Fault Prediction and Diagnosis of Wind Turbine Generators Using SCADA Data

Abstract

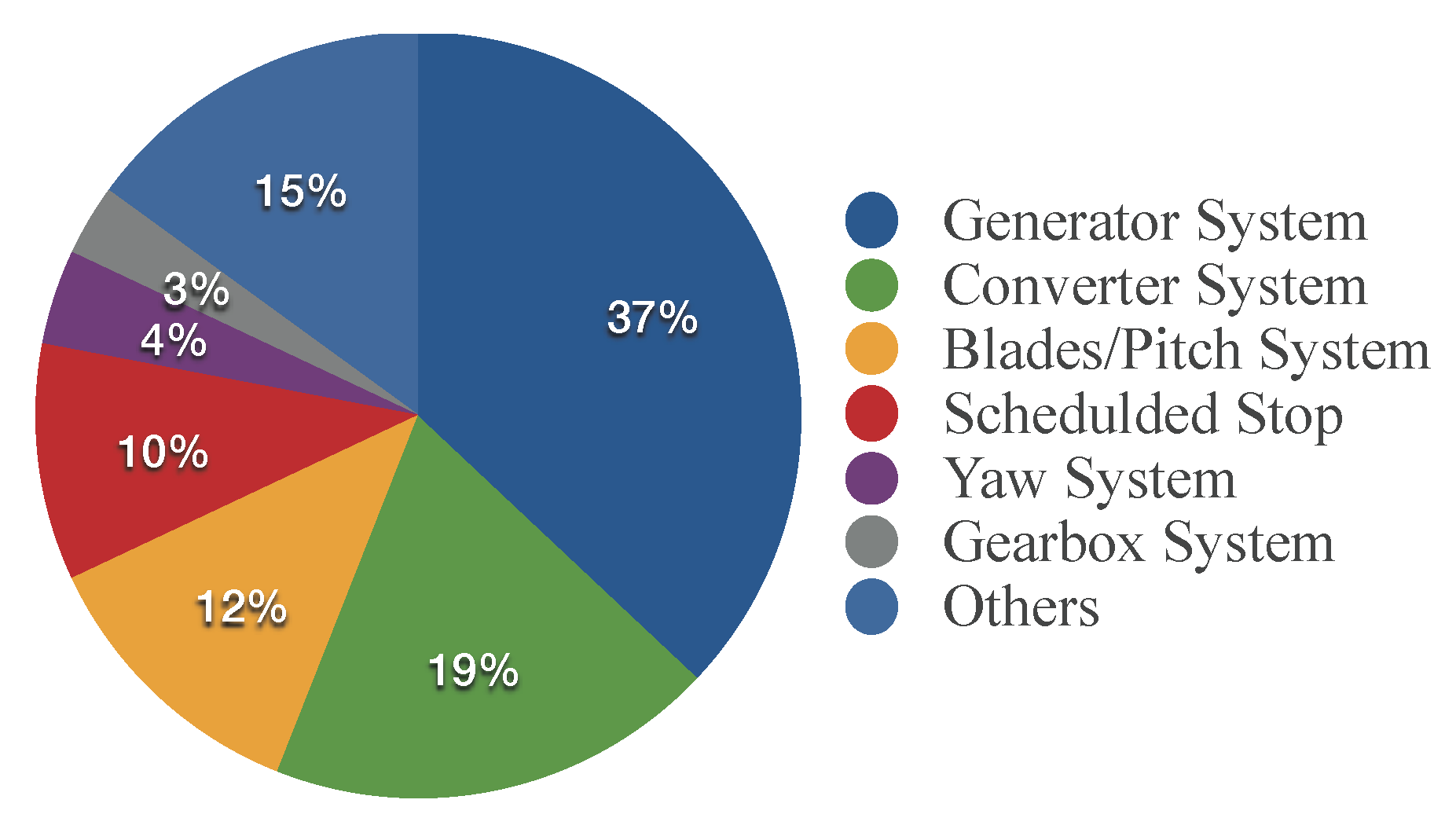

1. Introduction

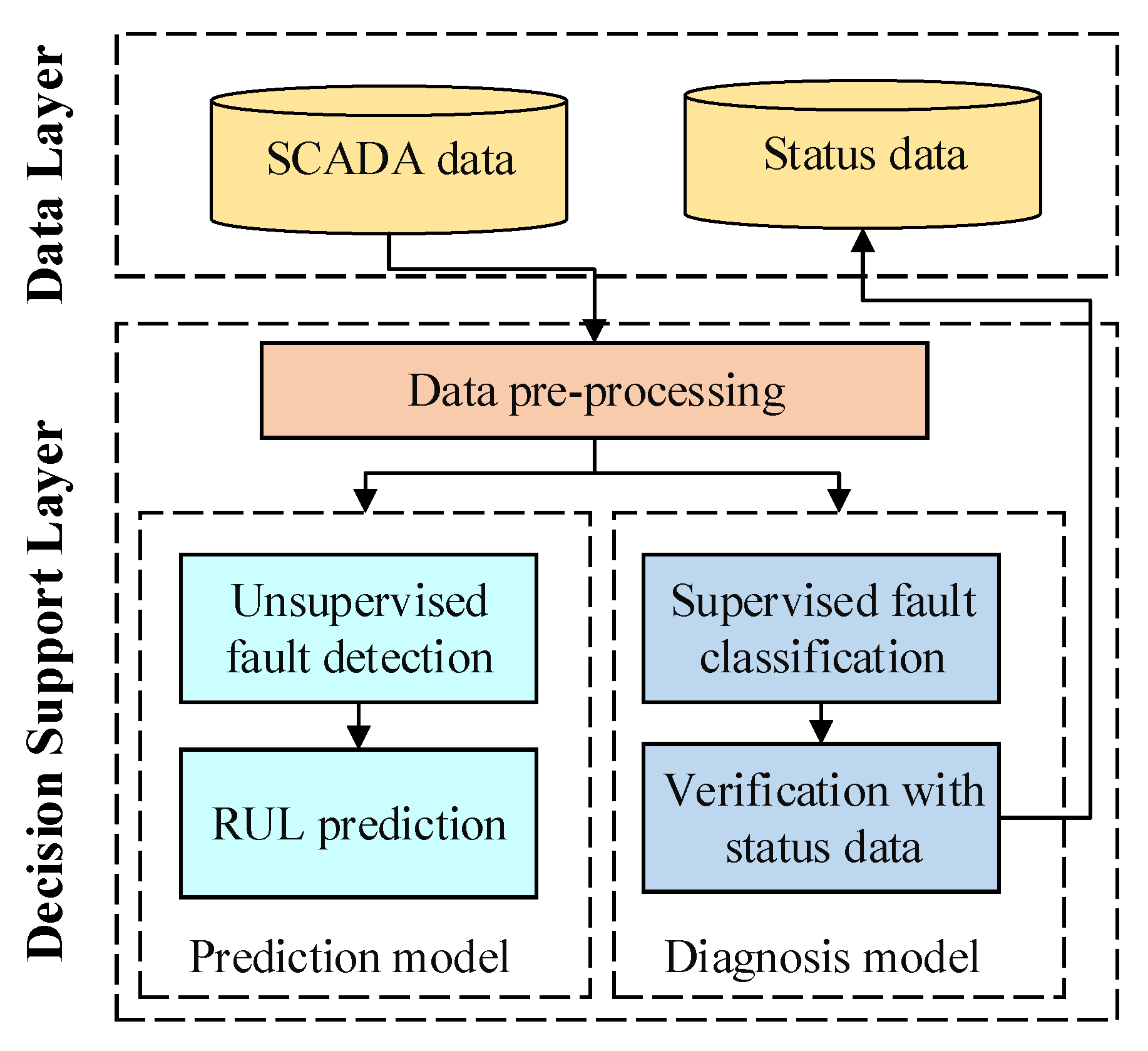

- We have conducted an extensive analysis of data (containing SCADA data and status data) collected by SCADA systems. We propose a data preprocessing procedure for the data, which mainly includes four steps: data cleaning, feature selection, feature reduction, and data set balancing. In particular, principal component analysis (PCA) is used to identify suitable features which can capture generator fault changes. The synthetic minority over-sampling technique (SMOTE) is used to tackle the imbalance characteristics of the data set with better accuracy.

- We have developed a solution containing a prediction model and diagnosis model. In the prediction model, the wind turbine generators’ remaining useful life (RUL) is predicted using an unsupervised clustering method. Also, a notion, the anomaly operation index (AOI), is proposed for better visualization of the wind turbine generators developing fault trajectories. We also present a RUL estimation method to predict generator RUL. The diagnosis model is a complementary tool for fault prediction. In the diagnosis model, we compare widely used classifiers and choose the most appropriate classifier for combination with the SMOTE for accurate fault diagnosis.

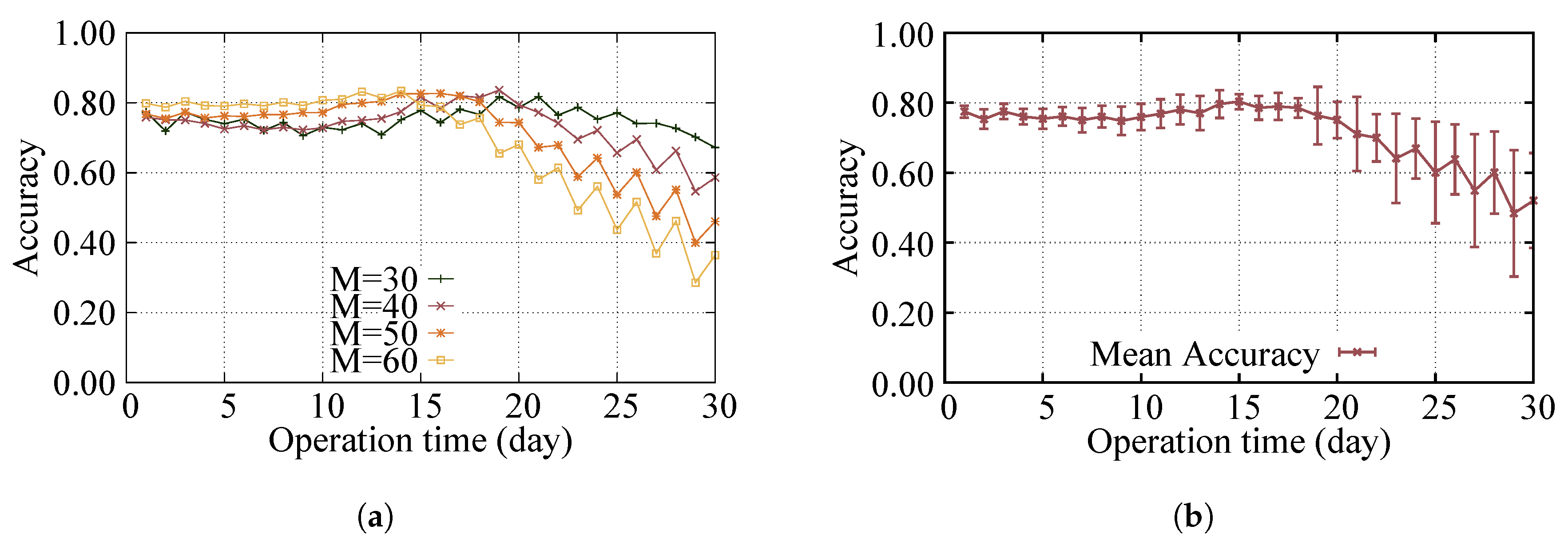

- The proposed solution has been adopted and evaluated using two wind power plants located in China. Experimental results show that emerging generator faults can be predicted 18 days ahead with about 80% accuracy. In addition, the diagnosis model can be a complementary tool for classifying generator failure types with over 94% accuracy when they occur.

2. Related Work

3. Challenges

4. Data Description and Pre-Processing

4.1. Data Collection

4.1.1. SCADA Data

- The condition parameters contain wind speed, wind direction, and ambient temperature, which can determine the power output of wind turbines.

- The health parameters contain main bearing temperature, low-speed shaft temperature, high-speed shaft temperature, and gearbox oil temperature, which can help analyze the health condition of wind turbines.

- The performance parameters contain rotor speed, impeller speed, generator speed and active power, etc., which measure wind turbines´ operational performance.

- The controlling parameters refer to the programmable logic controller code (PLC) state. There are 17 PLC state codes, which are system initialization, system interrupt, system maintenance, system power-generating, etc.

4.1.2. Status Data

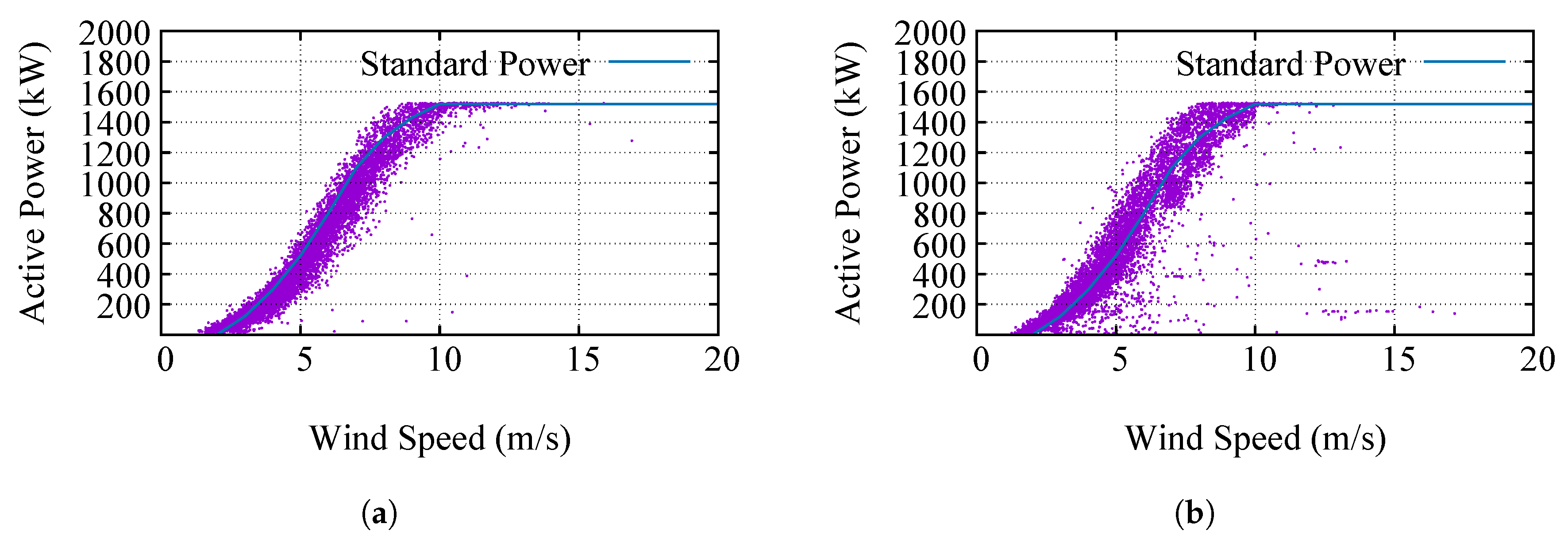

4.2. Data Cleaning

4.2.1. Removing Errors

4.2.2. Re-Sampling

4.3. Feature Selection

4.4. Feature Reduction

4.5. Data Set Balancing

| Algorithm 1 BalancingFeaturesSpace () |

| Require: Minority class (T is the number of minority class instances) in optimal features subset; Amount of SMOTE (); Number of nearest neighbors . |

| Ensure: synthetic instances in minority class. |

| for each instance in minority class M do |

| Compute nearest neighbors ; |

| while do |

| Randomly choose one neighbor from ; |

| Compute the distance between and ; |

| Generate a random gap (1); |

| Generate a synthetic instance ; |

| ; |

| end while |

| end for |

5. Prediction and Diagnosis Solution

5.1. Prediction Model

| Algorithm 2 Prediction () |

| Require: the instances set over a period of time ; the smooth window ; the boundary from normal to abnormal ; weight related to actual remaining useful life at any time slot for a normal wind turbine. |

| Ensure: remaining useful life at time t. |

| Cluster the set I. |

| Initialize the anomaly index container ; |

| for each do |

| Calculate instance number in the largest and densest cluster for a time period over to . |

| ; |

| end for |

| Initialize a counter container ; |

| for each element in z do |

| if then |

| ; |

| else |

| ; |

| end if |

| end for |

| return ; |

5.2. Diagnosis Model

5.2.1. Support Vector Machine

5.2.2. K-Nearest Neighbor

5.2.3. Artificial Neural Network

5.2.4. Naive Bayesian

6. Experiments and Results

6.1. Evaluation Metrics

6.1.1. Prediction Performance Metrics

6.1.2. Diagnosis Performance Metrics

6.2. Overall Performance

6.2.1. Prediction Performance

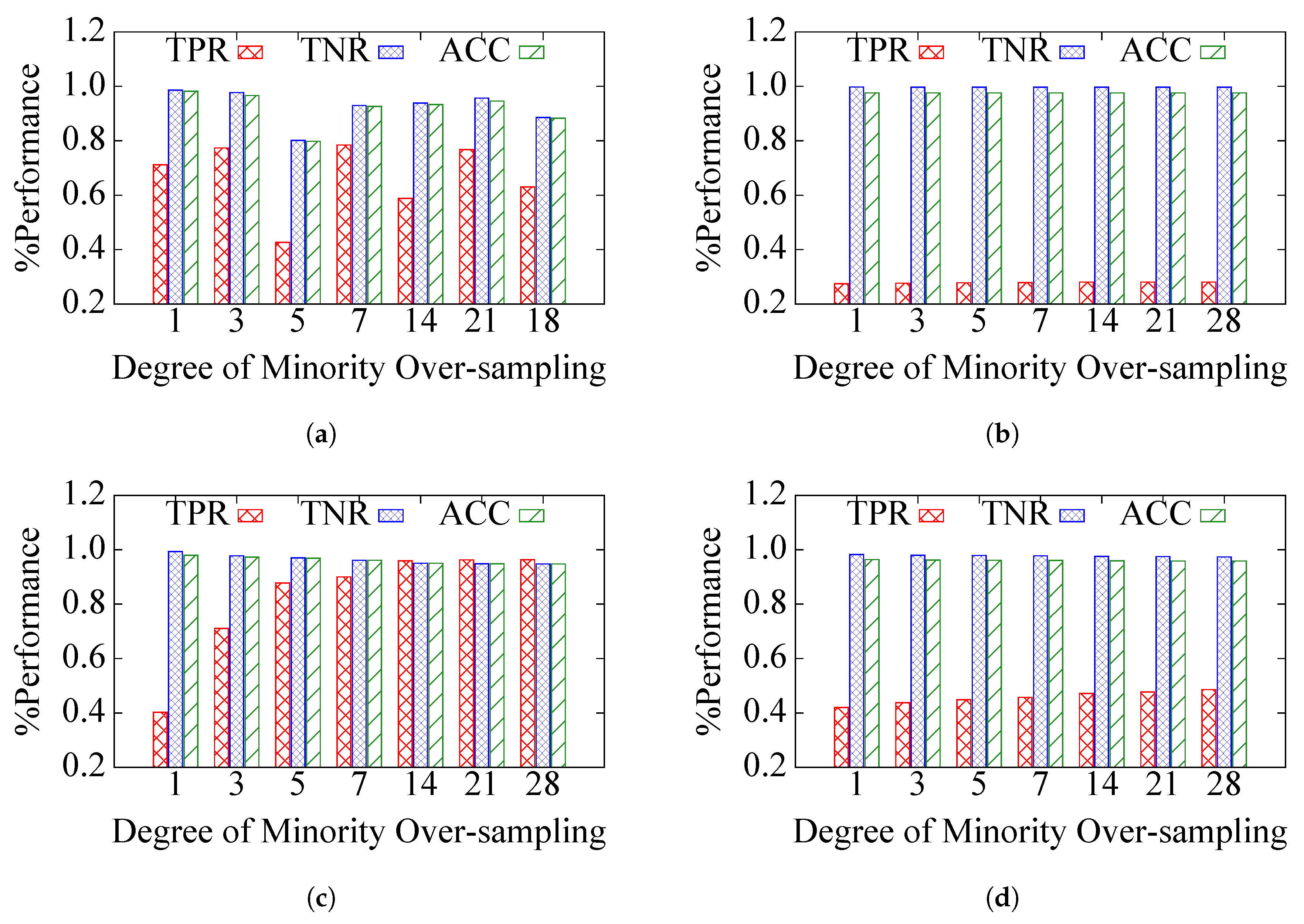

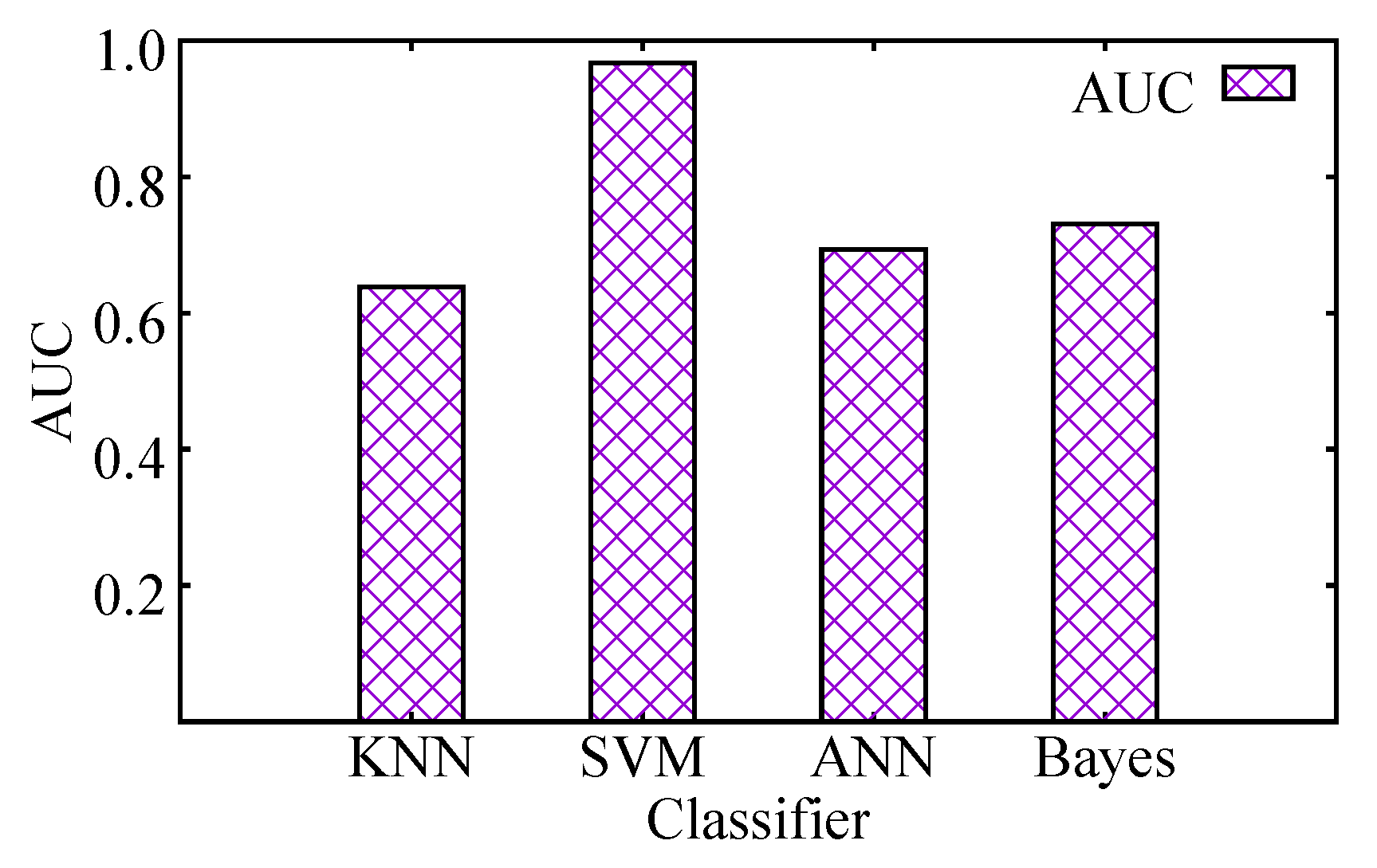

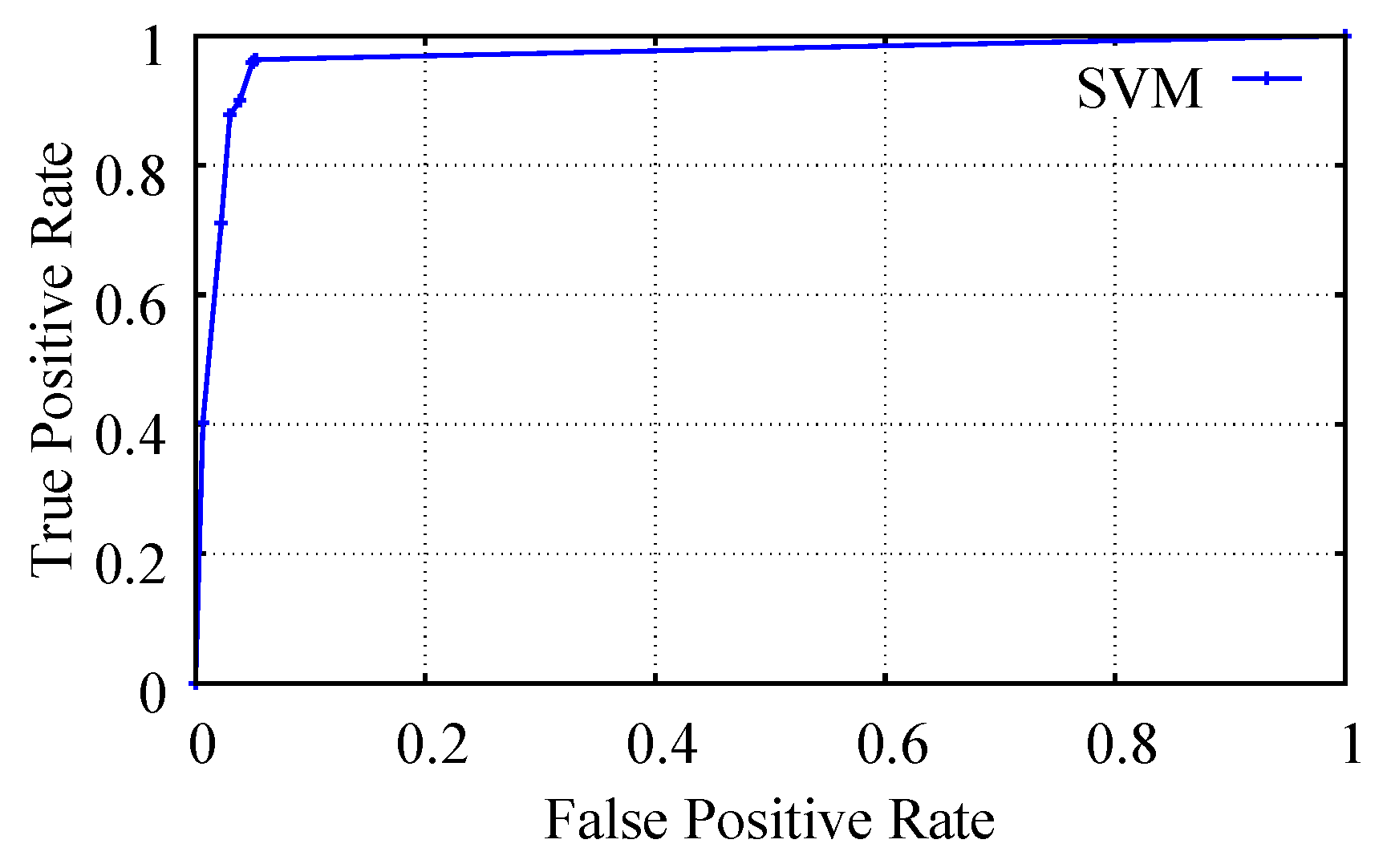

6.2.2. Diagnosis Performance

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pérez, J.M.P.; Márquez, F.P.G.; Tobias, A.; Papaelias, M. Wind turbine reliability analysis. Renew. Sustain. Energy Rev. 2013, 23, 463–472. [Google Scholar] [CrossRef]

- Lu, B.; Li, Y.; Wu, X.; Yang, Z. A review of recent advances in wind turbine condition monitoring and fault diagnosis. In Proceedings of the Power Electronics and Machines in Wind Applications, Lincoln, NE, USA, 24–26 June 2009; pp. 1–7. [Google Scholar]

- Tavner, P.J.; Xiang, J.; Spinato, F. Reliability analysis for wind turbines. Wind Energy 2007, 10, 1–18. [Google Scholar] [CrossRef]

- McMillan, D.; Ault, G.W. Quantification of condition monitoring benefit for offshore wind turbines. Wind Eng. 2007, 31, 267–285. [Google Scholar] [CrossRef]

- Márquez, F.P.G.; Tobias, A.M.; Pérez, J.M.P.; Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Yang, W.; Tavner, P.J.; Crabtree, C.J.; Feng, Y.; Qiu, Y. Wind turbine condition monitoring: Technical and commercial challenges. Wind Energy 2014, 17, 673–693. [Google Scholar] [CrossRef]

- Zaher, A.; McArthur, S.D.J.; Infield, D.G.; Patel, Y. Online wind turbine fault detection through automated SCADA data analysis. Wind Energy 2009, 12, 574–593. [Google Scholar] [CrossRef]

- Kim, K.; Parthasarathy, G.; Uluyol, O.; Foslien, W.; Sheng, S.; Fleming, P. Use of SCADA data for failure detection in wind turbines. In Proceedings of the American Society of Mechanical Engineers (ASME) 2011 5th International Conference on Energy Sustainability, Washington, DC, USA, 7–10 August 2011; pp. 2071–2079. [Google Scholar]

- Qiu, Y.; Feng, Y.; Sun, J.; Zhang, W.; Infield, D. Applying thermophysics for wind turbine drivetrain fault diagnosis using SCADA data. IET Renew. Power Gener. 2016, 10, 661–668. [Google Scholar] [CrossRef]

- Yang, W.; Court, R.; Jiang, J. Wind turbine condition monitoring by the approach of SCADA data analysis. Renew. Energy 2013, 53, 365–376. [Google Scholar] [CrossRef]

- Gill, S.; Stephen, B.; Galloway, S. Wind turbine condition assessment through power curve copula modeling. IEEE Trans. Sustain. Energy 2012, 3, 94–101. [Google Scholar] [CrossRef]

- Schlechtingen, M.; Santos, I.F. Comparative analysis of neural network and regression based condition monitoring approaches for wind turbine fault detection. Mech. Syst. Signal Process. 2011, 25, 849–1875. [Google Scholar] [CrossRef]

- Kusiak, A.; Verma, A. Analyzing bearing faults in wind turbines: A data-mining approach. Renew. Energy 2012, 48, 110–116. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Wang, K.S. Wind turbine fault detection based on SCADA data analysis using ANN. Adv. Manuf. 2014, 2, 70–78. [Google Scholar] [CrossRef]

- Kusiak, A.; Li, W. The prediction and diagnosis of wind turbine faults. Renew. Energy 2011, 36, 16–23. [Google Scholar] [CrossRef]

- Borchersen, A.B.; Kinnaert, M. Model-based fault detection for generator cooling system in wind turbines using SCADA data. Wind Energy 2016, 19, 593–606. [Google Scholar] [CrossRef]

- Gray, C.S.; Watson, S.J. Physics of failure approach to wind turbine condition based maintenance. Wind Energy 2010, 13, 395–405. [Google Scholar] [CrossRef]

- Kotsiantis, S.; Kanellopoulos, D.; Pintelas, P. Handling imbalanced datasets: A review. GESTS Int. Trans. Comput. Sci. Eng. 2006, 30, 25–36. [Google Scholar]

- Rahm, E.; Do, H.H. Data cleaning: Problems and current approaches. IEEE Data Eng. Bull. 2000, 23, 3–13. [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China GB/T18710. Methodology of Wind Energy Resource Assessment for Wind Farm; Standards Press of China: Beijing, China, 2002.

- Zhao, Y.; Li, D.; Dong, A.; Lin, J.; Kang, D.; Shang, L. Fault prognosis of wind turbine generator using SCADA data. In Proceedings of the North American Power Symposium (NAPS), Denver, CO, USA, 18–20 September 2016; pp. 1–6. [Google Scholar]

- Kleiminger, W.; Beckel, C.; Santini, S. Household occupancy monitoring using electricity meters. In Proceedings of the 2015 ACM International Joint Conference on Pervasive and Ubiquitous Computing, Osaka, Japan, 7–11 September 2015; pp. 975–986. [Google Scholar]

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Ling, C.X.; Li, C. Data mining for direct marketing: Problems and solutions. In Proceedings of the Fourth International Conference on Knowledge Discovery and Data Mining, New York, NY, USA, 27–31 August 1998; pp. 73–79. [Google Scholar]

- Chawla, N.V.; Bowyer, K.W.; Hall, L.O.; Kegelmeyer, W.P. SMOTE: Synthetic minority over-sampling technique. J. Artif. Intell. Res. 2002, 16, 321–357. [Google Scholar]

- Jardine, A.K.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Chen, P.; Pedersen, T.; Bak-Jensen, B.; Chen, Z. ARIMA-based time series model of stochastic wind power generation. IEEE Trans. Power Syst. 2010, 25, 667–676. [Google Scholar] [CrossRef]

- Chandola, V.; Banerjee, A.; Kumar, V. Anomaly detection: A survey. ACM Comput. Surv. (CSUR) 2009, 41. [Google Scholar] [CrossRef]

- Suykens, J.A.; Vandewalle, J. Least squares support vector machine classifiers. Neural Process. Lett. 1999, 9, 293–300. [Google Scholar] [CrossRef]

- Kim, H.E.; Tan, A.C.; Mathew, J.; Choi, B.K. Bearing fault prognosis based on health state probability estimation. Expert Syst. Appl. 2012, 39, 5200–5213. [Google Scholar] [CrossRef]

- Burges, C.J. A tutorial on support vector machines for pattern recognition. Data Min. Knowl. Discov. 1998, 2, 121–167. [Google Scholar] [CrossRef]

- Chang, C.C.; Lin, C.J. LIBSVM: A library for support vector machines. ACM Trans. Intell. Syst. Technol. 2011, 2. [Google Scholar] [CrossRef]

- Sinapov, J.; Wiemer, M.; Stoytchev, A. Interactive learning of the acoustic properties of household objects. In Proceedings of the IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; pp. 2518–2524. [Google Scholar]

| Wind Turbine Number | Number of Instances | Number of Instances |

|---|---|---|

| in the Majority Class | in the Minority Class | |

| 2 | 62,782 | 1022 |

| 10 | 62,535 | 2233 |

| 23 | 63,118 | 6 |

| 25 | 63,964 | 4342 |

| 27 | 63,288 | 1351 |

| 28 | 59,178 | 4342 |

| Parameters | Description/Value |

|---|---|

| Rated power | 1500 kW |

| Cut_in speed | 3 m/s |

| Cut_out speed | 20 m/s |

| Blade´s rotational speed | 9.7 rpm–19 rpm |

| Gearbox | 3 stage, 104.1 overall ratio |

| Generator´s rotational speed range | 1000 rpm–2000 rpm |

| Generator´s rated rotational range | 1800 rpm |

| WT No. | Fault Type | Cause | Maintenance Activities | Start Date | End Date |

|---|---|---|---|---|---|

| 1 | Blades/pitch system | Blade 2 fault | Tightening slip-ring | 16 June 2015 12:00:00 | 16 June 2015 05:24:00 |

| 28 | Generator system | Generator fault | Replacement | 26 July 2015 03:00:00 | 11 September 02:40:00 |

| Scope/Problem | Reasons/Remarks | |

|---|---|---|

| Attribute | Missing values | Unavailable values during data entry (dummy values or null) |

| Misfielded values | Data entry is not at the appropriate position | |

| Record type | Duplicated records | Same record represented twice |

| Contradicting records | Record with the same key is described by different values | |

| SCADA Features | Reasons for Wind Turbine Generator Fault Prediction and Diagnosis |

|---|---|

| wind speed | (1) miscorrelation of wind speed and generator active power indicates a fault in wind turbines [21]; |

| ambient temperature | |

| rotor speed | (2) miscorrelation between generator speed and generator active power indicates a fault in generator [10]; |

| generator rotational speed | |

| generator active power | (3) miscorrelation between generator speed and generator reactive power suggests an electrical fault in the generator [10]; |

| generator reactive power | |

| temperature of main bearing | (4) anomalous temperature changes caused by heat transfer can be helpful for figuring out the trajectory of a generator fault [9]; |

| temperature of low-speed shaft | |

| temperature of high-speed shaft | (5) shaft torque calculated in Equation 1 reflects the generator’s load [2], and it can be used as an indicator for a generator fault. |

| ANN | KNN | SVM | Naive Bayes | |

|---|---|---|---|---|

| 0.7115 | 0.2741 | 0.4025 | 0.4198 | |

| 0.9859 | 0.9975 | 0.9936 | 0.9827 | |

| 0.9821 | 0.9759 | 0.9796 | 0.9642 |

| ANN | KNN | SVM | Naive Bayes | |

|---|---|---|---|---|

| 0.7840 | 0.2808 | 0.9634 | 0.4862 | |

| 0.9294 | 0.9973 | 0.9476 | 0.9735 | |

| 0.9259 | 0.9758 | 0.9480 | 0.9583 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Li, D.; Dong, A.; Kang, D.; Lv, Q.; Shang, L. Fault Prediction and Diagnosis of Wind Turbine Generators Using SCADA Data. Energies 2017, 10, 1210. https://doi.org/10.3390/en10081210

Zhao Y, Li D, Dong A, Kang D, Lv Q, Shang L. Fault Prediction and Diagnosis of Wind Turbine Generators Using SCADA Data. Energies. 2017; 10(8):1210. https://doi.org/10.3390/en10081210

Chicago/Turabian StyleZhao, Yingying, Dongsheng Li, Ao Dong, Dahai Kang, Qin Lv, and Li Shang. 2017. "Fault Prediction and Diagnosis of Wind Turbine Generators Using SCADA Data" Energies 10, no. 8: 1210. https://doi.org/10.3390/en10081210

APA StyleZhao, Y., Li, D., Dong, A., Kang, D., Lv, Q., & Shang, L. (2017). Fault Prediction and Diagnosis of Wind Turbine Generators Using SCADA Data. Energies, 10(8), 1210. https://doi.org/10.3390/en10081210