Combustion-Related Properties of Poplar, Willow and Black Locust to be used as Fuels in Power Plants

Abstract

:1. Introduction

2. Materials and Methods

3. Experimental Procedure

Biomass Characterization

4. Results and Discussion

4.1. Physical Properties

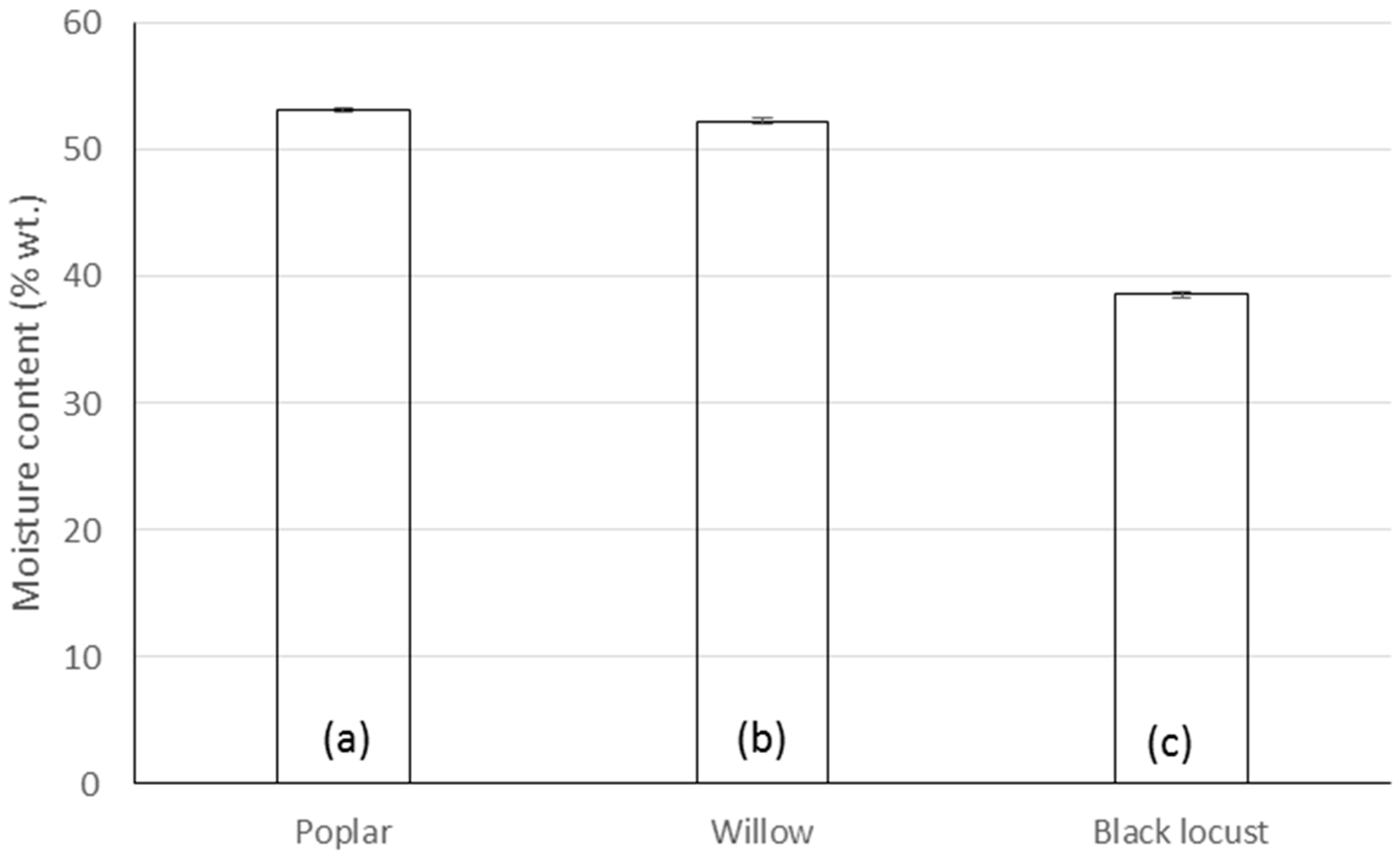

4.1.1. Moisture Content

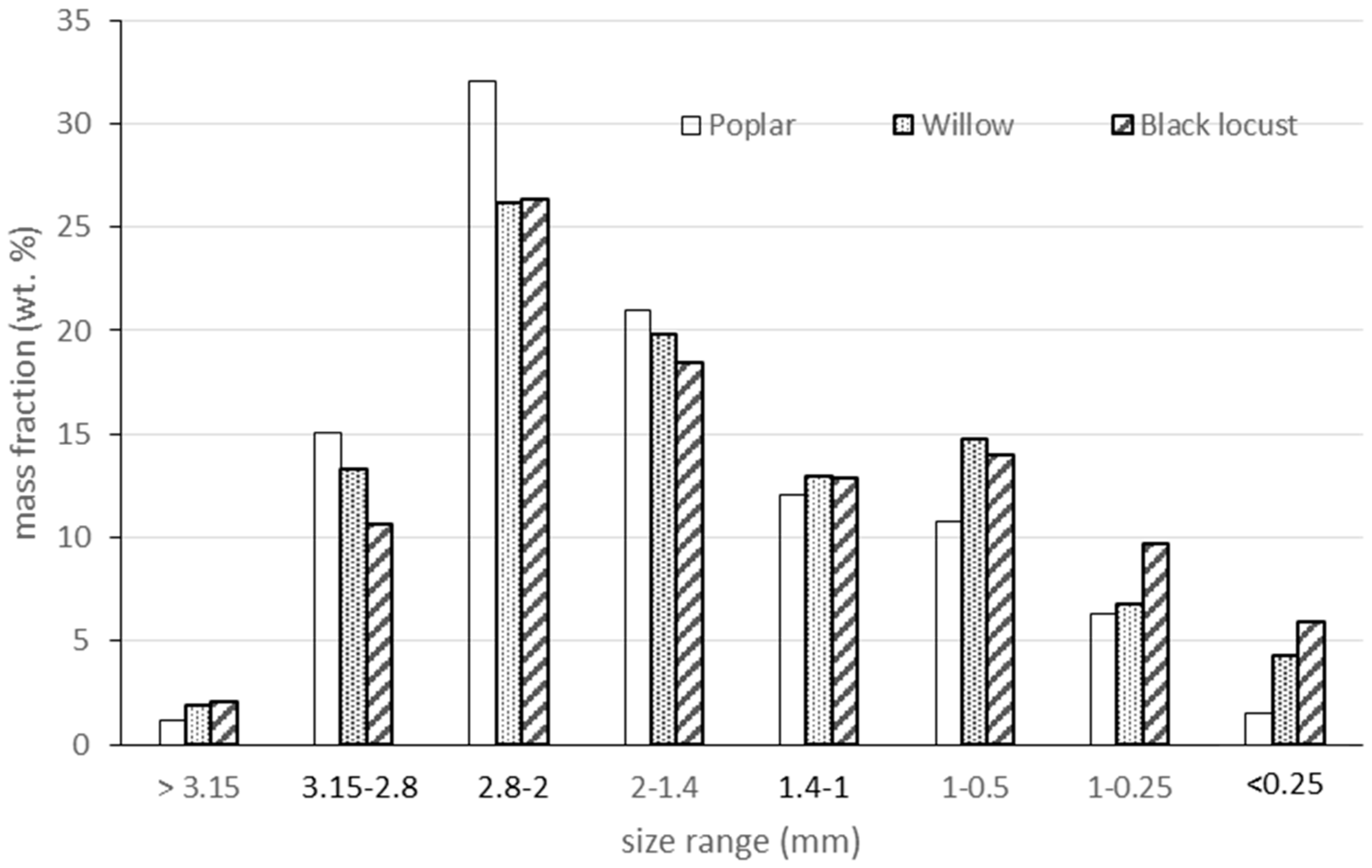

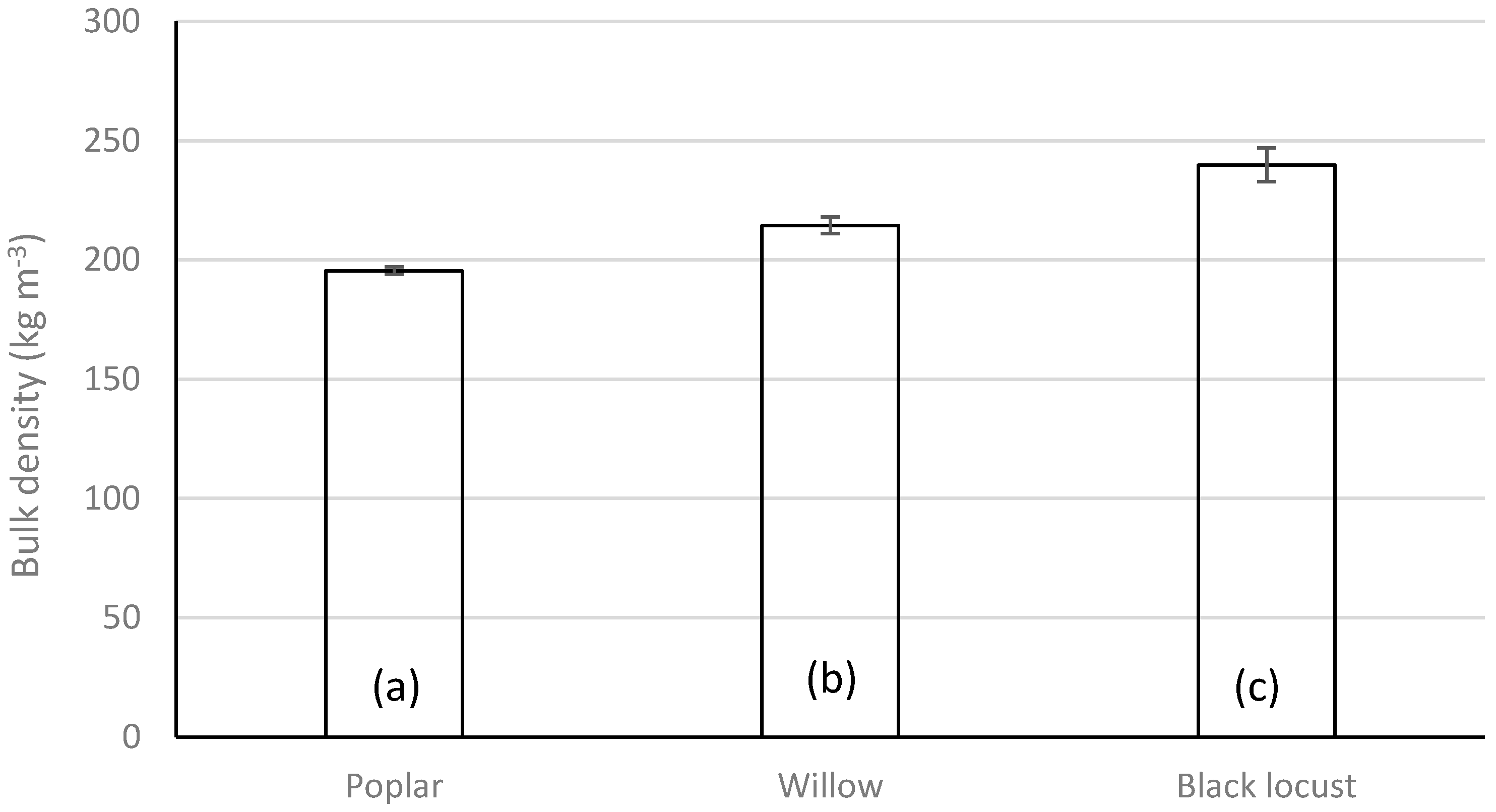

4.1.2. Particle Size Distribution and Bulk Density

4.2. Thermochemical Properties

4.2.1. Proximate Analyses and Ash Composition

4.2.2. Ultimate Analyses

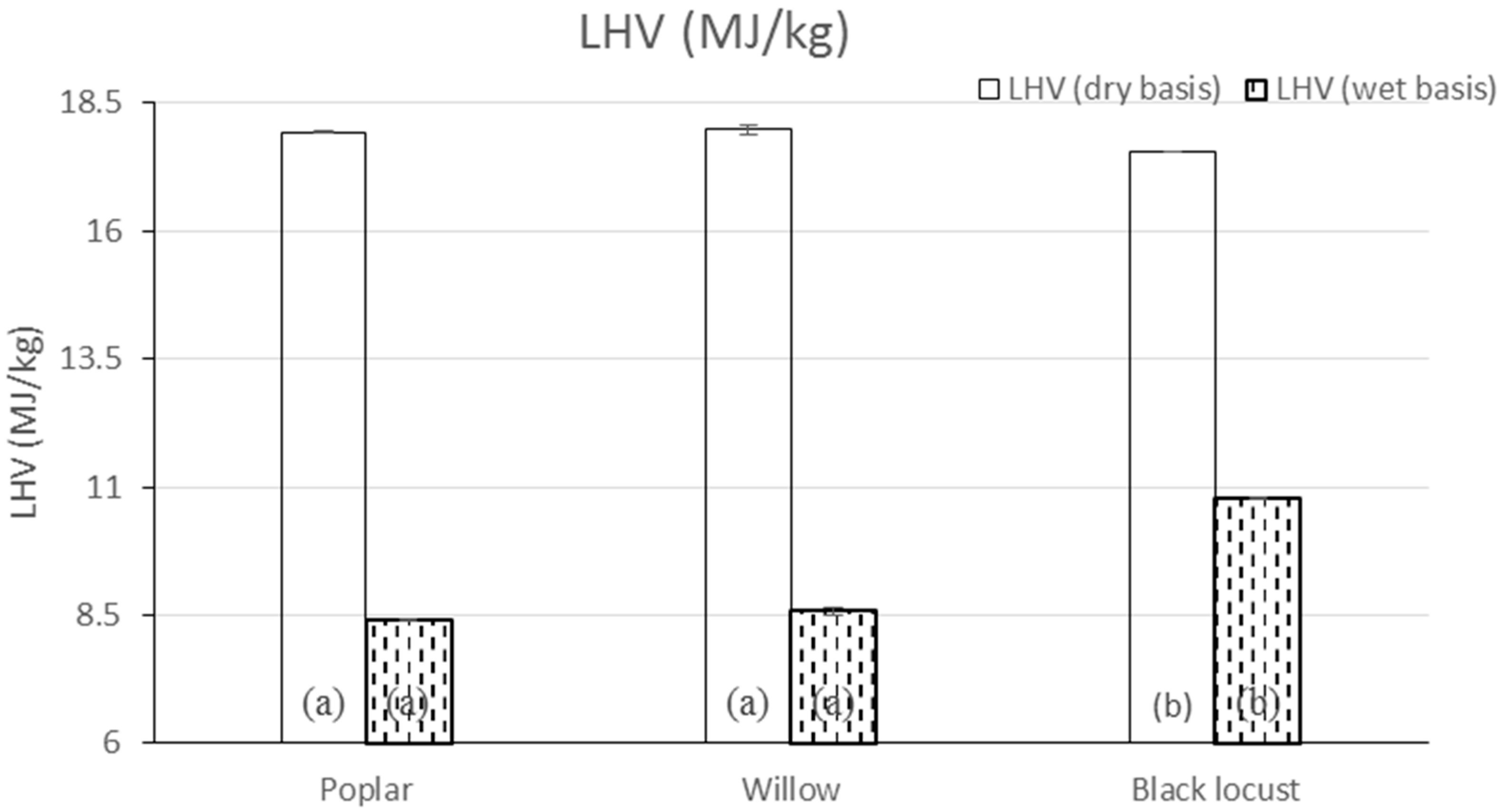

4.2.3. Lower Heating Value

5. Conclusions

- Based on the physical and thermochemical properties as well as on the production yield, willow seems to be the most suitable crop for use in combustion devices (low ash and high volatile content, high LHV on dry basis and very unlikely fouling problems).

- Despite the very low yield obtained for black locust (which was probably due to the unusual climatic conditions during the planting year), this specie could be cost-effective when constraints imposed by short storage periods (space availability and/or power production requirements) are limiting.

- The nitrogen and sulfur content in all the species suggests no problems related to SOX and NOx emissions.

- According to the fouling indexes determined, nor harmful corrosion caused by chlorine or fouling phenomena during combustion with any of the species are expected, those problems being minimized if willow is used.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Perlack, R.D.; Wright, L.L.; Huston, M.A.; Schramm, W.E. Biomass Fuel from Woody Crops for Electric Power Generation; Biofuel Feedstock Development Program Energy Division Environmental Sciences Division, Oal Ridge National Laboratory: Oak Ridge, TN, USA, 1995.

- Manzone, M.; Bergante, S.; Facciotto, G. Energy and economic evaluation of a poplar plantation for woodchips production in Italy. Biomass Bioenergy 2014, 60, 164–170. [Google Scholar] [CrossRef]

- Ericsson, K.; Rosenqvist, H.; Ganko, E.; Pisarek, M.; Nilsson, L. An agro-economic analysis of willow cultivation in Poland. Biomass Bioenergy 2006, 30, 16–27. [Google Scholar] [CrossRef]

- Morogues, F.D.; Berthelot, A.; Merlun, F. Thoughts on the profitability of short and very short rotation coppice cycles with eucalyptus and poplar. Rev. For. Fr. 2011, 63, 705–721. [Google Scholar]

- Manzone, M.; Bergane, S.; Facciotto, G. Energetic and economic sustainability of woodchips production by black locust (Robinia pseudoacacia L.) plantations in Italy. Fuel 2015, 140, 555–560. [Google Scholar] [CrossRef]

- Dimitriou, I.; Mola-Yudego, B. Poplar and willow plantations on agricultural land in Sweden: Area, yield, groundwater quality and soil organic carbon. For. Ecol. Manag. 2017, 383, 99–107. [Google Scholar] [CrossRef]

- Rösch, C.; Skarka, J.; Raab, K.; Stelzer, V. Energy production from grassland-Assessing the sustainability of different process chain under German conditions. Biomass Bioenergy 2009, 33, 689–700. [Google Scholar] [CrossRef]

- Robbins, M.P.; Evans, G.; Valentine, J.; Donninson, I.S.; Allison, G.C. New opportunities for the exploitation of energy crops by thermochemical conversion in Northern Europe and the UK. Prog. Energy Combust. Sci. 2012, 38, 138–155. [Google Scholar] [CrossRef]

- Sixto, H.; Hernández, M.J.; Barrio, M.; Carrasco, J.; Cañellas, I. Plantaciones del género Populus para la producción de biomasa con fines energéticos. Investig. Agrar. Sist. Recur. For. 2007, 16, 277–294. (In Spainish) [Google Scholar] [CrossRef]

- Kuzovkina, Y.; Weith, M.; Abalos, M.; Charles, J.; Hurst, S.; Mcivor, I.; Karp, A.; Trybush, S.; Labrecque, M.; Teodorescu, T. Salix: Botany and global horticulture. Hortic. Rev. 2008, 34, 447–489. [Google Scholar]

- Demirbas, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- EN 15103 Solid Biofuels. Determination of Bulk Density; Standard Number: BS EN 15103:2009; BSI: Brussels, Belgium, 2009. [Google Scholar]

- Paris, P.; Pisanelli, A.; Sabatti, M.; Mareschi, L.; Cannata, F.; Scarascia-Mugnozza, G. Short Rotation Forestry in Italy. In Proceedings of the II Sino-Italian Workshop on Agroforestry, Beijing, China, 23–25 November 2005; p. 9. [Google Scholar]

- Di Nasso, N.N.O.; Guidi, W.; Ragaglini, G.; Tozzini, C.; Bonari, E. Biomass production and energy balance of a 12-year-old short-rotation coppice poplar stand under different cutting cycles. GCB Bioenergy 2010, 2, 89–97. [Google Scholar] [CrossRef]

- Carmona, R.; Nuñez, T.; Alonso, M.F. Biomass yield and quality of an energy dedicated crop of poplar (Populus spp.) clones in the Mediterranean zone of Chile. Biomass Bioenergy 2015, 74, 96–1022. [Google Scholar] [CrossRef]

- Sixto, H.; Cañellas, I.; Arendonk, J.; Ciria, P.; Camps, F.; Sánchez, M.; Sánchez-González, M. Growth potential of different species and genotypes for biomass production in short rotation in Mediterranean environments. For. Ecol. Manag. 2015, 354, 291–299. [Google Scholar] [CrossRef]

- Nordin, A. Chemical elemental characteristics of biomass fuels. Biomass Bioenergy 1994, 6, 339–347. [Google Scholar] [CrossRef]

- Liao, C.; Wu, C.; Yan, Y.; Huang, H. Chemical elemental characteristics of biomass fuels in China. Biomass Bioenergy 2004, 27, 119–130. [Google Scholar]

- Tao, G.; Lestander, T.; Geladi, P.; Xiong, S. Biomass properties in association with plant species and assortments I: A synthesis based on literature data of energy properties. Renew. Sustain. Energy Rev. 2012, 16, 3481–3506. [Google Scholar] [CrossRef]

- Monedero, E.; Hernandez, J.J.; Cañellas, I.; Otero, J.M.; Sixto, H. Thermochemical and physical evaluation of poplar genotypes as short rotation forestry crops for energy use. Energy Convers. Manag. 2016, 129, 131–139. [Google Scholar] [CrossRef]

- Picchio, R.; Spina, R.; Sirna, A.; Monaco, L.A.; Civitarese, V.; Giudice, D.A.; Suardi, A.; Pari, L. Characterization of Woodchips for Energy from forestry and agroforestry production. Energies 2005, 5, 3803–3816. [Google Scholar] [CrossRef]

- Verani, S.; Sperandio, G.; Picchio, R.; Marchi, E.; Costa, C. Sustainability assessment of a self-consumption wood-energy chain on small scale for heat generation in central Italy. Energies 2015, 8, 5182–5197. [Google Scholar] [CrossRef]

- Tharakan, P.J.; Volk, T.A.; Abrahamson, L.P.; White, E.H. Energy feedstock characteristics of willow and hybrid poplar clones at harvested age. Biomass Bioenergy 2003, 25, 571–580. [Google Scholar] [CrossRef]

- Grunewald, H.; Böhm, C.; Quinkenstein, A.; Grundmann, P.; Eberts, J.; Wühlisch von, G. Robinia pseudoacacia L.: A lesser known tree species for biomass production. Bioenergy Res. 2009, 2, 123–133. [Google Scholar] [CrossRef]

- Hanover, J.W.; Mebrahtu, T. Robinia pseudoacacia: Temperate Legume Tree with Worldwide Potential; NFT Highlights; NFTA: Buffalo, NY, USA, 1991. [Google Scholar]

- Peters, K.; Bilke, G.; Strohbach, B. Ertragsleistung sechsjähriger Robinien (Robinia pseudoacacia) auf vier ehemaligen Ackerstandorten unterschiedlicher Bodengüte in Brandenburg. Arch. Forstwes. Landsch. 2007, 1, 26–28. (In German) [Google Scholar]

- Rédei, K. Black Locust (Robinia pseudoacacia L.) Growing in Hungary; Publications of the Hungarian Forest Research Institute: Budapest, Ungarn, 1998. [Google Scholar]

- Werner, A.; Vetter, A.; Reinhold, G. Leitlinie zur Effizienten und Umweltverträglichen Erzeugung Von Energieholz; Thüringer Landesanstalt für Landwirtschaft: Jena, Germany, 2006. (In German) [Google Scholar]

- EN 14780 Solid Biofuels. Sample Preparation; Standard Number BS EN 14780:2011; BSI: Brussels, Belgium, 2017. [Google Scholar]

- Tariq, A.S.; Purvis, M.R.I. NOx emissions and thermal efficiencies of small scale biomass-fuelled combustion plant with reference to process industries in a developing country. Int. J. Energy Res. 1996, 20, 41–55. [Google Scholar] [CrossRef]

- Erber, G.; Kanzian, C.; Stampfer, K. Predicting moisture content in a pine logwood pile for energy purposes. Silva Fenn. 2012, 46, 555–567. [Google Scholar] [CrossRef]

- Manzone, M. Energy and moisture losses during poplar and black locust logwood storage. Fuel Proc. Technol. 2015, 138, 194–201. [Google Scholar] [CrossRef]

- Eisenbies, M.H.; Timothy, A.; Patel, A. Changes in feedstock quality in willow chip piles created in winter from a commercial scale harvest. Biomass Bioenergy 2016, 86, 180–190. [Google Scholar] [CrossRef]

- Chirone, R.; Salatino, P.; Sacala, F. The relevance of attrition to the fate of ashes during fluidized bed combustion of a biomass. Proc. Combust. Inst. 2000, 28, 2279–2286. [Google Scholar] [CrossRef]

- Meszaros, E. Comparative study of the thermal behavior of wood and bark of young shoots obtained from an energy plantation. J. Anal. Appl. Pyrolysis 2004, 72, 317–328. [Google Scholar] [CrossRef]

- Khalil, R.A.; Mészáros, E.; Grønli, M.G.; Várhegyi, G. Thermal analysis of energy crops: Part I: The applicability of macro-thermobalance for biomass studies. J. Anal. Appl. Pyrolysis 2008, 81, 52–59. [Google Scholar] [CrossRef]

- Fernández, M.J.; Borjabad, E.; Barro, R.; Losada, J.; Bados, R.; Ramos, R.; Carrasco, J.E. Estudio sobre sinterización de las cenizas de biomasas en la combustión; Informe Técnico PSE on Cultivos: Soria, Spain, 2008. [Google Scholar]

- Obenberguer, I. Nutzung Fester Biomasse in Verbrennungsalagen unter Besondere Berücksichtigung des Verhalens Aschebildender Elemente. Schriftenreihe “Thermische Biomassenutzung”, Band 1; dbv-Verlag für die Technische Universität: Graz, Austria, 1997; ISBN 3-7041-0241-5. (In German) [Google Scholar]

- Vassilev, S.V.; Baxter, D.; Andersen, L.; Vassileva, C.; Morgan, T. An overview of the organic and inorganic phase composition of biomass. Fuel 2012, 94, 1–33. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.; Vassileva, C. An overview of the chemical composition of biomass. Fuel 2010, 84, 911–933. [Google Scholar] [CrossRef]

- Magasiner, N.; Kock, D.J. Design Criteria for Fibrous Fuel Fired Boilers. Energy World 1987, 150, 4–12. [Google Scholar]

- Miles, P.; Miles, J.N.; Baxter, L.L.; Bryers, R.W.; Jenkins, B.M.; Oden, L.L. Alkali Deposits Found in Biomass Power Plants—A Preliminary Investigation of Their Extent and Nature Summary Report for Natural Renewable Energy Laboratory; SciTech Connect: Golden, CO, USA, 1995.

- Klasnja, B.; Kopitovic, S.; Orlovic, S. Wood and bark of some poplar and willow clones as fuelwood. Biomass Bioenergy 2002, 23, 427–432. [Google Scholar] [CrossRef]

| Factors and Determination Methods | Location |

|---|---|

| Latitude (°) | 41.5996738 |

| Longitude (°) | −4.1280864 |

| Altitude (m, asl) | 756 |

| Annual mean temperature (°C) | 12.1 |

| Mean maximum temperature (°C) | 25.4 |

| Mean minimum temperature (°C) | −0.1 |

| Absolute maximum temperature (°C) | 36.7 |

| Absolute minimum temperature (°C) | −7.7 |

| Annual precipitation (mm) | 316 |

| K (pmm) by atomic emission | 219 |

| Mg (meq/100 g) by atomic absorption | - |

| Organic Matter (%) by Walkey-Black | 1.75 |

| Electric conductivity (mS/cm) by 1:2.5 | 0.82 |

| P (pmm) by Olsen | 5.8 |

| pH by 1:2.5 | 7.7 |

| Active lime (%) | 5.6 |

| Clay (%) by ISSS | 41.9 |

| Lime (%) by ISSS | 23.6 |

| Sand (%) by ISSS | 34.6 |

| Common Name | Species | Genotype | Production |

|---|---|---|---|

| Pl | Populus x euroamericana (Dode) Guinier | ‘AF2‘ | 7.15 |

| Willow | Salix trianda L. x Salis viminalis L. | ‘SA04‘ | 7.58 |

| Black Locust | Robinia pseudoacacia L. | 'Nyirsegi' | 0.91 |

| Property | Analytical Method | Equipment |

|---|---|---|

| Particle size distribution | EN 15149-1/EN 15149-2 | Mechanical sieve |

| Bulk density (ρb) | EN 15103 | Calibrate bottle |

| Sample preparation | EN 14780 | Mill |

| Heating value (LHV, HHV) | UNE 164001 | Calorimeter |

| Moisture content (Mm) | EN 14774-3/EN 14774-2 | Furnace |

| Ash content (A) | EN 14775 | Muffle furnace |

| Volatile matter(V) | EN 15148 | Muffle furnace |

| Carbon (C) | EN 15104 | Elemental analyzer |

| Hydrogen (H) | EN 15104 | Elemental analyzer |

| Nitrogen (N) | EN 15104 | Elemental analyzer |

| Oxygen (O) | EN 15289 | Elemental analyzer |

| Sulphur (S) | EN 15289 | Ion chromatograph |

| Chlorine (Cl) | By difference | - |

| Alkali metals (Na, K, Mg, P, Ca, Si) | By difference | Inductive coupled plasma optical emission spectrometer |

| Species | Factors Evaluated | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Volatile Matter | Ash Content | Carbon | Hydrogen | Nitrogen | Sulfur | Chlorine | |||||||||||||||

| µ | SD | µ | SD | µ | SD | µ | SD | µ | SD | µ | SD | µ | SD | ||||||||

| Poplar | 82.37 | 0.03 | a | 3.00 | 0.01 | a | 51.81 | 0.01 | a | 6.39 | 0.08 | a | 0.16 | 0.02 | a | 0.04 | 0.00 | a | 0.01 | 0.00 | a |

| Willow | 83.59 | 0.39 | b | 1.88 | 0.05 | b | 48.84 | 0.12 | b | 6.18 | 0.05 | b | 0.46 | 0.02 | b | 0.03 | 0.01 | a | 0.00 | 0.00 | a |

| Black locust | 81.33 | 0.06 | c | 3.33 | 0.07 | c | 51.51 | 0.18 | c | 6.44 | 0.09 | a | 0.63 | 0.15 | b | 0.05 | 0.00 | a | 0.02 | 0.00 | a |

| Species | Alkali Metals (wt %) | Index A | Index B | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| FU | FP | FPR | FU | FP | FPR | ||||||

| <0.10 | 0.10–1.00 | >1.00 | <0.17 | 0.17–0.34 | >0.34 | ||||||

| Ca | Mg | K | Si | Na | µ | SD | µ | SD | |||

| Poplar | 0.64 | 0.15 | 0.18 | 0.14 | 0.01 | 0.89 | 0.01 | a | 0.13 | 0.01 | a |

| Willow | 0.47 | 0.12 | 0.14 | 0.07 | 0.01 | 0.48 | 0.00 | b | 0.05 | 0.00 | b |

| Black locust | 0.00 | 0.11 | 0.23 | 0.12 | 0.01 | 0.85 | 0.00 | a | 0.15 | 0.00 | c |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monedero, E.; Hernández, J.J.; Collado, R. Combustion-Related Properties of Poplar, Willow and Black Locust to be used as Fuels in Power Plants. Energies 2017, 10, 997. https://doi.org/10.3390/en10070997

Monedero E, Hernández JJ, Collado R. Combustion-Related Properties of Poplar, Willow and Black Locust to be used as Fuels in Power Plants. Energies. 2017; 10(7):997. https://doi.org/10.3390/en10070997

Chicago/Turabian StyleMonedero, Esperanza, Juan José Hernández, and Rocío Collado. 2017. "Combustion-Related Properties of Poplar, Willow and Black Locust to be used as Fuels in Power Plants" Energies 10, no. 7: 997. https://doi.org/10.3390/en10070997

APA StyleMonedero, E., Hernández, J. J., & Collado, R. (2017). Combustion-Related Properties of Poplar, Willow and Black Locust to be used as Fuels in Power Plants. Energies, 10(7), 997. https://doi.org/10.3390/en10070997