Improving Tube Design of a Problematic Heat Exchanger for Enhanced Safety at Minimal Costs

Abstract

:1. Introduction

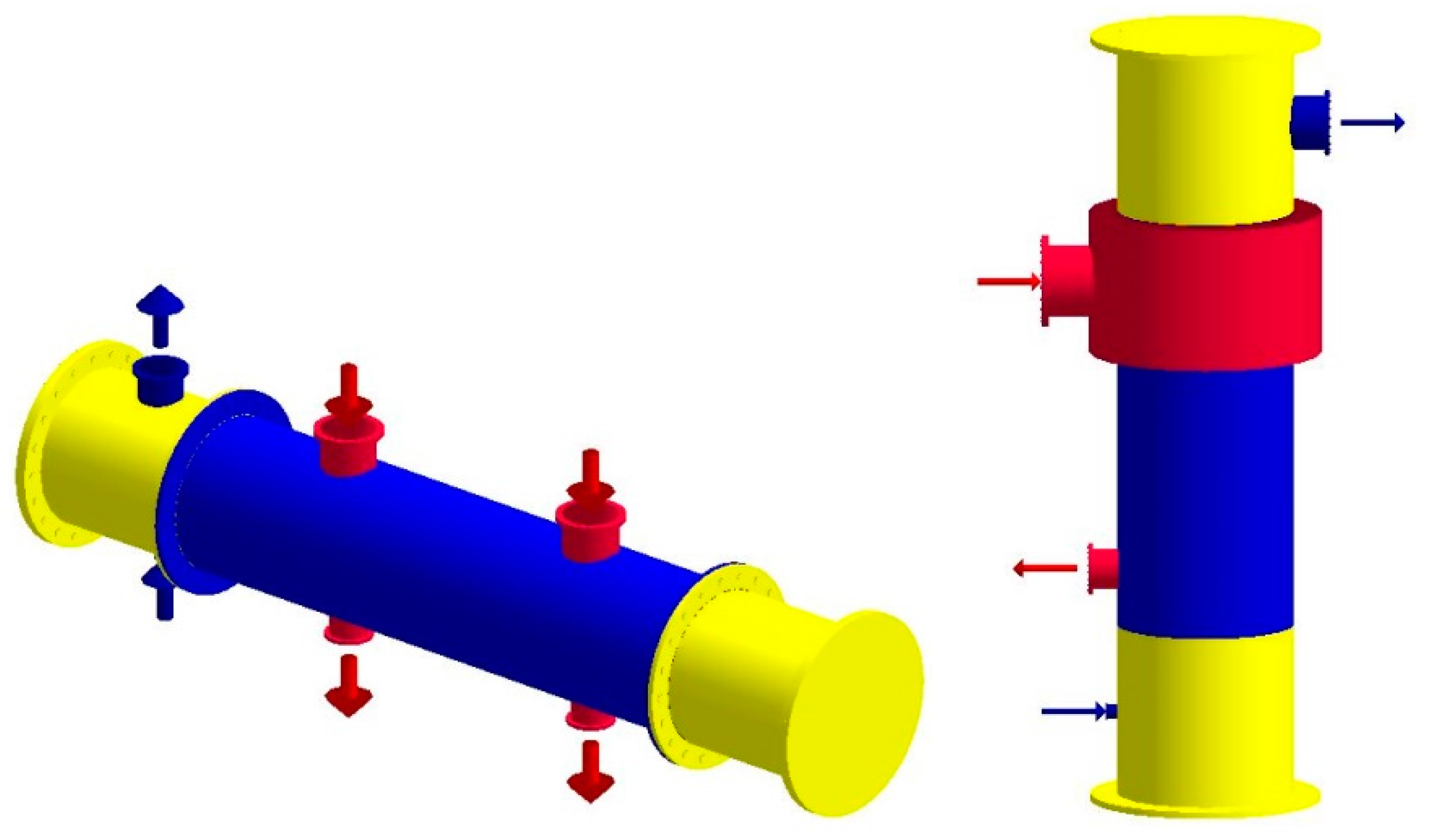

2. Problem Statement

3. Methodology

3.1. PrHA Safety Review of Crude Phenol Column

3.1.1. Risk Level Review of Tube Rupture Case in CPC Overhead Condenser

3.1.2. PSV Relieving Case Review of Crude Phenol Column

3.1.3. Safeguards Review for Tube Rupture Case in CPC Overhead Condenser

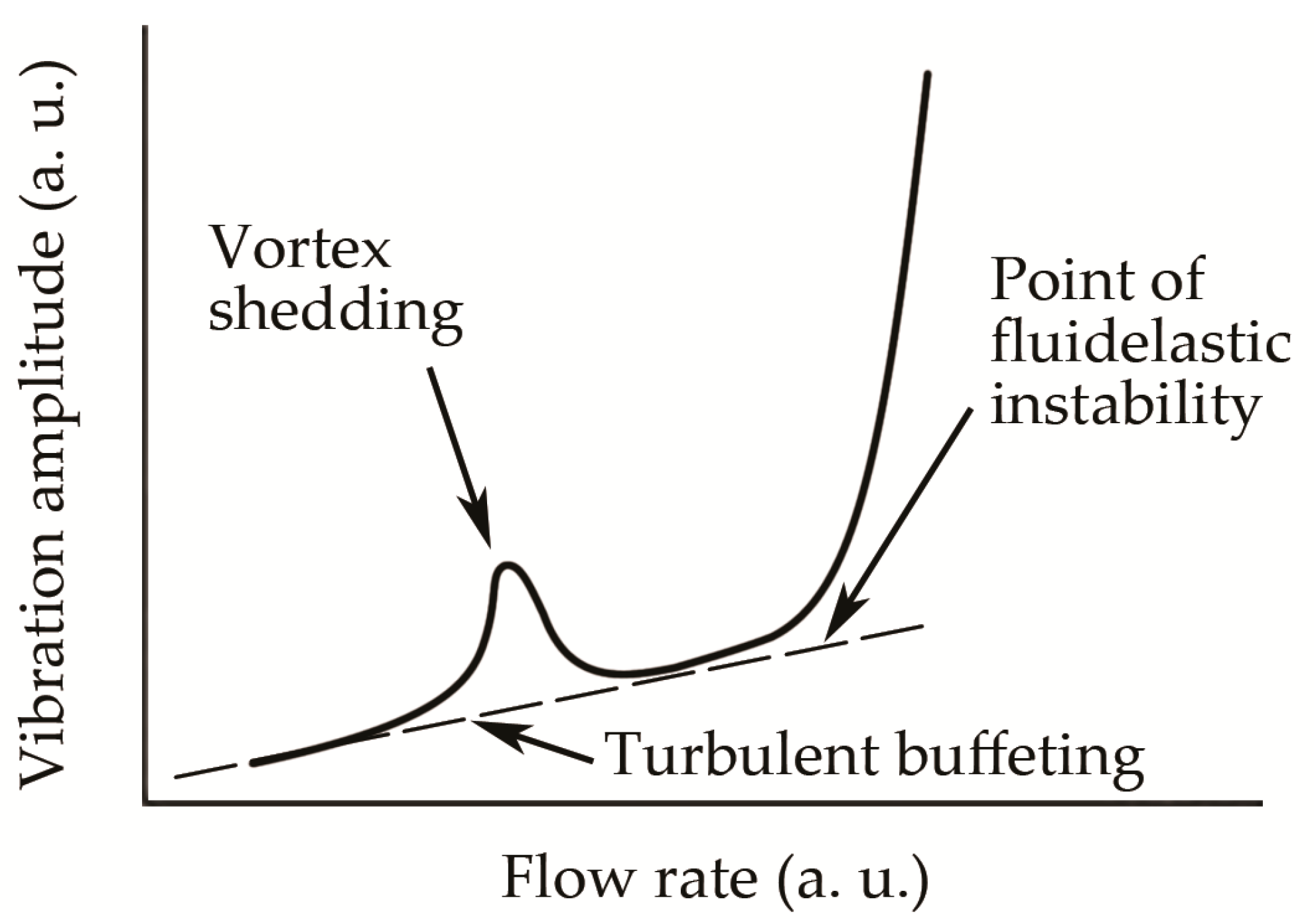

3.2. Mechanism of Flow-Induced Vibration

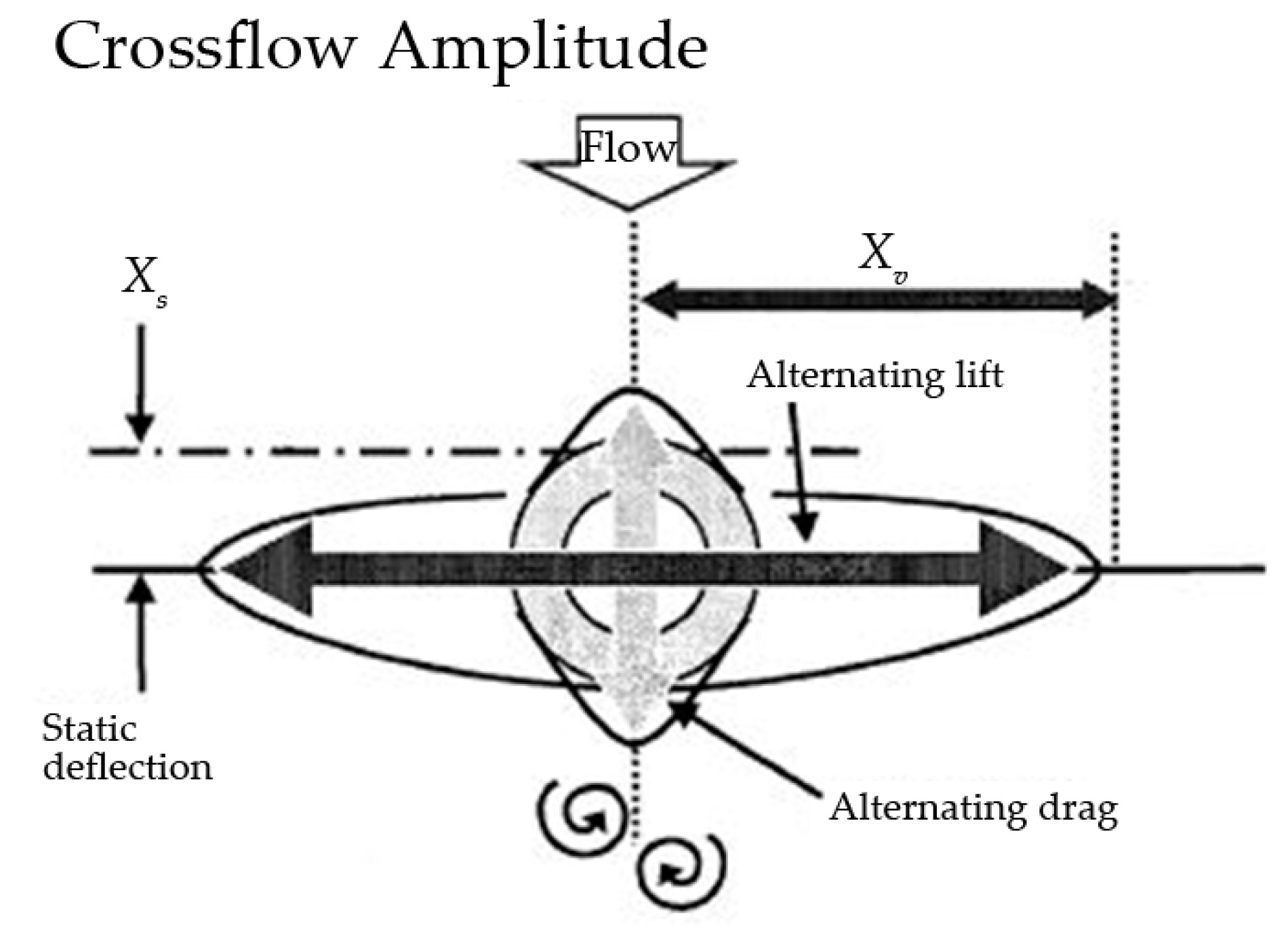

3.2.1. Vortex Shedding

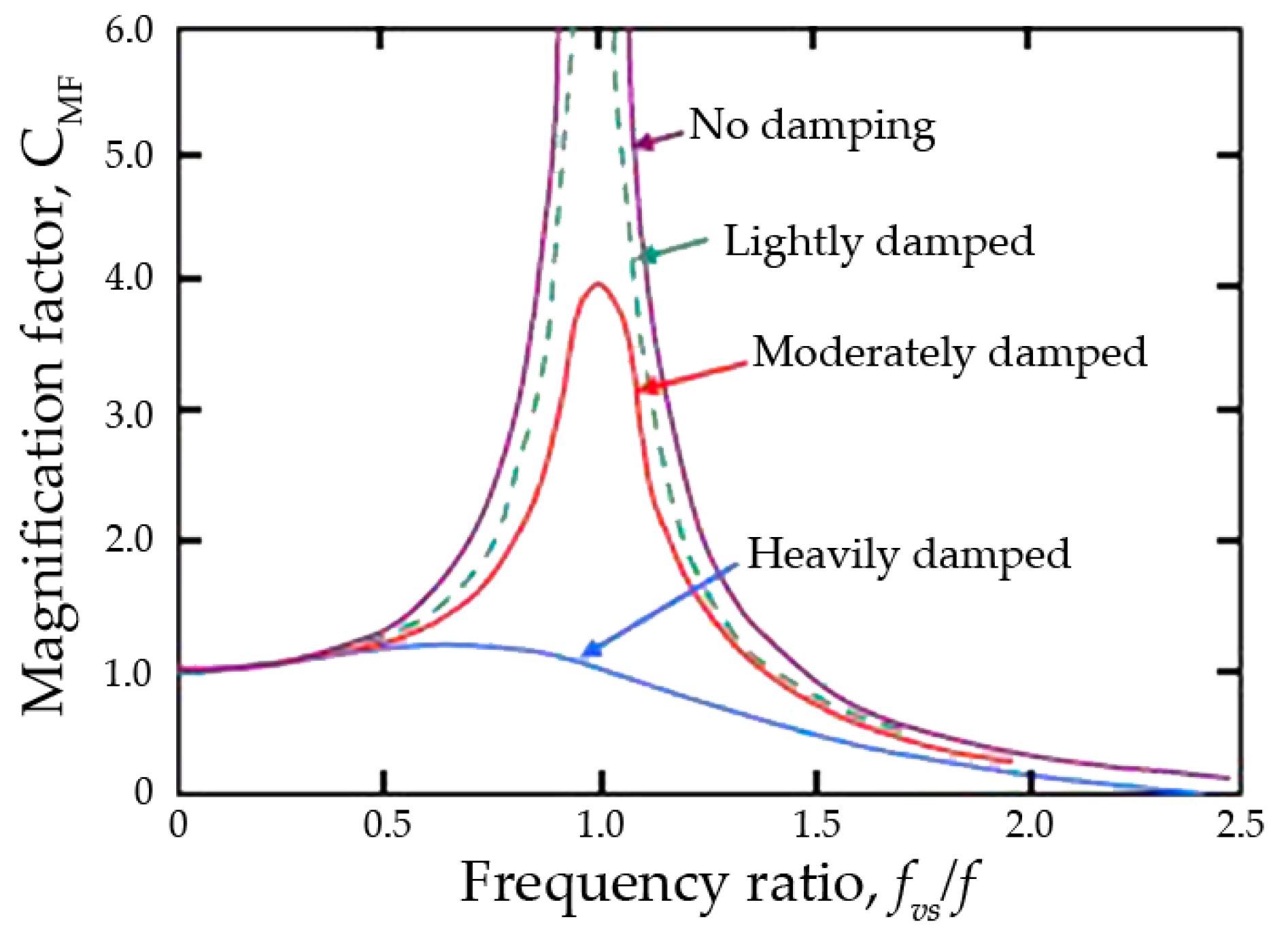

3.2.2. Fluidelastic Instability

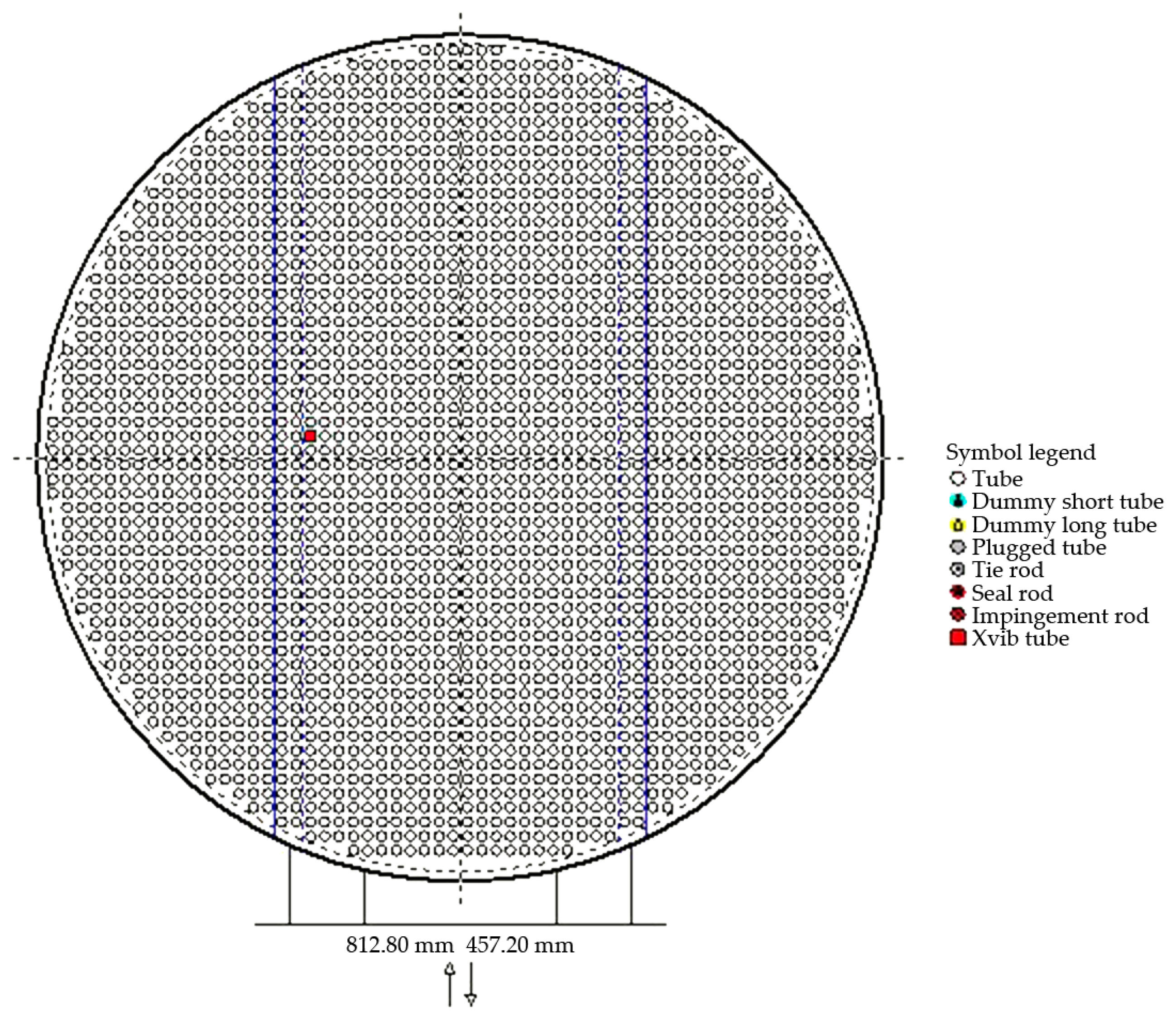

3.2.3. HTRI Vibration Analysis Program and Criteria

- -

- The criterion used to determine the existence of potential problems resulting from fluidelastic instability is the value of the crossflow velocity to critical velocity ratio. If this ratio exceeds 0.8 at any location, a fluidelastic instability vibration problem is probable.

- -

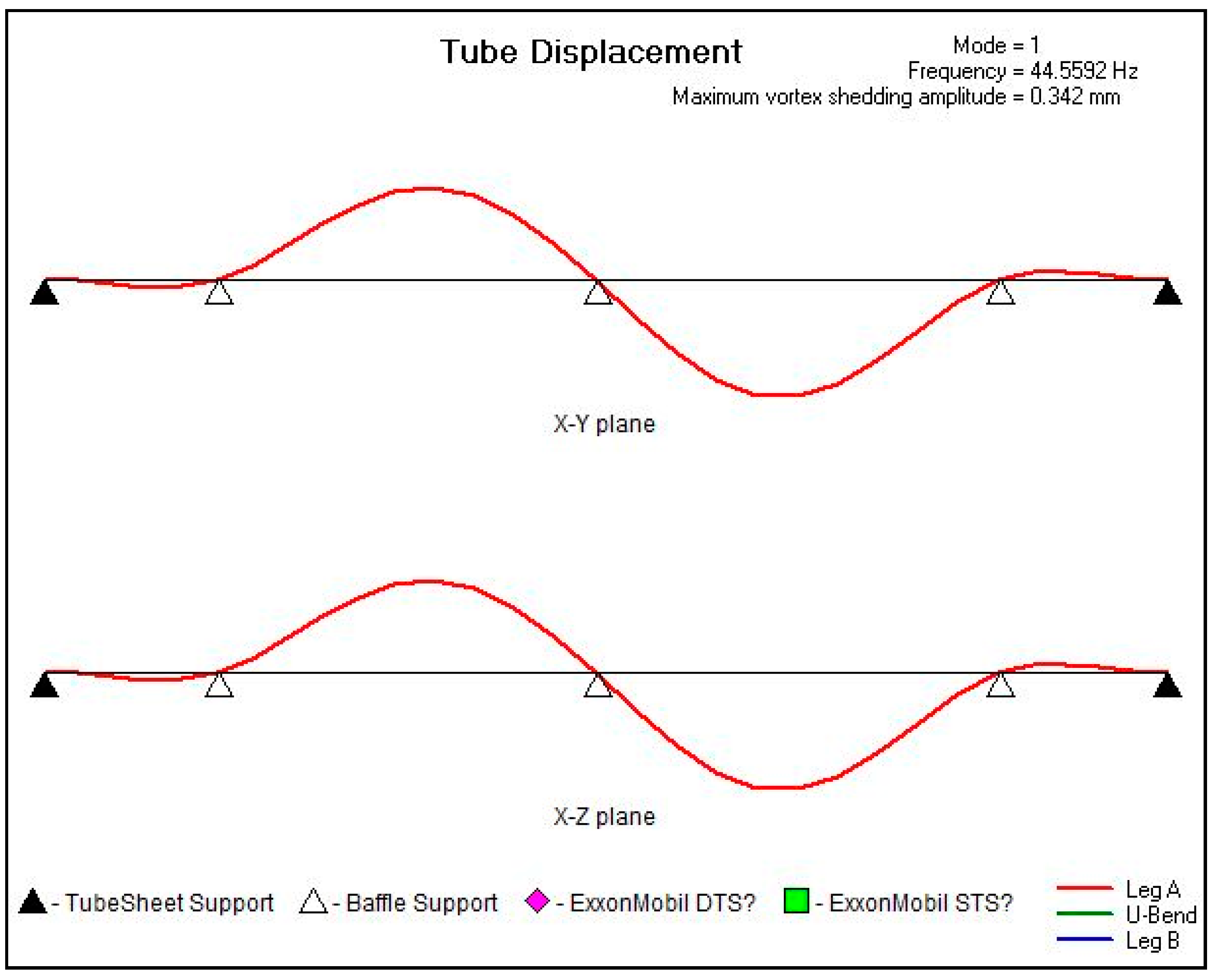

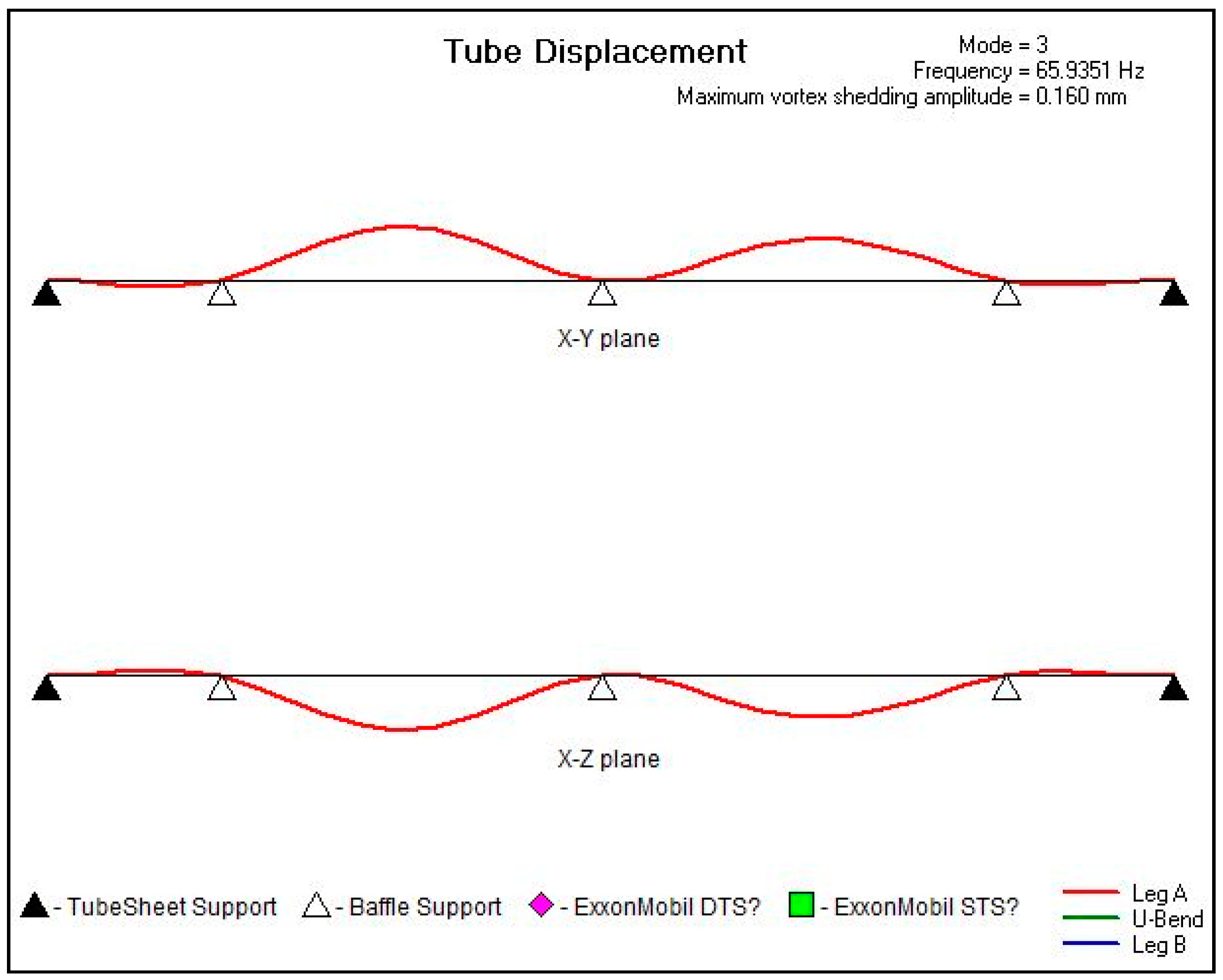

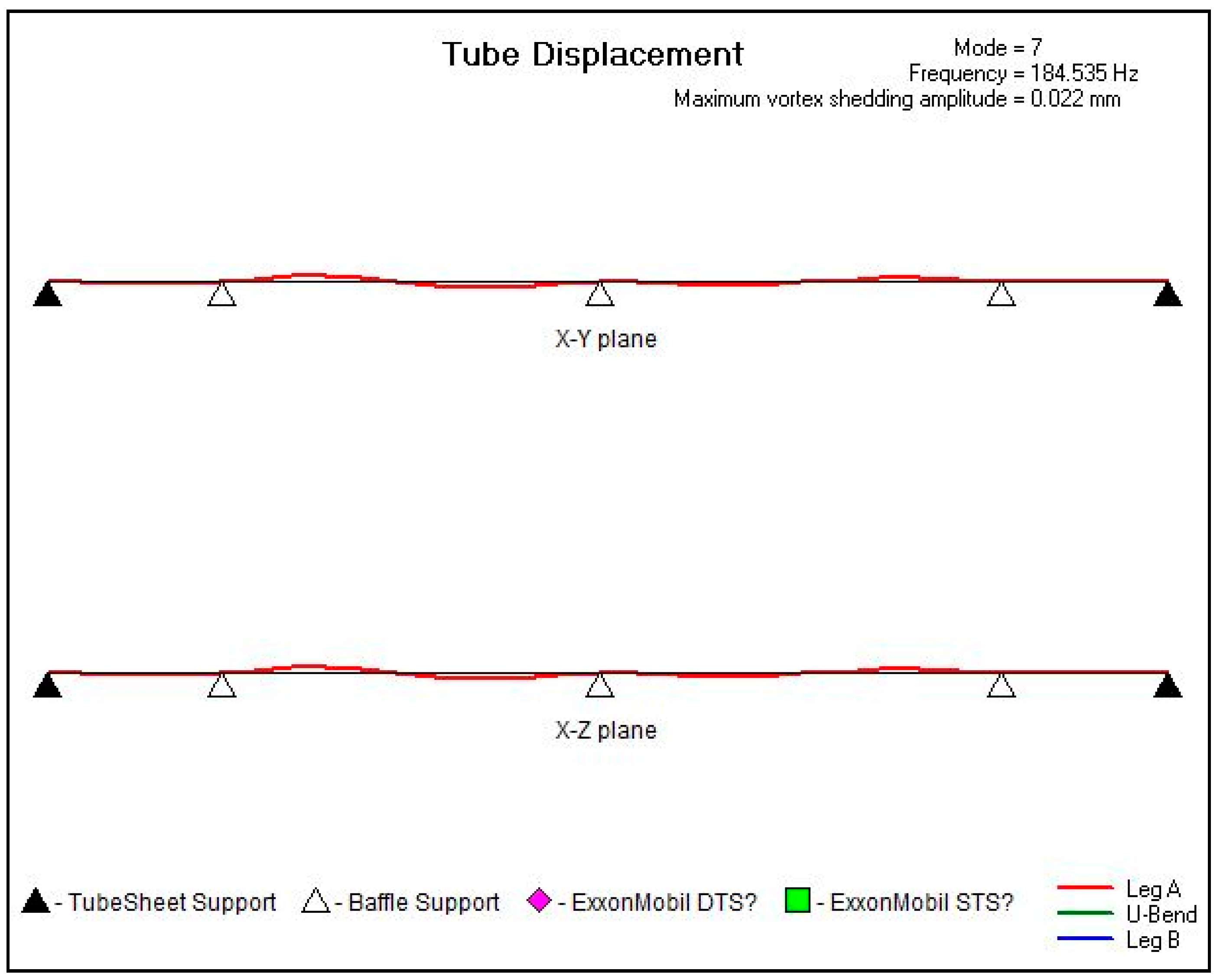

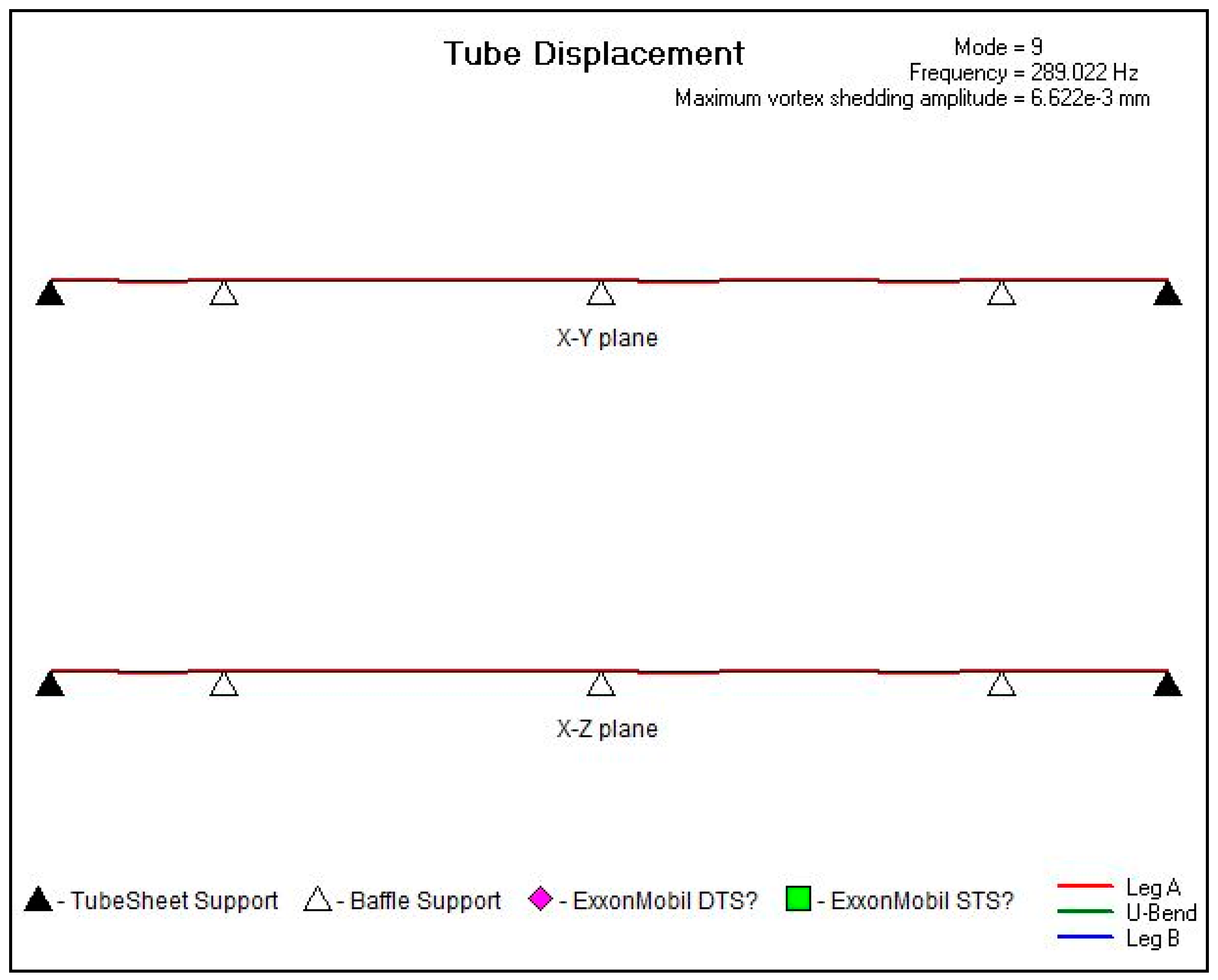

- The vortex shedding amplitude is less than 10% of the tube gap is needed to prevent flow-induced vibration problems caused by this mechanism. Xvib provides the vortex shedding amplitude with the maximum value, and the span where it occurs.

4. Results

5. Discussion

6. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- U.S. Department of Energy. DOE Handbook. Chemical Process Hazards Analysis; Order 703; U.S. Department of Energy: Washington, DC, USA, 1996; pp. 1–80.

- Tzou, T.L.; Edwards, D.W.; Chung, P.W.H. An explosion accident-causes and safety information management lessons to be learned. Inst. Chem. Eng. Symp. Ser. 1999, 149, 591–604. [Google Scholar]

- Liptak, B.G. Control and Optimization of Unit Operations. In Instrument Engineers’ Handbook: Process Control and Optimization, 4th ed.; Liptak, B.G., Ed.; CRC Press: Stamford, CT, USA, 2005; Volume 2, p. 2007. [Google Scholar]

- American Society of Mechanical Engineers (ASME). Boiler and Pressure Vessel Code: Section VIII, Division 1; ASME: New York, NY, USA, 2001. [Google Scholar]

- Palen, J.W. S-SS-3–12 Non-Segmental Baffles in Shell and Tube Heat Exchangers; HTRI: Navasota, TX, USA, 1999. [Google Scholar]

- API Standard 526—Flanged Steel Safety Relief Valves; American Petroleum Institute: Washington, DC, USA, 2002.

- Aspen HYSYS 8.6; Aspen Technology: Bedford, MA, USA, 2014.

- Measurement of Fluid Flow by Means of Pressure Differential Devices Inserted in Circular Cross-Section Conduits Running Full; ISO 5167:2003; ISO: Geneva, Switzerland, 2003.

- Pettigrew, M.J.; Sylvestre, Y.; Campagna, A.O. Vibration analysis of heat exchanger and steam generator designs. Nucl. Eng. Des. 1978, 48, 97–115. [Google Scholar] [CrossRef]

- Bearman, P.W. Vortex Shedding from Oscillating Bluff Bodies. Ann. Rev. Fluid Mech. 1984, 16, 195–222. [Google Scholar] [CrossRef]

- Païdoussis, M.P. Fluidelastic vibration of cylinder arrays in axial and cross flow: State of the art. J. Sound Vib. 1981, 76, 329–360. [Google Scholar] [CrossRef]

- Flow-Induced Tube Vibration. In HTRI Design Manual; HTRI: Navasota, TX, USA, 2009; Volume C.

- Païdoussis, M.P. Flow induced vibration in nuclear reactors and heat exchangers: Practical experiences and state of knowledge. In Practical Experiences with Flow-Induced Vibration; Naudascher, E., Rockwell, D., Eds.; Springer-Verlag: Berlin, Germany, 1980; pp. 1–81. [Google Scholar]

- Xist® HTRI Xchanger Suite, HTRI: Navasota, TX, USA. Available online: https://www.htri.net/xist.aspx (accessed on 19 September 2016).

- Xvib® Version 7.0, HTRI Xchanger Suite, HTRI. Available online: https://www.htri.net/xvib.aspx (accessed on 19 September 2016).

- Axial Flow in Tube Bundles with Rod-type Tube Support. In HTRI Design Manual; HTRI: Navasota, TX, USA, 2009; Volume B.

| Deviation | Causes | Consequences | Safeguards | Severity | Likelihood | Risk Level |

|---|---|---|---|---|---|---|

| Tube rupture | Tube leaks in overhead condenser of crude phenol column | Cumene/water leaks into crude phenol column overhead system. Potential cumene carryover to column side-cut. Potential off-spec phenol product | 1. Crude phenol column overhead cumene separation; 2. Phenol rectifier overhead cumene separation; 3. Manual sampling on phenol product rundown tank | 2 | 1 | 1 |

| Likelihood | Criteria |

|---|---|

| 1 | Very unlikely; once in more than 10 years |

| 2 | Not likely; once in 5–10 years |

| 3 | May occur; once in 1–5 years |

| 4 | Likely; once in 1 year |

| Severity | People | Assets | Environment | Reputation |

|---|---|---|---|---|

| 1 | Slight health effect/injury | Slight damage (less than US $100,000) | Slight effect | Slight impact |

| 2 | Minor health effect/injury | Minor damage (US $100,000–$1,000,000) | Minor Effect | Limited impact |

| 3 | Major health effect/injury | Localized damage (US $1,000,000–$10,000,000) | Localized effect | Considerable impact |

| 4 | Disabilities/fatalities | Major damage (greater than US $10,000,000) | Major effect | National impact |

| Caption | Likelihood → | ||||

|---|---|---|---|---|---|

| Risk Rank | 1 | 2 | 3 | 4 | |

| Severity ↓ | 1 | 1 | 1 | 2 | 2 |

| 2 | 1 | 2 | 2 | 3 | |

| 3 | 2 | 2 | 3 | 4 | |

| 4 | 2 | 3 | 4 | 4 | |

| Risk Level | Description |

|---|---|

| 1 | Acceptable as is—No action is necessary (low risk) |

| 2 | Acceptable with controls—Verify that procedures, controls and safeguards are in place (medium risk) |

| 3 | Undesirable—Should be mitigated to risk rank 2 or lower within reasonable period (high risk) |

| 4 | Unacceptable—Should be mitigated to risk rank 2 or lower as soon as possible (highest risk) |

| Relief Conditions | Units | General Tempered Water Failure | Reflux Stops | Pressure CV Fails Closed | Reboiler Tube Rupture | |

|---|---|---|---|---|---|---|

| Max accumulated pressure | % | 110 | 110 | 110 | 110 | |

| Accumulated pressure | kg/cm2 [a] | 4.88 | 4.88 | 4.88 | 4.88 | |

| Max allowable inlet line loss | kg/cm2 | 0.105 | 0.105 | 0.105 | 0.105 | |

| Pressure safety valve inlet condition | Inlet relieving pressure | kg/cm2 [a] | 4.88 | 4.88 | 4.88 | 4.88 |

| Inlet temperature | °C | 249 | 254 | 254 | 259 | |

| Vapor mass rate | kg/h | 52 | 48 | 56.6 | 22406 | |

| Molecular weight | - | 30.3 | 30.3 | 30.3 | 93.9 | |

| Compressibility factor | - | 0.938 | 0.938 | 0.938 | 0.938 | |

| K = Cp/Cv | - | 1.05 | 1.05 | 1.05 | 1.05 | |

| Liquid volume rate | m3/h | - | - | - | - | |

| Sp Gr (water = 1.000) | - | - | - | - | - | |

| Liquid viscosity | cP | - | - | - | - | |

| Relief header condition | Temperature | °C | - | - | - | - |

| Vapor mass rate | kg/h | - | - | - | - | |

| Molecular weight | - | - | - | - | - | |

| Liquid volume rate | m3/h | - | - | - | - | |

| Sp Gr (water = 1.000) | - | - | - | - | - | |

| Kd, coefficient of discharge | - | 0.975 | 0.975 | 0.975 | 0.975 | |

| Kb, BP correction factor (vap) | - | 0.680 | 0.680 | 0.680 | 0.680 | |

| Kw, BP correction factor (liq) | - | - | - | - | - | |

| Kv, viscosity correction factor (liq) | - | - | - | - | - | |

| KSH, steam superheat correction factor | - | - | - | - | - | |

| Required relief orifice area | cm2 | 0.27 | 0.25 | 0.25 | 66.67 | |

| Process Condition | Shell Side (Hot); (Phenol, Heavy Residues) | Tube Side (Cold); (Cumene, Water) | |||

|---|---|---|---|---|---|

| In | Out | In | Out | ||

| Operating temperature (°C) | 127.8 | 113.6 | 94.6 | 98.1 | |

| Operating gauge pressure (kg/cm2) | −0.851 | −0.874 | 0.333 | 0.115 | |

| Flow Rate (kg/h) | Vapor | 51,955 | 688 | 0 | 23,730 |

| Liquid | 5241 | 56,508 | 121,082 | 97,352 | |

| Density (kg/m3) | Vapor | 0.495 | 0.340 | - | 1.624 |

| Liquid | 987.5 | 1004.0 | 893.9 | 887.7 | |

| PSV Change List | Description |

|---|---|

| PSV size | To cover the excessive relieving load of overhead condenser tube rupture case, PSV size should be increased from 6Q8 to 8T10. |

| PSV cost | Two sets of new PSVs (8T10) are USD $7 985 (informed by PSV vendor) |

| PSV delivery time | New PSV delivery time to the site is 9–10 weeks (informed by PSV vendor) |

| PSV inlet/outlet pipe size | Main overhead pipe line size to be increased from 36 inch to 40 inch (SUS 304L) PSV inlet line size to be increased from 8 inch to 12 inch (SUS 304L) PSV outlet line size to be increased from 12 inch to 16 inch (SUS 304L) |

| Flare header size/flare stack capacity | Current flare header size (26 inch) and flare stack capacity (218.6 ton/h) will not be changed because tube rupture case is a single relieving case. |

| PSV inlet/outlet pipe arrangement | Thermal stress, pipe supports, and pipe arrangement of PSV inlet and outlet pipe should be designed again because the PSV inlet and outlet pipe size are increased. It is too difficult to specify the schedule delay impact to engineering, procurement, and construction due to above piping modification. |

| Mechanical Repair List | Description |

|---|---|

| Tube vibration analysis | Most of tube rupture cases are caused by tube vibration. To prevent tube vibration, the specific vibration analysis should be performed using Heat Transfer Research Inc. (HTRI) programs (Xist and Xvib) |

| Mechanical repair cost | If overhead condenser has a probability of tube vibration, an additional support grid should be provided to the longest tube spans. This repair cost is estimated to be USD $3250 (informed by a vendor) |

| Mechanical repair time | It will take about one week to finish providing the additional support grid (informed by a vendor) |

| Pipe modification works | For mechanical repair works, there are no related pipe modification works. |

| Fluidelastic Instability Check | Condenser Inlet | Condenser Center | Condenser Bundle Exit |

|---|---|---|---|

| Critical velocity 1 (m/s) | 18.16 | 20.28 | 4.11 |

| Baffle tip cross-flow velocity ratio 2 | 1.3995 | 0.8797 | 0.2229 |

| Average cross-flow velocity ratio 3 | 1.3951 | 0.8770 | 0.2222 |

| Span No. | Span Length (mm) | Element No. | Span Support | In-Plane Velocity (m/s) | Out-Plane Velocity (m/s) | Shellside Fluid Density (kg/m3) |

|---|---|---|---|---|---|---|

| 1 | 600 | 1 | Tubesheet | 23.6 | 0.6822 | |

| 2 | 23.6 | 0.6822 | ||||

| 3 | 23.6 | 0.6822 | ||||

| 4 | 23.6 | 0.6822 | ||||

| 5 | Additional Support | 23.6 | 0.6822 | |||

| 2 | 617 | 1 | 23.6 | 0.6822 | ||

| 2 | 23.6 | 0.6822 | ||||

| 3 | 23.6 | 0.6822 | ||||

| 4 | 23.6 | 0.6822 | ||||

| 5 | None | 23.6 | 0.6822 | |||

| 3 | 700 | 1 | −26.79 | 0.8145 | ||

| 2 | −26.79 | 0.8145 | ||||

| 3 | −26.79 | 0.8145 | ||||

| 4 | −26.79 | 0.8145 | ||||

| 5 | Baffle | −26.79 | 0.8145 | |||

| 4 | 700 | 1 | 18.3 | 1.4668 | ||

| 2 | 18.3 | 1.4668 | ||||

| 3 | 18.3 | 1.4668 | ||||

| 4 | 18.3 | 1.4668 | ||||

| 5 | None | 18.3 | 1.4668 | |||

| 5 | 700 | 1 | −10.06 | 1.9449 | ||

| 2 | −10.06 | 1.9449 | ||||

| 3 | −10.06 | 1.9449 | ||||

| 4 | −10.06 | 1.9449 | ||||

| 5 | Baffle | −10.06 | 1.9449 | |||

| 6 | 580 | 1 | −1.59 | 11.9024 | ||

| 2 | −1.59 | 11.9024 | ||||

| 3 | −1.59 | 11.9024 | ||||

| 4 | −1.59 | 11.9024 | ||||

| 5 | Tubesheet | −1.59 | 11.9024 |

| Mode 1 | Frequency 2 (Hz) | Ratio of Gap Velocity to Critical Gap Velocity 3 | Max. Vortex Shedding Amplitude 4 (mm) | Span Number 5 |

|---|---|---|---|---|

| 1, 2 | 44.56 | 0.7436 | 0.342 | 4 |

| 3, 4 | 65.94 | 0.4989 | 0.160 | 2 |

| 5, 6 | 146.48 | 0.2282 | 0.0310 | 5 |

| 7, 8 | 184.54 | 0.1964 | 0.0220 | 3 |

| 9, 10 | 289.02 | 0.1019 | 0.00662 | 6 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, I.-B.; Park, S. Improving Tube Design of a Problematic Heat Exchanger for Enhanced Safety at Minimal Costs. Energies 2017, 10, 1236. https://doi.org/10.3390/en10081236

Lee I-B, Park S. Improving Tube Design of a Problematic Heat Exchanger for Enhanced Safety at Minimal Costs. Energies. 2017; 10(8):1236. https://doi.org/10.3390/en10081236

Chicago/Turabian StyleLee, In-Bok, and Seunghee Park. 2017. "Improving Tube Design of a Problematic Heat Exchanger for Enhanced Safety at Minimal Costs" Energies 10, no. 8: 1236. https://doi.org/10.3390/en10081236

APA StyleLee, I.-B., & Park, S. (2017). Improving Tube Design of a Problematic Heat Exchanger for Enhanced Safety at Minimal Costs. Energies, 10(8), 1236. https://doi.org/10.3390/en10081236