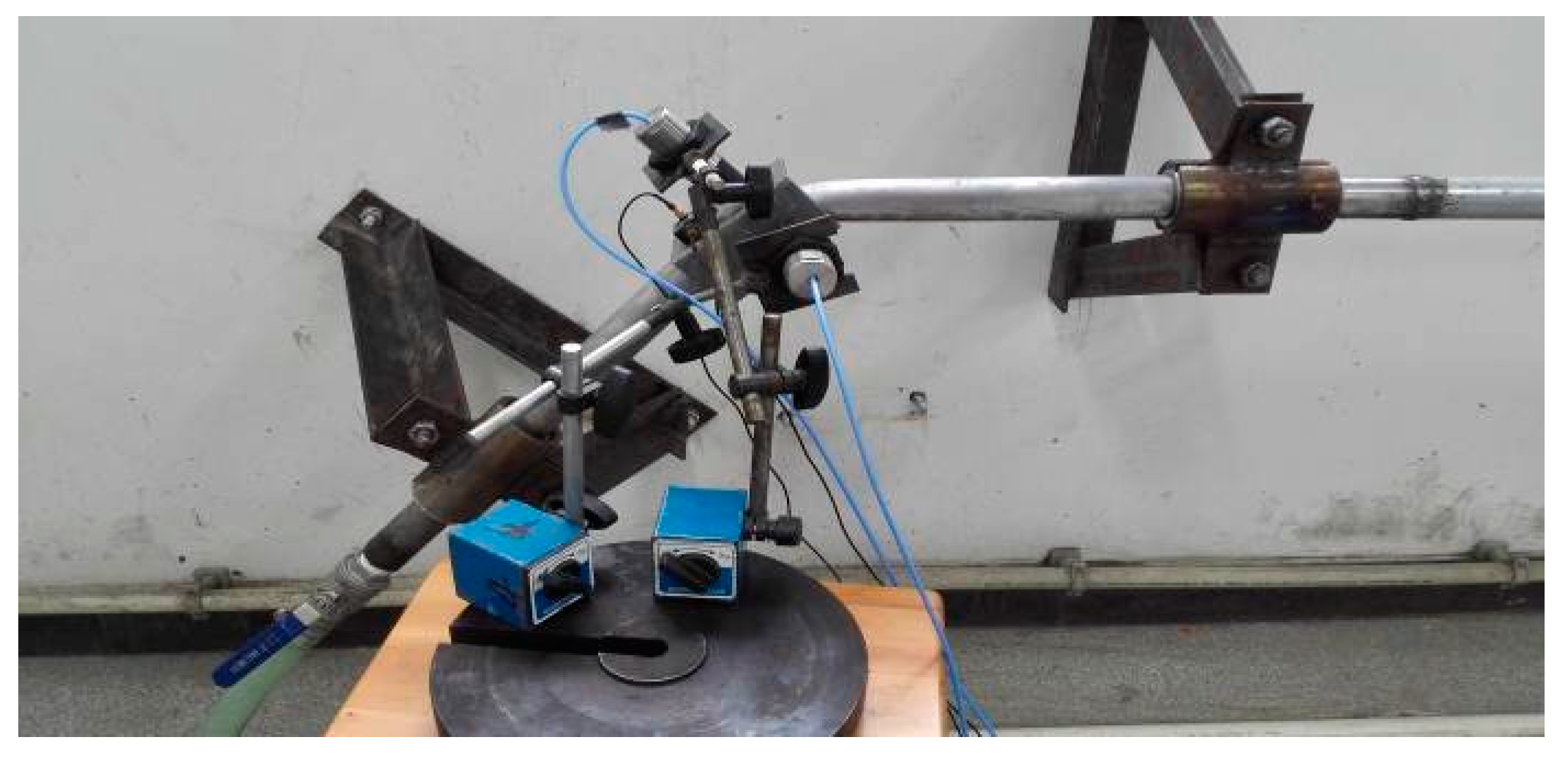

As shown in

Figure 7, the straight pipe is connected with the elbow, and the axis of the straight pipe and the elbow are in the Z-Y plane. The piston pump provides a pulsating flow at different flow rates and pressures for the entire experimental system, the signal acquisition and analysis system (including strain gauges, acceleration and displacement sensors) measures the different test points of the test section under each operating condition.

There are three different elbow structures in the experiment: the elbow angles are 45°, 60°, and 90°, respectively. The inlet end of straight pipe and outlet end of elbow are connected by a flexible hose with an inner diameter of 25 mm, and fastened through the clamp. The fixed straight pipe section is connected with the two ends of the elbow through rigid band joints, so as to replace the elbow with different angles (as a result of the use of flexible hose, metering pump water flow will lead to flexible hose vibration, this vibration is inevitably passed to the test straight pipe, which belongs to the external excitation load, and has a certain influence on the straight section test data).

The experimental principle as shown in

Figure 7, the elbow of test section is connected to a JD-1350/1.6-type plunger metering pump (pump maximum flow rate is 1350 L/h, the measurement accuracy is ±1%); the maximum pumping pressure is 1.6 MPa (accuracy: ±3%); the metering valve range is 1–100 mm (adjustment accuracy: 95%). The water flow through the metering pump from the water tank, through the LWGY-32 type turbine flow sensor (accuracy: ±0.5%R), a YB-2088 type pressure transmitter (accuracy: ±0.5%FS), transitional straight pipe with a length of 4 m (the material is the same as the elbow), elbow of test section, throttle valve and DN32 type rubber pressure-resistant steel pipe, then the water goes back to the water tank.

A flat steel plate (size of 40 mm × 40 mm × 1 mm) was mounted on the upper side of the pipe. Acceleration and displacement of the elbow can be obtained from measuring the steel plate’s acceleration and displacement using the piezoelectric three-way acceleration sensor (measuring accuracy is ±1%, frequency response is 1–5 kHz) which is fixed to two test surfaces and the non-contact eddy current displacement sensor (measuring accuracy is ±1%, frequency response is 0–10 kHz) which is parallel to the two test surfaces.

The output flow of piston pump has an obvious regular pulsation, so in order to avoid the non-real-time synchronization acquisition of the data, the TST5912 (Test Electron, Jingjiang, China) dynamic signal test and analysis system and the TST3826F (Test Electron, Jingjiang, China) dynamic and static strain test system were used to simulate the acceleration, displacement, stress and strain of different measuring points. The piston metering pump in supplying a pulsating flow will produce a certain degree of fluctuation due to pressure and flow changes. In the meantime, there will be varying degrees of air in the test pipe section, which will also affect the experimental results. Therefore, in each case, when the working condition is stable, continuous data collection is carried out for a certain period of time, and the data collected in each working cycle are compared and screened to ensure that the data is true and effective.

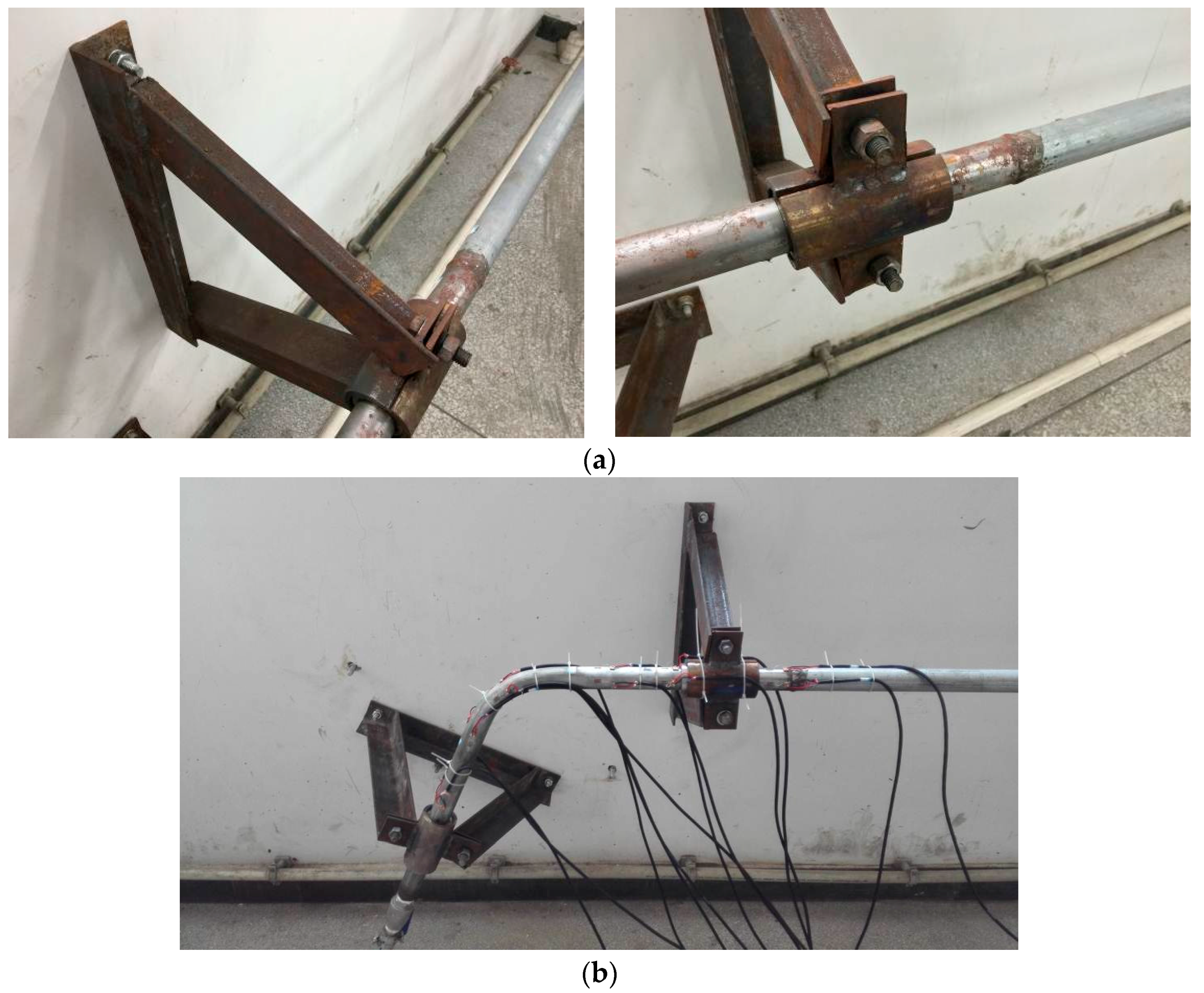

The test pipe is equipped with acceleration sensors, and there are six measuring points. The measuring points 1, 2, 3, 4 and 5 (denoted as TS1, TS2, TS3, TS4 and TS5) are on the straight pipe, and the measuring point 3 is the middle measuring point on the straight pipe. The clamped supported constraints of the straight pipe section and elbow section (taking the 60 degree elbow for instance) can be seen in

Figure 8. As shown in

Figure 9, the test straight pipe section is 4 m, and a measuring point is added every 1 m. There is only one measuring point at the bend, as shown in

Figure 10.

The experimental conditions are listed in

Table 2. Before the experiments, the acceleration, displacement sensors, flowmeter and pressure sensors should be corrected. The straight pipe measuring points are marked and the strain gauges stuck on (they are small and light, and will not affect the actual movement of the pipe). Before starting the pump test, we adjust the flow and pressure corresponding to each condition (flow control through the flow meter, control valve to achieve the required pressure value).

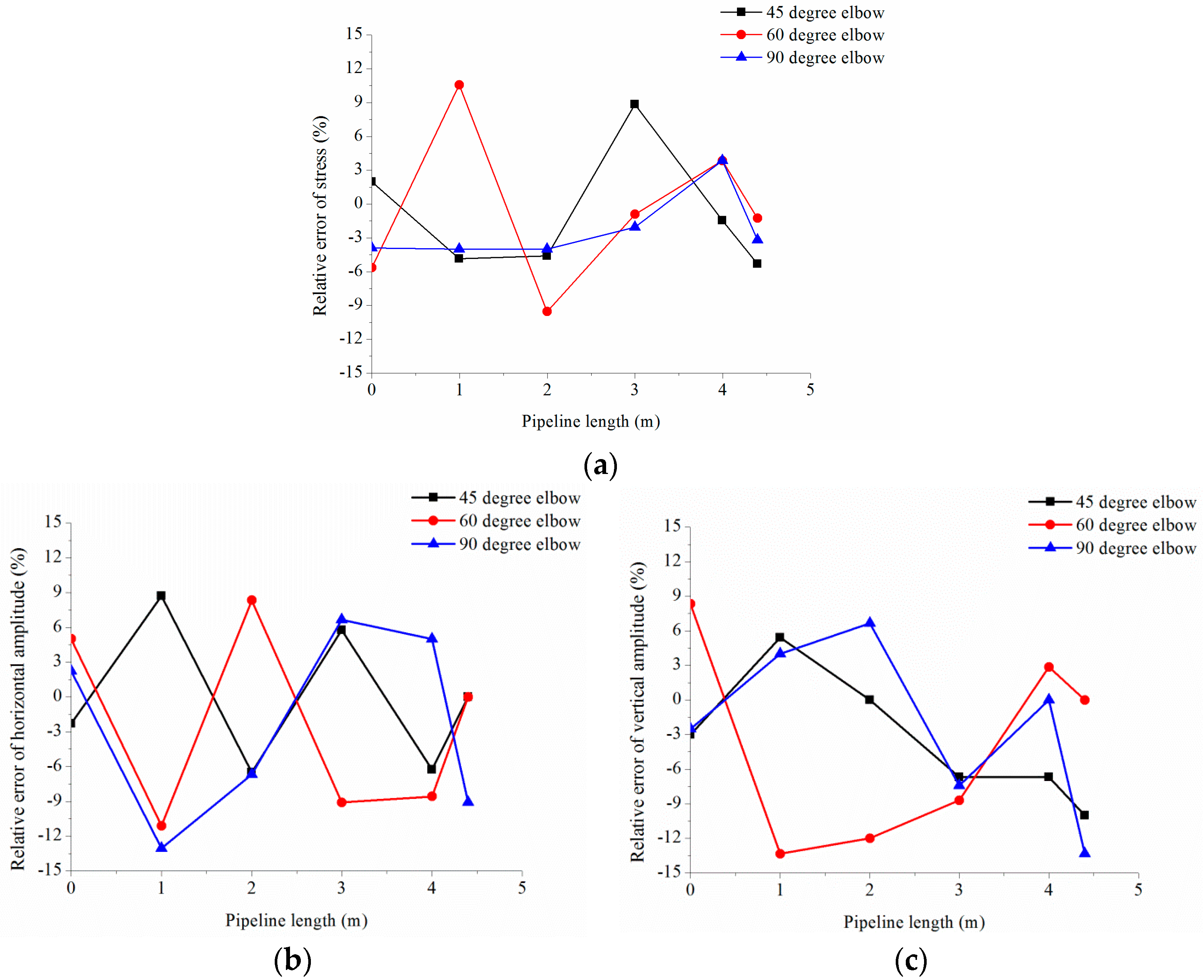

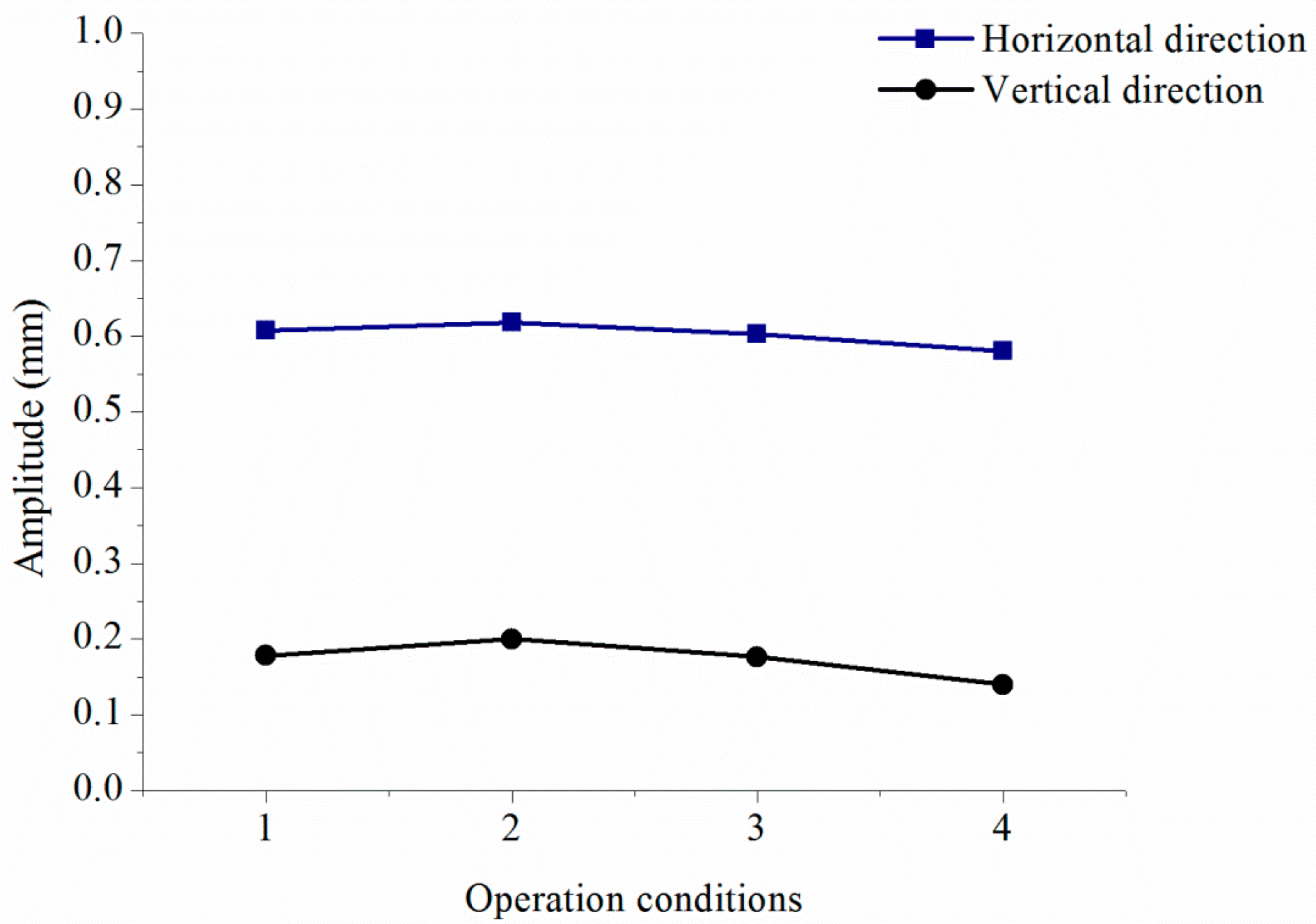

The stress, horizontal and vertical amplitudes test results of the pipeline are shown in

Figure 11. The relative error of the experimental and numerical simulation results are shown in

Figure 12. From

Figure 12, it can be concluded that the relative error range of stress is −9.55–10.57%, the relative error range of horizontal amplitude is −13.04–8.70%, and the relative error range of vertical amplitude is −13.33–8.33%. According to

Figure 12, an average relative error can be calculated, as shown in

Table 3. Based on the above results, the relative error is within the acceptable range (In engineering, the acceptable range refers to the average relative error of numerical simulation and experimental results within 15% [

21]), indicating that the numerical simulation method is more feasible.